Patents

Literature

172results about How to "No risk of secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium alginate-MOF (metal organic framework) composite spherule as well as preparation method and application thereof

InactiveCN105498695AStop erosionImprove acid resistanceOther chemical processesAlkali metal oxides/hydroxidesChemistryMaterial synthesis

The invention discloses a sodium alginate-MOF (metal organic framework) composite spherule as well as a preparation method and an application thereof, belongs to the field of material synthesis and overcomes the defect that a conventional MOF material has small grain size and poor acid resistance and is difficult to be separated from water. The co-precipitation technology is adopted, a sodium alginate-MOF mixed liquid is dropwise added to a precipitant solution containing calcium chloride, water and ethyl alcohol, a non-crosslinked composite spherule is obtained, then the composite spherule is added to a glutaraldehyde solution for cross-linking of a sodium alginate framework, the sodium alginate-MOF composite spherule is obtained, the grain size of the spherule is about 1 mm, and the composite spherule has the characteristics of high acid resistance, high separability from water, high water pollutant adsorption capacity, high mechanical strength, long service life, environment-friendliness and the like.

Owner:NANJING NORMAL UNIVERSITY

Method for removing hydroxyapatite modified eggshell adsorbent material and recycling phosphate from wastewater

InactiveCN102380350AShort hydraulic retention timeReduce construction costsOther chemical processesWater/sewage treatment by sorptionPhosphateHydraulic retention time

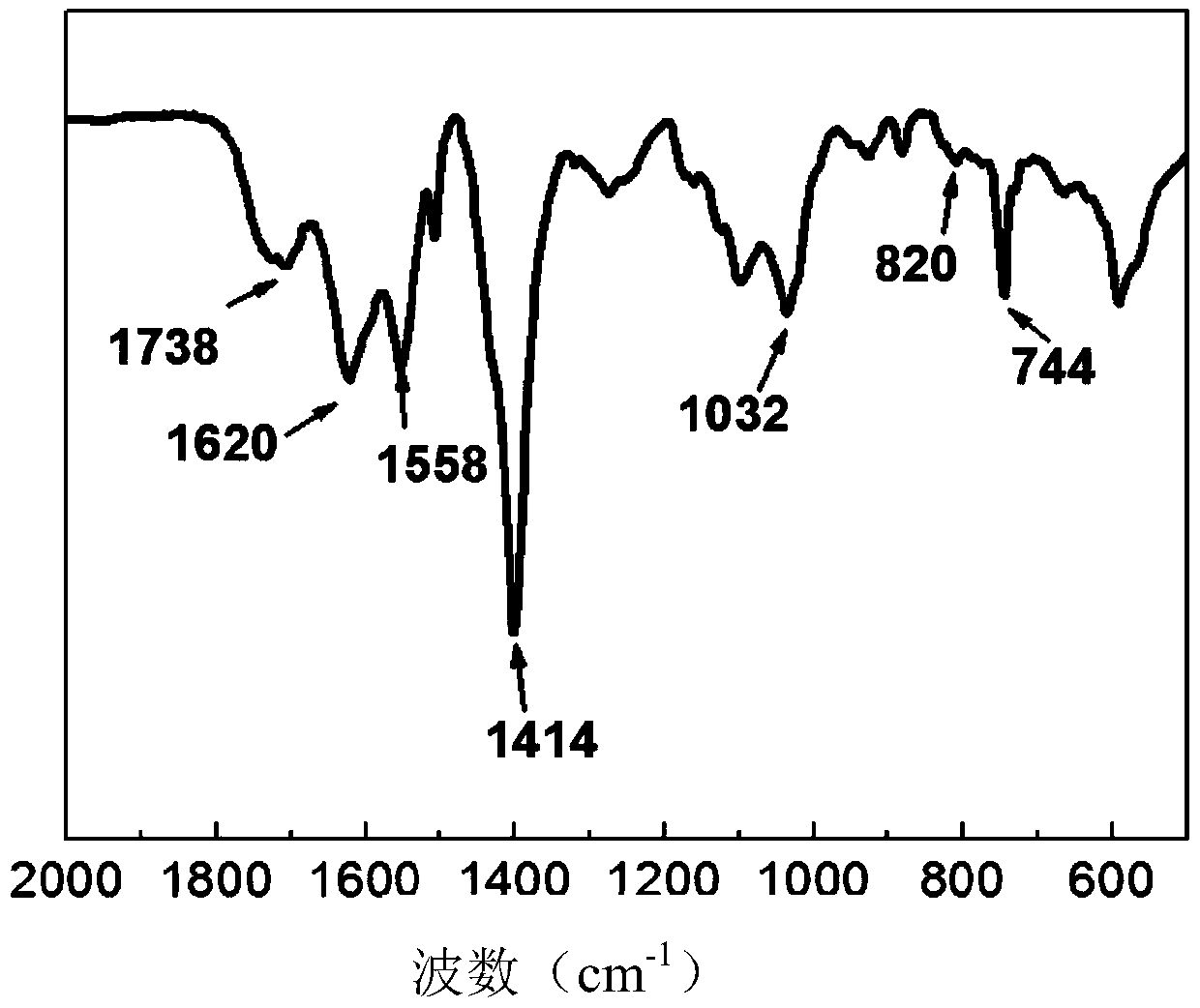

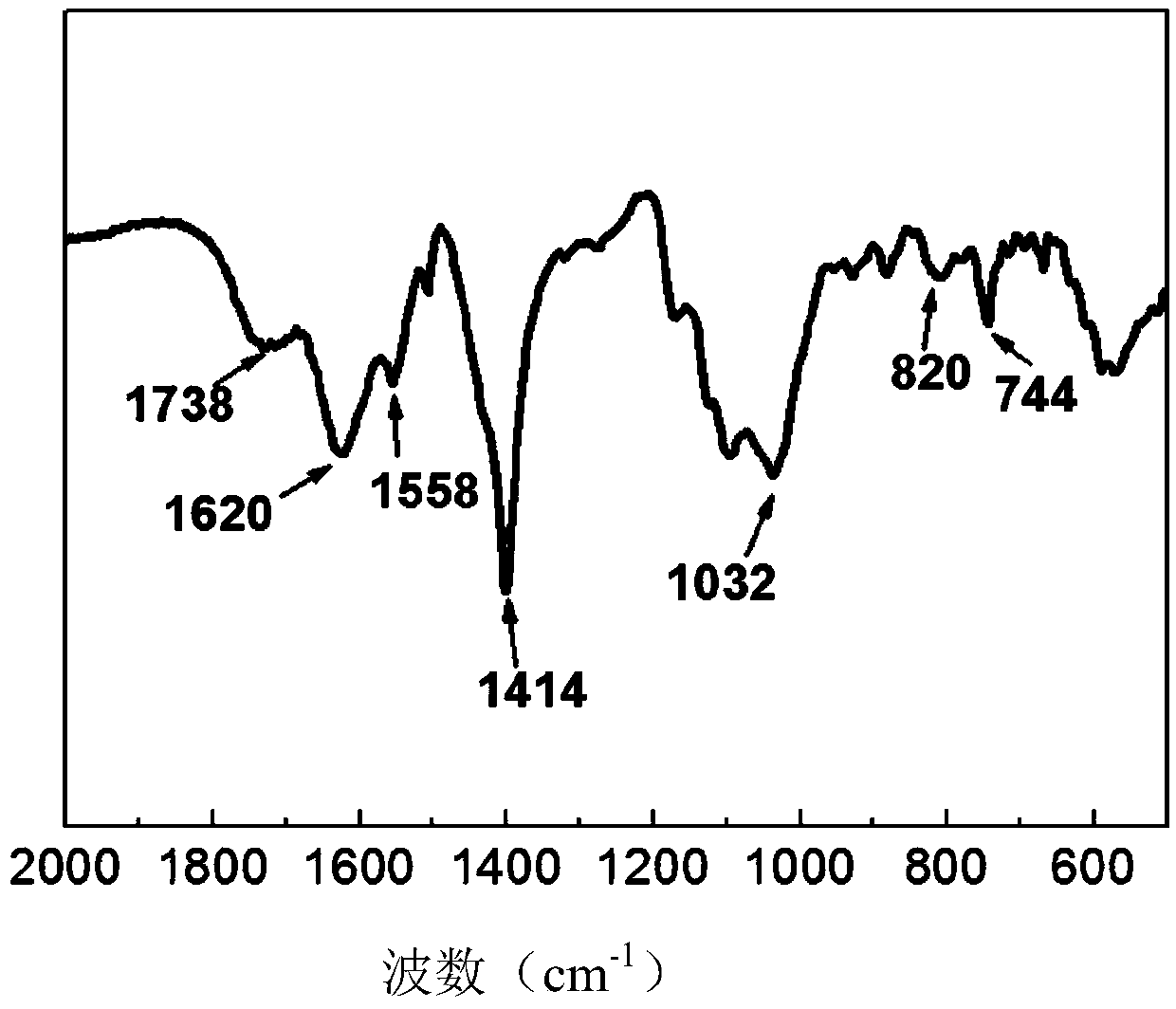

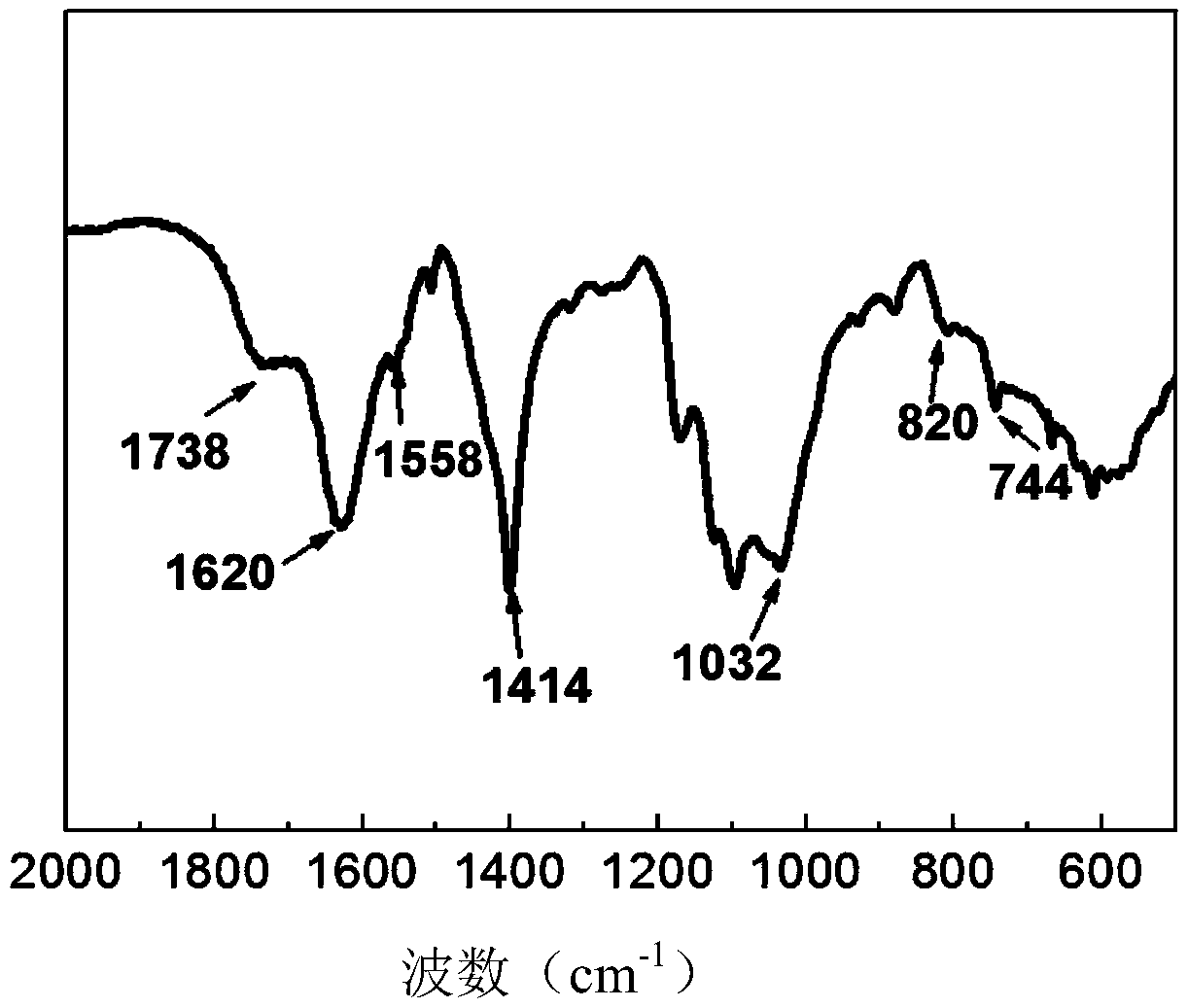

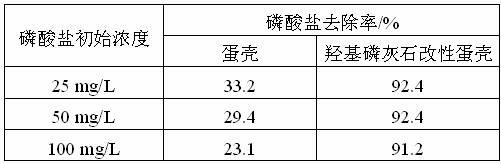

The invention relates to a hydroxyapatite modified eggshell adsorbent material as well as a preparation method and an application thereof. The invention also provides a method for removing the hydroxyapatite modified eggshell adsorbent material and recycling phosphate from wastewater. The invention has the advantages that: the speed of removing phosphate from the wastewater of the hydroxyapatite modified eggshell serving as an adsorbent is obviously higher than the speed of removing phosphate from the wastewater by using eggshell only; through the phosphorous removing process taking the hydroxyapatite modified eggshell as the adsorbent, the hydraulic retention time of a reactor is shorter, and the construction and operation cost is lower; the eggshell and hydroxyapatite do not release harmful ions in the phosphorous removing process, thereby avoiding the risk of secondary pollution on the water and protecting the environment.

Owner:SHANGHAI OCEAN UNIV

Preparation method of floating embedding bacterium agents for in-situ remediation of oil polluted water

InactiveCN102888392AAvoid competition effectsImprove purification effectMicroorganism based processesOn/in organic carrierPetroleum PollutionEnvironmental engineering

The invention relates to a preparation method of floating embedding bacterium agents for in-situ remediation of oil polluted water, specifically relating to a technology for fixing oil degradation bacteria by using expanded graphite, sodium alginate and calcium chloride, absorbing and degrading to purify the petroleum polluted water. The preparation method of the floating embedding bacterium agents comprises the following steps: adding petroleum degrading bacteria liquid into sodium alginate sol containing the expanded graphite, mixing uniformly, dropping into calcium chloride solution and cross-linking overnight at 4 degrees centigrade to obtain the floating embedding bacterium agents fixing hydrocarbon degradation bacteria. The floating embedding bacterium agents prepared by the preparation method has the advantages of high mechanical strength, good floatability and mass transfer performance and high degradation efficiency; the floating embedding bacterium agents can be directly put onto the surface of the petroleum polluted water; the embedding bacterium agents can float on an oil-water interface for long term so as to ensure effective contact between the bacterium agent and the petroleum; the embedding technology increases the concentration of microorganisms, prevents the bacteria influencing by the water using environment, effectively improves the degradation efficiency, recovers and recycles conveniently and has no secondary pollution risk.

Owner:TONGJI UNIV

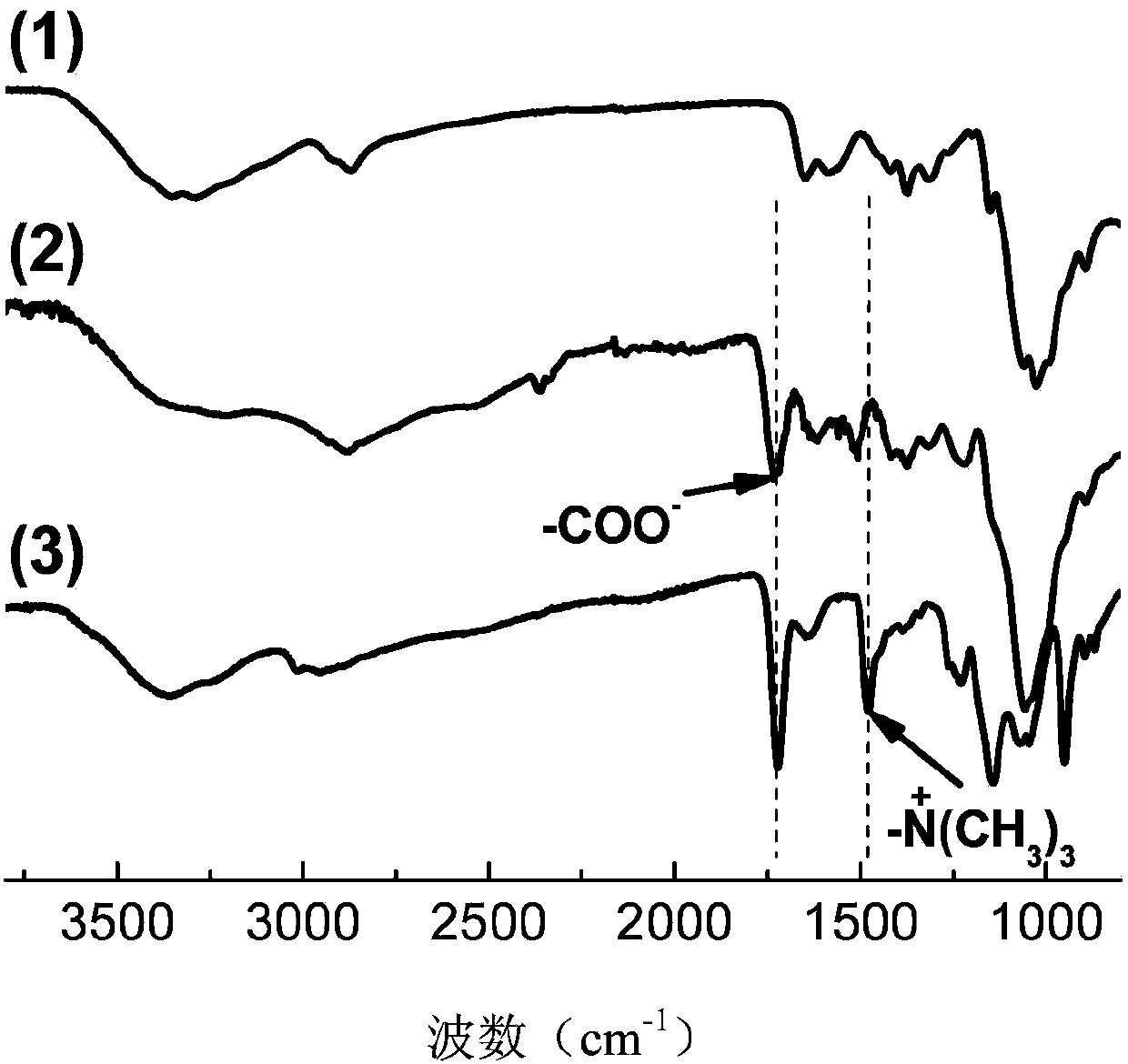

Chemical bond connected strong cationic grafted amphoteric chitosan flocculant and preparation method thereof

InactiveCN103387279AImprove solubilityGood flocculation effectWater/sewage treatment by flocculation/precipitationChemical oxygen demandCarboxylic acid

The invention relates to a chemical bond connected strong cationic grafted amphoteric chitosan flocculant which is obtained by grafting strong cationic monomers to amphoteric carboxymethyl chitosan in an acidic condition through copolymerization. The chemical bond connected strong cationic grafted amphoteric chitosan flocculant is in such a structure as follows: in the chemical bond connected strong cationic grafted amphoteric chitosan flocculant, degree of substitution of a carboxylic acid group is 5-90%, methylacryloyl oxyethyl trimethyl ammonium chloride is a strong cationic monomer, and polymethylacryloyl oxyethyl trimethyl ammonium chloride accounts for 5-80% by mass of the chemical bond connected strong cationic grafted amphoteric chitosan flocculant. The flocculant provided by the invention has amphoteric characteristics, so that not only is the flocculant property improved, but also the dissolving property is improved. The raw material chitosan is wide in source, natural, non-toxic and degradable. The flocculant has multiple functions of good flocculation effect, metal ion absorption, bacteriostasis, deodorization, decoloration, and effective reduction of COD (Chemical Oxygen Demand) value and the like.

Owner:NANJING UNIV

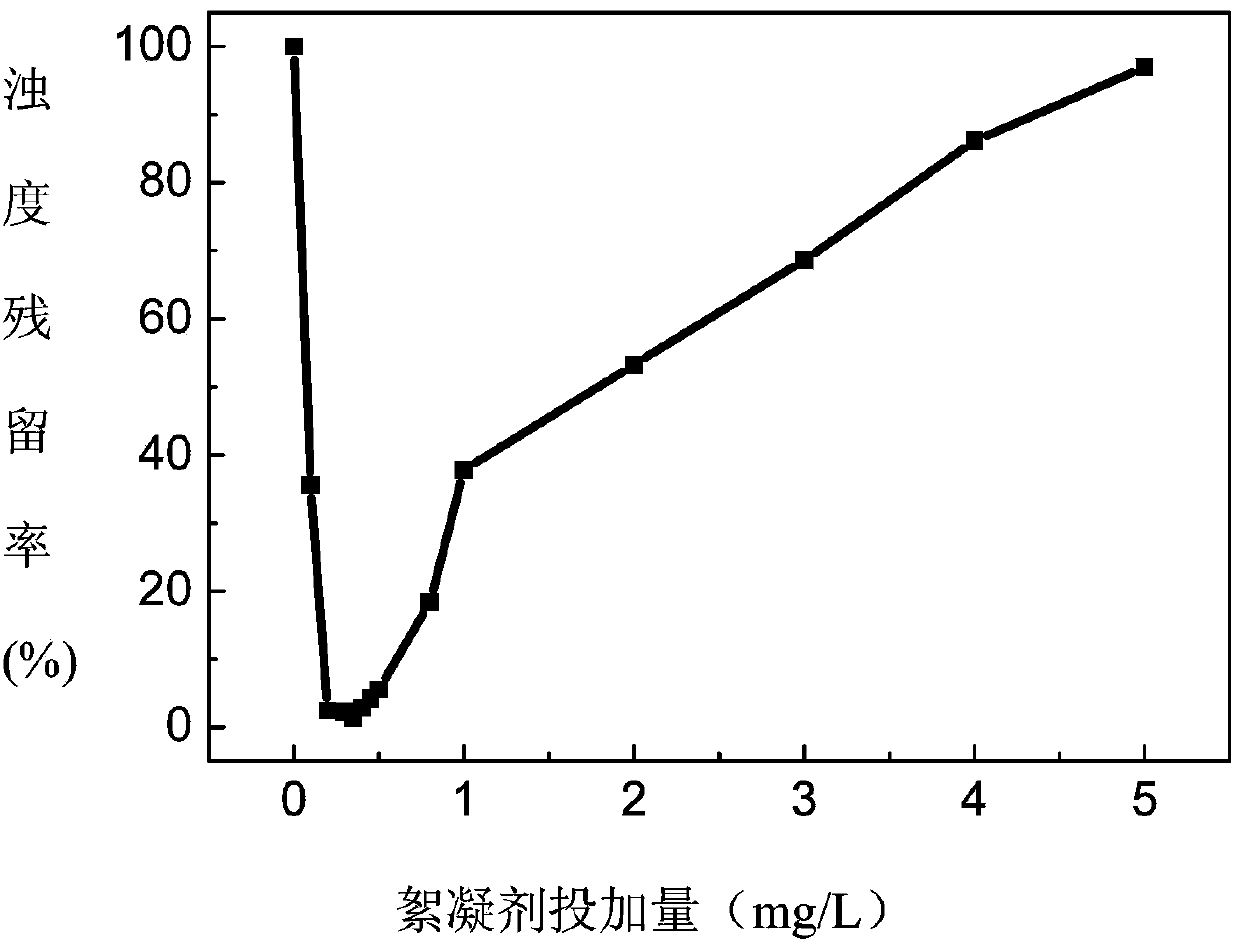

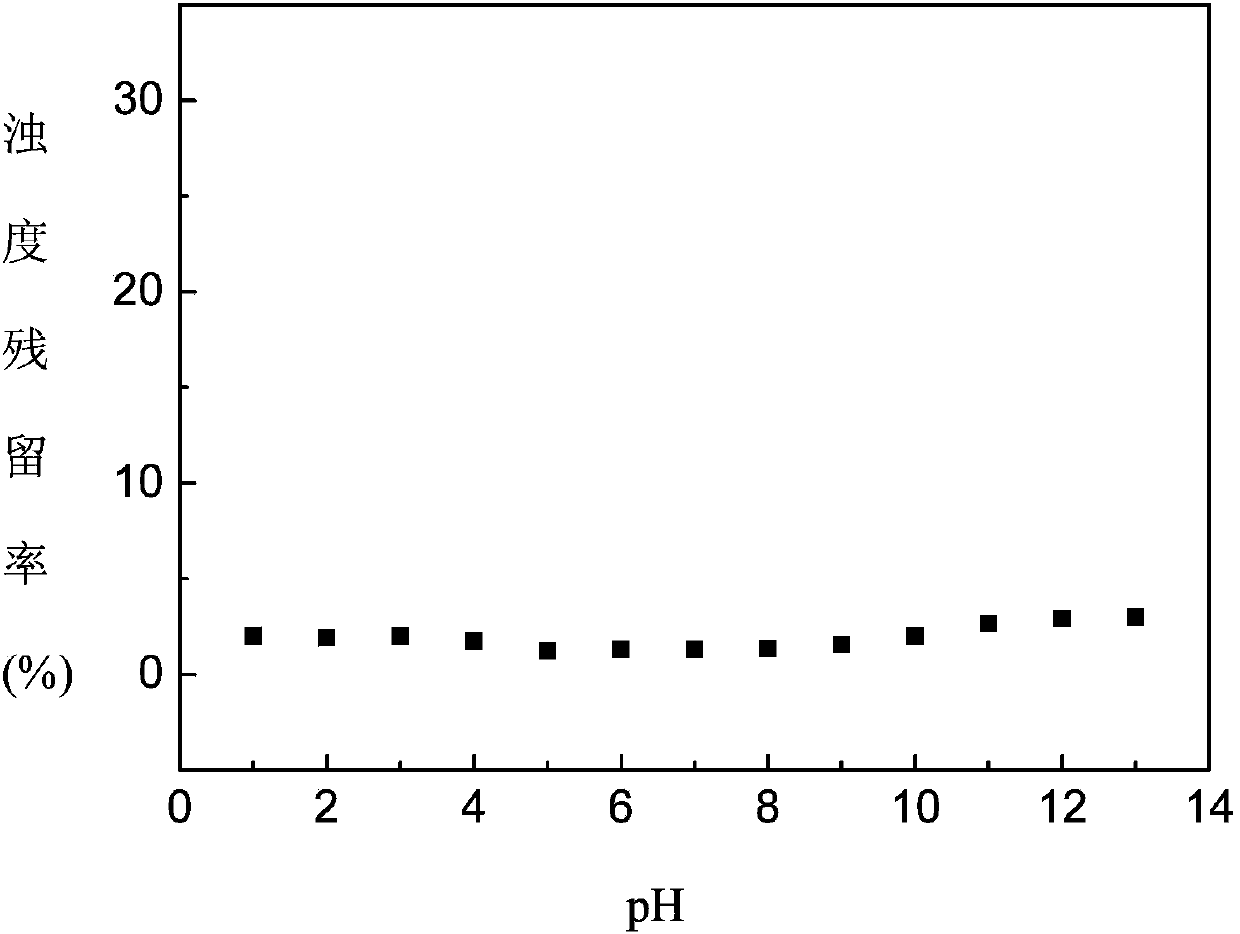

Organic polymer heavy metal chelating flocculant as well as preparation method and application thereof

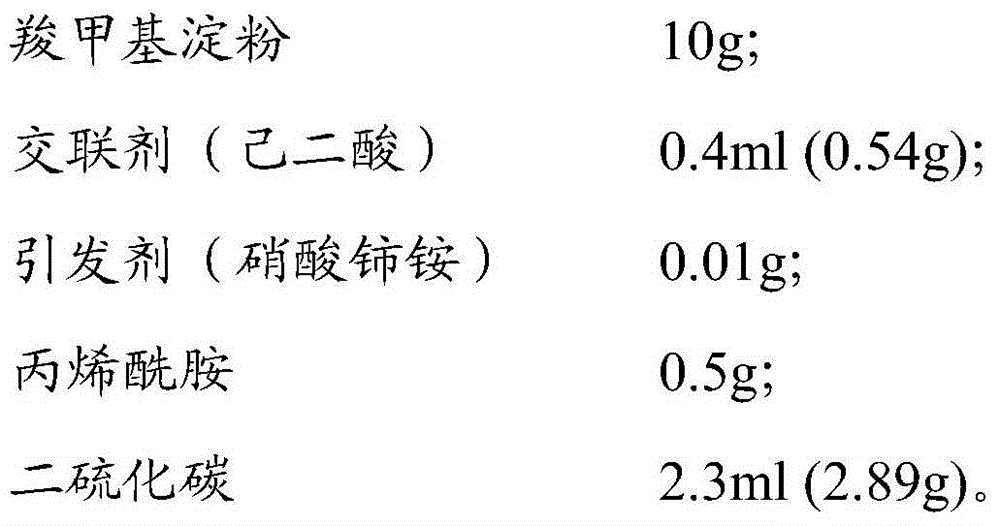

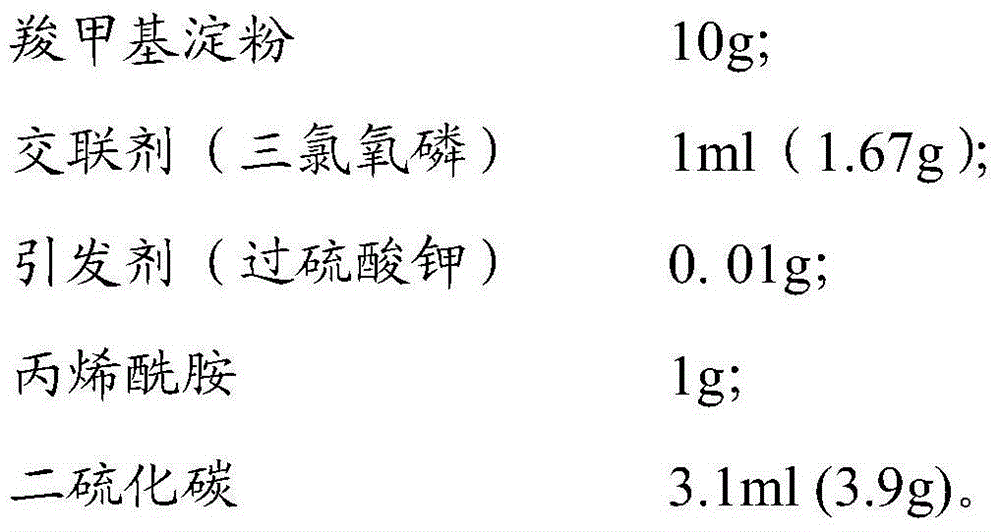

ActiveCN104649398AImprove the coordination effectEasy to removeWater contaminantsWater/sewage treatment by flocculation/precipitationHeavy metal chelationAdipic acid

The invention discloses an organic polymer heavy metal chelating flocculant as well as a preparation method and an application thereof. The organic polymer heavy metal chelating flocculant is prepared from the following raw materials in parts by weight: 100 parts of carboxymethyl starch, 5-20 parts of a crosslinking agent, 0.05-0.5 part of an initiator, 5-20 parts of acrylamide and 28-60 parts of carbon disulfide, wherein the crosslinking agent is adipic acid, phosphorus oxychloride or sodium trimetaphosphate. The organic polymer heavy metal chelating flocculant has the efficacies of both excellent heavy metal chelating precipitation and flocculation, has the advantages of rapidness in reaction speed, ideal effect of removing heavy metal ions, high treatment efficiency and the like, is low in dosage and cost and is capable of economically and efficiently treating sewage containing the heavy metal ions.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +2

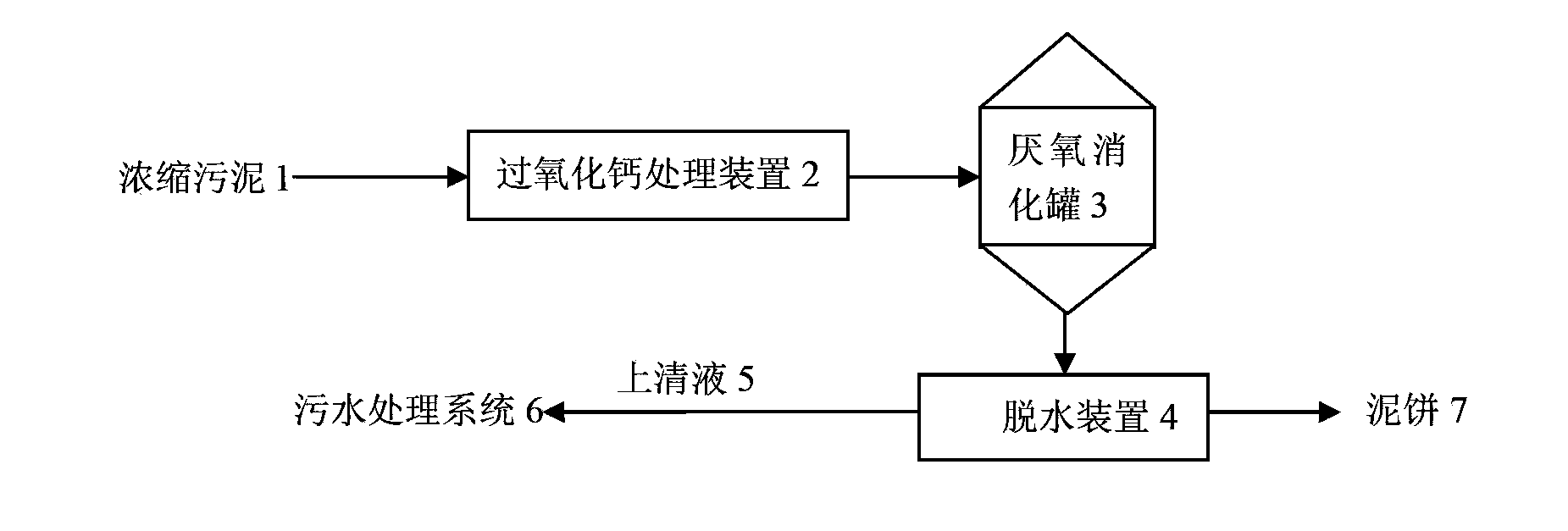

Method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge

ActiveCN103880259AEliminate Pollution PotentialImprove the efficiency of anaerobic digestionWaste based fuelBiological sludge treatmentBiogasAerobic digestion

The invention relates to a method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge, which comprises the following steps: 1)a calcium peroxide processing unit: placing the calcium peroxide in the sludge, wherein the mass ratio of calcium peroxide to sludge is 0.01: 1-0.6:1, reacting for 1-24 hours, and hydrolyzing the sludge; and 2)an anaerobic digestion unit: after processing the calcium peroxide, performing anaerobic digestion on sludge under the effect of anaerobe and amphimicrobe in an anaerobic digestion tank, rapidly using an organic compound in the sludge, conversing to methane, carbon dioxide and water, increasing the sludge biogas output and then realizing the quantitative reduction. Compared with the prior art, the method for promoting hydrolysis of sludge by using calcium peroxide and increasing effect of anaerobic digestion of sludge has the advantages of low cost, shortened digestion time and easy enforcement.

Owner:TONGJI UNIV

Method for extracting curcumin from turmeric

ActiveCN102617316AShort processNo risk of secondary pollutionCarbonyl compound separation/purificationSorbentSolvent

The invention relates to a method for extracting curcumin from turmeric. The method is characterized by comprising the following steps that: the turmeric is cleanly cleaned and is then crushed into turmeric powder, the turmeric powder and extraction solvents are mixed according to a certain proportion and are then subjected to backflow extraction, next, the separation is carried out under certain conditions to remove heavy metals, and finally, the precipitates are separated and crystallized to obtain curcumin. Compared with the prior art, the method has the advantages that the heavy metal separation and purification flow process is simple and short, the risk of secondary pollution caused by the additional addition of absorption agents or absorption media is avoided, and the heavy metal residue of products can be purified to a degree that the lead content is lower than 1.0PPM, the cadmium content is lower than 1.0 PPM, the mercury content is lower than 0.10 PPM, and the arsenic content is lower than 0.10PPM.

Owner:宁波中药制药股份有限公司

Preparation method of adsorption and catalysis material for removing heavy metals and organic pollutants in municipal sludge

InactiveCN104096540AImprove adsorption capacityHigh activitySludge treatmentPhysical/chemical process catalystsPhosphoric acidOrganopónicos

The invention relates to a preparation method of an adsorption-visible light catalysis material for removing heavy metals and persistent organic pollutants in municipal sludge, particularly to a biomass activated carbon supported P-TiO2 material with adsorption and visible light catalysis composite functions. Agricultural waste biomass, phosphoric acid and TiO2 are taken as main raw materials, under the airtight high-temperature pyrolysis condition, the phosphoric acid can be used as a biomass carbon activator and a TiO2 photo-catalysis dopant simultaneously, P-TiO2 can produce electrons-hole pairs under sunlight, when organic matters or metal ions are adsorbed on the surface of the P-TiO2, the electrons or holes can be obtained respectively, and corresponding redox reactions happen, so that the pollutants are removed. Meanwhile, the heavy metal ions in the sludge can be adsorbed and fixed by biomass activated carbon, so that the mobility and the bio-availability of the heavy metal ions are effectively reduced. The adsorption-visible light catalysis composite functional material prepared with the method has the characteristics of low price, high efficiency, wide application range, convenience in use and the like, and the risk of secondary pollution is avoided.

Owner:TONGJI UNIV

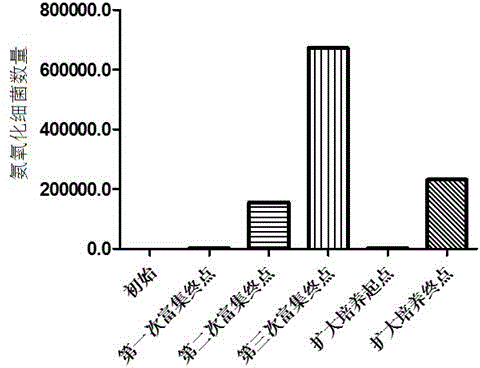

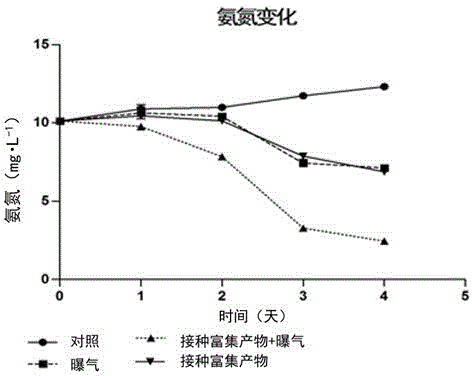

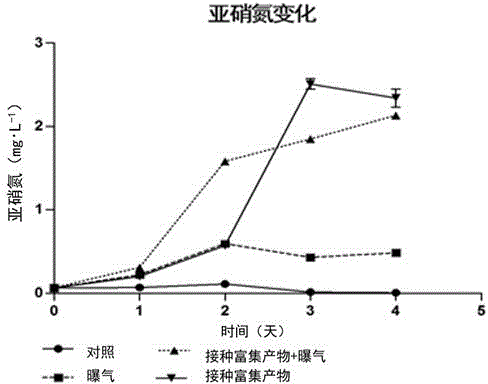

Enrichment culture method of indigenous nitrogen transforming microorganism and application of same to treatment of water ammonia-nitrogen pollution

InactiveCN104862257AAvoid adaptationAvoid security issuesBacteriaWater contaminantsMicroorganismNitrogen

The invention discloses an enrichment culture method of an indigenous nitrogen transforming microorganism and application of the same to the treatment of water ammonia-nitrogen pollution and belongs to the fields of environmental microbiology and environmental protection. An environmental sample is acquired from a water body required to be treated and cultured by a specific enrichment culture medium to obtain an enrichment culture seed of the indigenous nitrogen transforming microorganism. The enrichment culture seed and the enrichment culture medium are added into an in-situ water sample to carry out amplification culture, and then, the enrichment culture seed obtained through expansion culture is applied to the water body, so that the water ammonia-nitrogen pollution is treated. The efficient indigenous nitrogen transforming microorganism obtained through the method for carrying out enrichment amplification on the in-situ sample has better pertinence than a common commercial bactericide, and also avoids the adaptability of an external bactericide to the water body and potential ecological hazard. The rapid growth of the efficient indigenous nitrogen transforming microorganism is ensured through carrying out enrichment under manual controllable conditions, the effect is more stable than the effect of directly adding a growth promoter to the water body, and secondary pollution risks are avoided.

Owner:HUBEI UNIV OF TECH

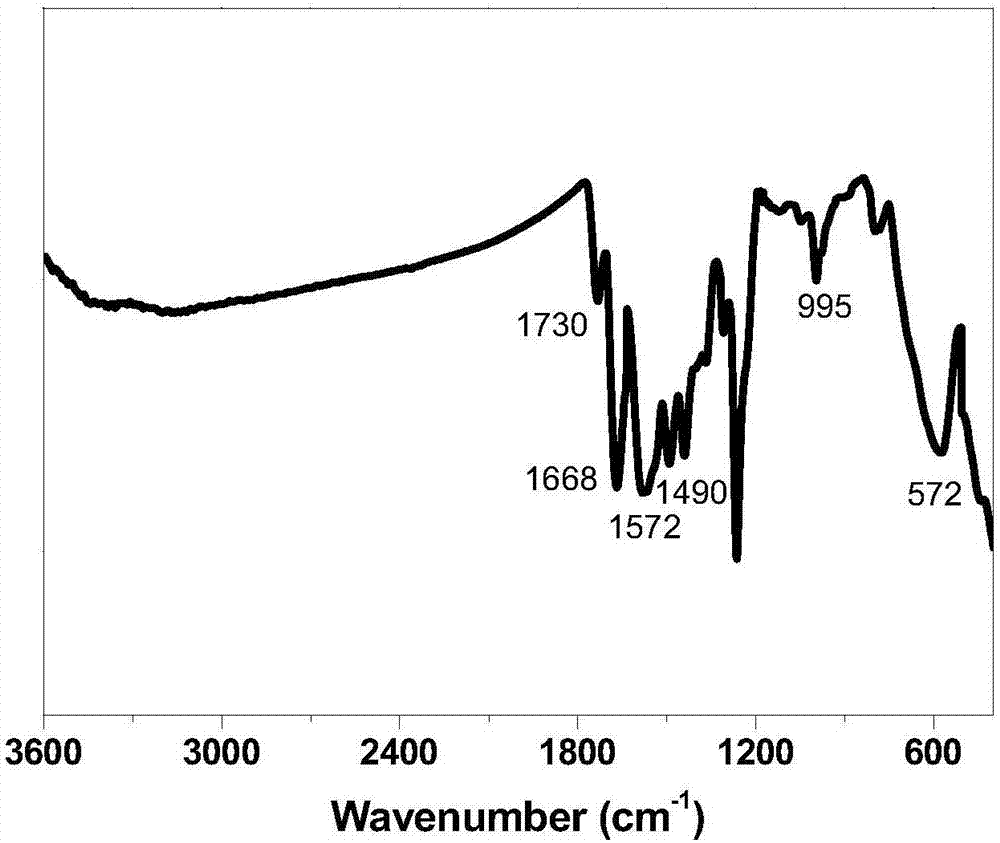

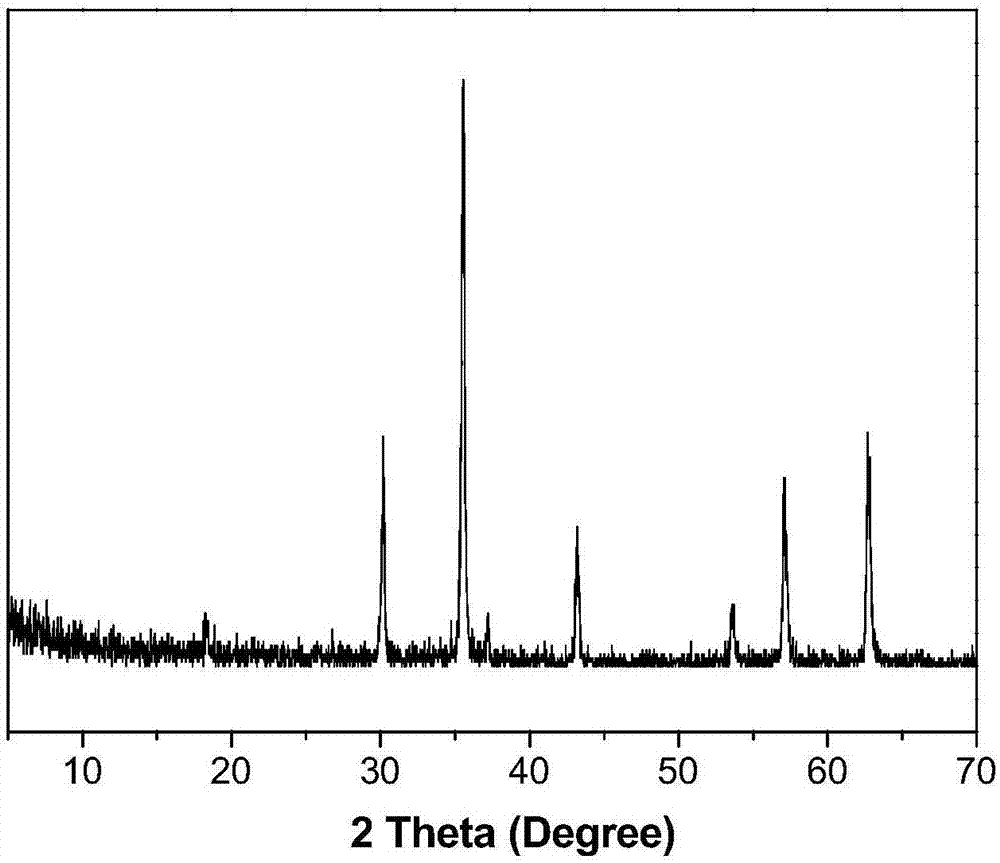

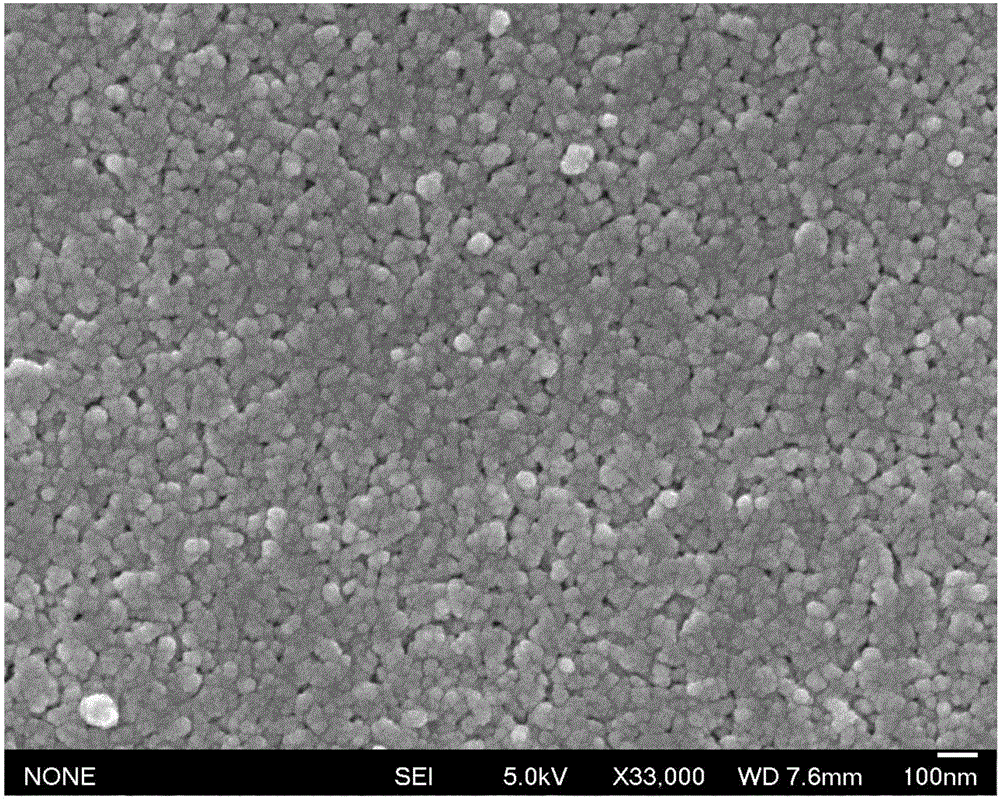

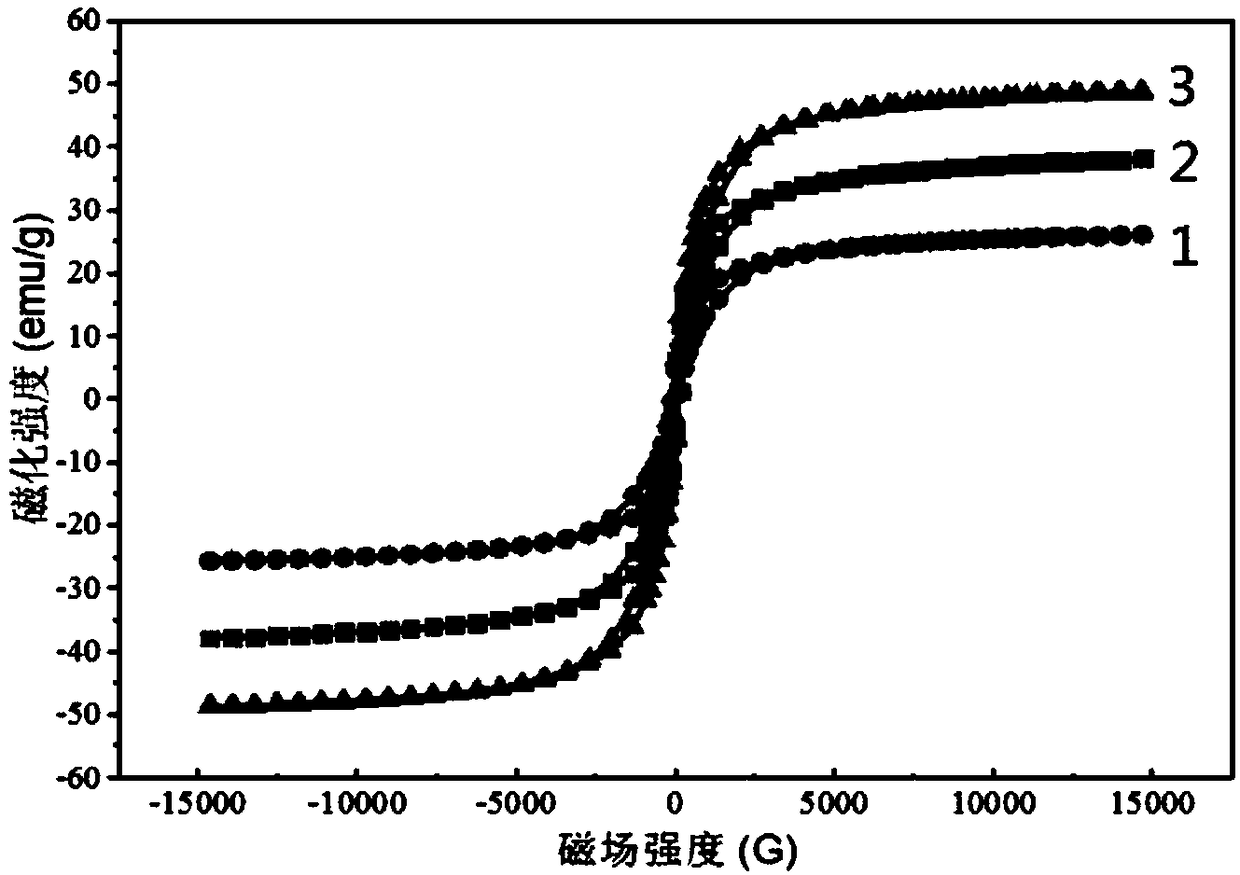

Magnetic covalent organic frame material and preparation method and application thereof

ActiveCN107159133ALarge adsorption capacityImprove stabilityOther chemical processesWater/sewage treatment by magnetic/electric fieldsSolventSmall particle

The invention discloses a magnetic covalent organic frame material and a preparation method and an application thereof. The magnetic covalent organic frame material takes piperazine and cyanuric chloride as the construction units to form a covalent organic frame, and then the covalent organic frame is loaded on the organic frame material formed on the surface of magnetic ferriferrous oxide. The organic frame material better solves the problems of small particle size, poor stability and difficult separating from a water body of the current covalent organic frame materials. The method employs a solvothermal method, and akes the magnetic ferriferrous oxide nano particles as a carrier, the material is immersed into a piperazine-containing ligand solution, a cyanuric chloride ligand solution is dropped, and a hydro-thermal reaction is carried out under constant temperature condition to obtain the magnetic covalent organic frame material. The material has the characteristics of strong separating capability in water, large adsorption quantity on pollutants in the water body, high mechanical strength and environmental friendliness.

Owner:NANJING NORMAL UNIVERSITY

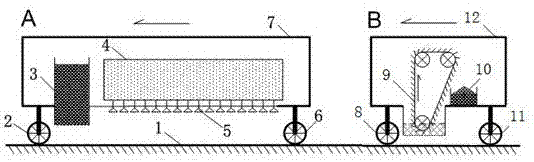

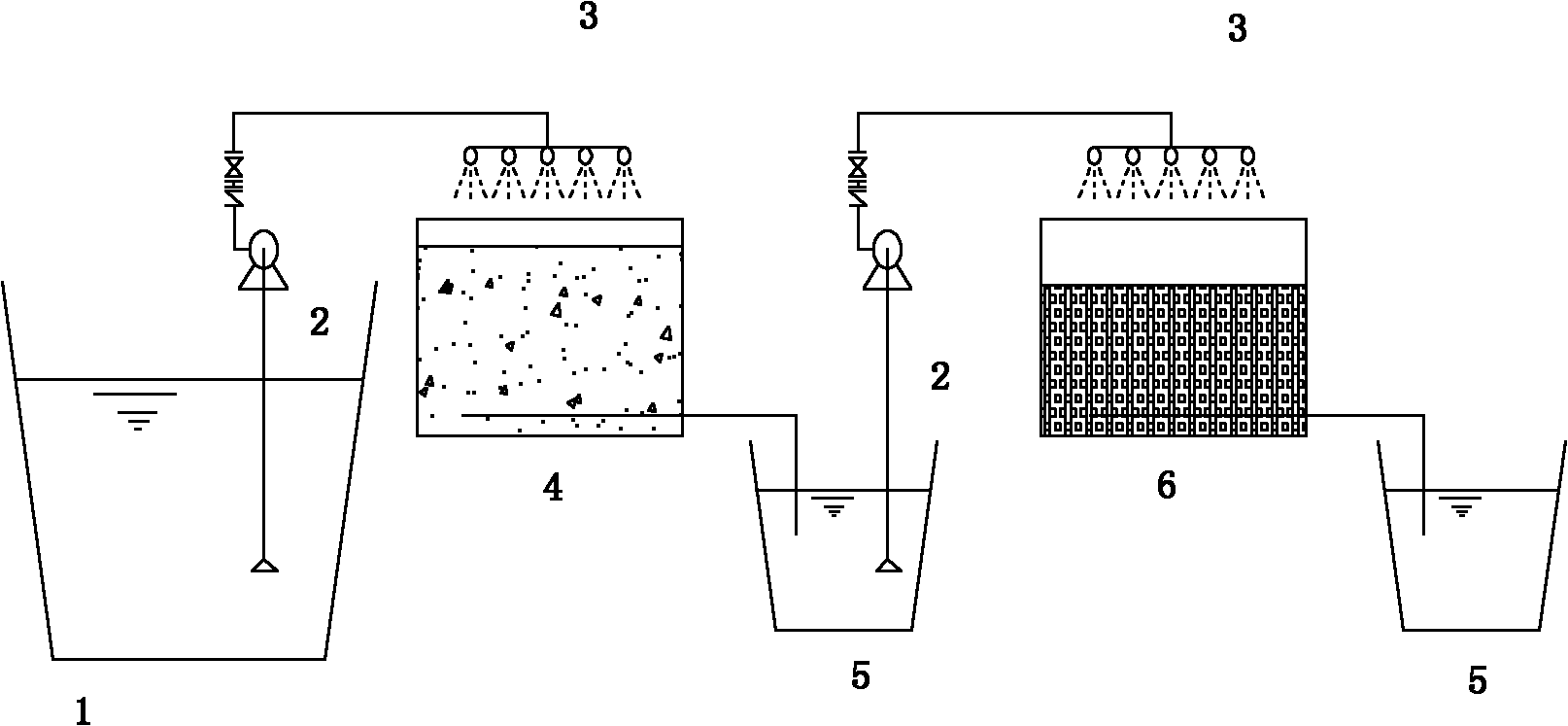

In-situ repair method and system for heavy meal cadmium and polycyclic aromatic hydrocarbon polluted farmland soil

The invention discloses an in-situ repair method and system for heavy meal cadmium and polycyclic aromatic hydrocarbon polluted farmland soil. The method comprises the following steps: (1) spreading a mixture of carbon coated porous foamed iron subparticles, a peroxide and sodium phytate into polluted soil; (2) spraying a hydrogen peroxide solution into the polluted soil, concentrating and removing pollutants such as polycyclic aromatic hydrocarbon and heavy meal cadmium in the soil; and then recycling carbon coated porous foamed iron subparticles. The system comprises a material spreading device and a recycling device, the material spreading device comprises a material spreading moving rack, and the material spreading moving rack is provided with a mixture hopper, a hydrogen peroxide solution storage tank and a hydrogen peroxide solution spray head; the recycling device comprises a recycling moving rack, and the recycling moving rack is provided with a magnet recycling device and a foamed iron recycling tank. The method is simple in process, low in cost and high in continuity, the damage on soil microorganisms and organic matters is avoided, and the risk of secondary pollution does not exist.

Owner:QINGDAO AGRI UNIV

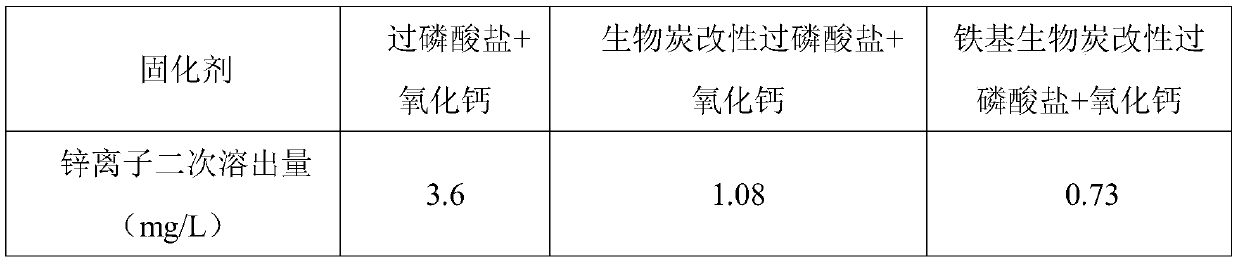

Heavy metal polluted soil solidification and repairing composite compound and solidification and repairing method

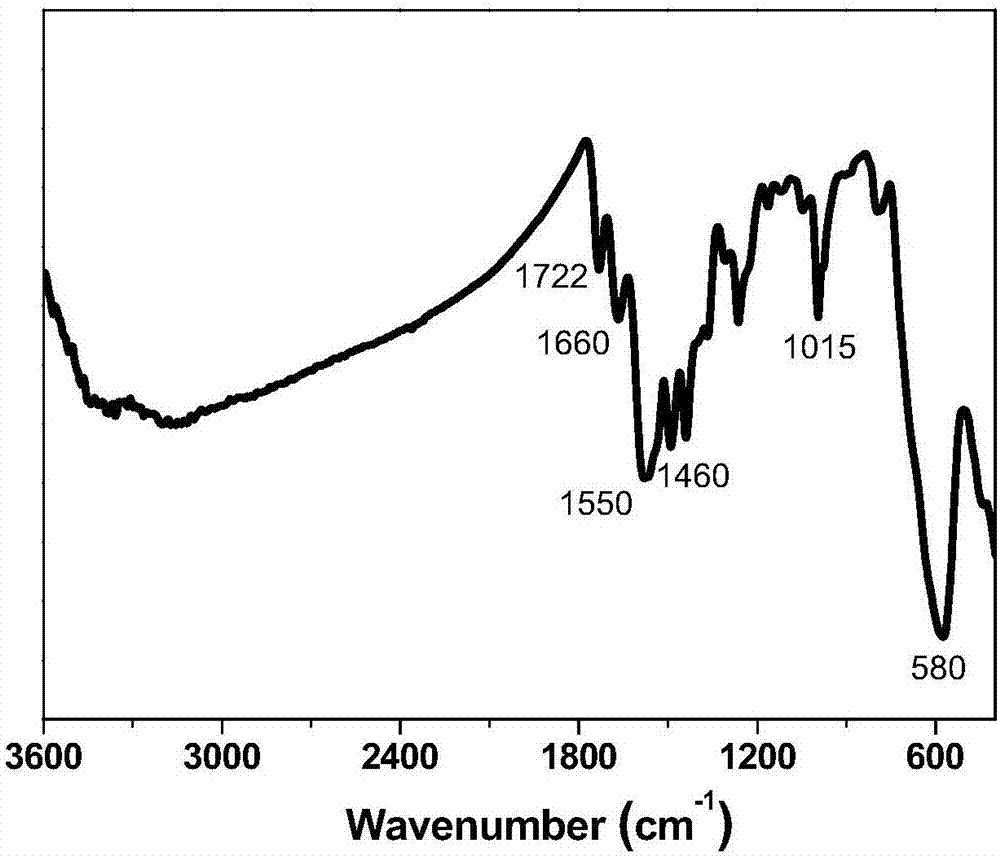

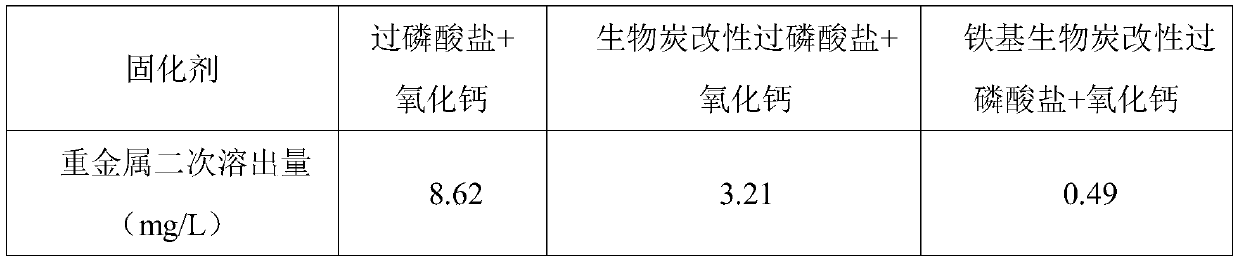

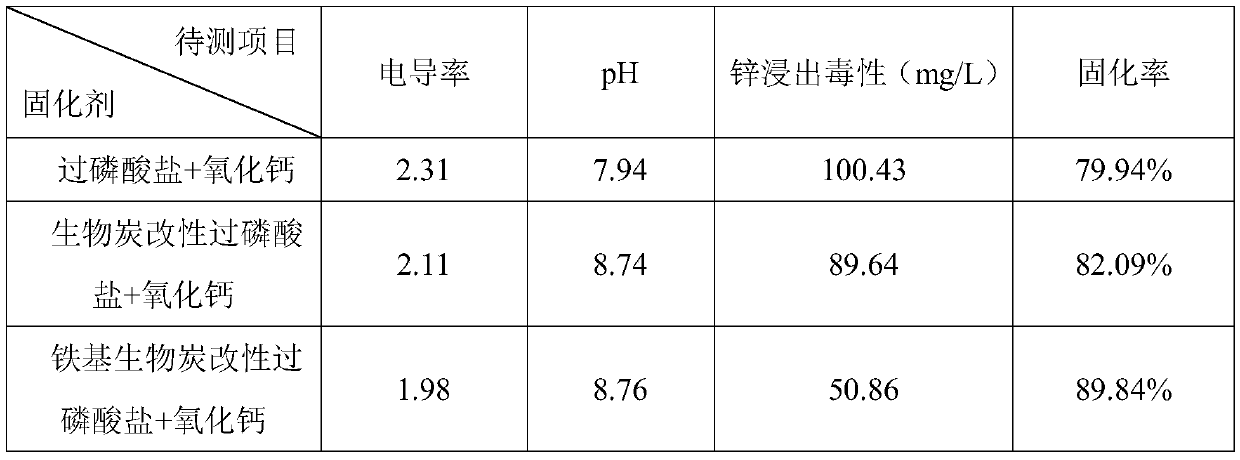

ActiveCN110699084AInhibit oxidative decompositionReduced risk of secondary dissolutionOther chemical processesContaminated soil reclamationIron saltsSoil heavy metals

The invention discloses a heavy metal polluted soil solidification and repairing composite compound and a solidification and repairing method. The composite compound comprises the following componentsin percentage by mass: 20-40% of quicklime and 60-80% of an iron-based biochar modified phosphate mineral, wherein the iron-based biochar modified phosphate mineral is obtained by uniformly mixing and drying an iron salt and biomass, further mixing the mixture with a phosphate mineral uniformly and performing co-pyrolysis. The method for solidifying and repairing heavy metal polluted oil by usingthe composite compound comprises the following steps: firstly, uniformly mixing the iron-based biochar modified phosphorate mineral with quicklime so as to obtain the heavy metal polluted soil solidification and repairing composite compound; applying the composite compound into heavy metal polluted soil, adding water, and performing uniform stirring; and performing maintenance of the best standards, so as to complete solidification repairing on the heavy metal polluted soil. By adopting the heavy metal polluted soil solidification and repairing composite compound, secondary dissolution of heavy metals can be greatly avoided, and the long-term stability of solidification of the heavy metal polluted soil can be greatly enhanced.

Owner:SOUTHEAST UNIV

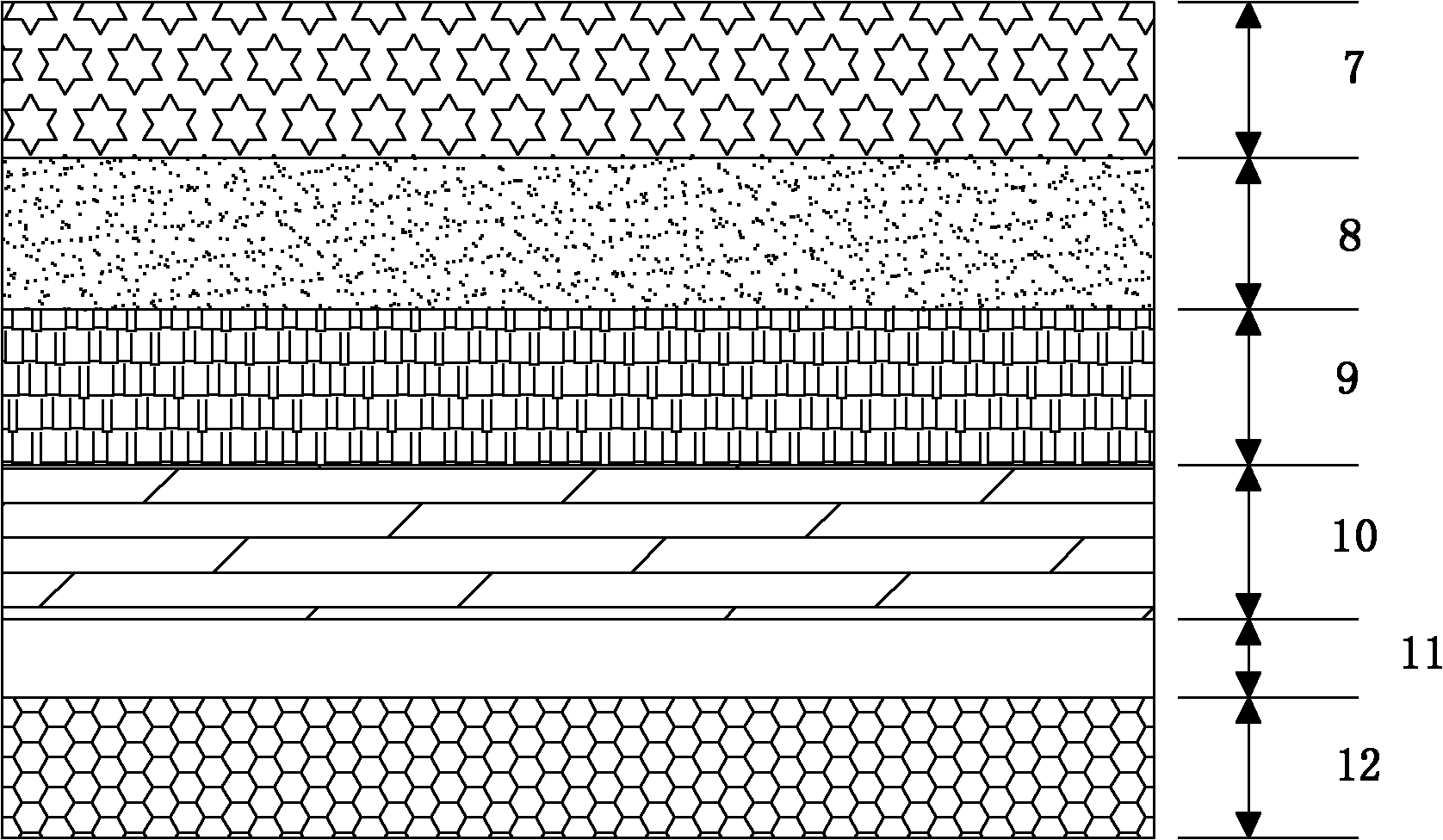

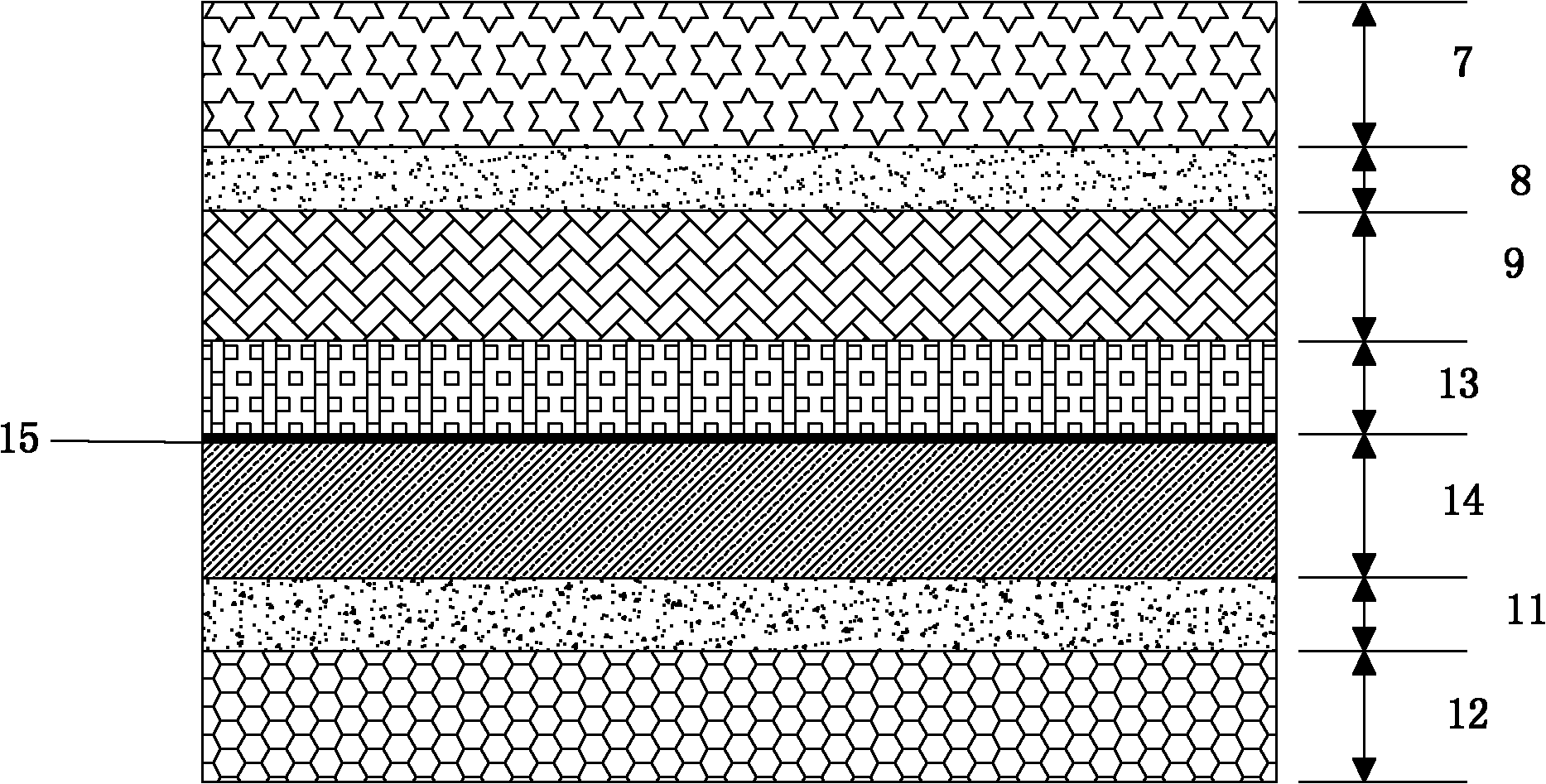

Method for processing CH4 in landfill site after acclimatizing and mineralizing garbage by utilizing percolate

InactiveCN101966422AAchieve enrichmentReduce the total equivalents releasedMethane captureWaste processingMacroporous resinChemistry

The invention discloses a method for processing CH4 in a landfill site after acclimatizing and mineralizing garbage by utilizing a percolate, belonging to the field of a percolate processing and greenhouse gas emission reduction method in a landfill site. The method comprises the following steps: (1) lifting the percolate to an adsorption material layer, wherein the adsorption material layer comprises an active carbon layer and a macroporous resin layer, and the water distribution load is 0.05 to 0.50m<3> / (m<3>mineralized garbage.d); (2) lifting the effluent of the garbage percolate after processing to a mineralized garbage packing layer to be processed, wherein the water distribution load is 0.05 to 0.30m<3> / (m<3>mineralized garbage.d); and (3) adding a mineralized garbage layer after acclimatizing the garbage percolate obtained by carrying out the step (2) between a drainage layer and a vegetable layer or below the drainage layer in the construction of a final covering layer in the landfill site.The invention has the advantages that the garbage percolate is processed; the mineralized garbage is recycled; the toxicity is eliminated and ammonia nitrogen components are remained by preprocessing the percolate; the acclimatization and enrichment of ammonia oxidation bacteria are utilized to oxidize CH4; and the release total equivalent of greenhouse gas in the landfill site is reduced.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Method for adsorbing phosphate in sewage by using eggshells

InactiveCN102190343AAchieve reuseRich sourcesWater/sewage treatment by sorptionSocial benefitsEggshell

The invention belongs to the field of phosphate-containing sewage treatment, and discloses a method for adsorbing phosphate in sewage by using eggshells. The method comprises the following steps that: first, cleaned and shell-membranes-removed eggshells are dried at a temperature of 102 to 105 DEG C, and are grinded; the grinded eggshells are screened with a sieve of 300 meshes, such that eggshell power with a gain size of less than 300 meshes is obtained; 0.2 to 5g of eggshell powder is added to 50 to 1000mL of sewage with a phosphate concentration of 0.2 to 20mg / L and a pH value of 7 to 10; the resulting mixture is stirred for 8 to 12 hours under a temperature of 10 to 40 DEG C, and with a rotary speed of 50 to 200 rpm, such that the adsorption process is finished. According to the method, the phosphate adsorption is realized with the phosphate absorbability of eggshells. Compared with current common phosphate treatment methods, the method provided by the present invention has characteristics of no secondary pollution, abundant raw material source, low operation cost, and stable phosphate removing effect. The method accords with an environmental protective idea of: restricting waste with waste, and brings in good social benefit and environmental benefit.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for preparing heavy metal adsorbent by utilizing caustic dross

ActiveCN103977754AAchieve reductionRealize resourcesOther chemical processesWater/sewage treatment by sorptionPhysical chemistryWaste treatment

The invention discloses a method for preparing a heavy metal adsorbent by utilizing caustic dross. The method comprises the following steps: (1) pretreating caustic dross; (2) synthesizing a powdery adsorbent; (3) preparing a forming adsorbent; (4) applying high-concentration heavy metal waste water. According to the invention, solid waste caustic dross of ammonia alkali factories is adopted as raw material to prepare a heavy metal adsorbent which is high in adsorption efficiency and is environment-friendly; not only is a high-additional-value resource road found for the caustic dross, and the solid waste treatment pressure of the ammonia alkali factories is relieved, but also the environment-friendly concepts of 'turning wastes into wealth' and 'treatment of wastes with processes of wastes against one another' are realized.

Owner:NANJING UNIV OF SCI & TECH

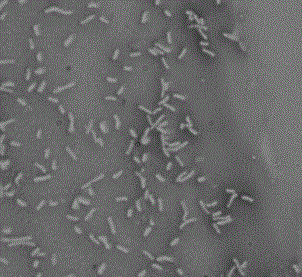

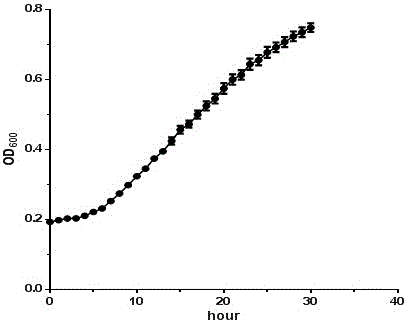

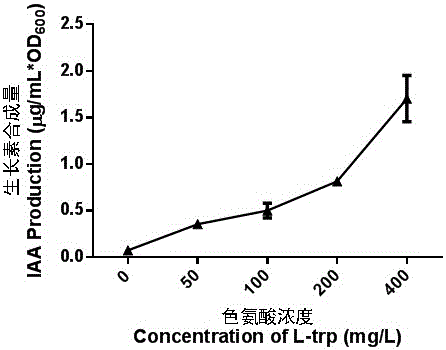

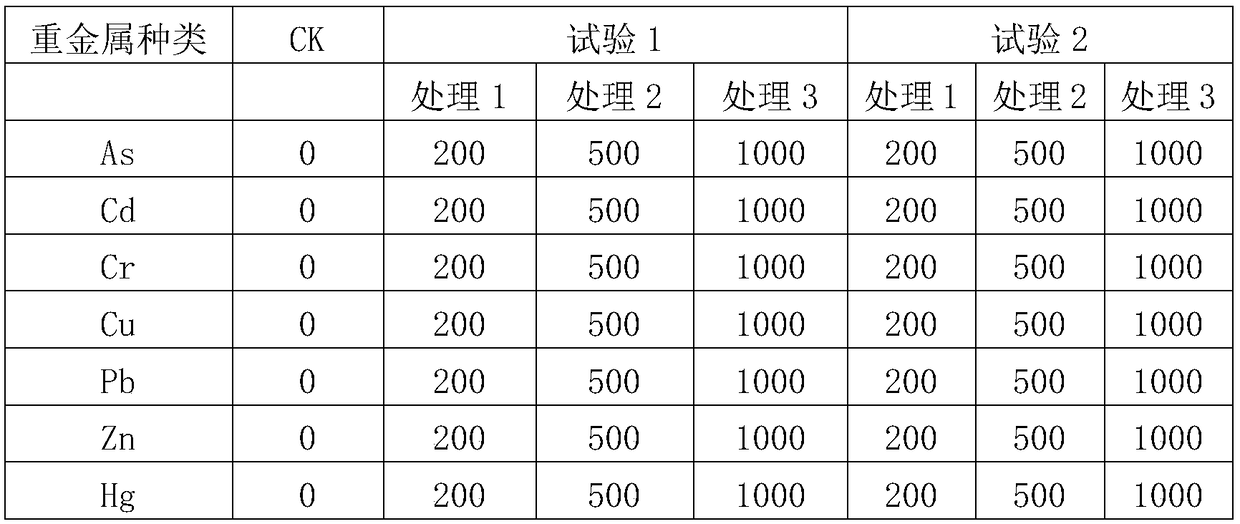

Rhizobium Scot1305 and application of rhizobium Scot1305 in promoting phytoremediation of heavy metal pollution of soil

ActiveCN106167774AImprove repair effectIncrease enrichment contentBacteriaContaminated soil reclamationRoot noduleSecreted substance

The invention provides rhizobium Scot1305 and a symbiotic system of rhizobium Scot1305 and plants is established. Due to nitrogen fixation function, siderophore secretion function and soluble phosphorus activity of the rhizobium strain and protection effect of the rhizobium strain on key enzyme of plant tocopherol synthesis, enhancement effect of the strain on phytoremediation of Co contaminated soil is realized. The strain can coexist with plants in Co contaminated soil, and can promote the extraction and enrichment of heavy metals Co in the aerial parts of plants, and finally achieve the purpose that the content of Co in soil meets the environmental safety standard.

Owner:SICHUAN INST OF ATOMIC ENERGY

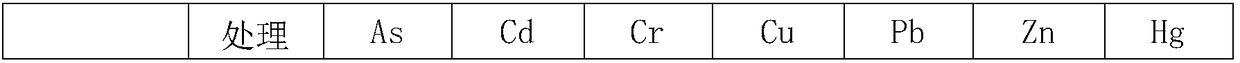

Compound repair agent for heavy metal polluted soil and application thereof

ActiveCN109233840AReduced mobility and bioavailabilityReduce environmental risksContaminated soil reclamationOrganic fertilisersFertilizerAgriculture

The invention relates to a compound repair agent for heavy metal polluted soil which is characterized by being prepared from the following raw materials in percent by weight: 40-55% of charcoal, 15-35% of bone powder and 15-35% of coal ash. By taking agricultural or industrial solid wastes which are wide in source and easy to obtain as a raw material, the compound repair agent is simple in process, sufficient in raw material, low in cost and obvious in application effect, reduces the heavy metal mobility and bioavailability of soil, and can solve the problem of sustainable utilization of heavymetal pollution in farmlands and fields of industrial and mineral industry. The application method is simple, the using process is labor-saving, the physical and chemical properties of soil can be also improved effectively, the fertilizer retaining and water retaining ability of soil is improved, and the compound repair agent is easy to popularize and apply.

Owner:ANSTEEL GRP MINING CO LTD

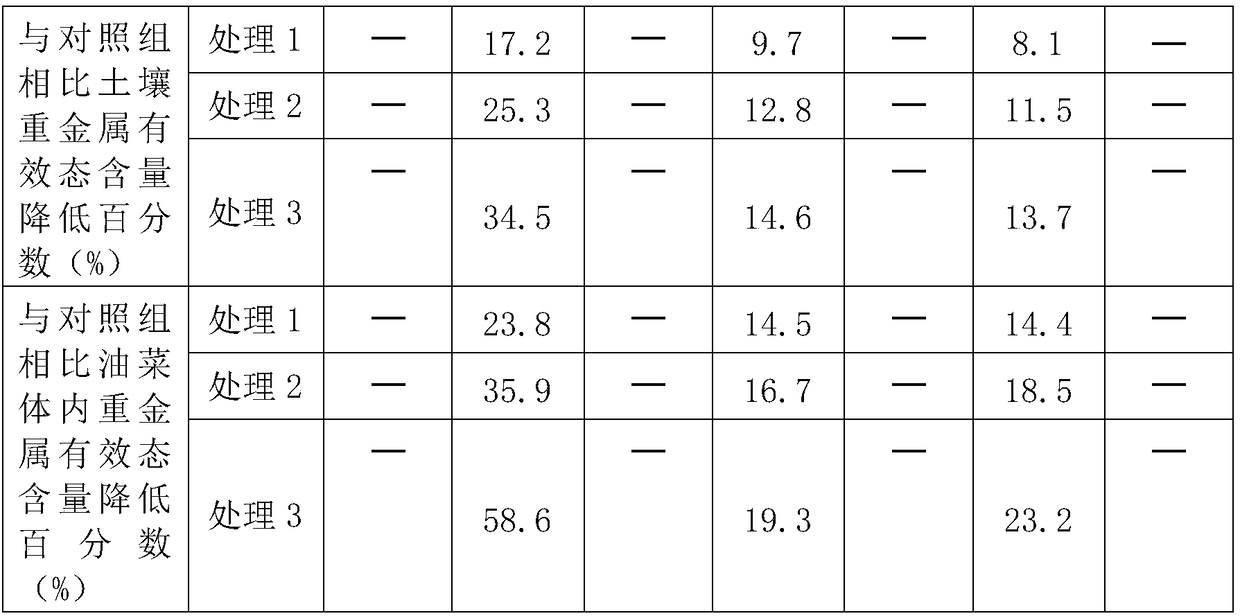

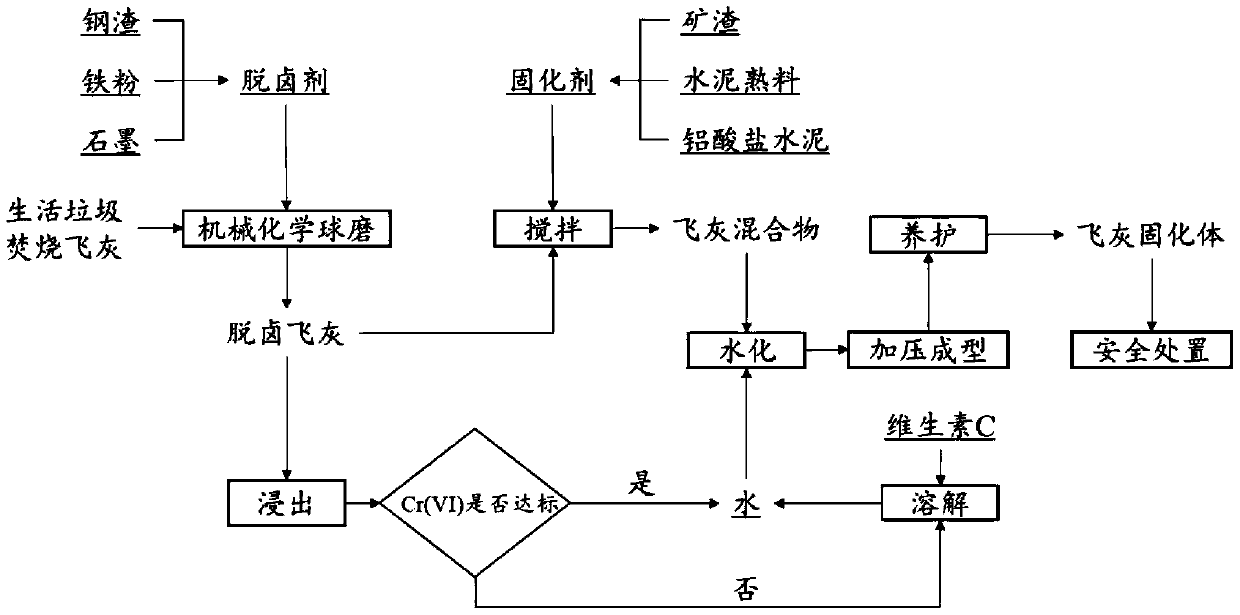

Cooperative treatment method for dioxin and heavy metal in flying ash on basis of steel slag and mineral slag

A cooperative treatment method for dioxin and heavy metal in flying ash on the basis of steel slag and mineral slag is characterized by comprising the following steps that (1) to-be-treated flying ashand a dehalogenation agent are mixed according to a mass ratio of 4:1-9:1, mixed milling is conducted by a planetary mill or a ball mill, and after 2-10 h of continuous ball milling, organochlorine degradation flying ash is obtained; (2) the organochlorine degradation flying ash and a curing agent are mixed according to the mass ratio of 4:1-9:1 and are stirred evenly, and a flying ash mixture isobtained; and (3) water or a reducing agent of the mass ratio of 15% is added into the flying ash mixture, the obtained mixture is put into a compaction die for compaction forming, pressure is 20-50kN, pressing time is 15-30 s, maintenance is conducted for 3-7 days, and a flying ash solidified body is obtained. Through the cooperative treatment method, dioxins and heavy metal pollutants can be treated simultaneously, steel slag serves as a main material of the dehalogenation agent and can be utilized efficiently, and the problem of a low comprehensive utilization rate of the steel slag is solved while the flying ash is treated.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Method for restoring heavy metal pollution soil

InactiveCN103111460ANo risk of secondary pollutionShort turnaround time for processing repairsContaminated soil reclamationBiologyIon

The invention provides a method for restoring heavy metal pollution soil. The method comprises the following steps of: firstly, breeding algae on soil, subsequently absorbing a large quantity of heavy metal ions by the algae in the growing process by the characteristic of absorbing the heavy metal ions; and cultivating angleworms when the algae grow lushly, wherein the angleworms like to eat organic substances in the soil, the algae are the first choice of food for the angleworms, and the algae with the heavy metal ions are swallowed by the angleworms, so that the heavy metal ions are absorbed through digestive systems of the angleworms along with the algae organic substances, and therefore, heavy metal can be enriched in the angleworm bodies; and finally, removing the heavy metal out form a soil system through a manner of taking out the angleworms.

Owner:ATK HLDG GRP CO LTD

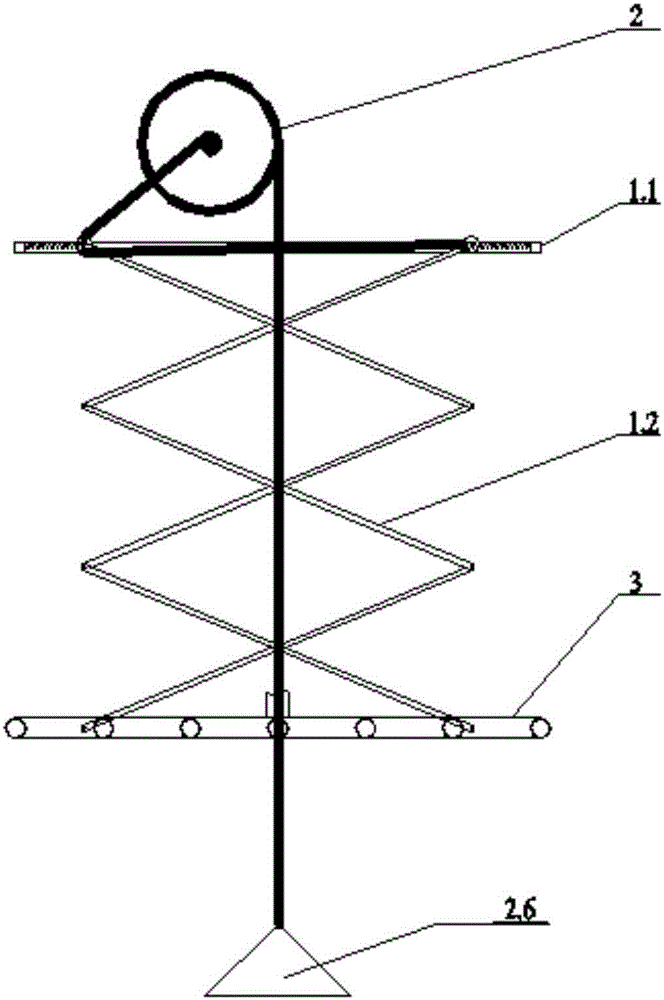

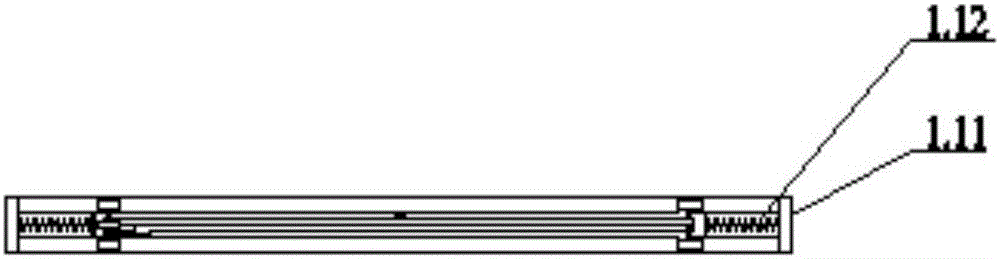

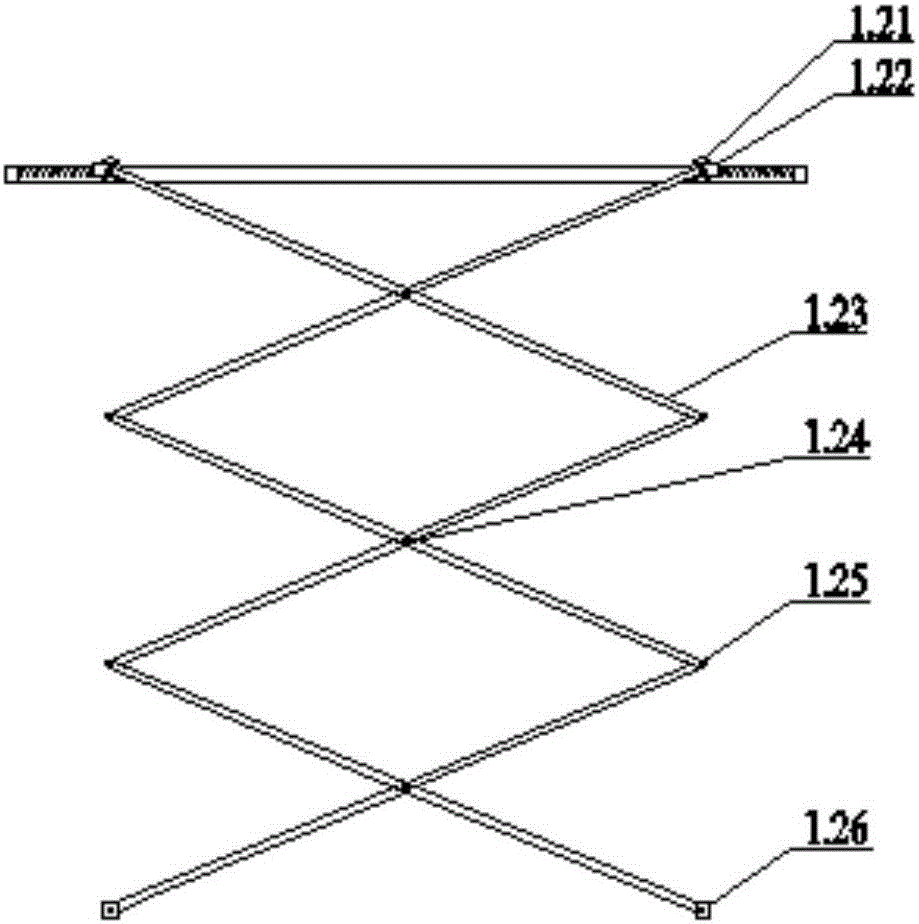

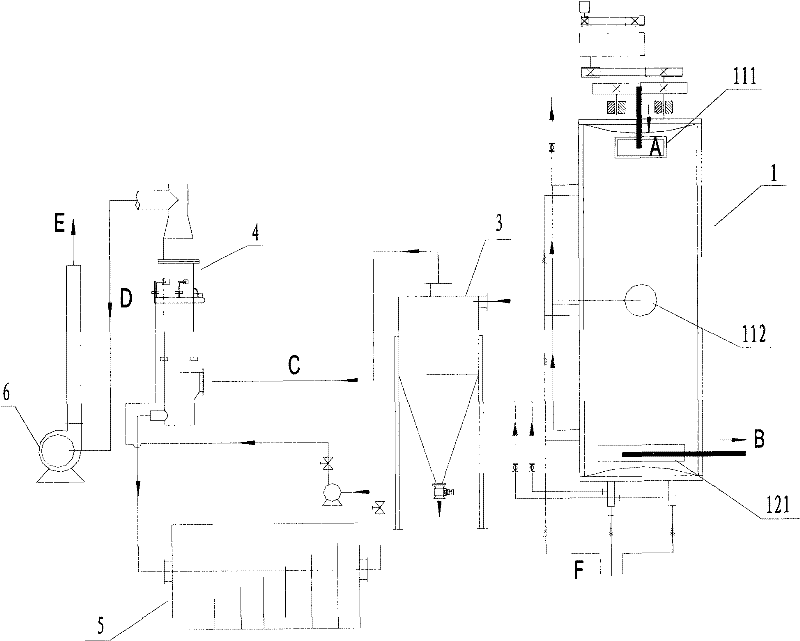

Automatic elevating apparatus and method of aeration tube of floating aerator

ActiveCN106430659AIncrease contact timeInhibition releaseTreatment using aerobic processesWater aerationEngineeringWater level

The invention discloses an automatic elevating apparatus and method of an aeration tube of a floating aerator, and belongs to the technical fields of water restoration and water treatment. The apparatus comprises a slide rail fixed on a floating aerator floating body, slidable mechanical arms are arranged at the top feet of the slide rail, the bottom foot of every mechanical arm is provided with a slidable aeration branch tube, a rope of a pulley group mechanism pulls a large fixed pulley fixed above the mechanical arm slide rail, the large fixed pulley coaxially drives a small fixed pulley having a certain ratio relative to the large fixed pulley to rotate, and the small fixed pulley controls the top feet of the X-shaped mechanical arms to move apart or close up, so a case that a rising or descending distance of the aeration branch tubes driven by the X-shaped mechanical arms is almost same to a distance of a weight moving closer to the water level is realized, and a gas conveying flexible tube is synchronously retracted or released by a gas conveying tube telescoping mechanism. The apparatus and the method allow the aeration tubes to be positioned in specific positions above the riverbed, reduce the disturbance to riverbed sediments and improve the oxygen charging efficiency.

Owner:沈晓笑

Method for removing and recovering phosphate in waste water

ActiveCN102432083AAchieve removalShort hydraulic retention timePhosphatesOther chemical processesPhosphate ionSorbent

The invention relates to the technical field of water quality purification and phosphoric waste water treatment and discloses a method for removing and recovering phosphate in waste water. The method comprises the following steps: feeding a calcite-hydroxyapatite composite material into waste water with the phosphate ion concentration being 10-500mg / L and the pH value being 3-10; and then oscillating or stirring the obtained solid-liquid mixture for 0.5-24 hours, wherein the usage ratio of the calcite-hydroxyapatite composite material to the waste water is 1-100g / L, and in the calcite-hydroxyapatite composite material, the weight ratio of calcite to hydroxyapatite is (1:1)-(100:1). In the method, the calcite-hydroxyapatite composite material is utilized as an adsorbent, so that the rate and the efficiency for removing and recovering the phosphate in the waste water are obviously higher than those under the condition that calcite is solely utilized as the adsorbent, thus rapidly and better realizing the removal of the phosphate in the waste water, shortening the hydraulic retention time of a reactor needed by a dephosphorization process, and lowering the constructing and operating costs of the dephosphorization process.

Owner:SHANGHAI OCEAN UNIV

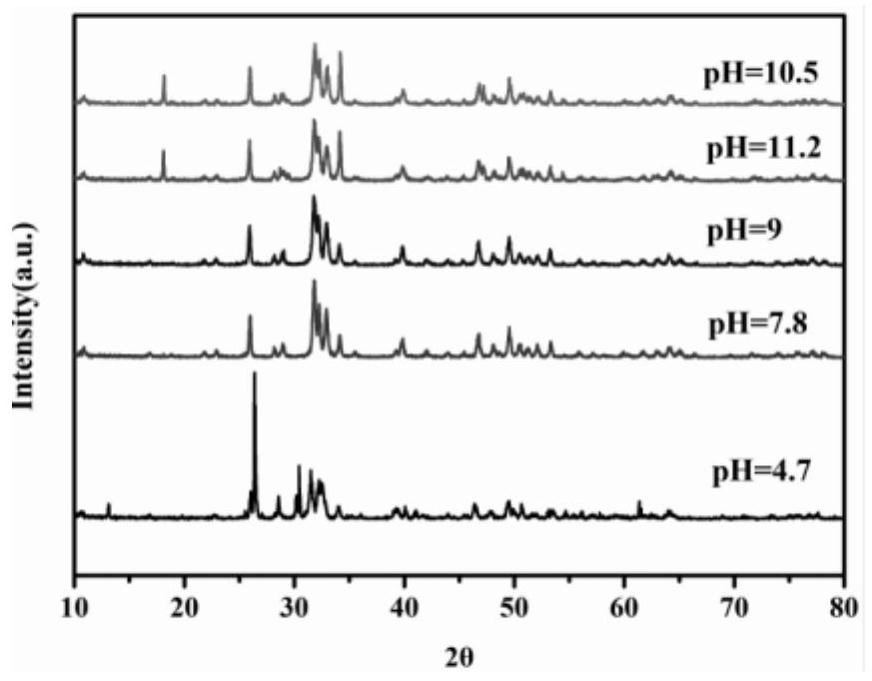

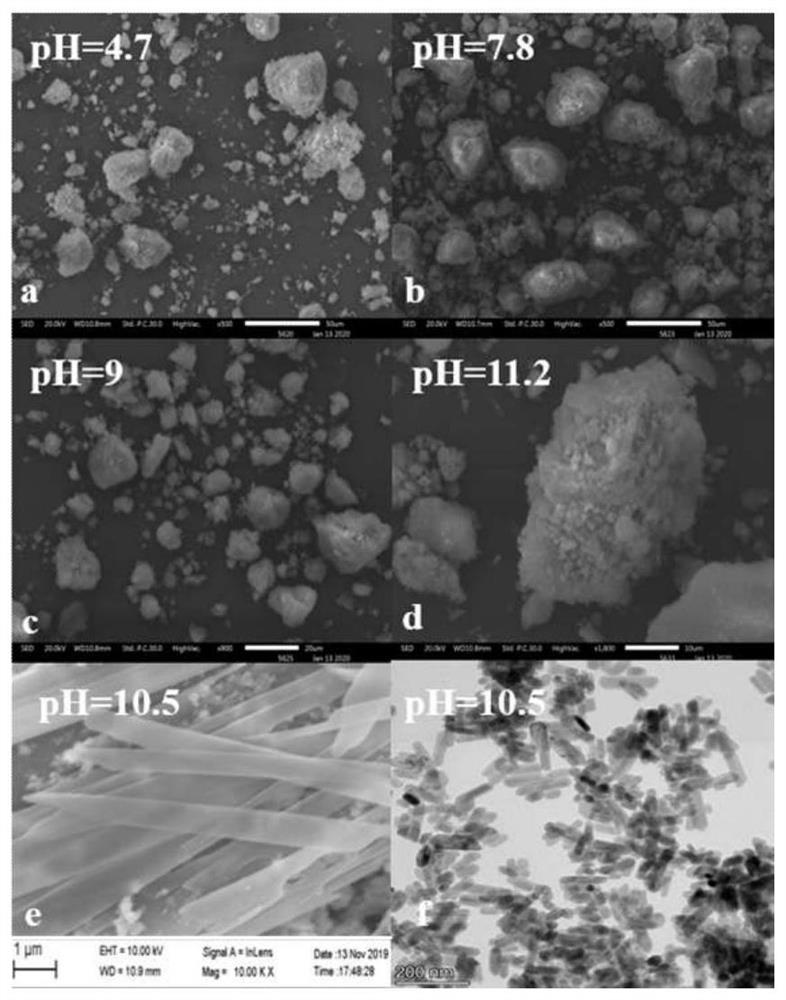

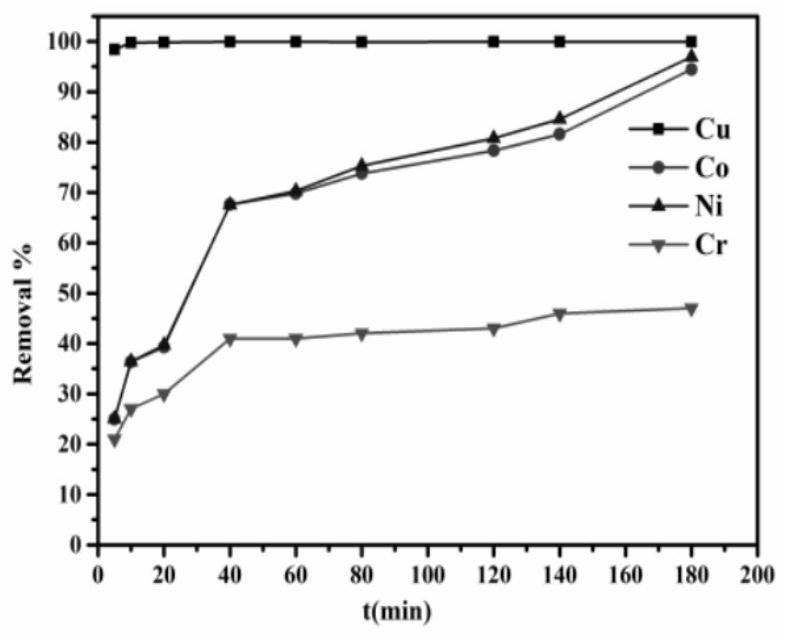

Hydroxyapatite-loaded nano zero-valent iron composite material as well as preparation method and application method thereof

ActiveCN111701562AEasy to prepareLow cost of preparationOther chemical processesWater contaminantsEnvironmental chemistryHexavalent chromium

The invention discloses a hydroxyapatite-loaded nano zero-valent iron composite material as well as a preparation method and an application method thereof. The preparation method comprises the following steps: by taking hydroxyapatite subjected to hydrothermal synthesis as a carrier, adsorbing Fe<2+> for several hours, reducing ferrous iron in an inert gas atmosphere to obtain nano zero-valent iron, washing, centrifuging, and freeze-drying to obtain the hydroxyapatite-loaded nano zero-valent iron composite material. According to the method, the removal effect on hexavalent chromium is the best, high-toxicity hexavalent chromium is reduced into low-toxicity hexavalent chromium, the removal rate can reach 100%, divalent heavy metal cations such as copper, cobalt and nickel in the wastewatercan be efficiently and rapidly removed at the same time, and the removal rate is also up to about 98%. The method can be applied to removal and purification of heavy metal ions in wastewater, and canalso be used for remediation of soil polluted by various heavy metals.

Owner:CENT SOUTH UNIV

Method for promoting generation of hydroxyl radicals from ozone

ActiveCN105800768AAccelerate the rate of processing reactionsReduce construction costsWater treatment compoundsWater/sewage treatment by oxidationReaction speedHydroxyl radical

The invention belongs to the field of water treatment, and in particular relates to a method for promoting generation of hydroxyl radicals from ozone. The method comprises the following steps: feeding ozone and thiosulfate into water with pollutants, and rapidly mixing to react, thereby prompting generation of the hydroxyl radicals from the ozone. The method provided by the invention is very fast in reaction speed, can lower the cost when being used in water treatment, can promote rapid reaction in acid, neutral and alkali environments without adjusting the pH value of a water body, is free of risk of secondary pollution and is beneficial to industrial application.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

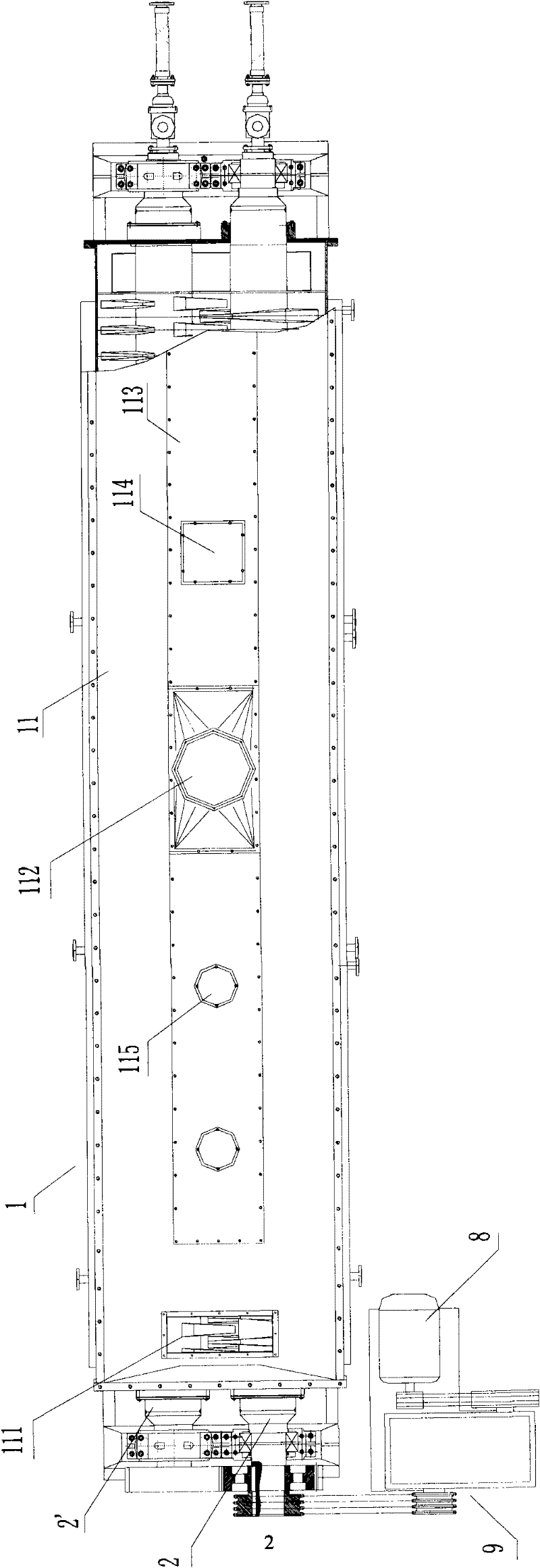

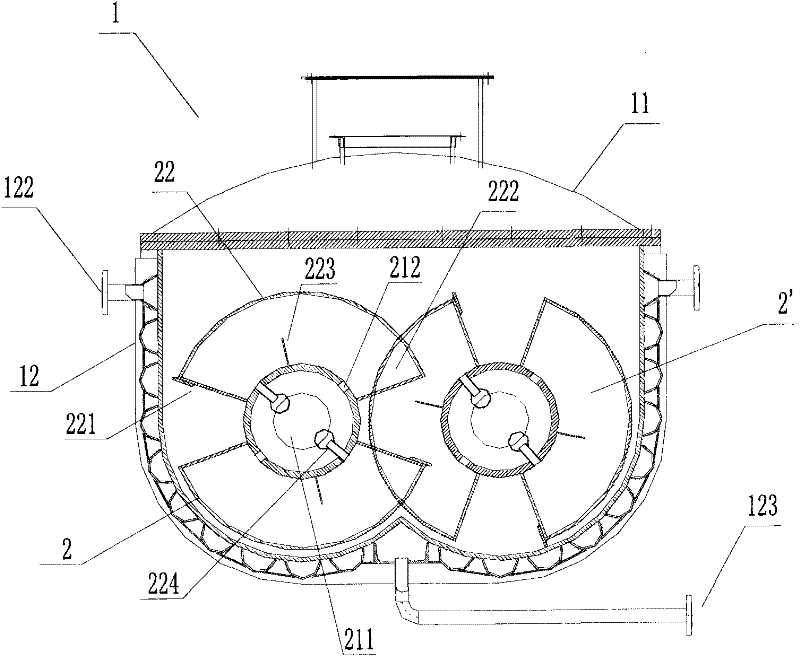

Sludge drying process and equipment

InactiveCN102295398ASmall starting currentImprove winding capacitySludge treatment by de-watering/drying/thickeningWater contentPre treatment

The invention relates to a sludge drying process and equipment. The process is: pretreat the sludge with high moisture content until the moisture content is lower than the set value, keep the temperature of the sludge constant, and input it into the sludge drying equipment, in which the sludge is continuously discharged to the It is pushed by the mouth, and the sludge is heated to above 120°C, accompanied by continuous stirring and crushing, and at the same time, the water vapor volatilized from the sludge is continuously drawn out by the air-inducing equipment until the sludge with the required moisture content is produced. The sludge is discharged from the drying equipment. The sludge drying equipment is produced for the improvement of the traditional hollow paddle dryer. The process of the present invention is simple and easy to operate, runs smoothly, and can make the degree of sludge drying more controllable, the sludge treatment capacity is larger, and there is no risk of secondary pollution; the equipment of the present invention has simple structure, stable operating performance, and high efficiency. High, and can achieve the goal of energy saving and emission reduction, it is expected to be widely used in the field of environmental protection and in chemical, pharmaceutical, food and other industries.

Owner:SUZHOU ZILI CHEM EQUIP

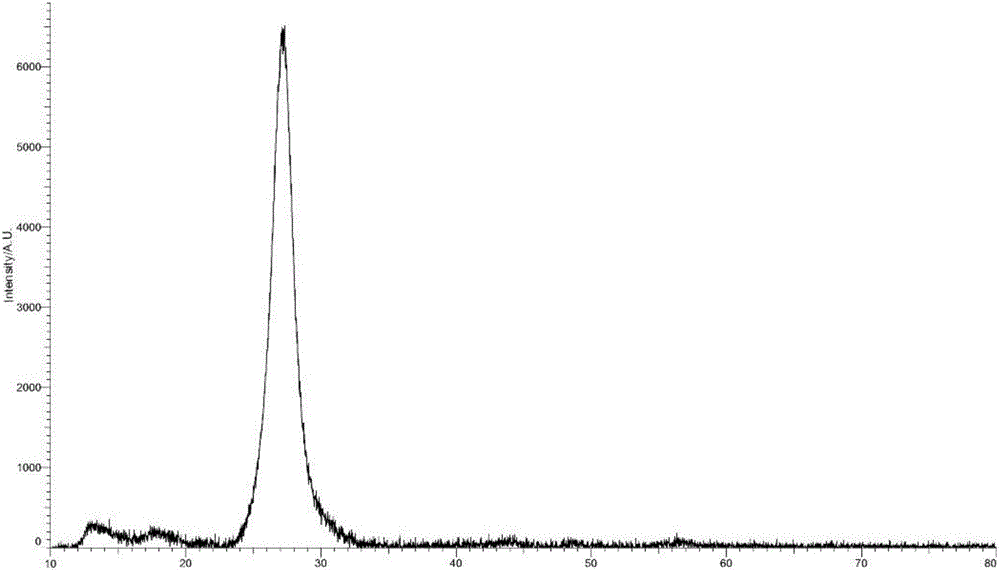

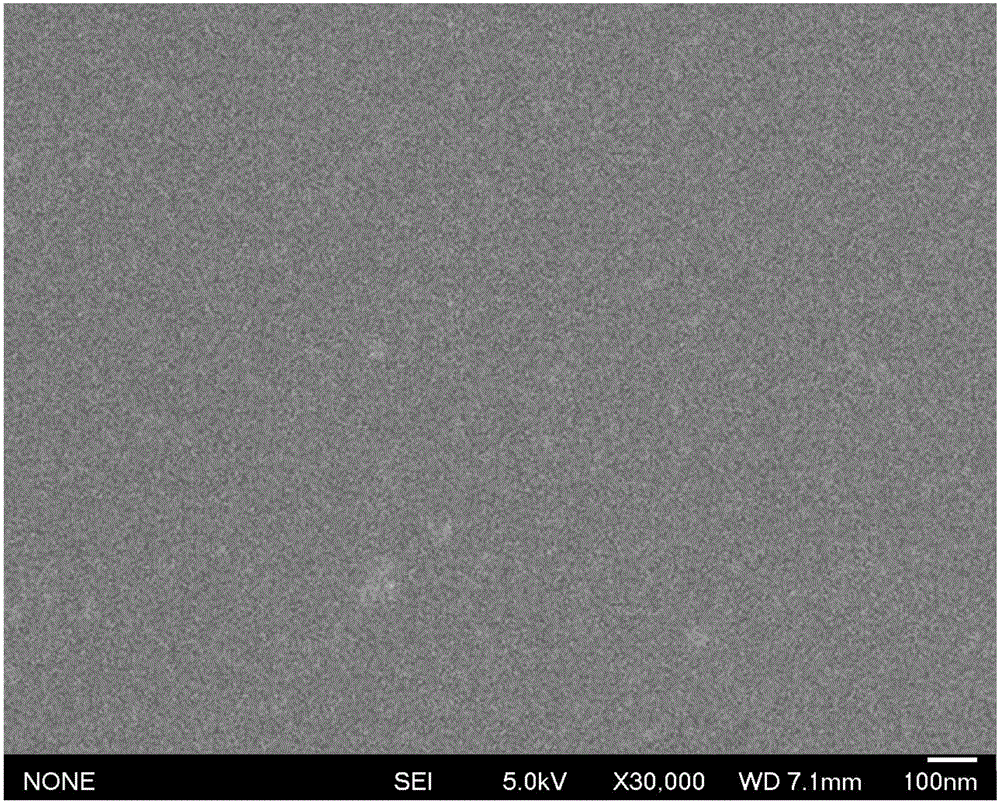

Method for catalytically degrading phthalate pollutant by directly utilizing sunlight

ActiveCN106745469APromote degradationApply evenlyWater/sewage treatment by irradiationWater treatment compoundsSolar photocatalysisAdditive ingredient

The invention discloses a method for catalytically degrading phthalate pollutant by directly utilizing sunlight, and belongs to the technical field of environmental engineering. The method comprises the following steps: preparing supernate by using low-price easily-available urea as a raw material through stepwise roasting, ultrasonic peeling and centrifuging; drying to obtain nano-carbon nitride having grain size mainly distributed in a range of 30-50nm; and modifying with a coupling agent, dispersing in a methyl alcohol solution, uniformly applying and immobilizing to the inner surface of a pre-treated glass container. The treated glass container serving as a catalyst can be used for remarkably accelerating the degrading process of phthalate under sunlight radiation, and the removal rate can be 95-100 percent. The method is applicable to actual operation of a pollutant treatment field, has high efficiency and low cost, is beneficial innovation of introducing sunlight catalysis to the environmental engineering; the catalyst is a non-metallic ingredient, does not have secondary pollution risk, has uniform and firm immobilization, is convenient for reclaiming and recycling after reaction, and has relatively good commercial value and application prospect.

Owner:SHANXI UNIV +1

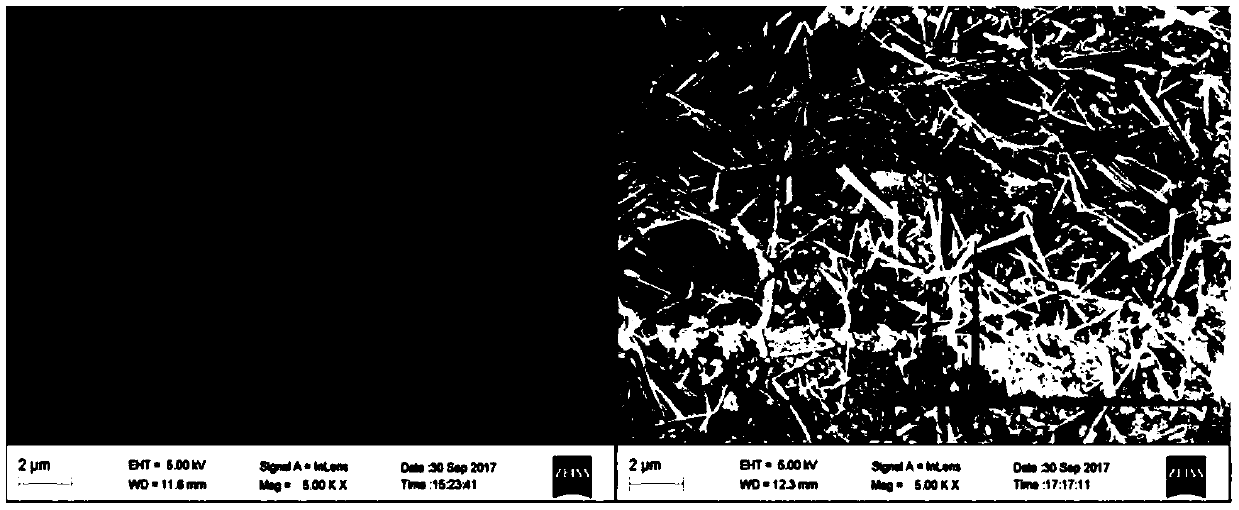

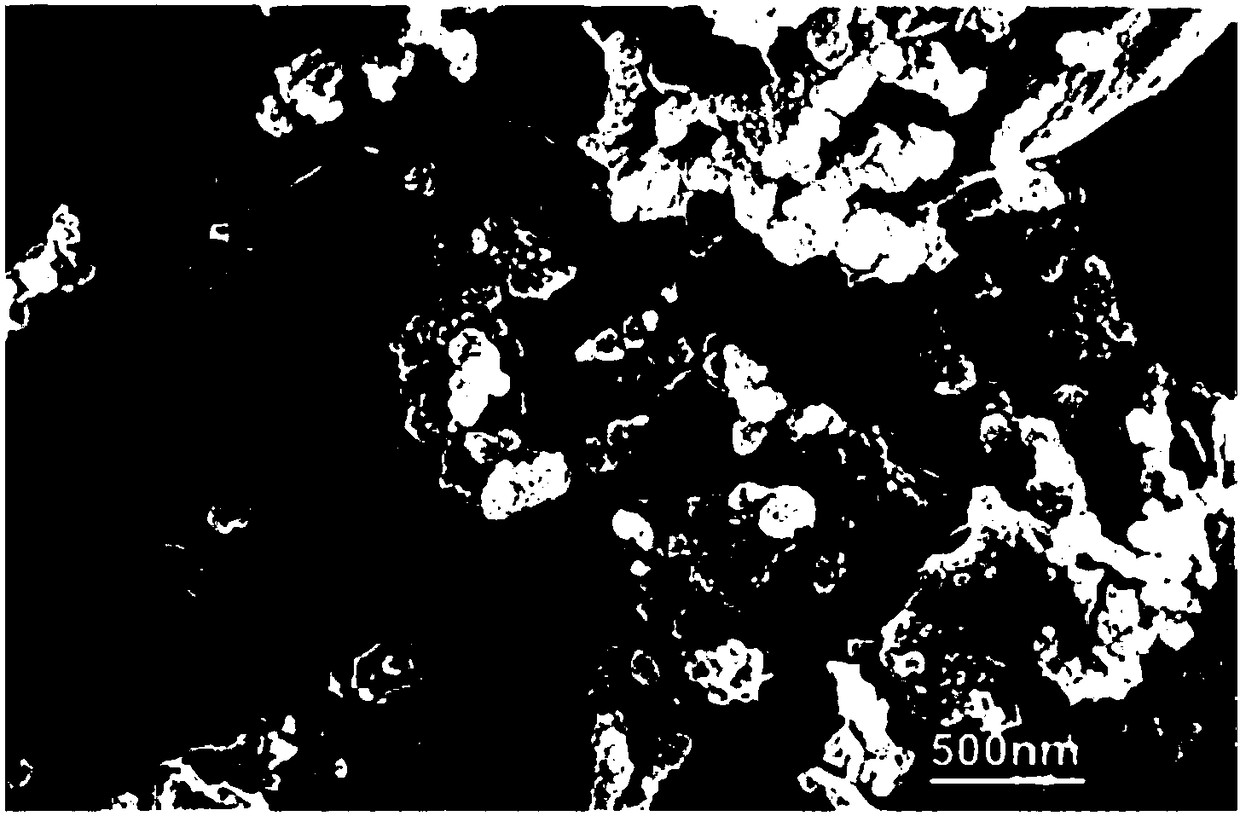

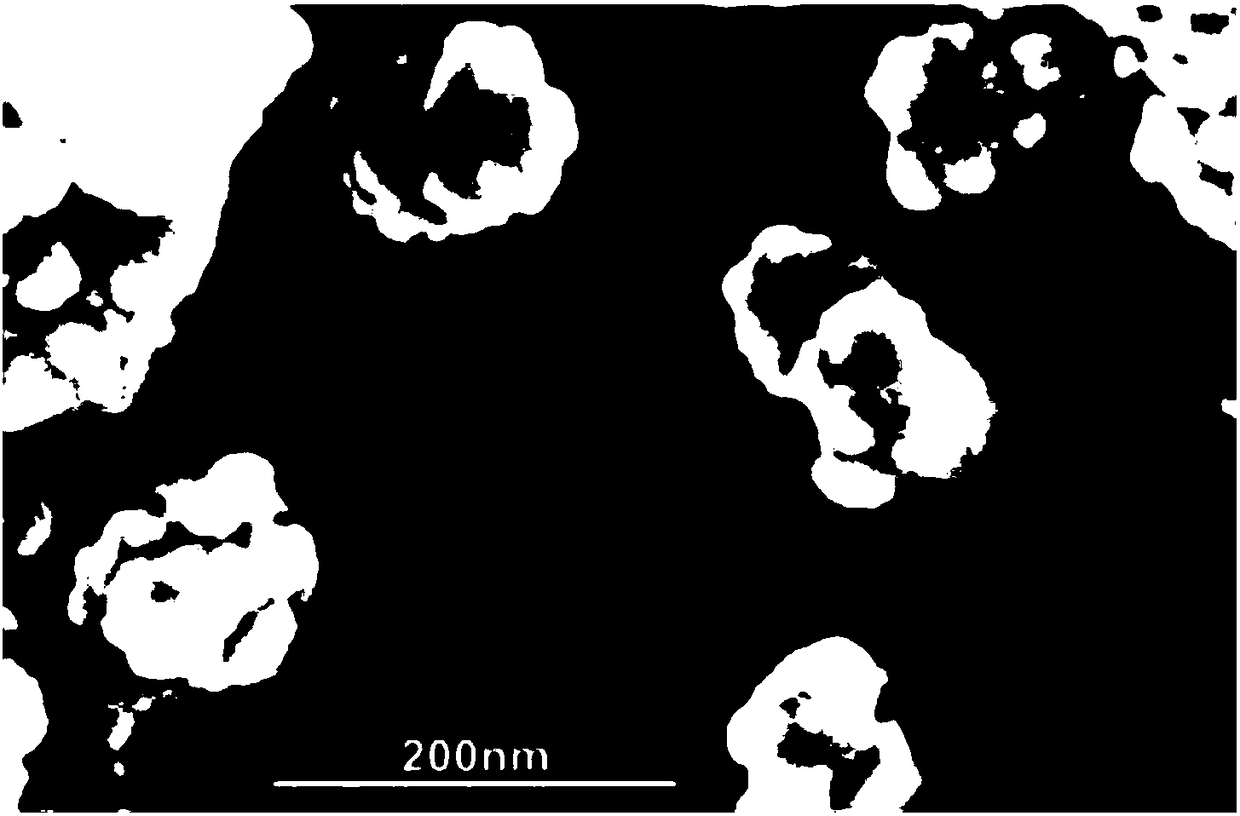

Preparation method of green composite nano magnetic material for effectively removing heavy metals in environment

InactiveCN108187623AWide variety of sourcesNo risk of secondary pollutionOther chemical processesWater contaminantsFiltrationPosterior composites

The invention discloses a preparation method of a green composite nano magnetic material for effectively removing heavy metals in an environment. The invention relates to the field of environmental functional materials, and particularly relates to a preparation method of a composite nano magnetic material. The invention aims at solving the technical problems that a current method of a biochar improved composite material is fussy, raw materials are expensive and meanwhile, a modified or improved material still has a certain risk of the secondary pollution to the environment and the like. The method comprises the following steps of 1, carrying out the pretreatment of biomass waste; 2, carrying out the thermal conversion from biomass to biochar; 3, carrying out the mixed culture of the biochar and ferric iron in a liquid phase; 4, carrying out a reduction reaction on suspension liquid by utilizing a liquid-phase deposition method, so as to obtain a nano zero-valent iron loaded carbon material, flushing, carrying out suction filtration, and oven-drying to obtain the green composite nano magnetic material. The green composite nano magnetic material is used for removing the heavy metalsin the environment, within a short time, has better removal capacity for six common heavy metals in the environment, and meanwhile, has higher magnetism; the removal efficiency reaches 95 percent or above, and the recycling is facilitated.

Owner:HARBIN INST OF TECH

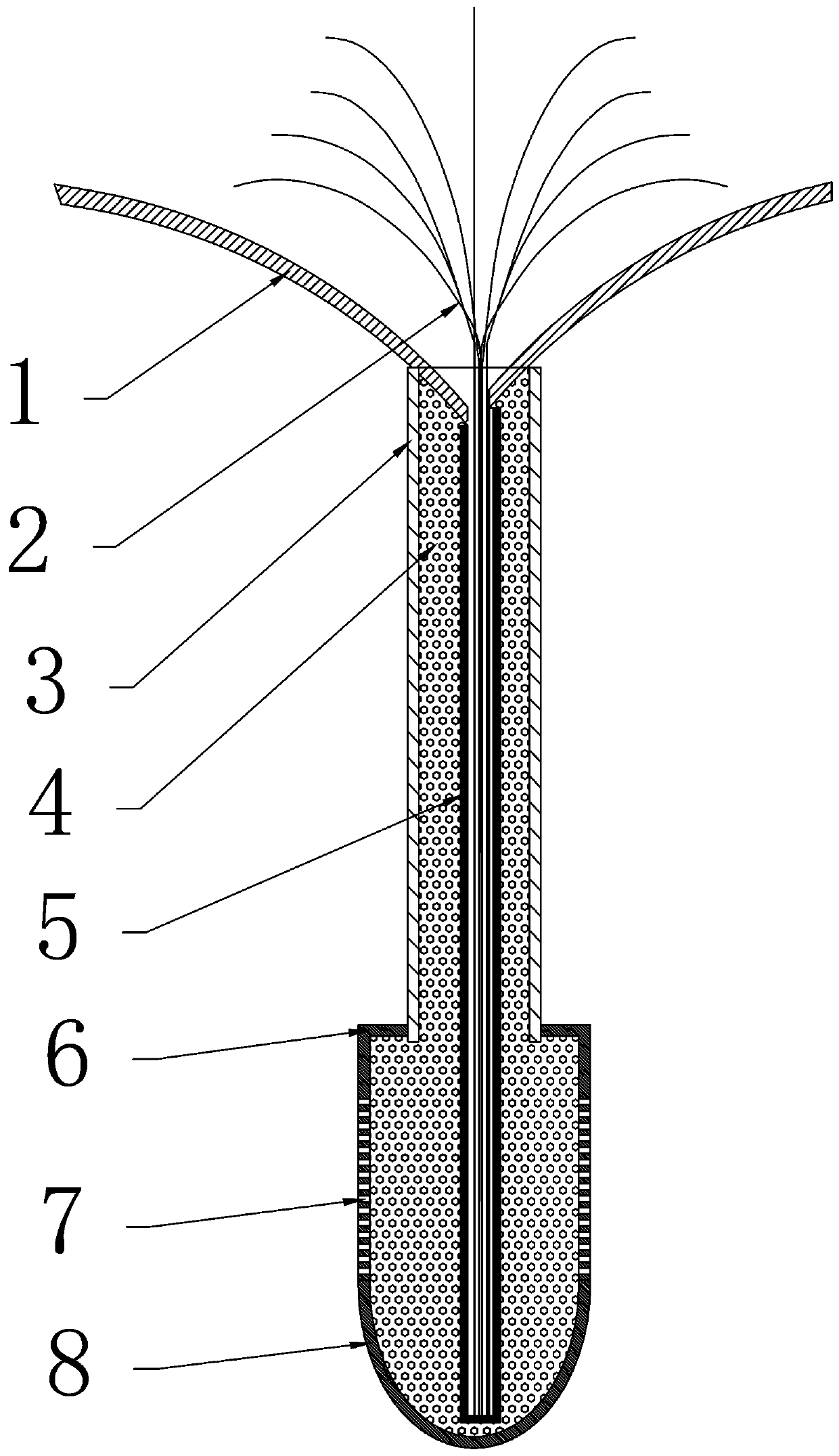

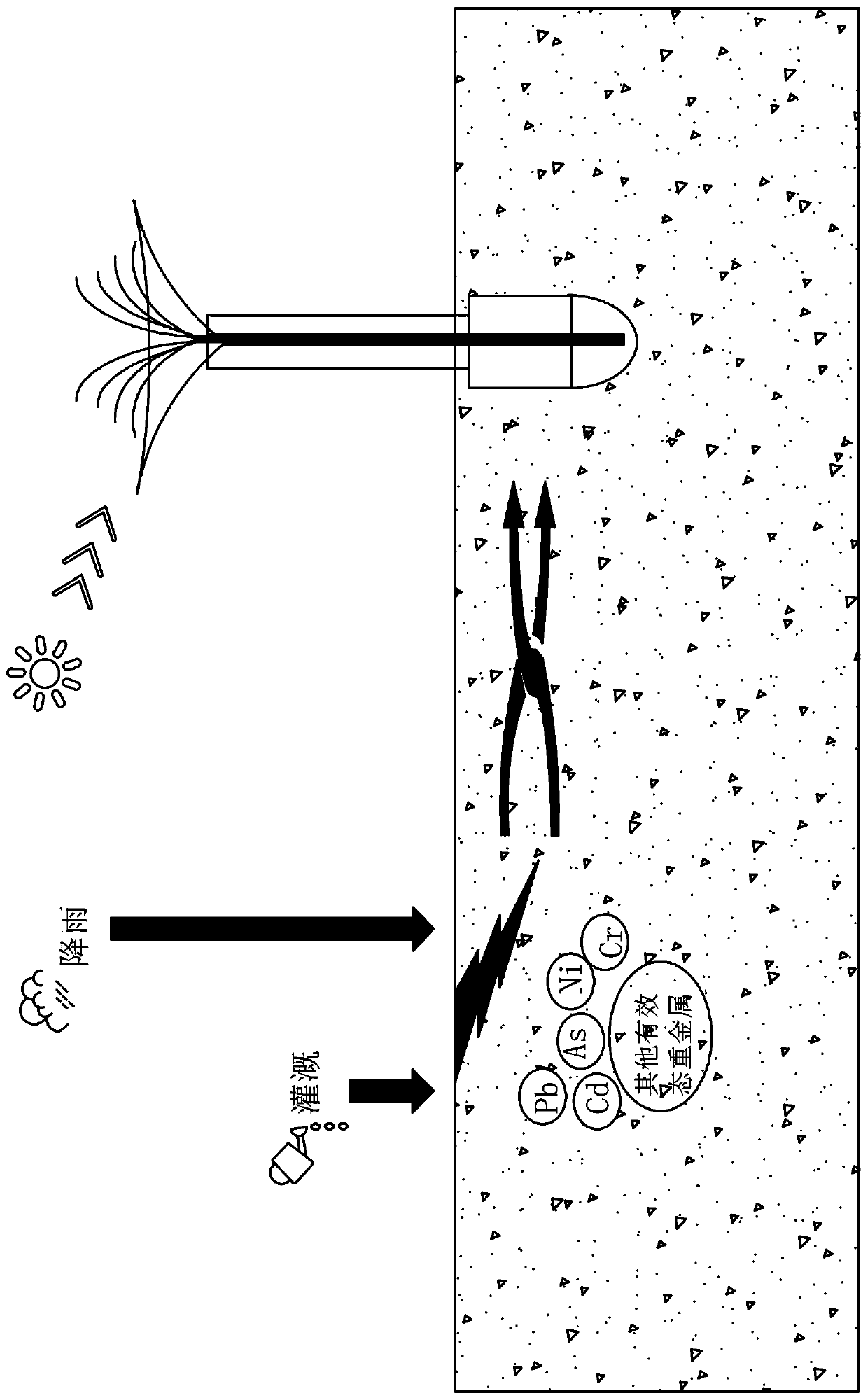

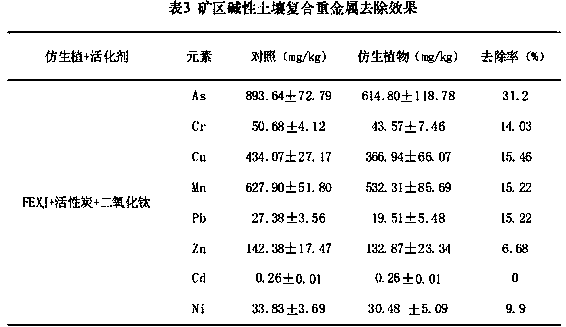

Accelerated transpiration based bionic plant for removing heavy metal pollution to soil and application of bionic plant

ActiveCN110076194AReduce concentrationLarge adsorption capacityContaminated soil reclamationActivated carbonSoil heavy metals

The invention relates to an accelerated transpiration based bionic plant for removing heavy metal pollution to soil and an application of the bionic plant. The bionic plant comprises bionic leaves, straight-through casing and straight-through middle rods and is filled with CaO, activated carbon, sepiolite, zeolite and other adsorption filler. The invention relates to a new technology for treatingheavy metal pollution to the soil on the basis of environmental physical geochemistry and plant water transpiration principles. Aluminum foil generates heat by use of sun irradiation, water absorptionand transpiration of the bionic plant are accelerated, the migration rate of the effective state of heavy metal to the bionic plant is increased, the enrichment capability of a remediation device isimproved, and the bionic plant can be applied to heavy metal pollution treatment of the farmland and the field.

Owner:HENAN QINGSHUIYUAN TECH

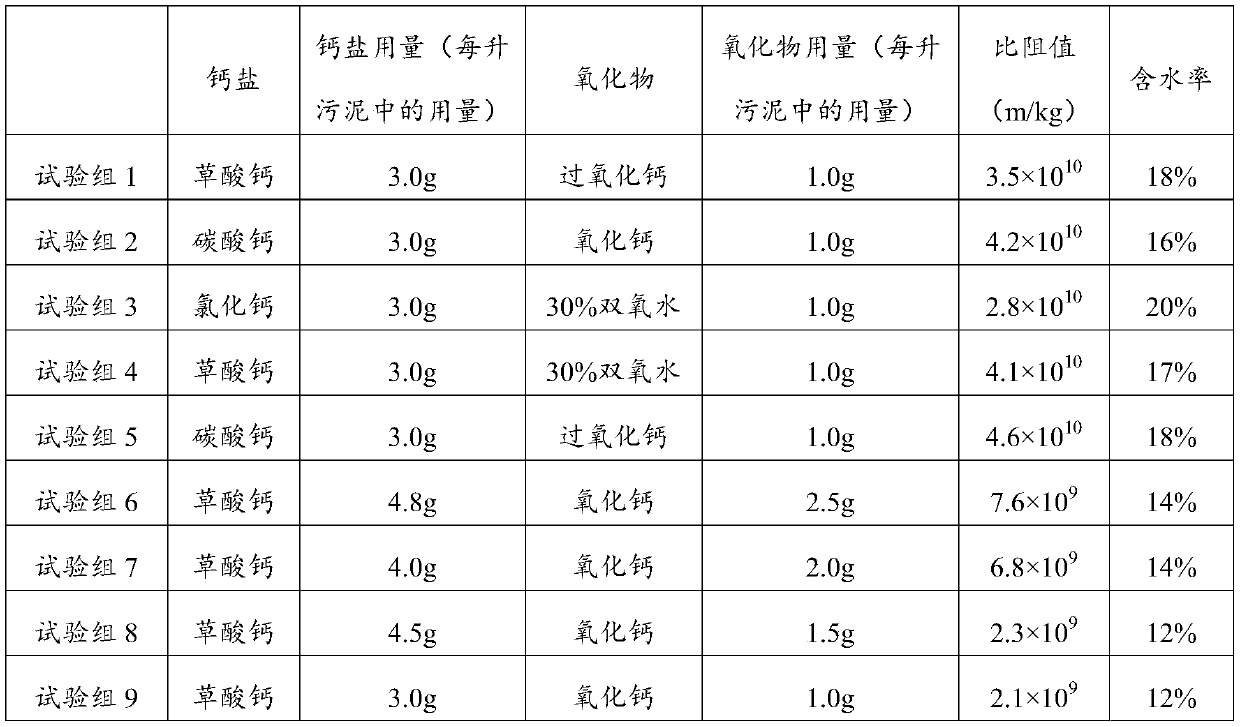

Sludge dehydrator and sludge dehydration method

InactiveCN110590121AReduce moisture contentReduce volumeSludge treatment by de-watering/drying/thickeningAccelerantWater content

The invention relates to a sludge dehydrator and a sludge dehydration method and belongs to technical fields of sludge treatment and environmental governance. The sludge dehydrator comprises an agentA and an agent B, wherein the agent A is a dehydration accelerant; and the agent B comprises a calcium salt and an oxide. The sludge dehydrator provided by the invention is adopted for sludge dehydration, the specific resistance of sludge can be within a range applicable to mechanical dehydration, the water content of the sludge can be reduced to 20% or less, the volume of the sludge can be reduced, and a basis is made for final disposal and application of the sludge.

Owner:SUN YAT SEN UNIV

Method for remediating polycyclic aromatic hydrocarbon composite contaminated soil by utilizing sulfate radical free radical advanced oxidation technology

ActiveCN109304362AGood removal effectImprove removal efficiencyContaminated soil reclamationOrganic fertilisersPolycyclic aromatic hydrocarbonSulfate radicals

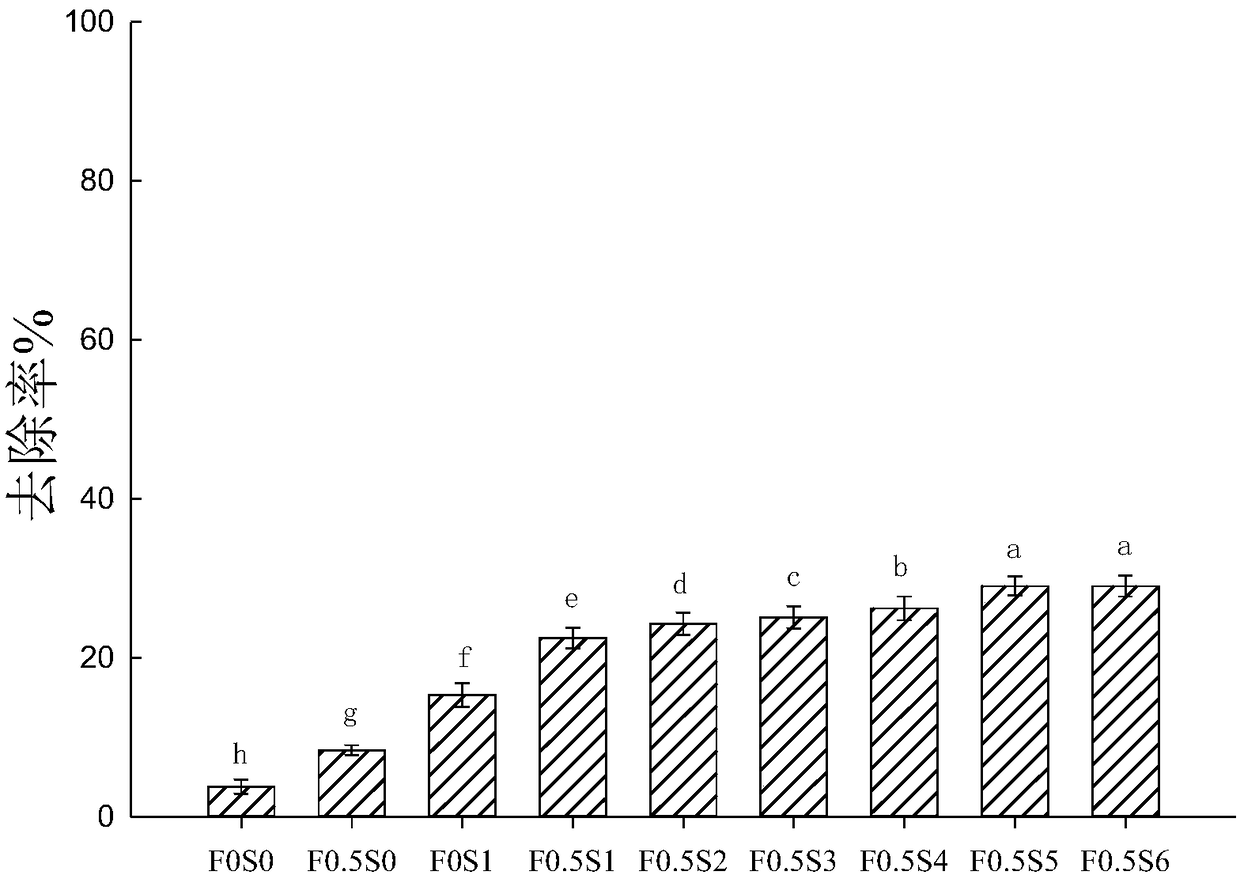

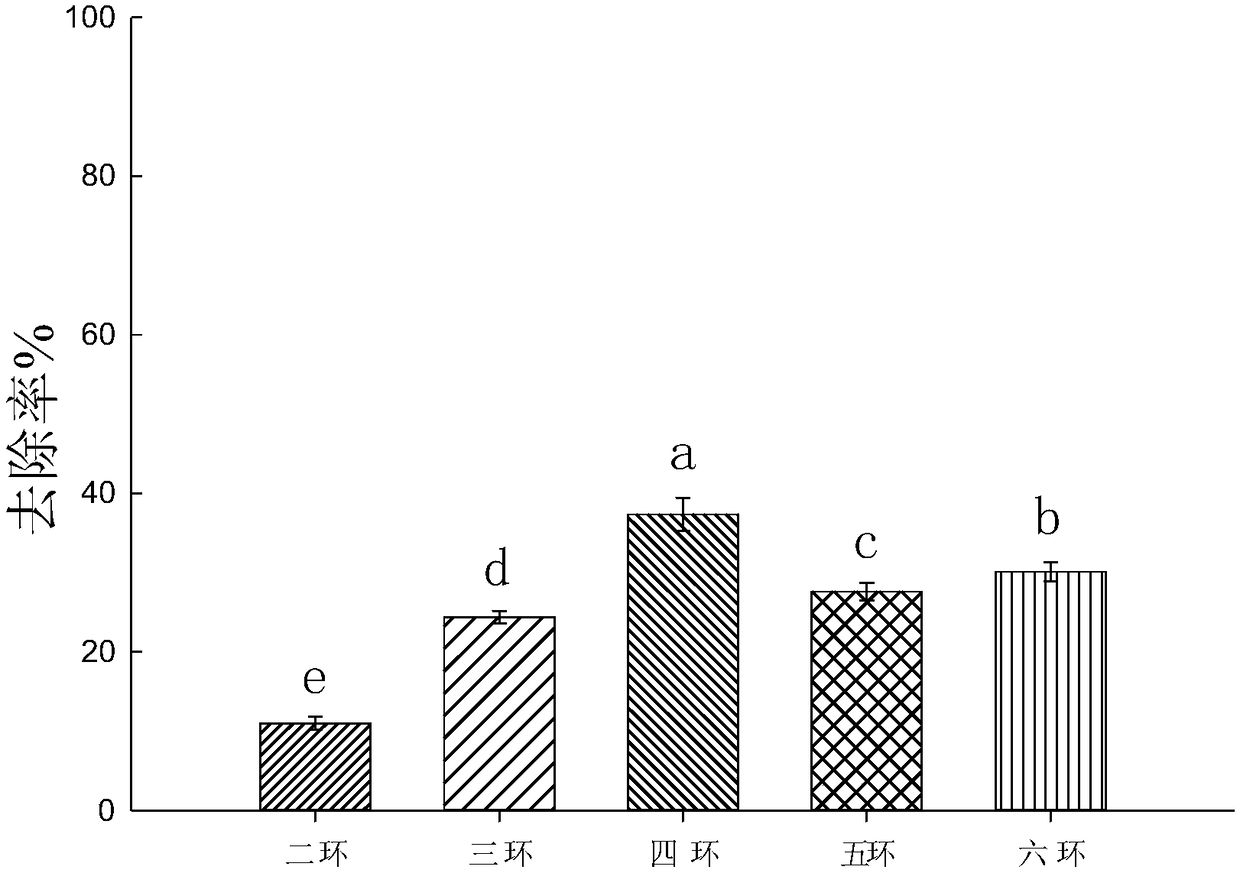

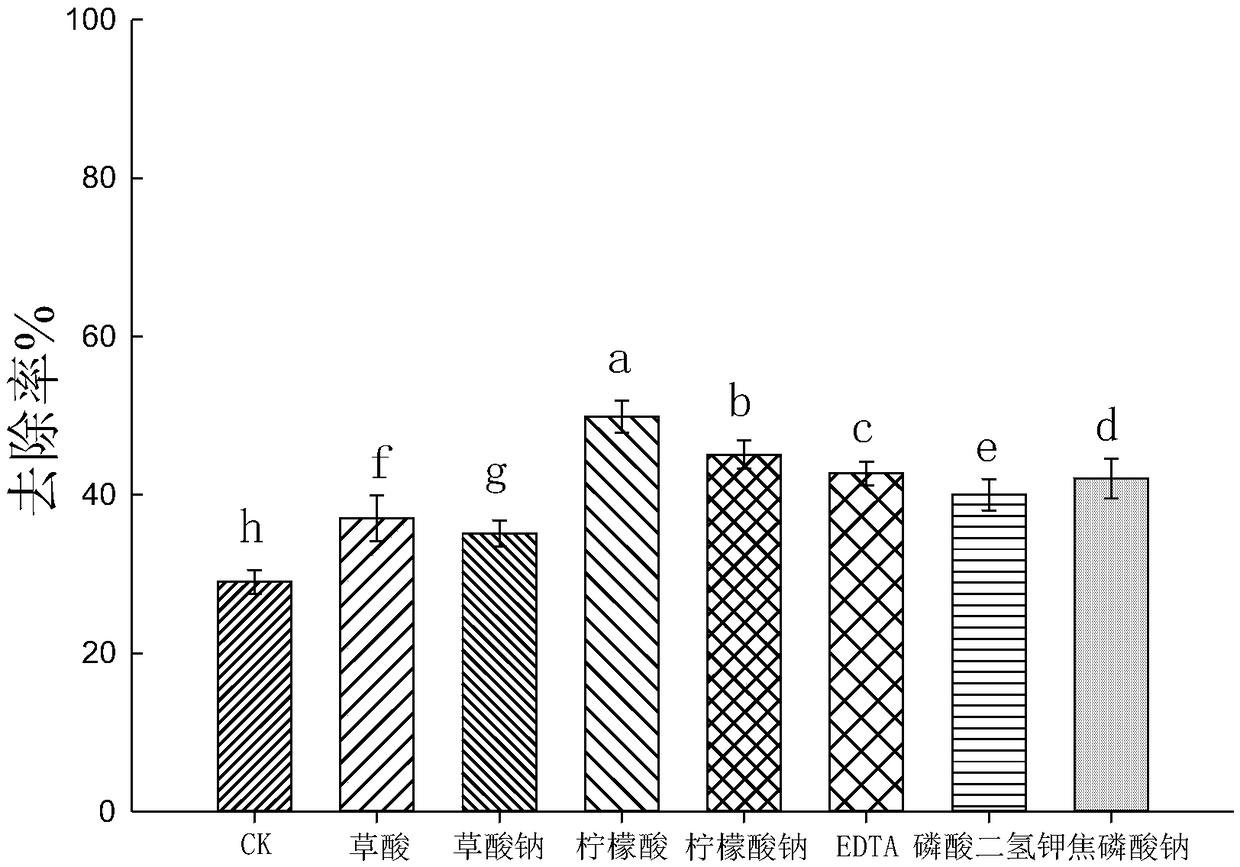

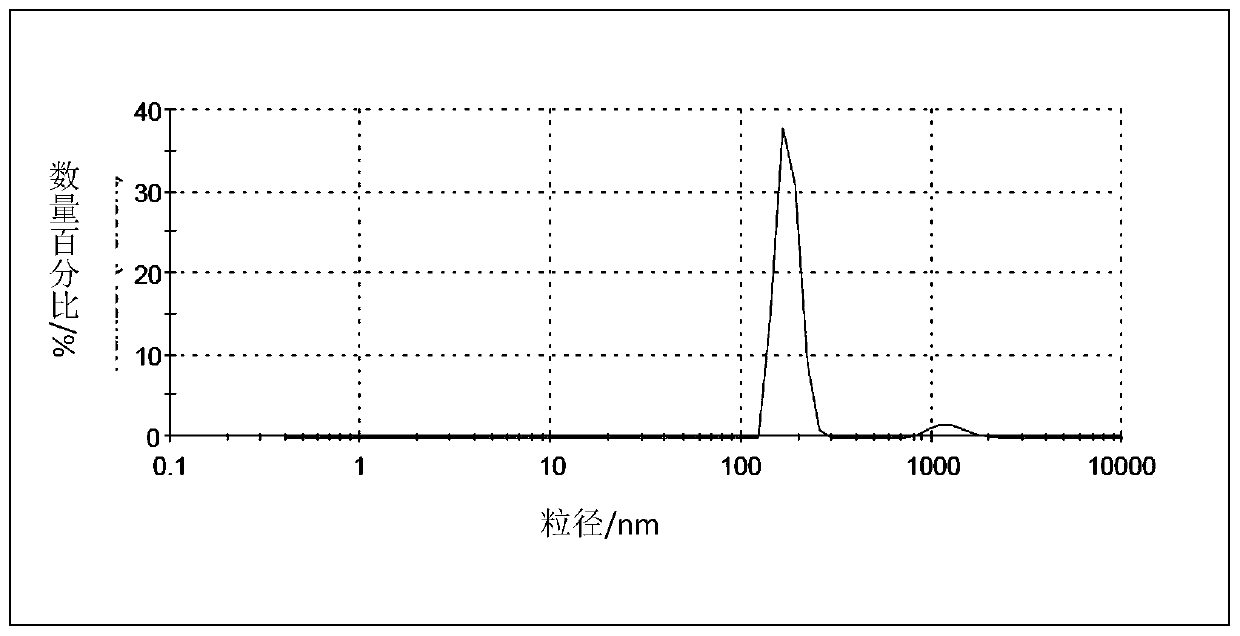

The invention discloses a method for remediating polycyclic aromatic hydrocarbon composite contaminated soil by utilizing a sulfate radical free radical advanced oxidation technology. The method comprises the steps of adding sodium persulfate, ferrous sulfate, citric acid and Igepal CA-720 into soil to be remediated, and reacting at 25 to 28 DEG C in dark place for 20 to 30 hours. According to themethod provided by the invention, the efficiency on removing PAHs of the soil reaches up to 80.8 percent, the removal rate of the PAHs in the contaminated soil is remarkably improved, the substrate action range is extended, the effect on removing tetracyclic PAHs is remarkably improved, the effect on removing other tricyclic and hexacyclic PAHs in the soil is further improved, and the applicationrange of the technology aiming at PAHs pollutants is further extended.

Owner:NANJING AGRICULTURAL UNIVERSITY

Modified nano zero-valent iron, a preparation method thereof and application on industrial seepage pit sediment heavy metal treatment

InactiveCN109848403AHigh reactivityImprove stabilityMaterial nanotechnologySludge treatmentSulfateNitrogen atmosphere

The invention discloses a preparation method and application of modified nano zero-valent iron. The preparation method comprises the following steps of dissolving ferrous sulfate salt in sophorolipidsolution, dropwise adding sodium borohydride solution into nitrogen atmosphere to carry out liquid-phase reduction to obtain the modified nano zero-valent iron. The modified nano zero-valent iron prepared has the advantages of being good in stability, good in dispersibility, strong in reaction activity, ecological friendly and the like, and has a good immobilization effect on Cd, Cr and Zn in heavy metal polluted sediment, and the content of Cd, Cr and Zn residues in the treated sediment is increased by 22.034%, 16.493% and 18.436% correspondingly, so that the modified nano zero-valent iron has excellent application value and wide application prospect for repairing heavy metal polluted sediment.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com