Organic polymer heavy metal chelating flocculant as well as preparation method and application thereof

An organic polymer and heavy metal technology, applied in the polymer field, can solve the problems of unsatisfactory effect, slow reaction rate, high cost, etc., and achieve the effect of no secondary pollution risk, easy control, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

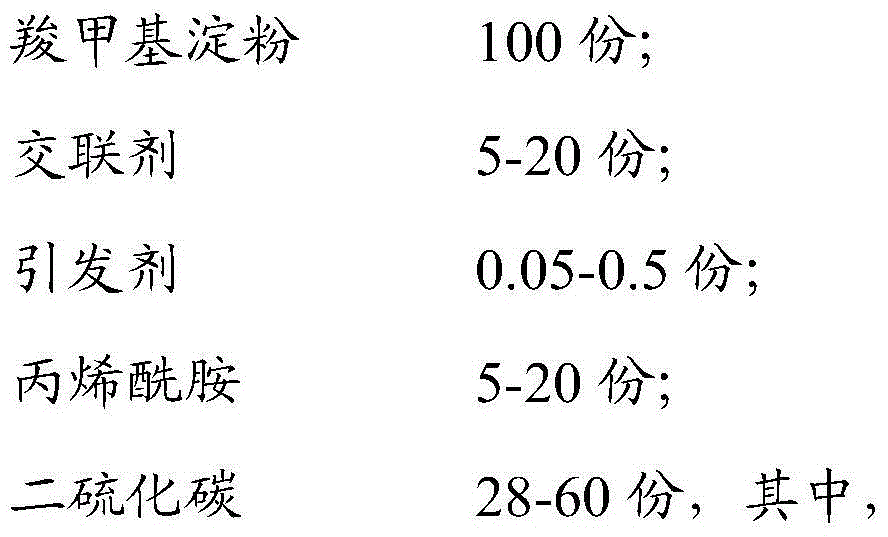

[0036] In this embodiment, an organic polymer heavy metal chelating flocculant is prepared from the following raw materials:

[0037]

[0038] The preparation method of above-mentioned organic polymer heavy metal chelating flocculant comprises the steps:

[0039] Cross-linking reaction: Add 40ml of 1% sodium chloride solution with a mass fraction of 10g to make a paste, put it in a water bath, adjust the pH value to 9 with sodium hydroxide, and at a temperature of 30°C, Slowly add 0.4ml adipic acid and stir for 1h;

[0040] Grafting acrylamide: Add 1ml of 1% cerium ammonium nitrate aqueous solution (containing 0.01g cerium ammonium nitrate), stir evenly, adjust the temperature to 35°C, adjust the pH to 4 with hydrochloric acid, add 0.5g acrylamide, blow in nitrogen, and stir Reaction 2h;

[0041] Sulfonation: adjust the pH value to 9, add 2.3ml of carbon disulfide, and stir for 2 hours at a temperature of 25°C;

[0042] Post-processing: the product is washed with water, ...

Embodiment 2

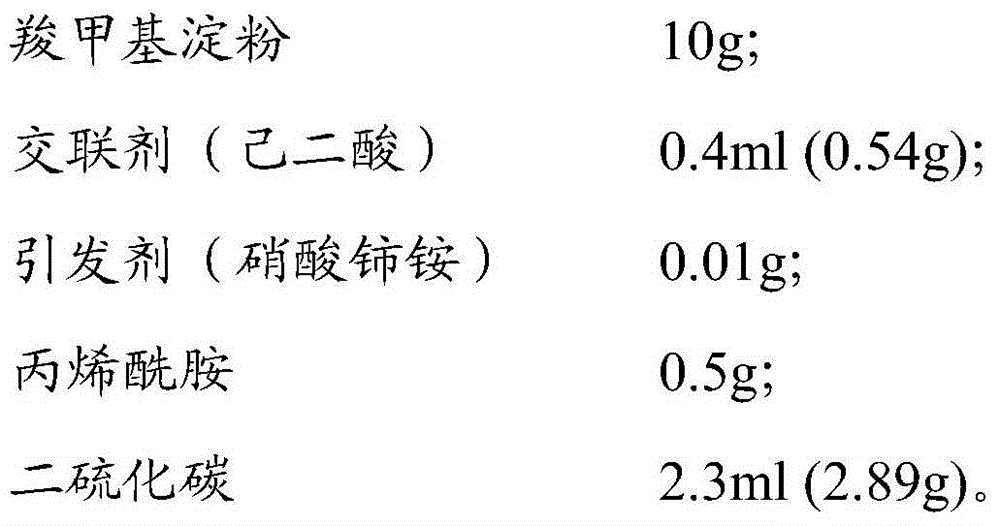

[0044] In this embodiment, an organic polymer heavy metal chelating flocculant is prepared from the following raw materials:

[0045]

[0046] The preparation method of above-mentioned organic polymer heavy metal chelating flocculant comprises the steps:

[0047] Cross-linking reaction: Add 30ml of 1% sodium chloride solution by mass fraction into 10g of carboxymethyl starch to make a paste, put it in a water bath, adjust the pH value to 10 with sodium hydroxide, and at a temperature of 30°C, Slowly add 1ml of phosphorus oxychloride and stir for 1h;

[0048] Graft acrylamide: Add 1ml of 1% potassium persulfate aqueous solution (containing 0.01g of potassium persulfate), stir well, adjust the temperature to 40°C, adjust the pH to 5 with hydrochloric acid, add 1g of acrylamide, blow in nitrogen, and stir to react 3h;

[0049] Sulfonation: adjust the pH value to 10, add 3.1ml of carbon disulfide, and stir for 2 hours at a temperature of 30°C to obtain the organic polymer hea...

Embodiment 3

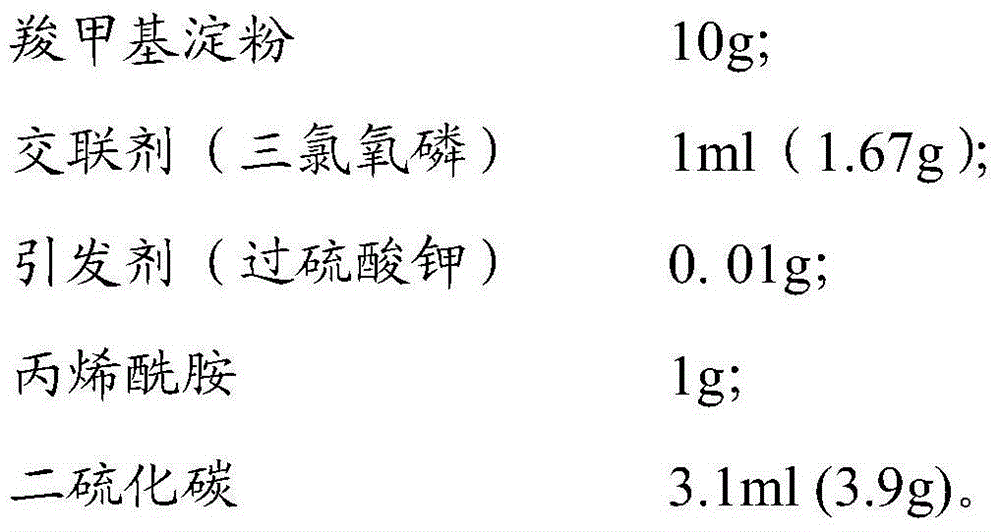

[0052] In this embodiment, an organic polymer heavy metal chelating flocculant is prepared from the following raw materials:

[0053]

[0054] The crosslinking agent is adipic acid.

[0055] The preparation method of above-mentioned organic polymer heavy metal chelating flocculant comprises the steps:

[0056] Cross-linking reaction: Add 15ml of 1% sodium chloride solution by mass fraction to 10g of carboxymethyl starch to make a paste, put it in a water bath, adjust the pH value to 12 with sodium hydroxide, and at a temperature of 50°C, Slowly add 2g of sodium trimetaphosphate, and stir for 2 hours;

[0057] Graft acrylamide: Add 1ml of 1% sodium persulfate aqueous solution (containing 0.01g of sodium persulfate), stir evenly, adjust the temperature to 50°C, adjust the pH to 7 with hydrochloric acid, add 2g of acrylamide, blow in nitrogen, and stir for reaction 5h;

[0058] Sulfonation: adjust the pH value to 12, add 4.6ml of carbon disulfide, and stir for 4 hours at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com