Semi-interpenetrating network hydrogel film material for extracting uranium from seawater and preparation method of semi-interpenetrating network hydrogel film material

A semi-interpenetrating network and film material technology, which is applied in the field of semi-interpenetrating network hydrogel film materials and preparation, can solve the problems of high cost and low uranium absorption by natural seawater, and achieves low cost, excellent mechanical properties, high selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Preparation and Characterization of Polyacrylamide Oxime PAO

[0041] The preparation of polyacrylamide oxime PAO comprises the following steps:

[0042] As in formula 1, add NH to 60mL DMF in a round bottom flask at 45°C 2 OH·HCl (80mmol) was dissolved, then added Na 2 CO 3 (40mmol) and NaOH (40mmol) and magnetically stirred for 3h, under the condition of constant temperature, polyacrylonitrile PAN (80mmol) was added to dissolve, then reacted at 65°C for 24h, supplemented with Na 2 CO 3 (20mmol), NaOH (20mmol) and hydroxylamine hydrochloride (40mmol) were reacted at 65°C for 12h, the reaction mixture was dropped into deionized water, and a white floc precipitate was obtained after filtering with a funnel, and dried under vacuum at 60°C 8h to obtain PAO.

[0043]

[0044] Characterization of polyacrylamide oxime PAO:

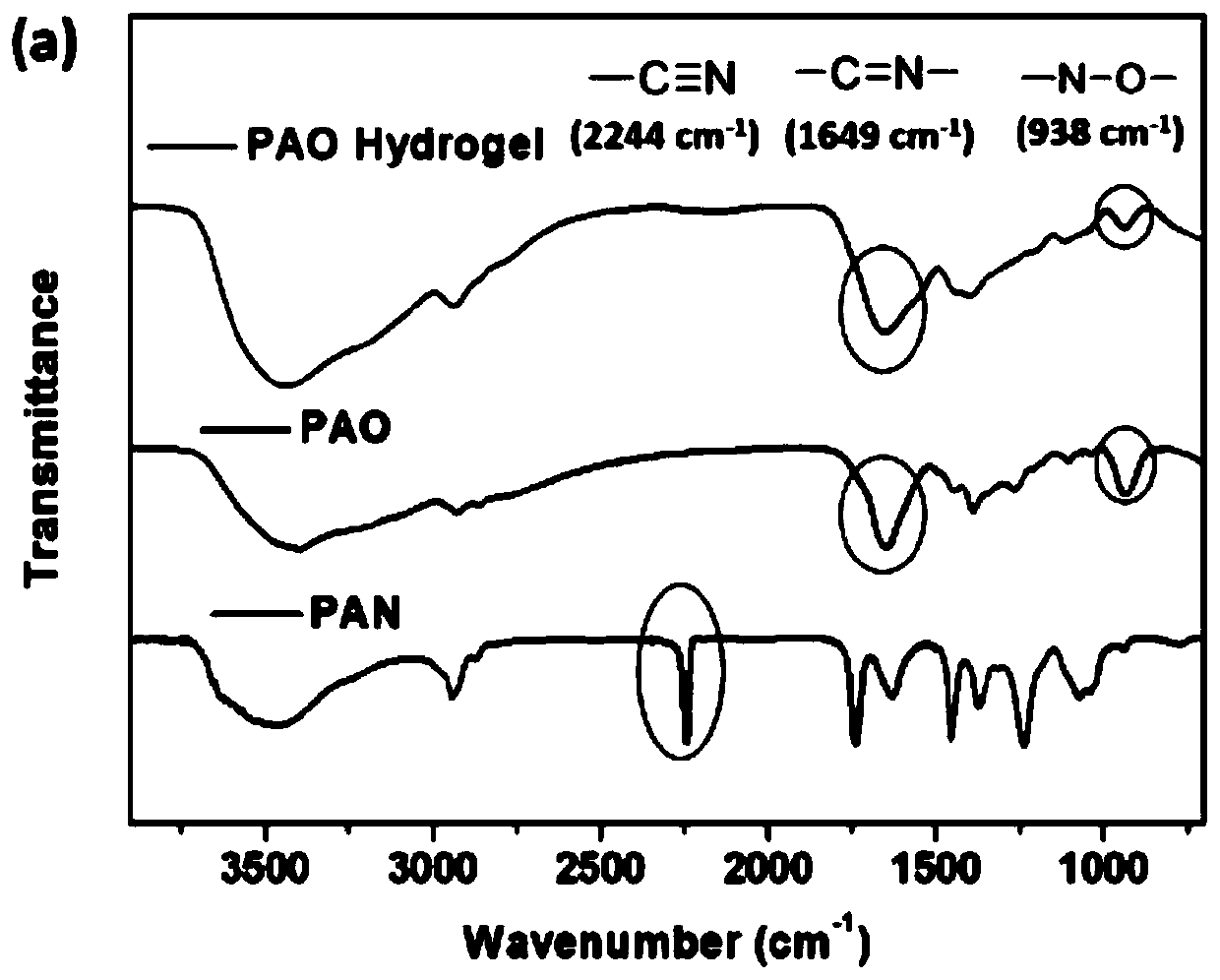

[0045] Depend on figure 1 It can be seen from the infrared spectrum that there is a C≡N infrared absorption peak (2244cm) in the inf...

Embodiment 2

[0047] Example 2: Preparation and performance characterization of a polyacrylamide oxime semi-IPN hydrogel

[0048] A kind of preparation of polyacrylamide oxime semi-interpenetrating network hydrogel, comprises the following steps:

[0049] Such as Figure 4 , 40 mg of PAO prepared in Example 1, 40 mg of monomer AAM, 6 mg of initiator AIBA, and 6 mg of cross-linking agent BIS were dissolved in 1 mL of 0.3 mol / L NaOH aqueous solution (pH 10), sonicated for 5 min, and then the prepared precursor Inject the liquid into a glass mold with a thickness of 0.2mm, and in sunlight (the measured ultraviolet intensity is 2.5±0.2mw / cm 2 ) under polymerization for 15min to prepare the polyacrylamide oxime semi-IPN hydrogel film, and the measured film thickness is 0.2mm. Such as figure 1 As shown in the mid-infrared spectrum, the 1649cm of the amidoxime group -1 (C=N) and 938cm -1 (N-O) The specific main peak indicates that PAO has been fixed in the PAAM semi-IPN, as Figure 5 The XPS...

Embodiment 3

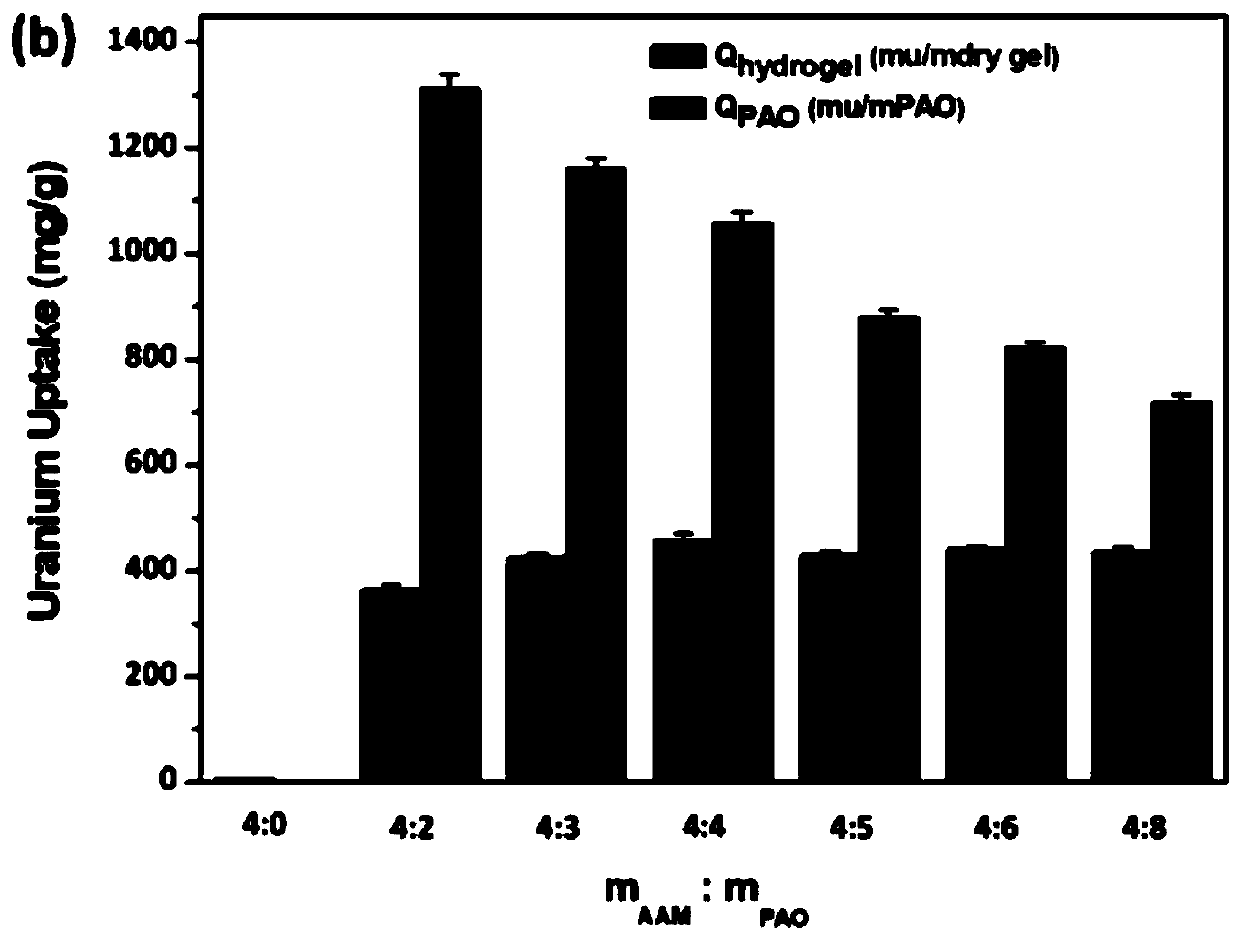

[0051] The difference between Example 3 and Example 1 is that the mass ratio of monomer acrylamide AAM and PAO is different, PAO is 0mg, 20mg, 30mg, 50mg, 60mg and 80mg, and the mass ratio of AAM and PAO is 0, 4:2, 4:3, 4:4, 4:5, 4:6, and 4:8.

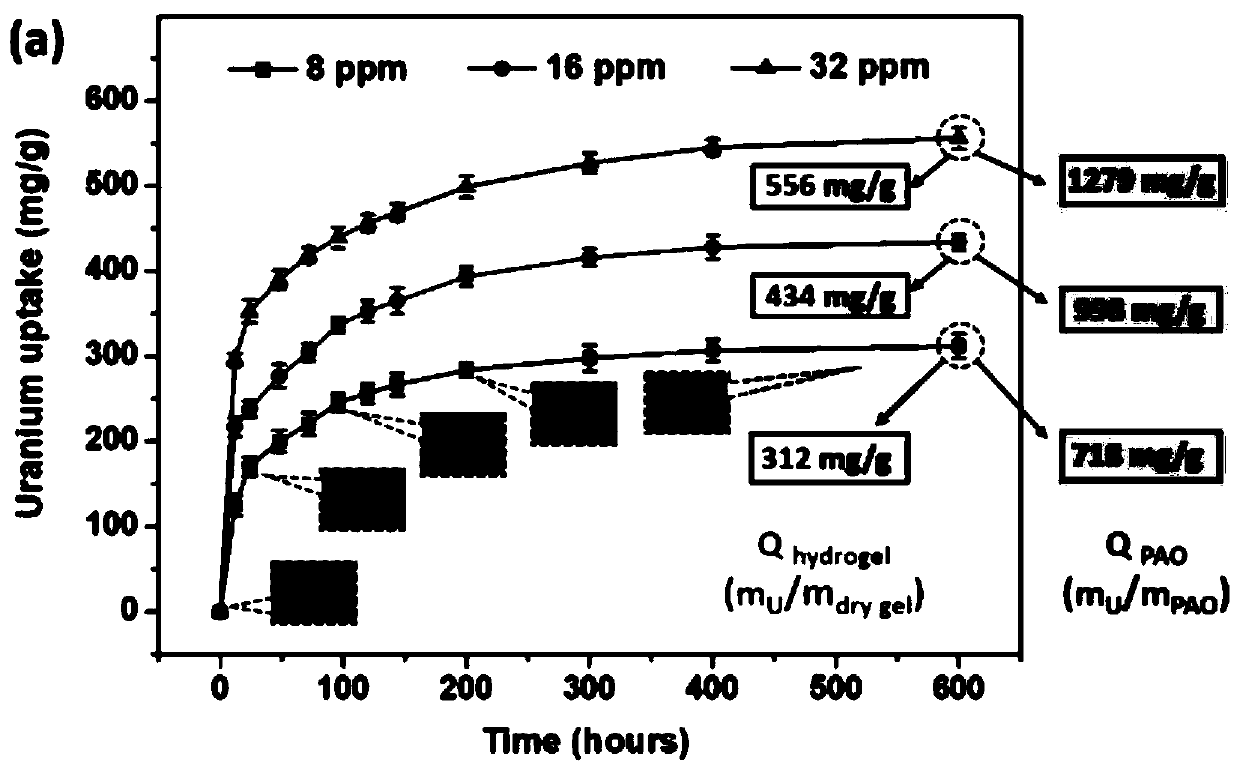

[0052] To study the uranium adsorption capacity test of polyacrylamide oxime semi-IPN hydrogel films prepared by different mass ratios of AAM and PAO monomers. Under the same conditions, the PAO hydrogel films were added to uranium-added seawater (32ppm) ,Such as Figure 9 As shown, the hydrogel with no PAO can hardly adsorb uranium (m AAM :m PAO =4:0), PAO hydrogels have outstanding uranium adsorption capacity. When increasing the ratio of PAO, the uranium adsorption capacity of the hydrogel (Q hydrogel ) began to increase; when m AAM :m PAO When the ratio reaches 4:4, continue to increase the ratio of PAO, Q hydrogel almost no change at all. On the other hand, when increasing the proportion of PAO, PAO(Q PAO , m U / m PAO )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com