Fe3O4@SiO2 magnetic nanospheres as well as preparation method and application thereof

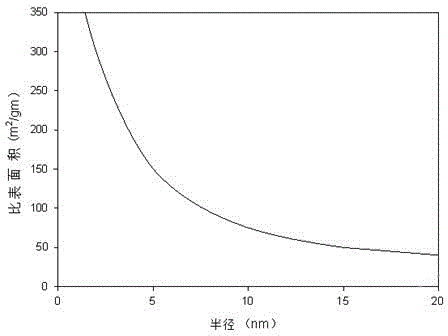

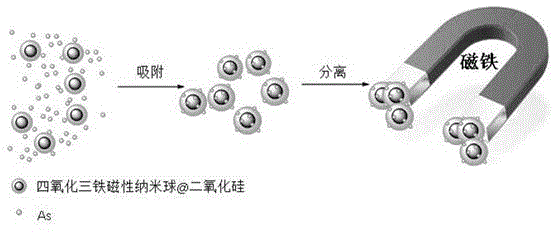

A magnetic nanosphere, magnetic technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of small specific surface area of ferric oxide nanoparticles, and the adsorption effect needs to be improved. , to achieve the effect of low cost, large specific surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

[0043] The preparation of embodiment 1 ferric oxide nanosphere

[0044] First, we used the co-precipitation method to prepare ferric oxide nanoparticles with a particle size of 8nm. The specific method is as follows:

[0045] FeCl 3 ·6H 2 O (0.4g, 1.4mmol) and FeSO 4 ·7H 2 O (0.2g, 0.7mmol), dissolved in 20mL of deionized water, ultrasonic 15min to remove oxygen.

[0046] The above solution was placed in a 50°C water bath under N 2 Under protection, after magnetic stirring for 15 min, 5 mL of ammonia water was slowly added dropwise (the dropping rate was 1 mL / min) therein, and the pH was adjusted to about 11, and the temperature was adjusted to 40°C.

[0047] Citric acid (0.16 g) was dissolved in 1 mL of water, added to the above reaction solution, and reacted for 1 h.

[0048] The resulting nanoparticles were prepared and washed twice with ethanol.

Embodiment 2 4

[0049] The preparation of embodiment 2 iron ferric oxide nanospheres

[0050] First, we used the co-precipitation method to prepare Fe3O4 nanoparticles with a particle size of 12nm. The specific method is as follows:

[0051] Will Fe 2 (SO 4 ) 3 (0.28g, 0.7mmol) and Fe(NO 3 ) 2 ·6H 2 O (0.20g, 0.7mmol), dissolved in 20mL of deionized water, ultrasonic 15min to remove oxygen.

[0052] The above solution was placed in a 60°C water bath under N 2 Under protection, after magnetic stirring for 60min, slowly dropwise (dropping speed is 1mL / min) NaHCO 3 Aqueous solution (0.02g / mL, 5mL), adjust the pH to around 10, and raise the temperature to 80°C.

[0053] Citric acid (0.16 g) was dissolved in 1 mL of water, added to the above reaction solution, and reacted for 1 h.

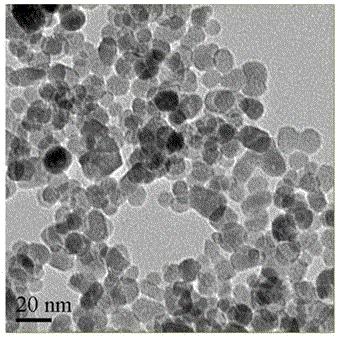

[0054] The resulting nanoparticles were prepared and washed twice with ethanol. Such as image 3 As shown, the average particle size of ferric oxide nanospheres prepared in this example is about 12 nm, and ...

Embodiment 3 4

[0055] The preparation of embodiment 3 iron ferric oxide nanospheres

[0056] First, we used the co-precipitation method to prepare Fe3O4 nanoparticles with a particle size of 12nm. The specific method is as follows:

[0057] FeCl 3 ·6H 2 O (0.4g, 1.4mmol) and Fe (NO 3 ) 2 ·6H 2 O (0.20g, 0.7mmol), dissolved in 20mL of deionized water, ultrasonic 15min to remove oxygen.

[0058] The above solution was placed in a 60°C water bath under N 2 Under protection, after magnetic stirring for 60min, slowly dropwise (dropping speed is 1mL / min) NaHCO 3 Aqueous solution (0.02g / mL, 5mL), adjust the pH to around 10, and raise the temperature to 80°C.

[0059] Citric acid (0.16 g) was dissolved in 1 mL of water, added to the above reaction solution, and reacted for 1 h.

[0060] The resulting nanoparticles were prepared and washed twice with ethanol.

[0061] with NaH 2 PO 4 solution or Na 2 HPO 4 solution instead of NaHCO 3 A solution can achieve the same effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com