Preparation method of macroporous carbon oxygen reduction catalyst containing sulfur, nitrogen and transition metal element

A technology of transition metal elements and procatalysts, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrical components, etc., to achieve the effect of increasing the concentration of conjugated electrons, uniform distribution, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: preparation of glucose thiourea prepolymer

[0025] Heat 3.96g of glucose to 40°C and dissolve in 3mL of deionized water, heat 1.52g of thiourea to 40°C and dissolve in 4mL of deionized water. Add the thiourea solution into the glucose solution. At this time, the mass ratio of glucose to thiourea is 1:0.38. Place it in a water bath at 85°C, add 0.5 mL of hydrochloric acid dropwise, and stir thoroughly. After reacting for 45 minutes, the viscosity of the liquid increased significantly, and after the color changed from colorless to light yellow to orange red, 40 mL of deionized water was added to terminate the polymerization, and cooled to obtain a glucose thiourea prepolymer solution.

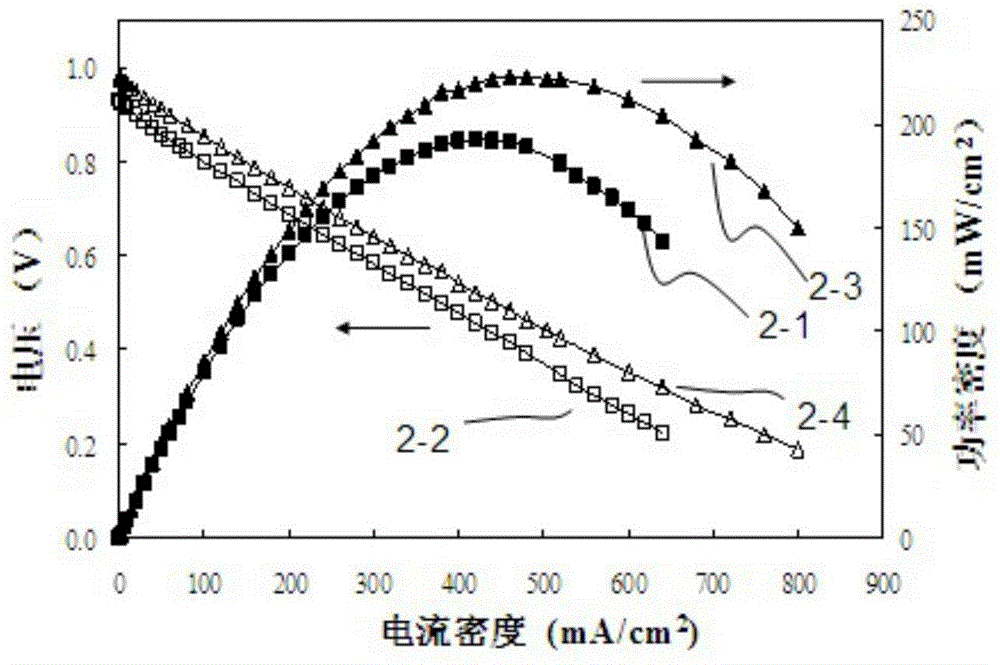

Embodiment 2

[0026] Embodiment two: preparation of catalyst precursor

[0027] Heat 3.96g of glucose to 40°C and dissolve in 3mL of deionized water, heat 3.96g of thiourea to 40°C and dissolve in 8mL of deionized water. Add the thiourea solution into the glucose solution. At this time, the mass ratio of glucose to thiourea is 1:1. Put it in a water bath at 85°C, add 0.5 mL of hydrochloric acid dropwise, and stir well. After reacting for 45 minutes, the viscosity of the liquid increased significantly, and after the color changed from colorless to light yellow to orange red, 40 mL of deionized water was added to terminate the polymerization, and cooled to obtain a glucose thiourea prepolymer solution.

[0028] Take another beaker and put nano-CaCO 3 Disperse 5g of the powder evenly in 30mL of manganese chloride solution (containing 0.1 mmol of manganese chloride) to obtain a suspension, add it to the above glucose thiourea prepolymer solution, heat in a water bath at 85°C, stir for 50 minut...

Embodiment 3

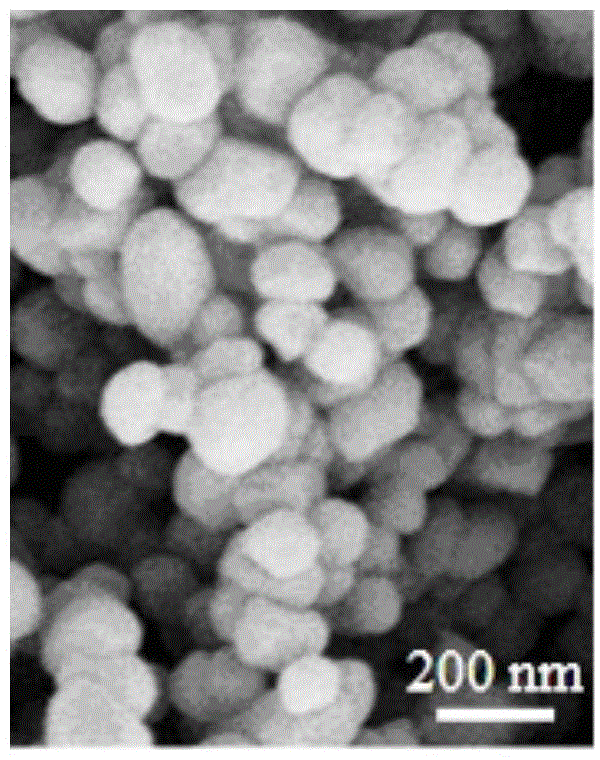

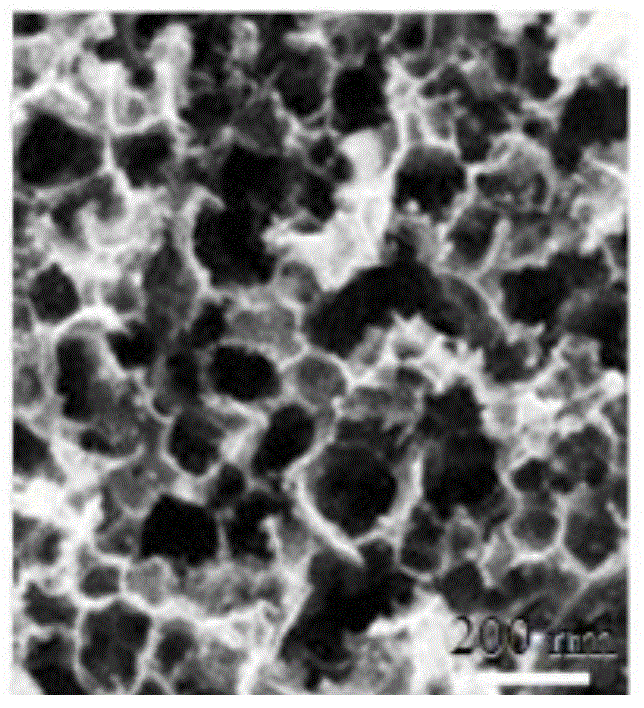

[0029] Example 3: Preparation of nitrogen-containing and sulfur-containing macroporous carbon-supported iron catalyst

[0030] Heat 3.96g of glucose to 40°C and dissolve in 3mL of deionized water, heat 9.12g of thiourea to 40°C and dissolve in 12mL of deionized water. Add the thiourea solution into the glucose solution. At this time, the mass ratio of glucose to thiourea is 1:2.3. Place it in a water bath at 85°C, add 0.5 mL of hydrochloric acid dropwise, and stir thoroughly. After reacting for 45 minutes, the viscosity of the liquid increased significantly, and after the color changed from colorless to light yellow to orange red, 40 mL of deionized water was added to terminate the polymerization, and cooled to obtain a glucose thiourea prepolymer solution.

[0031] Take another beaker and put nano-CaCO 3 5g of the powder is evenly dispersed in 30mL ferric sulfate solution (containing 0.5 mmoles of ferric sulfate) to obtain a suspension, which is added to the above glucose thio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com