Magnetic covalent organic frame material and preparation method and application thereof

A covalent organic framework, magnetic technology, applied in chemical instruments and methods, inorganic chemistry, other chemical processes, etc., can solve the problems of difficult separation and recovery, poor stability of COFs, etc., to achieve large adsorption capacity, high stability, and equipment. request simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

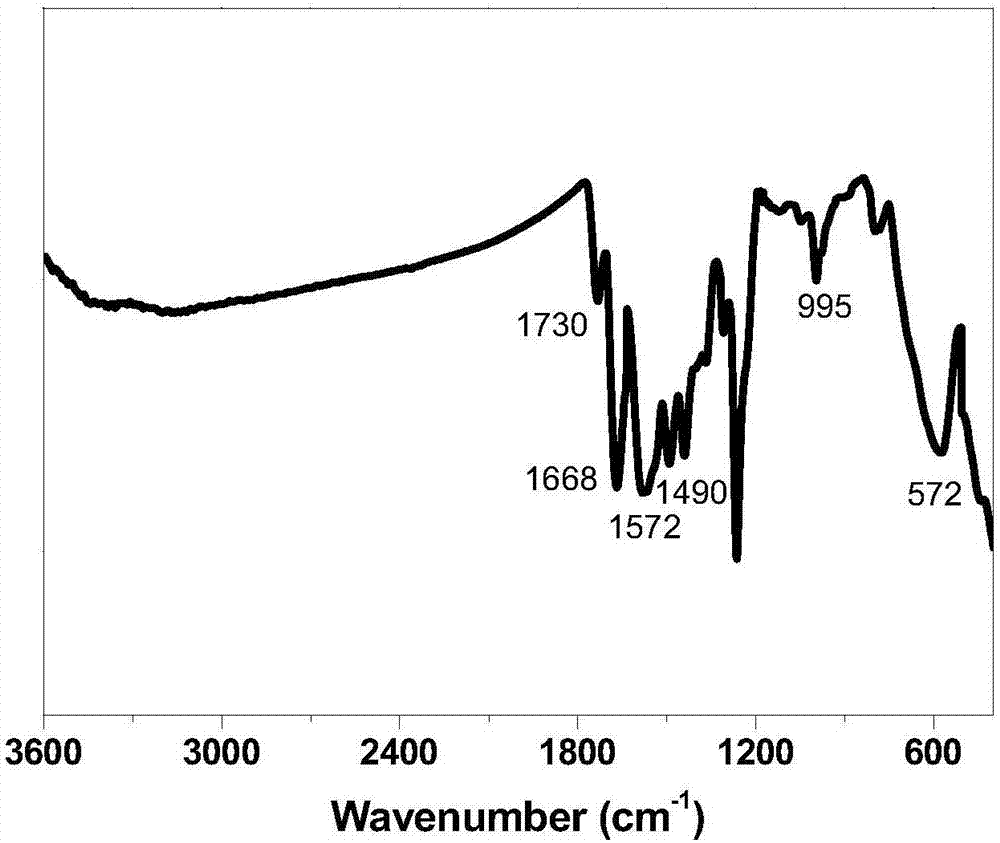

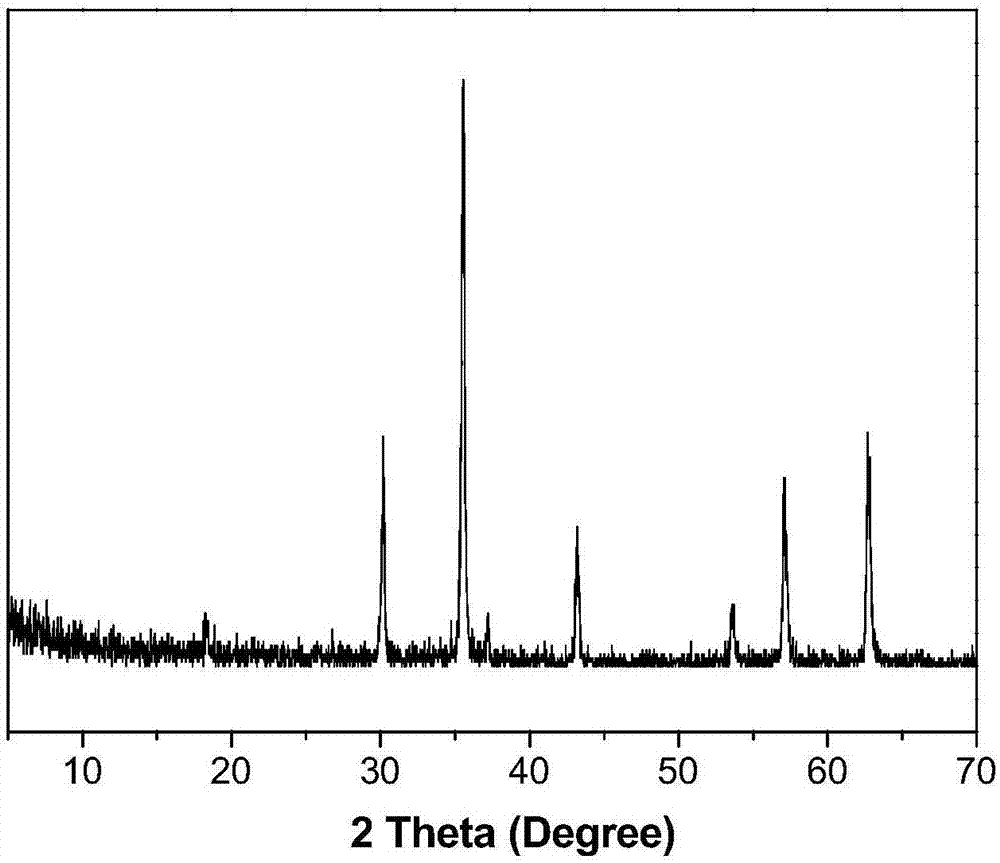

Embodiment 1

[0048]Dissolve the ligand piperazine in tetrahydrofuran at a mass ratio of 1:100, add magnetic iron ferric oxide nanoparticles (1:6 mass ratio to piperazine), and ultrasonically oscillate for 10 minutes, then put the above solution in a mechanically stirred Under normal circumstances, after heating to 80°C, continue to heat and reflux for 30 minutes, so that the system is completely mixed and uniform. Another cyanuric chloride was dissolved in tetrahydrofuran (mass ratio 1:100), and added dropwise to the above-mentioned reflux solution through a constant pressure dropping funnel. After the cyanuric chloride solution is added dropwise (the mass ratio of piperazine to cyanuric chloride is 1.2:1), keep the above system at 80° C. for 5 hours to obtain the crude product. The crude product obtained in the previous step is repeatedly washed with a strong magnet and a mixed solution of ethanol-water until there is no impurity, and then dried in an oven to obtain the final adsorbent. ...

Embodiment 2

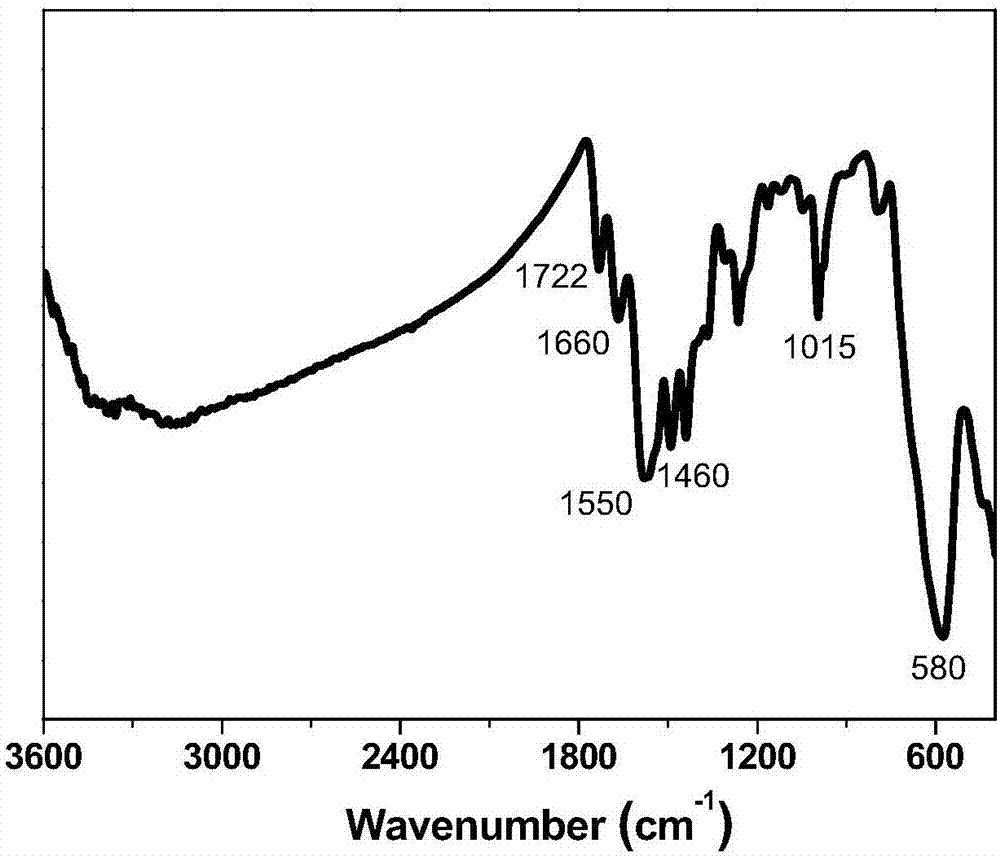

[0052] Dissolve the ligand piperazine in carbon tetrachloride at a mass ratio of 1:50, add magnetic iron ferric oxide nanoparticles (1:4 in mass ratio to piperazine), and ultrasonically oscillate for 10 minutes, then put the above solution in After heating to 100°C with mechanical stirring, continue to heat and reflux for 20 minutes, so that the system is completely mixed and uniform. Separately take cyanuric chloride and dissolve it in tetrahydrofuran (mass ratio: 1:50), and add the above-mentioned refluxing solution dropwise through a constant pressure dropping funnel. After the cyanuric chloride solution is added dropwise (the mass ratio of piperazine to cyanuric chloride is 0.5:1), keep the above system at 100°C for 4 hours to obtain the crude product. The crude product obtained in the previous step is repeatedly washed with a strong magnet and a mixed solution of ethanol-water until there is no impurity, and then dried in an oven to obtain the final adsorbent.

[0053] r...

Embodiment 3

[0056] The ligand piperazine was dissolved in tetrahydrofuran at a mass ratio of 1:25, and magnetic iron ferric oxide nanoparticles (1:2 mass ratio to piperazine) were added, and ultrasonically oscillated for 10 minutes, and then the above solution was stirred in a mechanically stirred Under normal circumstances, after heating to 120°C, continue to heat and reflux for 10 minutes, so that the system is completely mixed and uniform. Separately take cyanuric chloride and dissolve it in tetrahydrofuran (mass ratio: 1:25), and add the above-mentioned refluxing solution dropwise through a constant pressure dropping funnel. After the cyanuric chloride solution is added dropwise (the mass ratio of piperazine to cyanuric chloride is 2:1), keep the above system at 120° C. for 3 hours to obtain the crude product. The crude product obtained in the previous step is repeatedly washed with a strong magnet and a mixed solution of ethanol-water until there is no impurity, and then dried in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com