Method for processing CH4 in landfill site after acclimatizing and mineralizing garbage by utilizing percolate

A technology for mineralizing garbage and leachate, applied in the field of oxidation, can solve problems such as reducing methane concentration, and achieve the effect of avoiding pollution risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

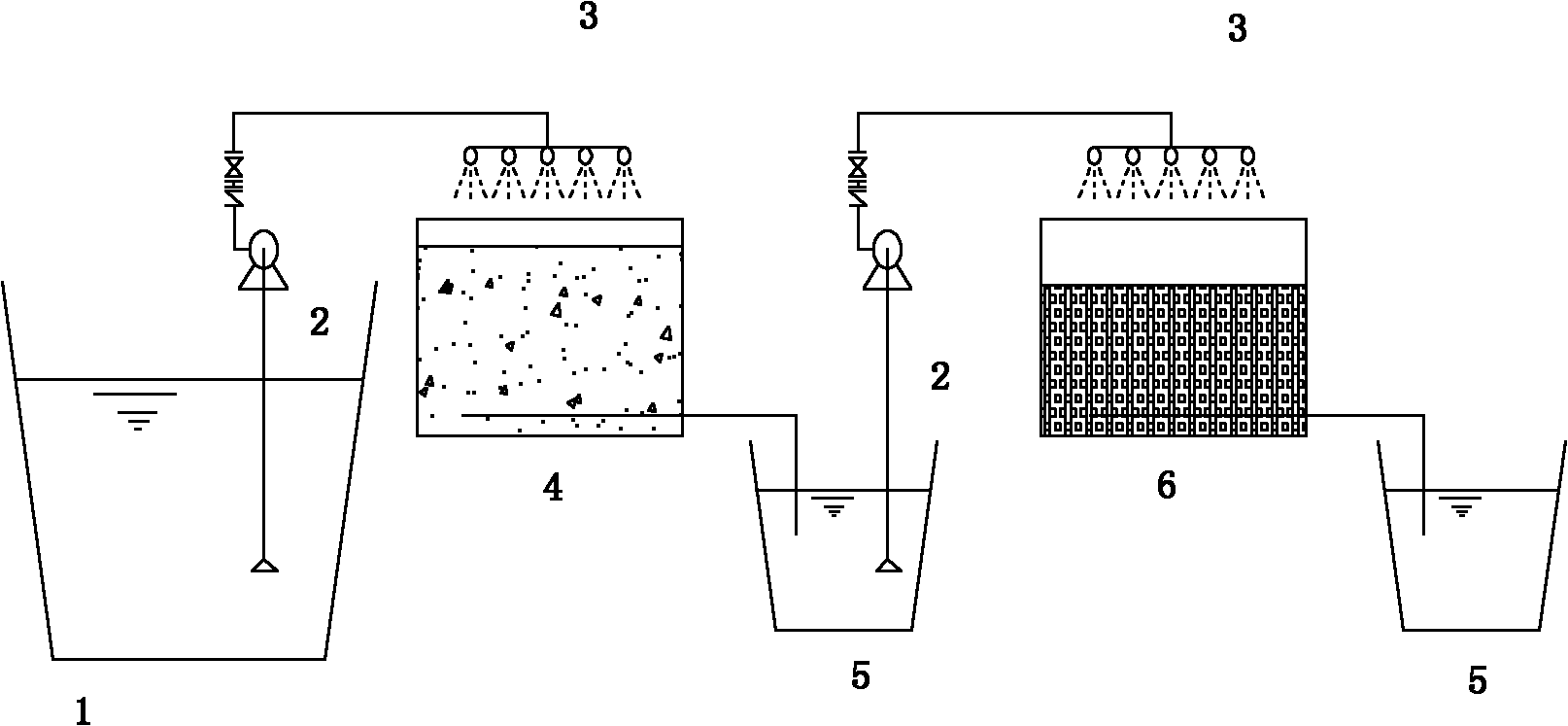

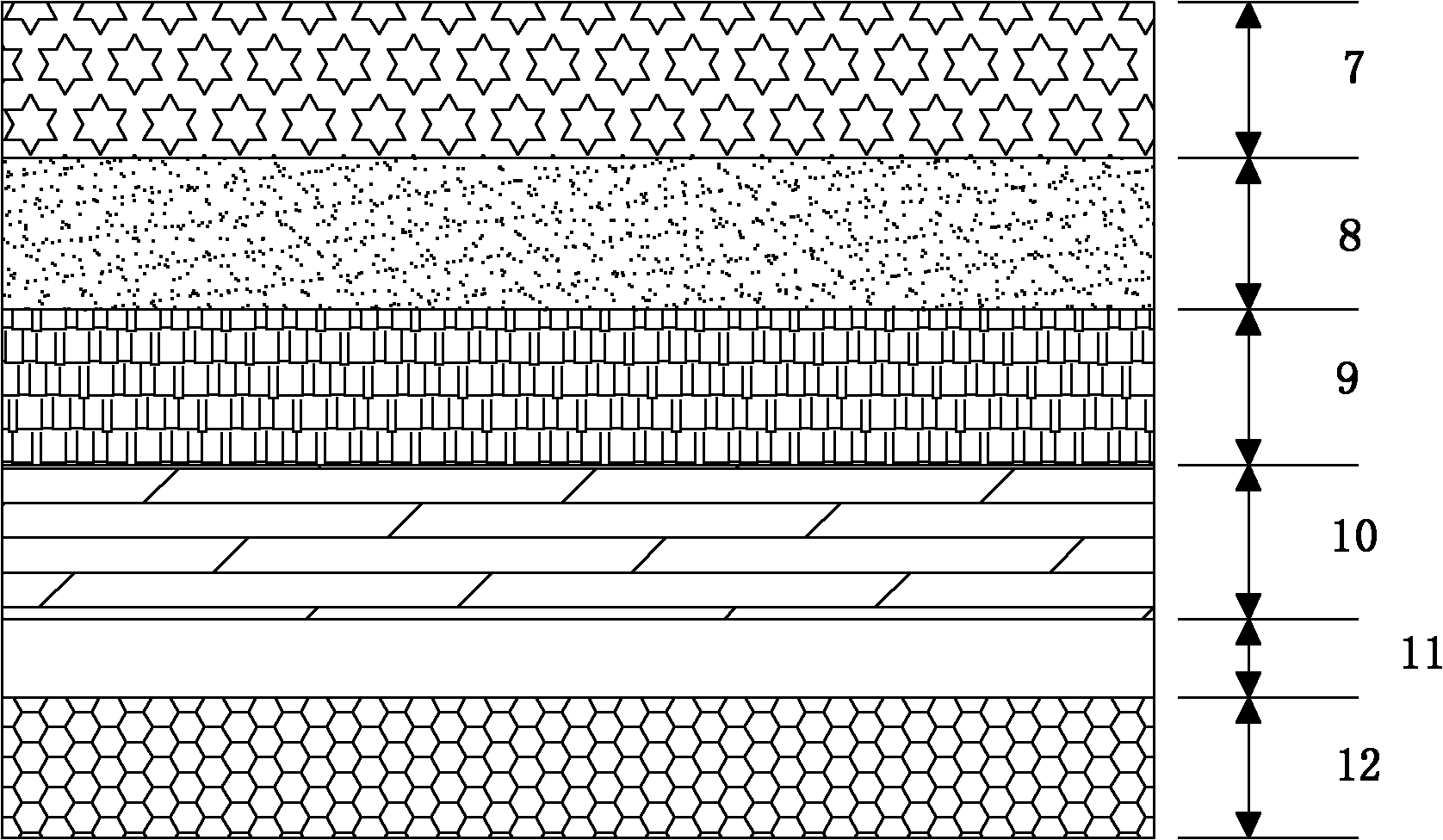

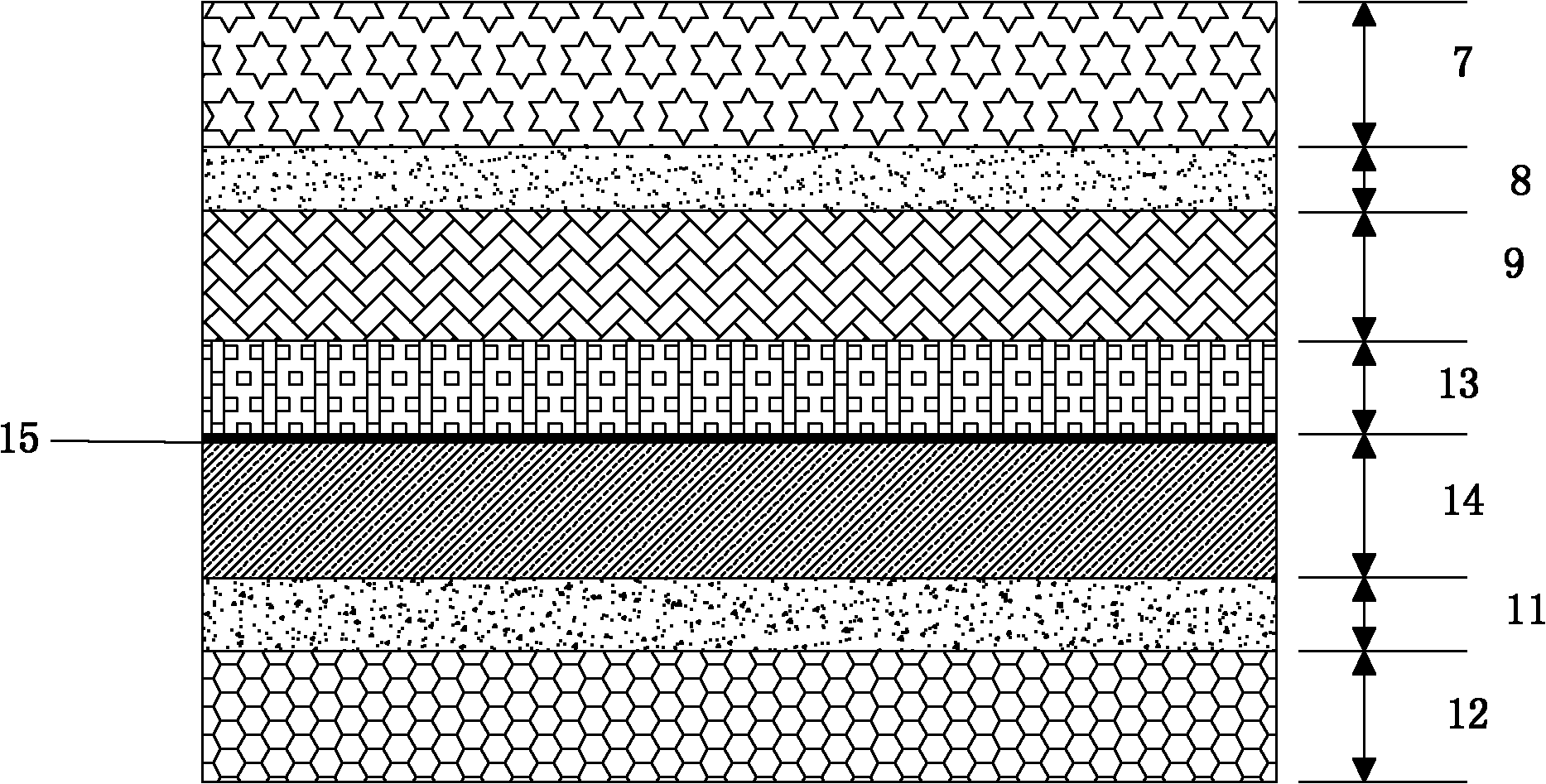

[0022] Embodiment 1: The landfill leachate is lifted from the landfill leachate regulating tank 1 by pump force 2, and passes through the water distribution pipeline 3 to the adsorption material layer 4, and the adsorption material layer adopts activated carbon layer (25cm high) / macroporous adsorption resin from top to bottom Layer (model H103, 25cm high, Nankai University Chemical Plant), the water quality index of leachate is: COD cr =3000-8000mg / L, BOD 5 =1000-2000mg / L, NH 4 + -N=1350-2870mg / L, Fe 3+ =1200-2300mg / L, Pb 2+ =12-35mg / L, Zn 2+ =123-267mg / L, the hydraulic load of water distribution is 0.03~0.15m 3 / (m 3 Under the operating conditions of the adsorption material d), the effluent water quality is COD cr =800-2500mg / L, BOD 5 =500-1200mg / L, NH 4 + -N=950-2500mg / L, Fe 3+ =100-350mg / L, pb 2+ =2-5mg / L, Zn 2+ =18-35mg / L. After the power of the secondary pump, the effluent is lifted to the mineralized garbage packing layer 6 ( figure 1 ), the water distribu...

Embodiment 2

[0029] Embodiment 2: The landfill leachate regulating tank 1 is lifted by the pump force 2, and passes through the water distribution pipeline 3 to the adsorption material layer 4, and the adsorption material layer adopts an activated carbon layer (30cm high) / macroporous adsorption resin layer (model D3520) from top to bottom. , 20cm high, Nankai University chemical plant), the water quality index of leachate is: COD cr =3500-12000mg / L, BOD 5 =3700-4500mg / L, NH 4 + -N=1780-2670mg / L, Fe 3+ =1100-2500mg / L, Pb 2+ =16.5-35.3mg / L, Zn 2+ =167-285mg / L, the hydraulic load of leachate distribution is 0.01~0.03m 3 / (m 3 Under the operating conditions of the adsorption material d), the effluent water quality is COD cr =1100-4600mg / L, BOD 5 =800-1200mg / L, NH 4 + -N=950-2380mg / L, Fe 3+ =80-260mg / L, pb 2+ =4.5-7.8mg / L, Zn 2+ =21-29 mg / L. The effluent is lifted to the mineralized garbage packing layer 6 by the power of the secondary pump, and the water distribution load is 0.15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com