Sludge drying process and equipment

A sludge drying and equipment technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problem of difficult breakthrough in the gelation process of the drying process, the reduction of the heat exchange effect between the blade shaft and the raw material, and the reduction of equipment processing capacity, etc. problems, to achieve the effect of controllable sludge drying degree, high sludge treatment efficiency, and reduced voltage fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

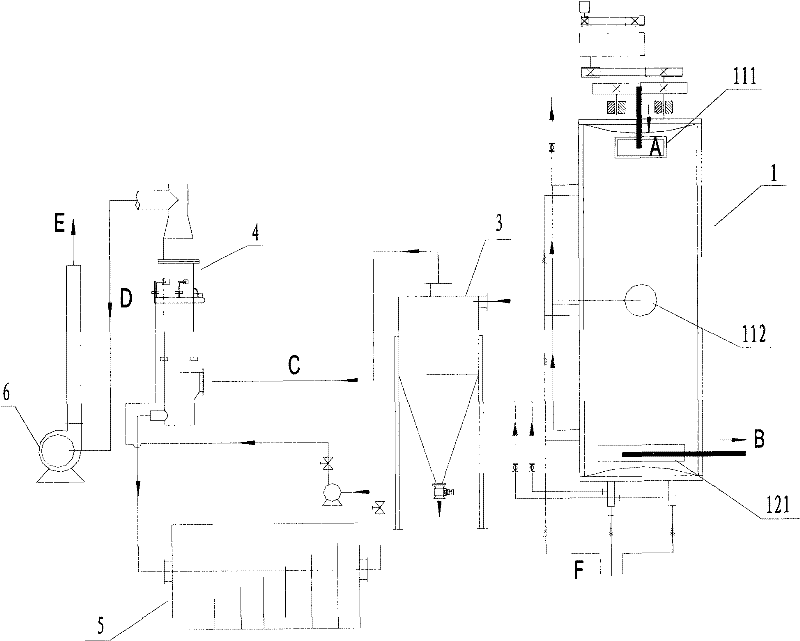

[0034] like figure 1 As shown, the steps included in the sludge drying process are:

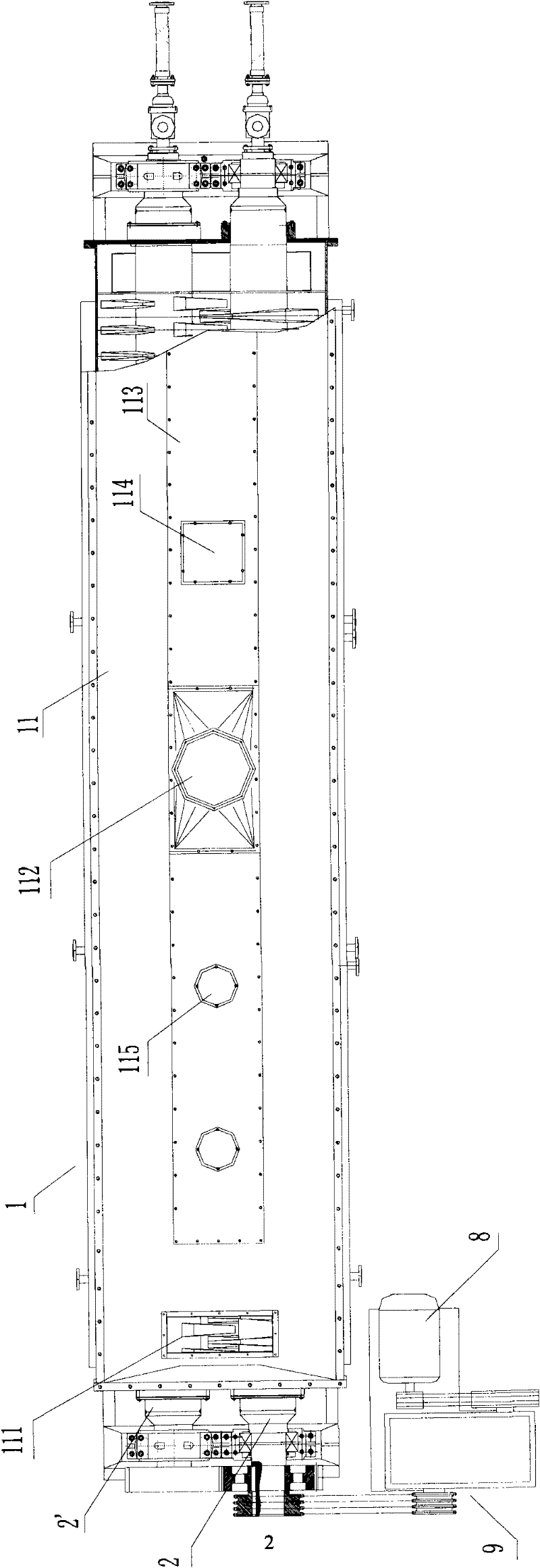

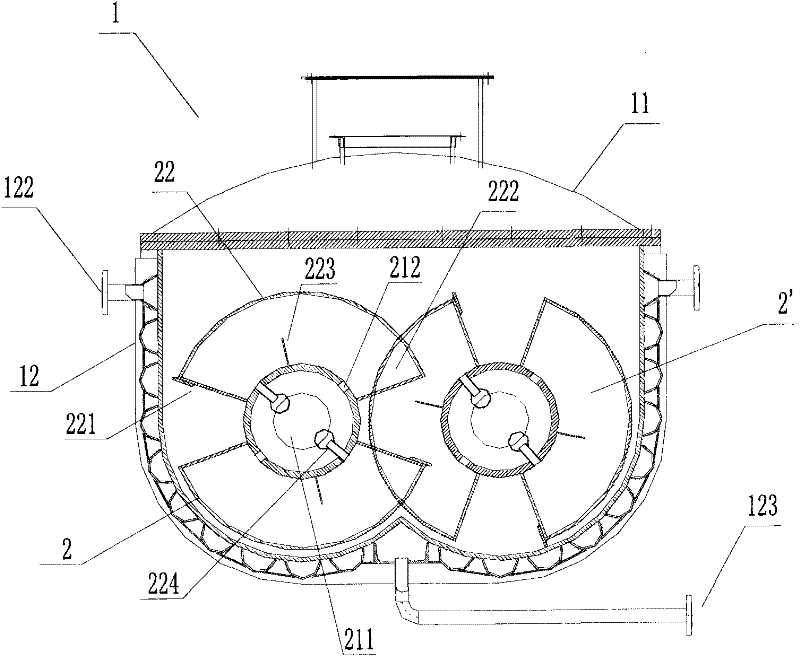

[0035] (1) Pretreat the sludge with a water content above 80% to a water content below 50%, keep the temperature of the sludge constant, and input it from a feed port 111 (A to) a sludge drying equipment 1 ;

[0036] (2) In the above-mentioned sludge drying equipment 1, the sludge is continuously pushed to the discharge port 121, and the sludge is heated to above 120°C, accompanied by continuous stirring and crushing treatment, and at the same time, the sludge The volatilized water vapor in the mud is continuously drawn out from the steam outlet 112 until the sludge with the desired moisture content is discharged from the sludge drying equipment (direction B).

[0037] The above-mentioned tail gas generated by the water vapor drawn from the sludge dryer by the air-inducing equipment is input into the incineration system after the dust removal treatment. The specific method of the dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com