Rectifier soft start circuit and control method thereof

A soft-start circuit and rectifier technology, applied in the field of power electronic AC, can solve the problems of long start-up time, affecting the life of components, and unable to achieve soft-start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

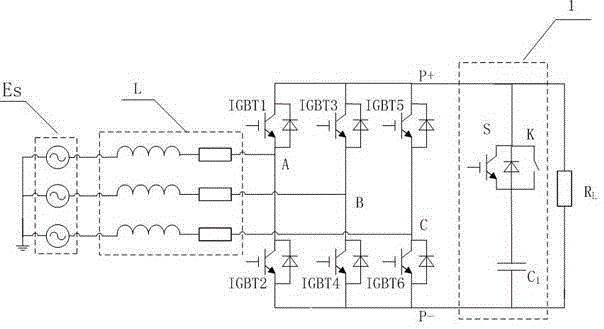

[0022] In this embodiment, a three-phase voltage-type PWM rectifier is taken as an example to further illustrate a rectifier soft-start circuit and a control method thereof in the present invention. Such as figure 1 As shown, the rectifier soft start circuit is arranged between the rectifier and the load, including: a first capacitor C 1 , current limiting unit, relay K, DSP processor (not shown in the figure), in this embodiment, the current limiting unit is the IGBT tube S containing anti-parallel diodes; wherein the three-phase rectifier bridge positive DC bus P+, IGBT tube The collector of S, one end of relay K, load R L One end of the three-phase rectifier bridge negative DC bus P-, the first capacitor C 1 The cathode, load R L The other ends of the IGBT tube S are connected together; the emitter of the IGBT tube S and the first capacitor C 1 The anode of the anode and the other end of the relay K are connected together; the DSP processor controls the on-off state of ...

Embodiment 2

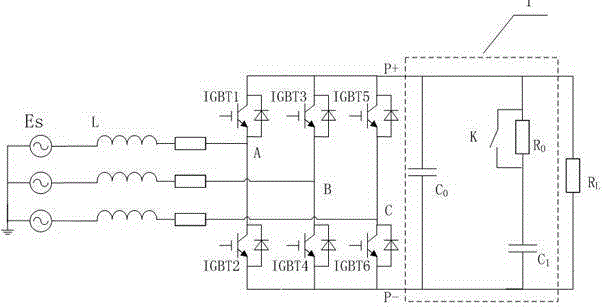

[0029] In this embodiment, a three-phase voltage-type PWM rectifier is also taken as an example to further illustrate a rectifier soft-start circuit and its control method described in the present invention. figure 2 It is a schematic circuit diagram of the present embodiment, including: a first capacitor C 1 , current limiting resistor R 0 (that is, the current limiting unit described in the present invention), relay K, DSP processor (not shown in the figure), by figure 2 It can be seen that the second capacitor C is also included in this embodiment 0 . The specific circuit connection is as follows: the second capacitor C 0 The anode of the three-phase rectifier bridge positive DC bus P+, one end of the relay K, the current limiting resistor R 0 One end of the load R L One end of the connected together, the second capacitor C 0 The cathode of the three-phase rectifier bridge negative DC bus P-, the first capacitor C 1 The cathode, load R L The other end of the relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com