Method for removing hydroxyapatite modified eggshell adsorbent material and recycling phosphate from wastewater

A technology of hydroxyapatite and adsorbent, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., to achieve the effect of low construction and operation costs and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Remove the inner membrane of the eggshell, and wash the eggshell repeatedly with tap water, and then dry, crush and sieve the eggshell powder to obtain 200-mesh eggshell powder for use; the preparation concentrations are 1 mol / L, 0.6 mol / L and 0.8 mol / L Ca(NO 3 ) 2 , (NH 4 ) 2 HPO 4 and NH 3 ·OH solution for later use.

[0024] (2) Take 10 g of spare eggshell powder and place it in a 250 mL Erlenmeyer flask; add 20 mL of spare Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 solution, and using NH 3 Adjust the pH of the solution to 9 with OH solution, centrifuge after stirring for 24 hours, wash the solid repeatedly with distilled water until the pH of the supernatant is close to 7, dry the solid at 105°C, and grind it through a 200-mesh sieve for backup The obtained solid is the hydroxyapatite modified eggshell adsorbent material.

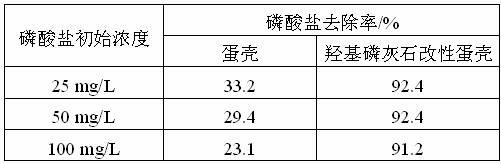

[0025] (3) Weigh 0.200 g of the adsorbents prepared by the above method and place them in 20 mL of 25, 50 and 100 mg PO 4 3- / L of phosph...

Embodiment 2

[0029] (1) Remove the inner membrane of the eggshell, and wash the eggshell repeatedly with tap water, and then dry, crush and sieve the eggshell powder to obtain 200-mesh eggshell powder for use; the preparation concentrations are 1 mol / L, 0.6 mol / L and 0.8 mol / L Ca(NO 3 ) 2 , (NH 4 ) 2 HPO 4 and NH 3 ·OH solution for later use.

[0030] (2) Take 10 g of spare eggshell powder and place it in a 250 mL Erlenmeyer flask; add 20 mL of spare Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 solution, and using NH 3 Adjust the pH of the solution to 9 with OH solution, centrifuge after stirring for 24 hours, wash the solid repeatedly with distilled water until the pH of the supernatant is close to 7, dry the solid at 105°C, and grind it through a 200-mesh sieve for backup The obtained solid is the hydroxyapatite modified eggshell adsorbent material.

[0031] (3) Weigh 0.200 g of the adsorbent prepared by the above method and place them in 25 mL of 100 mg PO 4 3- / L, the phosphate solutio...

Embodiment 3

[0033] (1) Remove the inner membrane of the eggshell, and wash the eggshell repeatedly with tap water, and then dry, crush and sieve the eggshell powder to obtain 200-mesh eggshell powder for use; the preparation concentrations are 1 mol / L, 0.6 mol / L and 0.8 mol / L Ca(NO 3 ) 2 , (NH 4 ) 2 HPO 4 and NH 3 ·OH solution for later use.

[0034] (2) Take 10 g of spare eggshell powder and place it in a 250 mL Erlenmeyer flask; add 20 mL of spare Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 solution, and using NH 3 Adjust the pH of the solution to 9 with OH solution, centrifuge after stirring for 24 hours, wash the solid repeatedly with distilled water until the pH of the supernatant is close to 7, dry the solid at 105°C, and grind it through a 200-mesh sieve for backup The obtained solid is the hydroxyapatite modified eggshell adsorbent material.

[0035] (3) Weigh 0.050, 0.100 and 0.200 g of the adsorbents prepared by the above method, respectively, and place them in 25 mL of 100 mg P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com