Anaerobic and aerobic flocculation precipitation sewage treatment process

A sewage treatment, anaerobic and aerobic technology, used in flocculation/sedimentation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Less capital investment and other problems, to achieve the effect of short hydraulic retention time, simple process flow, convenient operation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

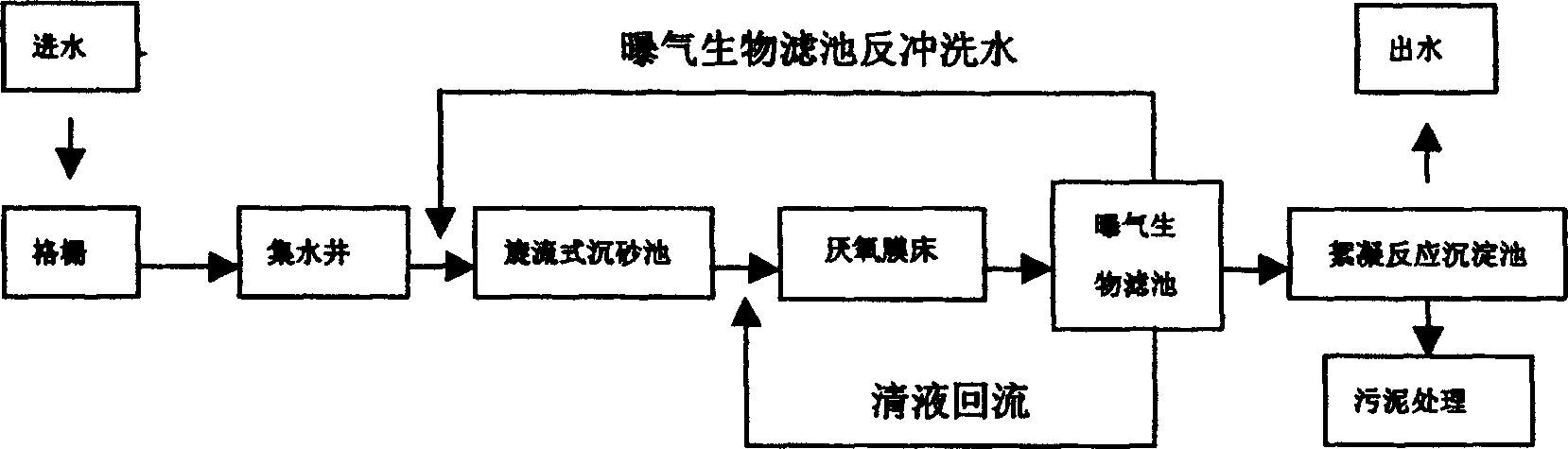

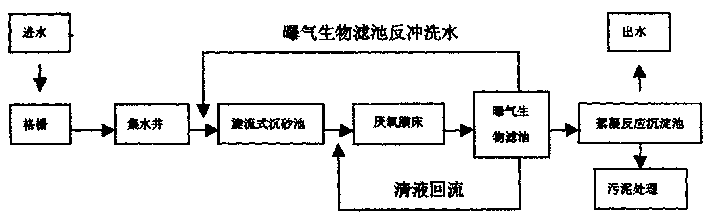

[0020] Embodiment of the anaerobic aerobic flocculation sedimentation sewage treatment process of the present invention The main part of the sewage treatment is a square concrete structure, mainly including a swirl type grit chamber, anaerobic membrane bed, aerated biological filter, flocculation reaction zone, vertical flow type Sedimentation tank, sludge concentration tank; swirl type grit chamber is a swirl structure, which can remove some particles and adjust water quality and water quality; the lower part of the anaerobic membrane bed is equipped with sewage distribution pipes and packing brackets, and anaerobic packing is placed ;The lower part of the biological aerated filter is equipped with a backwash pipe (that is, an outlet pipe), a filter plate, an aeration pipe and biological filter materials, and the upper part is equipped with a water inlet pipe and a backwash outlet pipe; the flocculation reaction zone adopts a folded plate structure; vertical flow The type sedi...

Embodiment 2

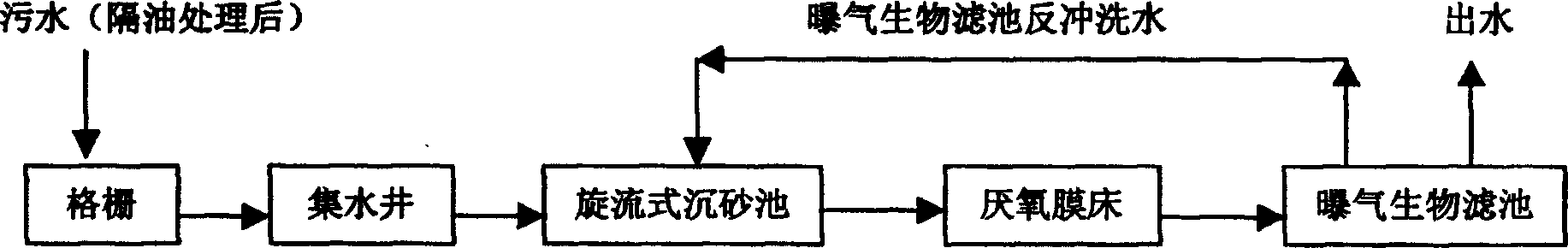

[0027] figure 2 Another process flow of the anaerobic aerobic flocculation sedimentation sewage treatment process of the present invention is shown. This process flow is suitable for sewage treatment with low phosphorus content. After that, it is driven by a water pump into the cyclone grit chamber to remove part of the suspended solids, and then the sewage enters the anaerobic membrane bed through the water distribution pipe for anaerobic biological treatment to remove some pollutants (COD Cr 、BOD 5 ), the residence time of sewage in the anaerobic membrane bed is 2 to 8 hours, and the volume load of the anaerobic membrane bed is 1.2 to 3.6kgCOD / m 3 .d; The water flowing out from the anaerobic membrane bed enters the biological aerated filter for aerobic biological treatment to further remove pollutants (COD Cr 、BOD 5 ), the residence time of sewage in the biological aerated filter is 1 to 4 hours, and the volume load of the biological aerated filter is 2.4 to 7.2kgCOD / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com