Method for treating wastewater by utilizing immobilized photosynthetic bacterium coupled film reaction system

A technology of photosynthetic bacteria and reaction system, which is applied in water treatment of special compounds, chemical instruments and methods, and wastewater treatment in processing processes, etc. It can solve the problems of weak resistance to pH load changes, poor tolerance of inorganic salts, and low degradation efficiency. , to achieve the effects of reducing operating costs, enhancing transfer, and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

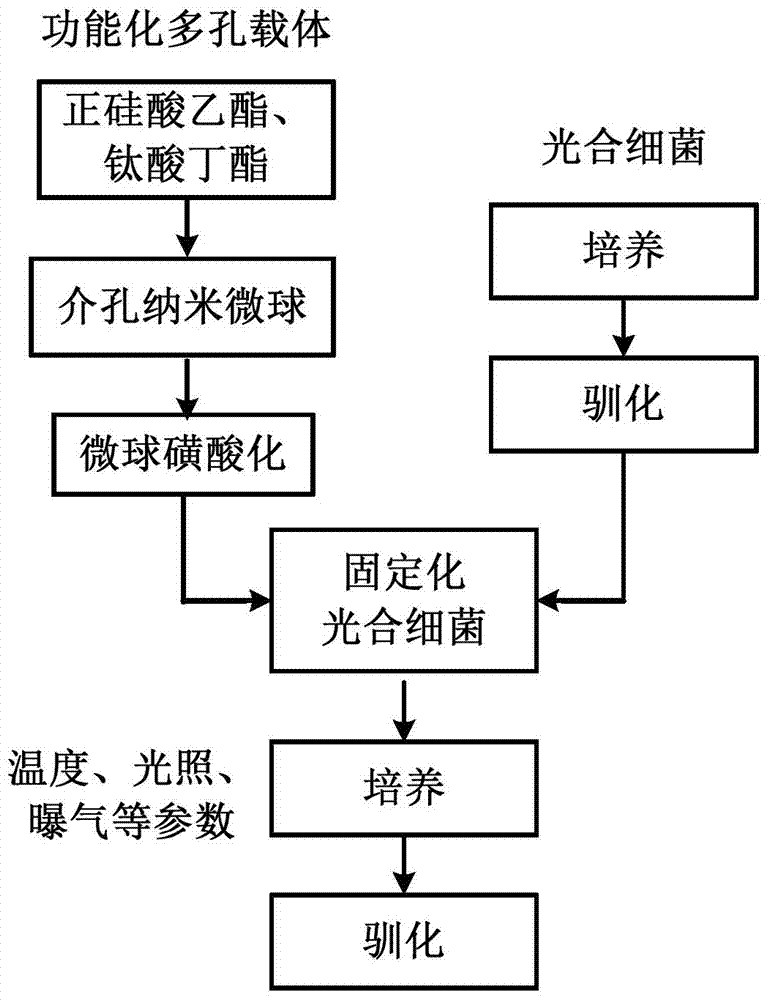

[0034] Example 1 Immobilized photosynthetic bacteria

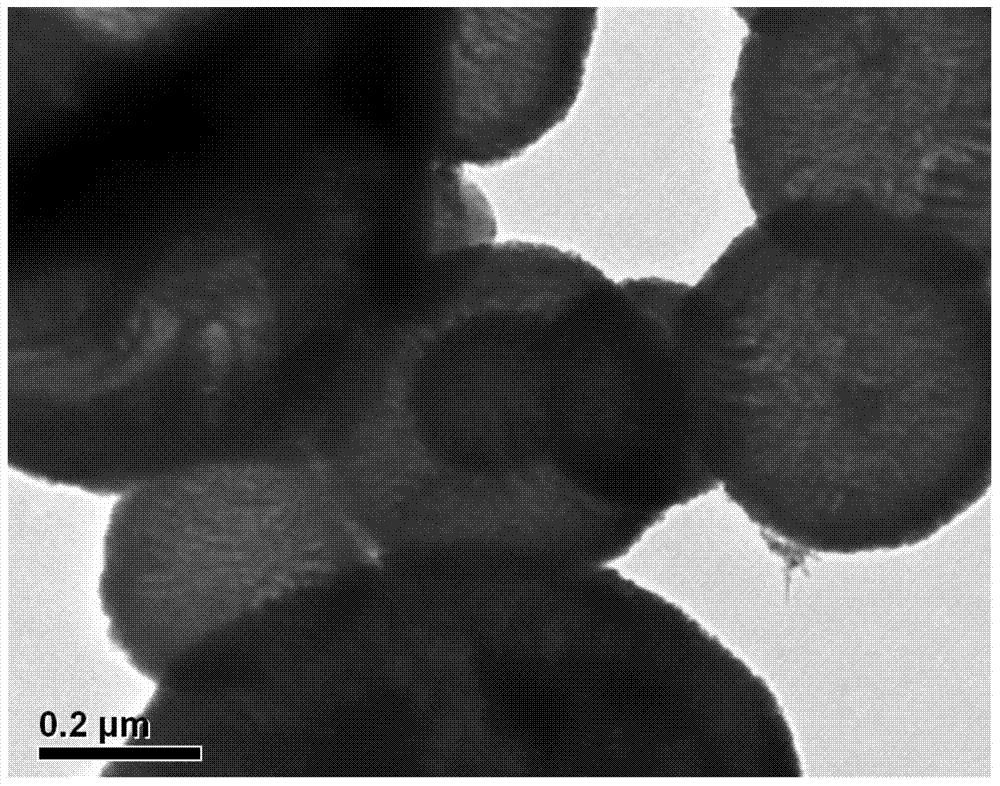

[0035] Sulfonated SiO 2 / TiO 2 The specific preparation method of mesoporous composite microspheres is: completely dissolve 0.85g sodium dodecylbenzene sulfonate in 80ml dilute HCl solution (HCl concentration is 0.1mol / L); mix 3ml ethyl orthosilicate and 0.2ml Add butyl titanate to the above solution, then pour it into the reactor and let it stand for 15 hours in an oven at 60°C. Centrifuge the obtained product, wash with deionized water and vacuum dry to prepare SiO 2 / TiO 2 Composite microspheres. The high temperature calcination method is used to remove the surfactant in the pores. The composite microspheres are calcined at 600℃ for 6h to prepare SiO 2 / TiO 2 Mesoporous composite microspheres. The prepared SiO 2 / TiO 2 Mesoporous composite microspheres (1.0g) are completely immersed in 10ml CH 2 Cl 2 After ultrasonic dispersion, 4ml of chlorosulfonic acid was added to the above mixture, sonicated, and reacted at room tem...

Embodiment 2

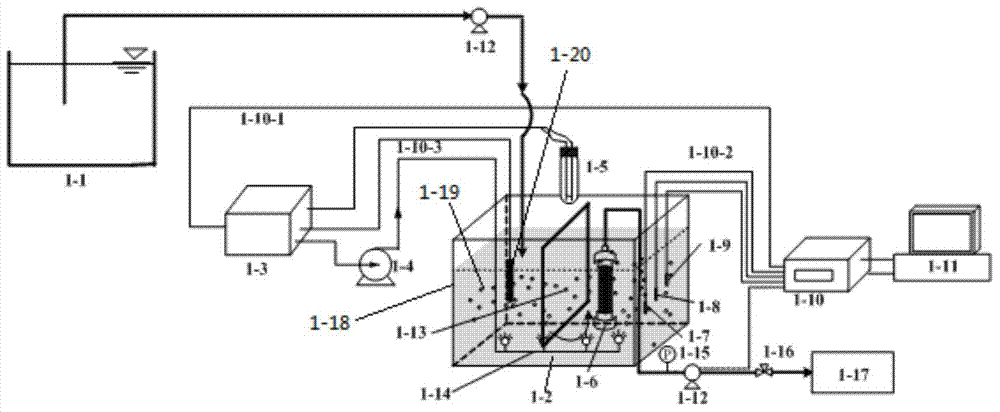

[0041] Using the immobilized photosynthetic bacteria filler prepared in Example 1, the immobilized photosynthetic bacteria coupled membrane reaction system of the present invention was used to treat methylene blue dye wastewater, and the COD and chromaticity of the membrane effluent and the change of membrane flux during the operation of the reaction system were measured.

[0042] The indicators of methylene blue dye wastewater: dye concentration is 150mg / L, COD is 500-800mg / L.

[0043] The operating conditions of the membrane bioreactor: the wastewater enters the bioreactor (50L) containing immobilized photosynthetic bacteria (prepared in Example 1) through the peristaltic pump from the original water tank, and the light source is turned on at the same time, and the microorganisms metabolize and decompose the organic matter. The oxygen concentration is set to 0.5mg / L, the temperature is controlled at 30°C, the light intensity is set to 3000lux, the hydraulic retention time (HRT) is...

Embodiment 3

[0059] The methylene blue in the liquid enrichment culture solution of Example 1 was replaced with Scarlet 4BS dye, and the other operations were the same as in Example 1 to prepare immobilized photosynthetic bacteria filler. The immobilized photosynthetic bacteria coupled membrane reaction system of the present invention was used to treat the direct Scarlet 4BS dye wastewater. Measure the COD and chromaticity of the membrane effluent and the change of membrane flux during the operation of the reaction system.

[0060] Direct scarlet 4BS dye wastewater indicators: dye concentration is 100mg / L, COD is 400-600mg / L.

[0061] The operating conditions of the membrane bioreactor: consistent with Example 2;

[0062] The concentration of the immobilized photosynthetic bacteria filler (prepared in Example 1) in the bioreactor was 10 g / L, the dissolved oxygen concentration was 0.5 mg / L, the temperature was 30° C., and the light intensity was 3000 lux.

[0063] by Figure 5 It can be seen that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com