High-collimation face type light source module and light output method thereof

A collimating surface type, light source module technology, applied in optics, light guides, optical components, etc., can solve the problems of prolonging battery life, unfavorable mass production, manufacturing difficulties, etc., to achieve the effect of improving light utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only auxiliary descriptions, but the present invention is not limited to the drawings and the embodiments.

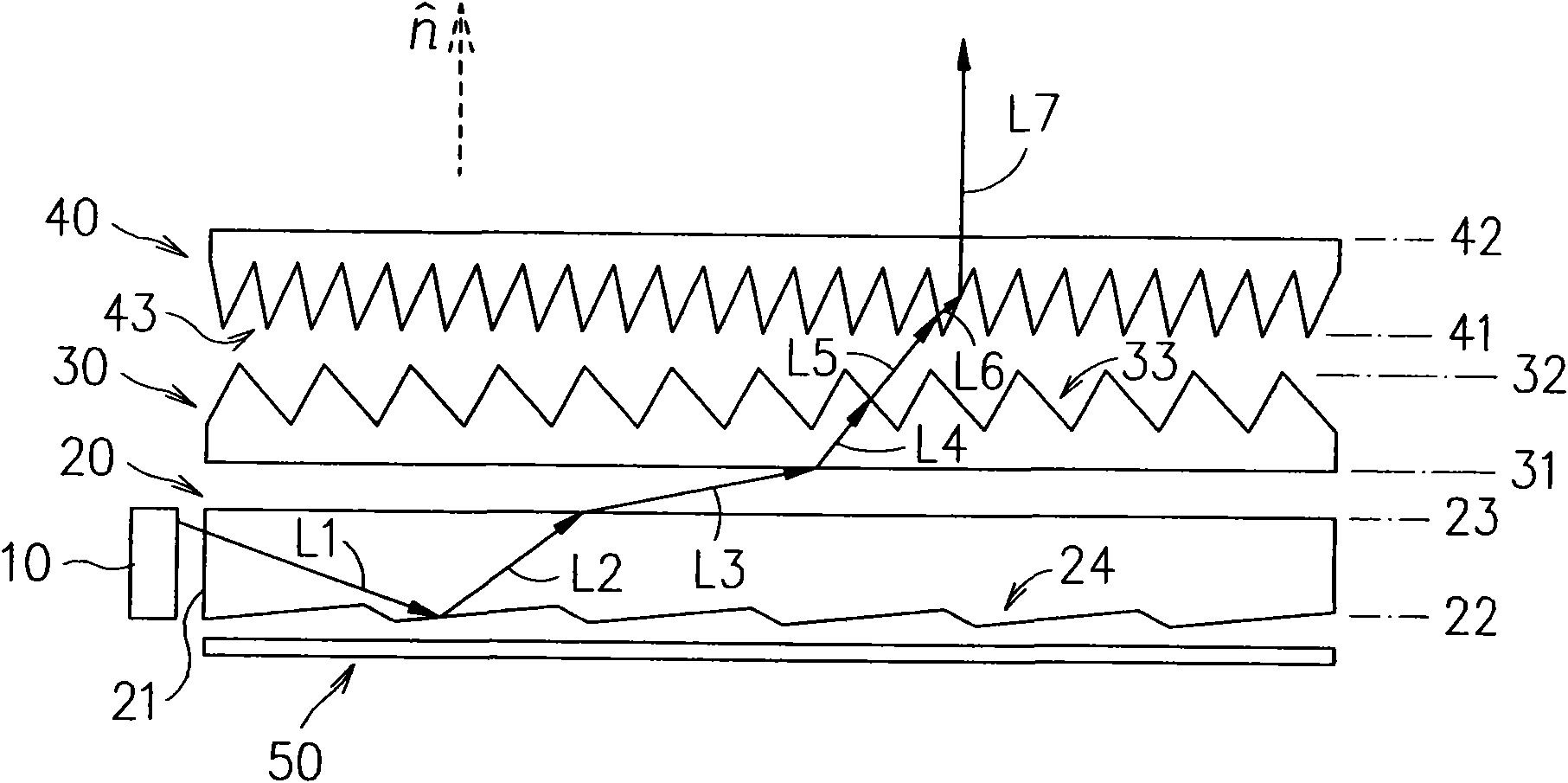

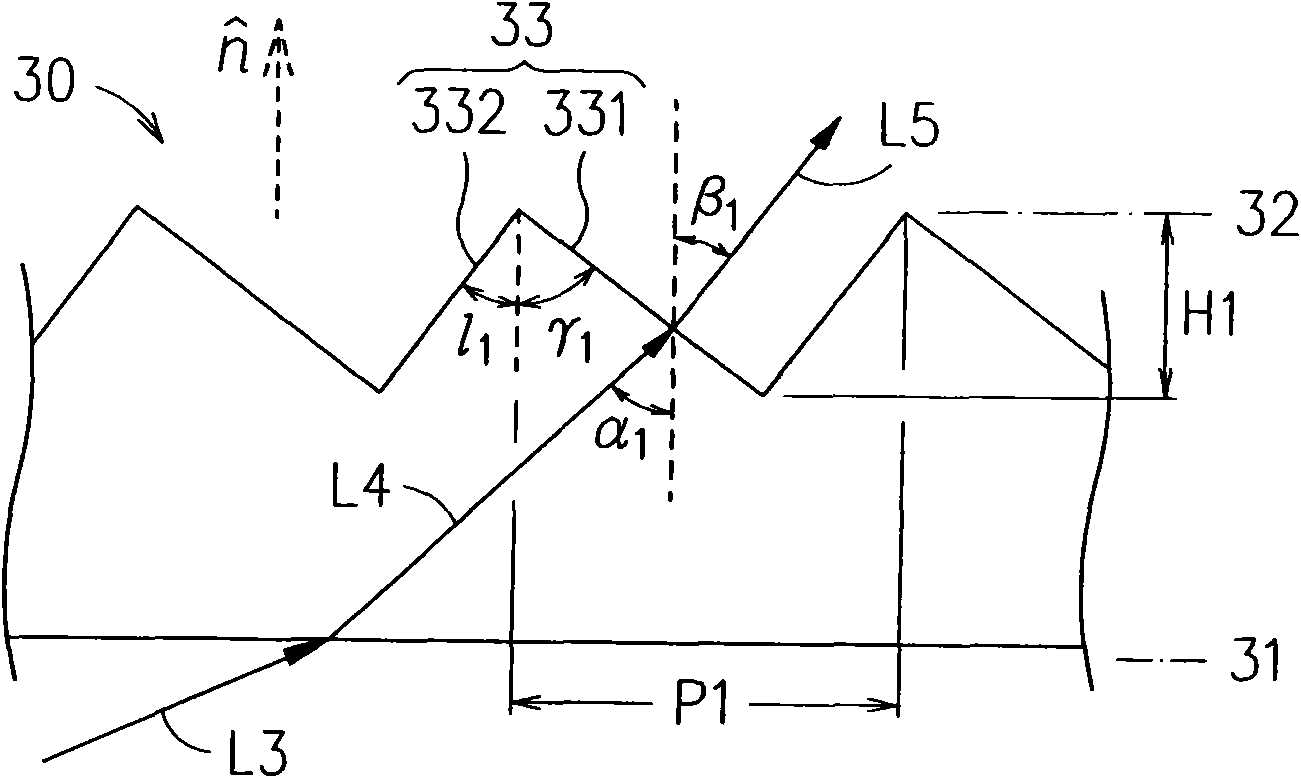

[0055] see figure 1 As shown, the highly collimated surface light source module provided by the present invention mainly includes at least one light source 10 , a light guide plate 20 , a converging film 30 and a straightening film 40 .

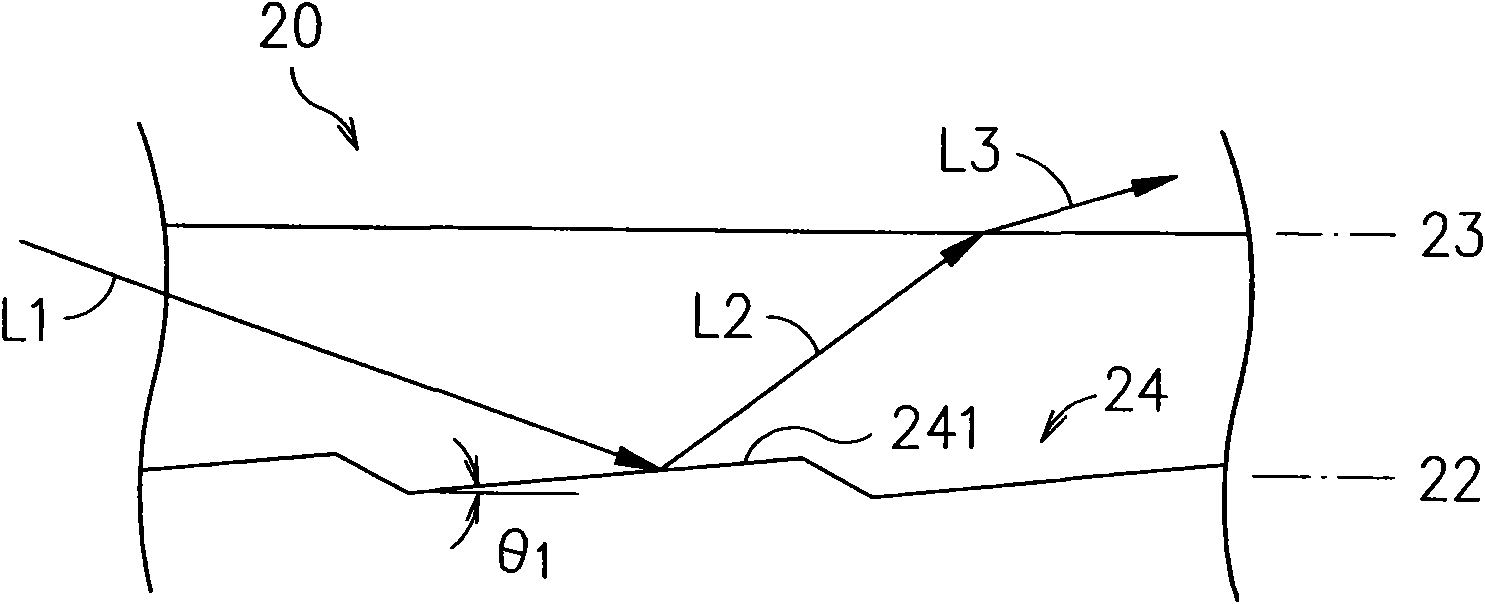

[0056] The light guide plate 20 has at least one side surface 21 , a bottom surface 22 and a top surface 23 . The light source 10 is disposed on the side surface 21 of the light guide plate 20 . The light source 10 can be a light emitting diode (LED) or a cold cathode fluorescent lamp (CCFL) , the light L1 generated by the light source 10 enters the light guide plate 20 from the side surface 21 of the light guide plate 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com