Light guide plate with concave microstructure and manufacturing method thereof

A light guide sheet and microstructure technology, which is applied in the field of light guide sheet, can solve the problems of increasing the thickness of the light guide sheet, difficulty in controlling the direction of light propagation, and the influence of light utilization rate, so as to achieve the effect of improving the utilization rate of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

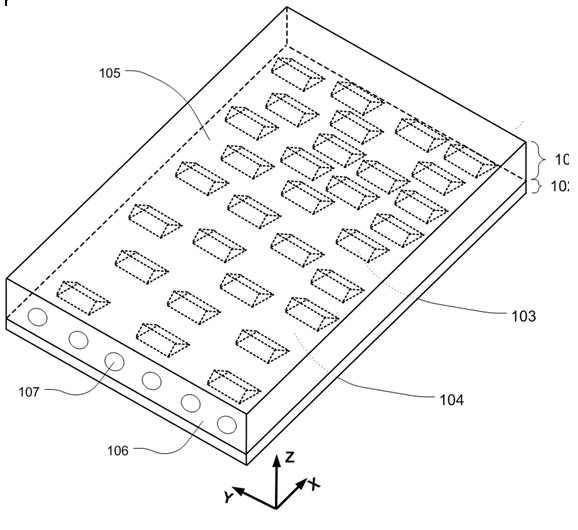

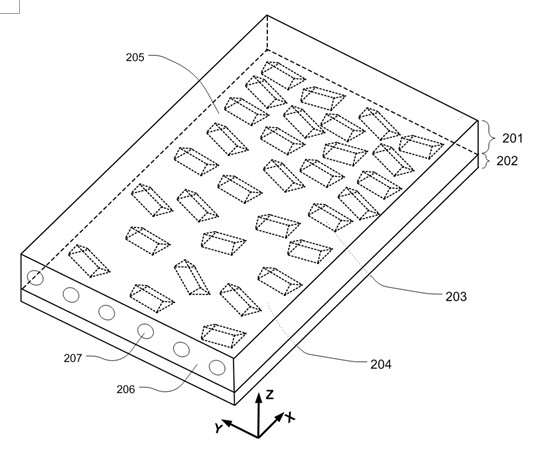

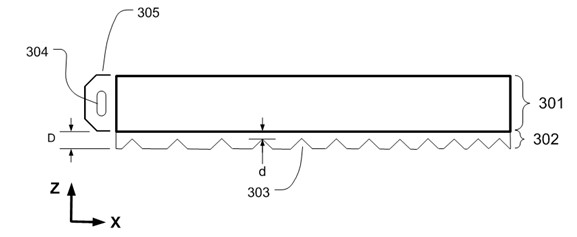

[0028] Depend on figure 1As shown, the light guide sheet of the present invention includes a substrate 101 and a structural layer 102 . The light guide sheet substrate 101 has transparent optical properties. Materials suitable as substrates include polycarbonate (PC), polymethyl methacrylate (PMMA), polyvinyl alcohol (PVA) and polyethylene terephthalic acid (PET). However, the substrate material is not particularly limited. Any material with optically transparent properties can be used as the substrate material. The thickness of the substrate is related to the size and performance of the light source. Generally, the thickness can be in the range of 0.1-10 mm. The light guide substrate 101 includes a -Z surface 104 and a +Z surface 105 parallel to the XY plane, and a light incident surface -X side 106 parallel to the YZ plane. In this example, structural layer 102 is located on the -Z surface of the substrate. The structural layer 102 contains a plurality of recessed micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com