Printing and dyeing wastewater pretreatment method based on anoxic zone phase separation technology

A printing and dyeing wastewater pretreatment technology, applied in anaerobic digestion treatment, textile industry wastewater treatment, waste fuel, etc., can solve the problem of aerobic section that cannot meet the requirements of wastewater discharge and the requirements of socio-economic environment and environmental conditions. Solve problems such as high organic load pressure, achieve the effect of improving chroma and COD removal rate, reducing engineering construction costs, and reducing organic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

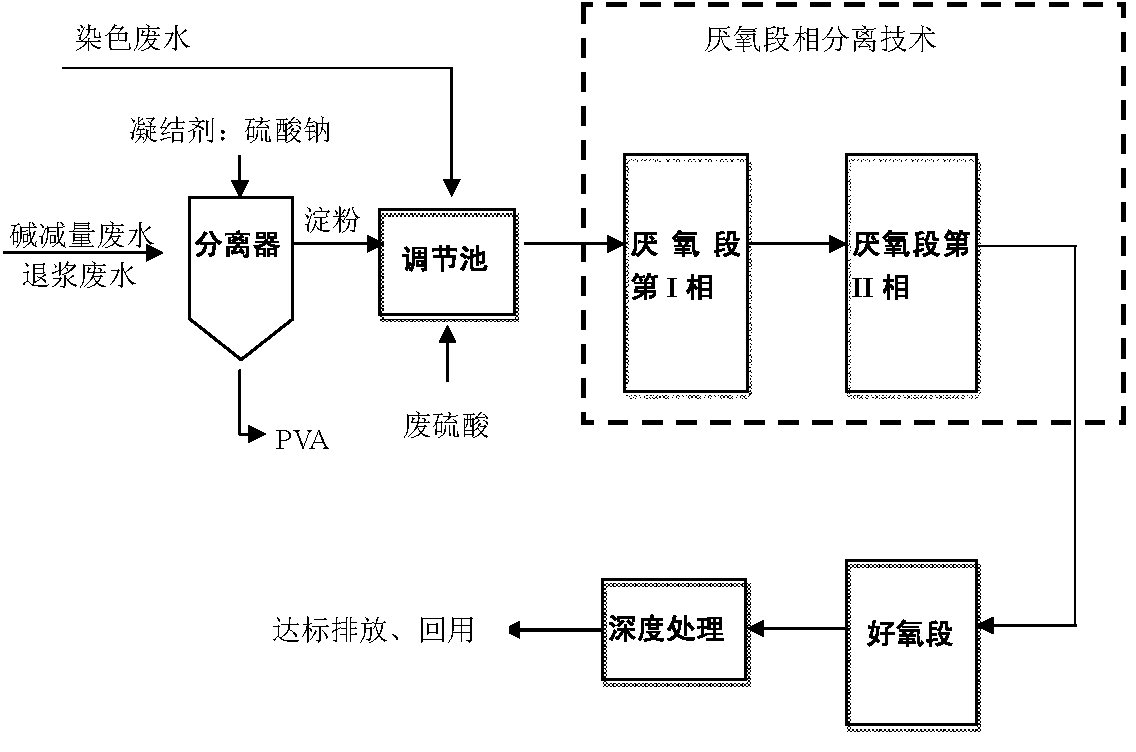

[0039] refer to figure 1 , a kind of printing and dyeing wastewater pretreatment method based on anaerobic section phase separation technology, described printing and dyeing wastewater comprises alkali reduction wastewater, desizing wastewater and dyeing wastewater, and described printing and dyeing wastewater pretreatment method comprises the following steps:

[0040] (1) Alkali reduction and desizing waste water is recovered by adding 7.8g / L sodium sulfate to the separator to recover PVA for resource utilization;

[0041] (2) Step (1) The effluent is mixed with the wastewater produced in the dyeing process of the printing and dyeing factory and then enters the adjustment tank, where the waste sulfuric acid is used to adjust the pH value to 7. The detected content of sulfate in the system is 710 mg / L, COD / SO 4 2- The mass ratio is 2.5;

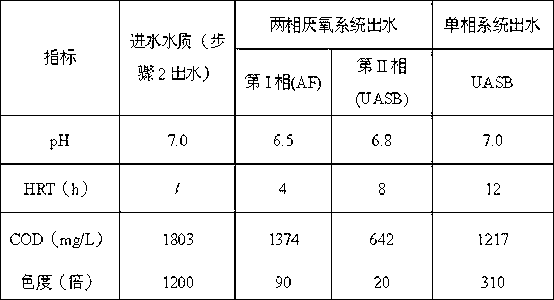

[0042] (3) The effluent from step (2) enters the phase I reactor of the two-phase anaerobic process. The reactor is an upflow anaerobic ...

Embodiment 2

[0050] refer to figure 1 , a printing and dyeing wastewater pretreatment method based on anaerobic phase separation technology, the printing and dyeing wastewater includes alkali weight reduction wastewater, desizing wastewater and dyeing wastewater, the anaerobic section includes phase I and phase II, the The printing and dyeing wastewater pretreatment method comprises the following steps:

[0051] (1) Add 5.2g / L sodium sulfate to the alkali reduction wastewater or desizing wastewater, and recover PVA in the separator for resource utilization;

[0052] (2) The effluent from step (1) is mixed with the wastewater generated in other processes and then enters the adjustment tank, where the pH is adjusted to 7 with sulfuric acid. The detected content of sulfate is 500 mg / L, COD / SO 4 2- The mass ratio is 3.6;

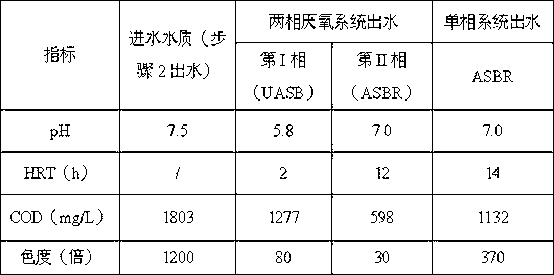

[0053] (3) The effluent from step (2) enters the first phase reactor of the anaerobic section, the reactor is an upflow anaerobic filter reactor (AF), which uses ceramsit...

Embodiment 3

[0061] refer to figure 1 , a kind of printing and dyeing wastewater pretreatment method based on anaerobic section phase separation technology, described printing and dyeing wastewater comprises alkali reduction wastewater, desizing wastewater and dyeing wastewater, and described printing and dyeing wastewater pretreatment method comprises the following steps:

[0062] (1) Alkali reduction and desizing waste water is recovered by adding 2.9g / L sodium sulfate to the separator to recover PVA for resource utilization;

[0063] (2) The effluent from step (1) is mixed with the wastewater produced in the dyeing process of the printing and dyeing factory, and then enters the adjustment tank, where the waste sulfuric acid is used to adjust the pH value to 6.8. The detected content of sulfate in the system is 220 mg / L, COD / SO 4 2- The mass ratio is 8.2;

[0064] (3) The effluent from step (2) enters the first phase reactor of the two-phase anaerobic process. The reactor is a sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com