Patents

Literature

84results about How to "Effective decolorization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

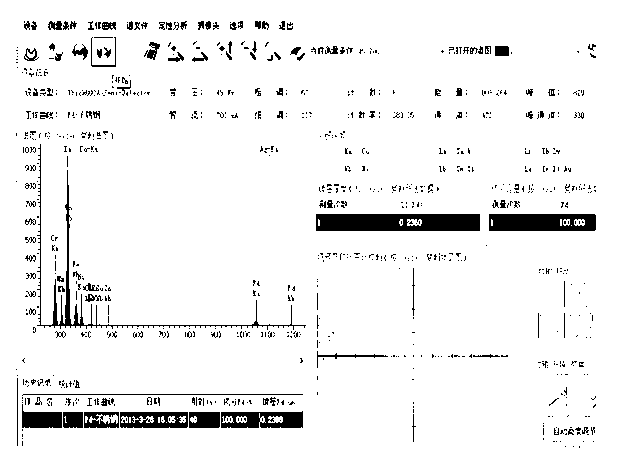

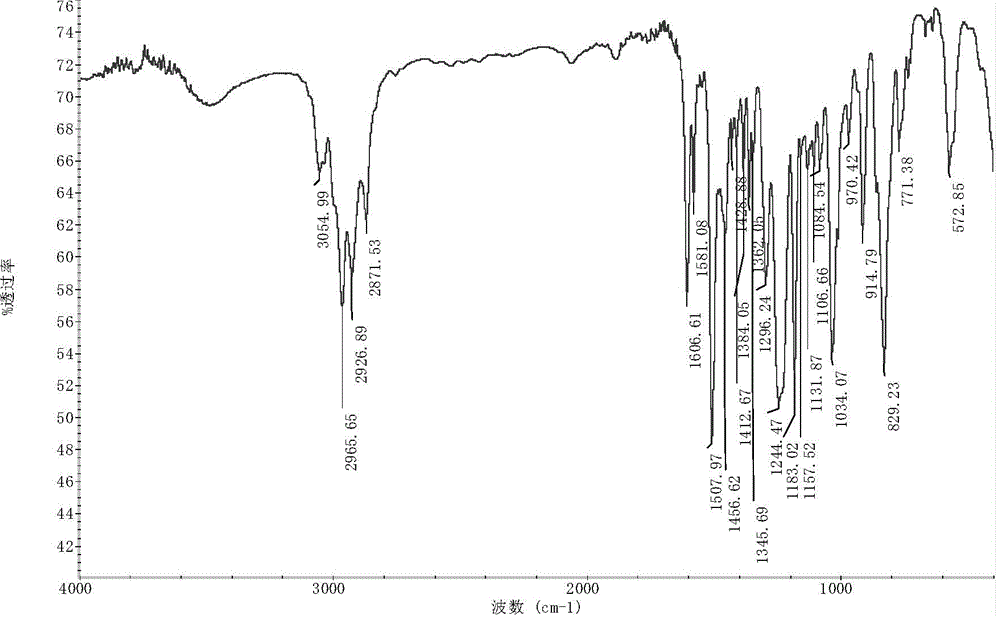

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

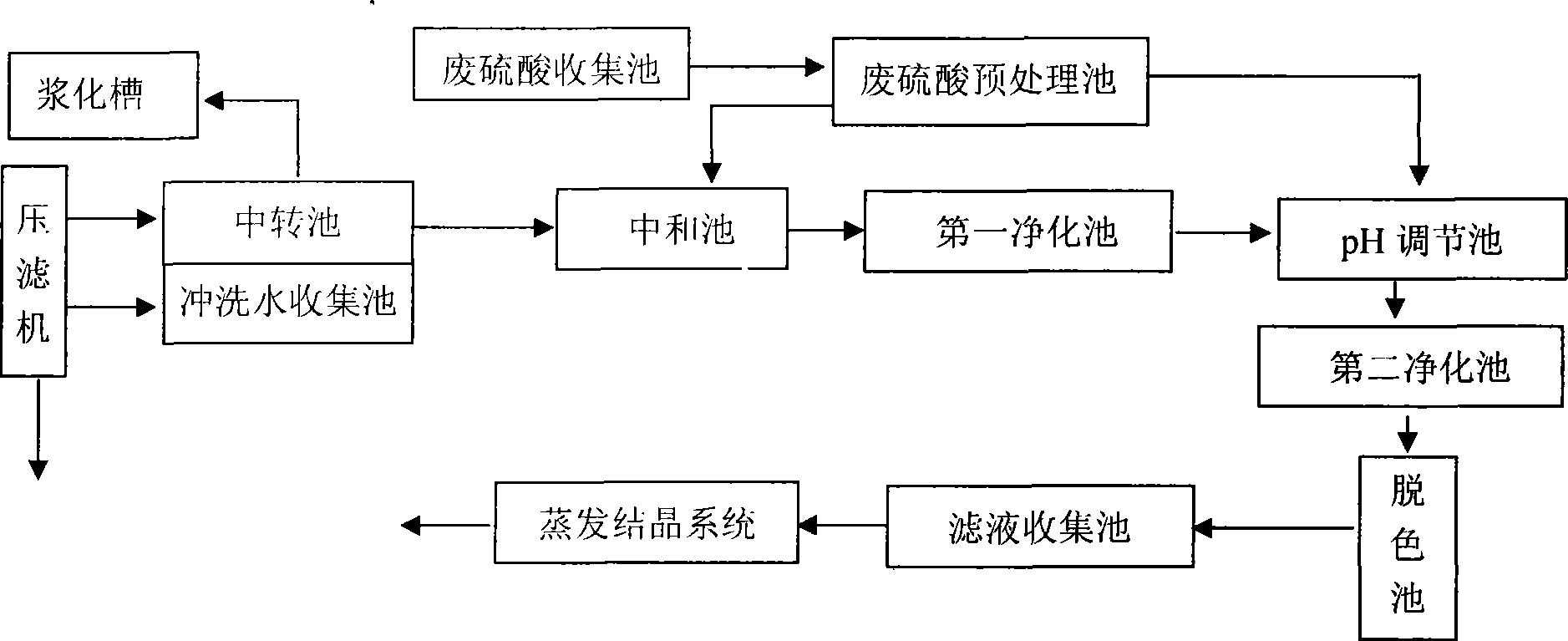

Method and device for recycling anhydrous sodium sulfate from desulfurization lead plaster filter liquor

ActiveCN101244831AEvaporative crystallizationGuaranteed Concentration RequirementsSulfate/bisulfate preparationAlkali metal sulfite/sulfate purificationFiltrationResource recovery

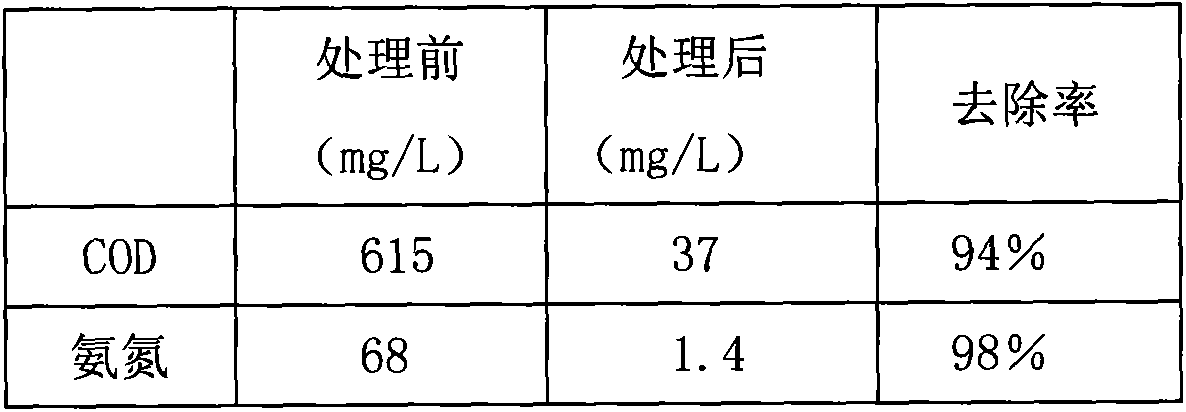

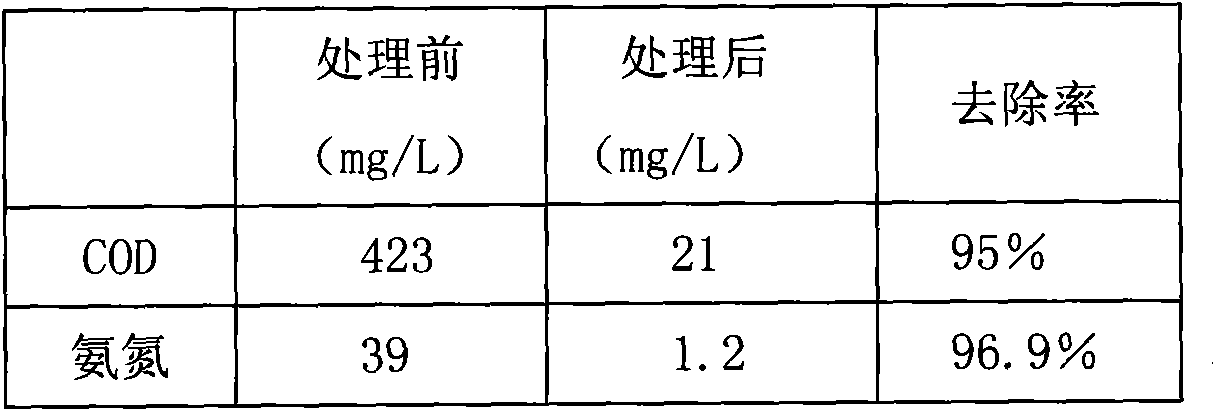

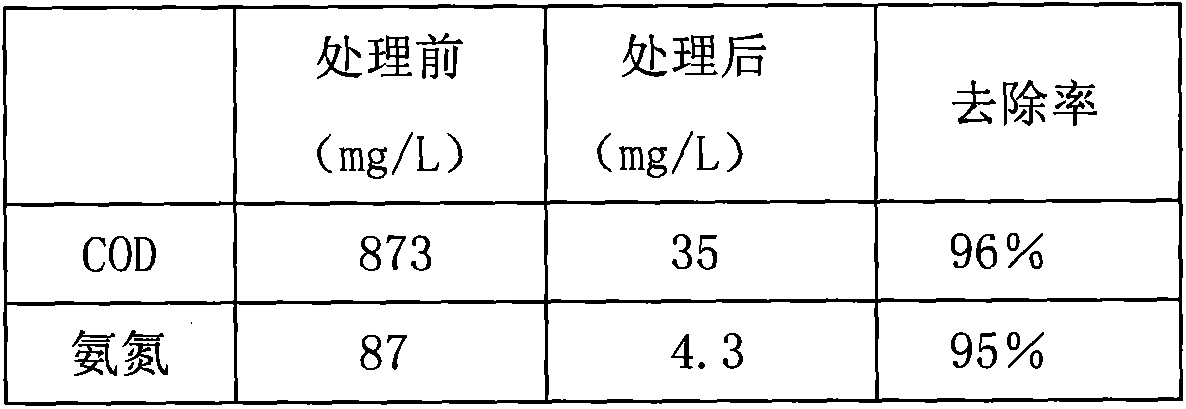

The invention relates to a method of recycling anhydrous sulfate sodium from de-sulfurized lead paste filtration, belonging to a resource recovery and utilization process, which avoids the disadvantages that waste sulfate is used and low concentration sulfate sodium is emitted into the environment. The method of the invention comprises: desulfurized lead paste filtration collection, sodium carbonate neutralization, first time heavy metal removal, filtration PH value adjustment, second-time heavy metal removal, decolorizing step, and vaporization and crystallization step; the device comprises a transfer tank, a neutralization tank, a first-stage purifying tank, a PH adjusting tank, a second-stage purifying tank, a decolorization tank, a filtration collection tank and a vaporization crystallization system; the waste sulfate collection tank is connected with a waste sulfate pre-processing tank, the waste sulfate pre-processing tank is respectively connected with the neutralization tank and the PH adjusting tank. The invention can directly recycle anhydrous sulfate sodium, the waste sulfate is used to neutralize the carbonate sodium remained in the filtration; the heavy metal ions and other ions in the filtration are removed according to two steps, so that the grade of obtained anhydrous sulfate sodium is equal to or larger than industrial grade.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for anaerobic-aerobiotic-microbial flocculation reinforced wastewater treatment

InactiveCN103964646AEfficient removalImprove biodegradabilityMultistage water/sewage treatmentAluminium chlorideFlocculation

The invention discloses a method for anaerobic-aerobiotic-microbial flocculation reinforced wastewater treatment. The method comprises the following steps of: 1) treating the wastewater to be treated in a regulation tank; 2) removing large floating matters and impurities out of the wastewater (treated in the regulation tank) by a grating device; 3) pumping the effluent obtained in the step 2) in a quick mixing tank, and adding a flocculant PAC (poly aluminium chloride) in the quick mixing tank and carrying out flocculation pre-precipitate; 4) carrying out anaerobic-aerobiotic treatment; 5) feeding the water body in a secondary sedimentation tank and adding 7.5vol% of a microbial flocculation agent and 5vol% of CaCl2 solution with a concentration of 1-1.5%, mixing for 8-10 minutes and then enabling the liquid to pass through a high-performance ceramic filter material with a particle size of 3-5mm and a quartz sand cushion laid on the bottom of the high-performance ceramic filter material; and 6) feeding the effluent obtained in the step 5) in an attapulgite adsorption tank for further adsorption bleaching, removing micropollutants, and disinfecting the effluent, wherein attapulgite is arranged in the attapulgite adsorption tank, a Pt metal screen is arranged on the attapulgite, and the attapulgite is loaded with Fe2O3 or CuO and NaCl; and finally draining water in a water collection tank.

Owner:NANJING UNIV

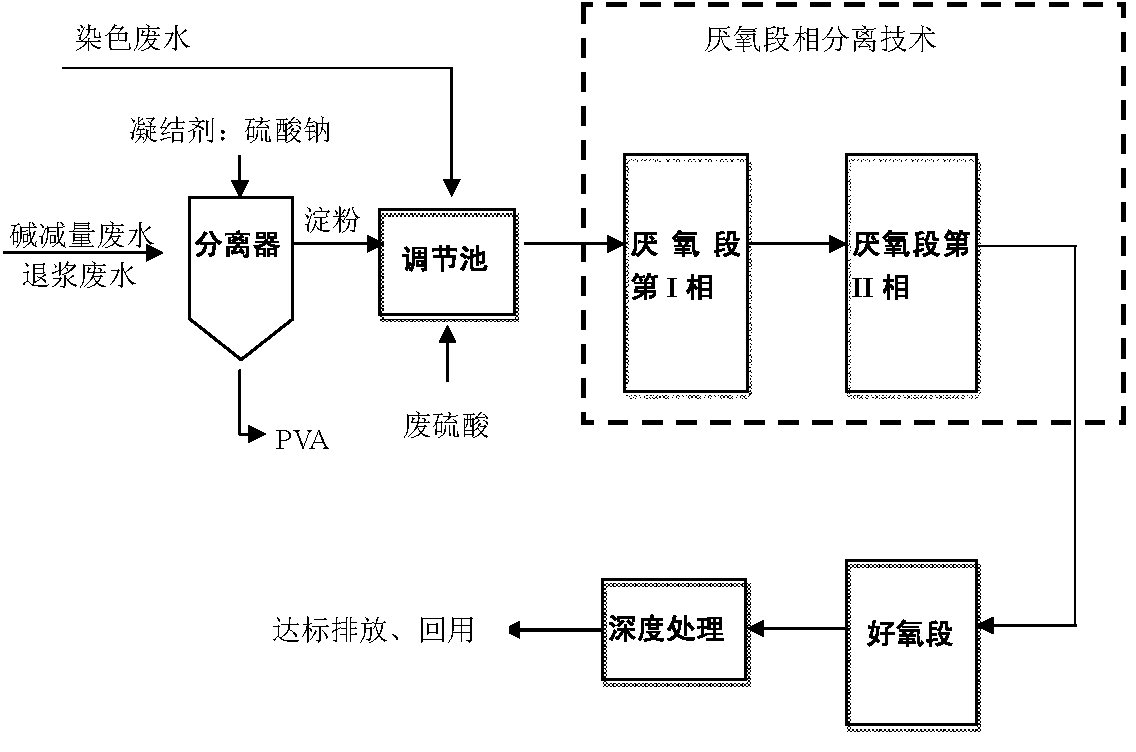

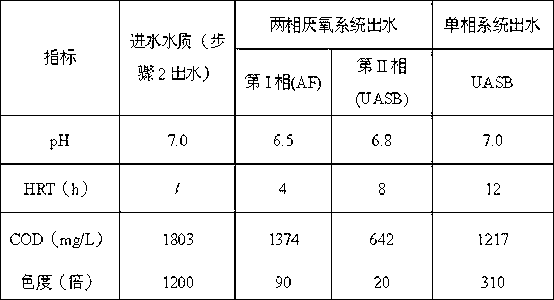

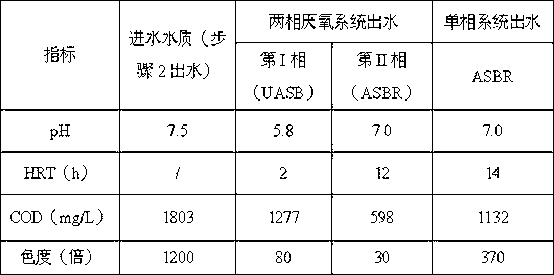

Printing and dyeing wastewater pretreatment method based on anoxic zone phase separation technology

ActiveCN103274524AImprove biodegradabilityEfficient removalWaste based fuelTreatment with anaerobic digestion processesChemical oxygen demandPretreatment method

The invention relates to a printing and dyeing wastewater pretreatment method based on an anoxic zone phase separation technology. According to the printing and dyeing wastewater pretreatment method, an anoxic zone is divided into a phase I and a phase II, namely a phase for hydrogen production and acid production through fermentation and a methanogenesis phase; an electron donor is provided by organic matters in the wastewater, and dye is effectively decolored in the phase I by using a sulfate reducing process and the reducing capacity of reduzate, namely the sulfide, therefore the biodegradability of the wastewater is improved; and the organic matters can be efficiently removed in the phase II. As an anoxic phase transformation technology in the printing and dyeing wastewater treatment course, the printing and dyeing wastewater pretreatment method is used for providing a two-phase anoxic system and carrying out pretreatment on the printing and dyeing wastewater; the chromaticity and the COD (Chemical Oxygen Demand) removal rates can be effectively increased, the biodegradability of the wastewater can be greatly improved, and the defects that a traditional anoxic process is instable in treatment effect, large in sludge yield and the like are overcome. The printing and dyeing wastewater pretreatment method can be used for effectively removing chromaticity and COD in the printing and dyeing wastewater, the removal rates of the chromaticity and the COD respectively reach more than 95 percent and 60 percent, and the organic loading to subsequent procedures is greatly reduced.

Owner:浙江一清环保工程有限公司

Method for preparing gypsum powder by microwave activation

The invention provides a method for preparing gypsum powder by microwave activation, comprising: according to the weight percent, firstly mixing 70-90% of desulfurization gypsum, 5-20% of modifying agent and 5-20% of bleaching agent in non-saturated vapor medium at the temperature of 120-180 DEG C, and then sending into microwave equipment for microwave drying and dewatering; meanwhile, arranginga ball-milling body inside a work cavity of the microwave equipment, and carrying out powder grinding on the mixed material when in drying and dewatering to prepare gypsum powder material; finally, sending the gypsum powder material out of the microwave equipment to be cooled. The method can be used for treating desulfurization gypsum which is industrial waste for a second time for recycling, andsecondary pollution can not be caused.

Owner:湖南安雅达建材科技有限公司

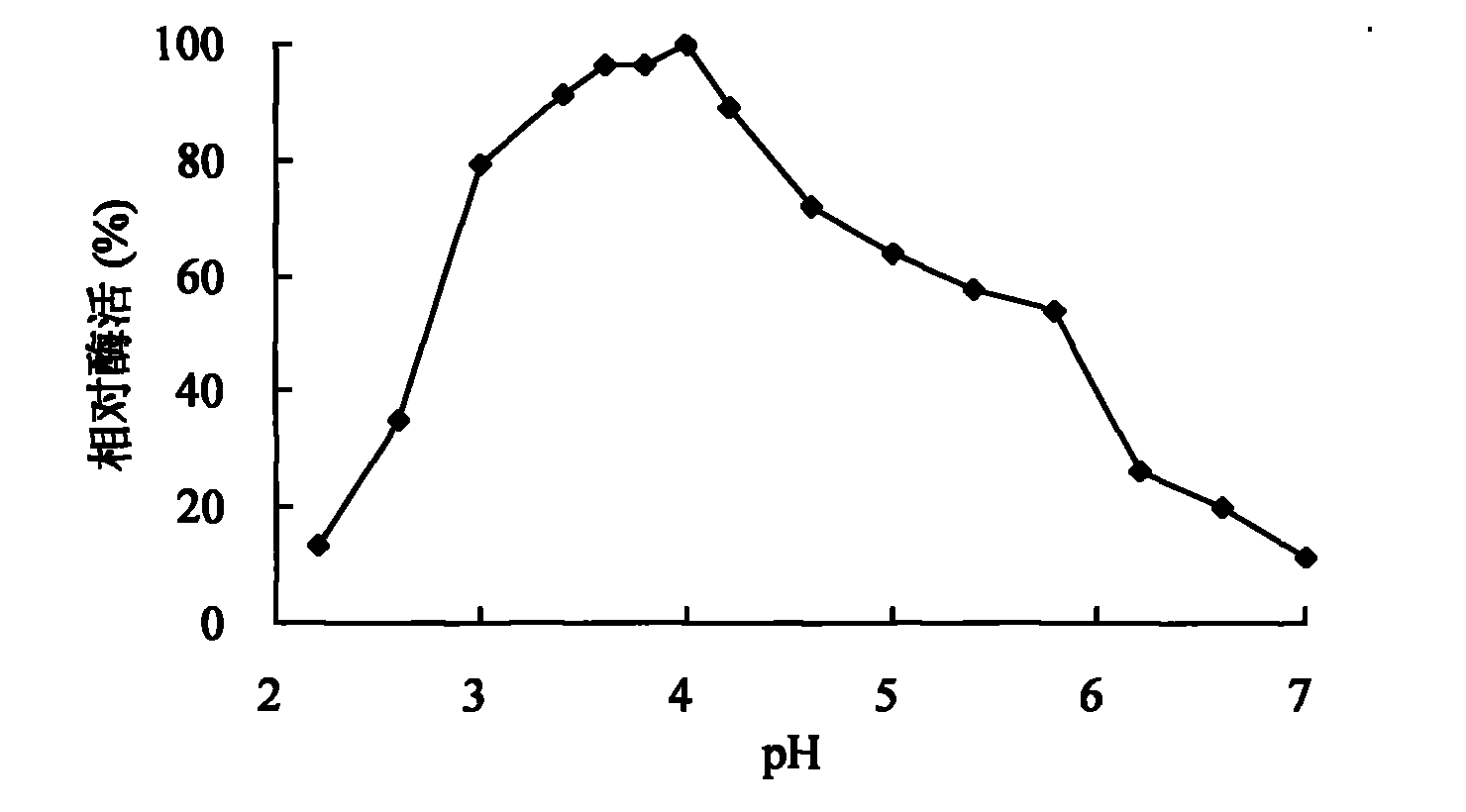

Laccase from Bacillus licheniformis LS04 and use thereof

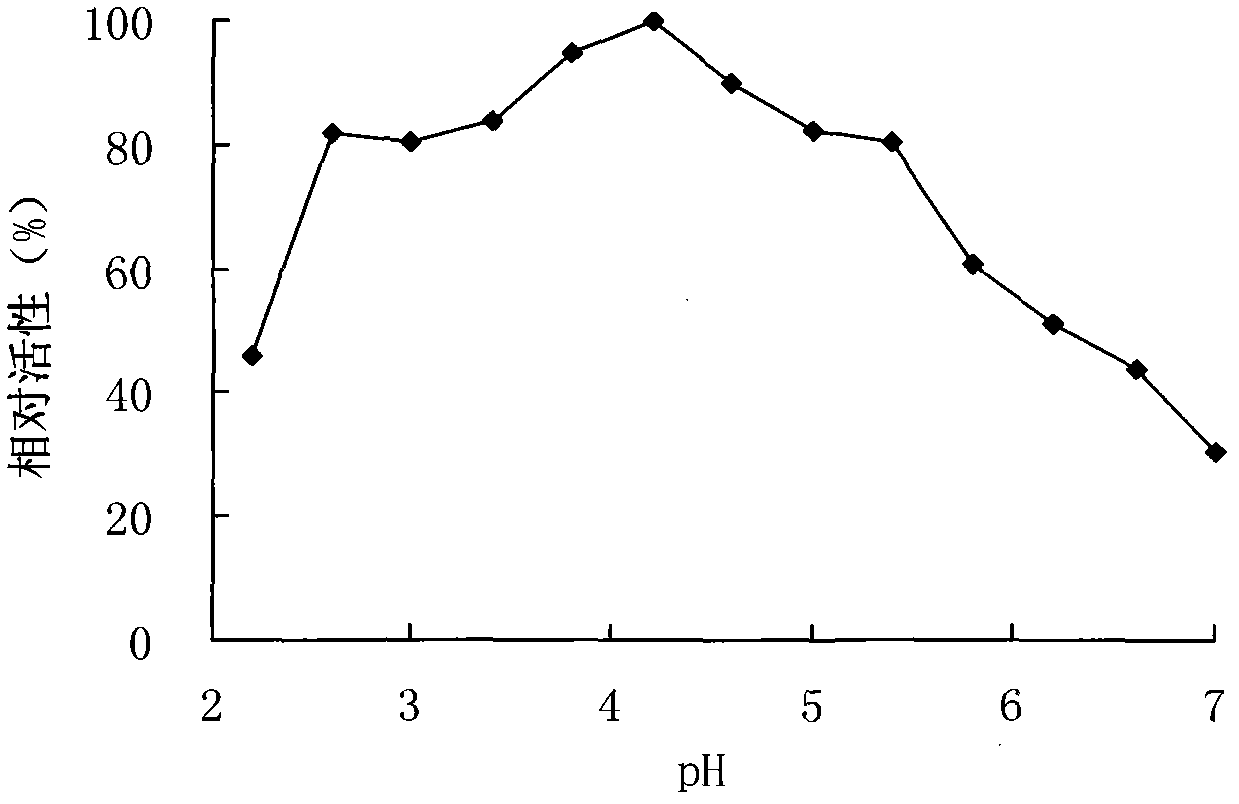

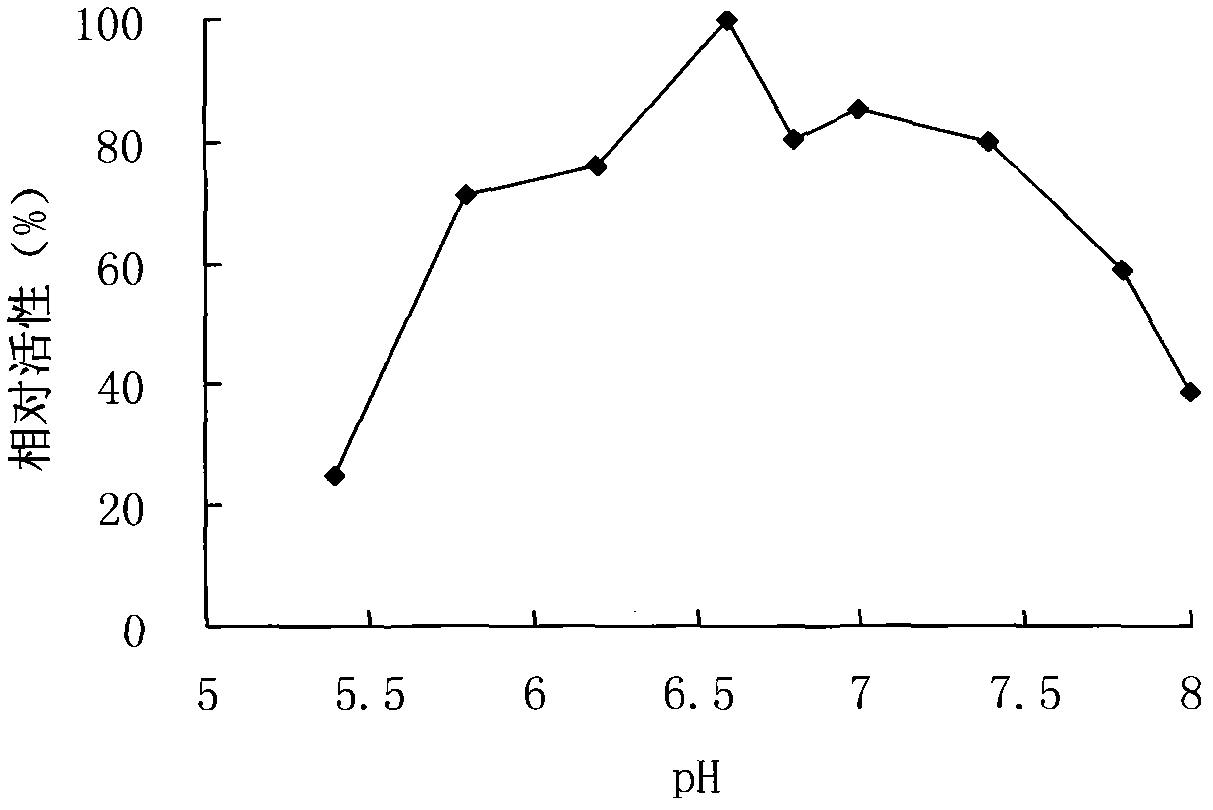

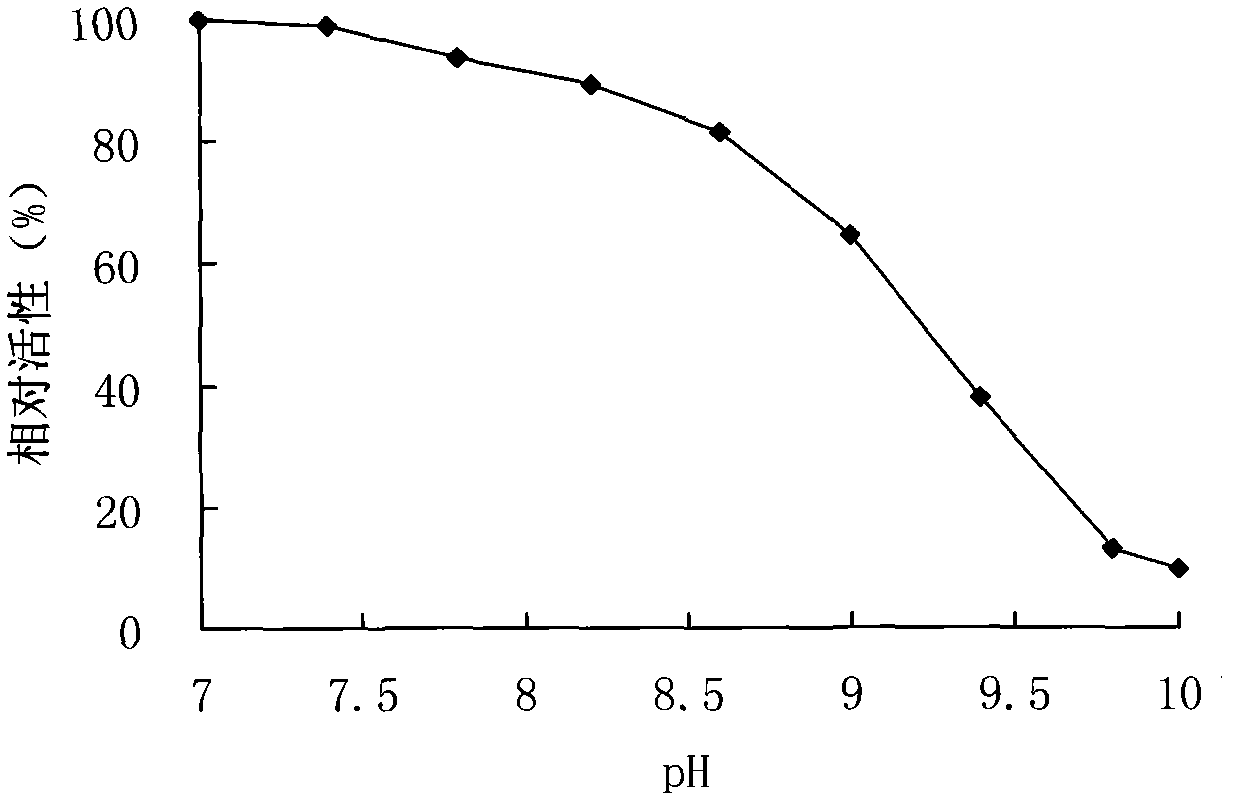

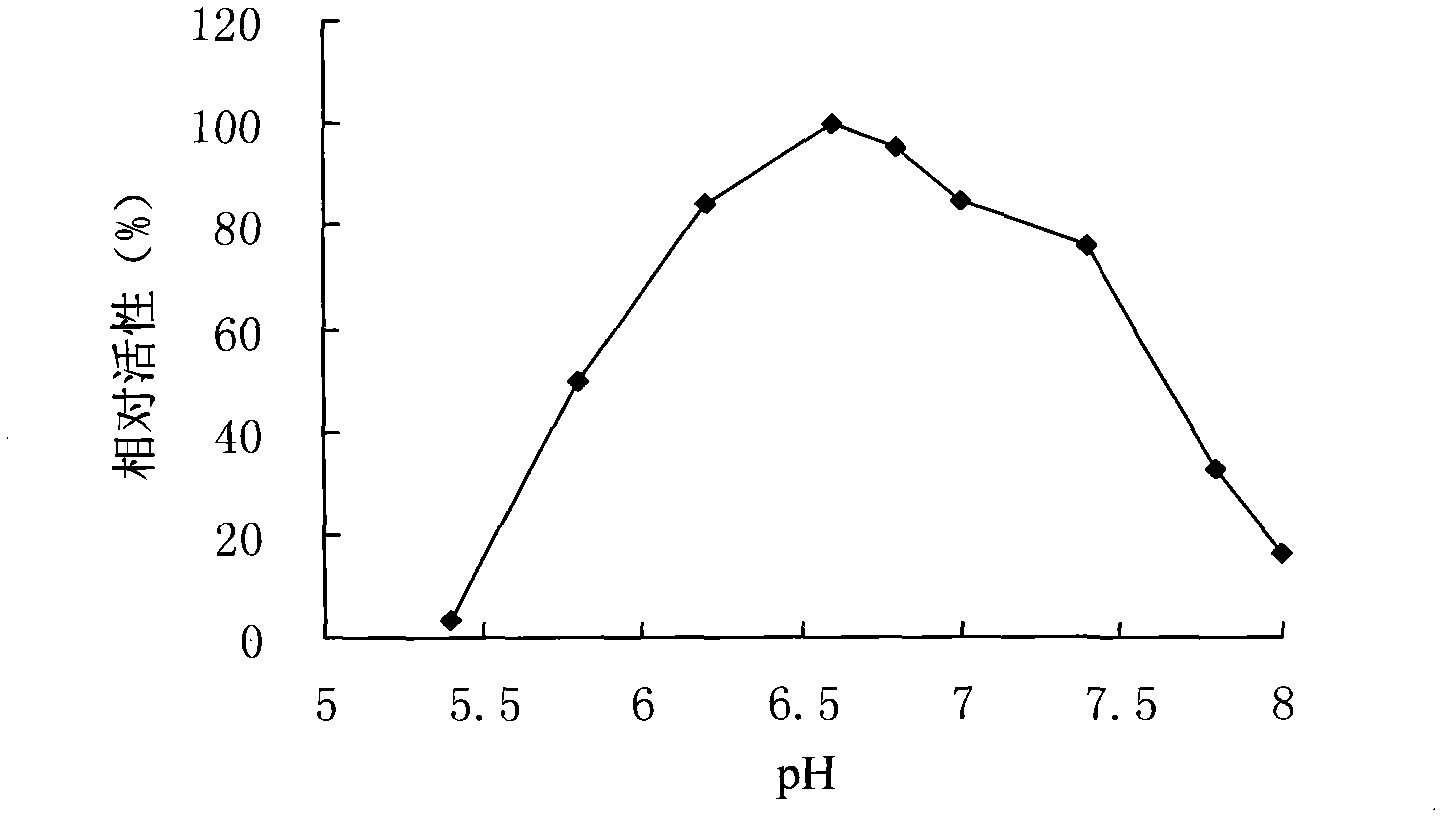

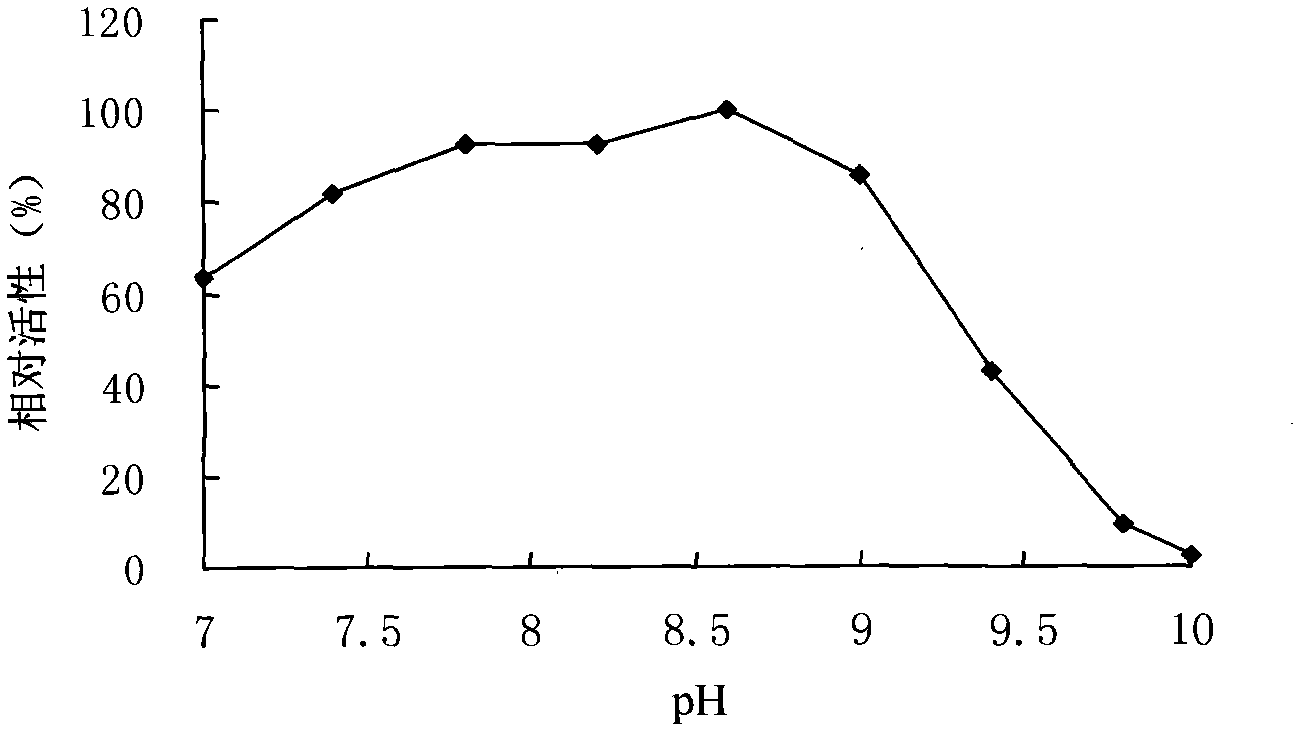

InactiveCN102154148AHigh activityImprove thermal stabilityBacteriaMicroorganism based processesBacillus licheniformisHigh concentration

The invention discloses preparation, a catalytic property and use in dye decolorizing of spore laccase from Bacillus licheniformis LS04 (CGMCC No.4263). The invention also relates to a nucleotide sequence coding the spore laccase. The invention also relates to a nucleotide sequence for coding the spore laccase. In the invention, Bacillus licheniformis LS04 ferments at 37 DEG C for 5 days on a solid sporulation culture medium, spores are washed off by deionized water, and pore suspension with laccase activity can be obtained by series measures such as lysozyme treatment. The spore laccase has high catalytic activity under alkaline and high-temperature conditions, can maintain high enzyme activity in high-concentration organic solvent and salt solution, has good decolorizing effect on synthesized dyes of different structures under action of an amboceptor and can be used for treating industrial dye waste water.

Owner:NORTHEAST FORESTRY UNIVERSITY

Deep bleaching method of stevioside

ActiveCN103709214AReduce consumptionQuick removalSugar derivativesSugar derivatives preparationActivated carbonEconomic benefits

The invention discloses a deep bleaching method of stevioside. The method comprises the following technological steps: (1) bleaching a stevioside extracting solution or a solution by using resin, so as to obtain a destaining solution; (2) adding an oxidant to the destaining solution, stirring and oxidizing a pigment, so as to obtain oxidized solution; (3) decomposing the pigment from the oxidized pigment in an illumination manner, so as to deeply remove the pigment in the extracting solution or the solution. By adopting the method, the oxidant pigment is added to the yellowish stevioside solution which is bleached by the resin to oxidize, and then the pigment is decomposed in the illumination manner, so that use of activated carbon is avoided, and consumption of the stevioside is reduced. Thus, the cost is saved, and the yield and the product quality are improved. A trace of pigment can be quickly removed by selecting the oxidant and the lighting condition of not generating impurities, so that the color of the product is pure white. Therefore, the deep bleaching method has the characteristics of being simple in technology, significant in effect, high in yield, low in cost, and good in economic benefits, the obtained product is pure white in color, and other impurities are not added.

Owner:CHENGUANG BIOTECH GRP CO LTD

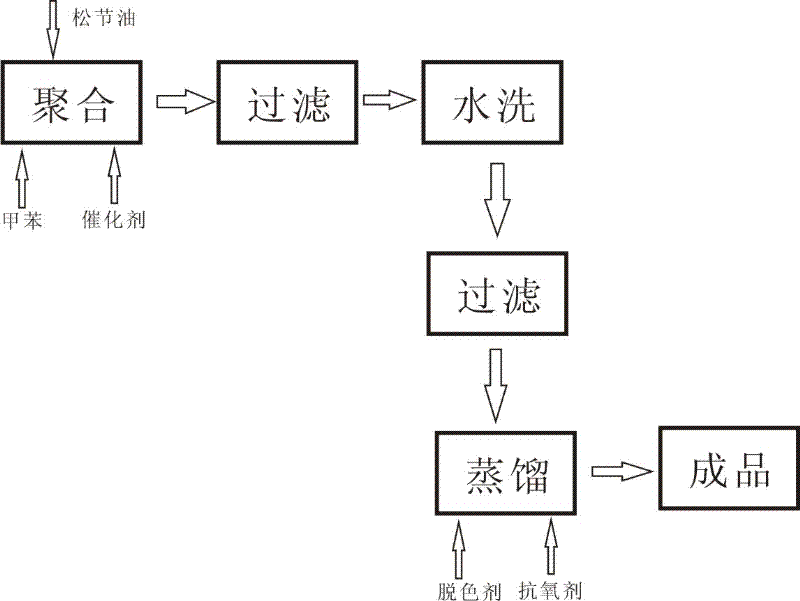

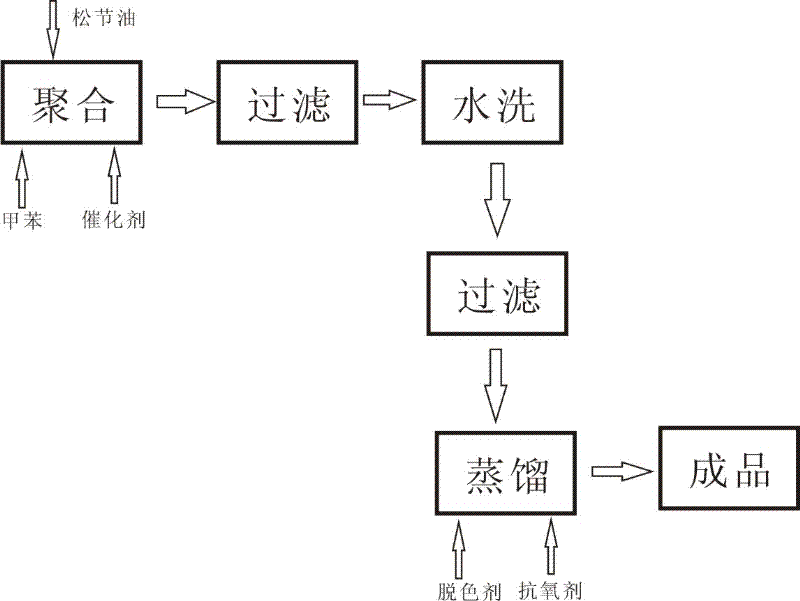

Ultralight-colored polyterprene resin production process

The invention discloses an ultralight-colored polyterprene resin production process. The ultralight-colored polyterprene resin production process includes polymerizing, washing and distilling, and turpentine oil and catalyst of alchlor are polymerized in a reactor during the polymerizing procedure. The ultralight-colored polyterprene resin production process is characterized in that 0.2% by weight of hindered phenol oxidation inhibitor and 0.1 % by weight of decolorizer are added into a polymerized mixed product which is washed during the distilling procedure. Since the core technology at international advanced level is combined with the antioxidant decolorizer and the hindered phenol oxidation inhibitor, the product can be decolored effectively, and mother liquid in color luster ranging from 7# to 8# can be decolored into the product in color luster of 1#. Besides, the filtering procedures are added before and after the washing procedure respectively, so that aluminum dross and impurities can be separated more thoroughly, separation rate can be up to 98% or above. Further, ions, low-boiling-point components and by-products can be separated completely by the aid of precise distilling equipment integrating with the optimum process, odor of products is lightened, and pollution to the environment is reduced.

Owner:GUANGDONG HUALIN CHEM

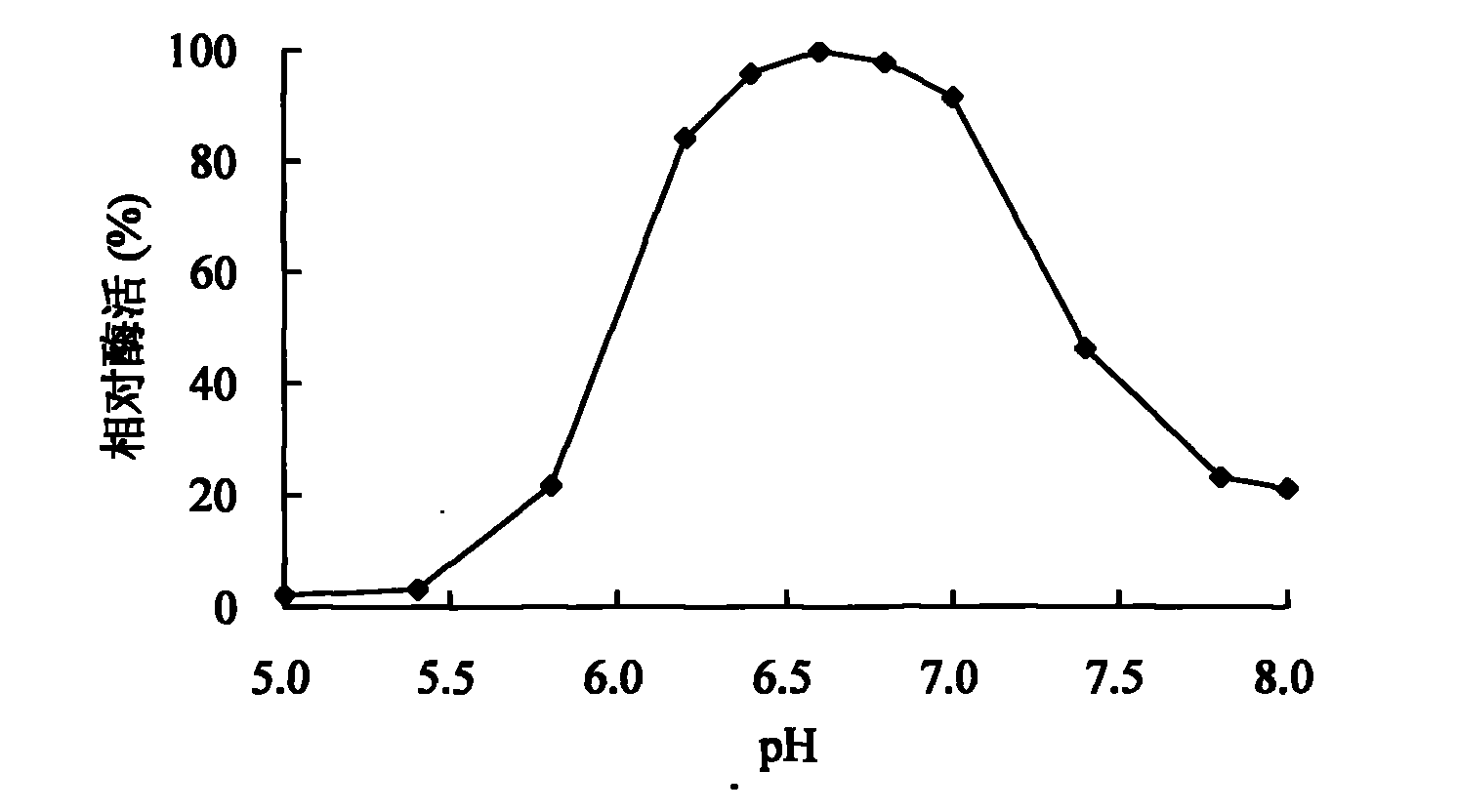

Bacillus amyloliquefaciens LC02 and application thereof

InactiveCN102115723AHigh activityImprove thermal stabilityBacteriaMicroorganism based processesBacillus amyloliquefaciensWastewater

The invention discloses a preparation method of bacillus amyloliquefaciens LC02 (CGMCC No.4258) spore laccase, the catalysis capability and the application in the decoloring the dye. The invention further relates to a nucleotide sequence which codes the spore laccase. The bacillus amyloliquefaciens LC02 is fermented on a solid state spore generating culture medium at 37 DEG C for 5 days, and the spore is washed by the deionized water to obtain the spore suspension liquid with the laccase activity by a series of measures such as the lysozyme. The spore laccase is better in catalytic activity under the alkaline and high-temperature conditions, is better in a decoloring effect to the synthetic dyes with different structures under the action of a medium, and is used for treating the industrial dye waste water.

Owner:NORTHEAST FORESTRY UNIVERSITY

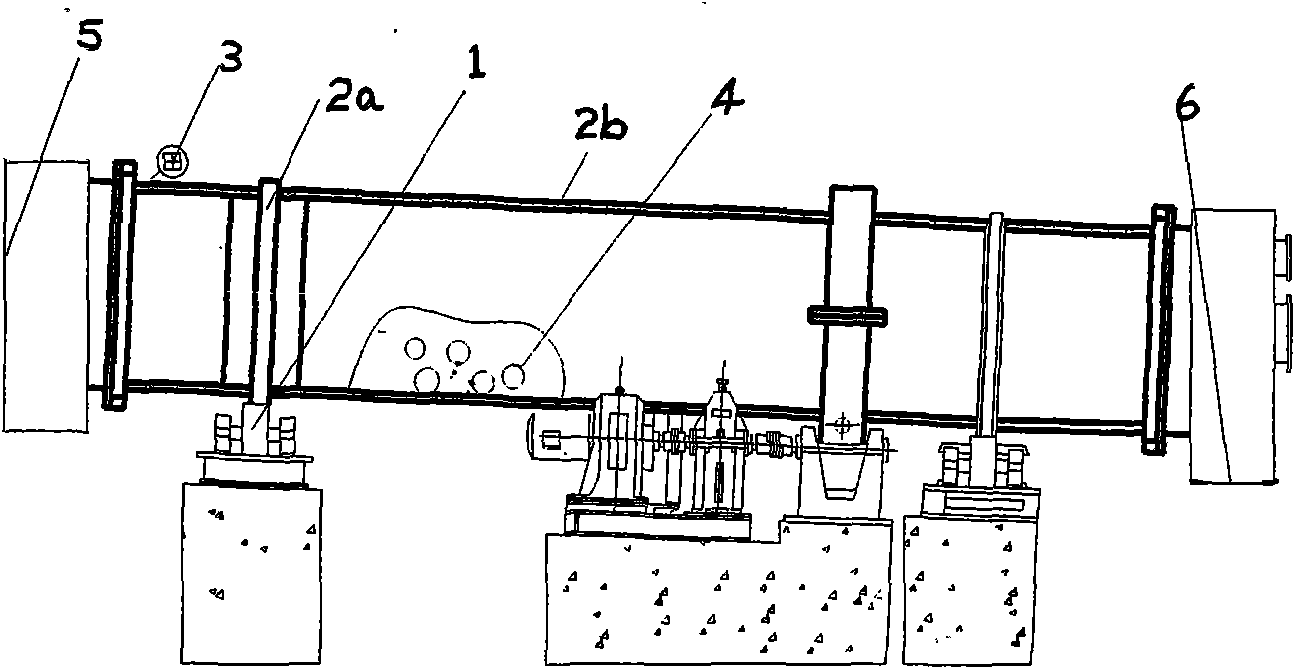

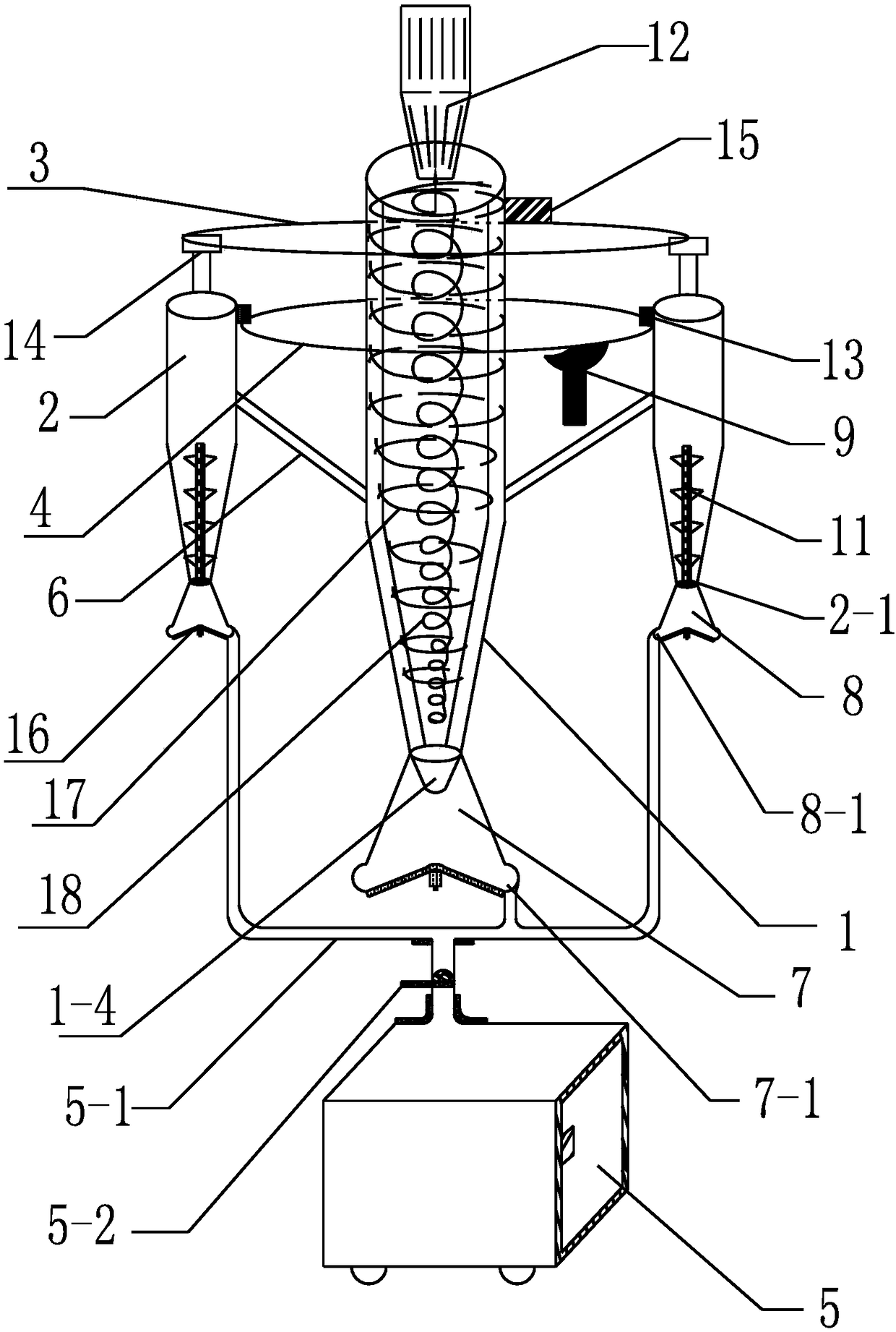

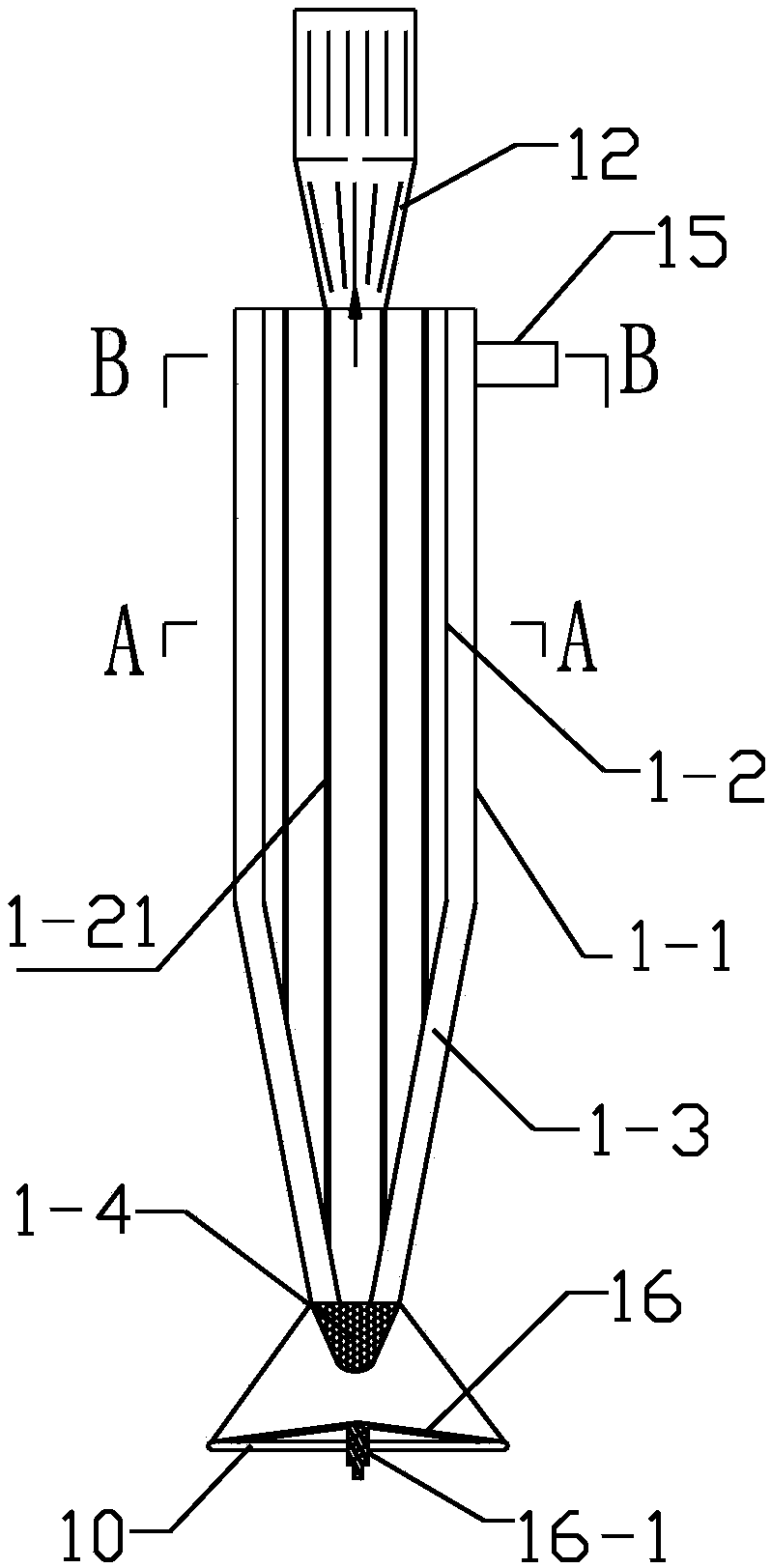

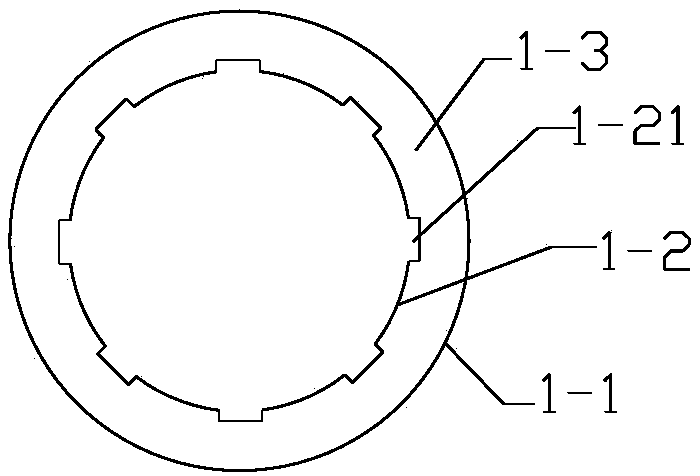

Multi-stage rotational flow separation and filtering device with opposite rotational flows and use method

PendingCN108579203AImprove separation efficiencyShorten separation distanceFiltration circuitsFiltrationEngineering

The invention provides a multi-stage rotational flow separation and filtering device with opposite rotational flows and a use method. The device comprises a main rotational flow separation cylinder, at least two secondary rotational flow separation cylinders, an annular feeding guide tube and an annular effluent guide tube, wherein feeding holes of multiple secondary rotational flow separation cylinders are serially connected with a solid-liquid mixture inlet through the annular feeding guide tube; the liquid outlet of each secondary rotational flow separation cylinder is communicated with thefeeding hole of the main rotational flow separation cylinder through the annular effluent guide tube. When the device is used, a solid-liquid mixture flows into the secondary rotational flow separation cylinders from top to bottom through the annular feeding guide tube, primary granule separation and filtration are carried out, the solid-liquid mixture is further fed into the main rotational flowseparation cylinder through the annular effluent guide tube under the action of rotational flows, secondary granule separation and filtration are carried out, and third separation and filtration arefinally carried out through a liquid discharge hole in the top of the main rotational flow separation cylinder. The device is capable of rapidly and effectively separating solid granules from the solid-liquid mixture, is simple and convenient to operate, and is capable of effectively lowering solid-liquid processing and production cost.

Owner:中冶华成(武汉)工程有限公司

Linolenic acid health edible oil and prickly ash seed dregs and its preparing method

InactiveCN1943372AHigh economic valueEffective separation and removal of impuritiesEdible oils/fatsFood preparationAcid valueEdible oil

A method for the preparation of edible oil rich in linolenic acid and the cake of zanthoxy lum seed, includes the steps: (1)preparing crude oil, includes choosing fresh zanthoxy lum seed, rolling seed kernel, leaching out oil; (2)refining, includes hydration degumming, deacidifing by adding alkali, washing away impurity, dehydrating, decolouring and deodouring. Said oil comprises: palmic acid 8-15%, palmitoleic acid 5-15%, oleic acid 30-40%, linolic acid 20-35%, alpha-linolenic acid 10-18%. The cake of zanthoxy lum seed is produced at the same time. Said method can control oil acid value and peroxide value and said oil has health-care function.

Owner:保靖土司王花椒科技开发有限公司

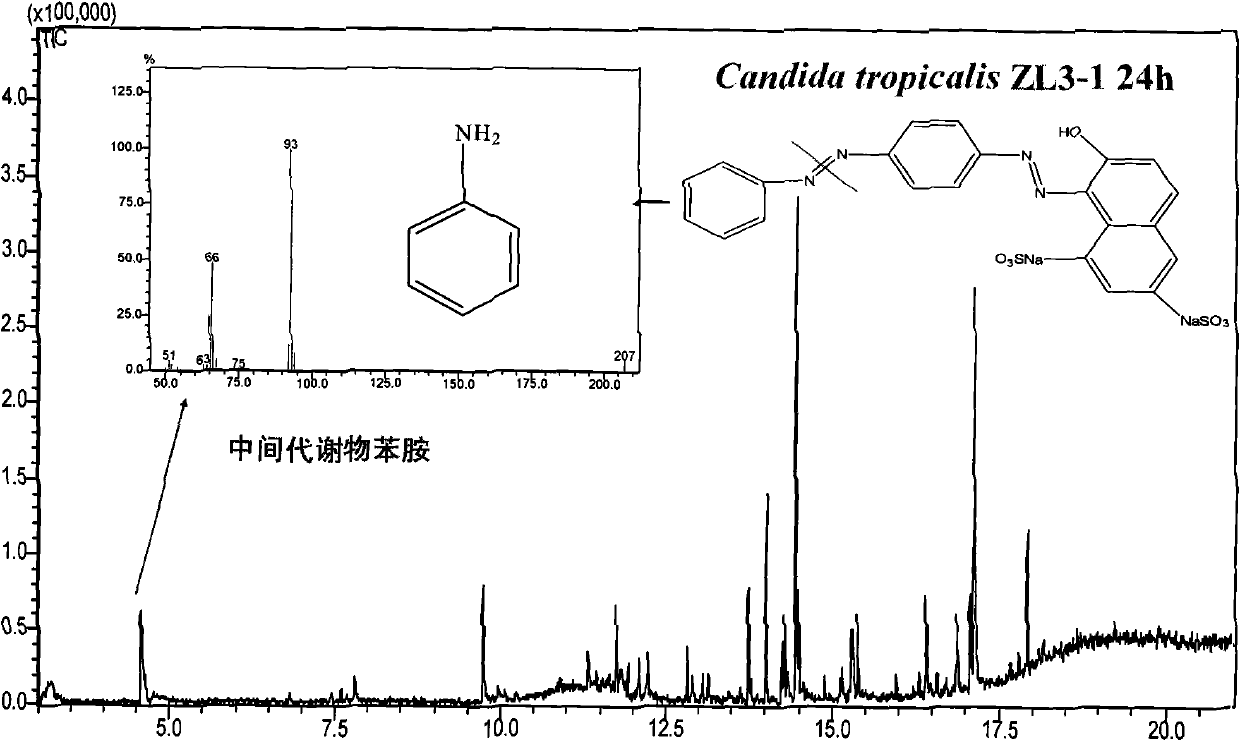

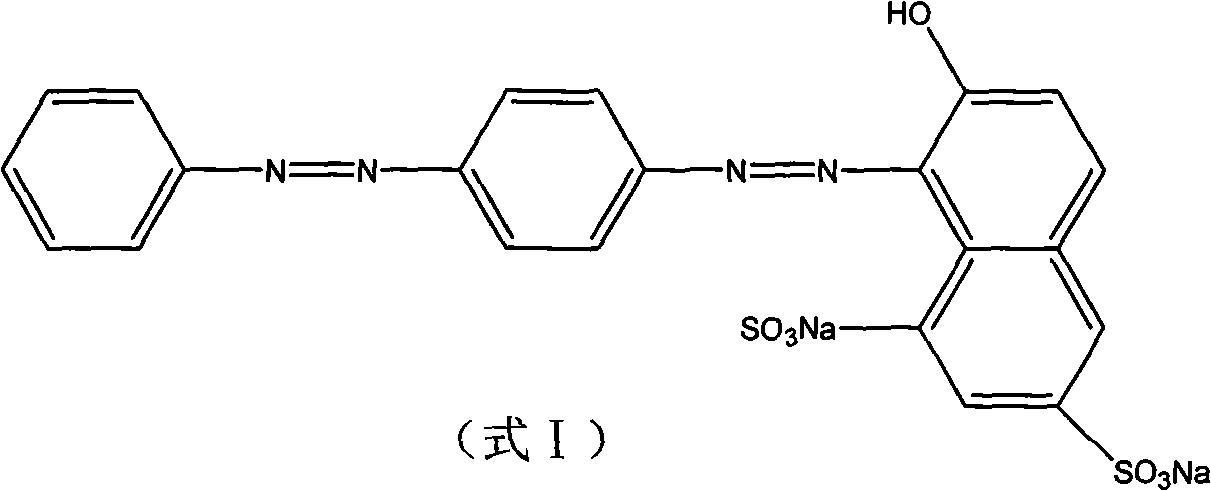

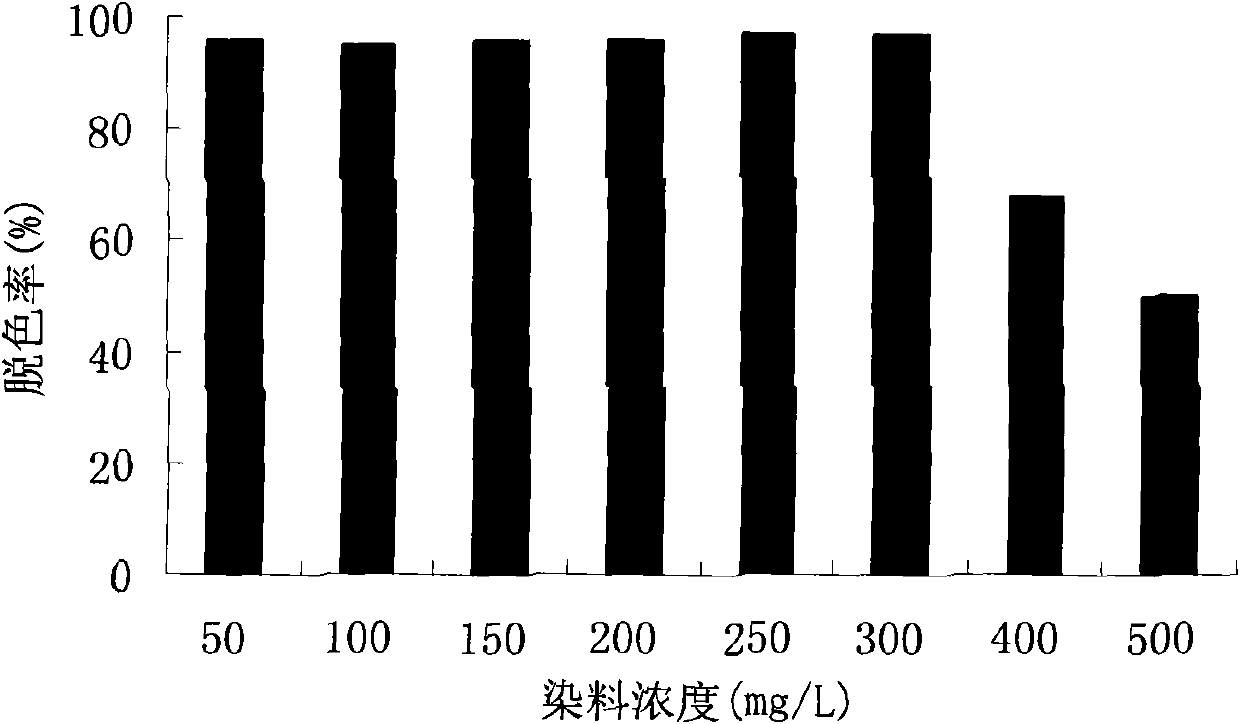

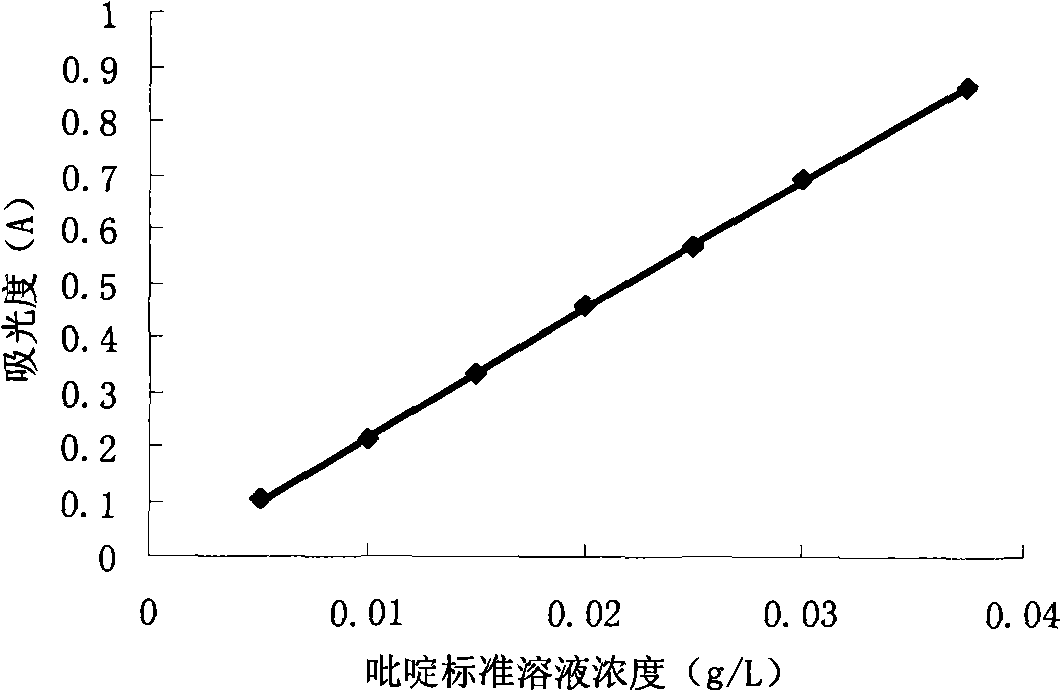

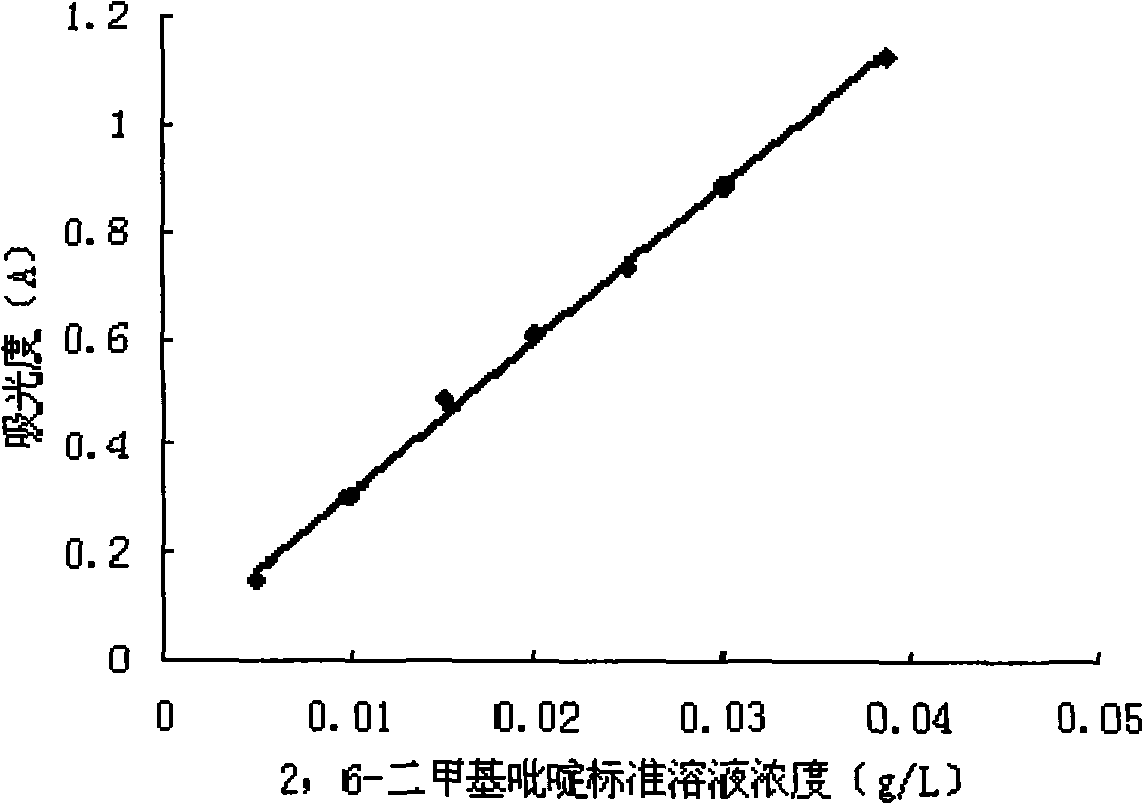

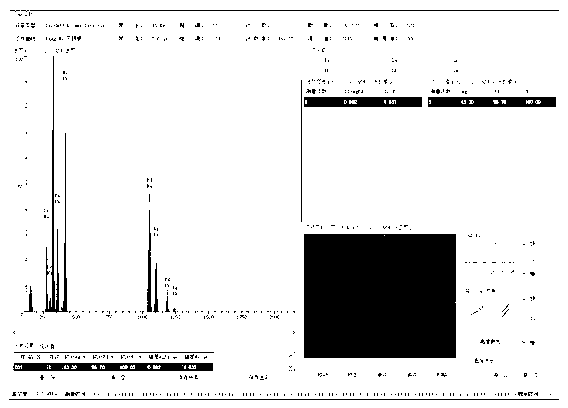

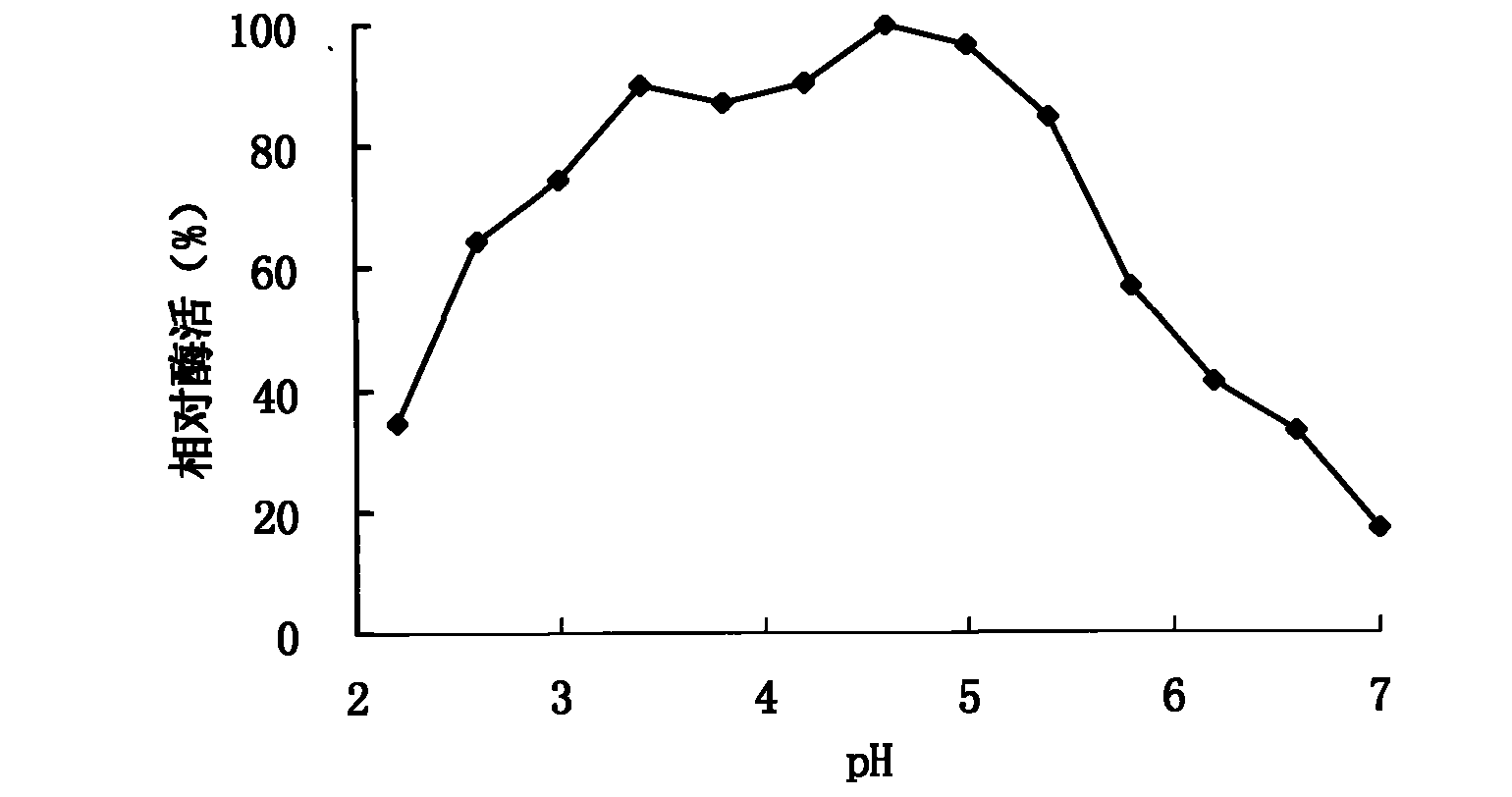

Yeast and application thereof in decolorization

InactiveCN101906388AEffective decolorizationThe cultivation method is simpleFungiTreatment using aerobic processesCandida tropicalisSalinity

The invention discloses yeast and application thereof in decolorization. The strain is Candida tropicalis YL3-1 CGMCC No. 3432 which has broad-spectrum azo dye decolorization and degradation capacity, can act on various azo dyes with different structures and has high decolorization capacity. The strain has the advantages of effectively decoloring high-salinity azo dye wastewater, along with simple culture method, high growth speed and high environmental applicability. The strain is used for the decolorization of printing wastewater and industrial wastewater associated with the use of the dye, can solve the problems existing in the prior art and has industrial application prospect.

Owner:TSINGHUA UNIV

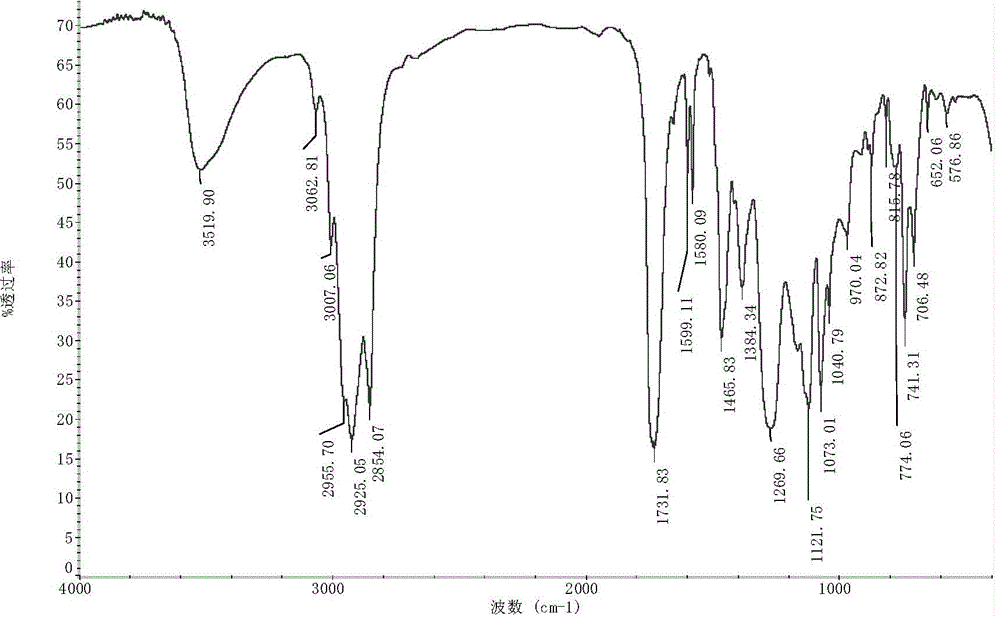

Discoloring method for reducing trans-fatty acid content of vegetable oil

InactiveCN101538508ALower trans fatty acidsLow in trans fatty acidsFatty-oils/fats refiningIsomerizationVegetable oil

The invention relates to a Discoloring method for reducing trans-fatty acid content of vegetable oil, belonging to the technical field of vegetable oil refining and discoloring. In the discoloring method, activated clay and neutralized vegetable oil are used as the raw material; on the one hand, discoloring earth is selected; and on the other hand, the discoloring technology of reducing fatty acid trans-isomer is obtained by controlling the discoloring temperature, the clay usage amount, the discoloring time and the stirring rate and integrally considering the trans-isomerization of discoloring effect and fatty acid. The invention reduces the content of trans-fatty acid formed during discoloring, builds up the discoloring technology of low trans-acid, plays a role of good guiding for improving the refining processing technology of vegetable oil and lays a foundation for constructing the processing technology of healthy vegetable oil.

Owner:SHANGHAI RONGS HEALTH IND CO LTD

Technology for producing peony seed oil

InactiveCN105567416APrevent discolorationIncrease profitFatty-oils/fats refiningFatty-oils/fats productionAcetic acidAlcohol

The invention discloses a technology for producing peony seed oil. The technology includes the following steps that firstly, low-temperature drying is conducted; secondly, dried peony seed powder is placed into a soxhlet extraction device, and a mixed solution of an extraction agent ethyl acetate, alcohol and petroleum ether is added for extraction; thirdly, vacuum concentration is conducted, ethyl acetate, alcohol and petroleum ether are recycled; fourthly, filtering is carried out through an oil filter, and solid residues are separated out; fifthly, deacidification is conducted; sixthly, decoloration is carried out; seventhly, deodorization is conducted. By means of the technology, the oil extraction rate of peony seeds can be effectively increased, the content of linoleic acid and linolenic acid in the peony seed oil is also increased, and accordingly the utilization rate of nutrients in the peony seeds is increased.

Owner:李小婷

Special palladium catalyst for sewage treatment and application thereof

InactiveCN103272614ARelieve pressureLow costSpecific water treatment objectivesWater contaminantsPtru catalystPalladium catalyst

The invention discloses a special palladium catalyst for sewage treatment. Stainless steel serves as a carrier, and a metal palladium layer is uniformed distributed on the surface of the stainless steel. The invention further discloses a preparation method of the special palladium catalyst for sewage treatment and an application of the special palladium catalyst for sewage treatment. The special palladium catalyst is low in operation cost, has a good decontamination effect, can effectively degrade organic matters, removes odor and carries out effective decoloration.

Owner:NANJING DELEI SCI & TECH

Method for classifying and recycling multiple resins in mixed waste paint

ActiveCN104910671AHigh Resin RecoveryHigh waste recycling economyPlastic recyclingCoatingsSolventChemistry

The invention discloses a method for classifying and recycling multiple resins in mixed waste paint. The method comprises the following steps: extracting waste residues by utilizing a mixed solvent of solvent gasoline and xylene, and recycling to obtain medium and long oil length alkyd resins; extracting the waste residues by using a xylene solvent, and recycling to obtain reclaimed resins comprising the main components such as epoxy resins and polyester resins; extracting the waste residues by using a mixed solvent of xylene and ketone, and recycling to obtain reclaimed resins comprising the main components such as acrylic resins; and extracting the waste residues by using a mixed solvent of xylene and benzyl alcohol, and recycling to obtain reclaimed resins comprising the main components such as amino resins. The method for recycling the waste residues of the paint disclosed by the invention has the advantages that the method is suitable for extracting the mixed paint residues of multiple kinds of paint, has high resin recycling rate and high waste recycling economical efficiency and is green and environment-friendly, real waste utilization is realized, and the like.

Owner:YONGKANG HONGYI TRADE

Linolenic acid health care edible oil, Chinese prickly ash seed meal and preparation method thereof

InactiveCN105886103AHigh economic valueEffective separation and removal of impuritiesFatty-oils/fats refiningFatty-oils/fats productionEdible oilΑ-linolenic acid

The invention discloses a linolenic acid health care edible oil, Chinese prickly ash seed meal and a preparation method thereof. The preparation method comprises the following steps: (1) preparing crude oil: picking high quality green prickly ash seeds, rolling the seeds, and extracting crude oil; (2) refining: subjecting the crude oil obtained in the step (1) to hydration degumming, alkali refining (for removing acid), water washing (for removing impurities), dehydration, discoloring, deacidification, and deodorization. The obtained linolenic acid health care edible oil comprises 8 to 15% of palmitic acid, 5 to 15% of palmitoleic acid, 30 to 40% of oleic acid, 20 to 35% of linoleic acid, and 10 to 18% of alpha-linolenic acid. At the same time, Chinese prickly ash seed meal is produced. Through the method mentioned above, the impurities are effectively separated and removed, the color and odor are eliminated; at the same time, the oleic acid value and peroxide value that continuously change during the production process are always controlled so as to produce the linolenic acid health care edible oil that meets the national sanitary standards of edible plant oil; the content of unsaturated fatty acid can reach 80% or more, the linolenic acid content is high, and thus the provided edible oil is very good.

Owner:重庆市涪陵区棋元粉丝厂

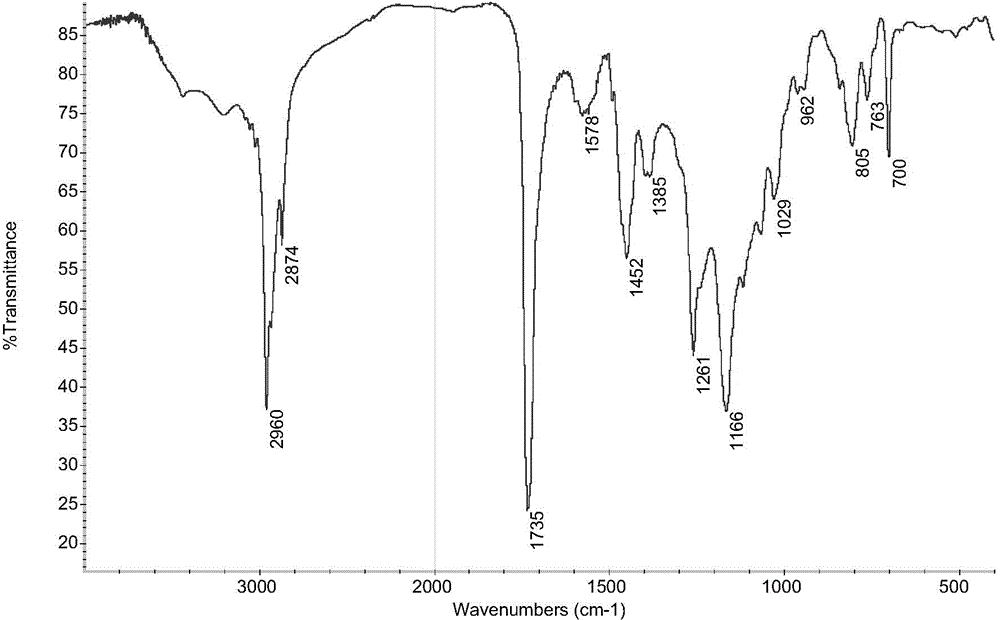

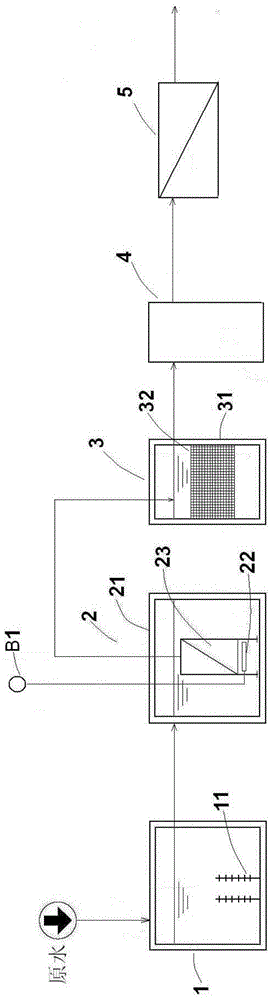

Waste water treatment device, and waste water treatment method

InactiveCN104609639AAvoid cloggingReduce organic contentMultistage water/sewage treatmentAnaerobic digestionWoven fabric

The invention provides a waste water treatment device, and a waste water treatment method. The waste water treatment device comprises an anaerobic tank used for anaerobic biological treatment of waste water under anaerobic conditions, and an aerobic membrane bioreactor used for anaerobic biological treatment and membrane filtration of waste water processed via the anaerobic tank; and a carrier composed of acrylic acid non-woven fabric is arranged in the anaerobic tank. The waste water treatment device is capable of improving adhesiveness of anaerobic microorganisms on the carrier, and realizing full proceeding of anaerobic biological treatment.

Owner:MITSUBISHI CHEM CORP +1

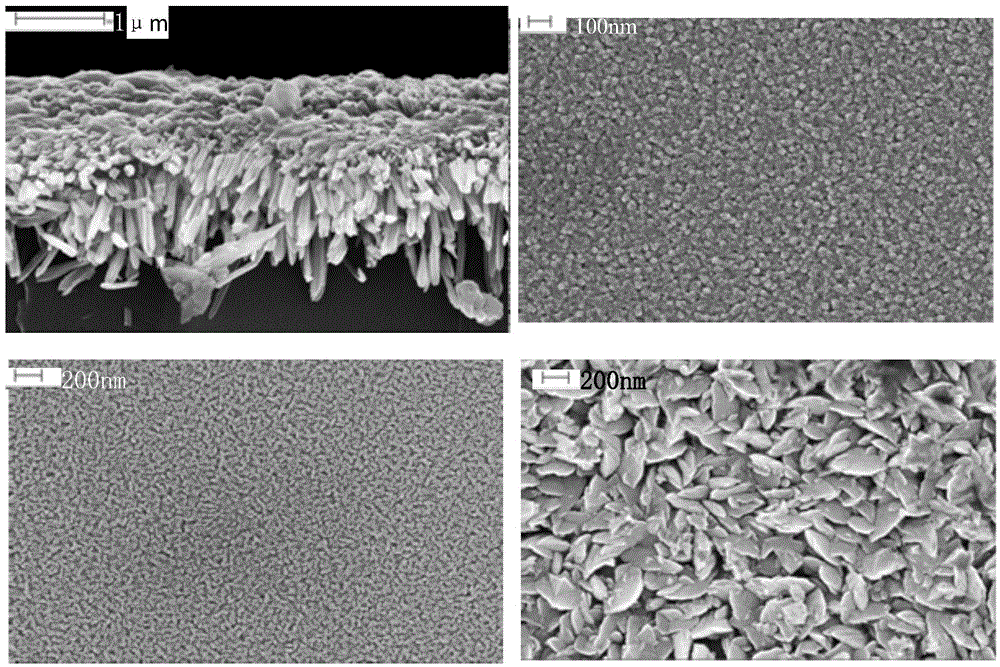

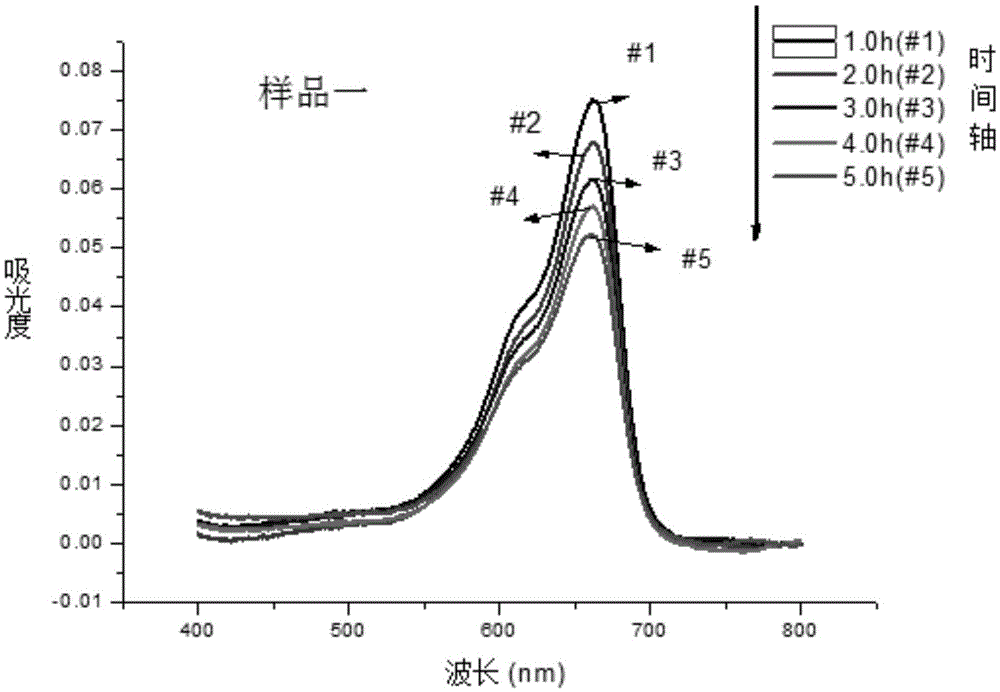

Method for degrading methylene blue solution

InactiveCN105461044ALarge specific surface areaStrong substrate adhesionWater contaminantsEnergy based wastewater treatmentAdhesion forceNano structuring

The invention discloses a method for degrading a methylene blue solution. According to the method, CuO is used as a catalyst for catalyze the decomposition of hydrogen peroxide to the methylene blue solution. As an effective catalyst, copper oxide can degrade sewage containing the methylene blue solution in a relatively short time. Furthermore, CuO is a nano-structured CuO membrane which has a large specific surface area and relatively strong base adhesion force and is capable of effectively catalyzing the decomposition of hydrogen peroxide to the methylene blue solution and effectively decoloring the methylene blue solution within 0.5 hour, and 100% degradation efficiency can be achieved within 4 hours; furthermore, the CuO membrane has very high stability and can be repeatedly used.

Owner:QUANZHOU NORMAL UNIV

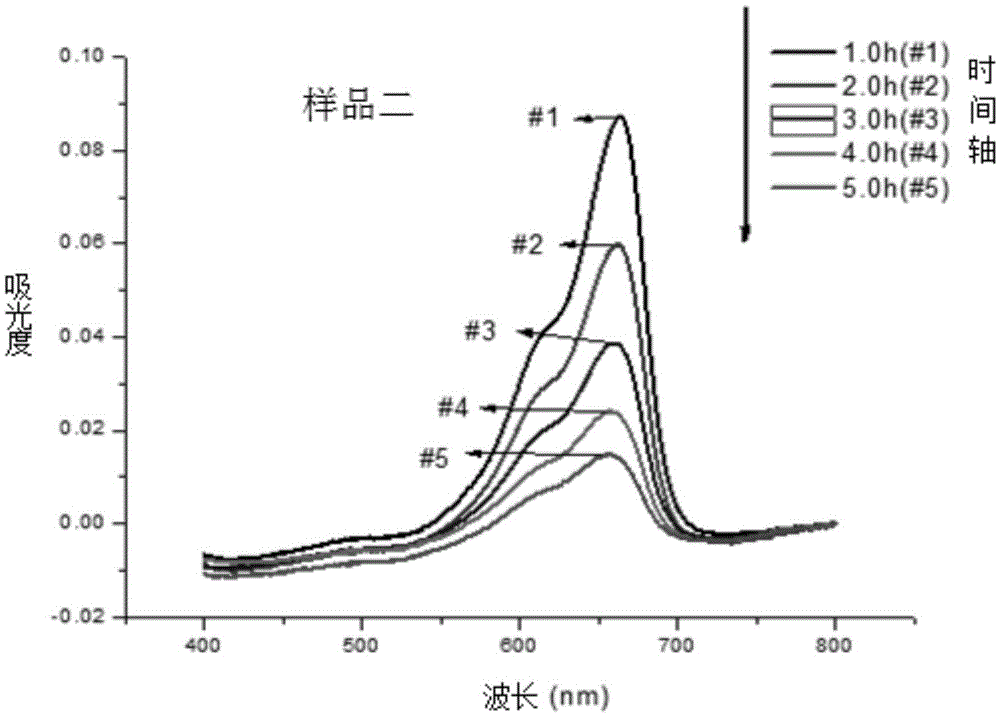

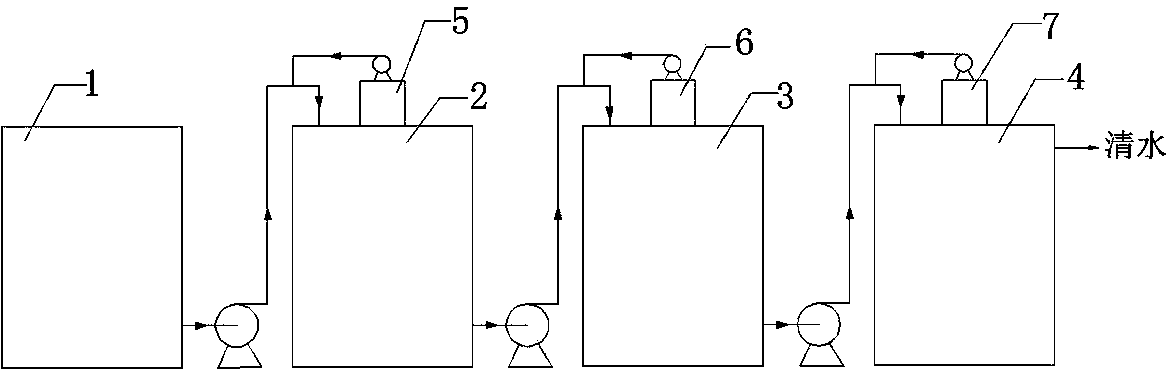

Sewage decoloration method

ActiveCN103466779AAdjust the dosage in timeResidual Active Chlorine ControlMultistage water/sewage treatmentWater/sewage treatment by oxidationAcetic acidWastewater

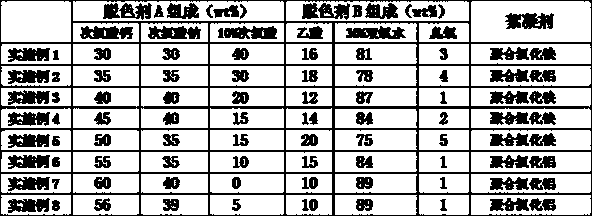

The invention provides a sewage decoloration method. A chemical oxidation method is adopted in the sewage decoloration method. The sewage decoloration method is characterized in that sewage which is treated with biotechnology is conveyed into a first decoloration tank through a pump, and meanwhile moderate decoloration agents A are added into the first decoloration tank. The sewage in the first decoloration tank is conveyed into a second decoloration tank through a pump, and meanwhile moderate decoloration agents B are added into the second decoloraton tank. The sewage in the second decoloration tank is conveyed into a waste water clarification tank through a pump, meanwhile, flocculants are added into the clarification tank for standing for 1-2h, and clear water is discharged, wherein the chromaticity of the clear water is smaller than 50. The decoloration agents A comprise, by weight, 30-60% of calcium hypochlorite, 30-40% of sodium hypochlorite and 0-40% of 10% hypochlorous acid solution. The moderate decoloration agents B comprise, by weight, 10-20% of acetic acid, 75-89% of 30% hydrogen peroxide solution and 1-5% of ozone. The sewage decoloration method has the advantages of being simple in technology, good in discharged water quality, low in chromaticity and the like.

Owner:广西贵港市蓝月亮水处理环保科技有限公司

High-efficiency pectin extraction process

The invention belongs to the technical field of pectin extraction, and particularly relates to a high-efficiency pectin extraction process, which comprises the steps of (1) preprocessing pericarp; (2)adding dry ice into the pericarp, stirring and mixing, putting an obtained mixture into a liquid nitrogen system, then standing the mixture of the dry ice and the pericarp at 20 to 40 DEG C, preserving the pericarp after the dry ice is sublimated; (3) adding an acid solution into the pericarp, regulating the pH to be 1.5 to 2.0, raising the temperature to 90 to 100 DEG C, performing heat preservation for 1 to 2h, filtering while the solution is hot to obtain pectin extract liquor; after cooling to 50 DEG C, adding amylase, stirring and mixing for 20 to 30min, then raising the temperature to 80 DEG C for enzyme deactivation; adding a decolorising agent, performing heat preservation for 20 to 30min, filtering to obtain discolored filter liquor; (4) concentrating the discolored filter liquor; (5) performing spray drying to obtain pectin powder. According to the high-efficiency pectin extraction process, the conventional breaking and squeezing extraction method is abandoned, the extraction of the pectin is facilitated; the method not only improves the extraction efficiency of the pectin, but also reduces the content of impurity in the pectin extract liquor.

Owner:DANGSHAN HAISHENG PECTIN

Fine processing method of fish oil

ActiveCN105907456AKeep active ingredientsReduce enzyme activityFatty-oils/fats refiningFatty-oils/fats productionFish oilOil water

The invention relates to the field of the processing of fish products and discloses a fine processing method of fish oil. The fine processing method of fish oil comprises the following steps: a, washing fish guts, removing giblets, pounding the fish guts to prepare a blank material; b, adding the blank material into an enzymolysis solution containing an immobilized magnetic composite enzyme for carrying out enzymolysis, and recycling the immobilized magnetic composite enzyme by using a magnet after carrying out enzymolysis; c, filtering the enzymolysis solution to remove residues, then standing and layering, and separating to obtain upper fish oil and lower oil-water mixed solution; d, transferring the oil-water mixed solution to a foam separating column, aerating the bottom of the foam separating column, generating a foam layer on the upper layer of the oil-water mixed solution, and separating the foam layer from the liquid in time; e, carrying out centrifugal separation on the oil-water mixed solution to obtain upper fish oil; f, mixing the upper fish oil obtained in step c with the upper fish oil obtained in step e to prepare the fish oil. The processing method of the fish oil is simple in the process and high in the extraction efficiency and the extraction rate; the processed fish oil is high in purity, free of fishy smell and pure in color.

Owner:广州长生康生物科技有限公司

A kind of efficient pectin extraction process

The invention belongs to the technical field of pectin extraction, and particularly relates to a high-efficiency pectin extraction process, which comprises the steps of (1) preprocessing pericarp; (2)adding dry ice into the pericarp, stirring and mixing, putting an obtained mixture into a liquid nitrogen system, then standing the mixture of the dry ice and the pericarp at 20 to 40 DEG C, preserving the pericarp after the dry ice is sublimated; (3) adding an acid solution into the pericarp, regulating the pH to be 1.5 to 2.0, raising the temperature to 90 to 100 DEG C, performing heat preservation for 1 to 2h, filtering while the solution is hot to obtain pectin extract liquor; after cooling to 50 DEG C, adding amylase, stirring and mixing for 20 to 30min, then raising the temperature to 80 DEG C for enzyme deactivation; adding a decolorising agent, performing heat preservation for 20 to 30min, filtering to obtain discolored filter liquor; (4) concentrating the discolored filter liquor; (5) performing spray drying to obtain pectin powder. According to the high-efficiency pectin extraction process, the conventional breaking and squeezing extraction method is abandoned, the extraction of the pectin is facilitated; the method not only improves the extraction efficiency of the pectin, but also reduces the content of impurity in the pectin extract liquor.

Owner:DANGSHAN HAISHENG PECTIN

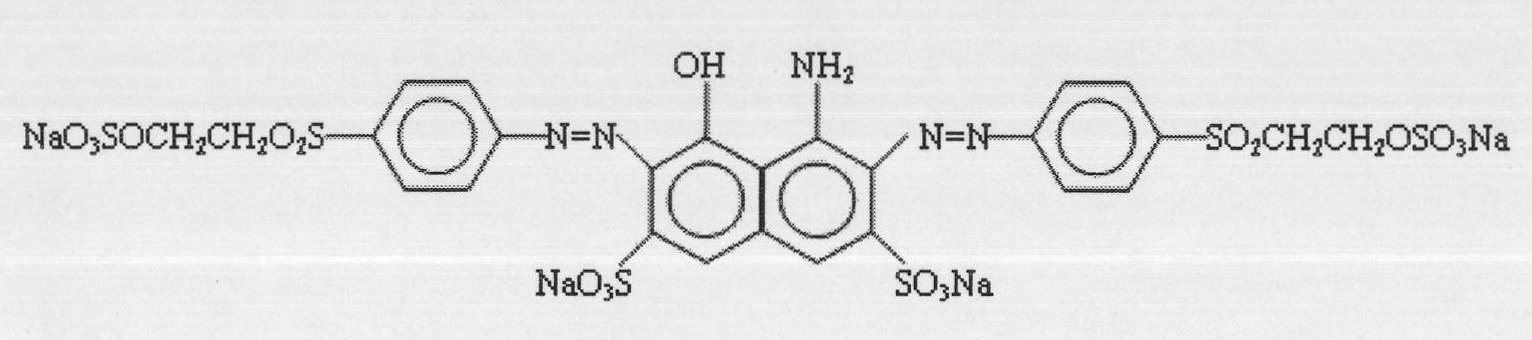

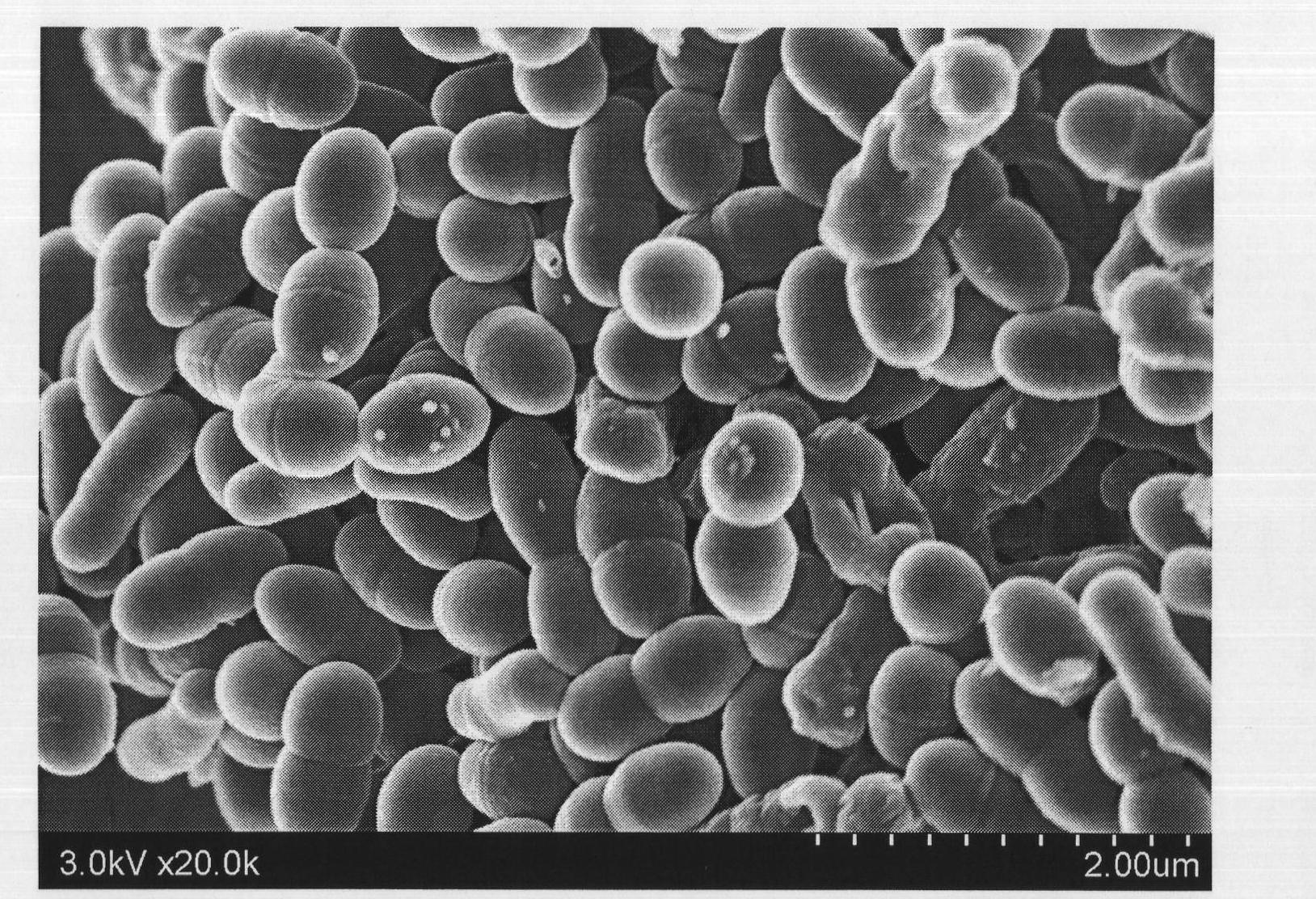

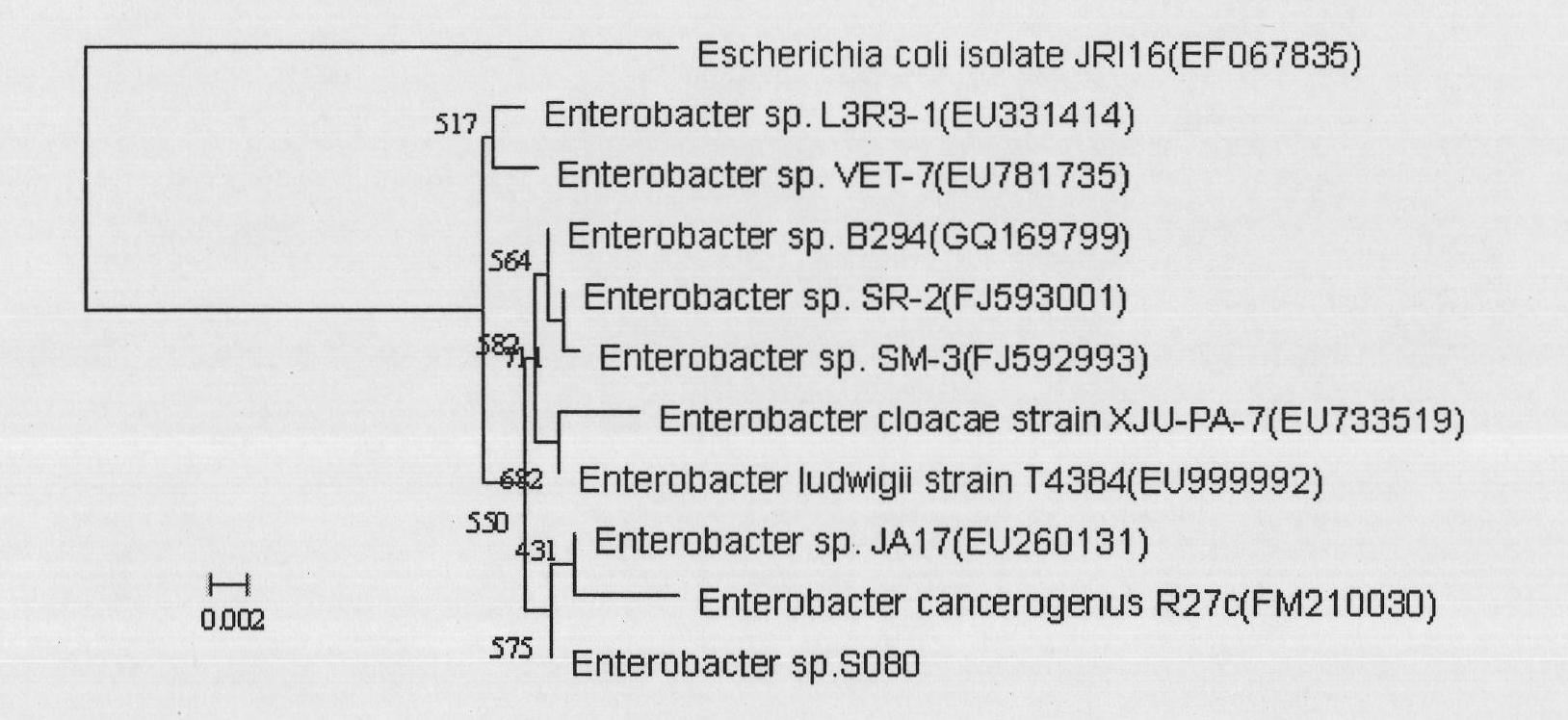

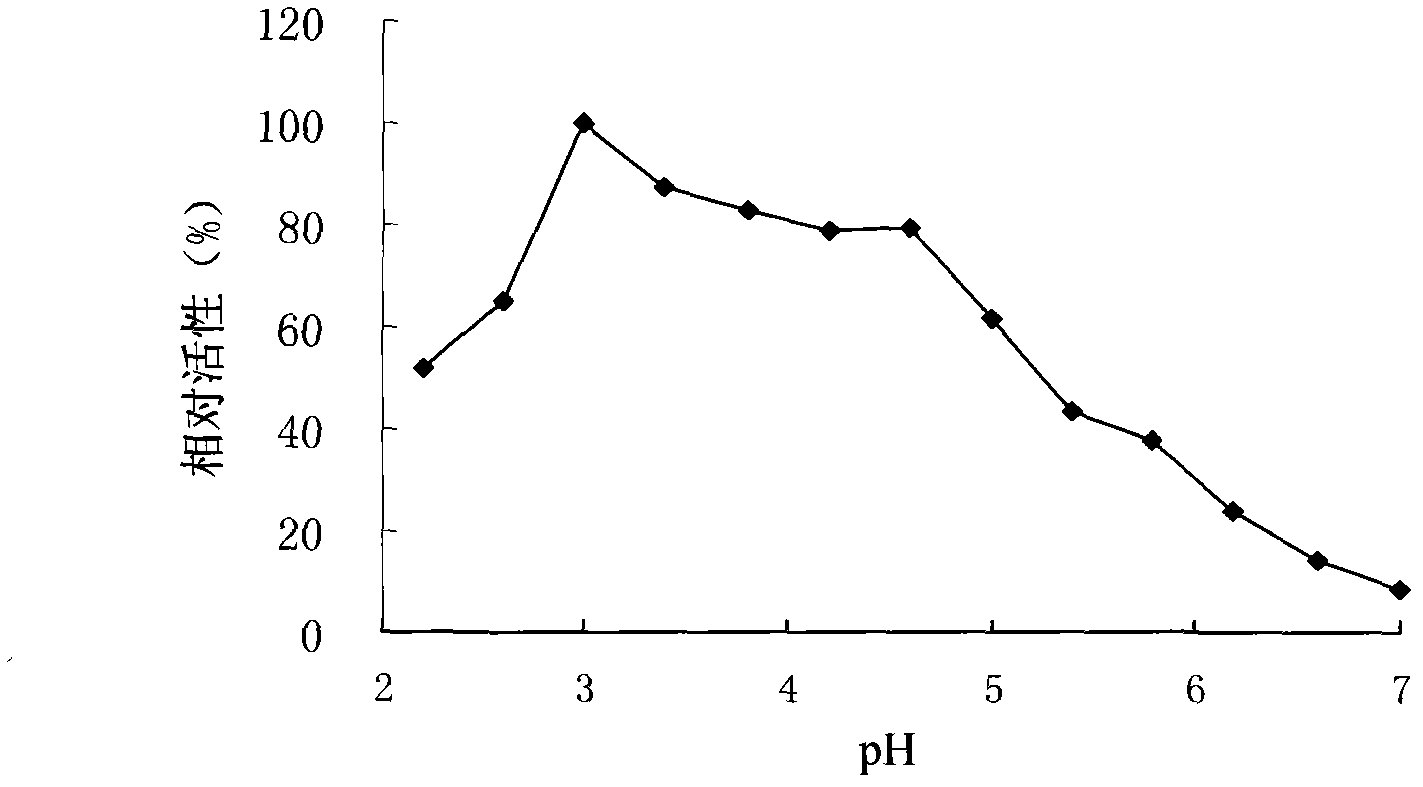

Extraction method of reactive black 5 dye efficient decolorizing bacteria

InactiveCN101845411AGood decolorizationHigh removal rateBacteriaMicroorganism based processesActivated sludgeCulture fluid

The invention relates to an extraction method of reactive black 5 dye efficient decolorizing bacteria, which comprises the steps of taking activated sludge and inoculating the activated sludge in an inorganic salt culture medium to carry out gradient pressure type domestication for 2 months, then inoculating the domesticated sample in the enrichment culture solution in the access amount of 5% for anaerobic cultivation at the temperature of 30 DEG C, simultaneously increasing the concentration of dye in the culture solution, finally carrying out separation and purification on the solid culture medium to ensure the growth of a single pure bacterial strain, and storing in a refrigerator of 4 DEG C after adding 50 wt% of glycerol for standby use. The method extracts active black 5 decolorizing bacterial strain from anaerobic activated sludge of an AAO system, the seed source is easily obtained and separated and purified simply and quickly, and the method has low cost and is environmental-friendly. The decolorization rate of the extracted bacterial strain on the reactive black 5 can reach 90 .48%, so the method has good application prospects.

Owner:DONGHUA UNIV

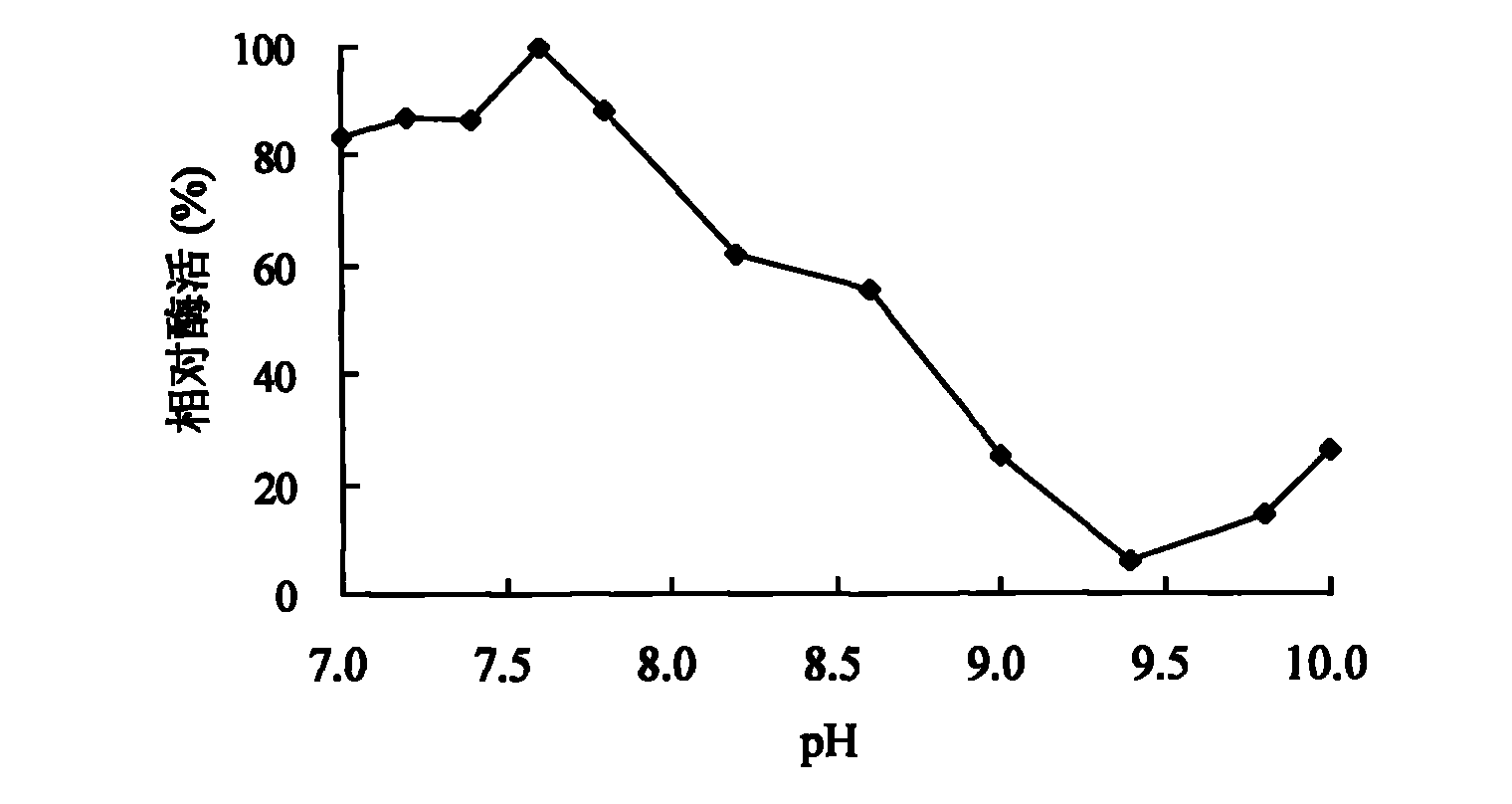

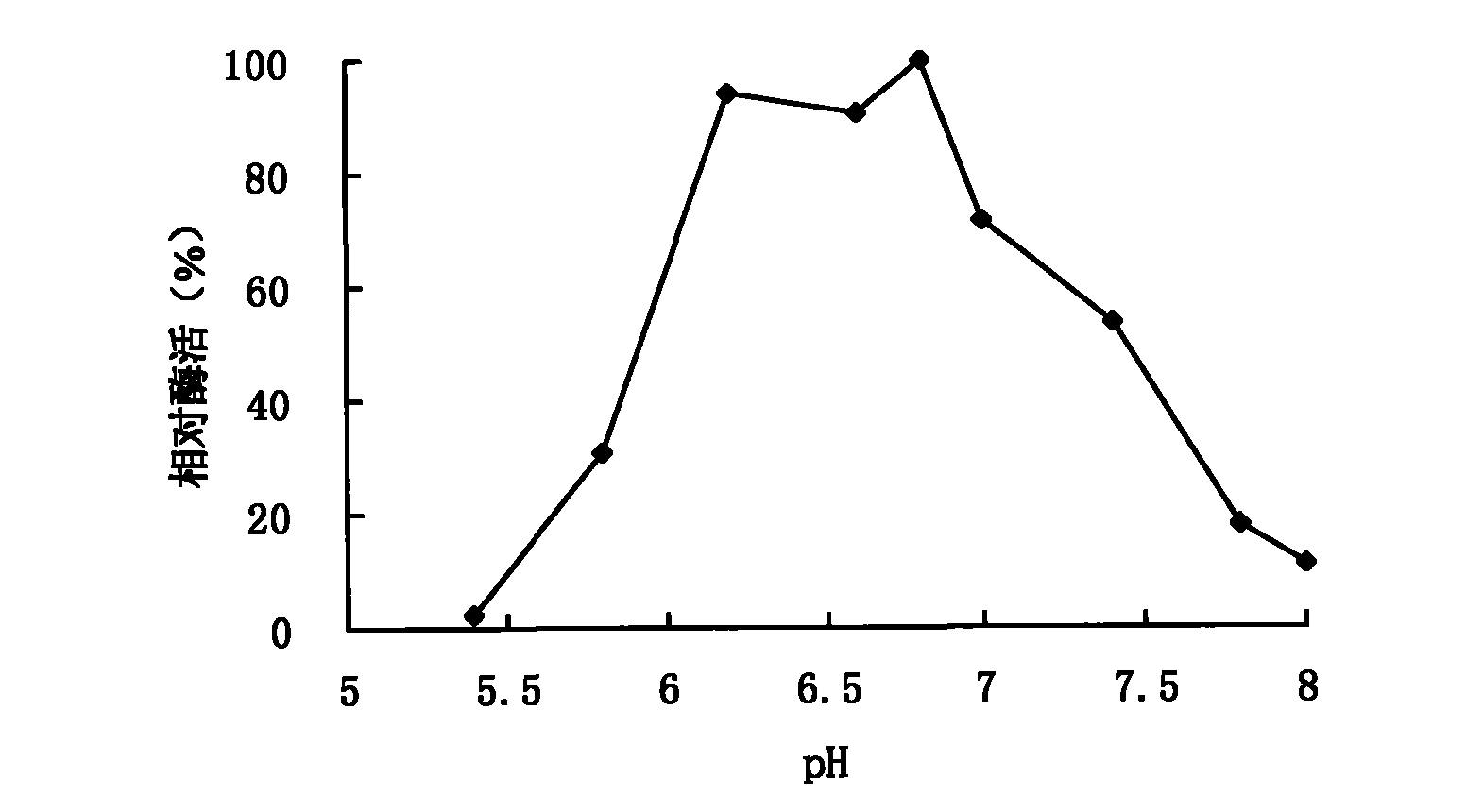

Bacillus amyloliquefaciens LS01 laccase and application thereof

InactiveCN102115724AHigh activityImprove thermal stabilityBacteriaMicroorganism based processesSporeNucleotide

The invention discloses a preparation method of bacillus amyloliquefaciens LS01 (CGMCC No.4260) spore laccase, the catalytic property of the spore laccase and application of the spore laccase to decoloring of a dye. The invention also relates to a nucleotide sequence for encoding the spore laccase. The method comprises the following steps of: fermenting bacillus amyloliquefaciens LS01 on a solid-state sporulation medium at the temperature of 37 DEG C for 5 days; flushing spores with deionized water; and performing a series of treatment such as lysozyme treatment to obtain a spore suspension with laccase activity. The spore laccase has high catalyst activity under alkaline and high temperature conditions, has good decoloring effects on synthetic dyes with different structures under the action of a mediator, and can be applied to treatment of industrial dye waste water.

Owner:NORTHEAST FORESTRY UNIVERSITY

Advanced treatment and reuse technology of car wash wastewater

InactiveCN107792970ASolve pollutionGood removal effectFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationActivated carbonElectrolysis

The present invention discloses an advanced treatment and reuse technology of car wash wastewater. The technology comprises the following steps: S1. collecting wastewater to be treated, removing sludge by a grid, and removing oil by an inclined plate; S2. adjusting the pH of the wastewater subjected to sludge and oil removal; S3. performing micro-electrolysis treatment on wastewater after pH adjustment, and conveying the upper-layer wastewater to a unit for downstream treatment process; S4. adjusting the pH of wastewater treated in the step S3, discharging suspended solids and floating flocksin the wastewater to a sludge pool; S5. pumping supernatant wastewater treated in the step S4 to a cyclone filter system for further solid-liquid separation; and S6. enabling wastewater treated by a rotary filter to pass through multi-stage filtration systems such as a micro filtration system, an activated carbon adsorption system, an ultrafiltration system, and a nanofiltration system in sequence, and guaranteeing outgoing water to meet the drinking water standard. The technology has reasonable design and high practicability, can realize automation work, and is simple to operate and suitablefor promotion.

Owner:福瑞莱环保科技(深圳)股份有限公司

Decolouring deodorizing sewage treatment agent

InactiveCN105253925AImprove removal efficiencyEasy to prepareWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationSodium BentoniteSodium phosphates

The invention discloses a decolouring deodorizing sewage treatment agent. The decolouring deodorizing sewage treatment agent is prepared from, by mass, 1.5 to 2.5 parts of polyacrylamide, 1 to 2 parts of a coagulant aid, 3 to 8 parts of potassium peroxodisulfate, 3 to 5 parts of bentonite, 10 to 20 parts of starch, 5 to 10 parts of solvent lignin, 5 to 10 parts of a sodium phosphate-sodium dihydrogen phosphate buffer system, 10 to 15 parts of nekal, 8 to 10 parts of polyepoxysuccinic acid, and 2 to 3 parts of aluminium polychlorid. The decolouring deodorizing sewage treatment agent is used for solving technical problems of the prior art that conventional flocculating agents are poor in effects, and secondary pollution is caused by reagent ingredients; the decolouring deodorizing sewage treatment agent is wide in pollutant treatment range, excellent in effect, and wide in raw material resource, is friendly to the environment, and is non-toxic; the structural design of the coagulant aid is special, and obvious effects on the aspects of algae killing, decolouring, deodorizing, and organic matter degradation are achieved.

Owner:ANQING FENGYUAN CHEM

Decoloring treatment method of printing and dyeing wastewater

InactiveCN103613224AGood physical contactNot easy to break awayMultistage water/sewage treatmentWaste water treatment from textile industryHydrogen peroxideDioxide titanium

The invention discloses a decoloring treatment method of printing and dyeing wastewater. The decoloring treatment method of the printing and dyeing wastewater is characterized by comprising the following steps: placing the printing and dyeing wastewater into a container or a treatment pond; performing suspended substance filtering treatment on the printing and dyeing wastewater; adding 3 to 6 square meters of nano-titanium dioxide immobilized catalytic pieces into each cubic meter of printing and dyeing wastewater which is subjected to filtering treatment; adding hydrogen peroxide, wherein the volume of the hydrogen peroxide is 0.001 to 0.01 percent of that of the printing and dyeing wastewater which is subjected to filtering treatment; stirring completely; irradiating by using a mercury lamp. The nano-titanium dioxide immobilized catalytic pieces are prepared by fixing titanium dioxide on the surface of ceramic by a physical burning and solidifying manner, have a good physical contact effect, are difficult to separate and achieve a long-term effective catalytic effect; the spectral range of the mercury lamp is wide and close to a natural spectrum, so the safety is higher; the nano-titanium dioxide immobilized catalytic pieces and organic matters in the printing and dyeing wastewater generate chemical reaction, so the color organic matters in the printing and dyeing wastewater can be effectively decolored and the treated water is free from secondary pollution.

Owner:乐山市洁宇纳米应用技术研究所

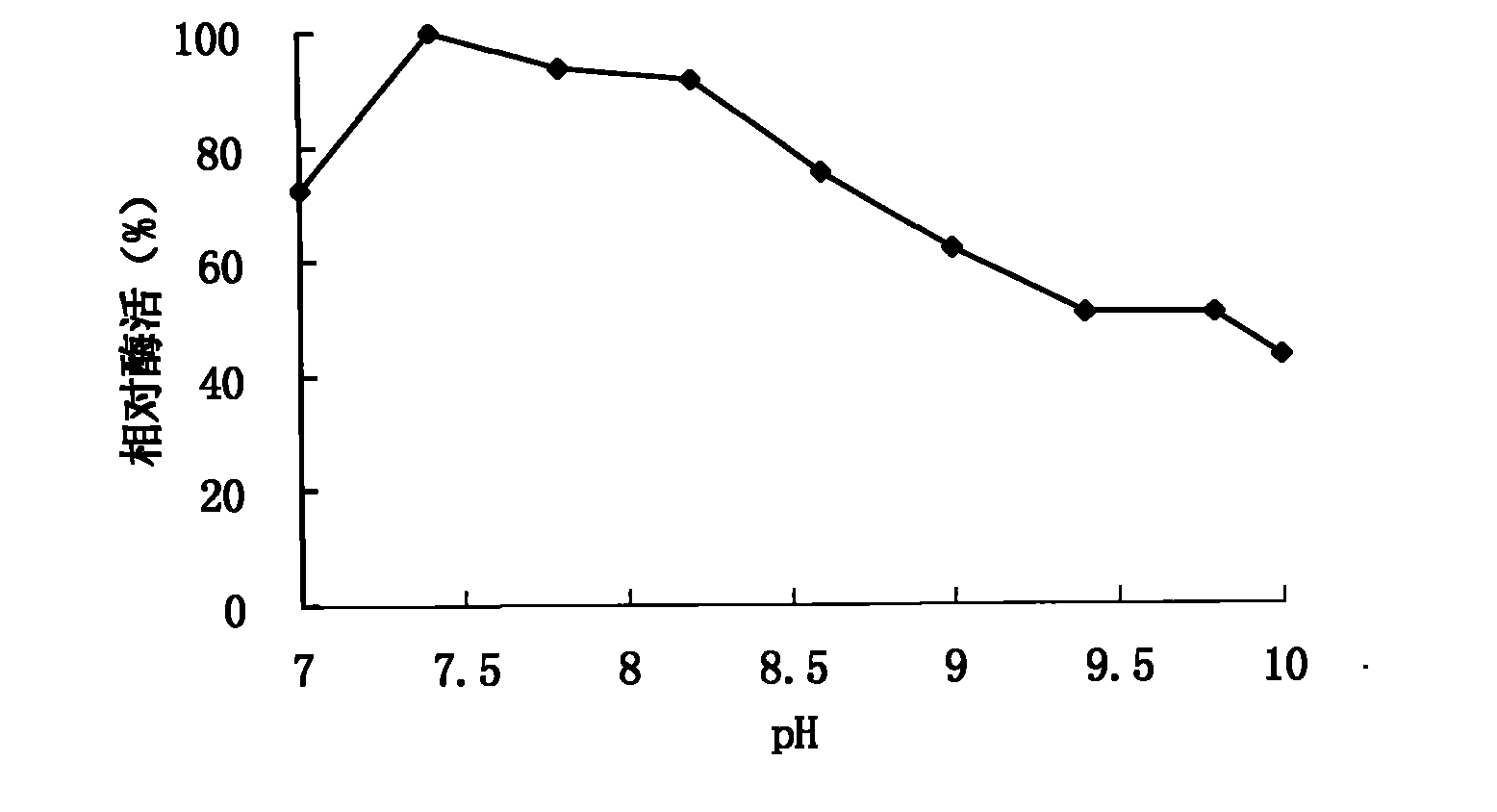

Laccase from Bacillus amyloliquefaciens LS05 and use thereof

InactiveCN102154152AHigh activityImprove thermal stabilityBacteriaMicroorganism based processesSporeBacillus amyloliquefaciens

The invention discloses a preparation method, a catalytic property and use in dye decolorizing of spore laccase from Bacillus amyloliquefaciens LS05 (CGMCC No.4264). The invention also relates a nucleotide sequence for coding the spore laccase. In the invention, the Bacillus amyloliquefaciens LS05 ferments at 37 DEG C for 5 days on a solid sporulation culture medium, the spores are washed off with deionized water, and pore suspension with laccase activity can be obtained by series measures such as lysozyme treatment. The spore laccase has high catalytic activity under alkaline and high-temperature conditions, has good decolorizing effect on synthesized dyes of different structures under action of an amboceptor and can be used for treating industrial dye waste water.

Owner:NORTHEAST FORESTRY UNIVERSITY

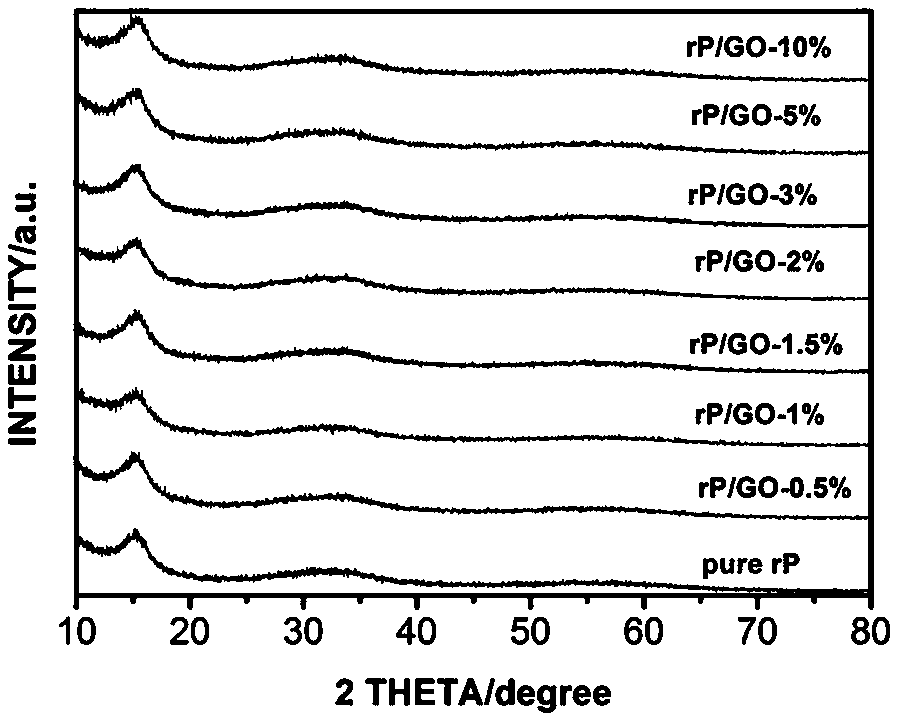

Graphene oxide/red phosphorus composite material as well as preparation method and application thereof

InactiveCN107715898AExcellent photocatalytic performanceImprove decolorization abilityPhysical/chemical process catalystsWater/sewage treatment by irradiationMethyl orangeOxide

The invention provides a graphene oxide / red phosphorus composite material as well as a preparation method and application thereof. According to the graphene oxide / red phosphorus composite material, red phosphorus is modified by utilizing nano graphene oxide, and the nano graphene oxide is supported on the red phosphorus. The graphene oxide / red phosphorus composite material has excellent photocatalytic performance, and can be used as a photocatalyst to effectively decolour a methyl orange solution under visible light, wherein the decolorization ability is remarkably improved compared with thatof a single red-phosphorus photocatalyst. Further, the method also provides a simple and feasible route for preparing the graphene oxide / red phosphorus composite material; and the operation of the preparation method is simple, the repeatability is strong, and the composite material can be suitable for industrialized production and preparation.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com