Special palladium catalyst for sewage treatment and application thereof

A technology of sewage treatment and palladium catalyst, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., to reduce pressure and cost, reduce treatment cost, and remove odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

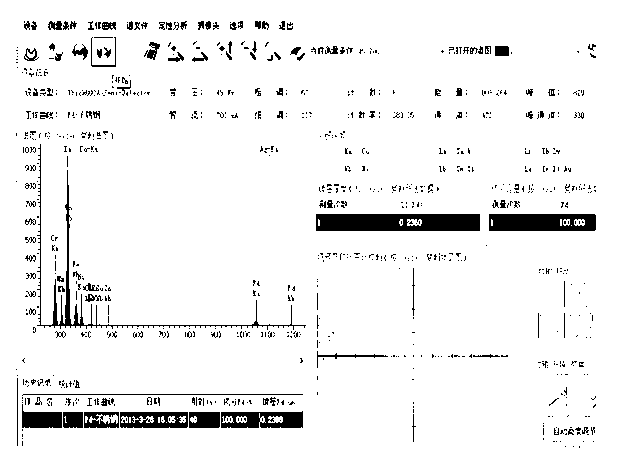

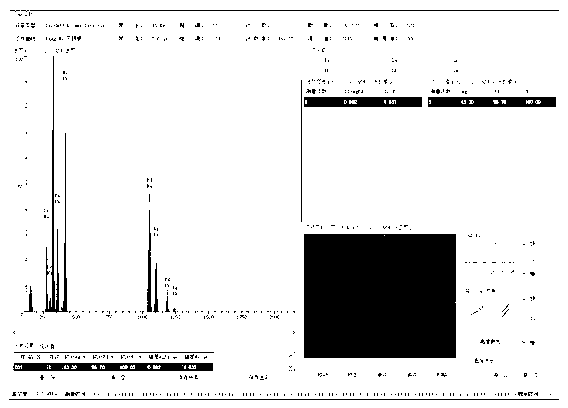

Image

Examples

Embodiment 1

[0035] Wherein, the pickling activation is to use 15wt% hydrochloric acid and pickling activation at 45°C.

[0036] Wherein, the operation of the chemical deposition is as follows: prepare 2-5g palladium chloride per square meter according to the surface area of stainless steel, dissolve it with 31wt% hydrochloric acid and pour it into 95 liters of pure water, add sodium citrate to the above solution 300g, add ammonia water to raise the pH value of the solution to 8~9, heat the solution to control the temperature at 65°C, put stainless steel into the above solution, and slowly add hydrazine hydrate N 2 h 4 .H 2 O, the total amount of hydrazine hydrate added is 100ml. After the hydrazine hydrate is evenly added within 2 hours, continue to control the solution temperature at 65° C., and finish the chemical deposition process after 1 hour.

[0037] The stainless steel sample treated by the method of this embodiment is subjected to X-fluorescence test, and it can be known that...

Embodiment 2

[0042] Wherein, the pickling activation is to use 15wt% hydrochloric acid and pickling activation at 45°C.

[0043] Wherein, the operation of described chemical deposition is as follows: according to the surface area of stainless steel per square meter, prepare working solution: 95 liters of pure water, add 200g sodium citrate, 200g EDTA, glucose 100g, add ammonia water and make the solution pH value rise to 9~10, heat to control the solution temperature at 65°C; prepare two solutions A and B before heating; preparation method of solution A: dissolve 2g palladium chloride with 31wt% hydrochloric acid, add ammonia water to make the pH value reach above 11 , add water to 1000mL for use; B solution preparation method: 1g AgNO 3 , add water to dissolve, add ammonia water 100mL, add water to 500mL for use; put the stainless steel into the working fluid with controlled temperature, add it into the above working fluid evenly within 2 hours according to the volume ratio A:B=2:1, and...

Embodiment 3

[0049] Example 4: Pilot test comparison of oxidation effect with or without catalyst.

[0050] Two 304 stainless steel reactors were made with the same design size and process. The diameter of the reactor was DN100mm and the length was 0.6 meters. 4.5 cubic decimeters of 304 stainless steel packing was placed inside the reactor. The specific surface area of the packing was 500 square meters per cubic meter. One of them is without any treatment (that is, there is no catalyst in the reactor); the inner stainless steel of the other one is the stainless steel containing palladium catalyst treated in Embodiment 1 (that is, there is a catalyst in the reactor). The pipes are connected with the pump and the Venturi mixer respectively, so that the sewage flows through the Venturi mixer through the outlet of the pump, and the ozone-containing gas is sucked into the catalytic reactor and then flows out.

[0051] Two kinds of stainless steel reactors were used to treat the sewage contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com