Patents

Literature

483results about How to "Good decolorization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for treating used water difficult to degradate by catalytic internal electrolysis of iron

InactiveCN1382649AWiden the potential differenceImprove the effect of electrolysisWater/sewage treatmentMultistage water/sewage treatmentElectrolysisSewage

A process for removing heavy metals and the organic substance difficult to degradate from sewage includes proportioning Fe and Cu, adding cationic surfactant modified zeolite, stirring, loading the mixture in filter pool, regulating pH value to 4.5-11, reaction, and regulating pH value to 8-9 to generate Fe(OH)3 as flocculant, which can coagulate the suspended solid and colloid and absorb and soluble pollutants for depositing them. Its advanrtages are high power, effect and high speed.

Owner:上海城市污染控制工程研究中心有限公司

Automatic machine laundering of fabrics

InactiveUS20050124521A1Good decolorizationGood removal effectDetergent mixture composition preparationOther washing machinesCombined useEngineering

The invention provides a method of laundering fabrics in an automatic washing machine having a drum wherein the automatic washing machine is operated so as to cause it to run through at least one wash cycle and at least one rinse cycle. Such a method comprises: (a) during the at least one wash cycle forming in the drum an aqueous washing liquor containing a detersive surfactant component and a detergent builder component, the aqueous wash liquor having pH above about 7; (b) contacting fabrics to be laundered with the aqueous wash liquor in the drum; (c) during the rinse cycle forming in the drum an aqueous rinse liquor and contacting the fabrics with the rinse liquor; (d) adding to the rinse liquor sufficient acid source to bring the pH of the rinse liquor in the range of from about 4 to about 7, preferably from about 4.5 to about 6.5. The use of this lowered pH in the rinse liquor gives a variety of cleaning benefits, and preferably fabric care benefits in combination with rinse additive, in the context of an automatic washing process. The invention also provides particular systems for application of the acid source to the rinse liquor.

Owner:THE PROCTER & GAMBLE COMPANY

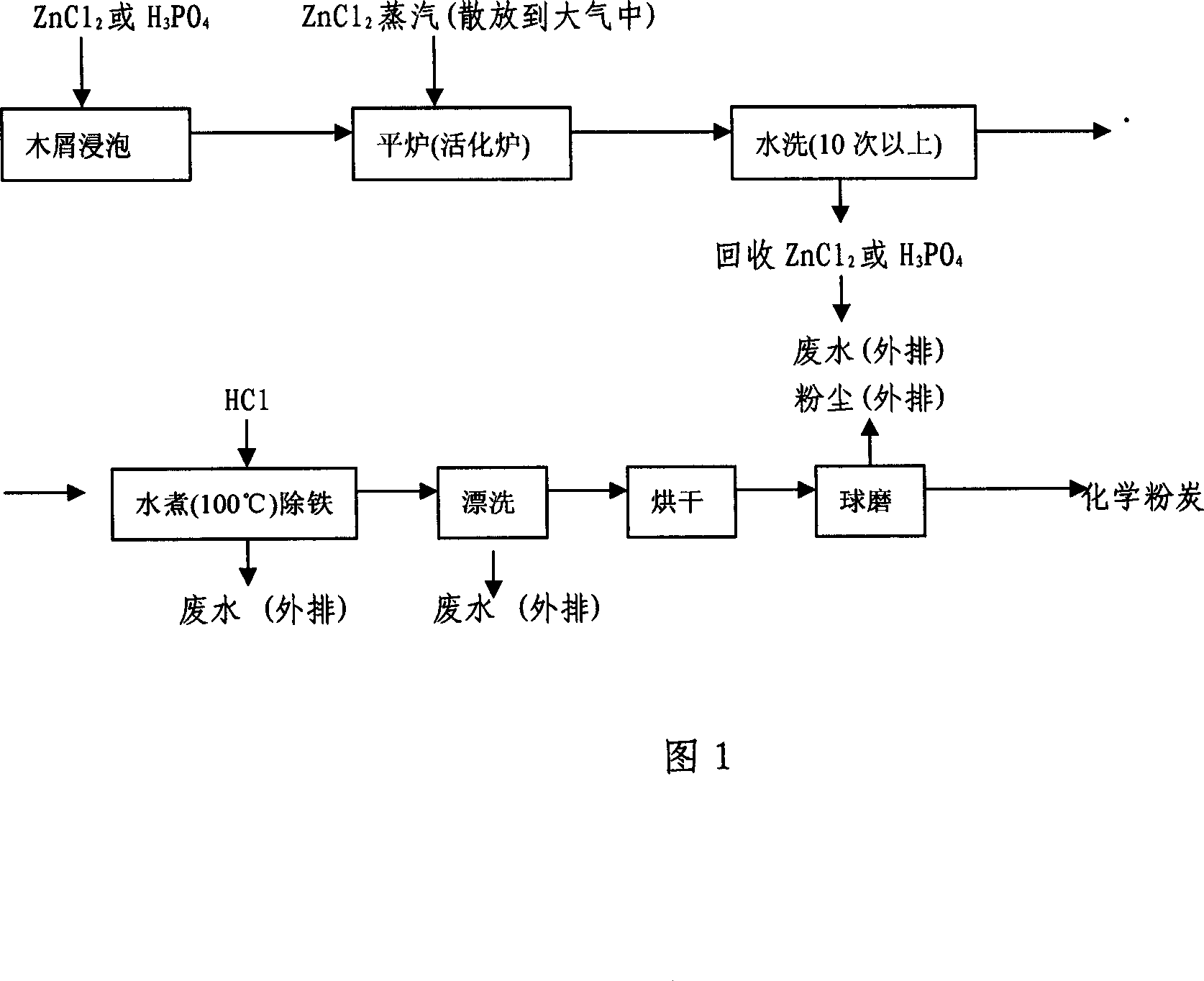

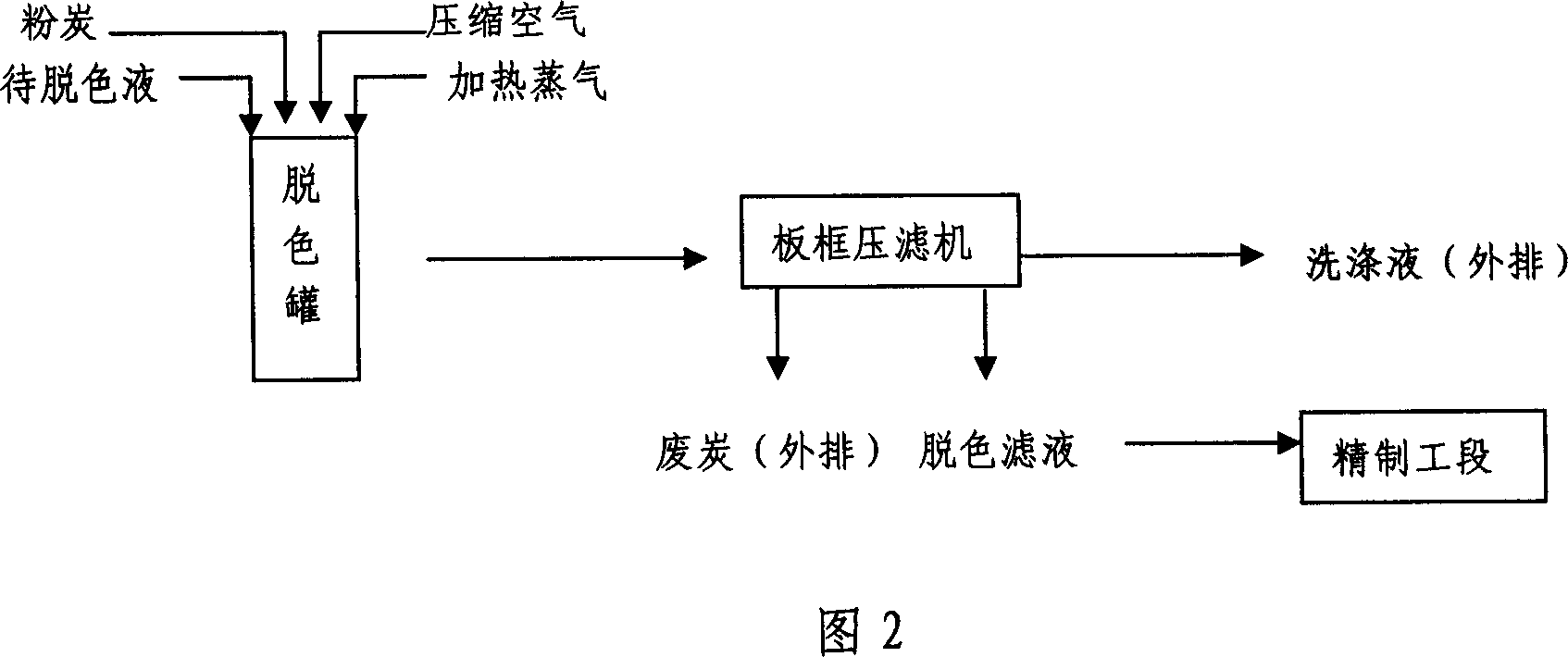

Granule decoloration active carbon and preparation method thereof

ActiveCN101054176AExcellent ability to remove macromolecular pigmentsGood decolorizationOther chemical processesActivation methodPhosphoric acid

The present invention relates to special active carbon for caramel decolorization and the preparation method thereof. The solid nutshell or coal serves as raw material which is processed by a physical chemistry immersion activation method to create active carbon. The immersion liquid is a water solution mainly comprising phosphoric acid, sodium hydroxide, magnesia and zinc chloride, wherein the proportioning by weight of each component is phosphoric acid: sodium hydroxide: magnesia: zinc chloride = 1:0.8~2.0:0.5~1.0:1~1.5. The obtained active carbon has an iodine value of 800~1000 mg / g, a caramel decolorization ratio of 80~100%, and a mechanical strength of 95%. The material is subjected to carbonizing, immersing, drying and activating treatment to create the active carbon product. The active carbon of the present invention has excellent decolorization property for macromolecule pigment, higher mechanical strength as general physical carbon, and wide application range. The traditional powdery carbon is replaced by granular activated carbon, the decolorizing pot is replaced by decolorizing column, the active carbon is changed from the disposable usage to the repeated and regenerated usage, and the decolorizing system can be continuously operated for a long time.

Owner:CHAOYANG SHENYUAN ACTIVE CARBON

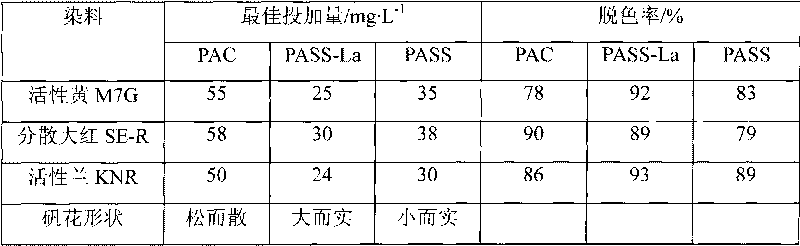

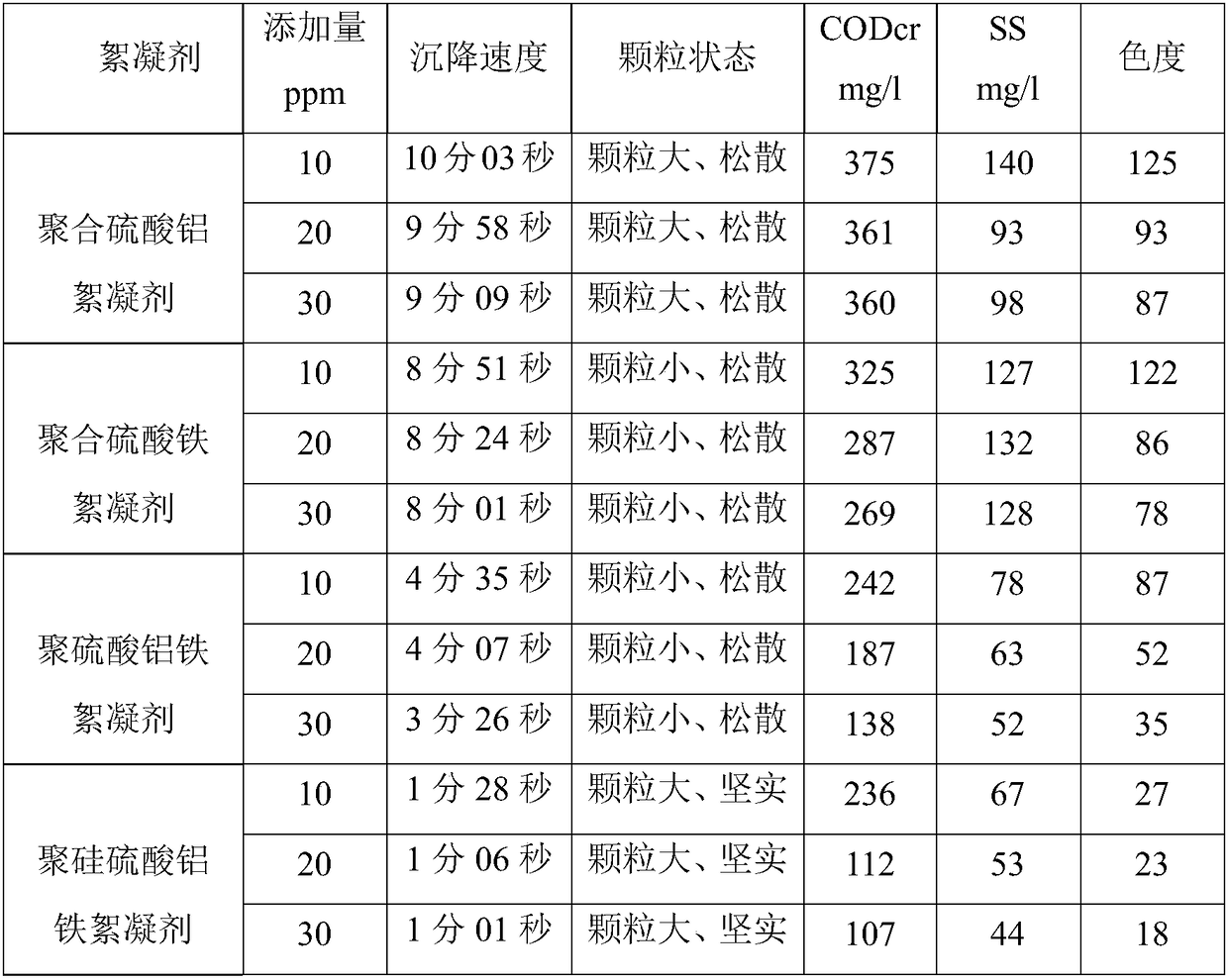

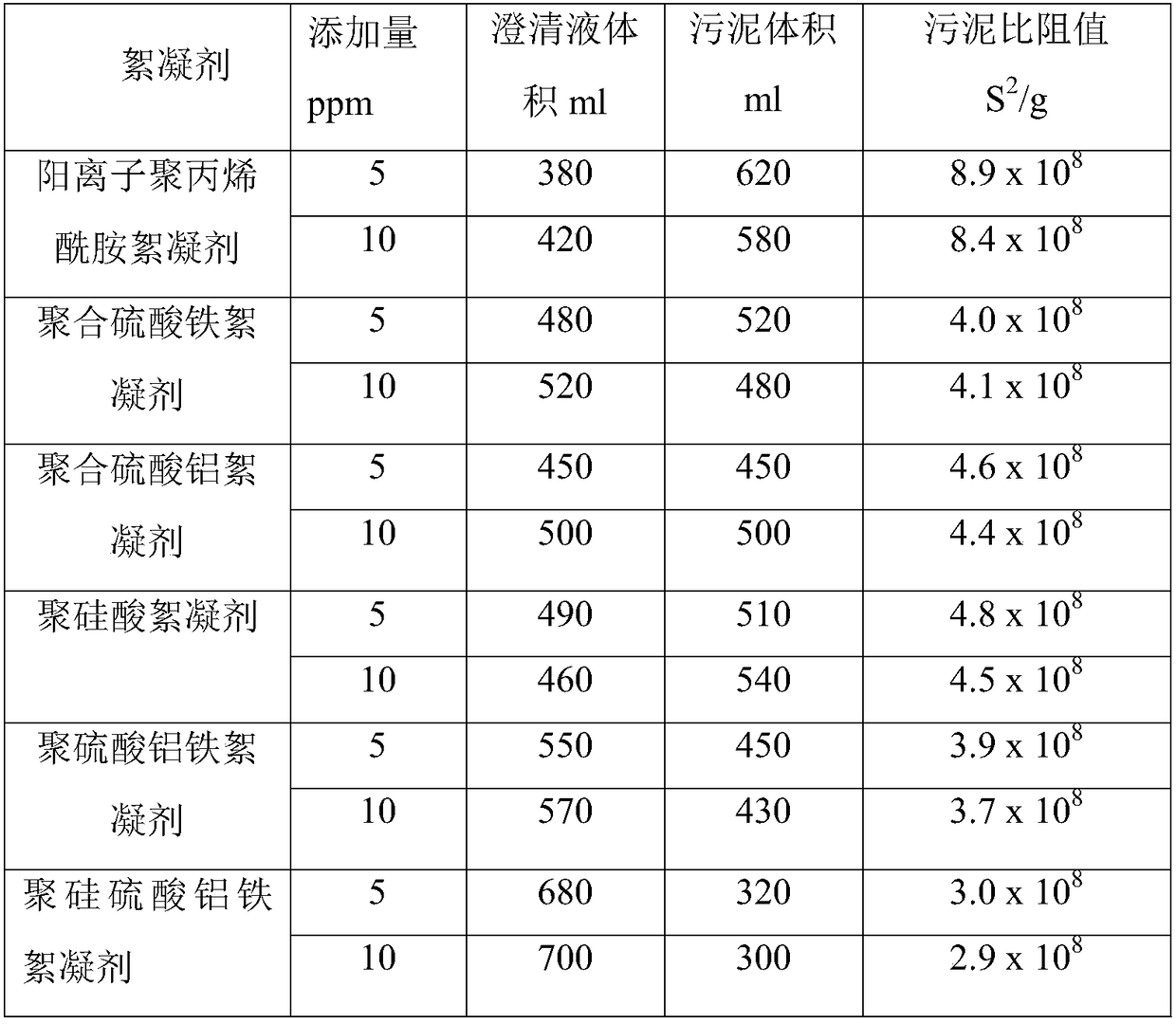

Composite flocculant and preparation method and application thereof

InactiveCN101734774AGood effectLow costWater/sewage treatment by flocculation/precipitationIron sulphateRare earth

The invention discloses a composite flocculant and a preparation method and application thereof. The flocculant is prepared from rare-earth carbonate, sodium silicate and ferric sulfate / aluminum sulfate serving as raw materials by a composite copolymerization method. The effect of the composite flocculant of the invention is superior to that of the conventional polymeric ferric / aluminum silicate sulfate; the chroma removal rate of wastewater reaches over 90 percent; the COD Cr removal rate reaches over 65 percent; the removal rate of total phosphorus reaches over 88 percent; and the expense of a wastewater treatment medicament is reduced by 10 to 20 percent compared with PASS. The composite flocculant has rapid, large and solid alumen ustum, reduces the use amount of a single dye wastewater coagulating agent by over one half compared with PAC and by over 20 percent compared with PASS, improves the chroma removal rate of the wastewater by about 10 percent, has low processing cost, and improves the processing effect.

Owner:GUANGDONG UNIV OF TECH

Method for preparing food hygiene-level active carbon by use of bagasse

ActiveCN103803547ASolve the reuse problemHigh dry matter contentCarbon compoundsActive agentBiological waste

The invention relates to an active carbon material, and particularly relates to a method for preparing food hygiene-level active carbon by use of biological waste resource bagasse. The method comprises the steps of collecting and cleaning the residual bagasse after sugar production; sufficiently fermenting at 10-50 DEG C, drying, grinding and sieving; then performing the operation treatment such as soaking in an active agent solution, charring, activation and the like on the pretreated bagasse; washing, drying and grinding to obtain a high-performance active carbon product which can be applied to decoloration, refining and impurity removal of the sugar industry and the fields of foods and medicines such as medicinal crude drugs and the like. According to the method provided by the invention, by adopting the waste bagasse as a raw material, the comprehensive utilization of resources and environmental protection are facilitated; moreover, the price is low, the product quality is high, and the economic and social benefits are good.

Owner:JIANGSU ZHUHAI ACTIVATED CARBON CO LTD

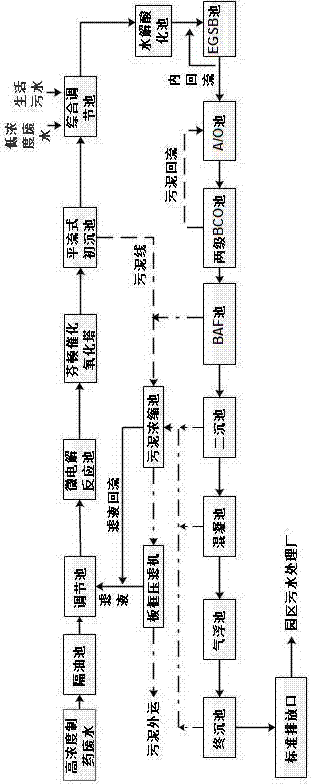

Pharmaceutical wastewater technology using microelectrolysis-Feton-EGSB (expanded granulate sludge bed)-A/O (anaerobic/aerobic)-BCO (biological contact oxidizing)-BAF (biological aeration filtering)-coagulation treatment

InactiveCN106927628AImprove B/C valueEfficient removalWater treatment compoundsSpecific water treatment objectivesHigh concentrationSludge

The invention relates to a pharmaceutical wastewater technology using microelectrolysis-Feton-EGSB (expanded granulate sludge bed)-A / O (anaerobic / aerobic)-BCO (biological contact oxidization)-BAF (biological aeration filtration)-coagulation treatment. High-concentration pharmaceutical wastewater is sequentially sent into an oil separation tank, a conditioning tank, a microelectrolysis reaction tank, a Feton catalytic oxidation tower, a horizontal flow type primary settling tank, a comprehensive conditioning tank, a hydrolysis acidifying tank, the EGSB, an A / O tank, a two-stage BCO tank, a secondary settling tank, a BAF tank, a coagulation tank, an air floating tank and a final settling tank to be treated, and then is drained after the standard is reached. The technology has the advantages that the technique is matured, the treatment effect is stable, and the anti-impact ability is strong; after the pharmaceutical wastewater is treated by the combined technology, the quality of drained water can reach the class-one standard of Comprehensive Drainage Standard of Wastewater (GB8978-1996).

Owner:NANCHANG UNIV

Composite flocculating agent for printing and dyeing waste water treatment

InactiveCN1654348AImprove decolorization efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSludge

The composite flocculant for treating printing and dyeing effluent consists of natural high molecular water soluble chitosan and polyaluminium chloride. The usage of the composite flocculant in treating printing and dyeing effluent includes regulating effluent to pH 6-8, and throwing composite flocculant in the amount of chitosan in 1-2 ppm and polyaluminium chloride in 100-250 ppm to result in printing and dyeing effluent decolorizing rate up to 91 %. The composite flocculant of the present invention has simple compounding process, easy use, low cost, small thrown amount, excellent decolorizing performance, fast deposition, small sludge amount, easy biodegradation, less secondary pollution of water and thus wide application foreground.

Owner:SHANGHAI NORMAL UNIVERSITY

A method using white-rot fungus and carrier to process persistent wastewater

InactiveCN101549936ALow costWide range of vector sourcesImmobilised enzymesBio-organic fraction processingCelluloseNatural product

The invention is a method using white-rot fungus and carrier to process persistent wastewater which belongs to the field of water treatment technology. It first uses the carrier to absorb COD in wastewater, then uses the carrier to provide cellulose stimulating substrate to the white-rot fungus for its enzyme production, processes the persistent substance adsorbed on the carrier, selects different natural products as the core materials of the carrier, and produces the carrier coat after NaOH treatment. When handling the waste water, it adjusts the initial wastewater pH, adds the carrier and white-rot fungi, and takes the water sample into the conical flask; places the sample in the shaking table with the temperature of 35-60 DEG C and shaking speed of 170rpm for processing. The treatment process of the invention only needs to adjust the initial pH, has no operation during the middle process and does not need re-adjustment for subsequent treatment; the carrier used with a wide variety of sources can be treated directly as the fertilizer together with the bacteria after use, and has no secondary pollution; it has apparent decolorization effect after processing with the decolorization rate of above 90%.

Owner:TSINGHUA UNIV +1

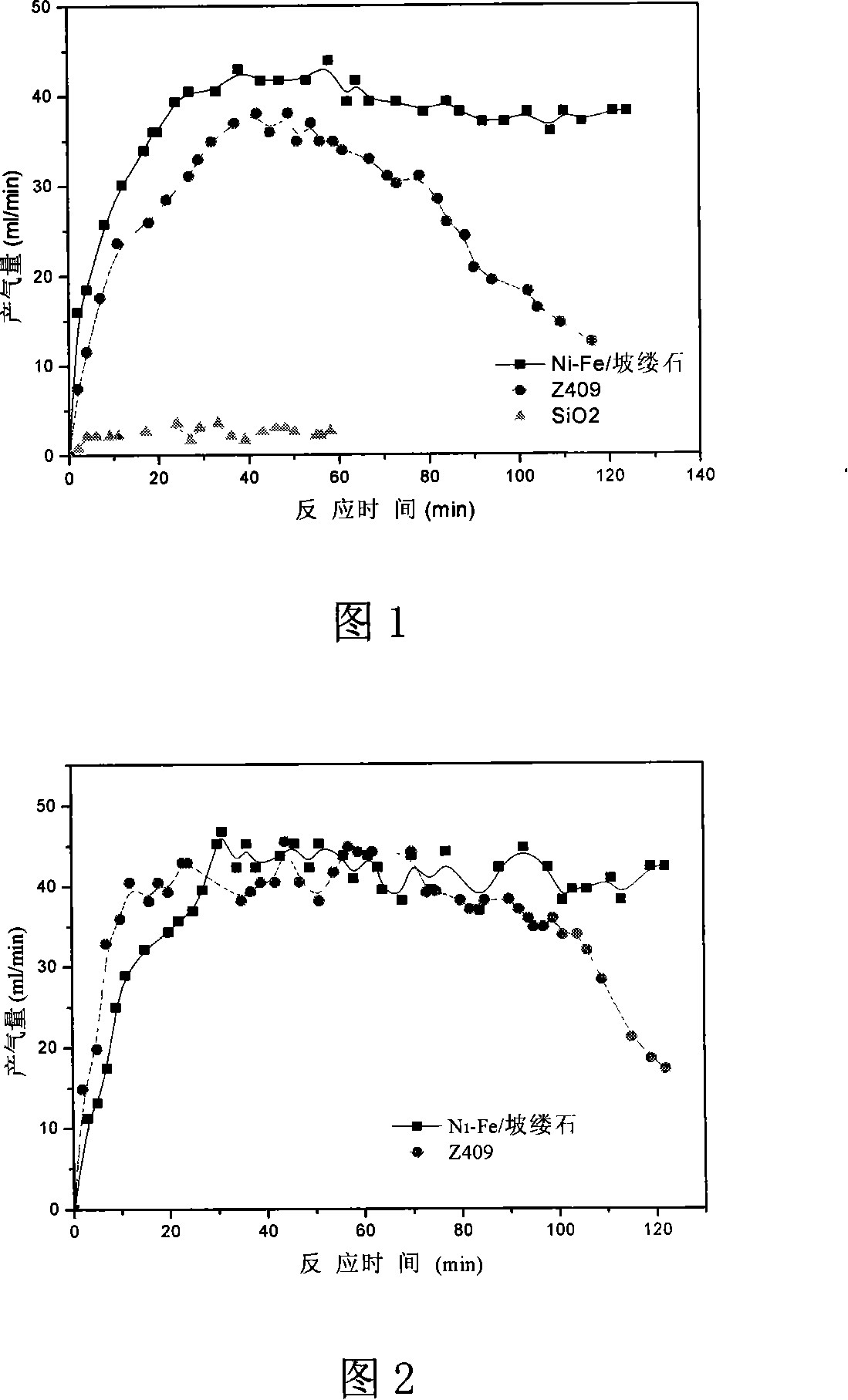

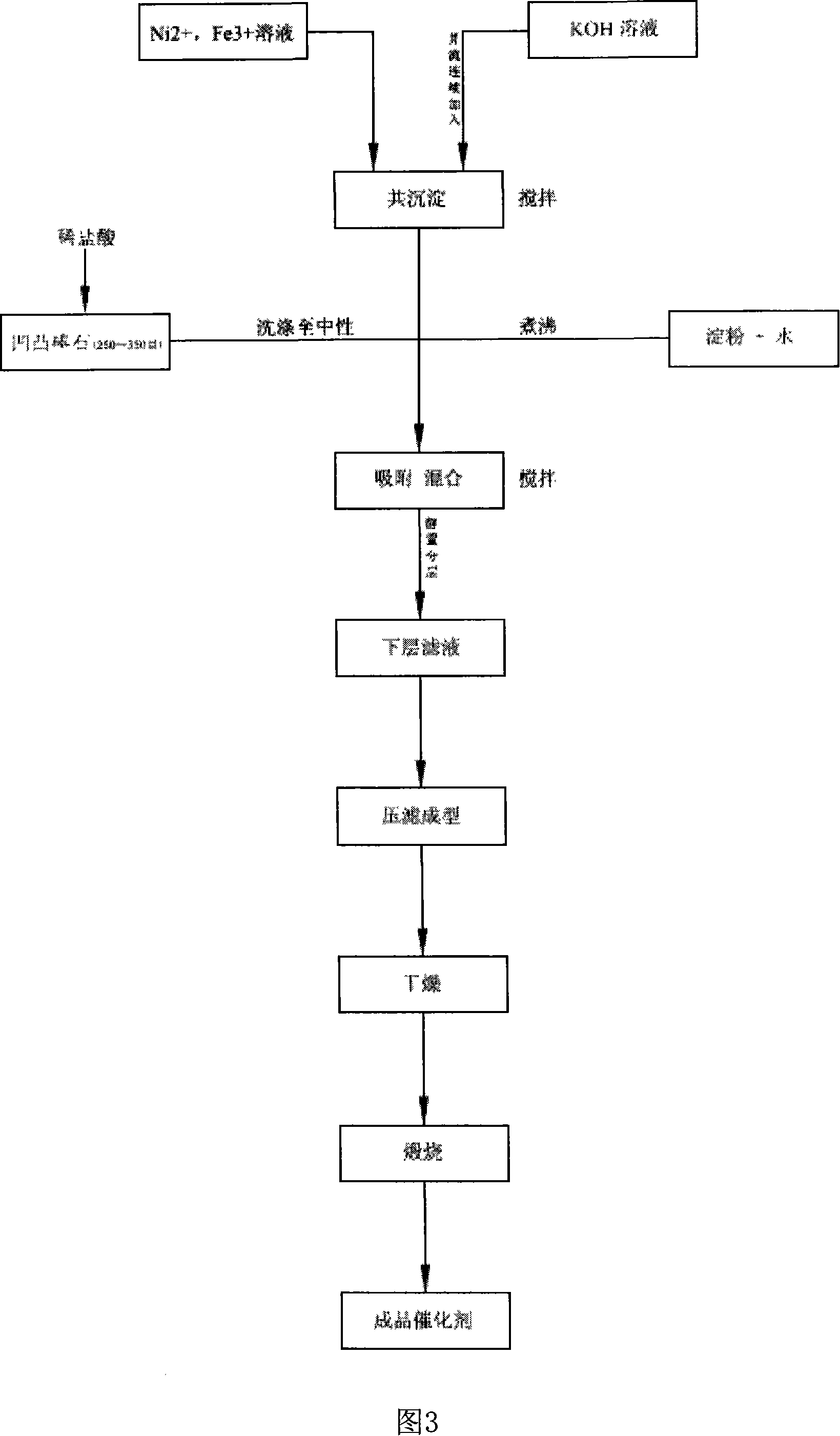

Palygorskite load nickel base biomass tar oil recapitalization hydrogen manufacturing catalyzer and preparation method thereof

InactiveCN101172232AHigh strengthWide variety of sourcesHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingAlkane

The invention discloses nickel-based catalyst taking a palygorskite as the carrier and a preparation method thereof, according to the weight percentage, the content of nickel oxide is 1 to 4 percent, ferric oxide is 5 to 20 percent, and potassium oxide is 1 to 10 percent. The nickel and the iron are supported onto the surface of the palygorskite in a way of coprecipitate adsorbing, and the catalyst is filtered, shaped, dried and calcined to obtain the finished catalyst. Under the operation condition of atmospheric pressure and 480 to 650 DEG C reaction temperature, in a fixed bed reactor, the gas production and the lytic rate of the pyrolytic tar are greatly improved, compared with the catalyst used for converting the commercial light oil vapour for hydrogen production, the prepared catalyst has the advantages of low cost, good low-temperature activity, easiness of restoration and strong anti-carbon deposition capability. The invention can be widely suitable for the hydrogen production from steam reforming of various types of paraffin in the chemical field and the chemical industry field.

Owner:DALIAN UNIV OF TECH

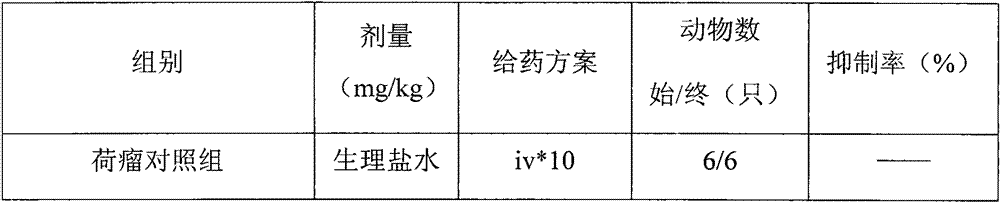

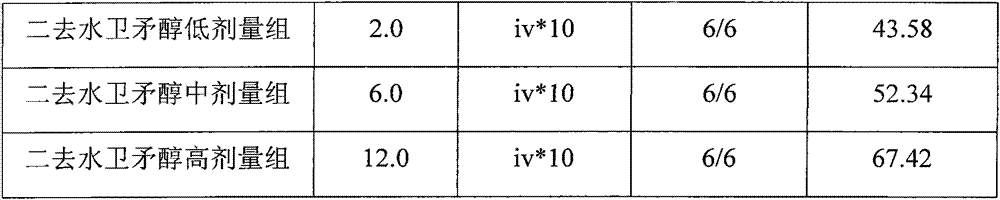

Method for preparing dianhydrogalactitol

InactiveCN103923039ASpeed up filteringGood decolorizationOrganic chemistryAntineoplastic agentsIon exchangeXylose

The invention discloses a method for preparing dianhydrogalactitol. The method comprises the following steps: diluting by a xylose mother liquor, carrying out decoloring filtration, carrying out ion exchange, and carrying out chromatographic separation to obtain a xylose and glucose mixed liquor and a galactose and arabinose mixed liquor; carrying out evaporative concentration on the galactose and arabinose mixed liquor, carrying out catalytic hydrogenation, carrying out decoloring filtration, carrying out ion exchange, and evaporating to supersaturation in order to obtain crystallized dulcitol; and reacting dulcitol with hydrobromic acid to prepare 1,6-bromodulcitol; and dissolving 1,6-bromodulcitol in t-butyl alcohol of potash, and carrying out an elimination reaction to prepare dianhydrogalactitol. The xylose mother liquor can be prepared by hydrolyzing one or more of corncobs, bagasse, sugarcane pith, cottonseed hulls and rice hulls. Highly pure dianhydrogalactitol can be produced through the method.

Owner:天津中津药业股份有限公司

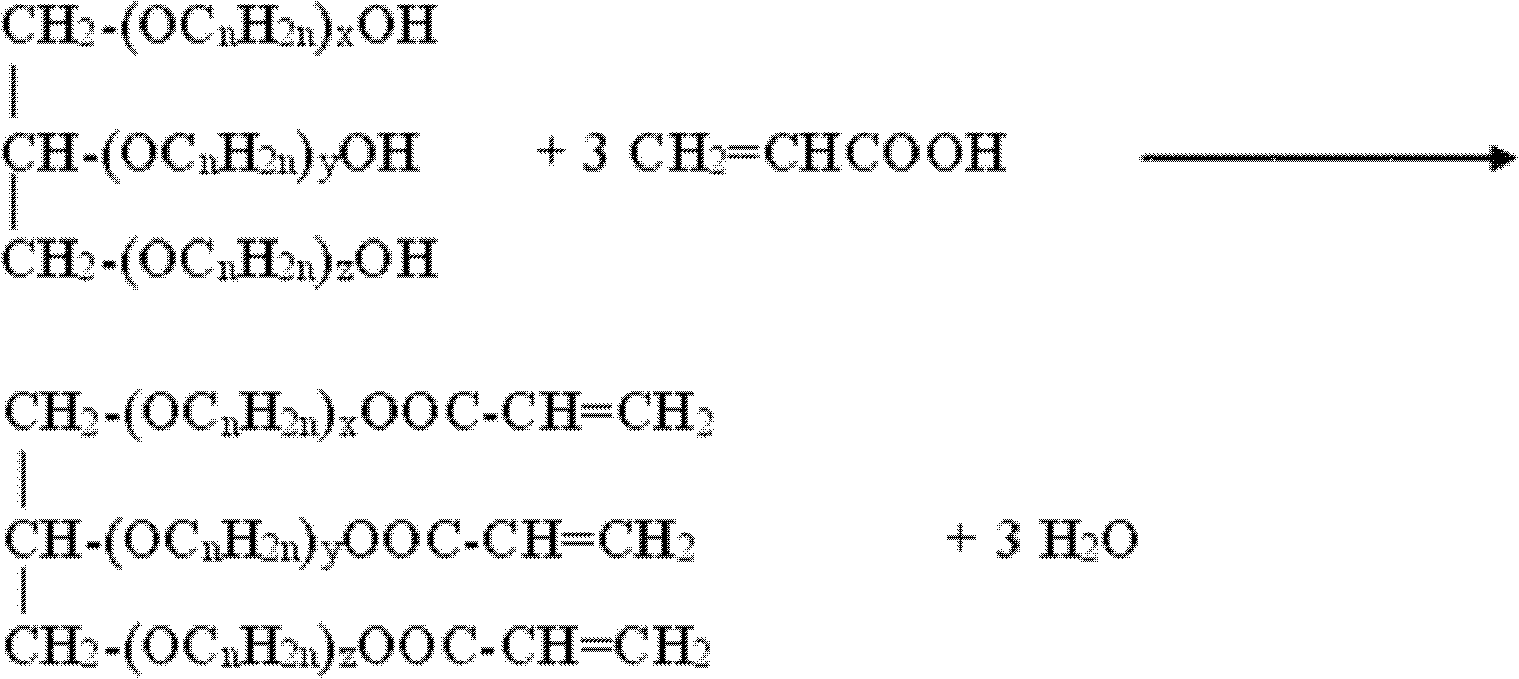

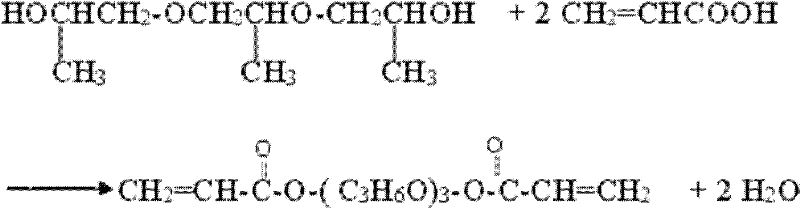

Clean production method of alkoxylation glycerol triacrylate

ActiveCN102503821ANo emissionsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSodium BentoniteAntioxidant

The invention belongs to the field of photocuring materials and relates to a clean production method of alkoxylation glycerol triacrylate. The method comprises the following steps that: (1) ethoxylation glycerol / propoxylation glycerol, acrylic acid, catalysts, solvents, polymerization inhibitors and antioxidants are subjected to esterification backflow dehydration; (2) soda flakes and a small quantity of water are added for neutralization; (3) magnesium polysilicate absorbing agents are added for absorbing salt generated during the neutralization; (4) the pressure reduction dehydration is carried out, and solvents are removed; (5) press filtering is carried out, and the magnesium polysilicate and the salt absorbed by the magnesium polysilicate are filtered away; (6) alkaline calcium bentonite and calcium bentonite are added, and decoloration, trace moisture removal and trace acid removal are carried out; (7) press filtering is carried out; and (8) product index detection is carried out. The method belongs to the high-yield clean production method of the ethoxylation glycerol triacrylate and propoxylation glycerol triacrylate and has the advantages that economic benefits and environment benefits are realized, and the problem of organic waste water pollution in the production process of the ethoxylation glycerol triacrylate and the propoxylation glycerol triacrylate is fundamentally solved.

Owner:JIANGSU LITIAN TECH

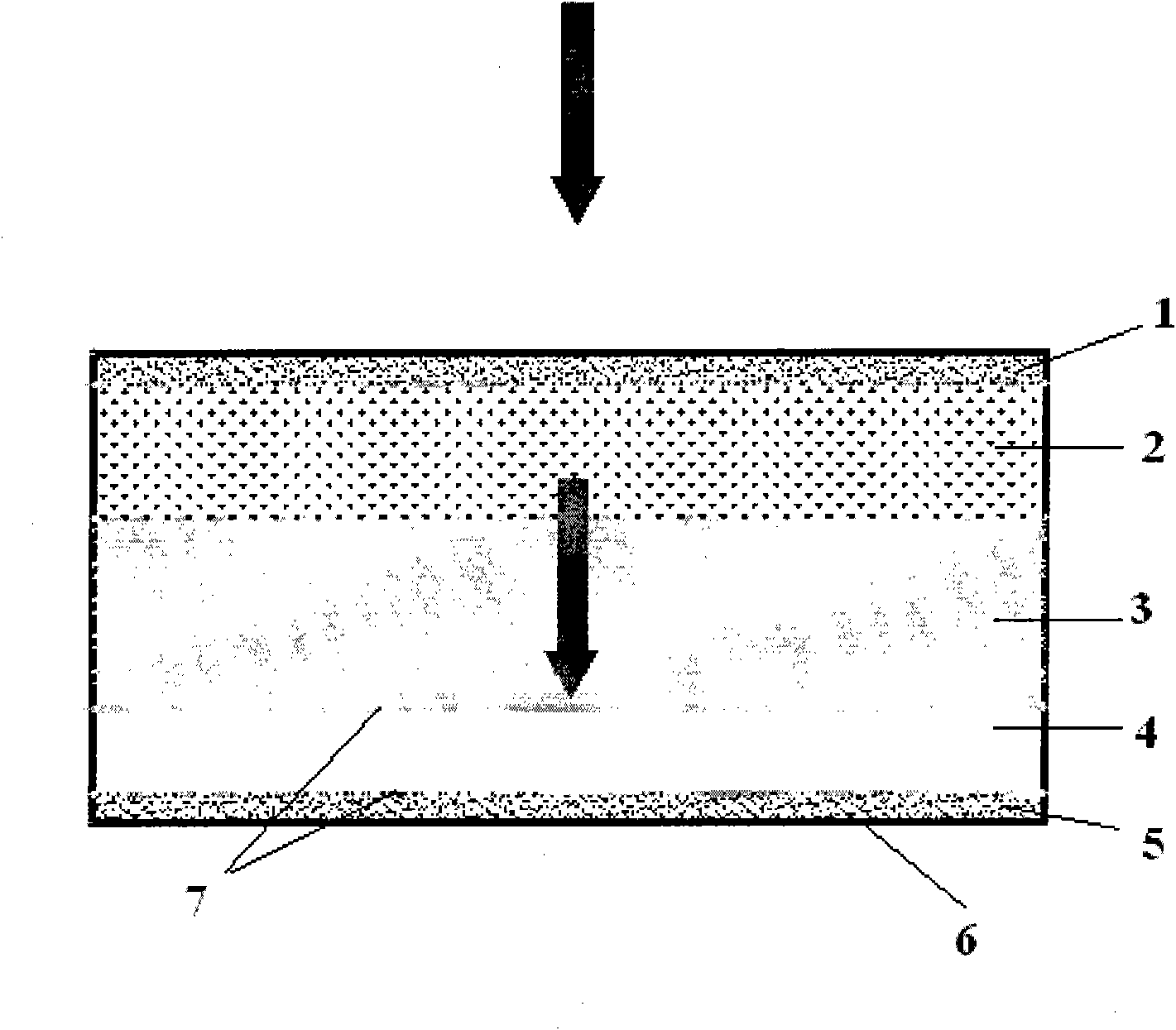

Composite permeable reactive barrier and in-situ treatment method thereof

InactiveCN102070262AGood decolorizationReduce pollutionMultistage water/sewage treatmentChemical reactionLoad resistance

The invention discloses an irregular landfill site leachate composite permeable reactive barrier and an in-situ treatment method thereof in the technical field of domestic garbage treatment of environmental protection. Active iron powder material, zeolite and active carbon are added into a barrier body; and when the leachate flows through the barrier body under the action of personal hydraulic gradient, the leachate and the barrier body fully undergo physical and chemical reaction, then most organic pollutants, ammonia nitrogen, heavy metals and colored substances in the leachate are removed, and the treated leachate is discharged after reaching the standards. The method is simple in construction, flexible in arrangement, low in running and maintenance expense and strong in impact load resistance, is economic and energy-saving, and has high practical value.

Owner:TSINGHUA UNIV

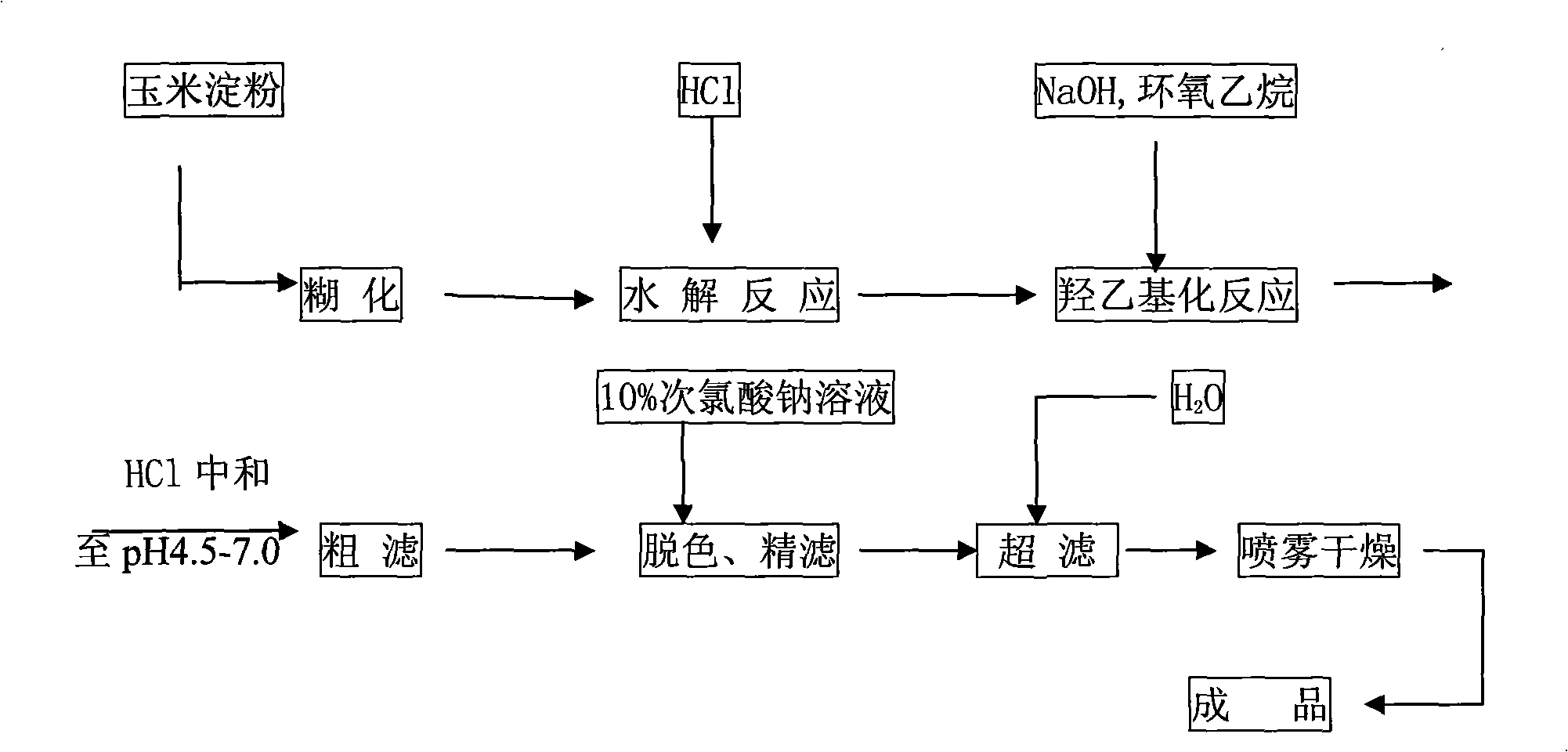

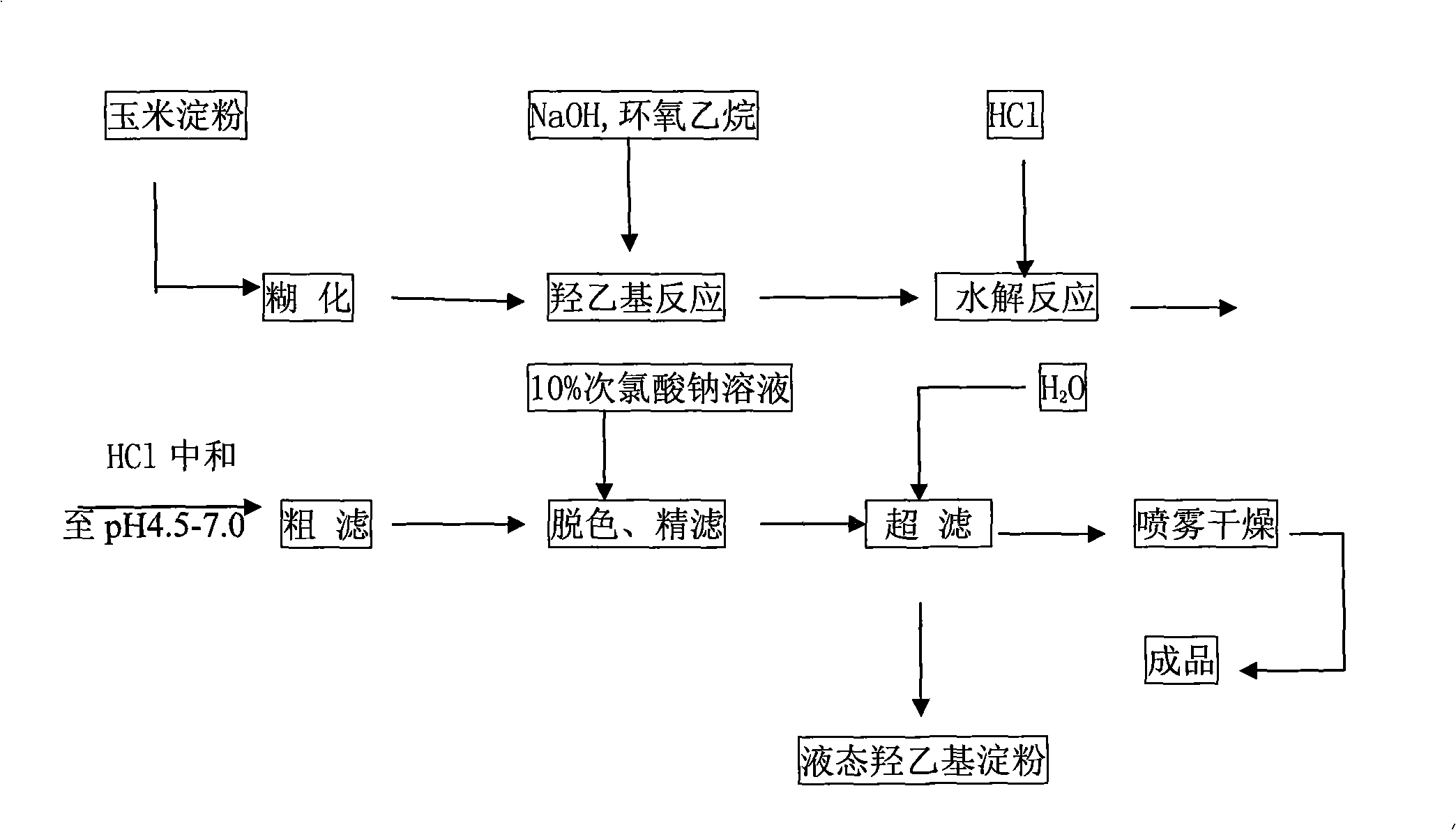

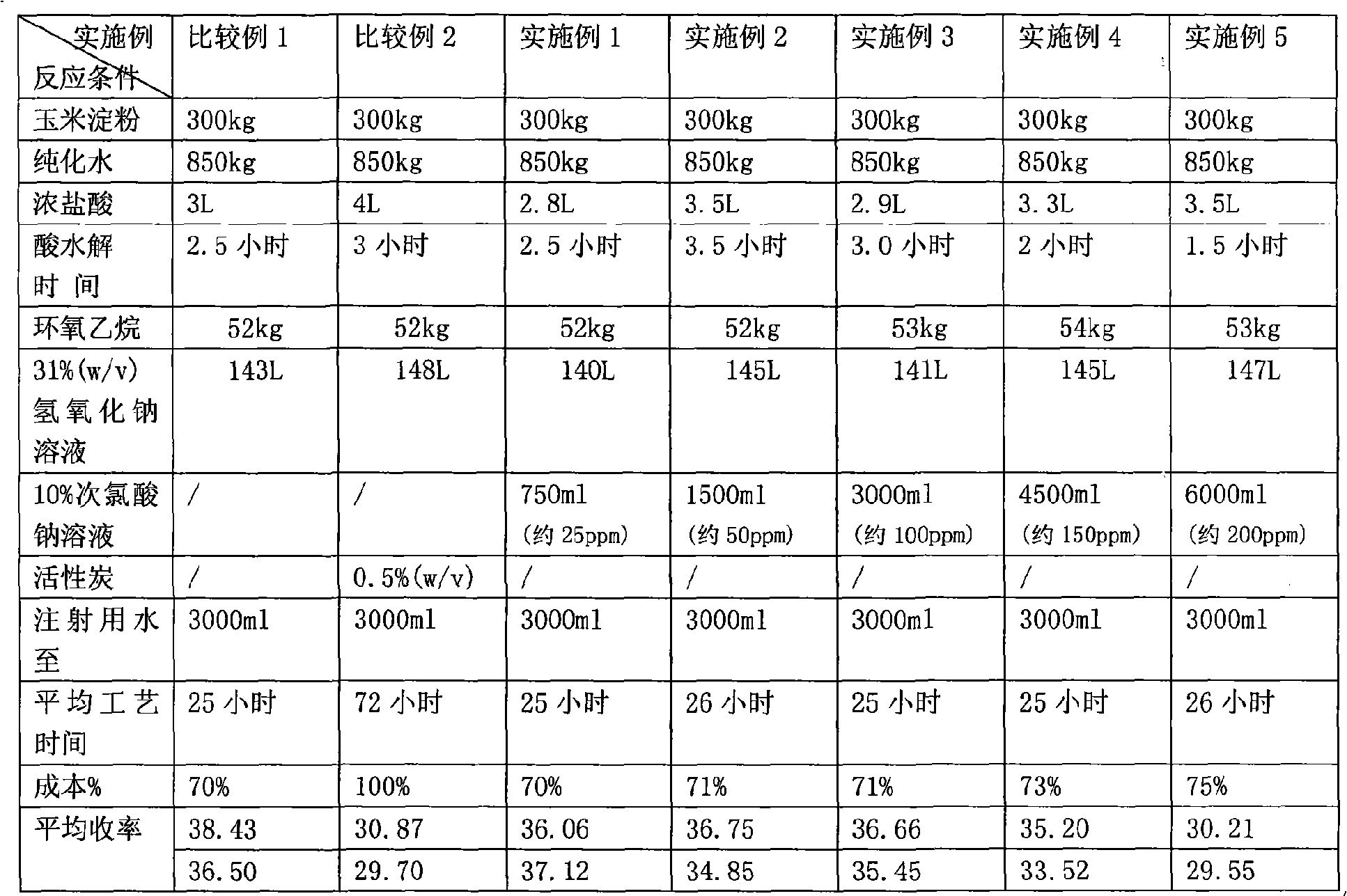

Method for preparation of hydroxyethyl starch

The invention provides a new technology for preparing raw materials of hydroxyethyl starch, which uses 50PPM to 200PPM sodium hypochlorite for decolorization and sterilization and substitutes the traditional technology using active carbon for decolorization, thus improving the production efficiency and the quality of the hydroxyethyl starch. The new technology overcomes such defects of the traditional technology using active carbon for decolorization as viscous material liquid, poor fluidity, long filtration time of material liquid, easy growth of bacteria in the material liquid, easy leakage of the active carbon from a filter and the like, thus not only greatly shortening the filtration time, but also guaranteeing the produced raw materials of hydroxyethyl starch to have stable batch and reliable quality and to meet the national standard.

Owner:赤峰迪生药业有限责任公司

Process for separating and purifying gamma-aminobutyric acid

ActiveCN101928736AGood decolorizationHigh purityOrganic compound preparationAmino-carboxyl compound preparationGamma-Aminobutyric acidImpurity

The invention discloses a process for separating and purifying a gamma-aminobutyric acid, which aims to effectively solve the problems of complex separation and purification steps and high industrial cost which are caused by complex components of fermentation liquor in the biological preparation of the gamma-aminobutyric acid. In the process, impurities in conversion liquor are reduced by adopting a bioconversion method to simplify a separation process, and the conversion liquor is simply decolored to obtain the gamma-aminobutyric acid with high purity and recovery rate. The process has the advantages of simple method and high recovery rate of products, and is suitable for large-scale industrial production.

Owner:JIANGNAN UNIV

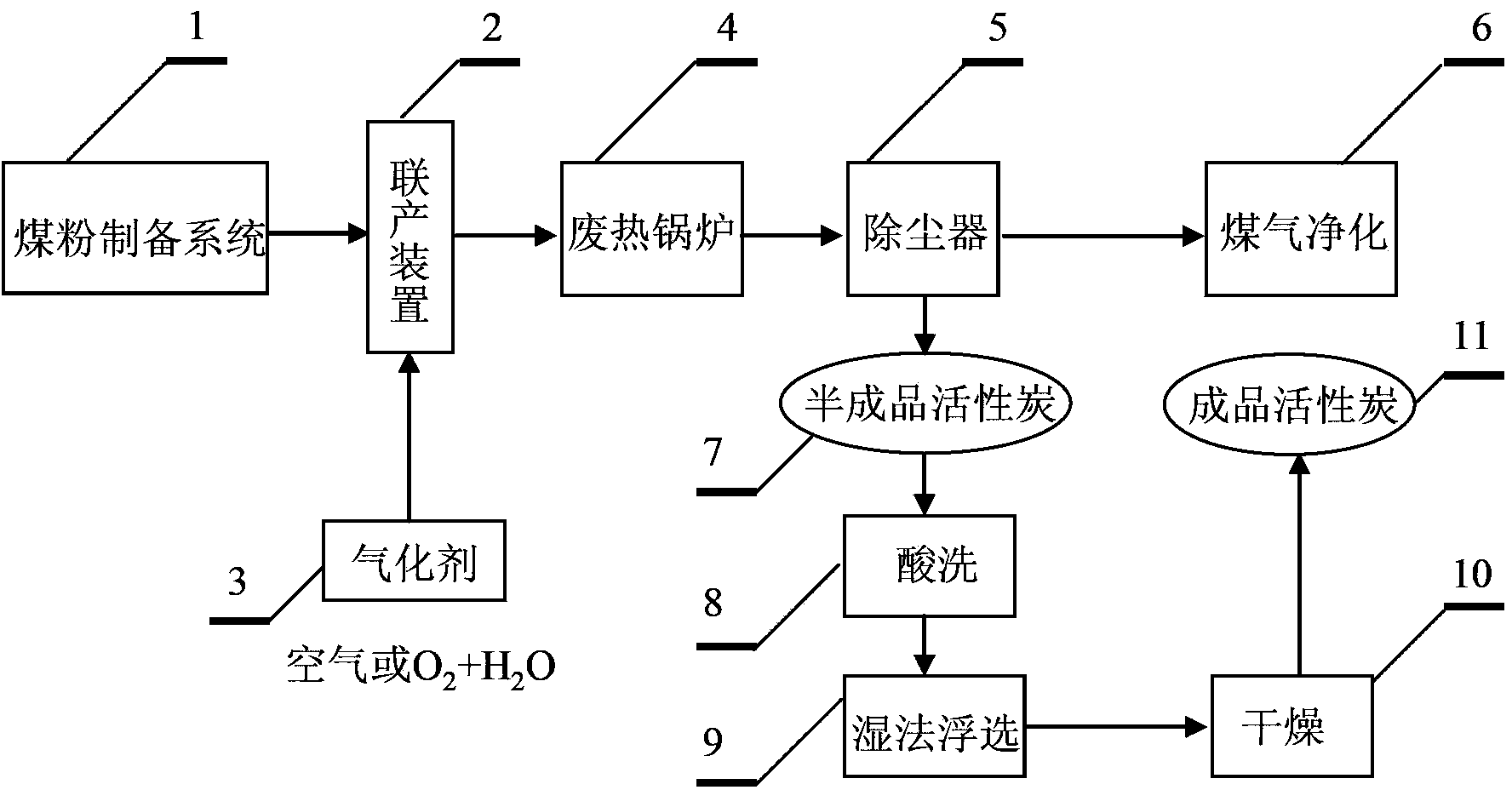

Method for coal gasification and quick co-production of activated carbon

InactiveCN103409168AReduce production energy consumptionImprove production efficiency and production scaleCarbon compoundsEnergy inputActivated carbonWork in process

A method for the coal gasification and the quick co-production of activated carbon belongs to the field of chemistry and chemical engineering, and is characterized in that dry coal powder or carbonous organic substances are taken as raw materials, air or the mixture of oxygen and water vapour is taken as a gasifying agent, the ratio of oxygen to coal is adjusted within the range from 0.3 to 0.58 Nm<3> / kg, the ratio of vapor to coal is adjusted within the range from 0.01 to 0.5 kg / kg, a co-production device is operated under the condition that the gasification reaction temperature is 1200-1400 DEG C and the operating pressure is 0.1-4.0 Mpa, and 75-90% of organic compositions in the dry coal powder or the carbonous organic substances can be converted into coal gas; the high-temperature coal gas from the co-production device is subjected to temperature reduction by a waste heat boiler and gas-solid separation by a dust remover, so as to obtain semi-finished activated carbon; finally, the semi-finished activated carbon is subjected to acid pickling, wet floatation and drying, so as to obtain the co-production activated carbon. According to the invention, the activated carbon product obtained by adopting the method has an advanced mesopore structure and excellent liquid phase adsorption and decoloration performance, the adsorbing and purifying effects to organic substances in water are superior to those of high-priced activated carbon products prepared by adopting certain traditional methods, no pollution is generated in the production, and the efficiency is high, so that the method is environment-friendly, and can be used for producing activated carbon in a clean manner.

Owner:DALIAN UNIV OF TECH

Rosa roxburghii polysaccharide, as well as preparation method and application thereof

The invention discloses a rosa roxburghii polysaccharide, as well as a preparation method and application thereof. The preparation method mainly comprises raw material pretreatment, extraction, deproteinization, de-coloration, alcohol precipitation, as well as separation and purification, wherein the extraction is to mix pretreated rosa roxburghii dry powder and water in a mass volume ratio of (1to 15) to (1 to 35), and perform extraction at a temperature of 55 to 95 DEG C; perform centrifugal separation to obtain a rosa roxburghii polysaccharide extracting solution, and concentrate the rosaroxburghii polysaccharide extracting solution under reduced pressure to 1 / 3 to 1 / 6 of the original volume to obtain a concentrated solution of the rosa roxburghii polysaccharide. The rosa roxburghii polysaccharide prepared by the invention has the advantages of high purity and uniform molecular weight. Compared with the existing rosa roxburghii polysaccharide, as proved by in-vitro fermentation experiments, the rosa roxburghii polysaccharide disclosed by the invention can promote the generation of short-chain fatty acids such as acetic acid, propionic acid and butyric acid, promote the growthof beneficial bacteria such as lactic acid bacteria and bifidobacterium, and can be taken as prebiotics. Meanwhile, the rosa roxburghii polysaccharide can inhibit the activity of alpha-glucosidase, and can be applied to healthy foods or medicines having auxiliary therapy effects on intestinal diseases and diabetes mellitus.

Owner:SOUTH CHINA UNIV OF TECH

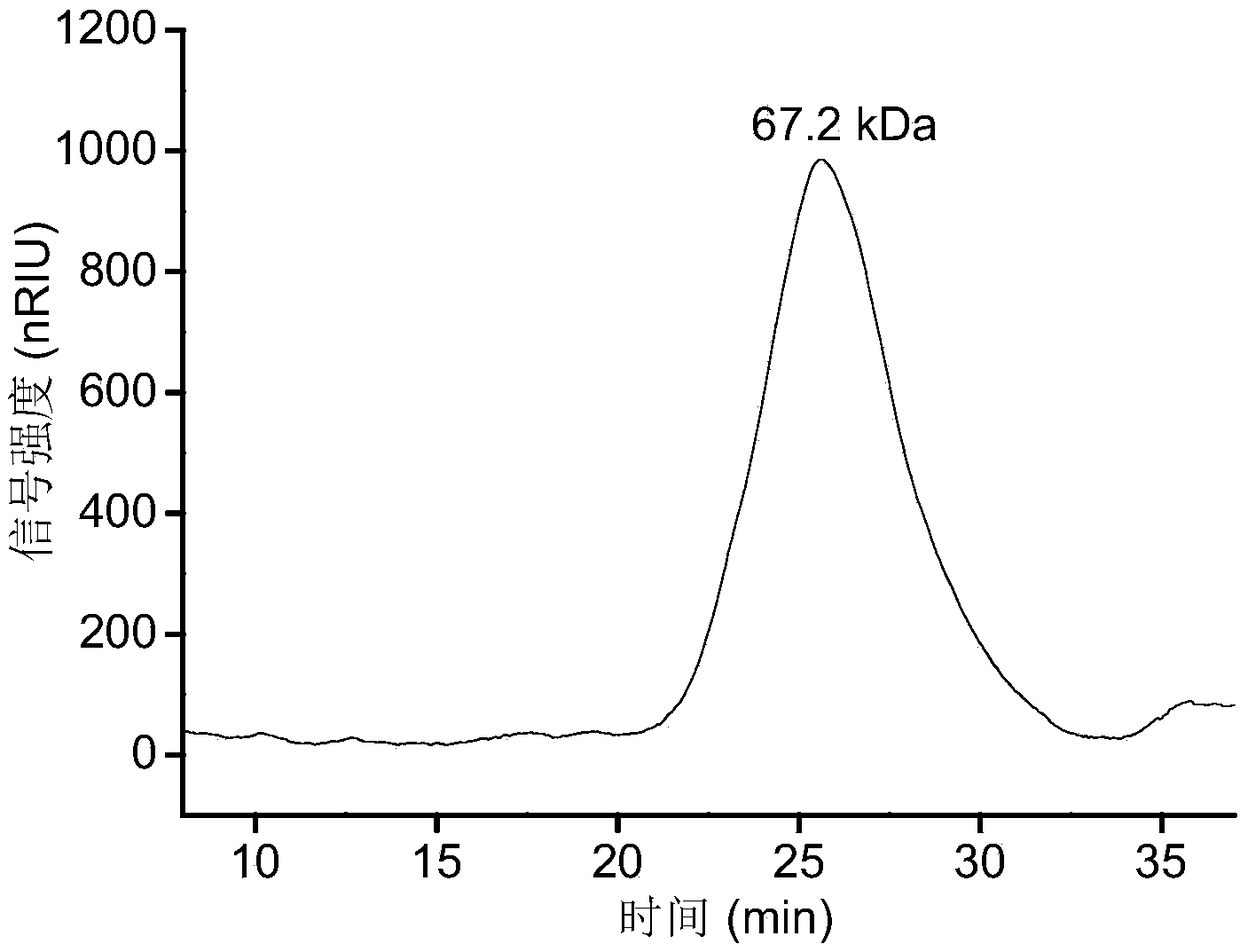

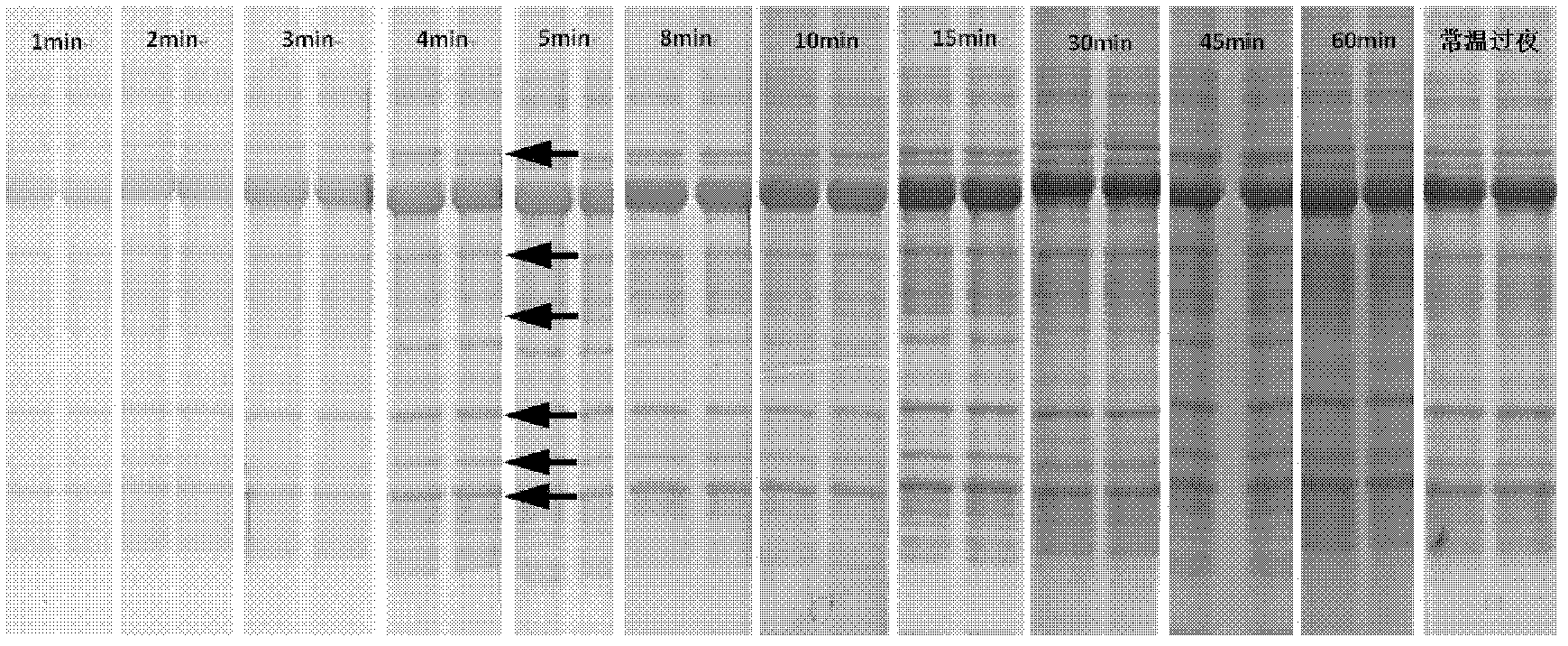

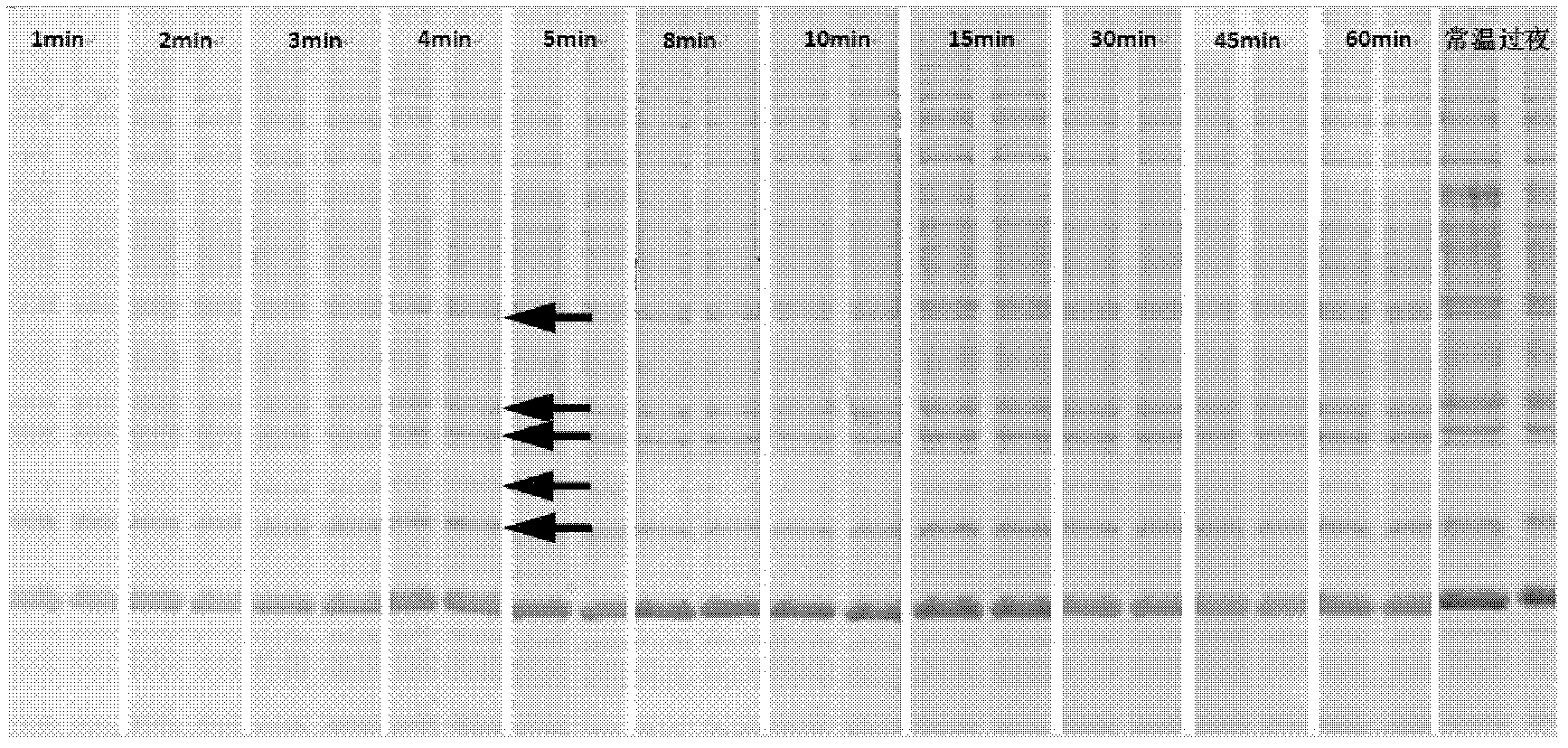

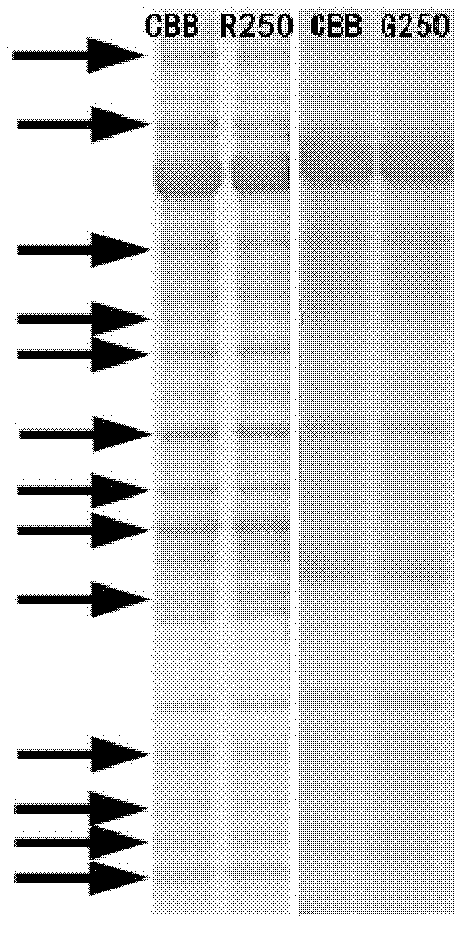

SDS-PAGE (sodium dodecyl sulfate polyacrylamide gel electrophoresis) coomassie brilliant blue R250 fast staining solution, staining method and application

InactiveCN102607920AUniform backgroundEasy to decolorizePreparing sample for investigationMaterial analysis by electric/magnetic meansAmmonium sulfateChemistry

The invention discloses SDS-PAGE (sodium dodecyl sulfate polyacrylamide gel electrophoresis) coomassie brilliant blue R250 fast staining solution, which includes from 20 to 40% of ethanol by volume percentage, from 5 to 10% of carbinol by volume percentage, from 0.5 to 1.25g / L of CBB (coomassie brilliant blue) R250 by mass concentration, from 2.5 to 5% of phosphoric acid by volume percentage and from 100 to 200g / L of ammonium sulfate by mass concentration. A fixing step and a sensitization step before staining are omitted, protein staining time can be shortened, and the possibility that protein samples are polluted is greatly reduced. The invention further discloses a method for staining SDS-PAGE gel by the aid of the staining solution and application of the staining solution in a protein two-dimensional gel electrophoresis and protein western blot qualitative diagnosis and / or quantification process.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

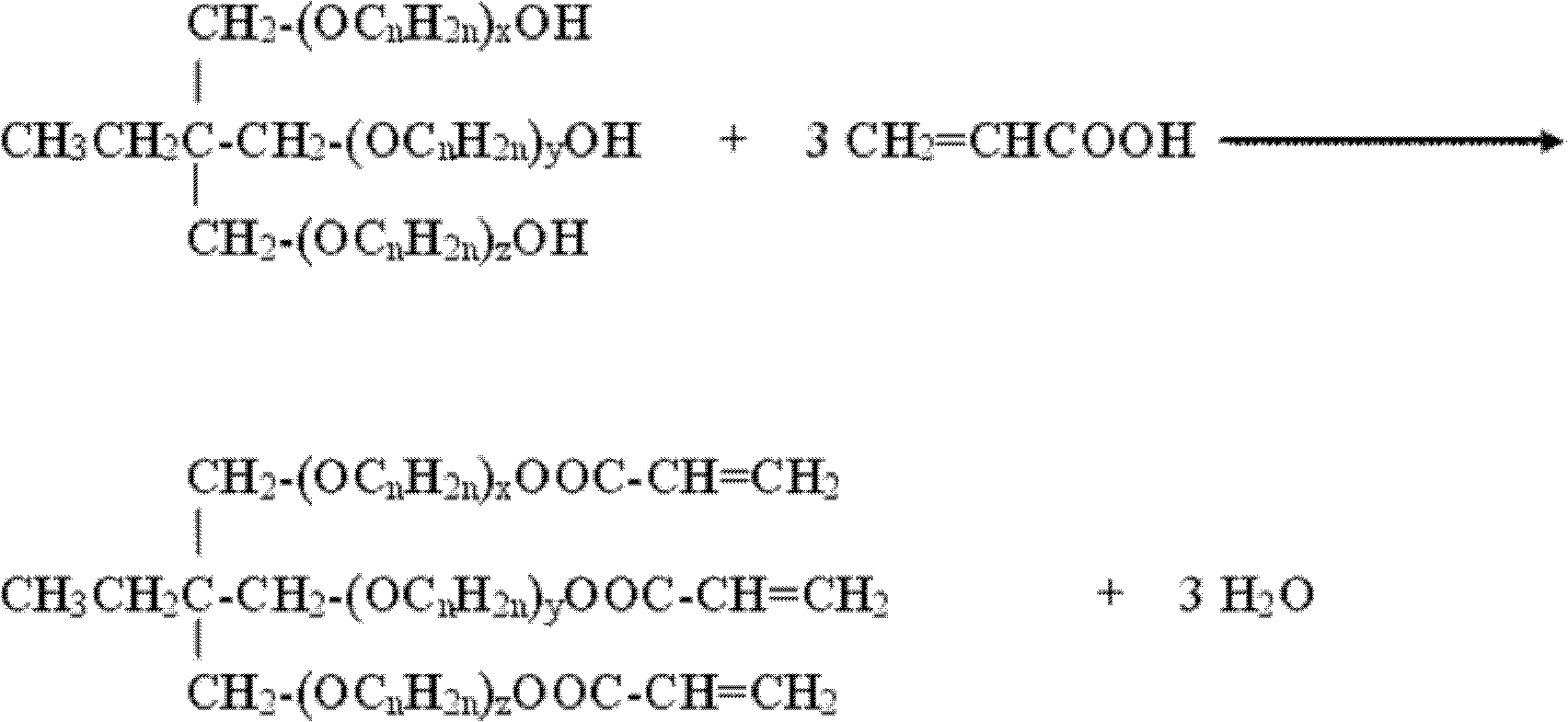

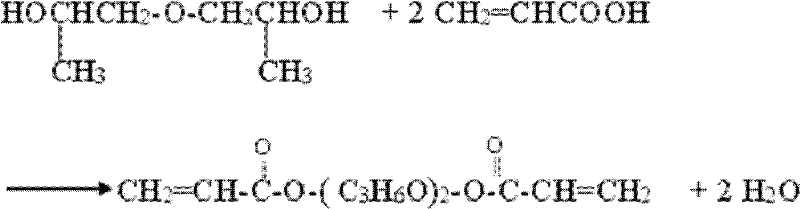

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolDipropylene glycol diacrylate

The invention which belongs to the light-cured material field relates to a clean production method of DPGDA or TPGDA. The method concretely comprises the following steps: 1, carrying out esterification reflux dehydration on dipropylene glycol / tripropylene glycol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; 2, adding sodium hydroxide and a small amount of water to neutralize; 3, adding a magnesium polysilicate adsorbent to adsorb a salt generated through neutralization; 4, carrying out reduced pressure dehydration and desolventization; 5, press-filtering to filter out magnesium polysilicate and the salt absorbed thereby; 6, adding alkaline calcium bentonit and calcium oxide to decolor, remove trace water and remove trace acids; 7, press-filtering; and 8, carrying out product index detection. The clean production method of the DPGDA or the TPGDA of the invention, which has the advantages of high yield, economic benefit possessing and environmental benefit possessing, fundamentally solves an organic wastewater pollution problem in the production process of the DPGDA or the TPGDA.

Owner:JIANGSU LITIAN TECH

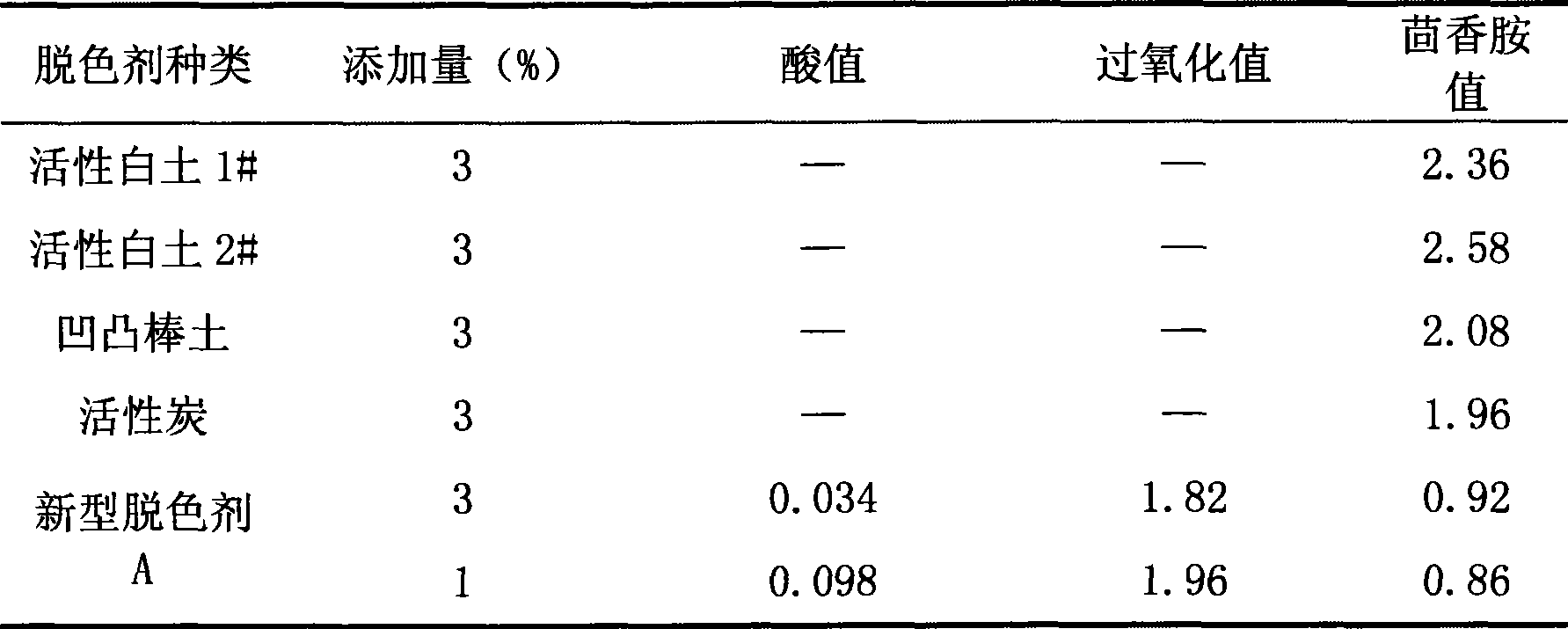

Decoloring agent for reducing anisidine value of soya-bean oil for injection and preparation method thereof

InactiveCN101497026AReduce the value of anisidineImprove hydrophobicityOther chemical processesFatty-oils/fats refiningM-AnisidineHusk

The invention discloses a decolorizer for reducing an anisidine value in soybean oil for injection and a method for preparing the same. According to the mass percentage, modified attapulgite is mixed with 2 to 3 percent of carbonized bean husk ash to prepare the decolorizer; and the method comprises the following steps: 1, purifying the attapulgite; 2, activating the attapulgite; 3, modifying the attapulgite; 4, preparing the carbonized bean husk ash; and 5, according to the mass ratio of 97-98:2-3, mixing the modified attapulgite with the carbonized bean husk ash in a stirring tank, and grinding the mixture by a pulverizer to obtain the decolorizer. The decolorizer prepared by the method has the advantages of quick decolorizing speed and good decolorizing effect.

Owner:江苏澳特邦非金属矿业有限公司

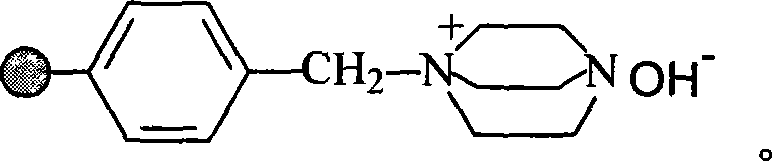

Method for producing epsilon-poly-L-lysine by reflux technique

This invention refer to a method that using backstreaming technology to produce epsilon -poly-L-diaminocaproic acid. It uses blanc Streptomyces that screened from soil to fermentepsilon -poly-L-diaminocaproic acid[resist to S-(2-aminoethyl)-L-cysteine(abbreviate AEC below), Glycine, sulfaguanidine],then make the penetrated liquid from later stage of extracted procession by periodic duty,to fermentepsilon -poly-L-diaminocaproic acid; the penetrated liquid from later stage of extracted procession can be used for next elution. Decolorize the broth by negion exchange resin. This invention has changed the procedure of producing technology.Not only raise the yield ofepsilon -poly-L-diaminocaproic acid, save cost, but also reduce exhaustion of ferment liquid waste and hydrochloric acid liquid waste in elution, lessen environmental pollution; The decolor effect is enhanced and the lose is reduced becouse of decoloring the broth by negion exchange resin.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

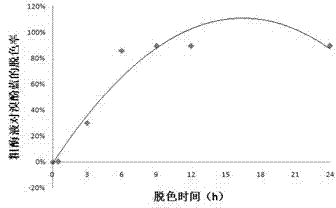

Method for preparing decoloring material of dyeing waste water by attapulgite ore

InactiveCN1843950AWith physical adsorptionExcellent chemical flocculation and decolorizationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionManganeseRoom temperature

The invention relates to method for preparing decolouring material for printing and dyeing wastewater, which employs concave-convex stick mineral as main raw material (80-100 mu), mixing with sulfuric acid of 1.5-3.0 mol / l, the ratio between solid and liquid is 1:2-3, activating under room temperature for 1-2 hours; adding 0-5% of metallic sulphate such as iron, manganese and alumium (weight by metallic oxide); neutralizing with basic solution of 3-6 mol / l to make pH be about 7-8; solid-liquid separating, granulating (3-5 mm), drying, calcining under 700 Deg. C for 0.5-2 hours, and getting product. The invention can get side product of Na2SO4 10H2O or (NH4)2SO4 from filtering liquor; the decoloring material can be reused for more than four times after being immersed with ammonia sulfate of 1.5-6.0 mol / l for 2-5 minutes and calcined under 300 Deg.C for 5-25 minutes; the decoloration rate is over 94%, and decoloration rate with reused decoloraing material is over 91%. The invention is characterized by simple producing process, low cost and no pollution.

Owner:SICHUAN UNIV

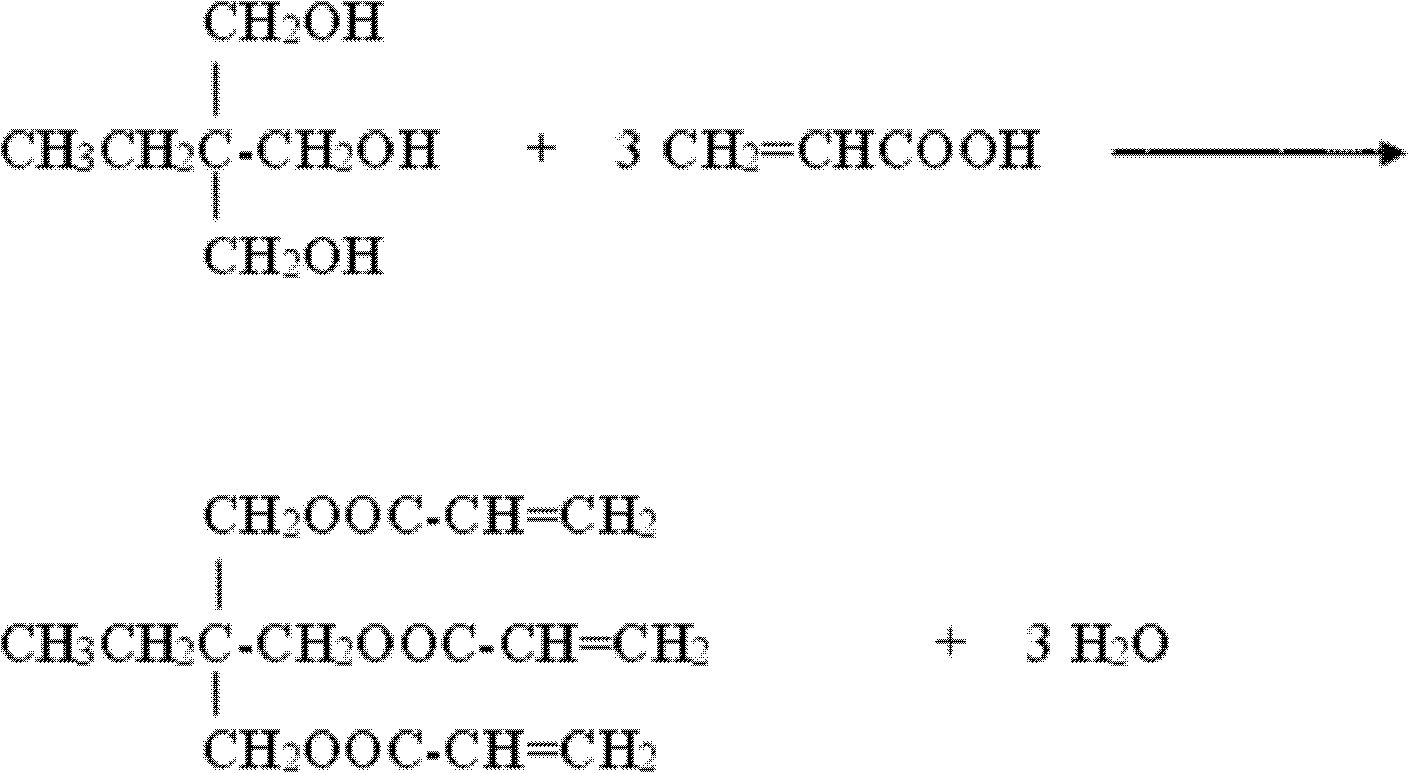

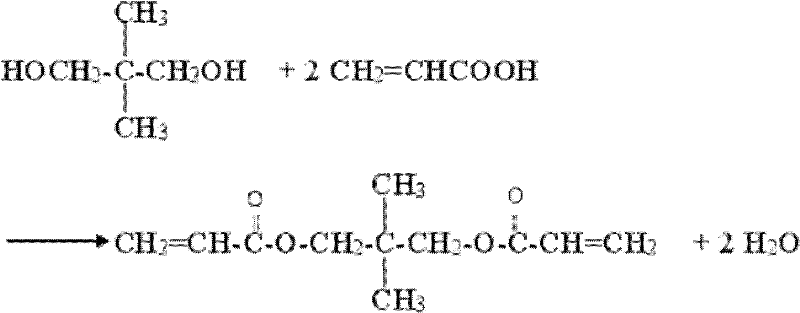

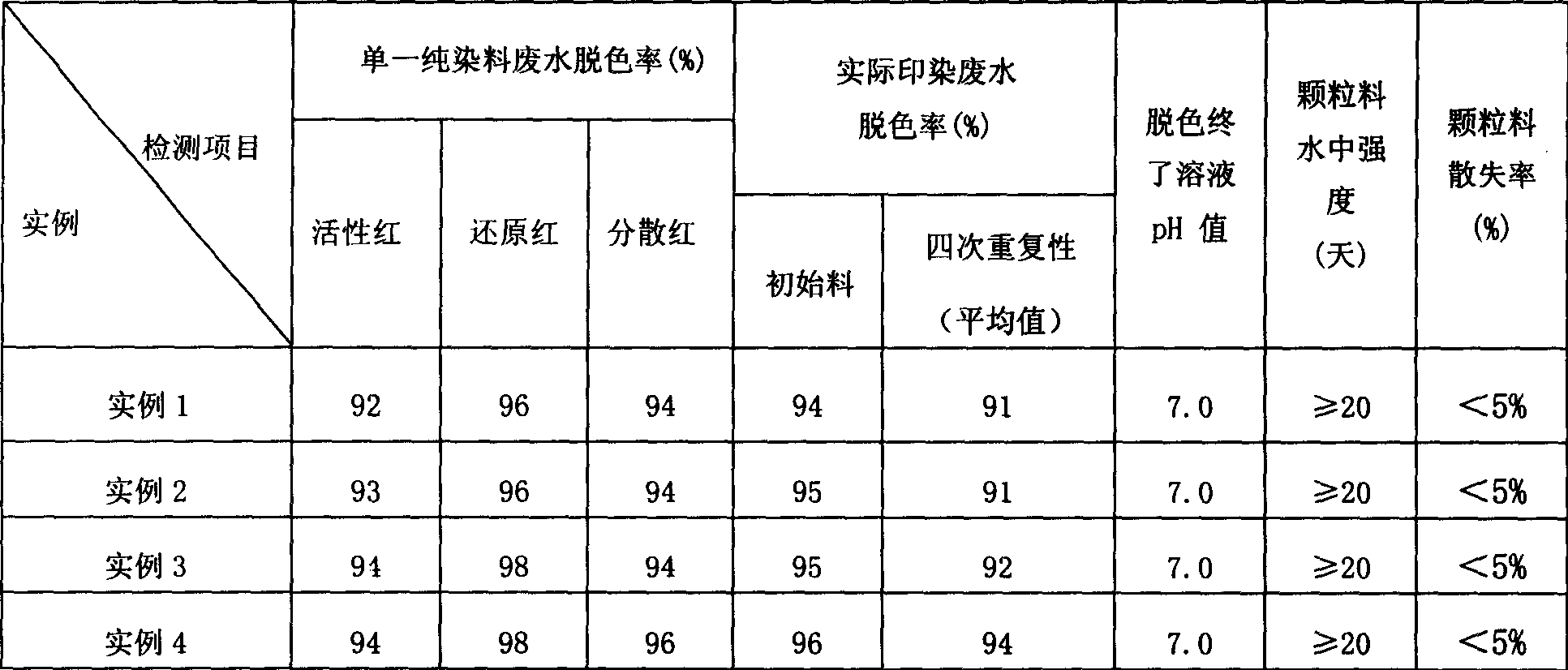

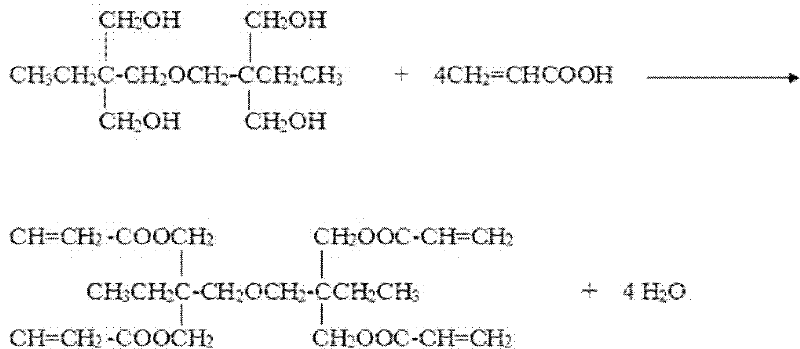

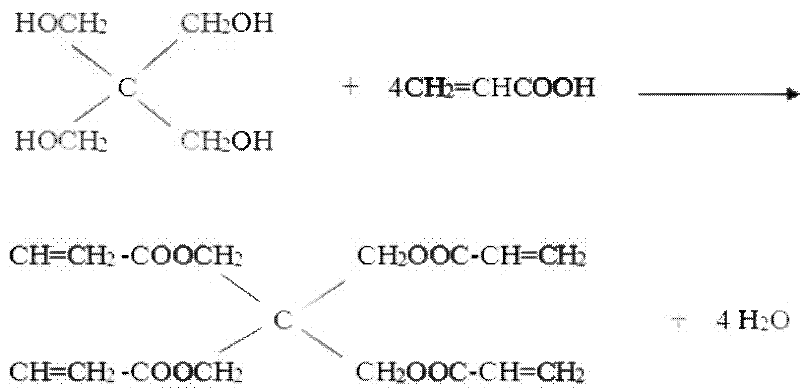

Cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester

ActiveCN102643197ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSorbentSolvent

The invention belongs to the field of photo-curing material, and relates to a cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester. The method specifically comprises the following steps of: (1) dehydrating di-trimethylolpropane / pentaerythritol, crylic acid, catalyst, solvent, polymerization inhibitor and antioxygen by means of esterification and backflow; (2) adding sheet alkali and a small quantity of water to neutralize; (3) adding magnesium polysilicate adsorbent to adsorb and neutralize the generated salt; (4) dehydrating in a pressure reducing way, and removing solvent; (5) carrying out filter pressing, filtering out the magnesium polysilicate and salt adsorbed by the magnesium polysilicate; (6) adding alkaline calcium bentonite and calcium oxide, to remove color, trace moisture and trace acid; (7) carrying out filter pressing; and (8) detecting the indexes of a product. The invention belongs to a cleaning production method for the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester, which is good in economic benefit and environmental benefit, so that the problem of organic waste water pollution when the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester is produced can be basically solved.

Owner:JIANGSU LITIAN TECH

Preparation technology of efficient polymeric aluminum chloride for wastewater treatment

InactiveCN103738992AGood processing effectImprove protectionAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWastewater

The invention relates to a preparation technology of efficient polymeric aluminum chloride for wastewater treatment. The preparation technology is mainly technologically characterized by comprising the following steps: with hydrochloric acid, aluminum hydroxide and a polymerization regulator as main raw materials, producing a liquid solution by a high-temperature, low-pressure and alkaline adjustment two step method; and producing powdery solid by a centrifuging or pressure spray drying and curing environment-friendly technology. The preparation technology disclosed by the invention is advanced in process, high in production efficiency, fast in purification speed, good in treatment effect, wide in application field, low in treatment cost, energy-saving and environment-friendly, and has important application and popularization values by adjusting the raw material ratio in production.

Owner:TIANJIN SHUIJIE PURIFICATION MATERIAL CO LTD

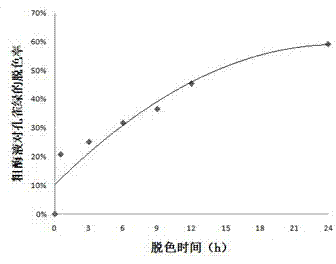

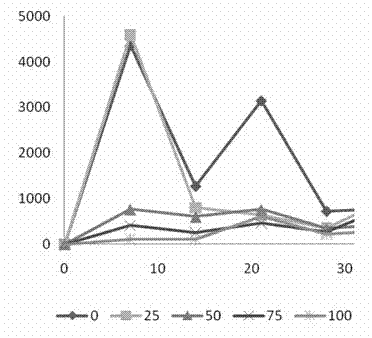

Method for treating dye waste water by enzyme production through mixed biomass fermenting

InactiveCN102583769ASimple methodEasy to operateWaste water treatment from textile industryBiological water/sewage treatmentMalachite greenCongo red

The invention discloses a method for treating dye waste water by enzyme production through mixed biomass fermenting. In the method, white rot fungi which can generate a lignin degrading enzyme system are used as a fermenting enzyme-production strain; a solid and liquid culture method is adopted, a cottonseed hull and / or paddy straw are / is used as a fermentation substrate, and lignin degrading enzyme is induced to obtain an optimal lignin degrading enzyme system; and finally, crude enzyme liquid is extracted, separated and prepared and can be used for decoloring treatment of waste water of commonly-used synthetic dye, such as Congo red, phenol red, bromophenol blue, crystal violet, malachite green and the like so as to obtain the optimal decoloring effect of dye sewage. The method is simple and is easy to operate. The enzyme system induced by the method disclosed by the invention has high enzymolysis efficiency, and the optimal decoloring effect can be achieved by adopting the enzyme system to treat the dye waste water.

Owner:KUNMING UNIV OF SCI & TECH

Waste water treatment method combining Fenton oxidization and microwave catalysis phase

InactiveCN101767859AGood decolorizationShorten the oxidation reaction timeWater/sewage treatment by irradiationWater/sewage treatment by oxidationIndustrial waste waterMicrowave

The invention discloses a method for treating industrial waste water by combining Fenton oxidization and a microwave catalysis phase. The method comprises the following steps of: adjusting the PH value of the waste water to be smaller than 6; adding a Fenton reagent and uniformly stirring; ensuring that the waste water with the added Fenton reagent flows through a microwave field; and ensuring that the waste water flowing through the microwave field is subjected to solid, liquid and gas three-phase separation, and if necessary, neutralizing and separating acid in obtained liquid. In the invention, the industrial waste water is continuously treated under a flowing condition by utilizing the modes of oxidizing organic matters in the industrial waste water by using the Fenton reagent and catalyzing an oxidizing reaction process by microwaves, thus the invention has the characteristics of short treatment time, good reaction effect, high COD (chemical oxygen demand) removal rate and space saving so as to truly realize the industrial application of the Fenton method.

Owner:却力挥

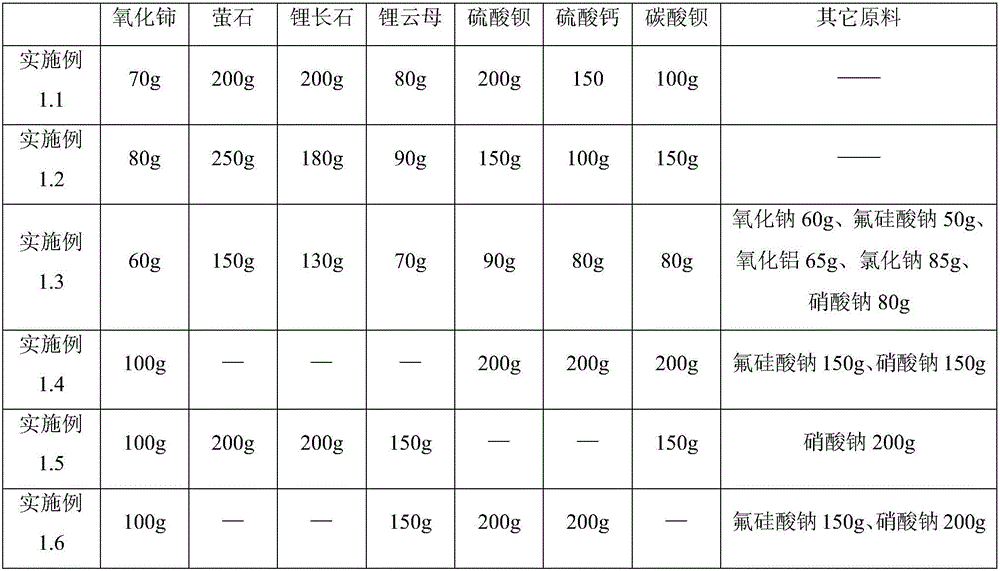

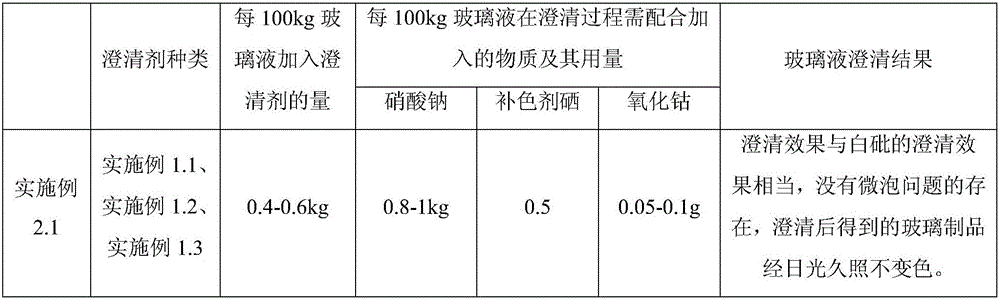

Glass clarifying agent and preparation method thereof

The invention provides a glass clarifying agent. The glass clarifying agent is prepared from components of raw materials in parts by weight as follows: 5-10 parts of cerium oxide, 10-25 parts of fluorite, 10-25 parts of lithium feldspar, 5-10 parts of lepidolite, 5-20 parts of barium sulfate, 5-15 parts of calcium sulfate and 5-15 parts of barium carbonate. The glass clarifying agent has excellent clarifying effect, can realize the clarifying effect the same as that of arsenic trioxide, can also remarkably reduce the use quantity of production raw materials introduced through matching with the clarifying agent and reduces the production cost of glass, and the comprehensive effect is better than that of arsenic trioxide; besides, the problem of glass defects caused by high probability of microbubbles on a glass panel with the adoption of a cerium oxide and sulfate composited clarifying agent is solved by means of the glass clarifying agent. The preparation method of the glass clarifying agent is simple, realizes safe production, prevents environmental pollution and is applicable to large-scale production.

Owner:郑国利

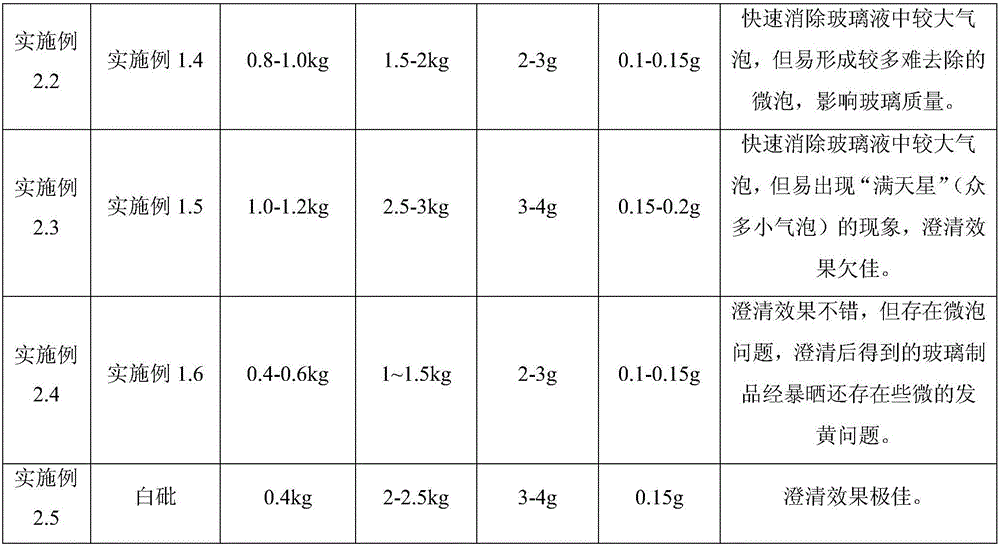

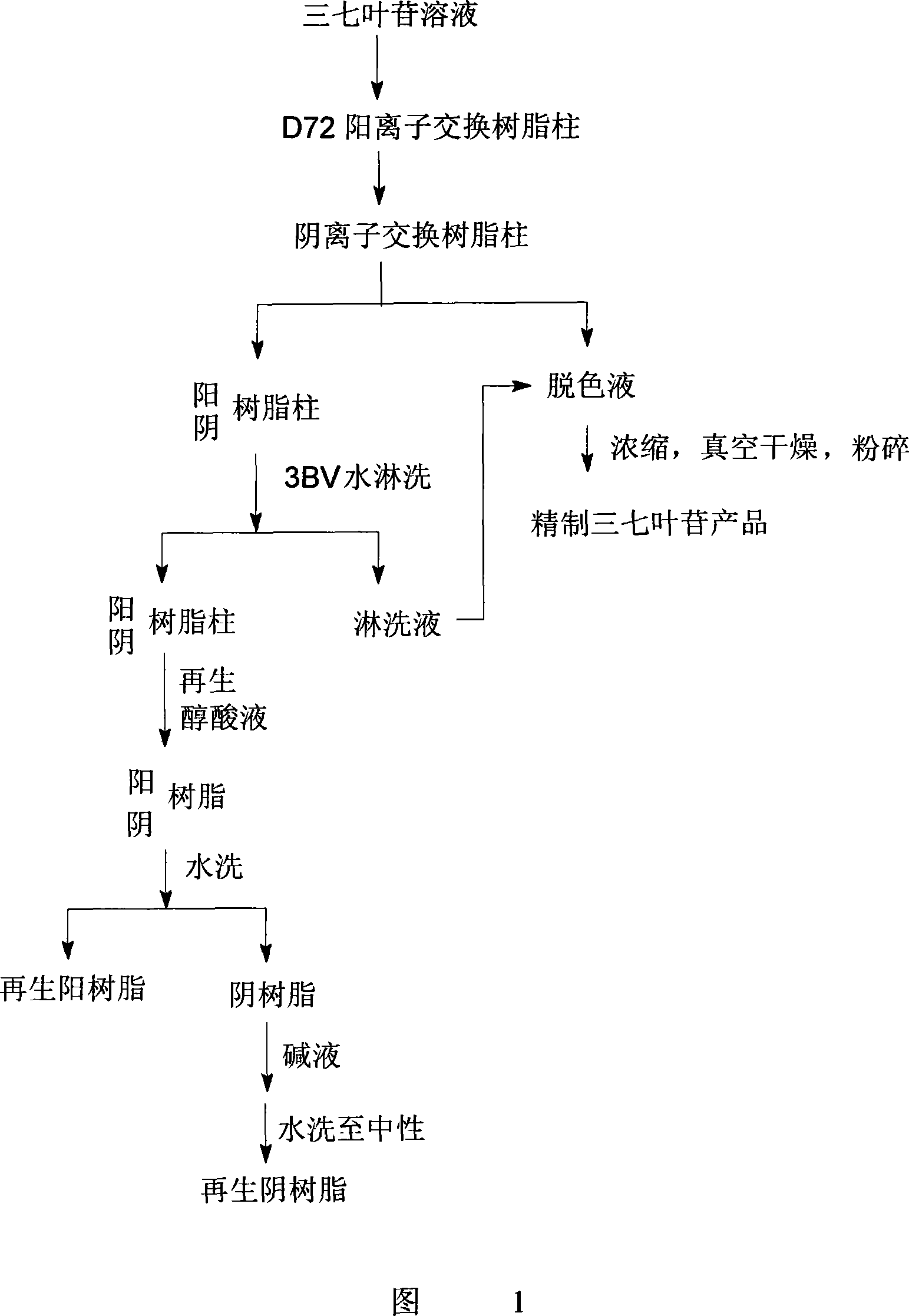

Decolor refined technology of notoginseng total saponin duolite method

InactiveCN101229207AHigh purityGood lookingSugar derivativesSugar derivatives preparationPANAX NOTOGINSENG ROOTAlcohol

The invention relates to a decoloration refining process of total saponins of panax notoginseng leaf ions exchange resin and a resin regeneration method. The decoloration refining process is: first cation-exchange the dilute alcohol water solution of the total saponins of panax notoginseng leaf with resin column and then anion-exchange resin column to decolorate, and when the decoloration is completed, shower the resin column to reduce the loss of total saponins of panax notoginseng leaf and then depressing and steaming the solution and the shower solution, and the product is formed when the leftover is dried. The failure resin can regenerate to get the decoloration ability. The invention method can improve the purity of the produced total saponins of panax notoginseng leaf to more than 90 percent, and improve the exterior color and further be crystallized and purified to get products with high purity. The invention of ion-exchange resin decoloration refining process does not lead into other chemical matters in the process of total saponins of panax notoginseng leaf decoloration, thus avoiding polluting the product again in the process of decoloration. The decoloration process is easy, and the cost is low, while the decoloration effect is obvious and the equipment structure is simple.

Owner:NANKAI UNIV

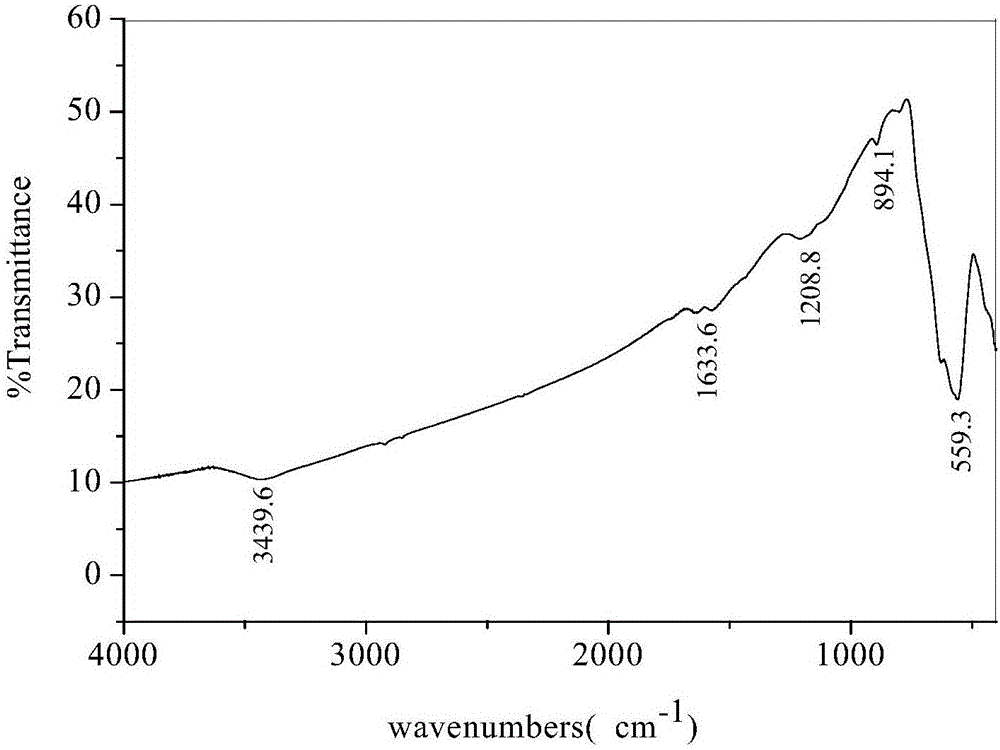

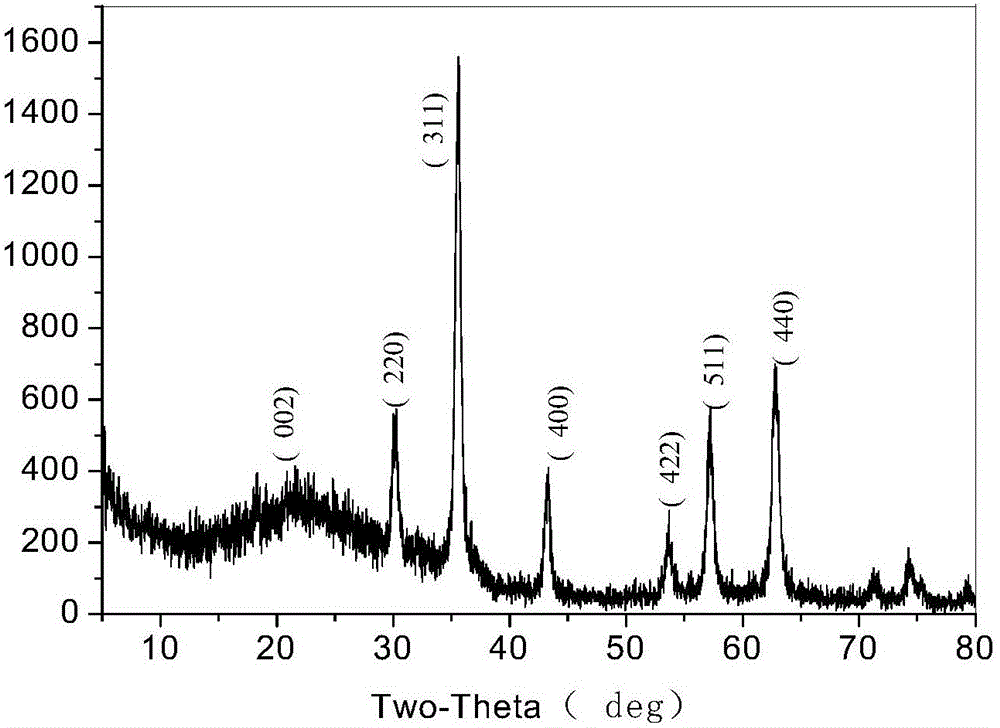

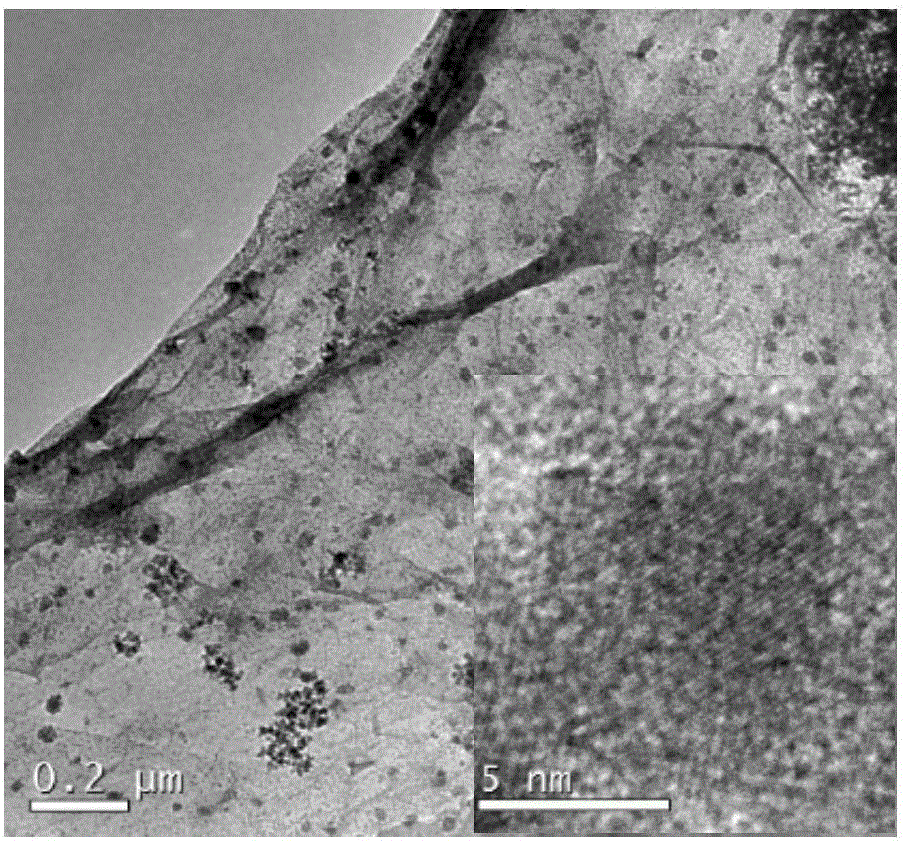

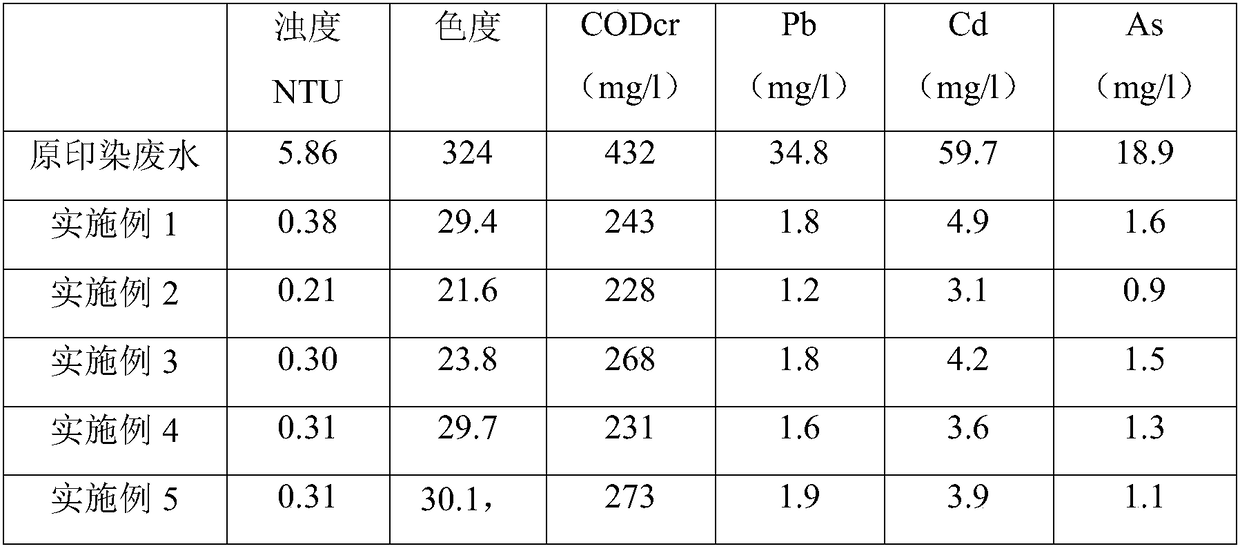

Preparation method and applications of graphene/Fe3O4 magnetic nanometer composite material

InactiveCN106475100ASimple methodEase of large-scale industrial productionWater contaminantsEnergy based wastewater treatmentPtru catalystDistilled water

The invention relates to a preparation method and applications of a graphene / Fe3O4 magnetic nanometer composite material, and belongs to the technical field of magnetic nanometer composite materials. A purpose of the present invention is to solve the problems of low efficiency and difficult recovery of the existing catalyst. The preparation method comprises: a, adding a graphene oxide dispersion liquid to distilled water, stirring, carrying out ultrasonic treatment, centrifugating, and taking the upper layer graphene oxide solution so as to be spare; b, mixing FeCl3.6H2O and FeSO4.7H2O, adding deionized water, and dissolving; c, adding the obtained solution to the graphene oxide solution, and uniformly stirring to obtain a mixing solution; d, adding ammonia water to the mixing solution in a dropwise manner, and crystallizing to obtain a composite material dispersion liquid; and e, carrying out ultrasonic treatment on the dispersion liquid, carrying out suction filtration to separate a graphene / Fe3O4 magnetic nanometer composite material, washing, and drying to obtain the graphene / Fe3O4 magnetic nanometer composite material. The method of the present invention can be used for preparing the graphene / Fe3O4 magnetic nanometer composite material.

Owner:江苏金茂源生物化工有限责任公司

Method for preparing polysilicate ferro-aluminum sulfate composite flocculant from red mud waste

InactiveCN108083345AHigh molecular weightGood flocculation effectIron sulfatesWater/sewage treatment by flocculation/precipitationRed mudSilicon oxide

The invention discloses a method for preparing a polysilicate ferro-aluminum sulfate composite flocculant from red mud waste. The method comprises the following steps: (1) putting red mud waste and anactivating agent into a muffle furnace to be roasted and grinding the red mud waste to obtain activated red mud powder; (2) putting an oxidizing agent and the activated red mud powder into a sulfuricacid solution to react; (3) adding adjusting salt to adjust a molar ratio of Fe to Al to Si in the solution as 1 to 1 to (0.2 to 0.7), utilizing a pH conditioning agent to adjust a pH of the solutionto 1 to 6; (4) adding a stabilizer to react and filtering to obtain the polysilicate ferro-aluminum sulfate composite flocculant. By means of the method disclosed by the invention, ferric oxide, aluminum oxide and silicon oxide in the red mud waste are effectively utilized to prepare the polysilicate ferro-aluminum sulfate composite flocculant; not only are the problems that the waste red mud occupies a lot of land and pollutes underground water are solved, but also the waste red mud can be resourcefully utilized, production cost is low, added value of products is high, and a novel way for comprehensively utilizing the red mud waste is provided.

Owner:SUN YAT SEN UNIV

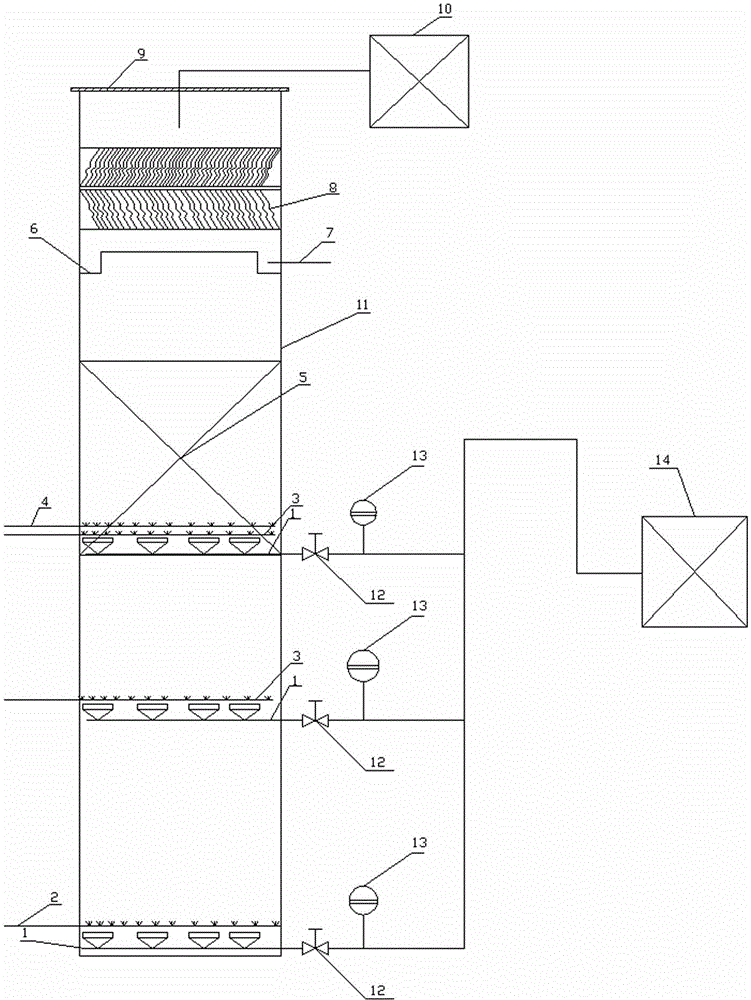

Catalytic ozonation water treatment device

InactiveCN104150578ANot ruled outReduce processing costsWater/sewage treatment by oxidationIndustrial waste waterLiquid state

The invention belongs to the field of industrial waste water deep treatment equipment, and particularly relates to a multi-stage advanced catalytic ozonation water treatment device. The device mainly comprises a titanium microporous aerator, H2O2 feeding systems, liquid-state specific catalyst feeding systems, solid-state specific catalysts, a corrugated plate demister and a tail gas collection and destruction system. Waste water flows in the treatment device through a water inlet pipe, the bottom, the middle part and the upper part of the treatment device are respectively provided with a different amount of ozone feeding systems, H2O2 feeding systems, liquid-state specific catalyst feeding systems, and solid-state specific catalysts, and meanwhile, tail gas is demisted through a corrugated plate and then is collected and delivered to the destruction system for destruction, so as to avoid the pollution to an environment. According to the catalytic ozonation water treatment device, the color and COD in industrial waste water can be effectively removed, the treatment method is simple, and the cost is low and the treatment efficiency is high.

Owner:TAIZHOU INST OF SCI &TECH NUST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com