Method for treating dye waste water by enzyme production through mixed biomass fermenting

A technology for biomass fermentation and dye wastewater, applied in the field of environmental treatment, can solve the problems that the advantages cannot be effectively exerted, and it is not conducive to optimizing the enzymatic hydrolysis efficiency of lignin-degrading enzymes, and achieves the best decolorization effect, high enzymatic hydrolysis efficiency, high enzymatic hydrolysis efficiency, etc. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

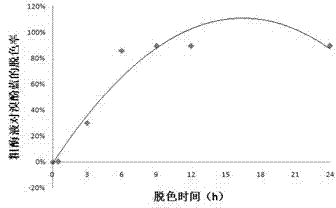

[0032] Embodiment 1: The method for treating dye wastewater by using mixed biomass fermentation to produce enzymes, the specific steps are as follows:

[0033] (1) Trametes trogii ATCC 200800 Cultivation of Seeds

[0034] Inoculate the hyphae of Trametes trichotilloides on the wort medium (MEA), cultivate at 30°C for 8 days to obtain slant seeds, inoculate the activated slant seeds on the wort medium, and cultivate at 30°C for 6 days to obtain solid fermented seeds;

[0035] (2) Enzyme production by fermentation

[0036] Inoculate the solid fermented seeds into the solid fermentation substrate, inoculate 4 pieces of bacteria blocks (diameter of the bacteria block is 1cm) per 5g of the substrate, and cultivate at 35°C for 7 days;

[0037] The composition of the enzyme-producing solid fermentation substrate is 2% by mass of malt extract, 13mM copper sulfate, 20% by mass of a mixture of cottonseed hulls and rice straw (the mixing ratio of cottonseed hulls and rice stalks is ...

Embodiment 2

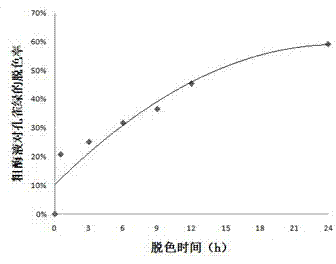

[0047] Embodiment 2: This method of utilizing mixed biomass fermentation to produce enzymes to treat dye wastewater, the specific steps are as follows:

[0048] (1) Trametes trogii ATCC 200800 Cultivation of Seeds

[0049] Inoculate the hyphae of Trametes trichotillomyces on malt extract medium (MEA), cultivate at 35°C for 10 days to obtain slant seeds, inoculate the slant seeds on wort medium, and cultivate at 35°C for 4 days to obtain solid fermented seeds;

[0050] (2) Enzyme production by fermentation

[0051] Inoculate the solid fermentation seeds into the solid fermentation substrate, inoculate 4 pieces of bacteria blocks (diameter of the bacteria block is 1cm) per 5g of the substrate, and incubate at 35°C for 21 days;

[0052] The composition of the enzyme-producing solid fermentation substrate is 2% by mass of malt extract, 13mM copper sulfate, 20% by mass of a mixture of cottonseed hulls and rice straw (the mixing ratio of cottonseed hulls and rice stalks is show...

Embodiment 3

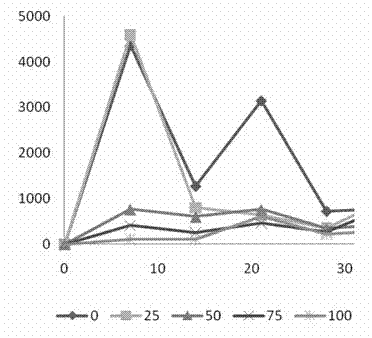

[0061] Embodiment 3: The method for treating dye wastewater by using mixed biomass fermentation to produce enzymes, the specific steps are as follows:

[0062] (1) Trametes trogii ATCC 200800 Cultivation of Seeds

[0063] Inoculate the mycelium of Trametes trichotilloides on the slant of potato dextrose agar, cultivate at 37°C for 6 days to obtain slant seeds, inoculate the slant seeds on the slant of potato dextrose agar, and cultivate at 37°C for 2 days to obtain solid fermented seeds;

[0064] (2) Enzyme production by fermentation

[0065] Inoculate the solid fermented seeds into the solid fermentation substrate, and inoculate 4 pieces of bacteria blocks (diameter of the bacteria block is 1cm) per 5g of the substrate, and cultivate at 37°C for 15 days;

[0066] The composition of the enzyme-producing solid fermentation substrate is 2% by mass of malt extract, 13mM copper sulfate, 0.5% by mass of a mixture of cottonseed hulls and rice straw (mixed at a mass ratio of 1:1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| escape rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com