Method for preparing decoloring material of dyeing waste water by attapulgite ore

A technology of printing and dyeing wastewater and attapulgite, which is applied in the direction of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of low mechanical strength and blister strength of granular materials, poor recyclability, and high corrosion of equipment. Achieve excellent decolorization performance, eliminate pollution, reduce the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Attapulgite clay 100kg, 80 mesh, and H concentration of 1.5mol / L 2 SO 4 Mix with a solid-liquid ratio of 1:2.5, activate at room temperature for 2 hours, then neutralize with 5mol / L NaOH to a pH value of about 7.5, separate solid-liquid once, granulate into 3-5mm pellets, dry at 90°C, and then After calcining at 700°C for 1 hour, 85kg of printing and dyeing wastewater decolorization material can be obtained. The produced filtrate is evaporated and concentrated, crystallized and separated to obtain Na 2 SO 4 10H 2 The O by-product is about 70kg, and the mother liquor is recycled.

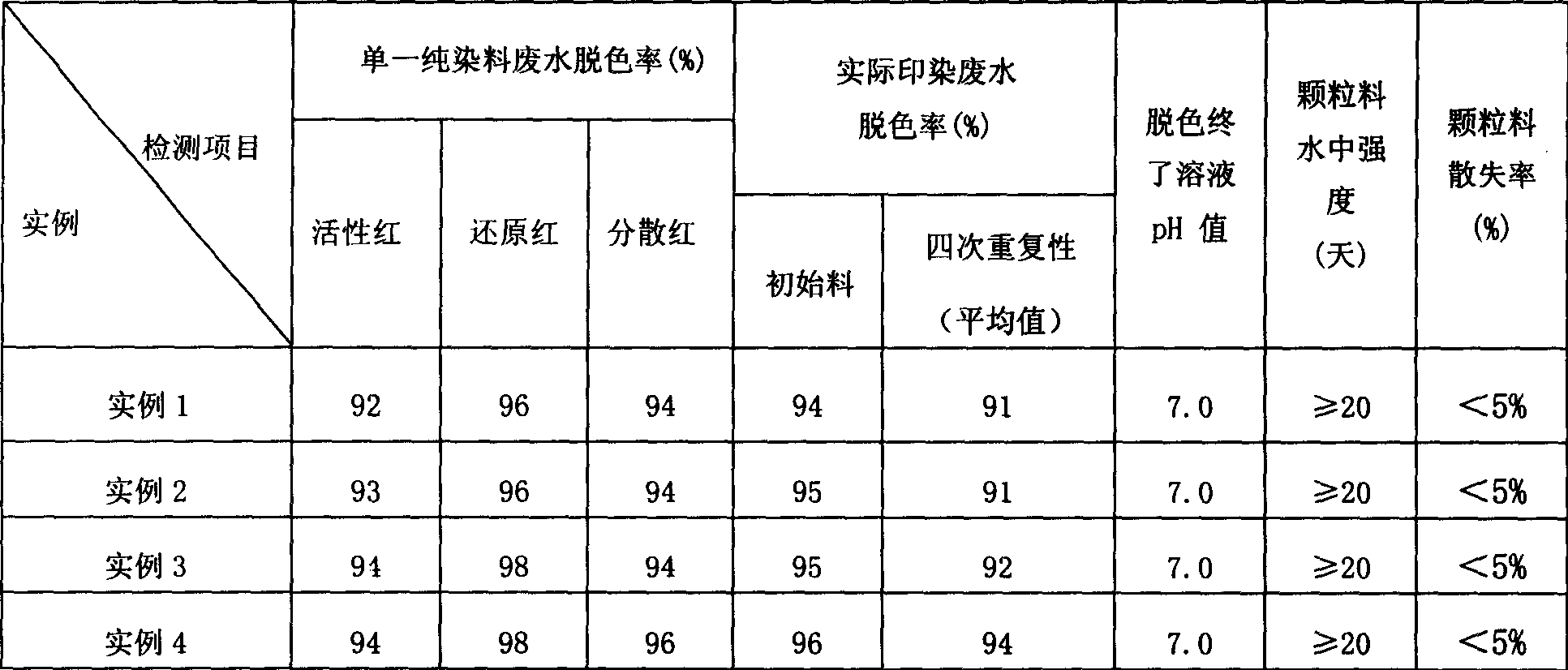

[0022] Soak the decolorized material in a 5mol / L ammonium sulfate solution for 3 minutes and then calcinate it at 300°C for 5 minutes, which can be used repeatedly. The particle strength of the decolorizing material and its decolorizing effect on a single pure dye with different properties and actual printing and dyeing wastewater are shown in Table 1.

example 2

[0024] Attapulgite clay 100kg, 80 mesh, and the H concentration of 2.0mol / L 2 SO 4 Mix with a solid-liquid ratio of 1:2.0, activate at room temperature for 2 hours, then neutralize with 5mol / L NaOH to a pH value of about 7.5, separate solid-liquid once, granulate into 3-5mm pellets, dry at 90°C, and then After calcining at 700°C for 1 hour, 90kg of printing and dyeing wastewater decolorization material can be obtained. The produced filtrate is evaporated and concentrated, crystallized and separated to obtain Na 2 SO 4 10H 2 The O by-product is about 70kg, and the mother liquor is recycled.

[0025] Soak the decolorized material in 3mol / L ammonium sulfate solution for 3min and then calcinate at 300°C for 5min, which can be used repeatedly. The particle strength of the decolorizing material and its decolorizing effect on a single pure dye with different properties and actual printing and dyeing wastewater are shown in Table 1.

example 3

[0027] Attapulgite clay 100kg, 100 mesh, and H concentration of 1.5mol / L 2 SO 4 Mix with a solid-liquid ratio of 1:2.0, activate at room temperature for 1.5 hours and add 5kg of ferrous sulfate, then neutralize with 5mol / L NaOH to a pH value of about 7.5, separate solid-liquid once, and granulate into 3-5mm granules. After drying at 90°C and calcining at 700°C for 1 hour, 90kg of printing and dyeing wastewater decolorization material can be obtained. The produced filtrate is evaporated and concentrated, crystallized and separated to obtain Na 2 SO 4 10H 2 O by-product about 80kg, mother liquor recycling.

[0028] Soak the decolorized material in 2mol / L ammonium sulfate solution for 3 minutes and then calcinate it at 300°C for 5 minutes, which can be used repeatedly. The particle strength of the decolorizing material and its decolorizing effect on a single pure dye with different properties and actual printing and dyeing wastewater are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com