Method for preparing decolorizing material for printing and dyeing wastewater

A printing and dyeing wastewater and decolorization technology, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage treatment, etc., can solve the problems of low particle mechanical strength and blister strength, and achieve improved decolorization performance, increased specific surface area, and improved The effect of decolorization adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

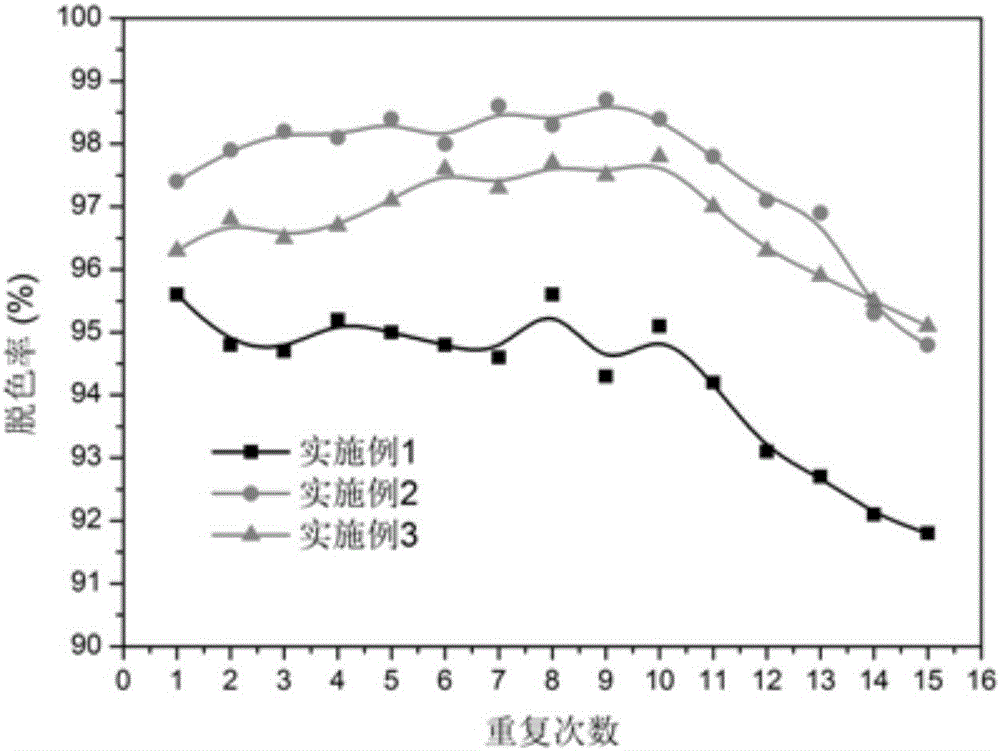

Embodiment 1

[0027] Attapulgite 500g, 80 mesh, mixed with urea and sodium hexametaphosphate solution with a concentration of 10wt%, wherein the volume ratio of attapulgite to urea is 1:0.5, and the addition of sodium hexametaphosphate is 1 / 2 of the attapulgite quality 10%. After activation at normal temperature for 2 hours, granulate (3-5mm) through a granulator, and after drying at 70°C, slowly raise the temperature to 400°C for heat treatment for 2 hours, and the heating rate of heat treatment is 1.2°C / min; remove the organic components, The attapulgite porous printing and dyeing wastewater decolorization material is obtained.

Embodiment 2

[0029] Attapulgite 500g, 80 mesh, mixed with urea and sodium hexametaphosphate solution with a concentration of 10wt%, wherein the volume ratio of attapulgite to urea is 1:0.6, and the addition of sodium hexametaphosphate is 1 / 2 of the attapulgite quality 10%. After activation at normal temperature for 1 hour, granulate (3-5mm) through a granulator, and after drying at 60°C, slowly heat up to 380°C for 4 hours and heat treatment at a rate of 1.0°C / min; remove the organic components, The attapulgite porous printing and dyeing wastewater decolorization material is obtained.

Embodiment 3

[0031] Attapulgite 500g, 80 mesh, mixed with urea and sodium hexametaphosphate solution with a concentration of 10wt%, wherein the volume ratio of attapulgite to urea is 1:0.7, and the addition of sodium hexametaphosphate is 1 / 2 of the attapulgite quality 10%. After activation at normal temperature for 3 hours, granulate (3-5mm) through a granulator, and after drying at 80°C, slowly raise the temperature to 390°C for heat treatment for 3 hours, and the heating rate of heat treatment is 0.8°C / min; remove the organic components, The attapulgite porous printing and dyeing wastewater decolorization material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com