Patents

Literature

42results about How to "Shorten the oxidation reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

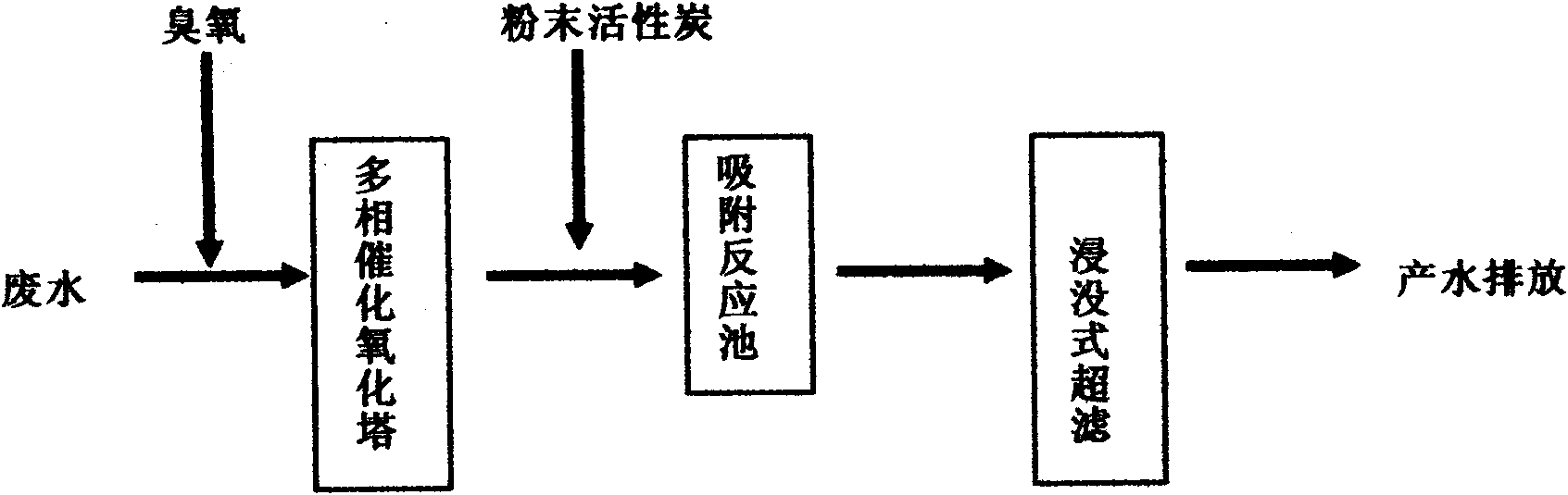

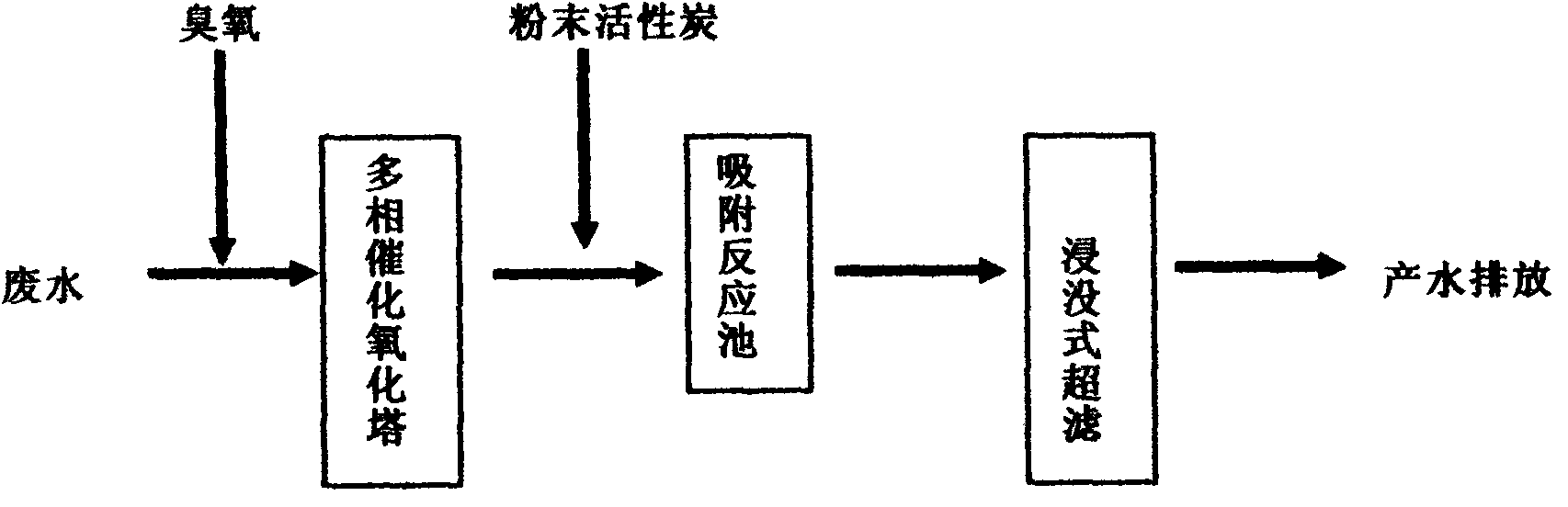

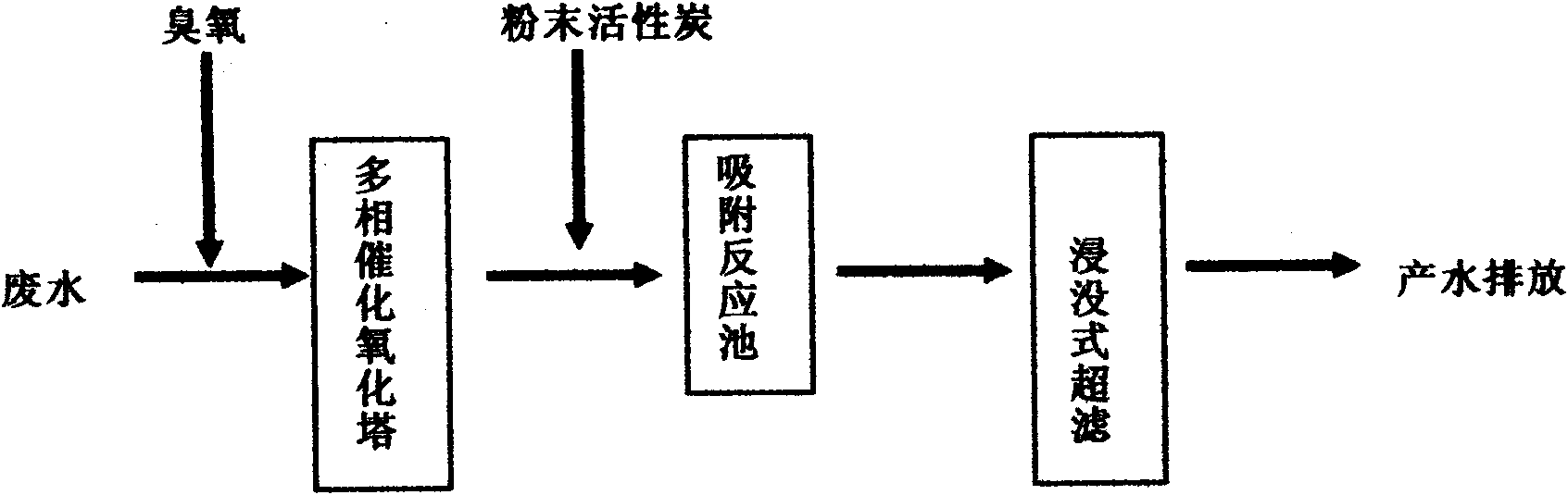

Reverse osmosis concentrated water treatment method

ActiveCN102372376AGuaranteed treatment effectShorten the oxidation reaction timeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationCatalytic oxidation

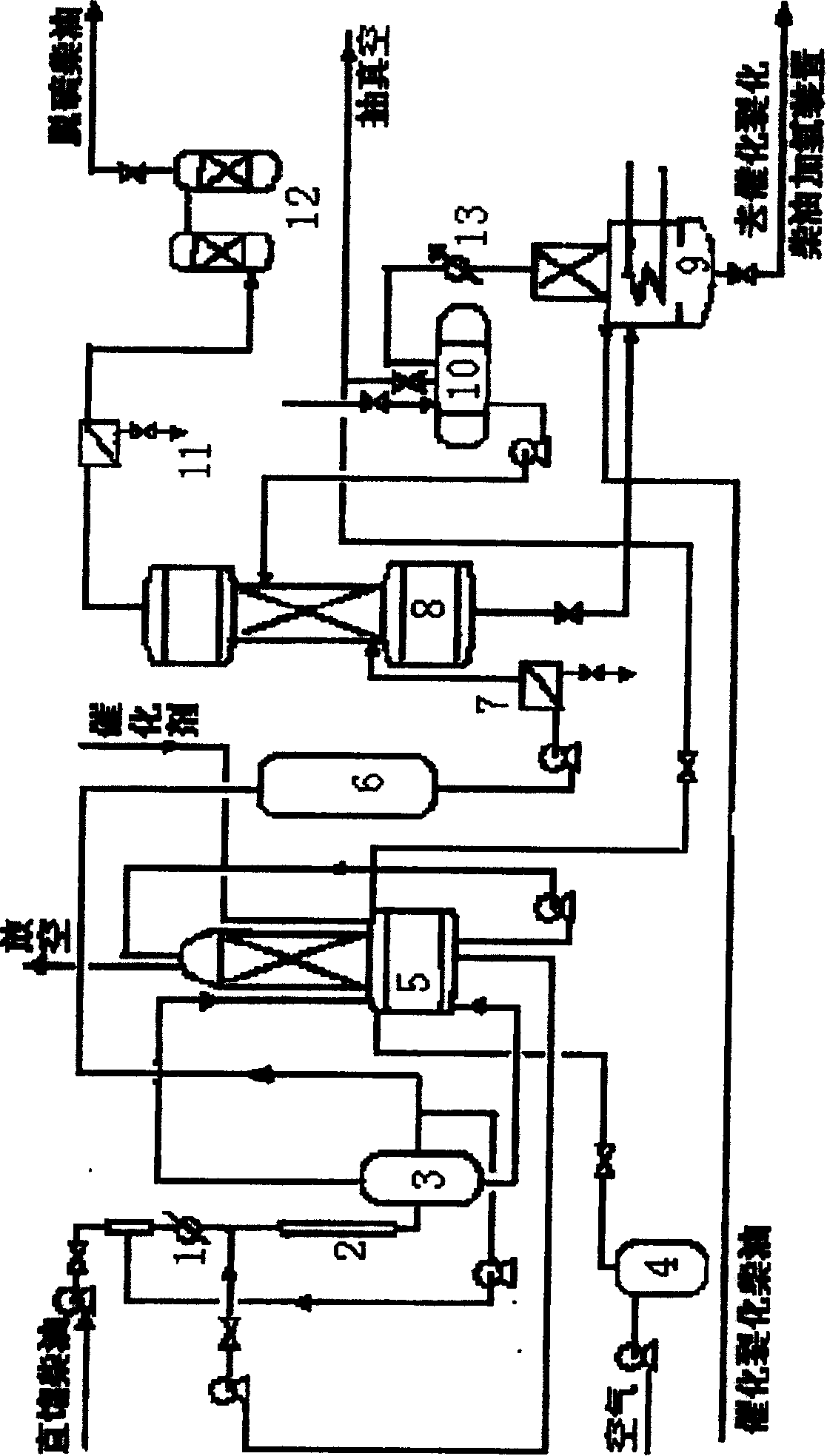

A reverse osmosis concentrated water treatment method comprises the following steps: (1) adopting multi-phase catalytic oxidation technique to achieve deep oxidation and maximally remove organic pollutants in wastewater; (2) adding the effluent after catalytic oxidation into an adsorption reaction tank, in which a proper amount of powdered active carbon is added, and fully reacting for a period of time by aeration or stirring and the like to adsorb organic pollutants in the wastewater, wherein the adsorption effect depends on the addition amount of the powdered active carbon; and (3) filtering the effluent after the adsorption reaction by submerged ultrafiltration to further improve the quality of the effluent, which can be discharged directly. According to the reverse osmosis concentrated water treatment method, the oxidation reaction time can be reduced and the oxidation reaction effect can be enhanced at the same time, and not only can the wastewater treatment effect be ensured but also the treatment cost is greatly lowered when the method is in combination with the powdered active carbon adsorption process. In addition, the method has the advantages of simple process flow and high operability, and is worth popularizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

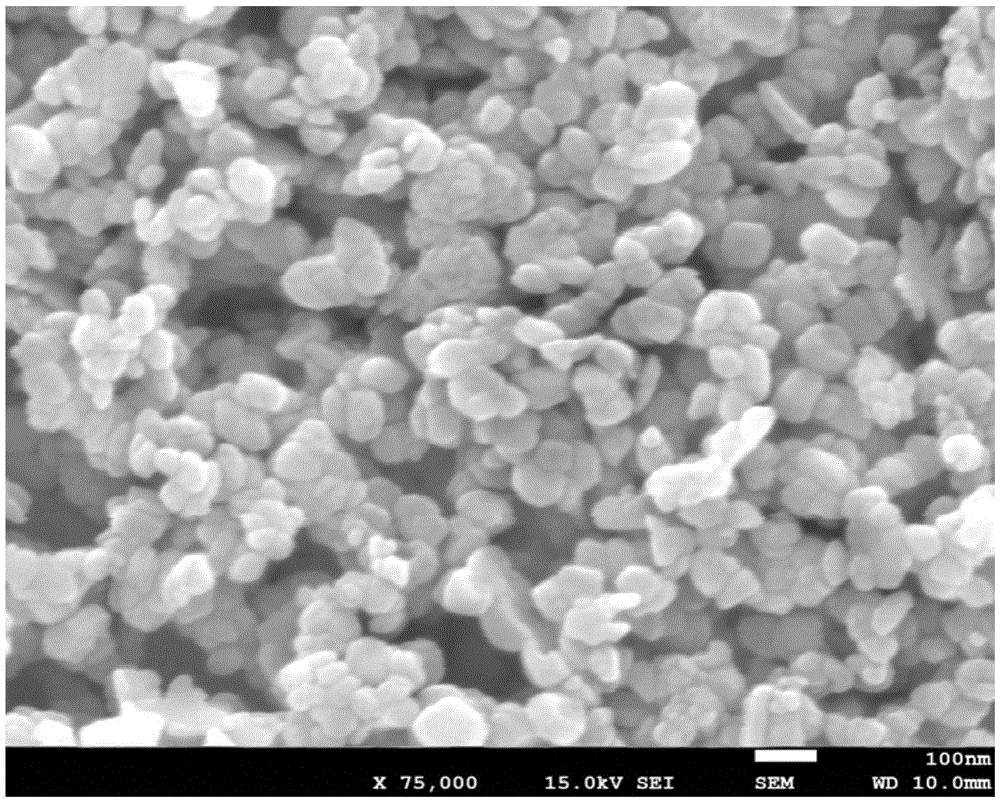

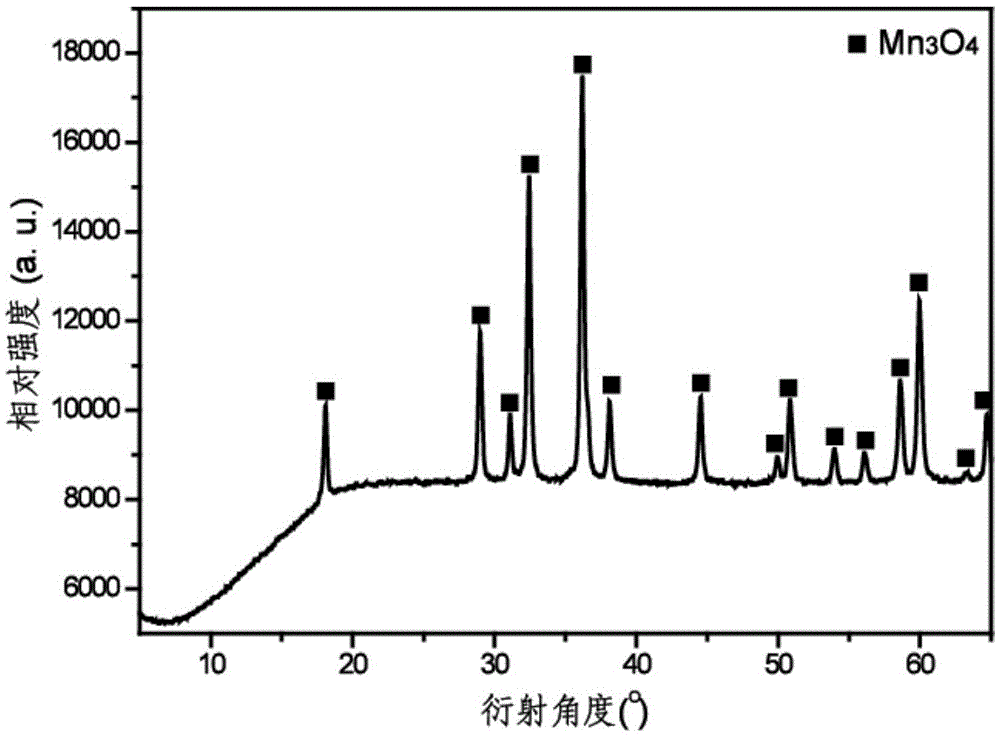

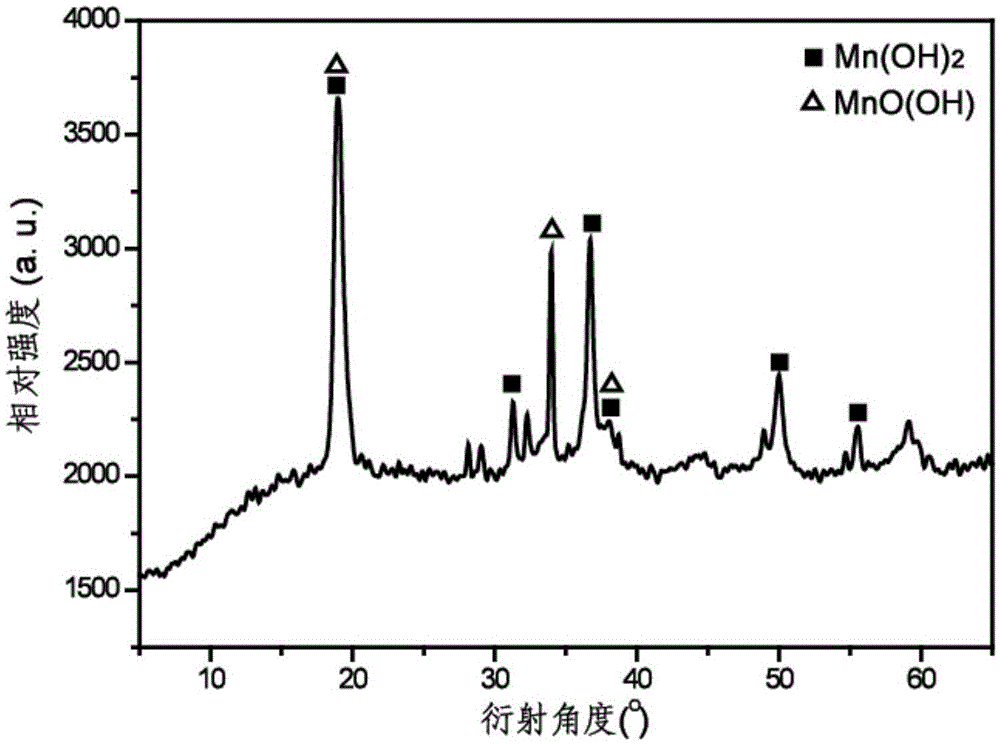

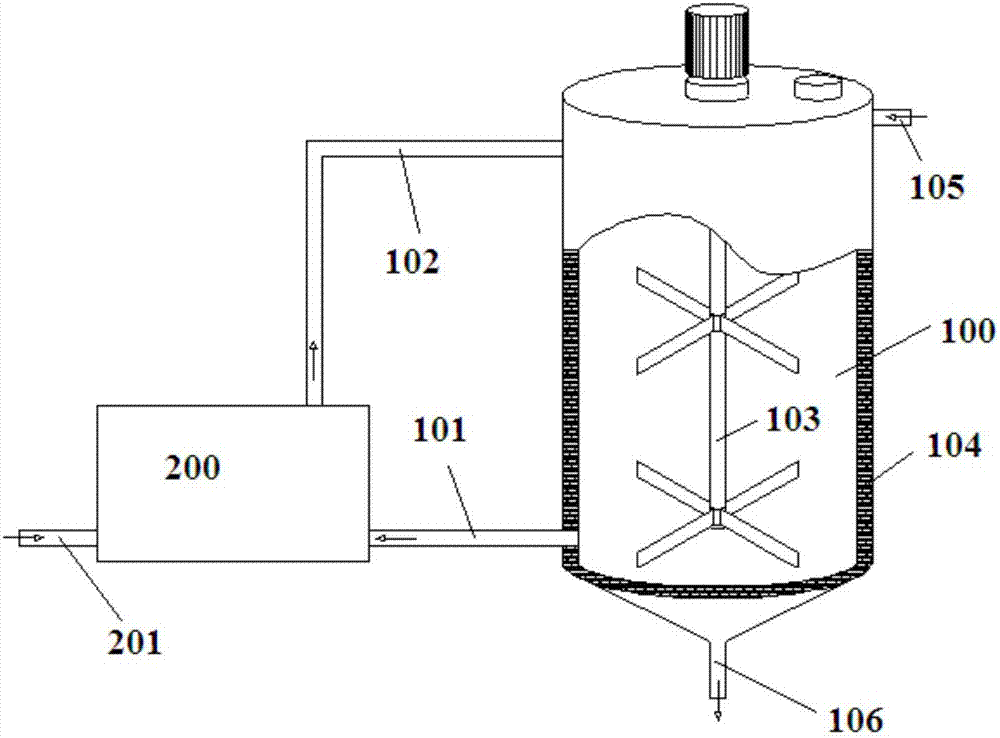

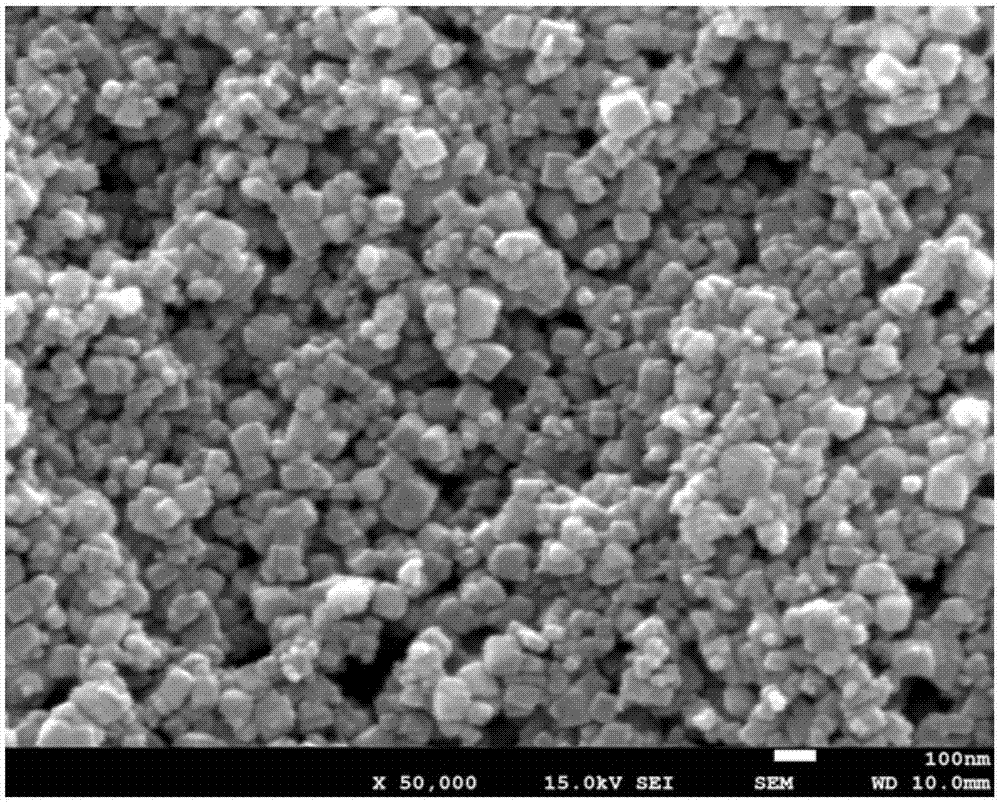

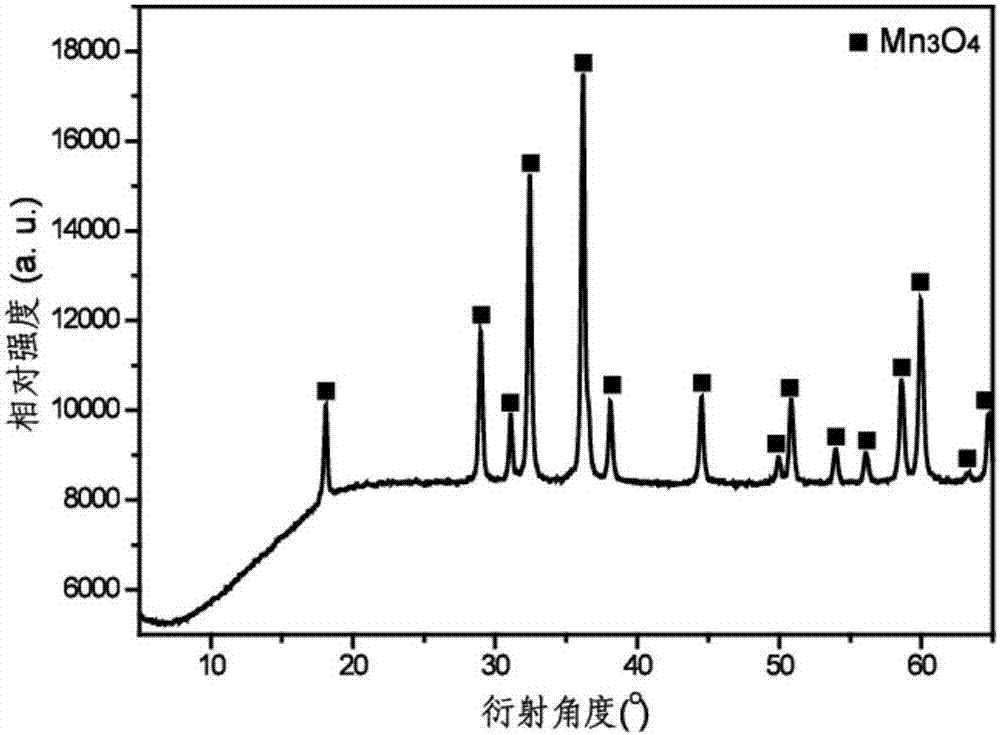

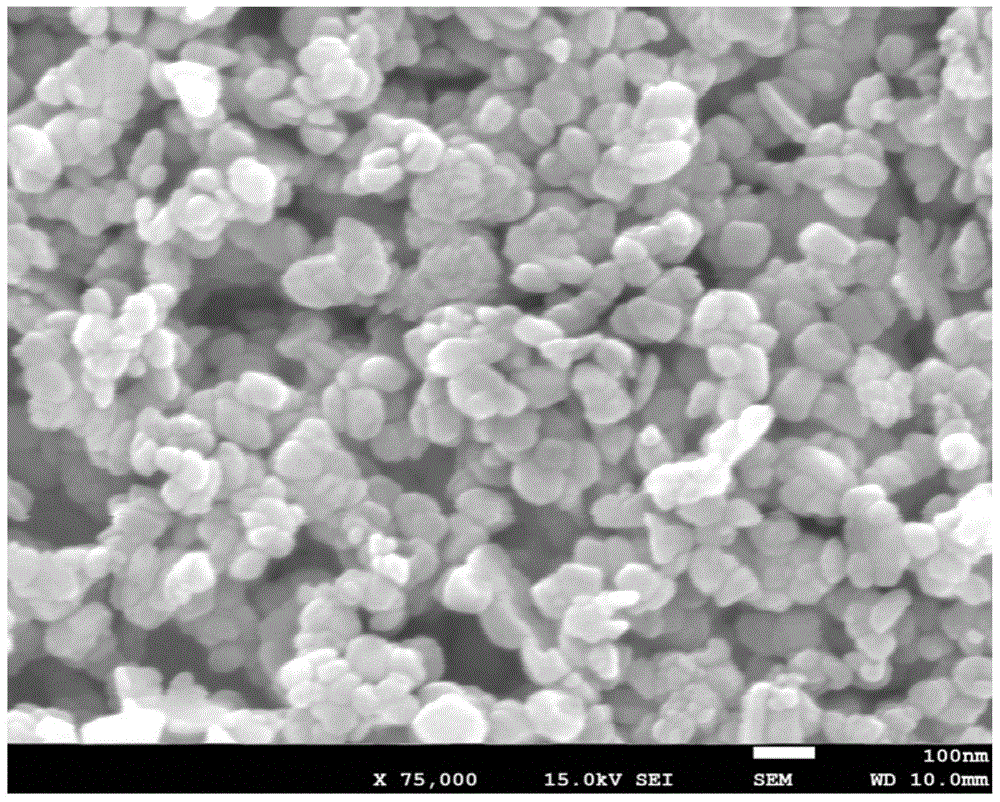

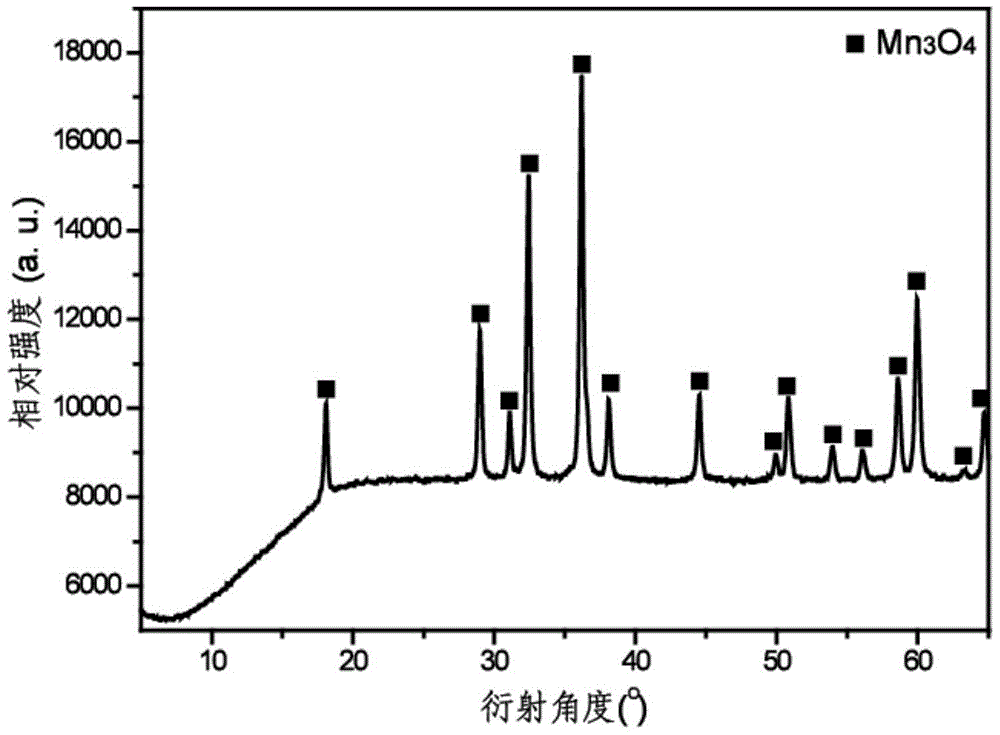

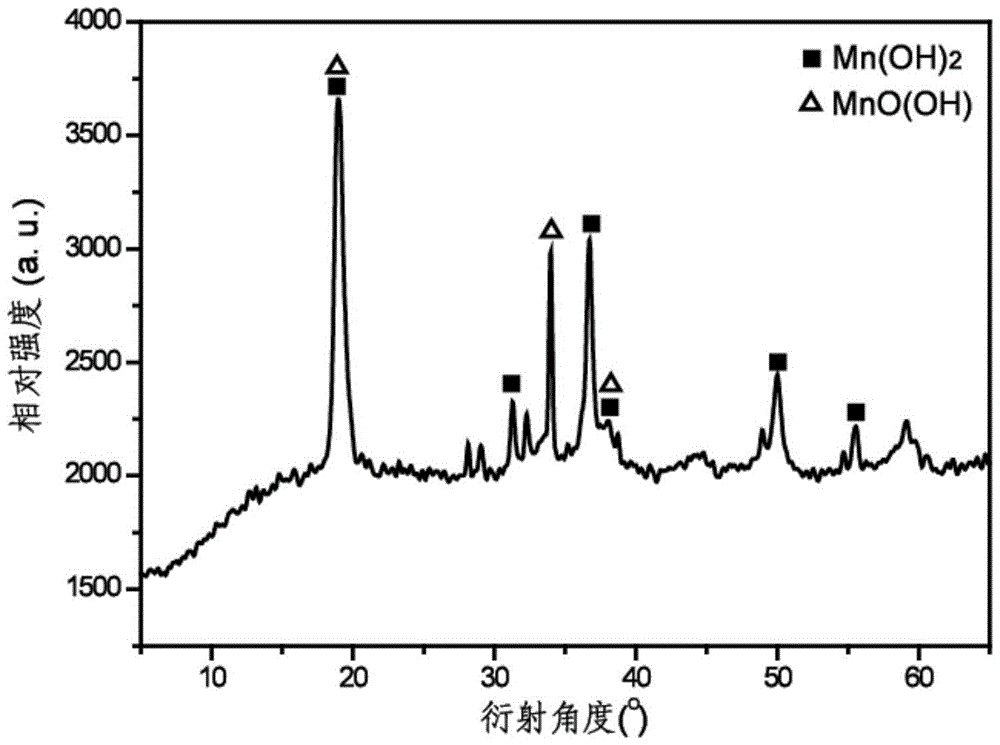

Preparation method for manganic manganous oxide

ActiveCN105417586AImprove solubilitySpeed up replenishmentManganese oxides/hydroxidesReaction rateAtmospheric pressure

The invention relates to a preparation method for manganic manganous oxide. The method is as follows: in an enclosed reaction container, a manganese source with an average valence of manganese being less than 8 / 3 is placed in a reaction solution, the reaction is carried out with heating, the situation is kept that the pressure or partial pressure of oxidizing gases in the reaction system is more than or equal to 1 standard atmospheric pressure, and a crude product of manganic manganous oxide can be prepared after the reaction is completed. Optionally, the enclosed reaction container has an oxidizing gas inlet or has an oxidizing gas inlet and a generation gas outlet simultaneously. The oxidation reaction rate is raised, the oxidation reaction time is shortened, the manganic manganous oxide crystal growth integrality is raised, the crystal defect is reduced, and high purity and high quality are obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

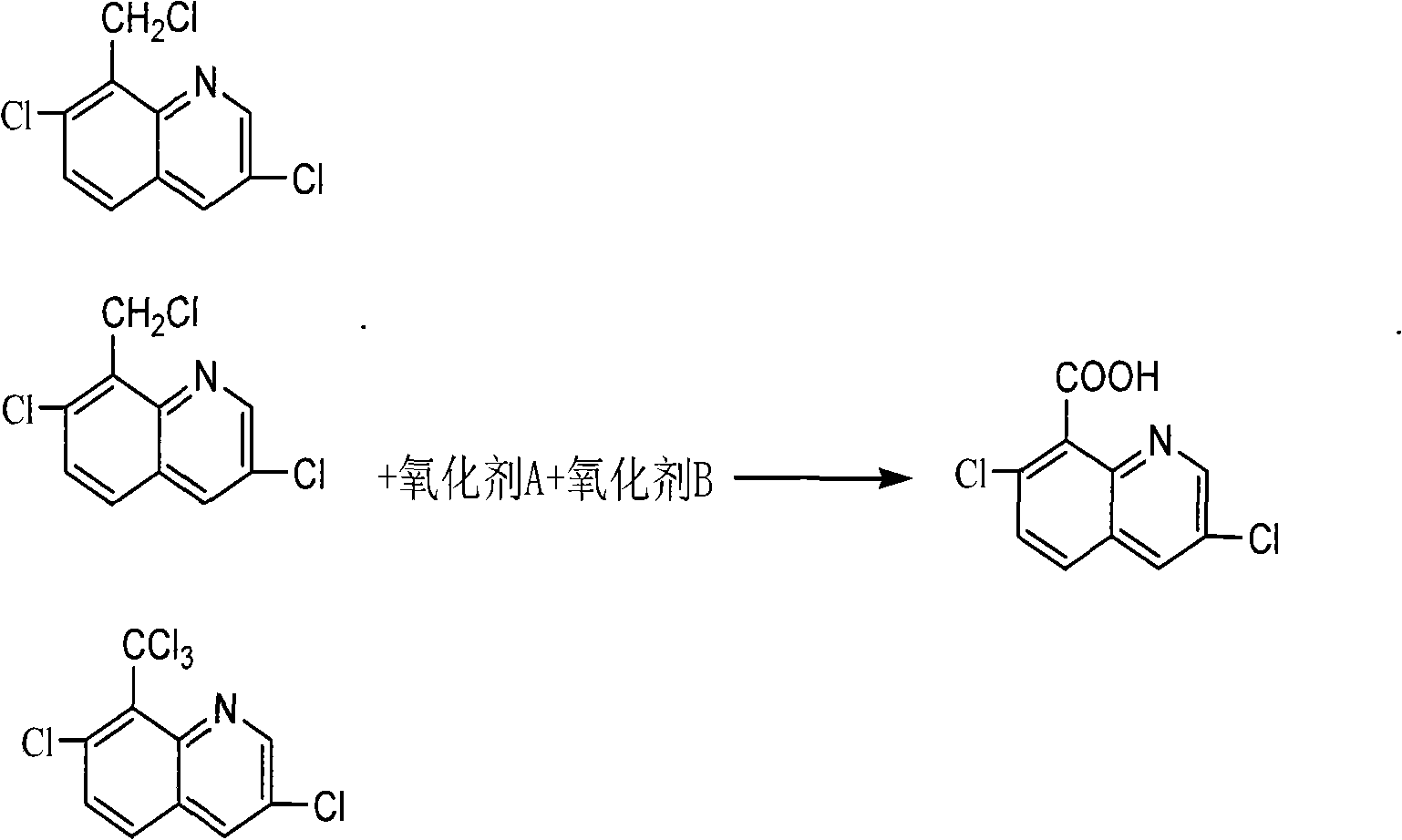

Process for synthesizing quinclorac by oxidizing reaction

The invention provides an oxidizer used in the di-chlorine quinoline acid synthesis technology, which can effectively improve the problems that the time of the oxidation operation is long, the production capacity is limited, and the generated waste acid is not easy to be processed in the prior art. The oxidizer is oxyacid of chlorine, bromine and iodine and salts thereof, and peroxide. The invention further provides a novel method for synthesizing di-chlorine quinoline acid oxo by utilizing the novel oxidizer.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Waste water treatment method combining Fenton oxidization and microwave catalysis phase

InactiveCN101767859AGood decolorizationShorten the oxidation reaction timeWater/sewage treatment by irradiationWater/sewage treatment by oxidationIndustrial waste waterMicrowave

The invention discloses a method for treating industrial waste water by combining Fenton oxidization and a microwave catalysis phase. The method comprises the following steps of: adjusting the PH value of the waste water to be smaller than 6; adding a Fenton reagent and uniformly stirring; ensuring that the waste water with the added Fenton reagent flows through a microwave field; and ensuring that the waste water flowing through the microwave field is subjected to solid, liquid and gas three-phase separation, and if necessary, neutralizing and separating acid in obtained liquid. In the invention, the industrial waste water is continuously treated under a flowing condition by utilizing the modes of oxidizing organic matters in the industrial waste water by using the Fenton reagent and catalyzing an oxidizing reaction process by microwaves, thus the invention has the characteristics of short treatment time, good reaction effect, high COD (chemical oxygen demand) removal rate and space saving so as to truly realize the industrial application of the Fenton method.

Owner:却力挥

One-step reaction method for preparing 4-nitropyridine-nitrogen oxide and halogenated-4-nitropyridine-nitrogen oxide

InactiveCN1743313AShort reaction timeShorten the oxidation reaction timeOrganic chemistryAcetic anhydrideNitration

This invention relates to a preparation method for 4-nitropyridines-nitrogenoxides and halogenated-4-nitropyridines-nitrogenoxides by one step, merging the separated oxidation and nitration into a single step. In the oxidation reaction, acetic anhydride, concentrated sulfuric acid, maleic anhydride and sodium bisulphate are added as catalyser; in nitration reaction, sodium nitrate is added to accelerate reaction. This method shortens the reaction time, especially the oxidation time reduced by half. After nitration reaction, 30~50% sodium hydroxide, instead of solid sodium carbonate, is used to neutralize the resultant solution to directly get the nitration resultants. In this method, the yield is more than 10% higher than that of routine methods and the production cost is cut down meanwhile.

Owner:ZHANJIANG NORMAL UNIV

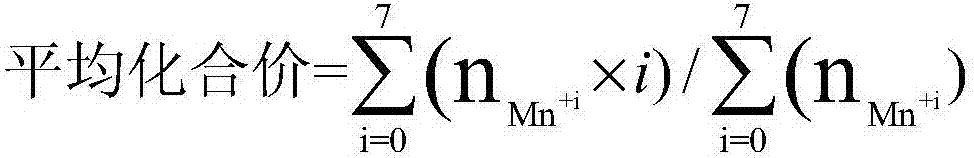

Non-manganese element-containing trimanganese tetraoxide complex, preparation method, used reaction system and uses thereof

ActiveCN107540021AImprove solubilityImprove dissolution rateHybrid capacitor electrodesCell electrodesGeneration rateReaction rate

The present invention relates to a preparation method and a preparation system of a trimanganese tetraoxide complex. The preparation method comprises: introducing micro-nano gas bubbles into a reaction liquid mixture containing a manganese source and a non-manganese element-derived raw material to obtain a reaction liquid-gas mixture, and carrying out a reaction to obtain a non-manganese element-containing trimanganese tetraoxide complex, wherein the micro-nano gas bubbles contain oxidizing gas, can be introduced along with a solvent, can be directly introduced along with the reaction mixture,can be continuously introduced, and can further be introduced in one time. According to the present invention, by introducing the micro-nano gas bubbles containing the oxidizing gas into the reactionsystem containing the manganese source and the non-manganese element-derived raw material, the oxidation reaction rate is improved, and the oxidation reaction time is shortened; and the generation rate of the trimanganese tetraoxide complex is increased, the particle size of the trimanganese tetraoxide complex is reduced, and the develop integrity of the trimanganese tetraoxide complex crystal and the mixing uniformity of the complex are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

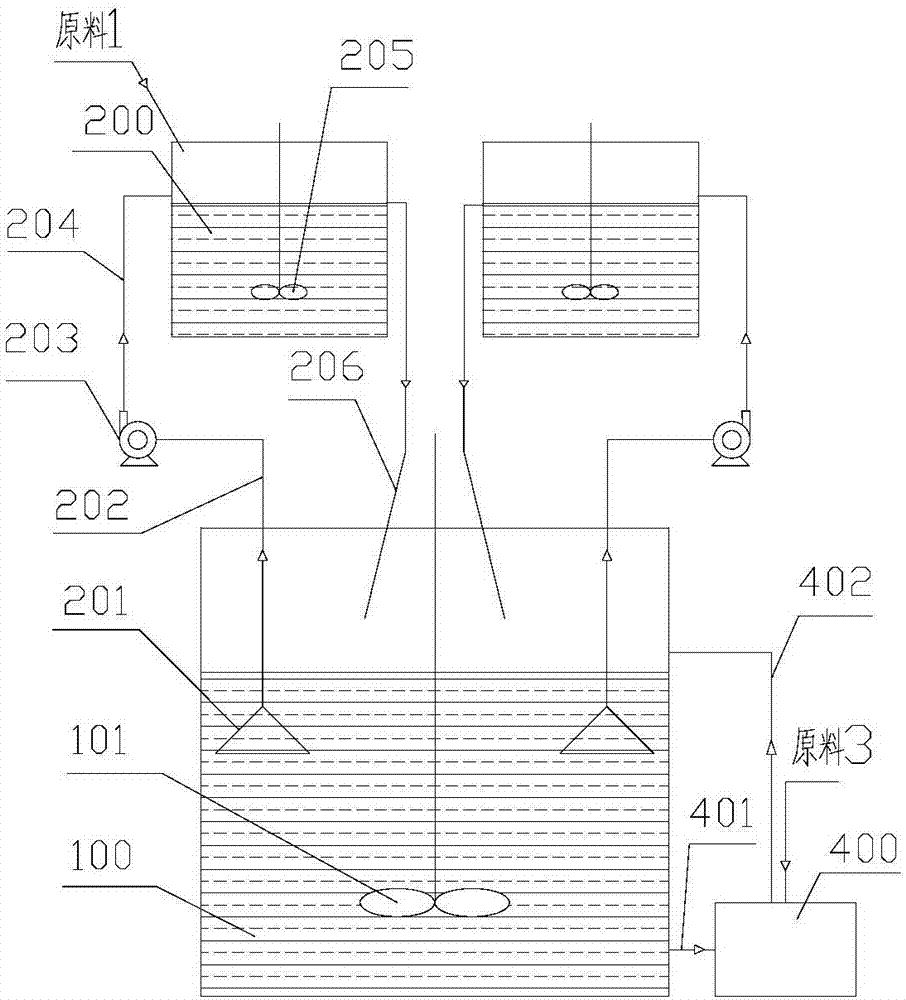

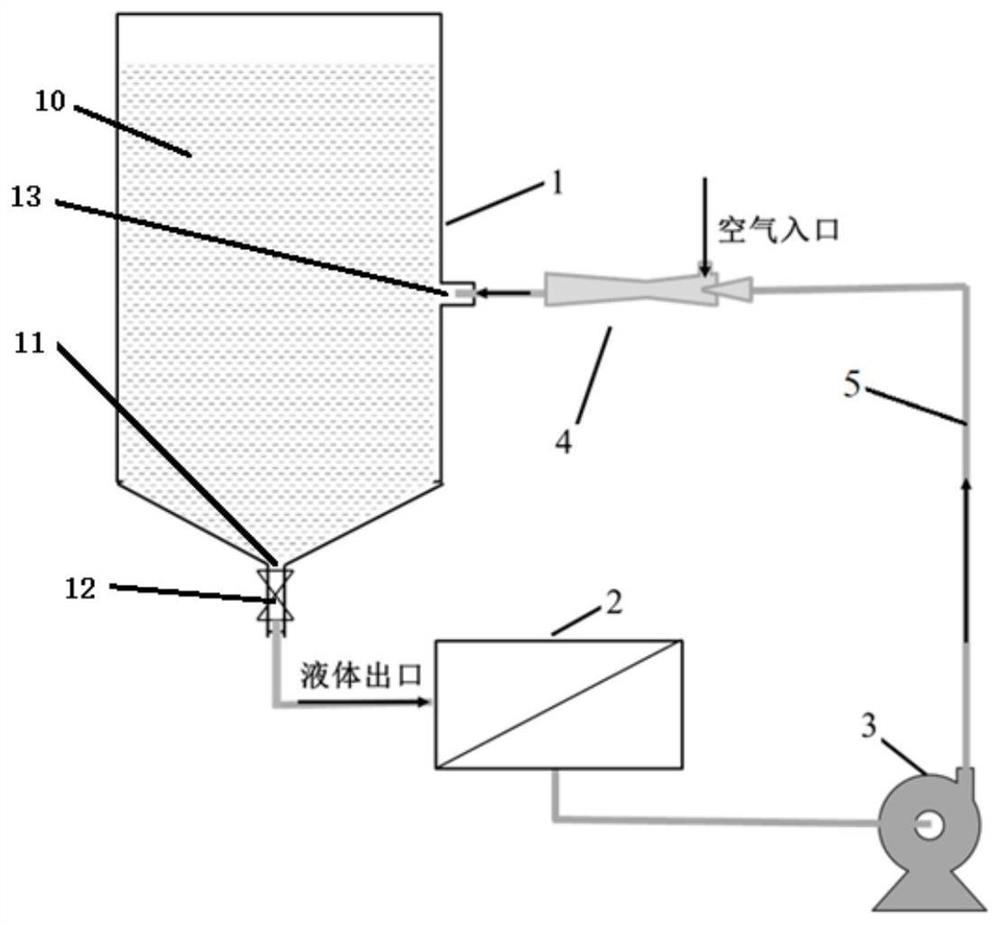

Preparation method and used reaction system of trimanganese tetraoxide, and uses of used reaction system

ActiveCN107540022AGuaranteed SolubilityGuaranteed dissolution rateManganese oxides/hydroxidesMicro nanoGeneration rate

The invention relates to a preparation method and a preparation system of trimanganese tetraoxide. The preparation method comprises: introducing micro-nano gas bubbles into a reaction liquid mixture containing a manganese source to obtain a liquid-gas mixture containing the micro-nano gas bubbles and the reaction liquid mixture, and carrying out a reaction to obtain trimanganese tetraoxide, wherein the micro-nano gas bubbles contain oxidizing gas, and the average valence of the manganese in the manganese source is less than 8 / 3. According to the present invention, by introducing the micro-nanogas bubbles containing the oxidizing gas into the reaction system containing the manganese source, the oxidation reaction rate is improved, and the oxidation reaction time is shortened; and the generation rate of the trimanganese tetraoxide is increased, the particle size of the trimanganese tetraoxide is reduced, the develop integrity of the trimanganese tetraoxide crystal is improved, and the defect of the crystal is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing 2-butenoic acid

ActiveCN101979371AWell mixedIncrease reaction pressureOrganic compound preparationChemical/physical/physico-chemical nozzle-type rreactors2 Butenoic AcidsOxygen

The invention provides a method for producing 2-butenoic acid, which comprises the following steps: preparing mixed feed liquid from 2-butenoic aldehyde, normal hexane and water in a weight ratio of 1:1:0.05-0.08; mounting an ejector pump on an oxidation reaction kettle for spraying the mixed feed liquid into the oxidation reaction kettle; introducing oxygen into the oxidation reaction kettle to perform a reaction under a condition that the reaction pressure in the oxidation reaction kettle is 0.1 to 0.6MPa and a condition that the temperature is 25 to 35 DEG C to obtain oxidation reaction solution; distilling the oxidation reaction, distilling the remaining 2-butenoic aldehyde under a reduced pressure, recovering the 2-butenoic aldehyde, distilling the remaining normal hexane at normal pressure and obtaining filtrate; and cooling the filtrate to -5 DEG C to 5 DEG C, precipitating, crystallizing and filtering and drying the crystals to obtain the 2-butenoic acid product. The production method has the advantages that: the reaction speed is high; the product yield is high; the energy consumption is small; and the quality of the product obtained is high.

Owner:HENAN ZAITI BIO TECH

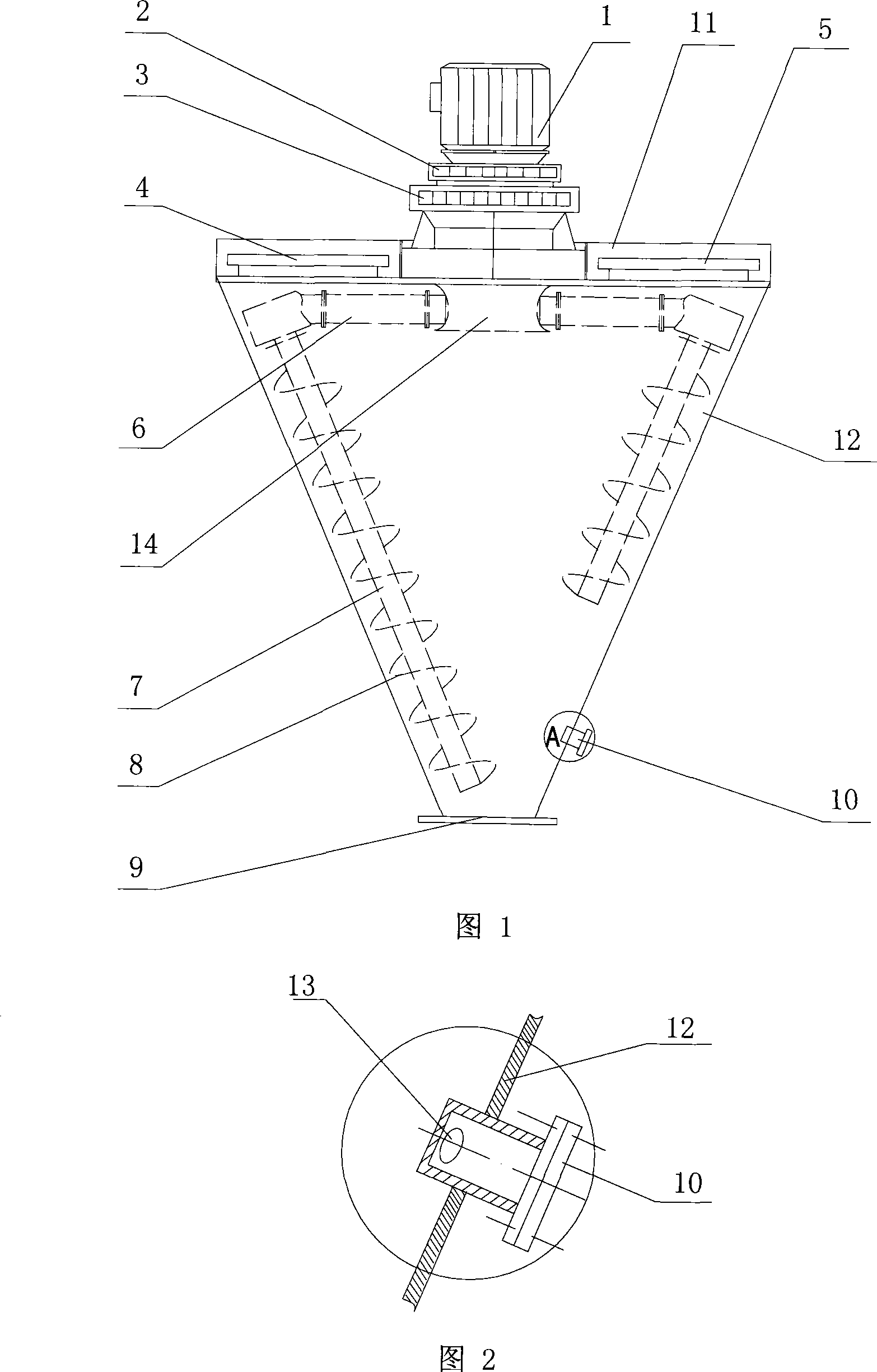

Method for producing iron oxide desulphurizing agent in normal temperature

InactiveCN101219320AHas desulfurization activityEmission reductionChemical industryDispersed particle separationStationary phaseSulfur

The invention relates to a production method for a normal temperature iron oxide desulfurizer, which is characterized in that the production method comprises the steps that: 1) the selection of raw materials according to mass percentage is 10-85 percent of ferrous sulfate heptahydrate, 5-80 percent of insoluble carbonate and 0.5-40 percent of metamanganate according to weight percentage, and the ferrous sulfate heptahydrate, the insoluble carbonate and the metamanganate are prepared for spare; 2) mixing: the insoluble carbonate and the metamanganate are mixed for 20-30 minutes inside a premixer, in which the ferrous sulfate heptahydrate is then fed for continuous mixing; meanwhile, the water is sprayed into the premixer for 5-20 minutes, and the quantity added of the water is 2-40 percent of the weight of the ferrous sulfate heptahydrate, the insoluble carbonate and the metamanganate, thus obtaining a mixture A; 3) stationary phase reaction: the mixture A is added into a conical shell of a stationary phase reactor through a solid material feed inlet of the stationary phase reactor and is reacted through stirring and the action of adequate oxygen, thus obtaining a mixture B; 4) the normal temperature iron oxide desulfurizer is obtained through storing, prilling and drying. The method is characterized by environment protection, energy saving, low production cost, etc.; in addition, the desulfurizer has high purifying rate for removing sulfur.

Owner:湖北蓝焰生态能源有限公司

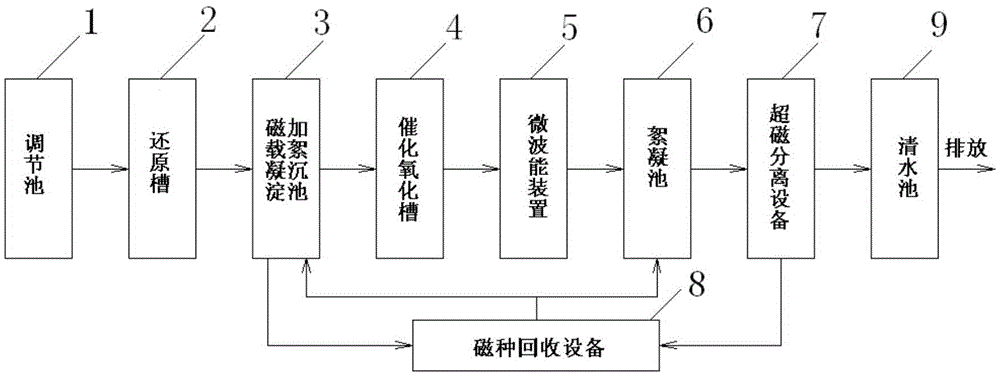

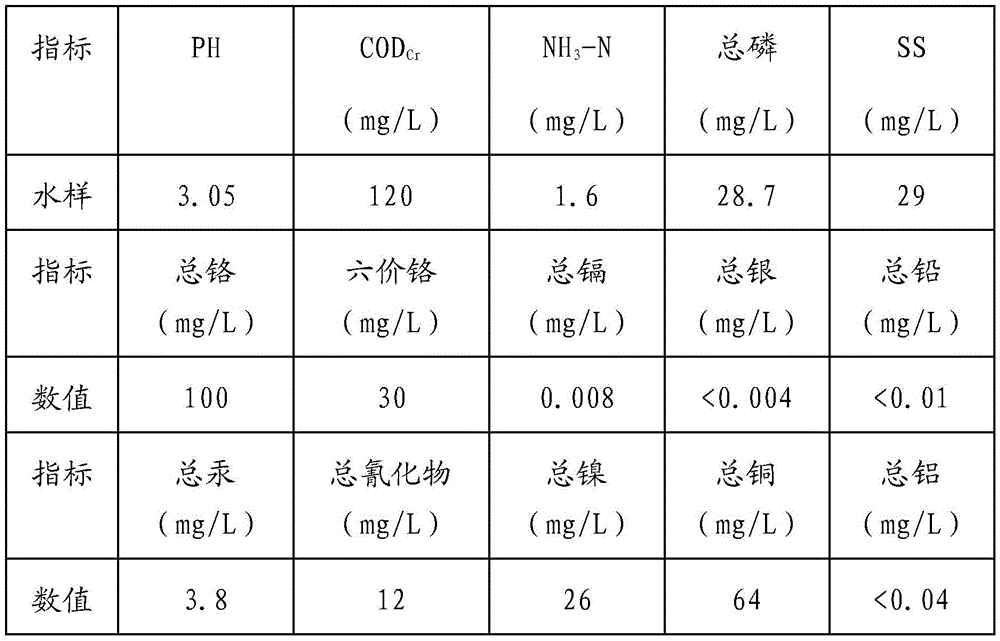

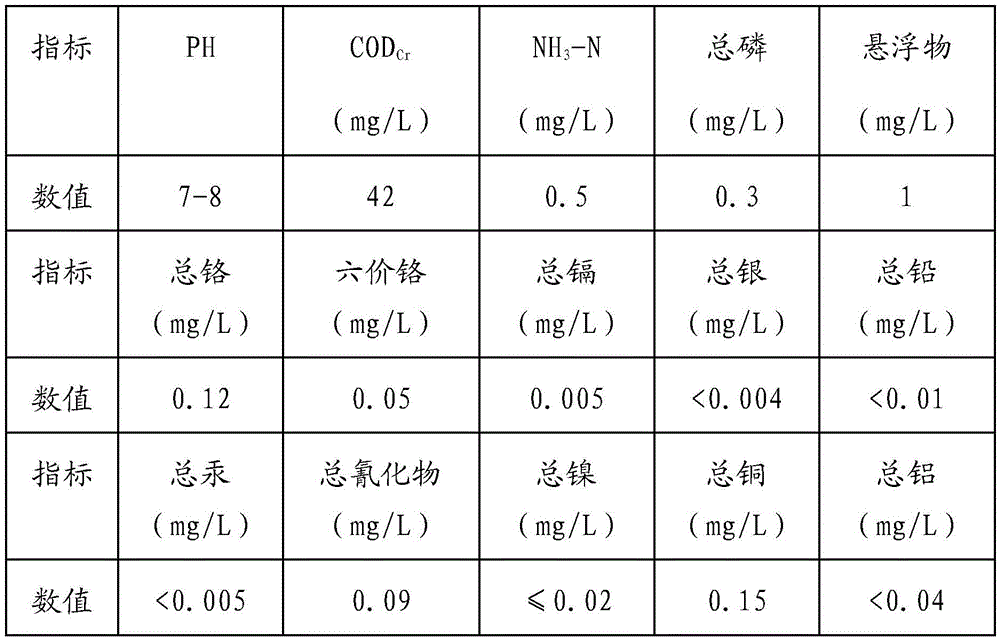

Effluent treatment technology and system based on combination of super magnetic separation and microwave energy technology

InactiveCN105540988AReduce sedimentation residence timeImprove efficiencyWater contaminantsMultistage water/sewage treatmentEnergy technologyMicrowave

The invention provides an effluent treatment technology and system based on combination of super magnetic separation and microwave energy technology. The treatment technology comprises the following steps: S10, adding a reducing agent into the effluent, and enabling a reducing reaction to obtain a mixed liquid A; S20, adding nanoscale magnetic seed powder, a flocculating agent and a coagulant aid to the mixed liquid A, and then conducting flocculating settlement; S30, collecting the supernatant after settlement, adding an oxidizing agent and a catalyst to the supernatant, enabling oxidation reaction to obtain a mixture B; S40, further strengthening the oxidation reaction in a microwave field to obtain a mixture C; S50, adding the nanoscale magnetic seed powder, the flocculating agent and the coagulant aid to the mixture C, and conducting the flocculating settlement reaction to obtain a mixture D; S60, separating effluent, sludge and flocculated grains from the mixture D; S70, recycling the nanoscale magnetic seeds from the flocculated grains.

Owner:航天圣诺(北京)环保科技有限公司

Clean production method of vanillin

ActiveCN104844436AAvoid decompositionInhibit aggregationOrganic compound preparationCarbonyl compound preparationSolventMandelic acid

The invention discloses a clean production method of oxidizing 3-methoxy-4-hydroxy mandelic acid for joint production of vanillin and superfine silver powder under an alkaline condition by adopting silver nitrate. The clean production method comprises the following steps: adding a silver nitrate solution, a 3-methoxy-4-hydroxy mandelic acid solution and a sodium hydroxide solution in a parallel flow manner into a reactor, reacting to generate a 3-methoxy-4-hydroxy acetophenone sodium solution and superfine silver powder, filtering and separating the generated silver powder, washing with deionized water and ethyl alcohol sequentially, and drying to obtain the superfine silver powder, wherein the reduction yield of the silver powder is 99.4 per cent to 100 per cent; acidizing filter liquor after the silver powder is separated, performing decarboxylation on 3-methoxy-4-hydroxy benzoylformic acid to generate the vanillin, using methylbenzene to extract the vanillin therein, recycling the methylbenzene solvent, and performing recrystallization on residues in an ethanol aqueous solution to obtain the vanillin, wherein the oxidation yield of the methoxy-4-hydroxy mandelic acid is 95.7 per cent to 98.5 per cent. The silver nitrate is taken as an oxidizing agent to prepare the vanillin, so that the oxidation yield is improved, and the oxidation reaction time is shortened. Two practical fine chemical products can be produced simultaneously, the raw materials can be sufficiently utilized, the generation of waste materials is reduced, the production cost is reduced, and the technological process is safe and environment-friendly.

Owner:TIANJIN VOCATIONAL INST

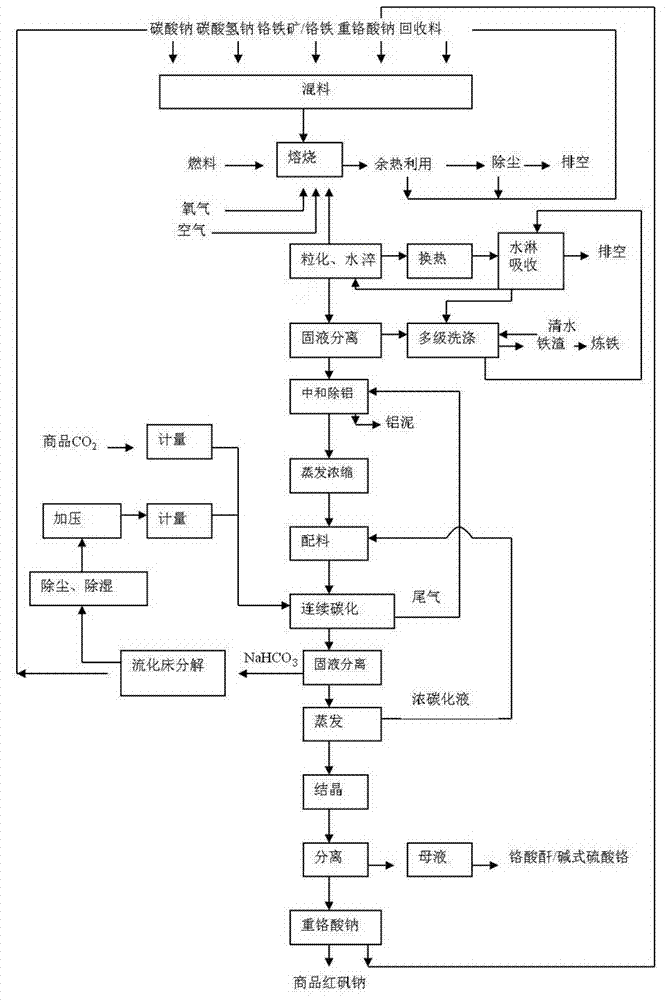

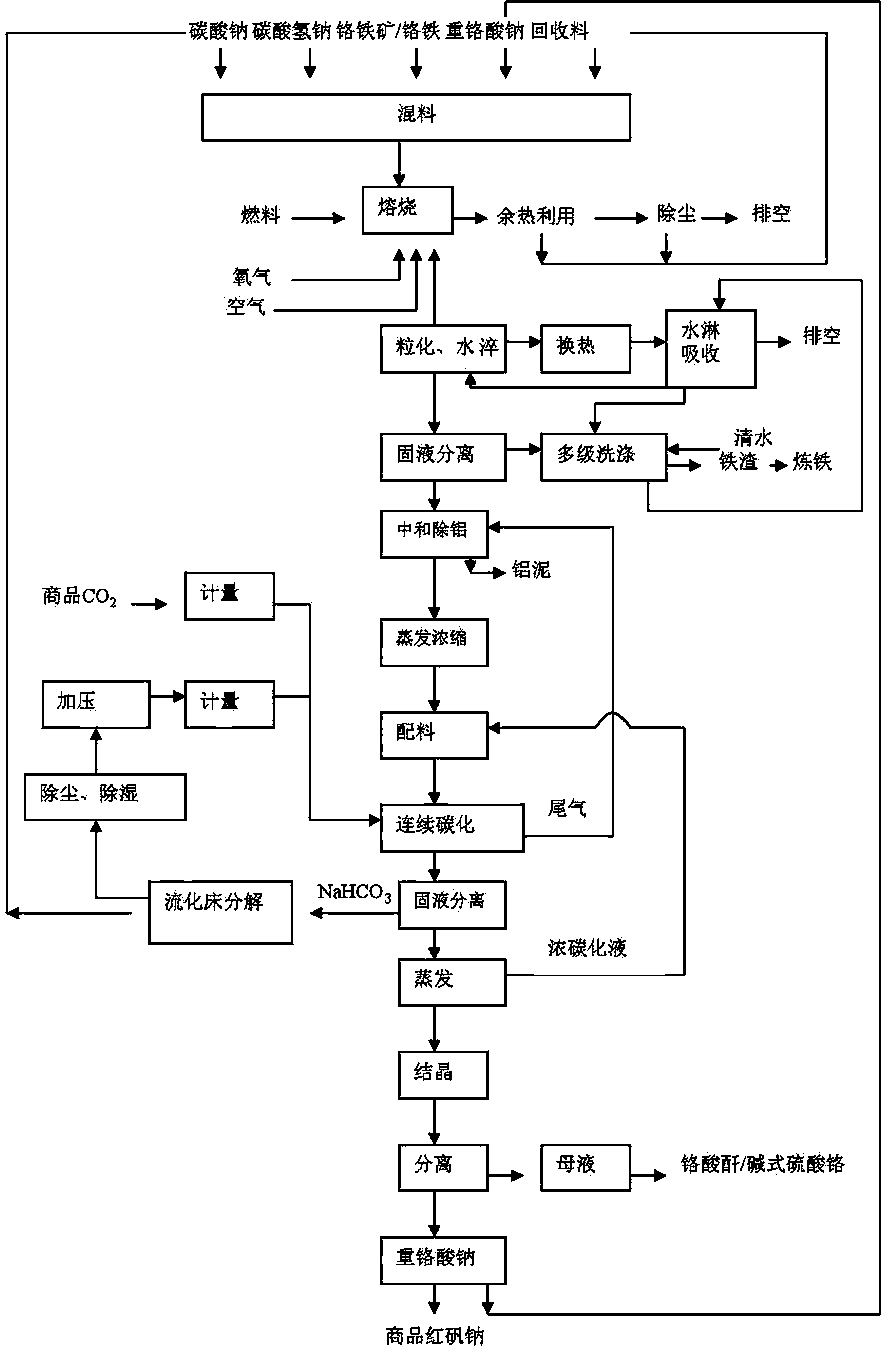

Method for preparing sodium dichromate by sodium-based molten salt oxidation continuous carbonization

ActiveCN103086433AIncrease production capacityShortened mass transfer efficiencyChromates/bichromatesMolten stateCarbonization

The invention discloses a method for preparing sodium dichromate by sodium-based molten salt oxidation continuous carbonization, belonging to the technical field of sodium dichromate. The method comprises the following steps of: (A) mixing materials: mixing chromite powder or ferrochromium powder, sodium-based alkali compound, sodium dichromate and reclaimed materials to form raw material; (B) oxidizing roasting: adding the raw material into a rotary kiln to form molten state and take oxidation reaction, wherein the draw ratio of the rotary kiln is 3-6; (C) leaching: conveying the molten salt into a granulator through a discharge chute to perform granulating and water quenching, and separating slurry to get the sodium chromate solution; (D) carbonization: neutralizing the sodium chromate solution and removing the aluminum from the sodium chromate solution to get the sodium chromate neutral solution; evaporating the sodium chromate neutral solution for concentration, dosing, and then, taking carbonization reaction in a continuous carbonization tower, treating the carbonized liquid with solid-liquid separation to get the carbonized clear liquid, and evaporating and crystallizing the carbonized clear liquid to get the sodium dichromate after separation. The method can effectively prevent accidents, such as accretion, improves the production rate of the kiln, improves the utilization rate of sodium resource by more than 50% and greatly improves the product quality of the sodium dichromate.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

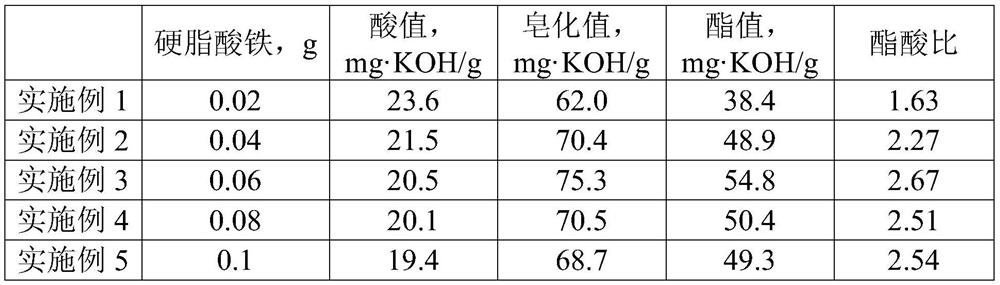

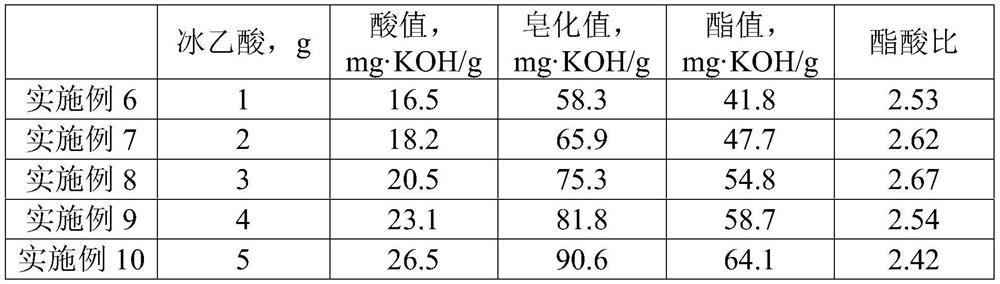

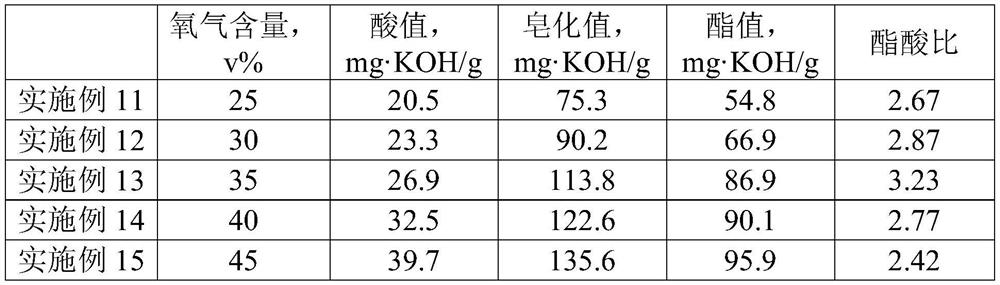

Oxidized wax and preparation method thereof

ActiveCN112852486AControl product distributionIncrease the ester-acid ratioPetroleum chemical modificationPtru catalystCatalytic oxidation

The invention relates to the field of preparation of oxidized wax, in particular to oxidized wax and a preparation method thereof. The method comprises the following steps: in the presence of a catalyst and an auxiliary agent, molten Fischer-Tropsch wax and oxygen-containing gas are subjected to a catalytic oxidation reaction to obtain oxidized wax, wherein the catalyst is an iron-based catalyst and / or a cobalt-based catalyst. According to the method provided by the invention, the Fischer-Tropsch wax is subjected to oxidation reaction to realize directional oxidation, so that the product distribution of the oxidized wax product is controlled, the reaction product is performed towards the target of generating more esters, and the ester-acid ratio of the oxidized wax product is increased; meanwhile, the production cost is reduced, and industrial production design is facilitated.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

Method for producing 2-butenoic acid

ActiveCN101979371BWell mixedIncrease reaction pressureOrganic compound preparationChemical/physical/physico-chemical nozzle-type rreactors2 Butenoic AcidsOxygen

The invention provides a method for producing 2-butenoic acid, which comprises the following steps: preparing mixed feed liquid from 2-butenoic aldehyde, normal hexane and water in a weight ratio of 1:1:0.05-0.08; mounting an ejector pump on an oxidation reaction kettle for spraying the mixed feed liquid into the oxidation reaction kettle; introducing oxygen into the oxidation reaction kettle to perform a reaction under a condition that the reaction pressure in the oxidation reaction kettle is 0.1 to 0.6MPa and a condition that the temperature is 25 to 35 DEG C to obtain oxidation reaction solution; distilling the oxidation reaction, distilling the remaining 2-butenoic aldehyde under a reduced pressure, recovering the 2-butenoic aldehyde, distilling the remaining normal hexane at normal pressure and obtaining filtrate; and cooling the filtrate to -5 DEG C to 5 DEG C, precipitating, crystallizing and filtering and drying the crystals to obtain the 2-butenoic acid product. The production method has the advantages that: the reaction speed is high; the product yield is high; the energy consumption is small; and the quality of the product obtained is high.

Owner:HENAN ZAITI BIO TECH

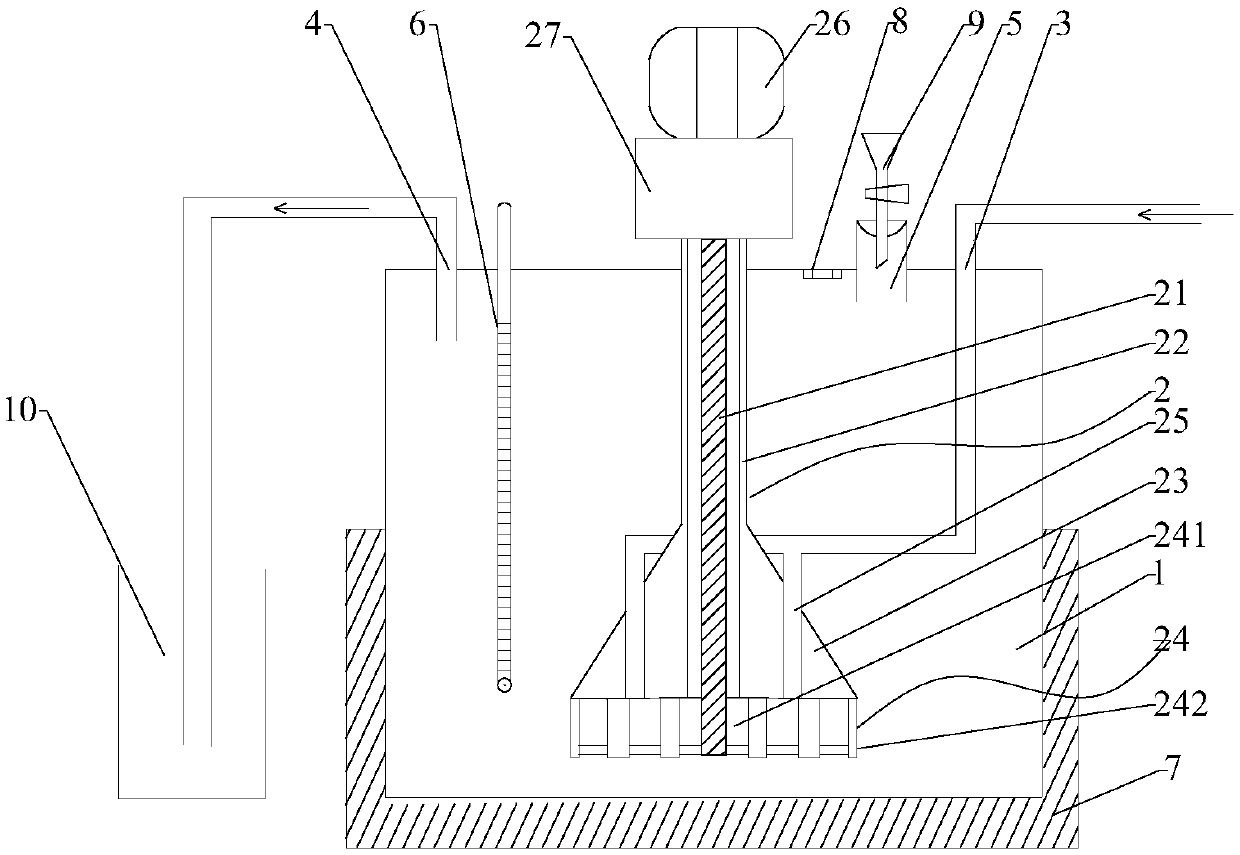

Process and device for preparing ferric chloride

The invention belongs to the technical field of waste liquid treatment, and provides a device for preparing ferric chloride. The device comprises a reaction groove, wherein the reaction groove comprises a reaction groove body, a stirring mechanism, an air inlet, an air outlet and a catalyst inlet; the air inlet and the air outlet are both formed in the upper part of the reaction groove body; the stirring mechanism extends into the reaction groove body; the stirring mechanism comprises a transmission shaft, a hollow shaft sleeve and an impeller; the hollow shaft sleeve is sleeved on the transmission shaft; the impeller is arranged below the hollow shaft sleeve; an air inlet pipeline is connected to the air inlet; and the air inlet pipeline is connected with the impeller. The invention further provides a process for preparing ferric chloride by adopting the device for preparing ferric chloride. The process includes taking a pickling waste liquid as a raw material; adopting NH4Cl, NH4NO3,MnCl2 or HNO3 as cocatalysts, and cooperating with a main catalyst NaNO2 to jointly catalyze an oxidation reaction of ferrous chloride, hydrogen chloride and oxygen or air under normal pressure. Thedevice and the process solve the problems of high danger and high cost of adopting high-temperature high-pressure oxidation pickling waste liquid in the preparation of ferric chloride in the prior art.

Owner:唐山达润达危废处理有限公司 +1

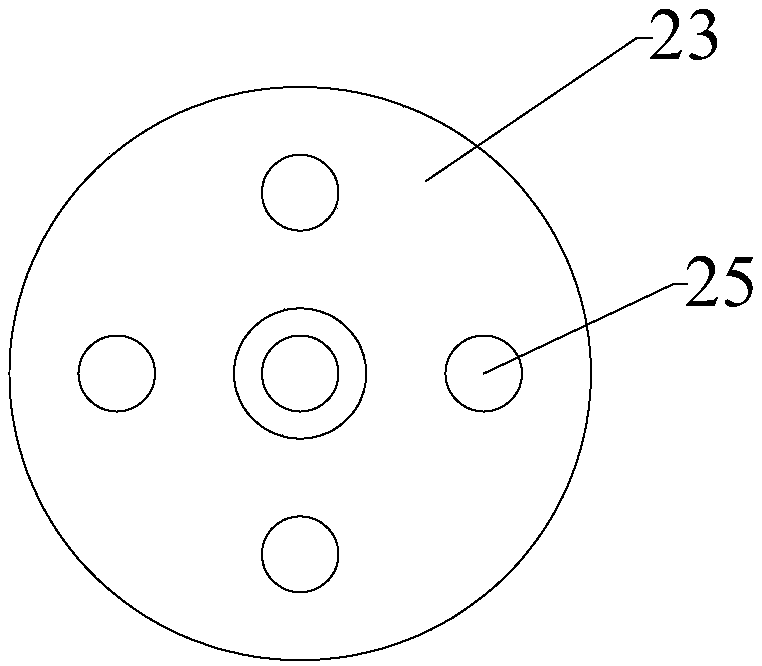

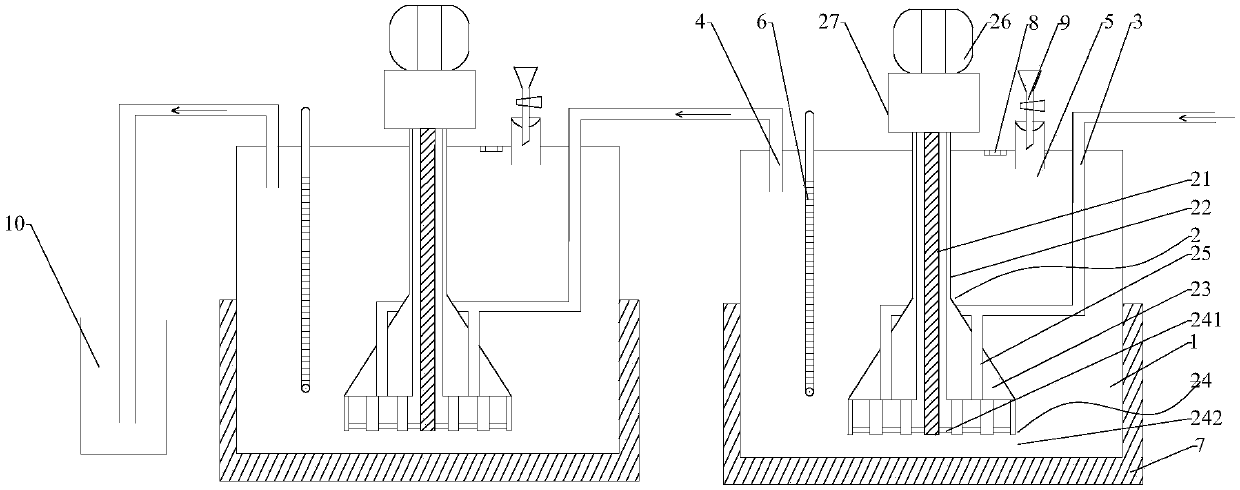

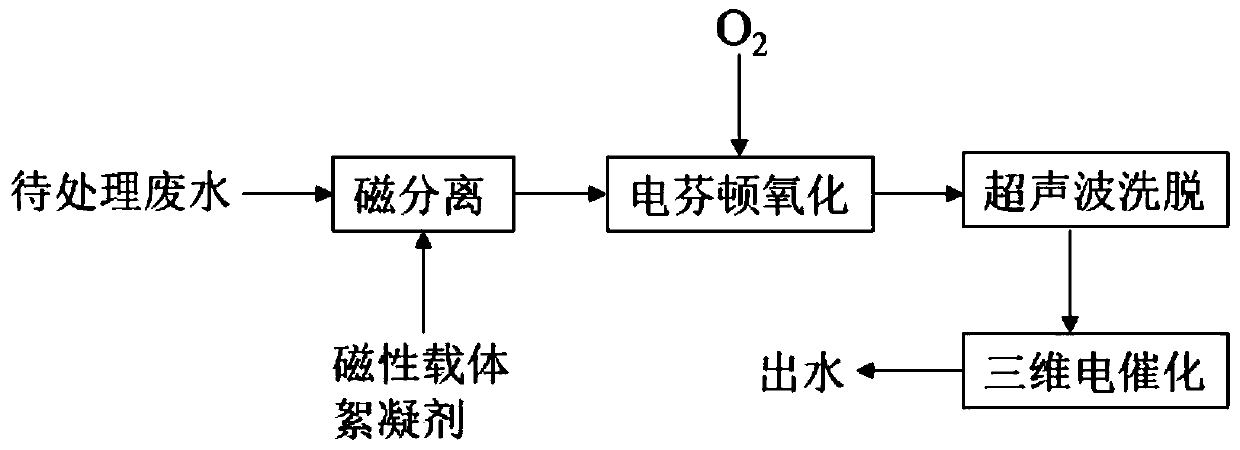

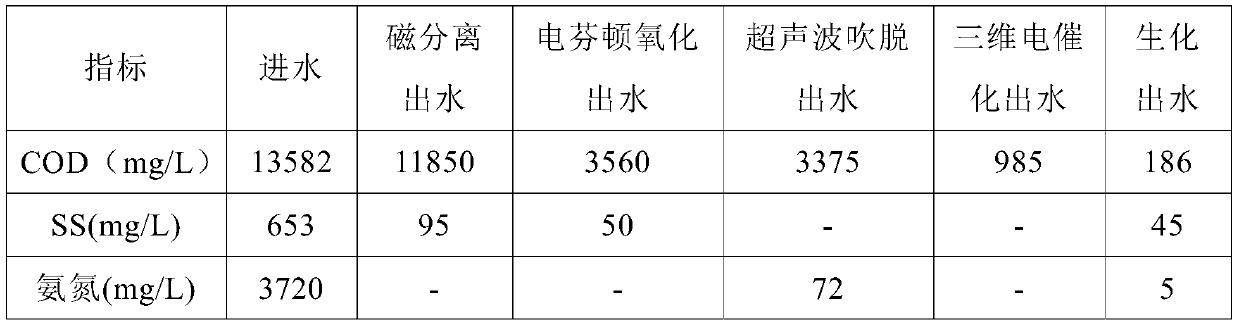

Comprehensive treatment method for high-salinity high-concentration organic wastewater

InactiveCN109851149AGood effectShort reaction timeWater contaminantsMultistage water/sewage treatmentHigh concentrationReaction rate

The invention relates to the technical field of water treatment and discloses a comprehensive treatment method for high-salinity high-concentration organic wastewater. The method comprises the steps of subjecting the wastewater to be treated to magnetic separation treatment, Fenton oxidation treatment, blow-off treatment, electrocatalytic treatment and biochemical treatment sequentially and finally yielding water. According to the method, a variety of wastewater treatment technologies are properly optimized and combined, and thus, defects of single treatment technologies are made up, so that the method has the advantages that the effect of treating the organic wastewater is good, the reaction time is short, and a good reaction rate can be maintained under low-temperature conditions.

Owner:南京华创环境技术研究院有限公司

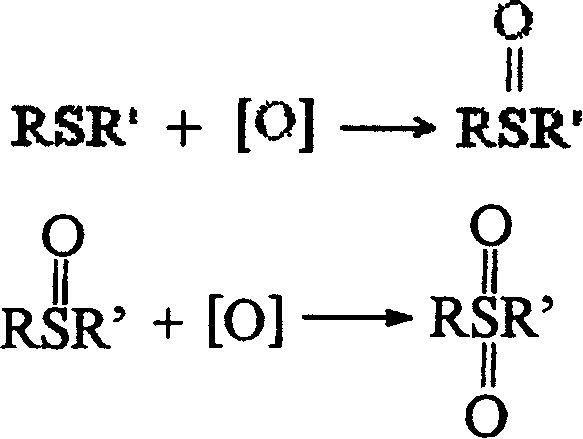

Process of catalyzing oxidizing desulfating for straight distillation diesel oil

ActiveCN100386410CReduce sulfur contentWell mixedHydrocarbon oils refiningDistillationCatalytic oxidation

The invention relates to desulfurating method for the straight-run diesel oil by the oxidation. The nitrate acid which is 35-70%wt is the oxidant the volume ration of the straight-run diesel oil and the oxidant is 100:5-50. The reaction temperature is 40-80DEG C and the time is 1-30min. The oxidant after reaction can be recovered. The diesel oil product can be got after the extraction, the filtering and adsorption. The processes can desulphurate and deacidification at the same time, so it has the low cost according to the hydrotreating for the FCC diesel oil and the devulcanization by the H2O2.

Owner:PETROCHINA CO LTD

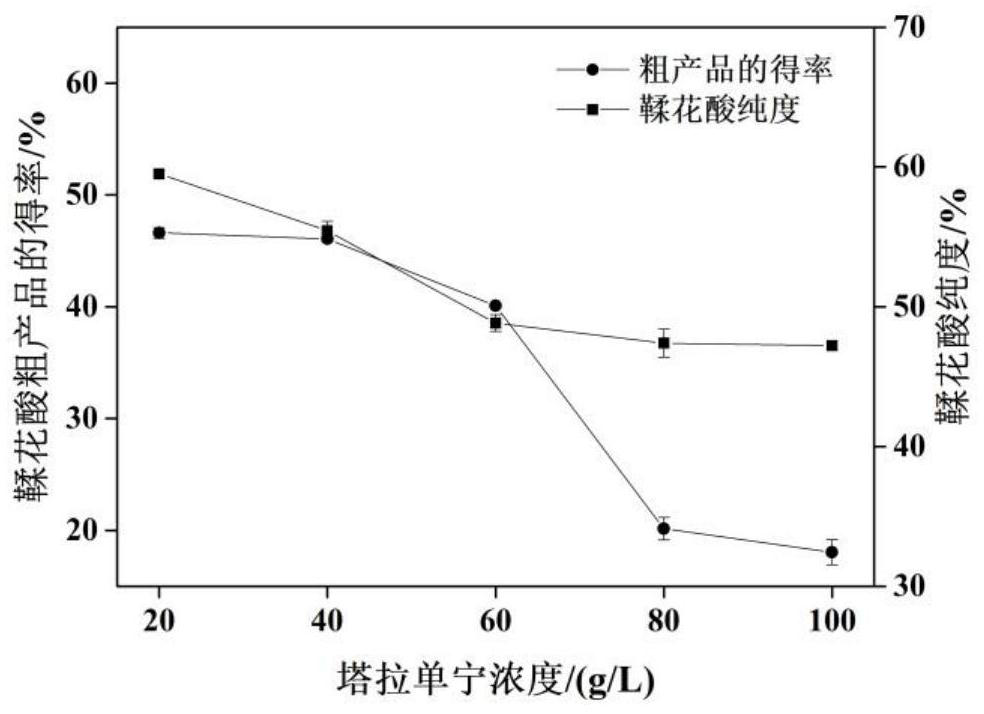

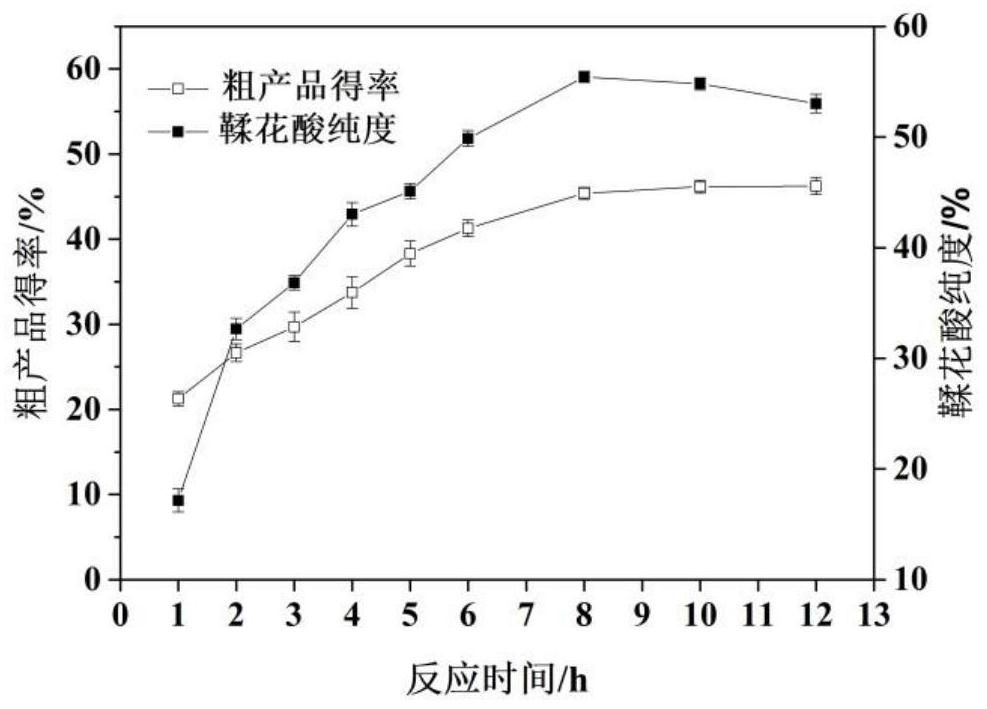

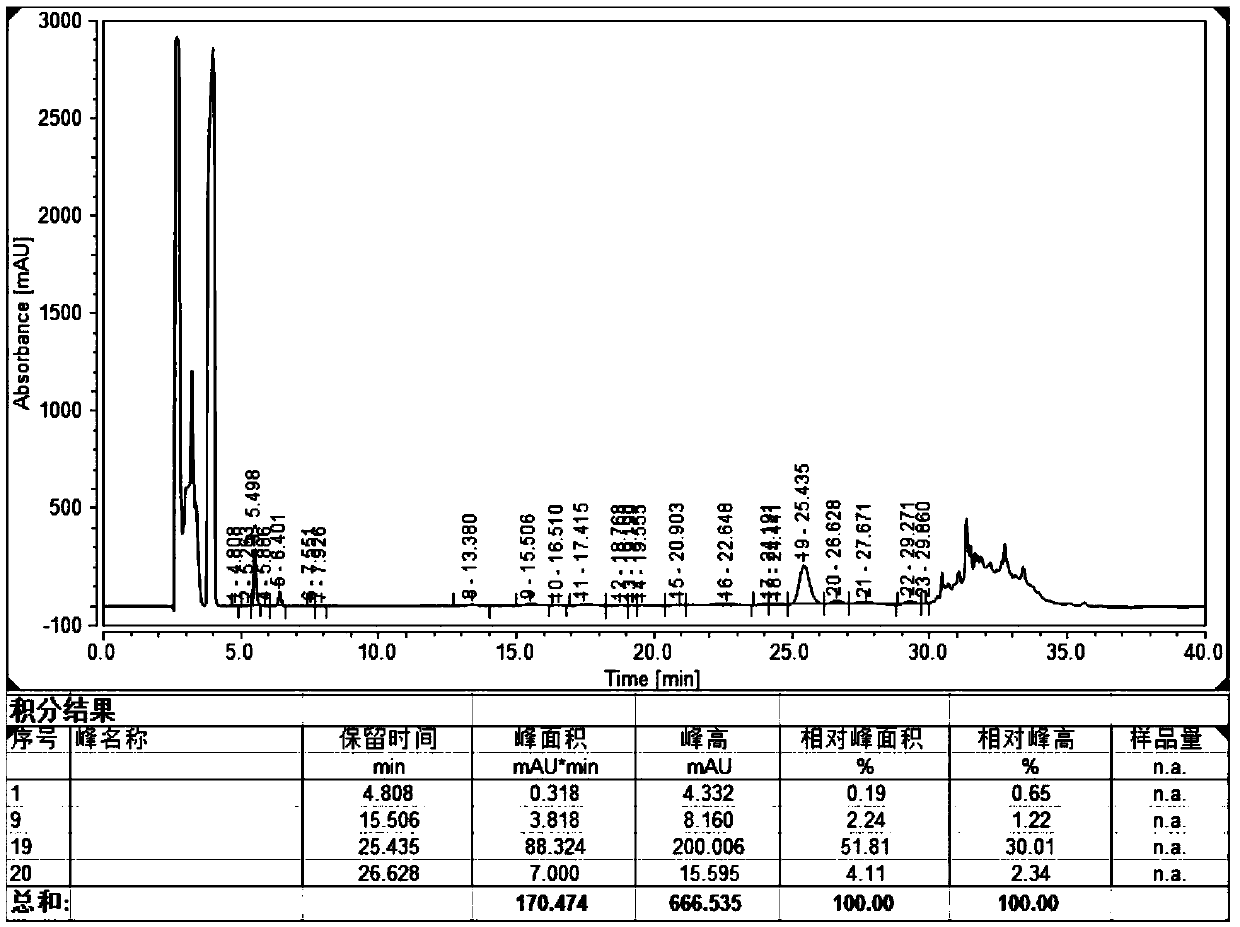

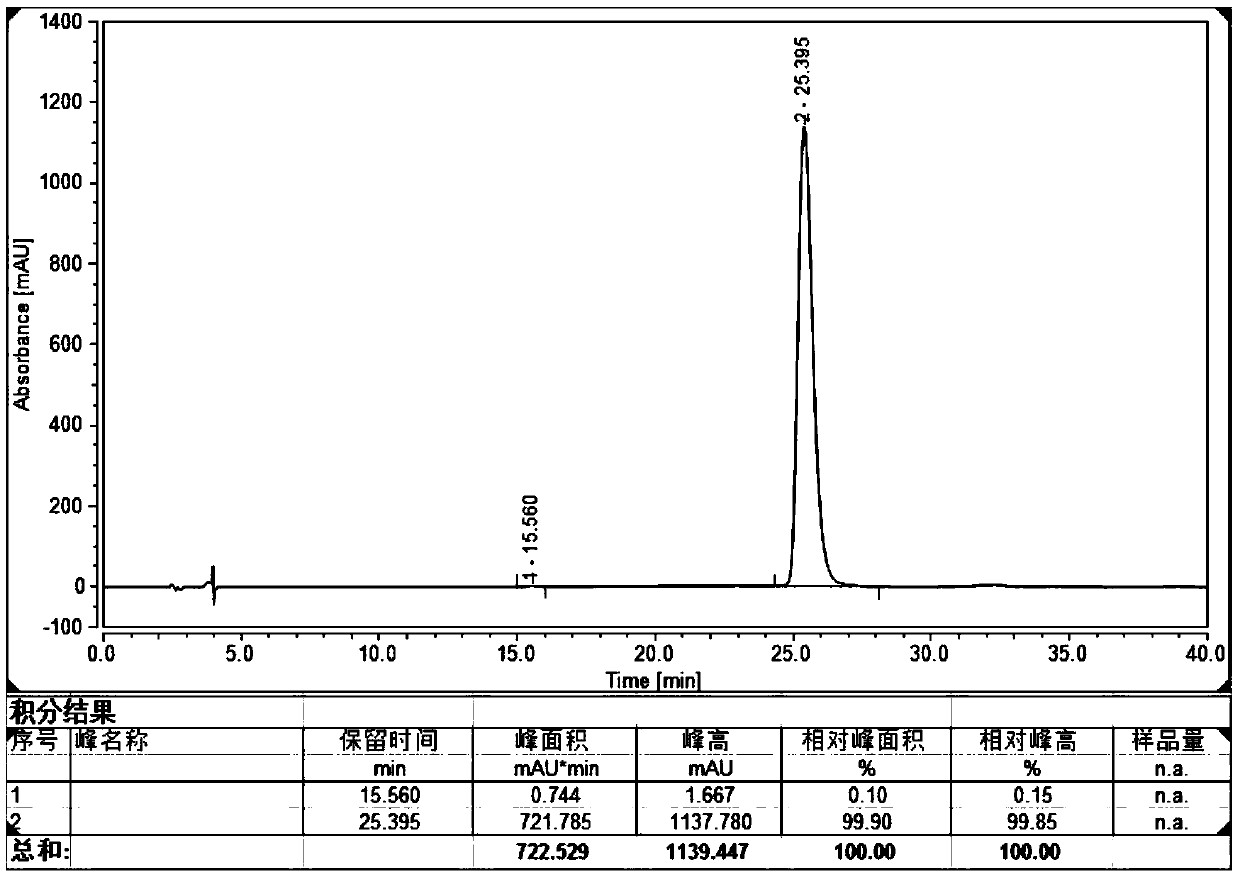

Method for preparing ellagic acid by using tara tannin

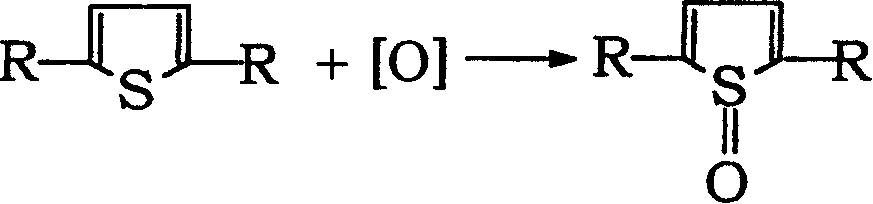

ActiveCN112645961AIncrease contact areaPromote oxidation reactionOrganic chemistryChemical/physical/physico-chemical stationary reactorsBiotechnologyOrganic chemistry

The invention discloses a method for preparing ellagic acid by using tara tannin. The method comprises the following steps: under the action of a jet pump, repeatedly mixing tara tannin reaction liquid with air, carrying out oxidation reaction to prepare ellagic acid, and also purifying or / and refining the crude ellagic acid product prepared by oxidation treatment to obtain high-purity refined ellagic acid. The ellagic acid prepared by adopting the method is high in yield and purity, the thermal stability of the ellagic acid is improved, the ellagic acid is prepared by combining a liquid-gas jet oxidation method and a solvent washing method, the ellagic acid preparation time is greatly shortened, the purity of the ellagic acid is obviously improved, the production efficiency of industrial production of the ellagic acid is remarkably improved, the method is suitable for industrial large-scale production of ellagic acid, and widens the application of ellagic acid in the fields of medicines and cosmetics.

Owner:WUFENG CHICHENG BIOTECH +1

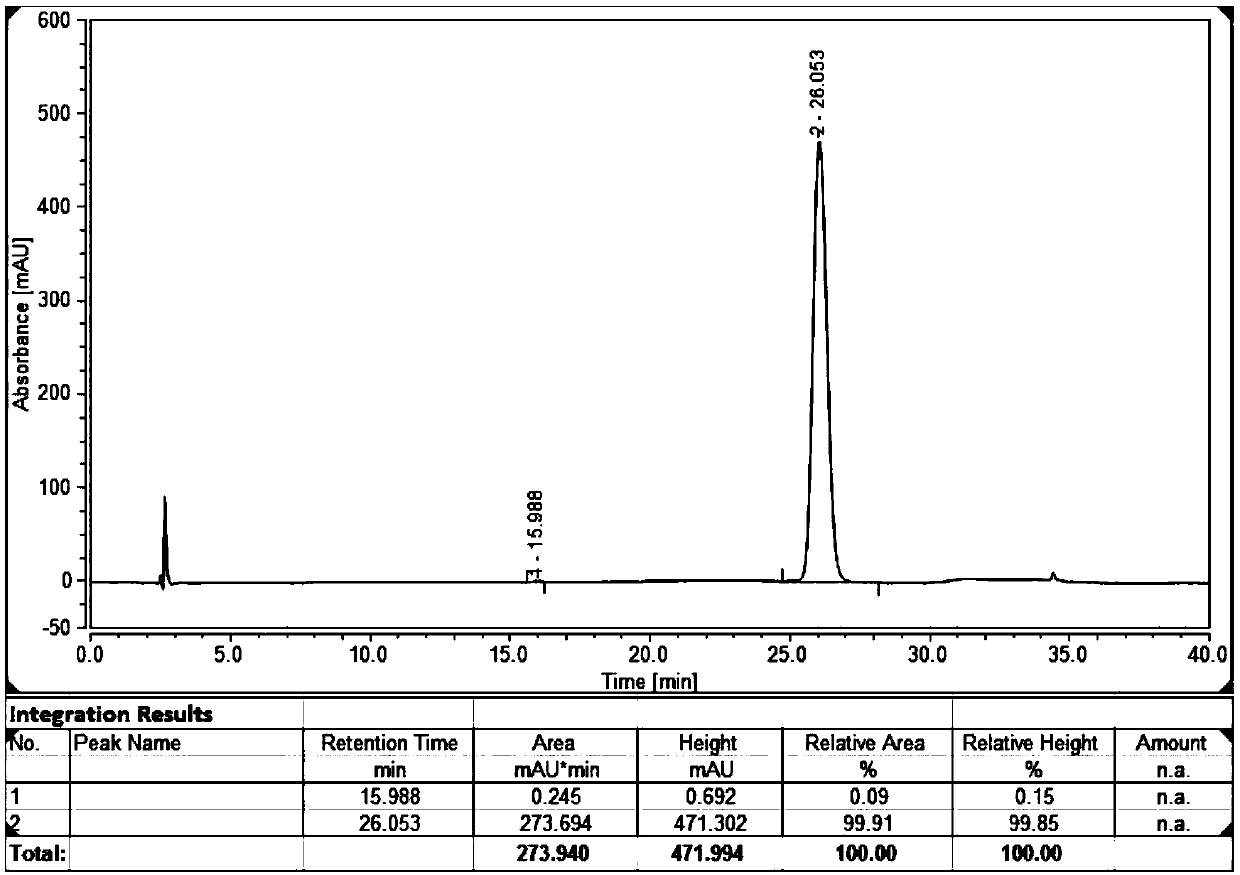

Method for preparing and purifying polypeptides

ActiveCN110845599AShorten the oxidation reaction timeEffective separation and removalGastrin releasing peptidePeptide preparation methodsMethionine biosynthesisOrganic chemistry

The invention belongs to the technical field of medicine, and particularly discloses a method for preparing and purifying polypeptides. A method for inhibiting methionine oxidation is used in the preparation and purification process of ularitide, so that the purity of the purified refined ularitide is as high as 99.90%, and methionine oxidation impurity peptides are controlled within 0.1%.

Owner:LUNAN PHARMA GROUP CORPORATION

Ferrous air oxidation reaction catalyst

ActiveCN103816938AHigh speedLower activation energyOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatment by oxidationNitritePhysical chemistry

The invention discloses a ferrous air oxidation reaction catalyst which comprises the components in parts by weight: 10-30 parts of nitrite, 10-20 parts of soluble copper salt, 2-10 parts of strong oxidization acid, 8-20 parts of a copper complexing agent, 2-8 parts of a copper ion stabilizing agent, 0.3-0.8 part of a mildew preventive and 32-49 parts of deionized water. All components in the catalyst can have reaction with ferric ions and oxygen molecules at the same time, so that the activity of a reaction process is reduced; therefore, the ferric ion oxidization reaction speed is greatly increased, and the oxidization reaction time is shortened.

Owner:BAOSHAN IRON & STEEL CO LTD

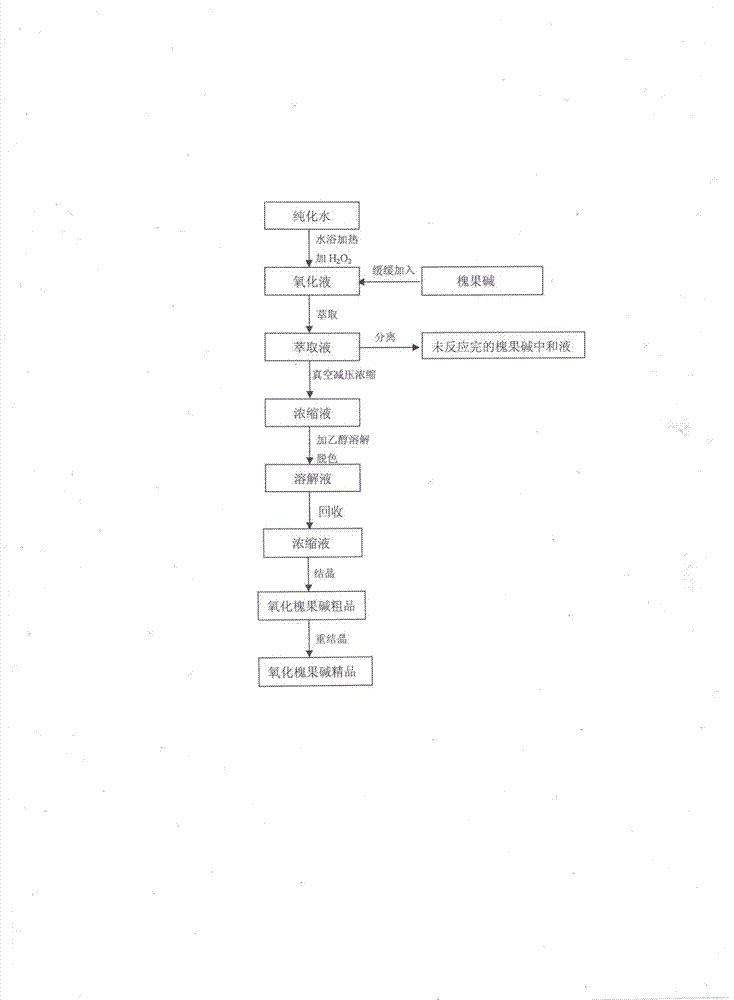

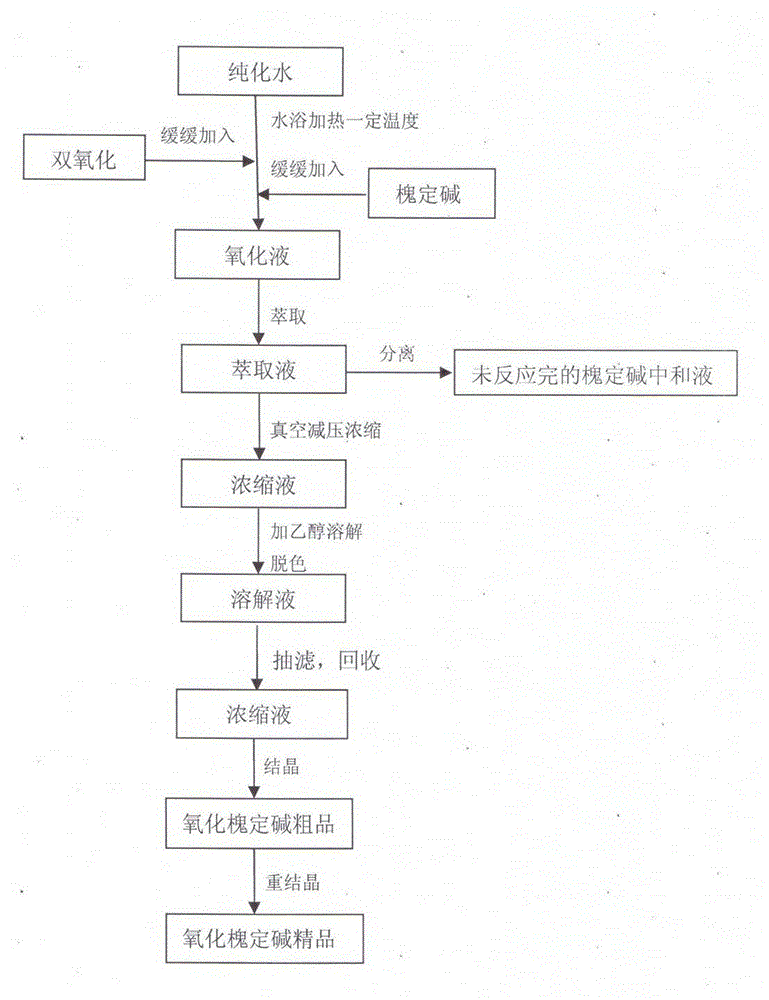

Preparation method high-purity high-yield oxysophocarpine

The invention provides a preparation method high-purity high-yield oxysophocarpine. The method comprises the following steps: firstly heating purified water in a water bath to a certain temperature, adding hydrogen peroxide, slowly adding sophocarpine, reacting at a certain temperature till hydrogen peroxide is completely consumed, then extracting the residual small amount of sophocarpine; performing reduced pressure concentration of the reaction solution, adding alcohol substances into the concentrate for dissolution, adding alumina for decoloring, performing suction filtration; continuing to perform reduced pressure concentration, adding ketone substances for crystallization, and performing recrystallization to obtain oxysophocarpine. The process method is simple and practical, low in cost, high in purity, high in yield, and suitable for industrial production.

Owner:NINGXIA BAUHINIA PHARMA

High-softening-point asphalt preparation method suitable for asphalt-based spherical activated carbon raw materials

ActiveCN109251759ARealize continuous productionSimple processWorking-up pitch/asphalt/bitumen by chemical meansHeptaneCoal

The invention relates to a high-softening-point asphalt preparation method suitable for asphalt-based spherical activated carbon raw materials, special asphalt with the softening point of 130-220 DEGC is used as a raw material, a synergistic effect of negative pressure extraction and thermal polymerization reaction is utilized, a double-screw extruder with a certain number of vacuumizing ports isadopted, and the molecular weight distribution, softening point, group composition and other physical and chemical properties of high-softening point coal asphalt can be adjusted by adjusting the temperature and the extrusion speed of each temperature zone of the double-screw extruder, the number, the setting positions and the vacuum degrees of the vacuumizing ports. The softening point of the prepared high softening point asphalt is 240-280 DEG C, the content of n-heptane soluble substances is lower than 10%, the content of toluene soluble substances is lower than 30%, the content of quinoline insoluble substances is higher than 35%, the content of pyridine insoluble substances is higher than 20%, and the ash content is 0.02-8%. The high-softening-point asphalt preparation method has important significance for promotion of resource reutilization of the special asphalt and the asphalt-based spherical activated carbon and related materials (such as asphalt-based foam carbon).

Owner:湖南曦威新材料有限公司

Reverse osmosis concentrated water treatment method

ActiveCN102372376BGuaranteed treatment effectShorten the oxidation reaction timeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationCatalytic oxidation

A reverse osmosis concentrated water treatment method comprises the following steps: (1) adopting multi-phase catalytic oxidation technique to achieve deep oxidation and maximally remove organic pollutants in wastewater; (2) adding the effluent after catalytic oxidation into an adsorption reaction tank, in which a proper amount of powdered active carbon is added, and fully reacting for a period of time by aeration or stirring and the like to adsorb organic pollutants in the wastewater, wherein the adsorption effect depends on the addition amount of the powdered active carbon; and (3) filtering the effluent after the adsorption reaction by submerged ultrafiltration to further improve the quality of the effluent, which can be discharged directly. According to the reverse osmosis concentrated water treatment method, the oxidation reaction time can be reduced and the oxidation reaction effect can be enhanced at the same time, and not only can the wastewater treatment effect be ensured but also the treatment cost is greatly lowered when the method is in combination with the powdered active carbon adsorption process. In addition, the method has the advantages of simple process flow and high operability, and is worth popularizing.

Owner:CHINA PETROLEUM & CHEM CORP +1

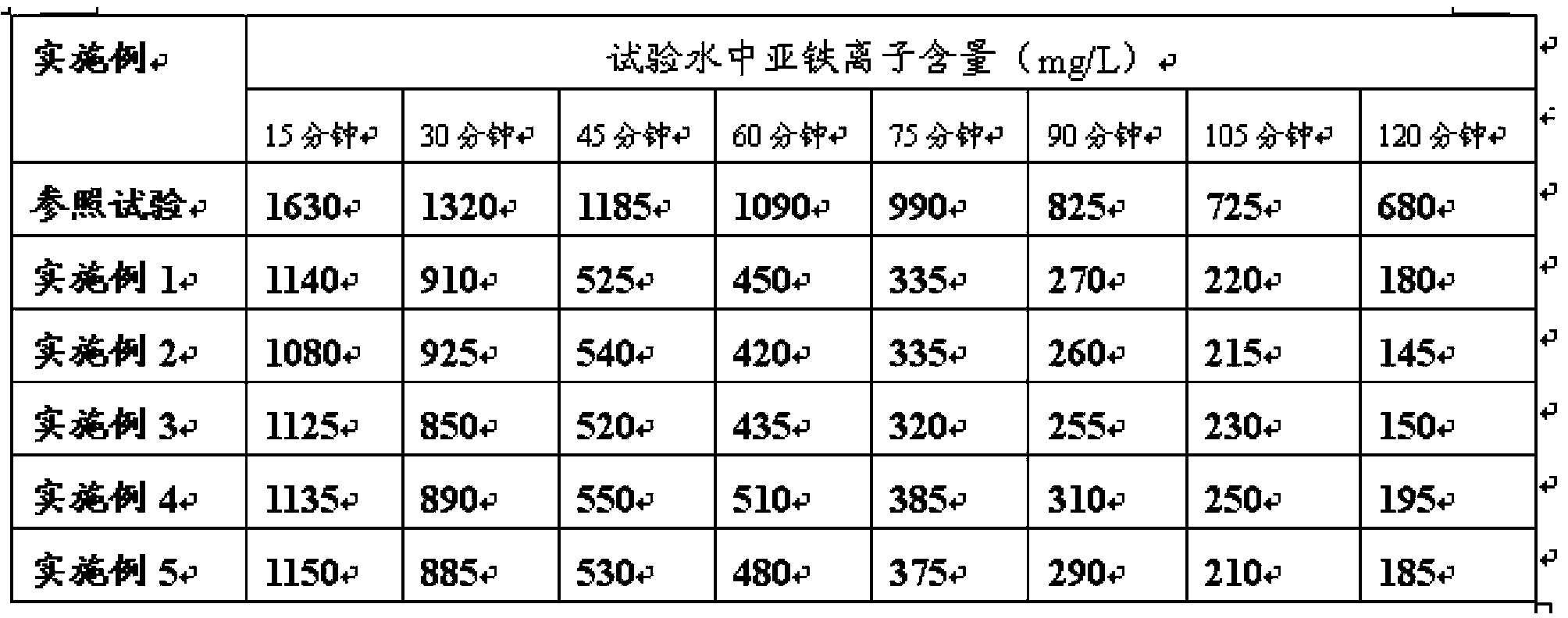

Method for preparing high-purity high-yield oxysophoridine

InactiveCN102863443AThe oxidation reaction is rapid and sufficientShorten the oxidation reaction timeOrganic chemistryBenzeneWater baths

The invention provides a method for preparing high-purity high-yield oxysophoridine. The preparation method comprises the following steps of: heating purified water in an oxidation tank to a certain temperature in water bath; adding hydrogen peroxide; uniformly mixing by stirring; slowly adding sophoridine; stirring until the sophoridine is dissolved; after hydrogen peroxide is completely reacted at a certain temperature, extracting residual sophoridine by using benzene or ether to obtain a reacted solution; concentrating the reacted solution under reduced pressure to obtain a concentrated solution; adding alcohol to dissolve the concentrated solution; decoloring a solution by adding a decoloring agent; performing suction filtration on the decolored solution to obtain filtrate; concentrating the filtrate under reduced pressure; adding ketone substances and performing crystallization to obtain a coarse product of oxysophoridine; and performing re-crystallization to obtain purified oxysophoridine. The process method is simple and practical and is applied to industrialized production, the cost is low, the purity is high, and the product yield is high.

Owner:NINGXIA BAUHINIA PHARMA

Method for preparing sodium dichromate by sodium-based molten salt oxidation continuous carbonization

ActiveCN103086433BIncrease production capacityShortened mass transfer efficiencyChromates/bichromatesMolten stateCarbonization

The invention discloses a method for preparing sodium dichromate by sodium-based molten salt oxidation continuous carbonization, belonging to the technical field of sodium dichromate. The method comprises the following steps of: (A) mixing materials: mixing chromite powder or ferrochromium powder, sodium-based alkali compound, sodium dichromate and reclaimed materials to form raw material; (B) oxidizing roasting: adding the raw material into a rotary kiln to form molten state and take oxidation reaction, wherein the draw ratio of the rotary kiln is 3-6; (C) leaching: conveying the molten salt into a granulator through a discharge chute to perform granulating and water quenching, and separating slurry to get the sodium chromate solution; (D) carbonization: neutralizing the sodium chromate solution and removing the aluminum from the sodium chromate solution to get the sodium chromate neutral solution; evaporating the sodium chromate neutral solution for concentration, dosing, and then, taking carbonization reaction in a continuous carbonization tower, treating the carbonized liquid with solid-liquid separation to get the carbonized clear liquid, and evaporating and crystallizing the carbonized clear liquid to get the sodium dichromate after separation. The method can effectively prevent accidents, such as accretion, improves the production rate of the kiln, improves the utilization rate of sodium resource by more than 50% and greatly improves the product quality of the sodium dichromate.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

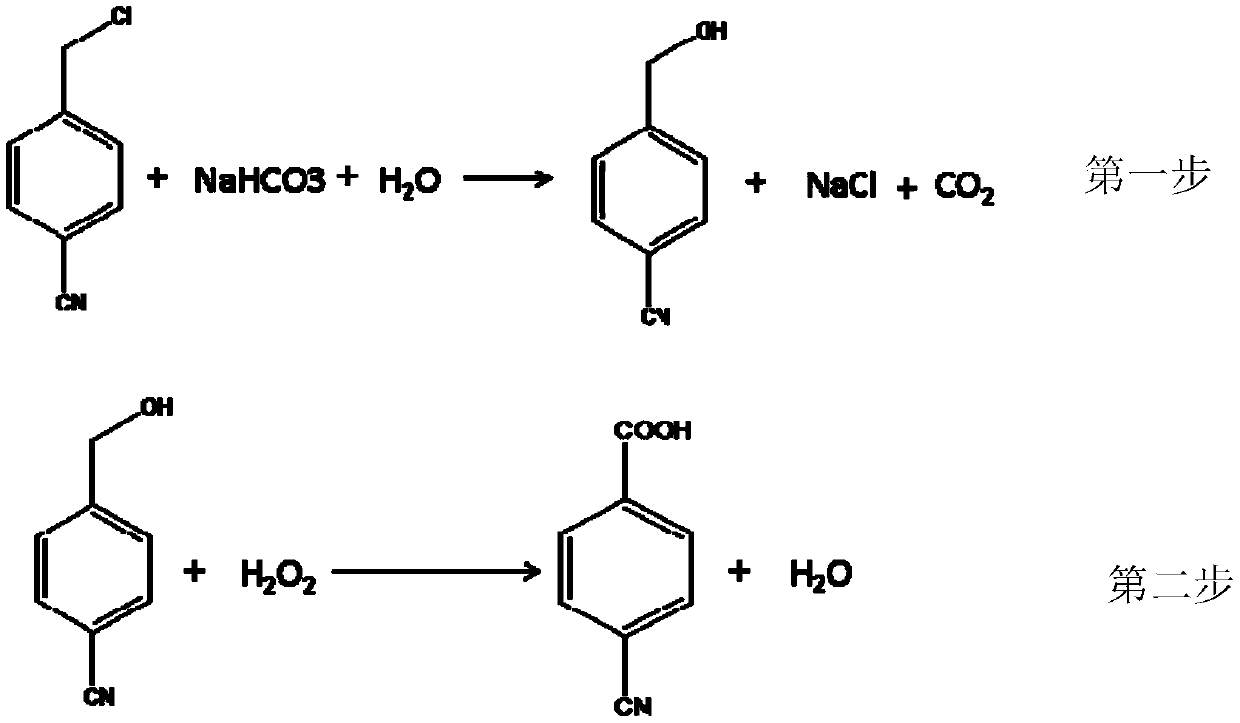

A kind of preparation method of p-cyanobenzoic acid

ActiveCN107556214BShorten the timeShorten the oxidation reaction timeCarboxylic acid nitrile preparationOrganic compound preparationAlcoholPhase-transfer catalyst

Owner:DALIAN QIKAI MEDICAL TECH

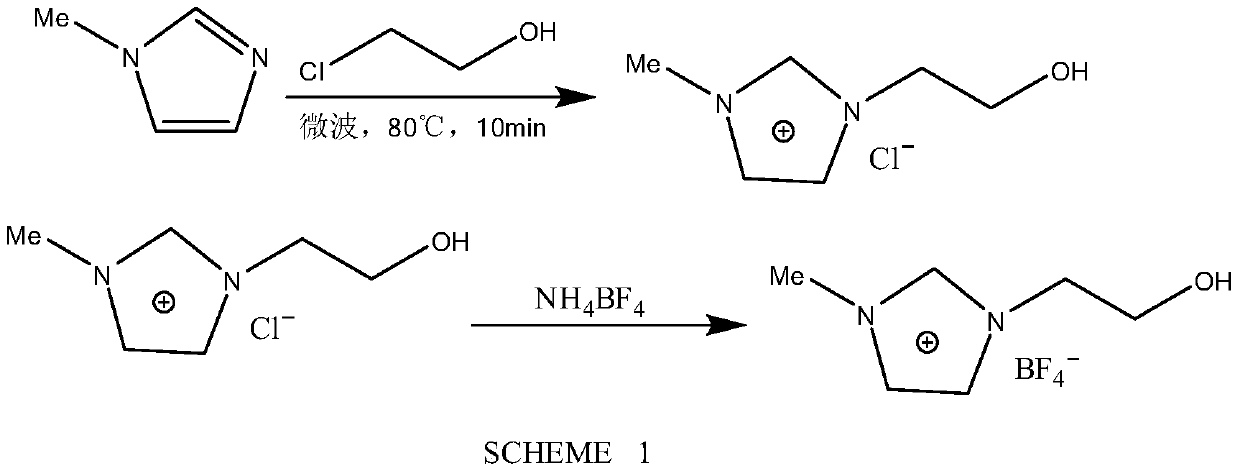

A kind of synthetic method of ularitide

InactiveCN106554406BHigh purityAvoid it happening againDepsipeptidesPeptide preparation methodsDisulfide bondingFluid phase

The invention relates to the technical field of medicament, and discloses a synthetic method for ularitide. According to the synthetic method, the protected Tyr and an ionic liquid carrier are coupled under the action of a coupling system; according to the peptide sequence of the ularitide, residual protected amino acid is prepared through solid-phase synthesis, an ularitide linear peptide ionic liquid peptide carrier is obtained, and a linear peptide crude product is obtained through cracking; the linear peptide crude product is oxidized, and a disulfide bond-containing ularitide crude product is obtained; and the ularitide crude product is purified, and fine peptide is obtained. The room temperature ionic liquid carrier is used for replacing a resin carrier in traditional solid-phase synthesis and an organic solvent and water liquid phase oxidizing medium in the oxidization link, the purity of the crude peptide of the ularitide linear peptide obtained through solid-phase synthesis is obviously increased, meanwhile, the oxidization reaction time can be greatly shortened, operation is convenient, and generation of organic waste liquid is avoided.

Owner:HYBIO PHARMA

Preparation method of hydroxycamptothecine

InactiveCN108752361AShorten the oxidation reaction timeIncreased oxidation reaction yieldOrganic chemistrySolventChemistry

The invention belongs to the technical field of synthetic drugs, and particularly relates to a preparation method of hydroxycamptothecine. An acid solvent dissolves camptothecin, an oxidizing agent sodium perborate is added, the reaction liquid is subjected to vacuum concentration after a constant temperature reaction is completed, ice water is added till a crystal is completely separated out, filtration, washing and drying are conducted, and 1-deoxycamptothecine is obtained; dioxane, acetonitrile, water and concentrated sulfuric acid are added into 1-deoxycamptothecine to be dissolved and stirred, the mixture is illuminated with an ultraviolet high pressure mercury lamp, and the ice water is condensed and flows back; vacuum concentration is conducted, the ice water is added till the crystal is completely separated out, filtration, washing and drying are conducted, and a crude product is obtained; and the crude product is purified. The preparation method of hydroxycamptothecine is simple to operate, safe and economic, green and environmentally friendly, and high in total yield.

Owner:SICHUAN AGRI UNIV

A kind of trimanganese tetraoxide and preparation method thereof

ActiveCN105417586BImprove solubilitySpeed up replenishmentManganese oxides/hydroxidesReaction rateCrystallographic defect

The invention relates to a preparation method for manganic manganous oxide. The method is as follows: in an enclosed reaction container, a manganese source with an average valence of manganese being less than 8 / 3 is placed in a reaction solution, the reaction is carried out with heating, the situation is kept that the pressure or partial pressure of oxidizing gases in the reaction system is more than or equal to 1 standard atmospheric pressure, and a crude product of manganic manganous oxide can be prepared after the reaction is completed. Optionally, the enclosed reaction container has an oxidizing gas inlet or has an oxidizing gas inlet and a generation gas outlet simultaneously. The oxidation reaction rate is raised, the oxidation reaction time is shortened, the manganic manganous oxide crystal growth integrality is raised, the crystal defect is reduced, and high purity and high quality are obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of synthetic method of ularitide

InactiveCN106554407BHigh purityHigh yieldDepsipeptidesPeptide preparation methodsDisulfide bondingOrganic solvent

The invention relates to the technical field of medicament, and discloses a synthetic method for ularitide. According to the synthetic method, ularitide linear peptide crude peptide or fine peptide is added in ionic liquid with the melting point below 20 DEG C, oxidization is conducted for 0.5-3 h in the alkaline environment, and a disulfide bond ularitide crude product is obtained. According to the synthetic method, the room temperature ionic liquid carrier is used for replacing an organic solvent and water liquid phase oxidizing medium in the traditional oxidization link, the crude peptide purity of the ularitide obtained through solid-phase synthesis and the total fine peptide yield are obviously increased, meanwhile, the oxidization reaction time can be greatly shortened, operation is convenient, and generation of organic waste liquid is avoided.

Owner:HYBIO PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com