Patents

Literature

58results about How to "Effective separation and removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

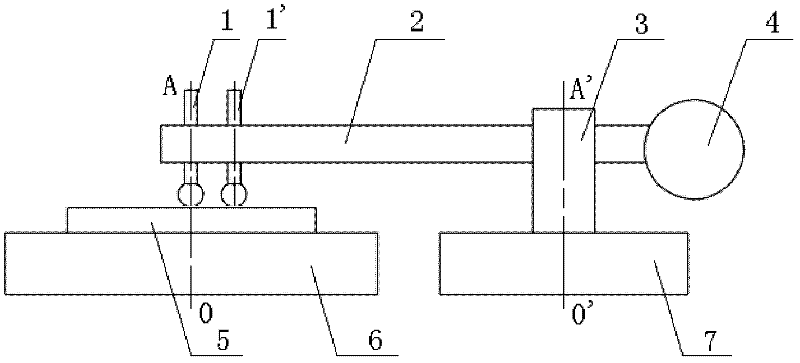

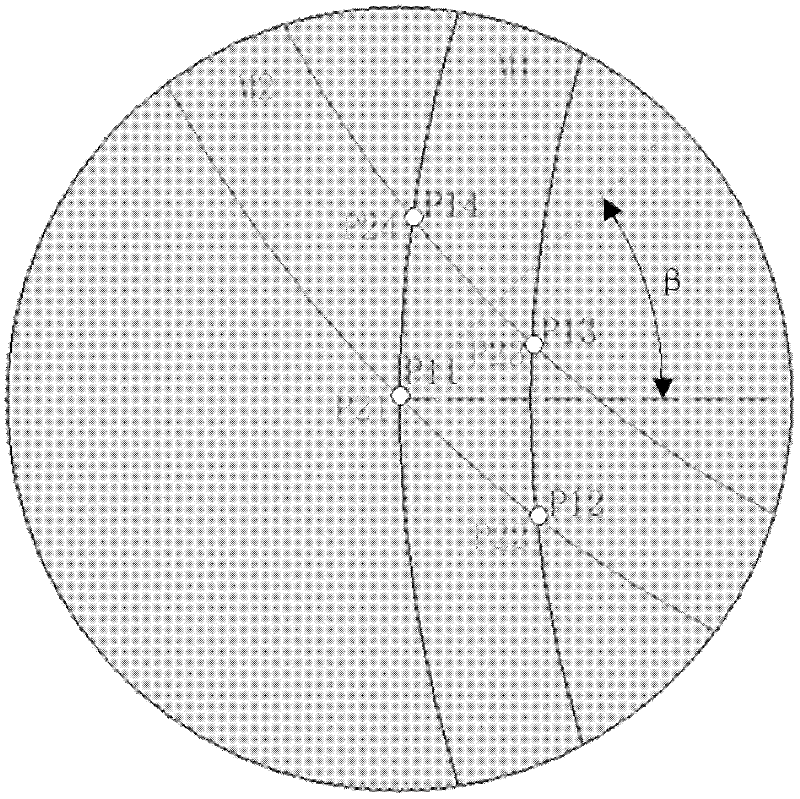

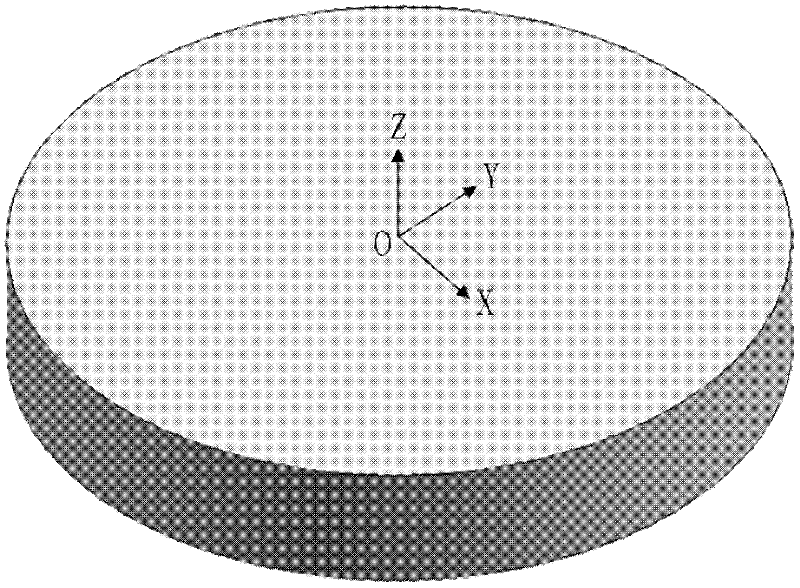

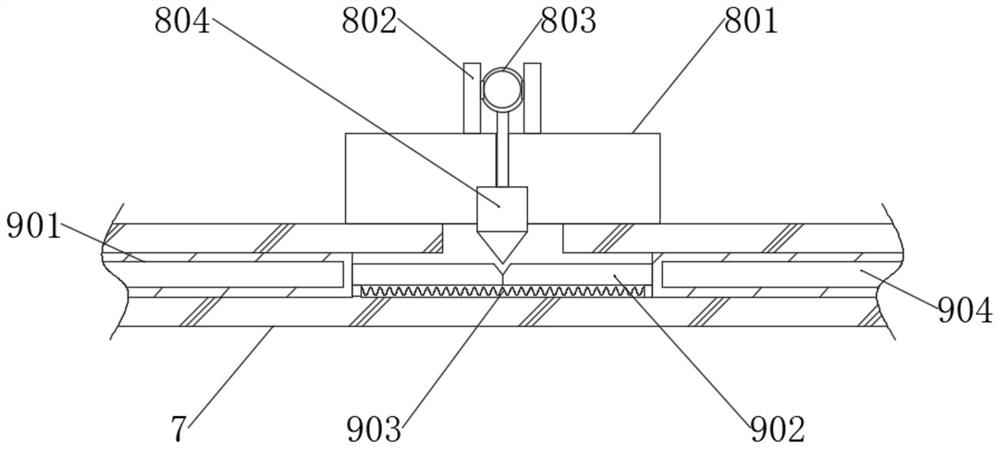

Measuring device of workpiece rotary table error separation based on double-probe scan data splicing and method thereof

InactiveCN102519416AEffective separation and removalHigh measurement accuracyMeasurement devicesOptical processingMotion error

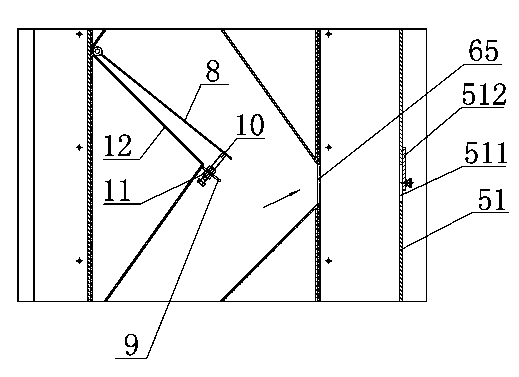

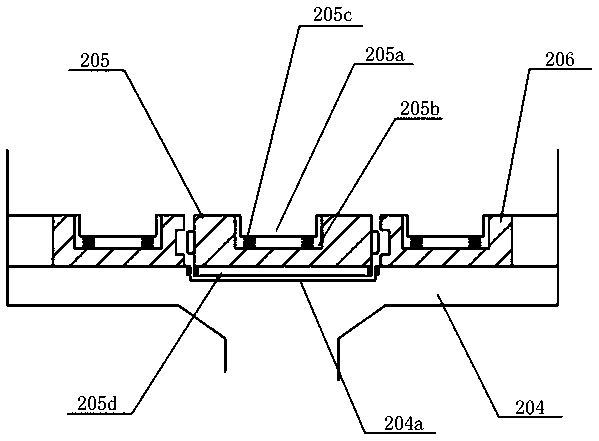

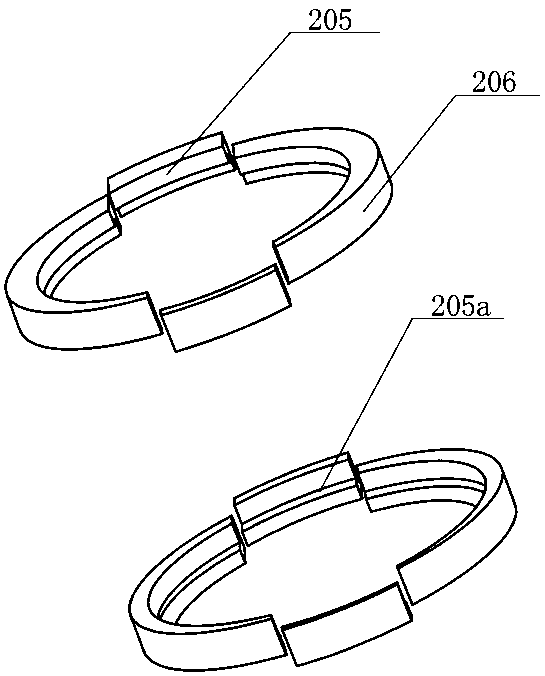

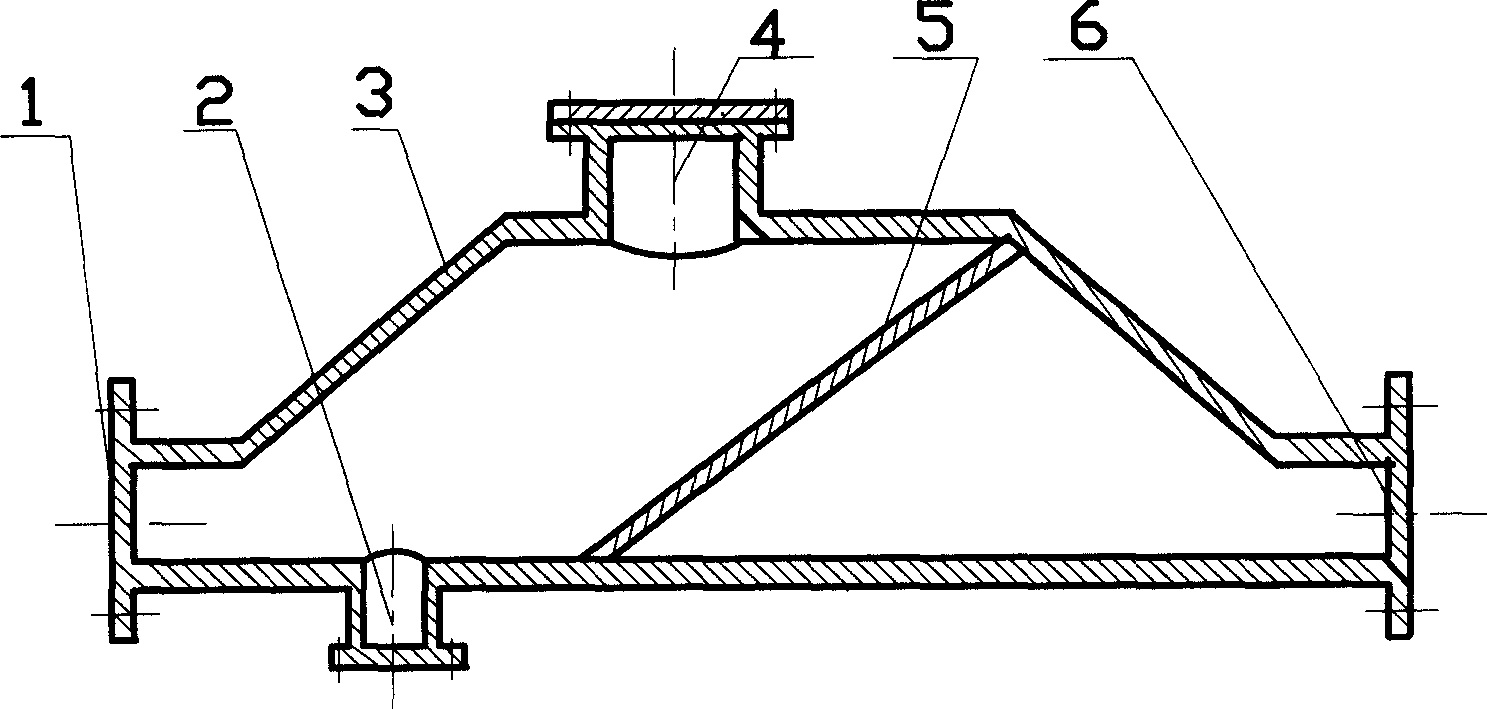

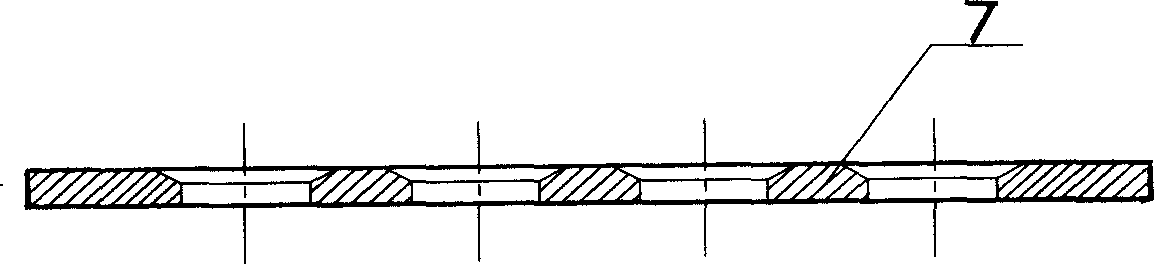

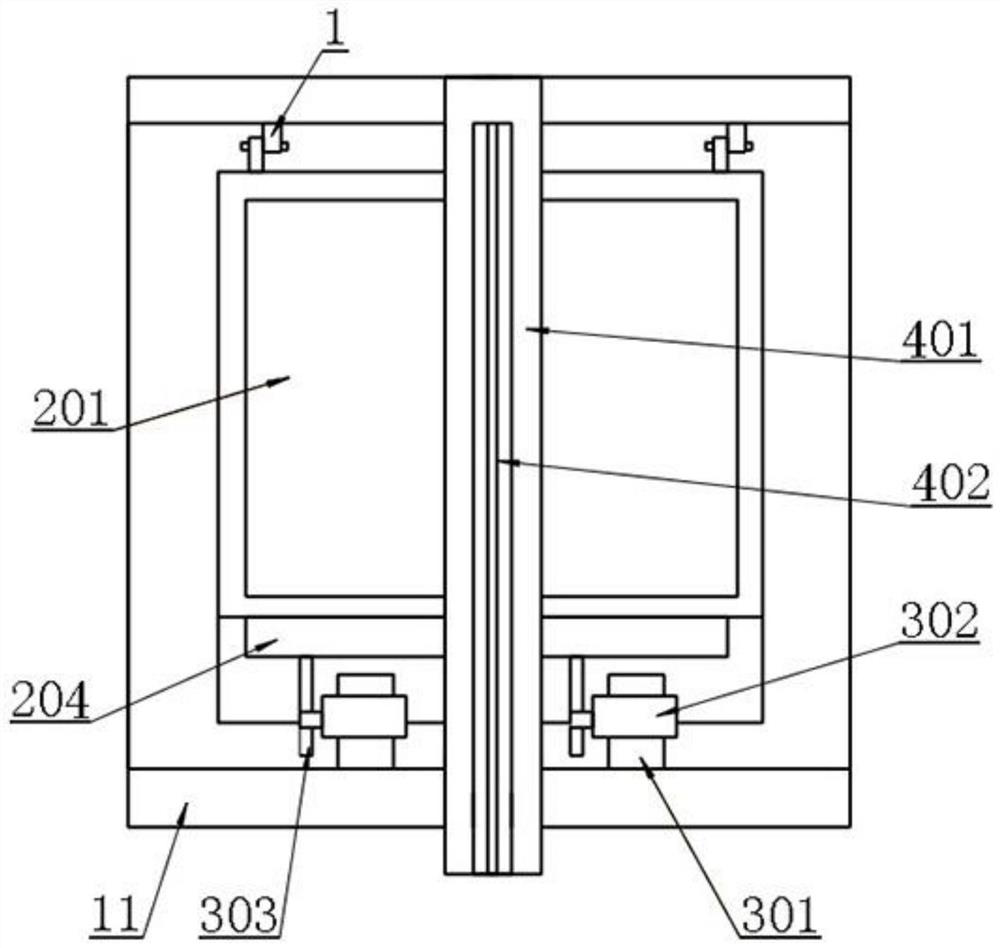

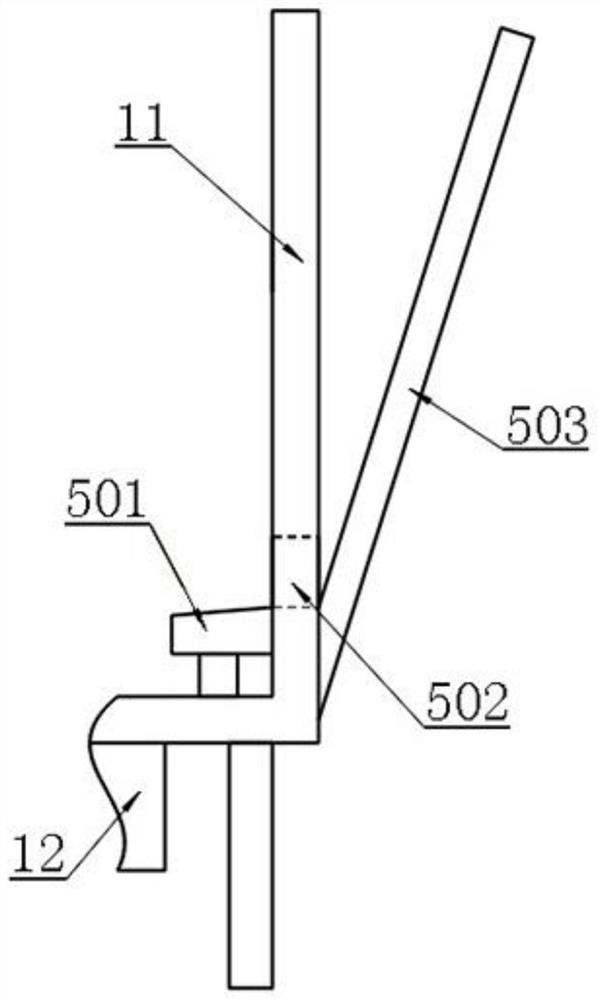

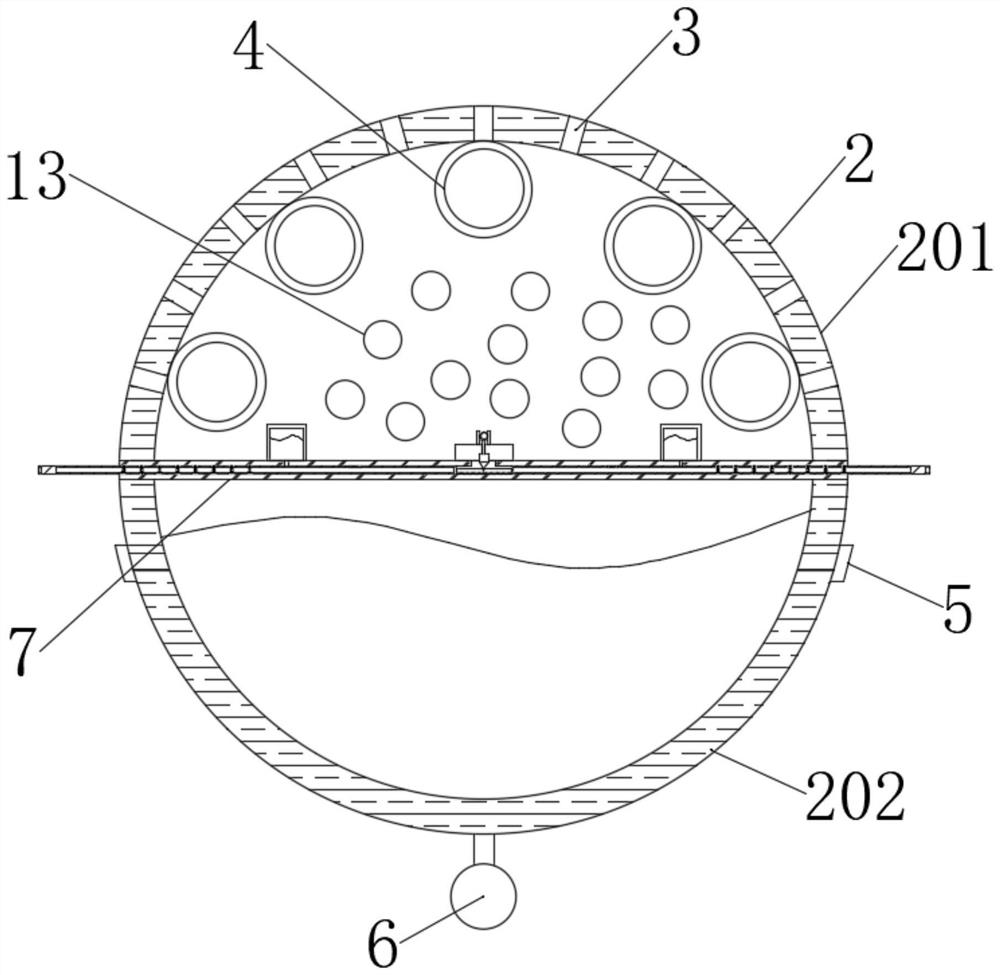

The invention discloses a measuring device of workpiece rotary table error separation based on double-probe scan data splicing and a method thereof. The device employs two sets of probe systems (1, 1') to carry out scanning measurement simultaneously on a swing arm contourgraph which is formed by a probe system (1), a transverse arm (2), a column (3), a counterweight (4), a standard flat crystal (5), a workpiece rotary table (6) and a transverse arm rotary table (7). After two sets of the probe systems scan one time, two scanning loci M1 are obtained, then the workpiece rotary table is rotated with a certain angle beta and scanning is carried out once more, and another two scanning loci M2 are obtained. According to the device and the method, a method of double-probe scan data splicing is employed, influence of a motion error of the workpiece rotary table on a measurement result can be effectively separated and removed, thus measurement precision is raised substantially, and a practical solution scheme is provided for on-position measurement of the swing arm contourgraph at an optical processing field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

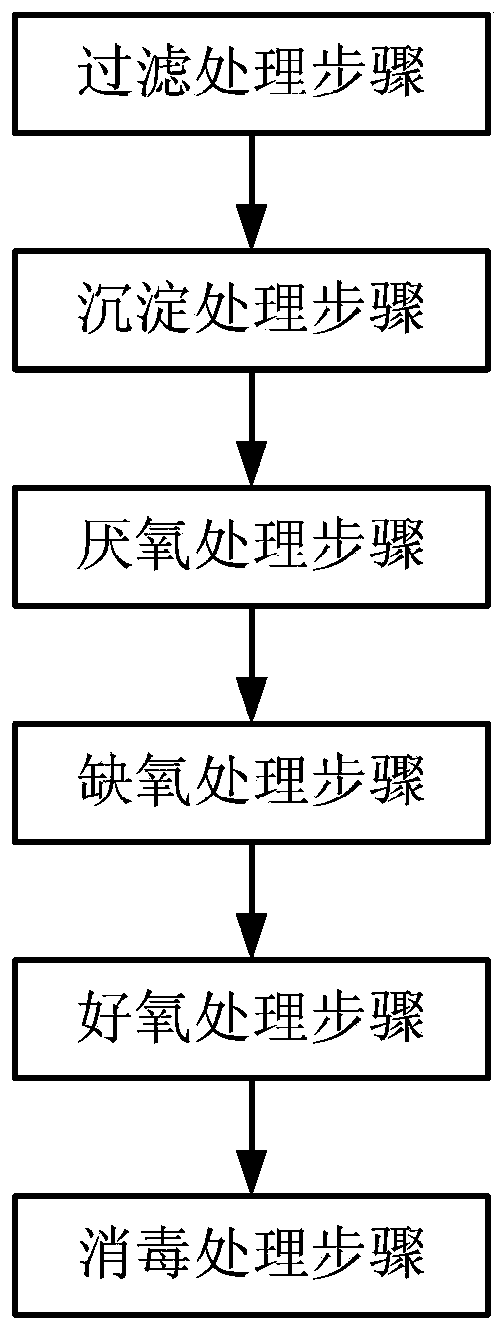

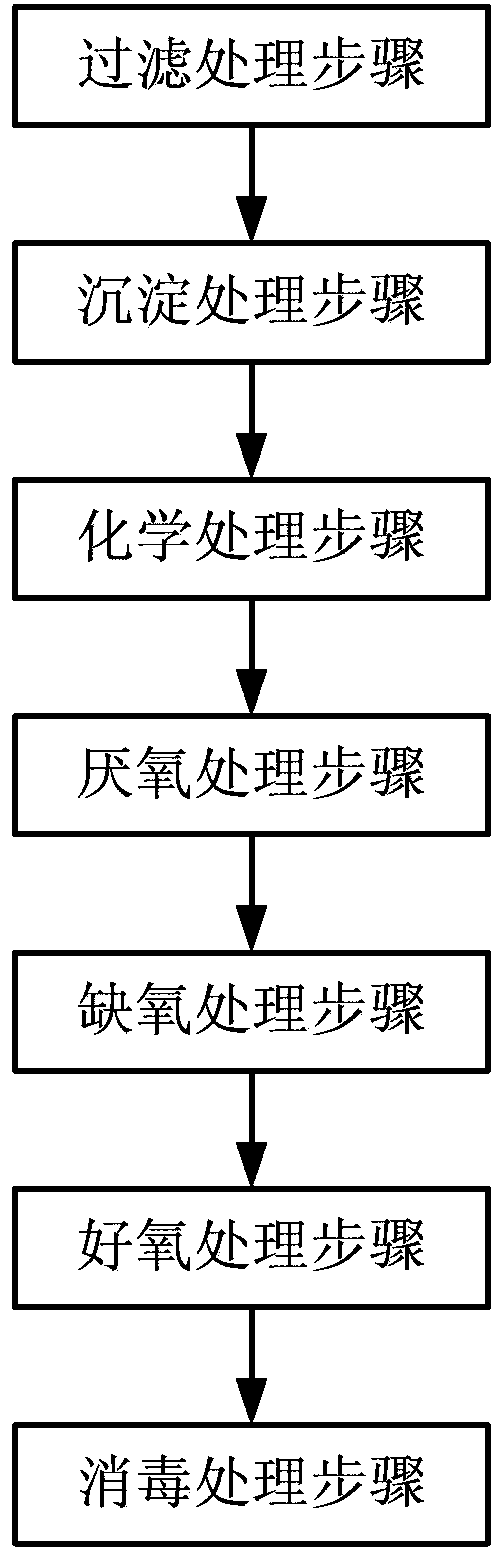

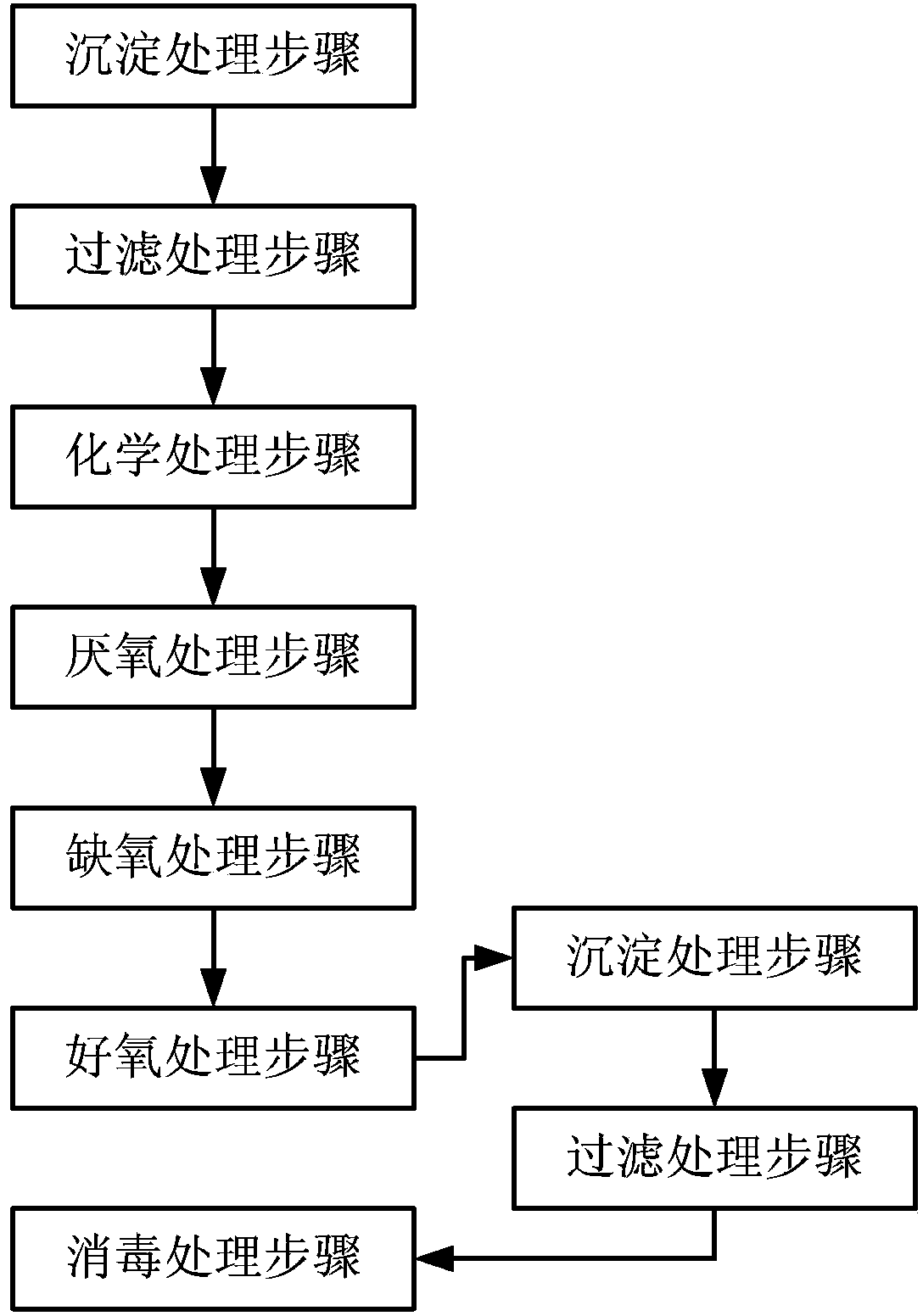

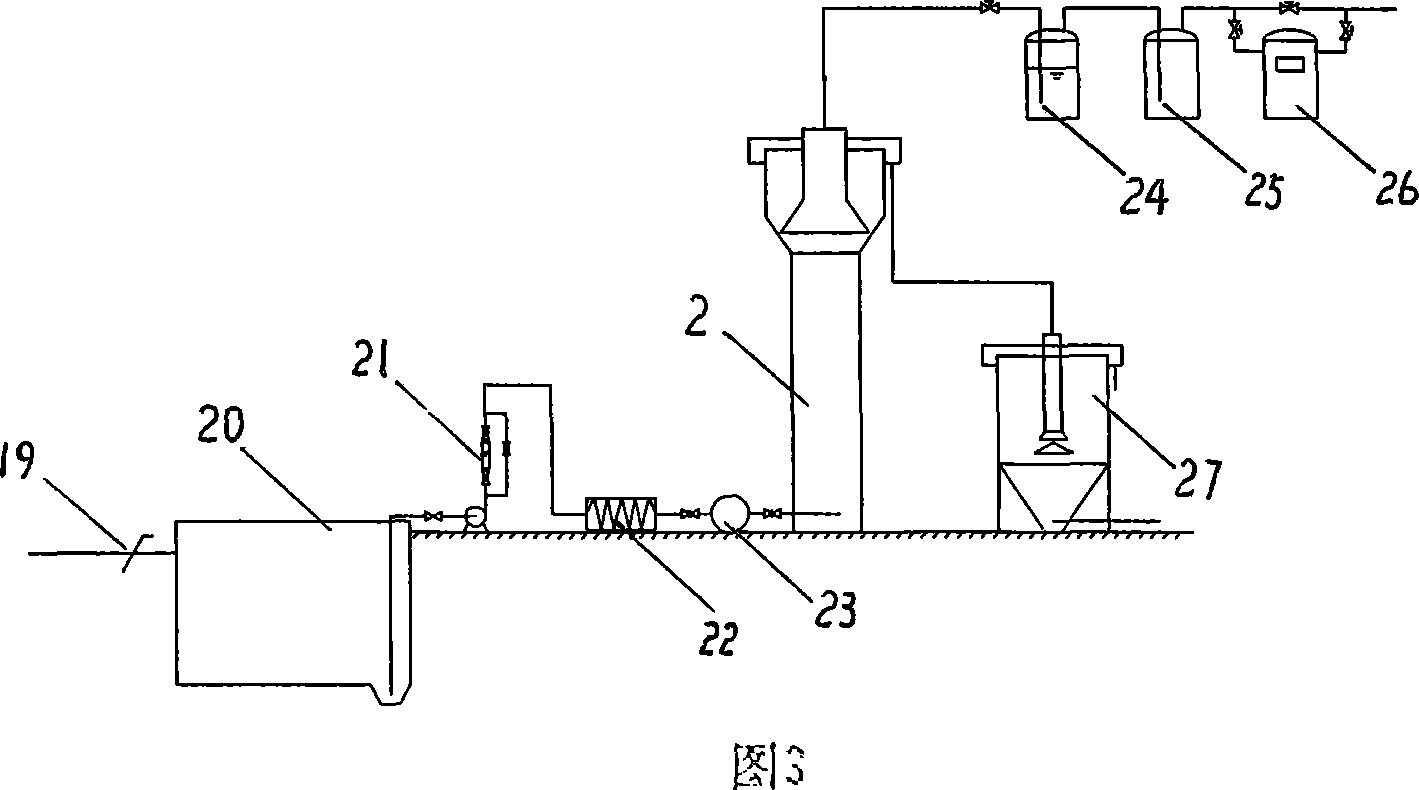

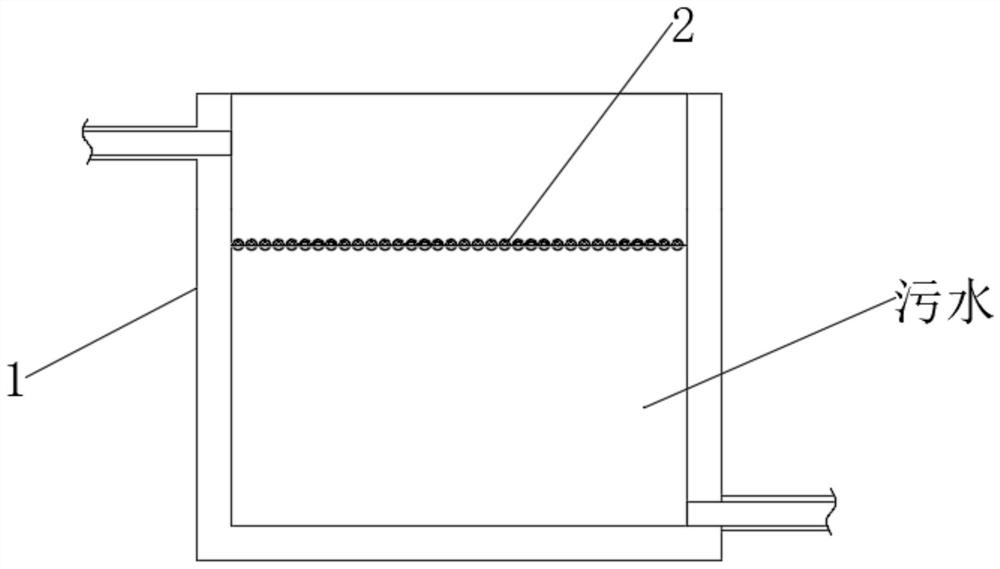

Sewage treating method

InactiveCN103395943AEffective separation and removalTake advantage ofMultistage water/sewage treatmentMedicineSewage

The invention discloses a sewage treating method sequentially comprising the following sewage treating steps of: a filtering treatment step, a precipitating treatment step, an anaerobic treatment step, an anoxic treatment step, an aerobic treatment step, and a disinfecting treatment step. According to the scheme, a multi-stage treatment way is adopted by the sewage treating method; principally, by virtue of physical decontamination treatment combined with biological decontamination treatment, contaminants contained in sewage can be effectively separated out and removed from water; as a result, harmful materials are converted into harmless materials and useful materials and water is purified; besides, resources are utilized sufficiently; the sewage treating method has wide market application significance.

Owner:李志强

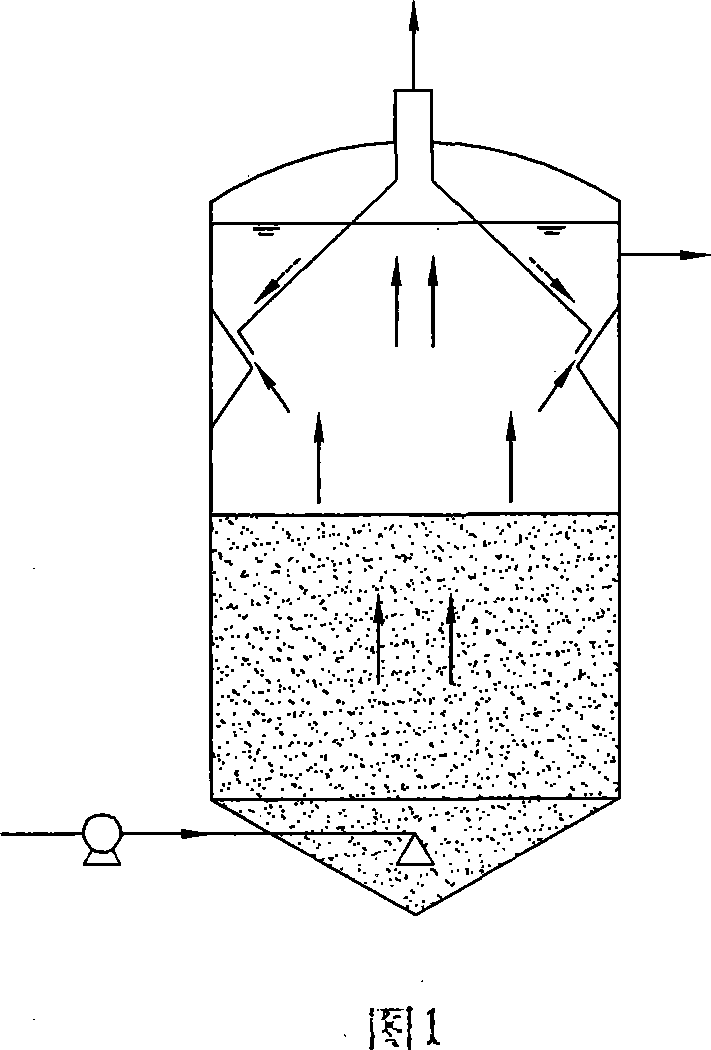

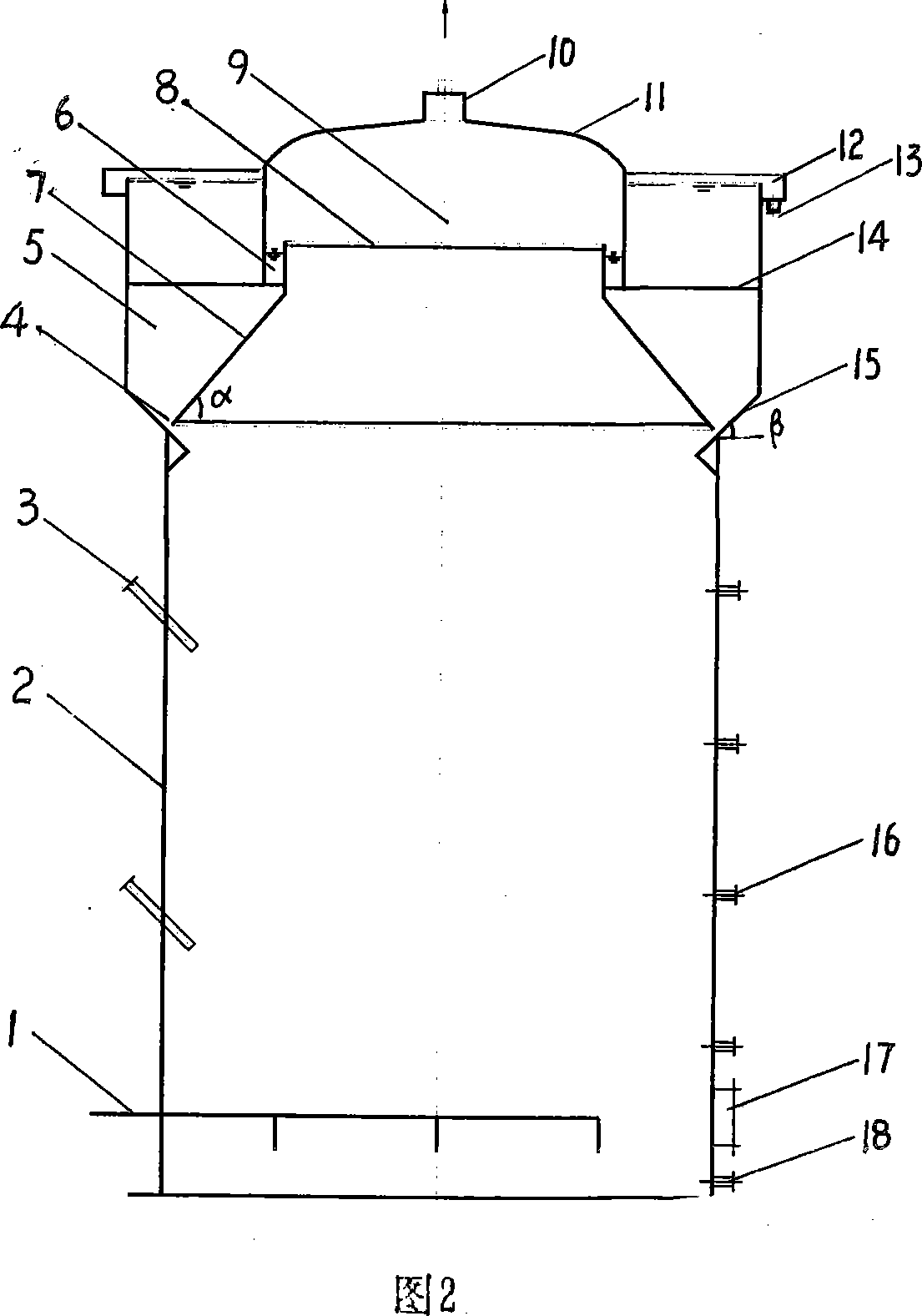

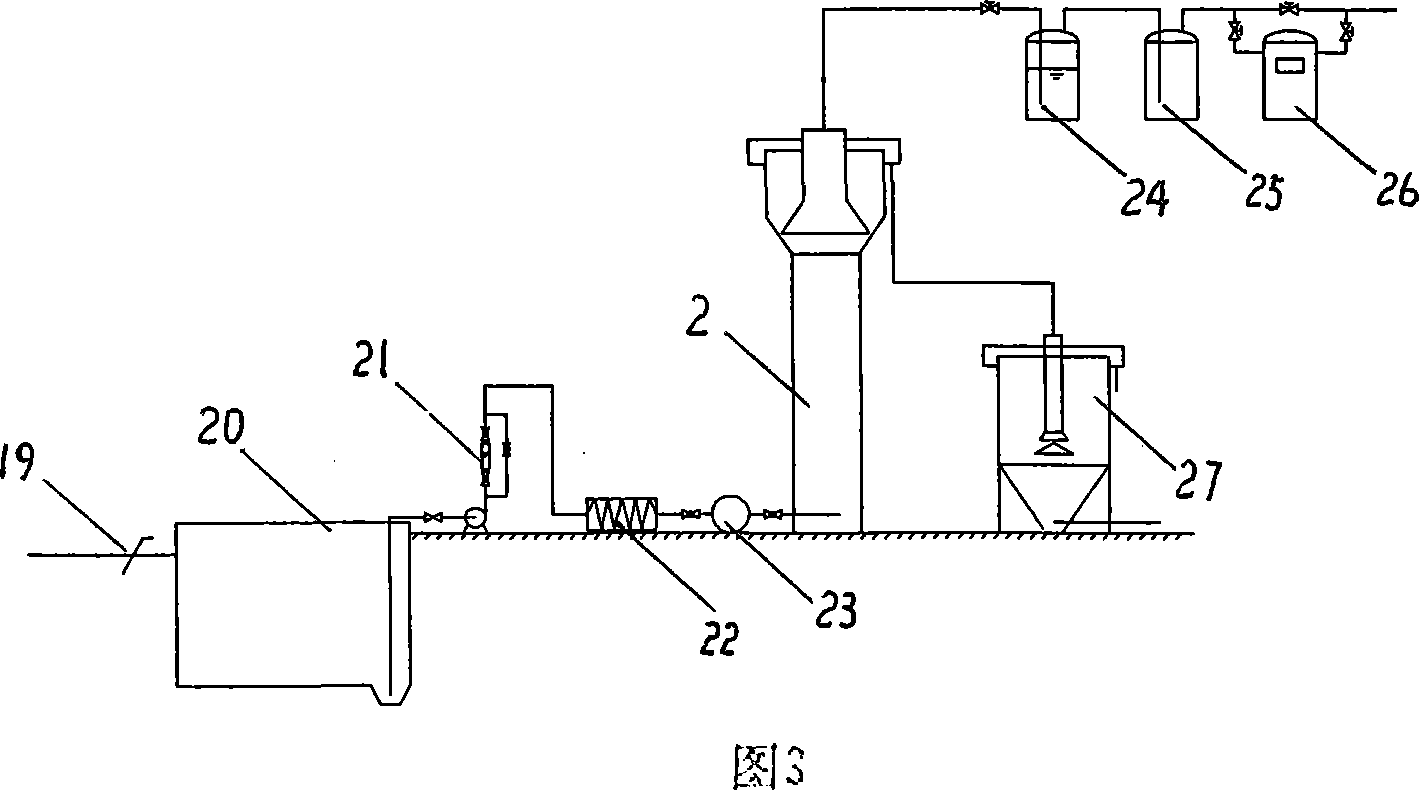

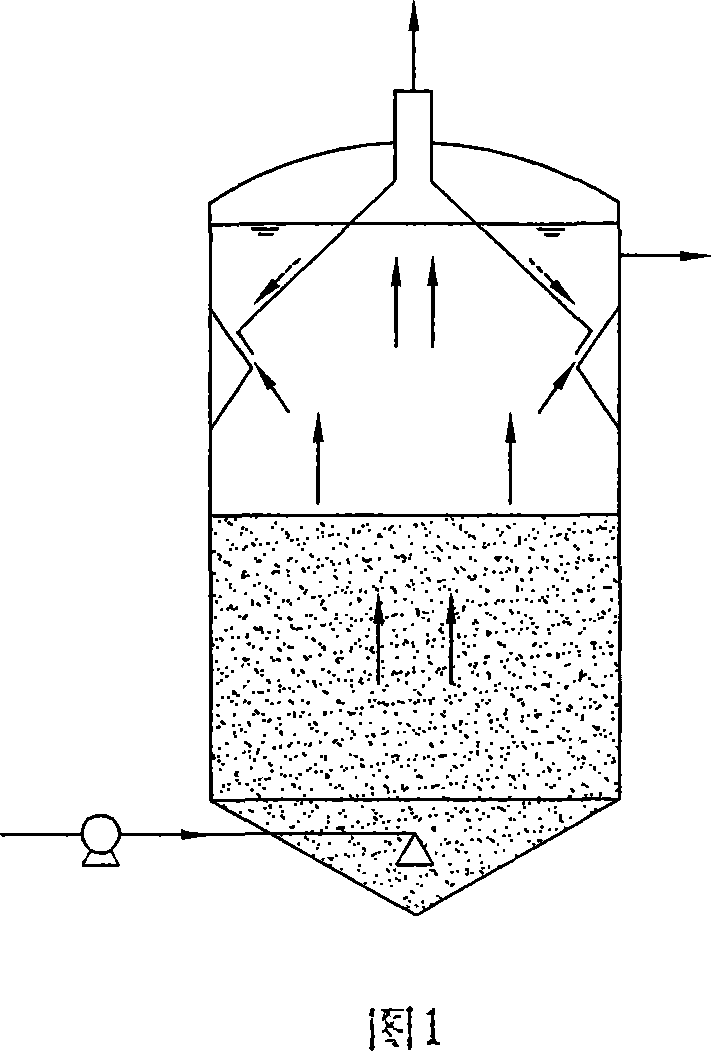

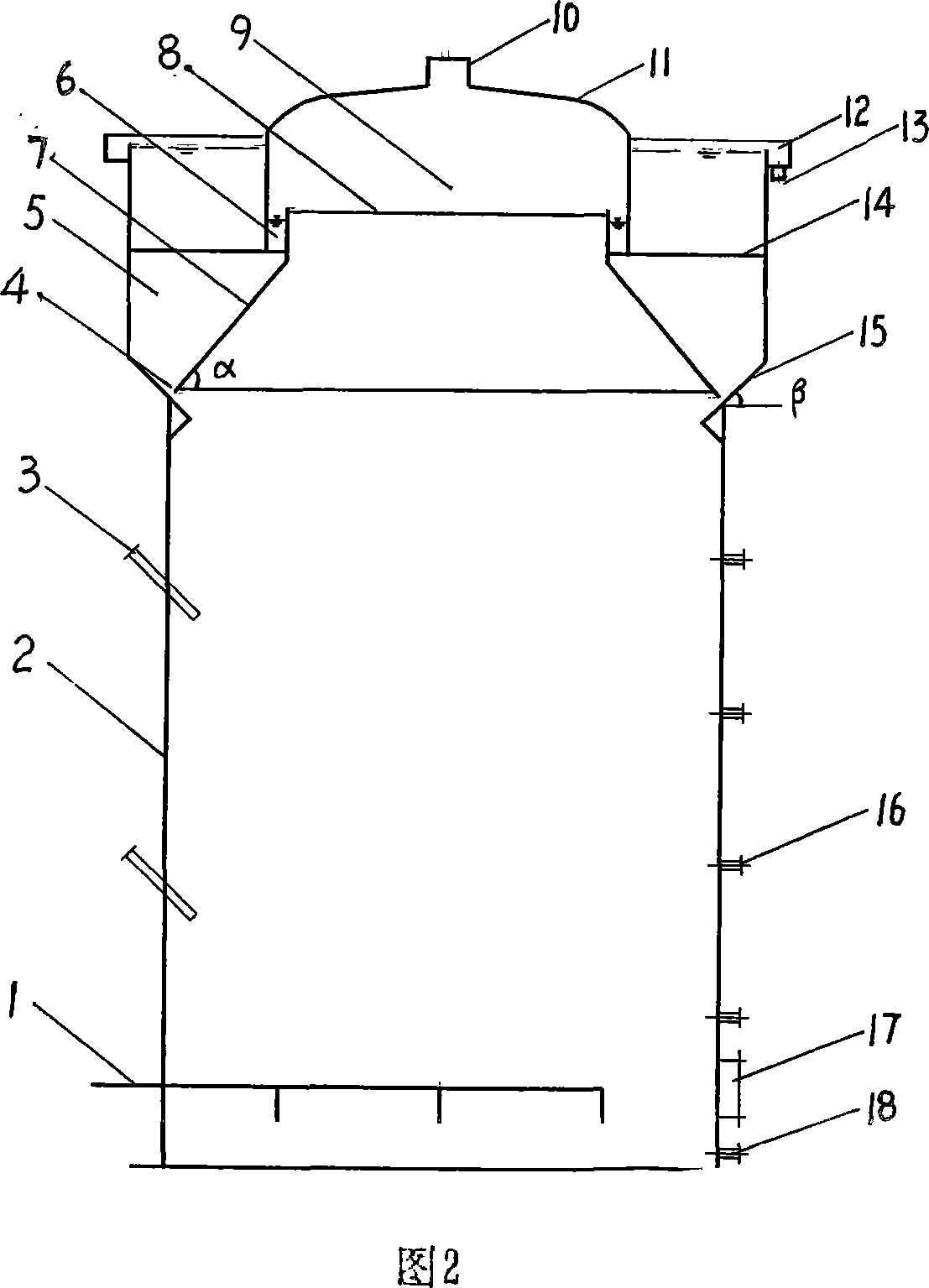

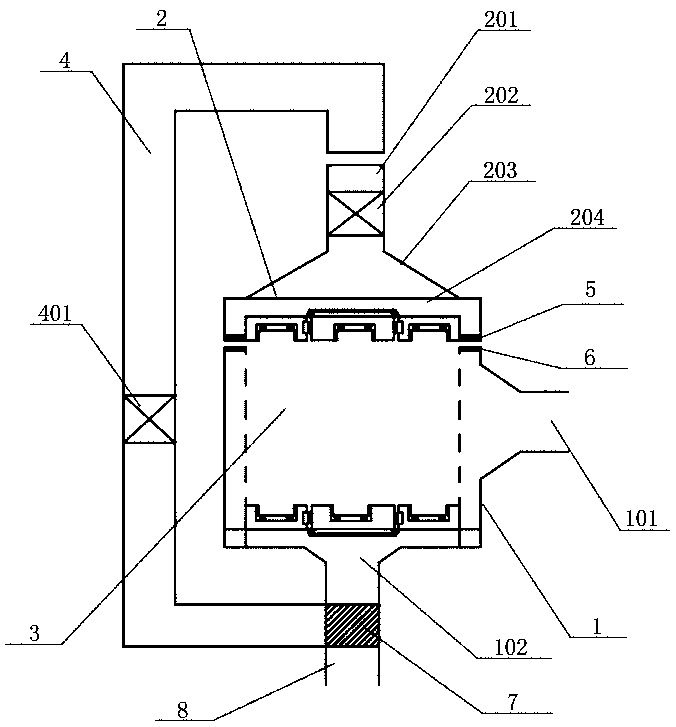

Upflow type anaerobic reactor

ActiveCN101054234AGood separation effectGood solid-liquid separation effectWaste based fuelTreatment with anaerobic digestion processesThree-phaseInlet flow

The invention relates to an up flow type anaerobic reactor, which comprises a barrel of the reactor, a water distributor pipe arranged on the lower end of the barrel, a three phase separator composed of a cone diversion drum arranged on the upper end of the barrel and a gas hood arranged on the upper end of the cone diversion drum, a circular passage arranged between the lower end of the gas hood wall and cone diversion drum wall, a circular passage arranged between the cone diversion drum and the upper wall of the barrel, a settling zone barrel arranged on the upper end of the reactor barrel, a drain trough arranged on top of the settling zone barrel, the combination of two circular passages can separate sludge with water, gas with water at different position, has good separating effect of gas, sludge, water, thereby avoiding the problem of return-sludge flow interfered by inlet flow because of mixed liquor ascent passage sharing one passage with return-sludge flow in a conventional three phase separator, the invention can keep liquid flow in settling zone steady, fluid state closing to laminar flow, has good solid-liquid separation effect.

Owner:沃克福德环境科技(深圳)有限责任公司

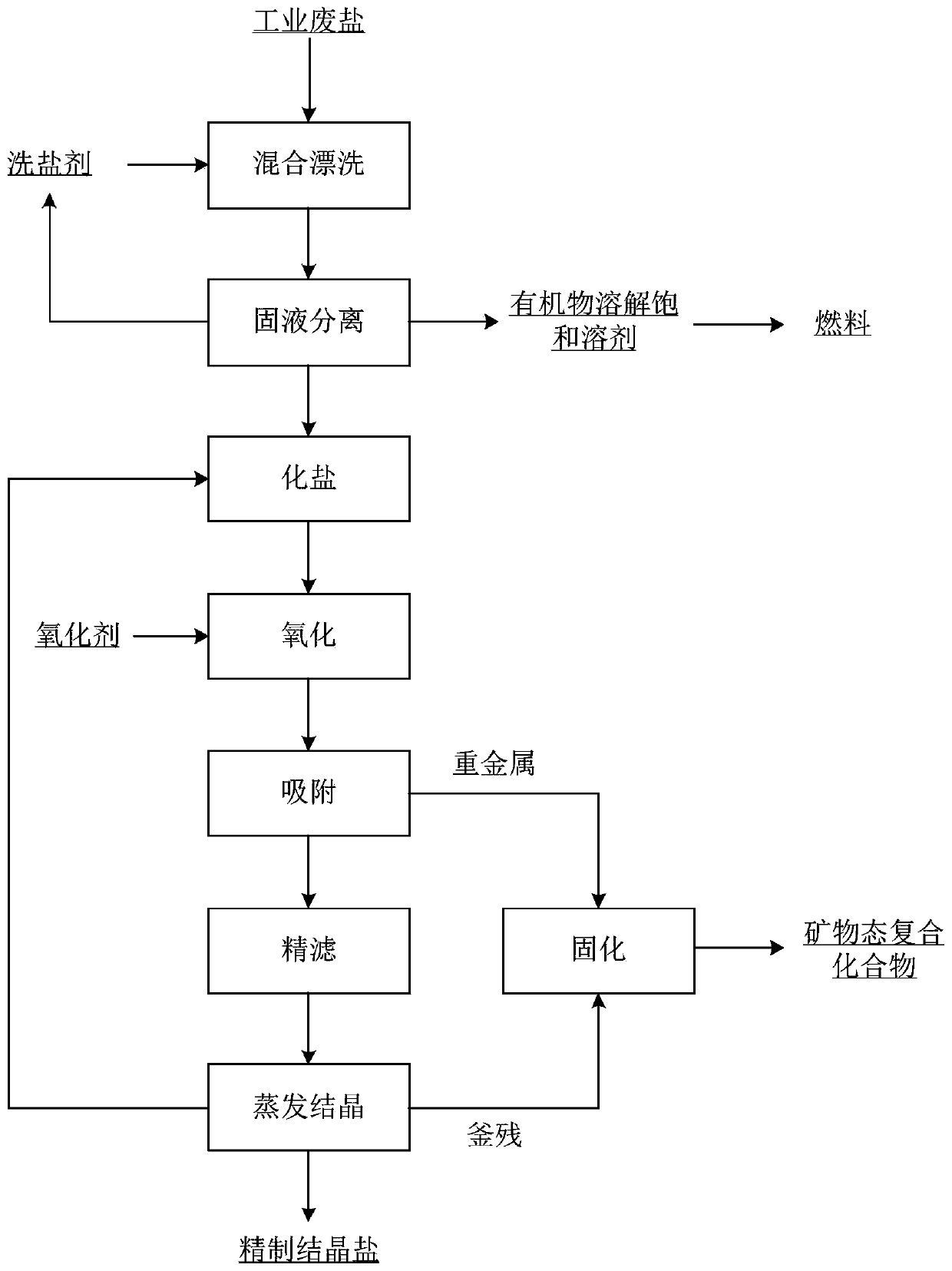

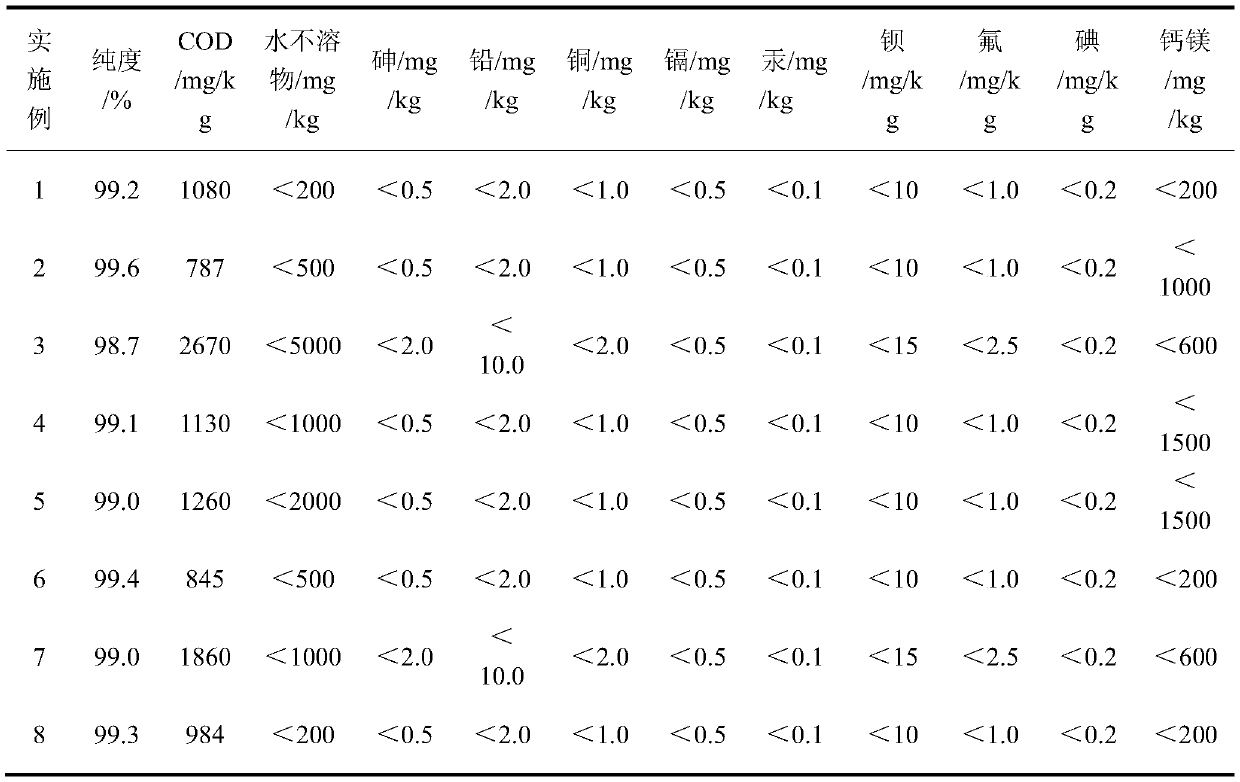

Method for refining industrial waste salt

InactiveCN110642270AAchieve refinementMaximize resource utilizationAlkali metal sulfite/sulfate purificationAlkali metal halide purificationFiltrationProcess engineering

The invention relates to a method for refining an industrial waste salt. The method comprises the following steps: the industrial waste salt is mixed and preprocessed with a salt leaching agent, and then solid-liquid separation is carried out to obtain a preprocessed salt and a filtrate; the preprocessed salt is subjected to salt dissolving, and then is oxidized to obtain a primary treatment liquid; and the primary treatment liquid is adsorbed and finely filtered, and then is crystallized to obtain a refined crystallized salt. The method realizes effective separation of organic matters and salt in the waste salt, ensures effective separation and removal of the organic matters in the industrial waste salt and adsorption and fine filtration removal of other impurities in the industrial wastesalt, and realizes the refining of the high-quality crystallized salt. The method has the advantages of simple process, low energy consumption, low cost and mild conditions, does not produce industrial three wastes in the treatment process, and is an environmentally-friendly salt refining technology.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

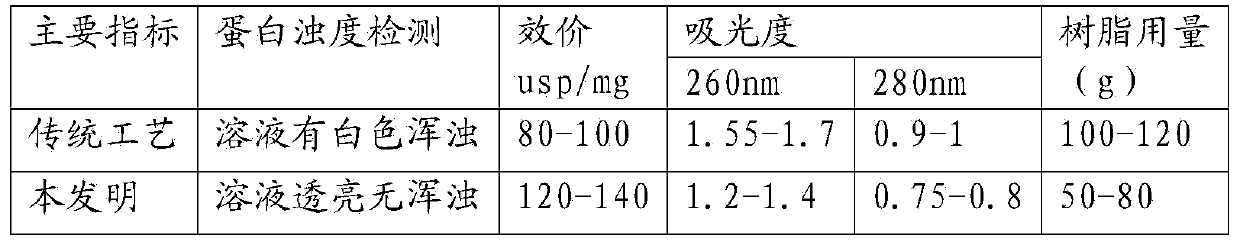

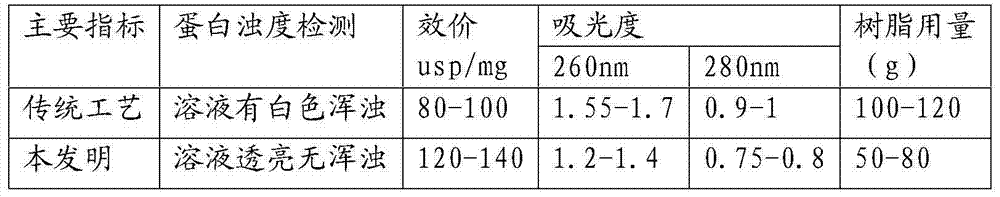

Extraction method of heparin sodium crude product

The invention relates to an extraction method of a heparin sodium crude product, which comprises the steps that a raw material from a fresh pork lung or a thawy pork lung is minced into a pasty material; a cell activator is added for catalysis; biological enzyme enzymolysis, decontamination, separation and filtering are performed; a solution containing heparin sodium is obtained; resin adsorption, elution, organic solvent precipitation and drying are performed; and the heparin sodium crude product is obtained. The extraction method of the heparin sodium crude product can improve the product quality, can increase an effective yield, can lower the production cost, is suitable for industrial production, reduces waste emission, and has social, environmental and economic benefits.

Owner:湖南迪博制药有限公司

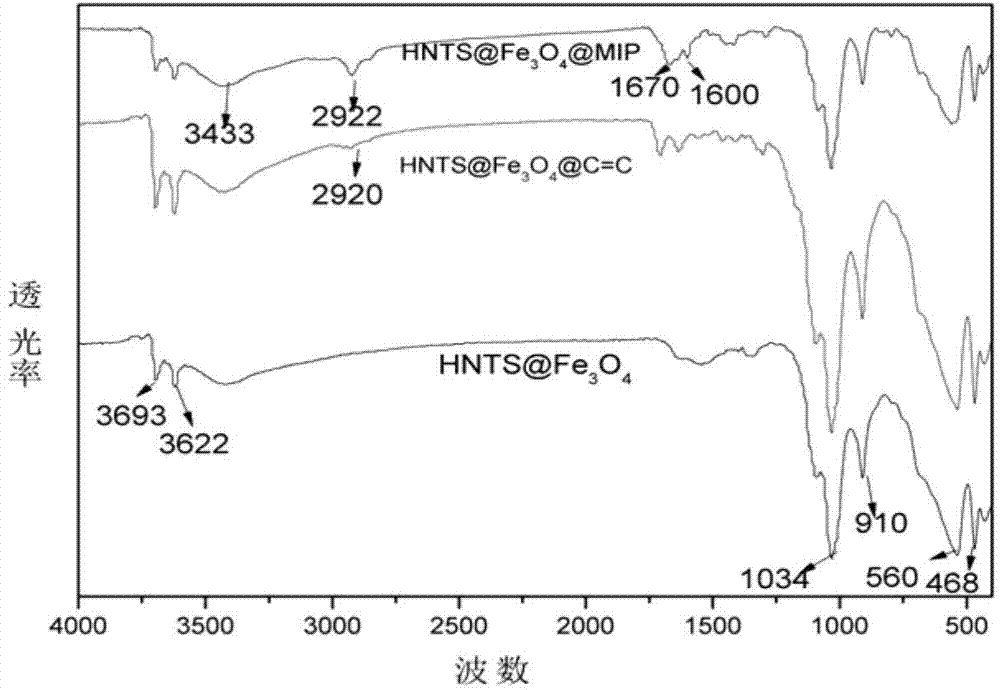

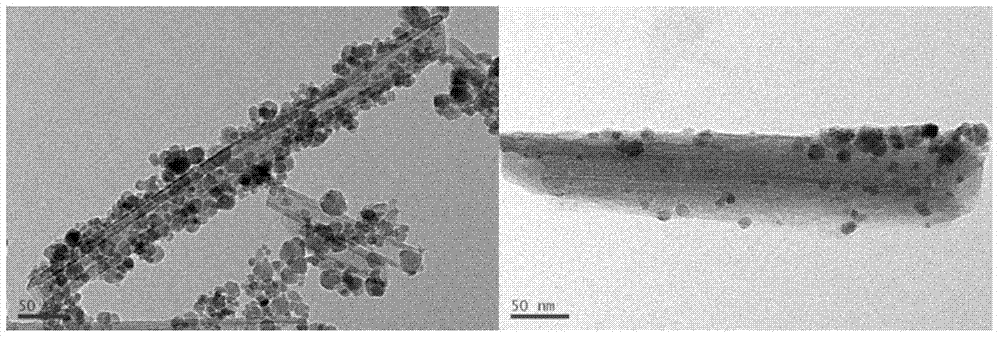

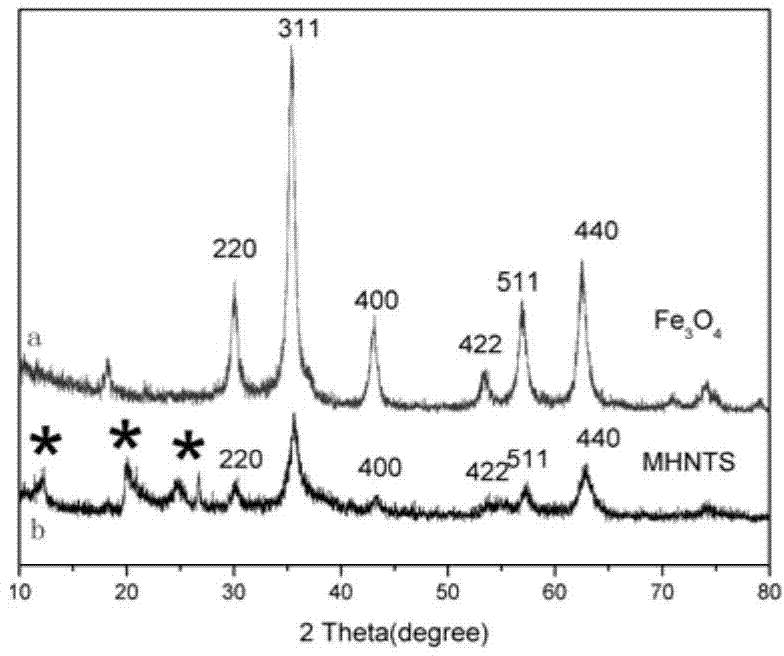

Method for preparing magnetic halloysite molecularly imprinted polymer with specific adsorption to 2,4-dichlorophenoxyacetic acid

The invention discloses a method for preparing a magnetic halloysite molecularly imprinted polymer with specific adsorption to 2,4-dichlorophenoxyacetic acid. The preparation method comprises the following steps: preparing magnetic halloysite nano-tubes by using corroded halloysite nano-tubes by a coprecipitation method; reacting the magnetic halloysite nano-tubes and methacrylate in methylbenzene to obtain magnetic halloysite nano-tubes with double-bond-modified surfaces; after polymerizing the magnetic halloysite nano-tubes with double-bond-modified surfaces, the polymerized monomers and a crosslinker by taking the 2,4-dichlorophenoxyacetic acid as a template, then removing the 2,4-dichlorophenoxyacetic acid to obtain the magnetic halloysite molecularly imprinted polymer with specific adsorption to the 2,4-dichlorophenoxyacetic acid. The raw materials used in the preparation method are low in cost; the preparation method is easy to operate and easy to implement; the prepared magnetic halloysite molecularly imprinted polymer is stable in structure, has specific adsorption to the 2,4-dichlorophenoxyacetic acid, and can effectively separate and remove the 2,4-dichlorophenoxyacetic acid from a complex system.

Owner:CENT SOUTH UNIV

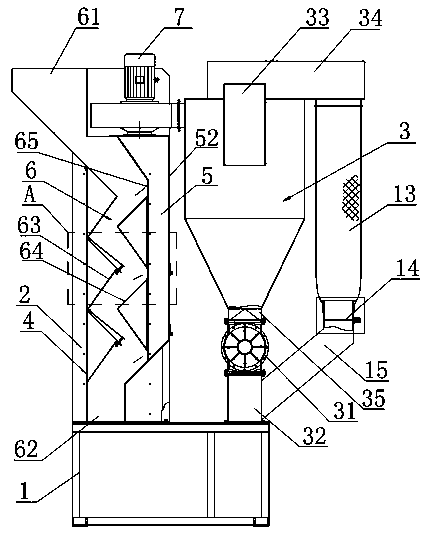

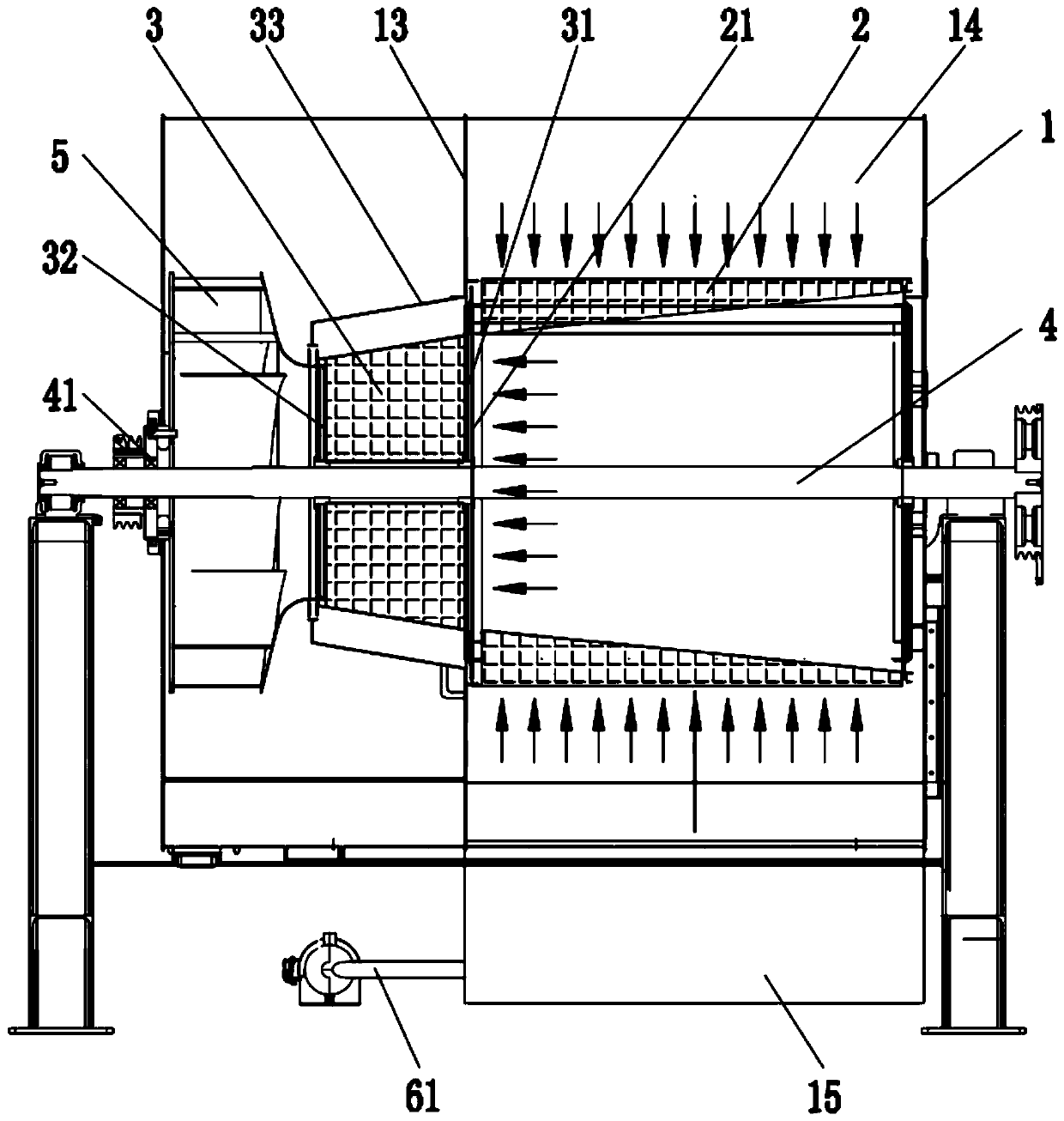

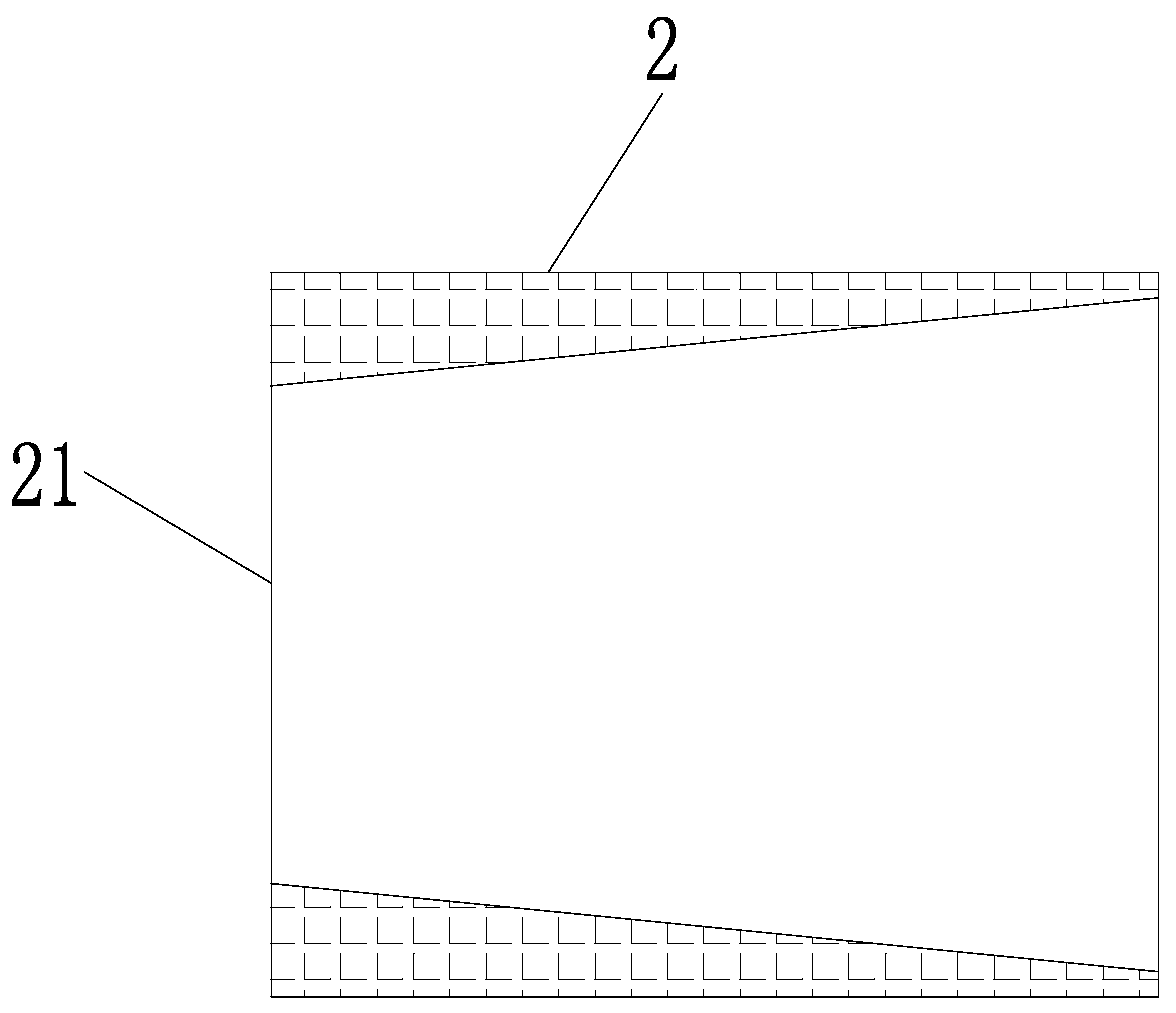

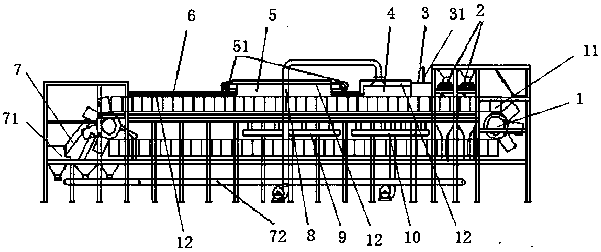

Chip and film separation device

InactiveCN103447236ASimple structureEffective separation and removalGas current separationAir volumeEngineering

The invention discloses a chip and film separation device capable of regulating the air volume in a separation channel and improving a separation effect. The chip and film separation device comprises a separation box body and a cyclone separator which are supported on a rack; the separation box body is formed by a separation channel box body and an air duct box body; the separation channel with a feed inlet and a discharge port is formed in the separation channel box body; the bent zigzag shape of the separation channel is formed by bending back and forth first and second side plates downwards; the first and second side plates are respectively provided with a plurality of external bent parts and internal bent parts; the second side plate of the separation channel is at least provided with a label outlet; each label outlet is respectively positioned at the end part of each external bent part on the second side plate; a box body inner side plate of the air duct box body is provided with through holes with the same number with the label outlets; the label outlets are correspondingly communicated with the through holes; an outer side plate of the air duct box body is at least provided with one providing wind port with a regulating cover board; the top of the air duct box body is connected with a fan; and an exhaust outlet of the fan is communicated with the cyclone separator.

Owner:JIANGSU ASG PACKAGING MACHINERY GRP

Three-phase separator for high efficiency anaerobic reactor

InactiveCN101054235AReduced release rateReduce entrainmentLiquid degasificationTreatment with anaerobic digestion processesWide mouthThree-phase

The invention relates to a three phase separator of an up flow type anaerobic reactor, which is composed of a cone diversion drum arranged on the upper end of a anaerobic reactor barrel, a gas hood arranged on the upper end of the cone diversion drum, a gas chamber is composed of the gas hood and a wide mouth of the cone diversion drum, a circular passage arranged between the lower end of the gas hood wall and the upper end of the cone diversion drum wall, a circular passage arranged between the lower end of the cone diversion drum wall and the upper wall of the anaerobic reactor barrel, a gas chamber with bigger volume and a bigger gas liquid separation interface is composed of a circular wide mouth on upper of the cone diversion drum and a cylinder gas hood, can reduce release rate of biogas and aqueous vapour entraining amount discharged from the reactor barrel, adopting the invention, gas in mixture liquor of gas, sludge and water can not enter into the settling zone barrel, gas can be separated and removed effectively to avoid gas leaking to the settling zone barrel to interfere solid-liquid separation effect.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

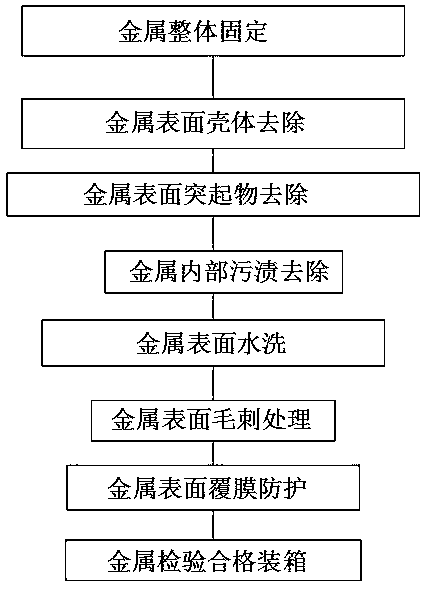

Metal surface treatment method

The invention discloses a metal surface treatment method. The metal surface treatment method specifically comprises the following steps: step I of integrally fixing metal: fixing to-be-treated metal through a clamping mechanical hand, tilting the to-be-treated metal to an angle of 30-60 degrees through the clamping mechanical hand, fixing a ring of protective shell outside the metal, and preventing waste generated in later-stage treatment from splashing out. In practical use, a metal surface shell is removed, and a high-frequency vibrator is fixedly arranged on a metal surface for performing high-frequency vibratory separation on to-be-separated shell of metal and waste, an air blower is adopted to perform blow-separating on waste, and unstable metal is broken after being vibrated by the high-frequency vibrator, so that precision of metal integer can be detected, a later-stage use breakage condition is prevented, and a high-pressure water spraying gun is used for removing stains left on the surface.

Owner:泽涵电气(内蒙古)有限公司

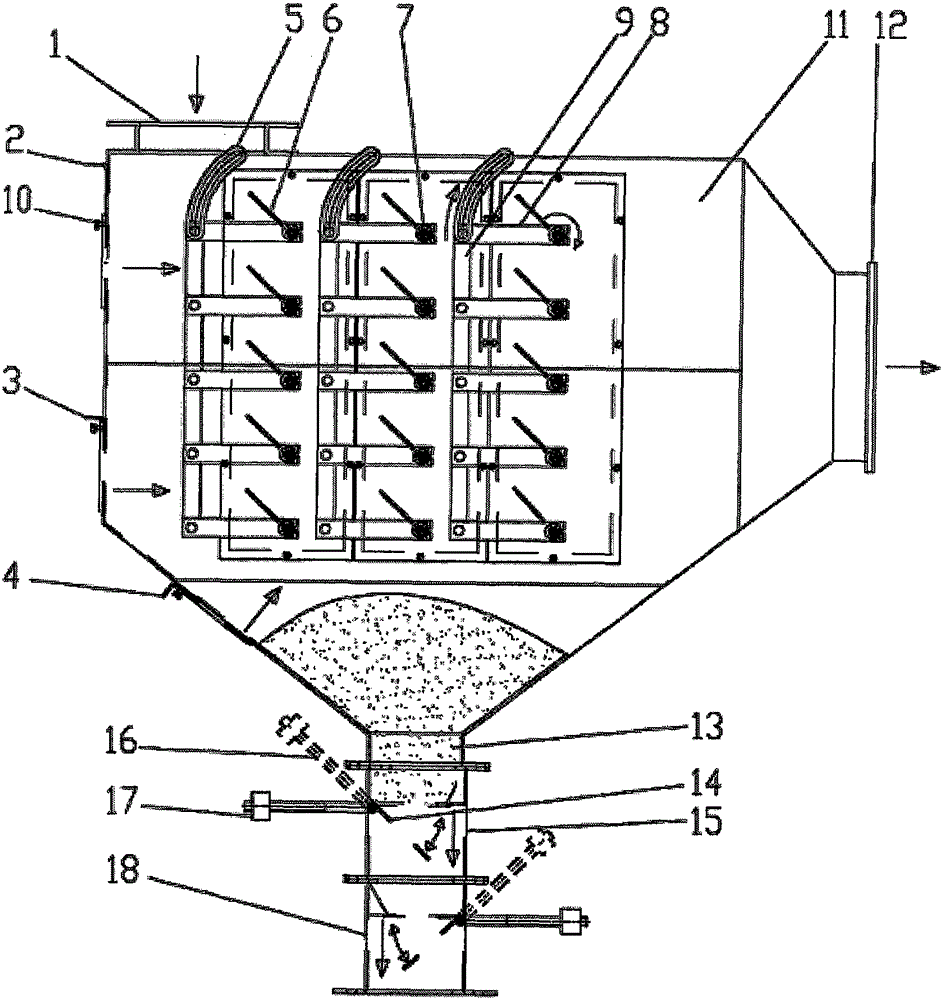

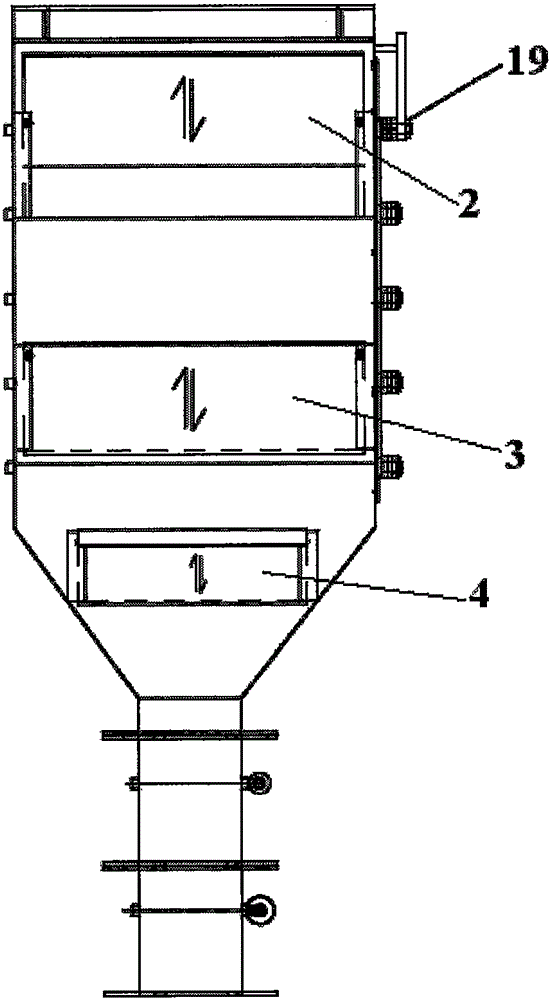

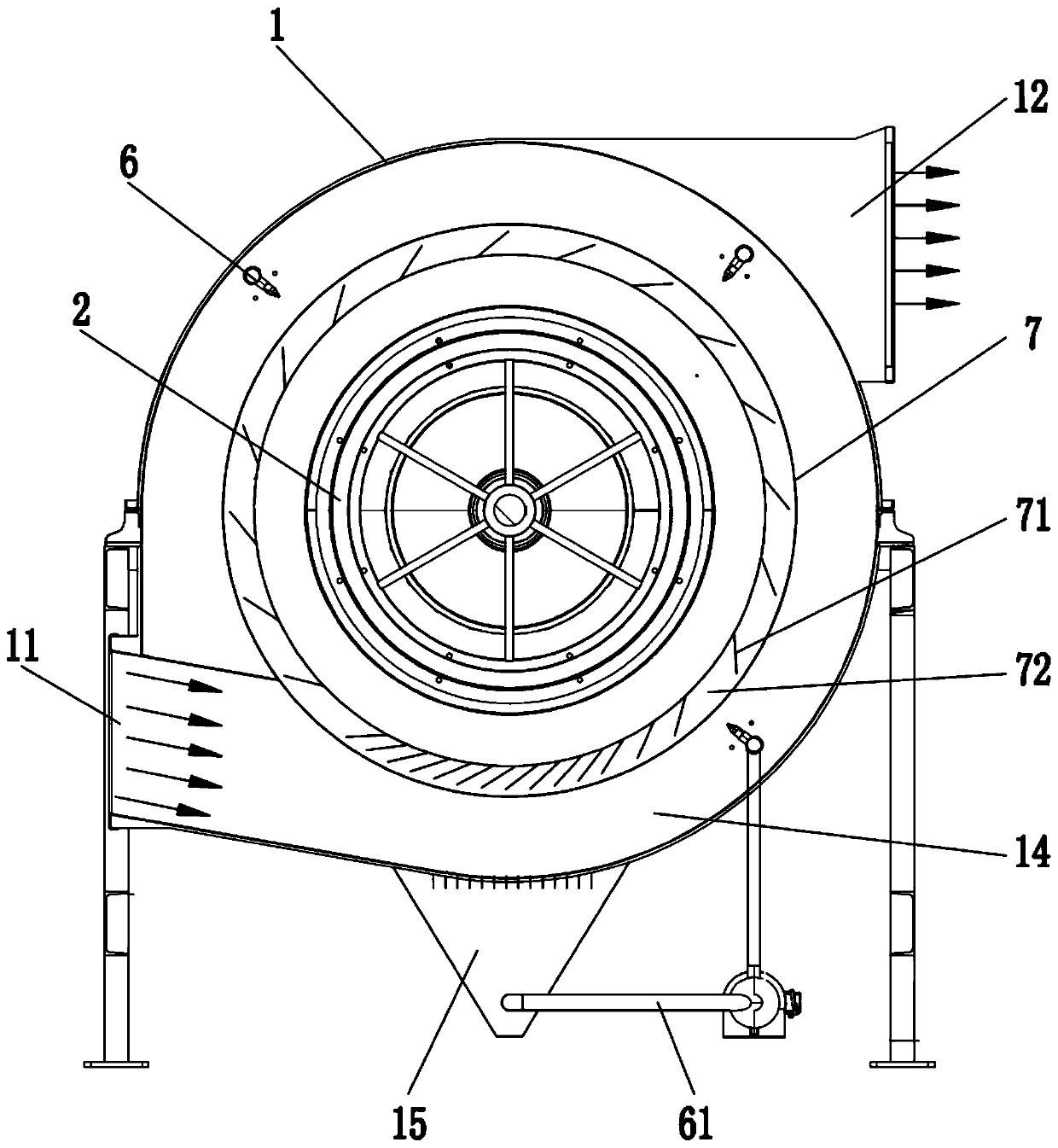

Sand separating and removing device used for powdery material

InactiveCN105537116AFull recoveryEffective separation and removalGas current separationRotational axisEngineering

The invention provides a sand separating and removing device used for a powdery material. The sand separating and removing device comprises a sealed box, wherein a charge hole is formed in the top of the box; a sand drainage hole is formed in the bottom of the box; air inlet doors and a discharge hole are respectively arranged at left and right sides of the box; material separating plates and rotary shafts are uniformly distributed in the box; the two ends of each rotary shaft are respectively mounted on the front wall and the rear wall of the box; the material separating plates are mounted on the rotary shafts and rotate along with the rotary shafts; a regulating device used for regulating an angle between the material separating plates and an air inlet direction is further arranged on the outer wall of the box; the regulating device comprises a regulating lever and a connecting row; when the connecting row moves, the regulating lever is driven to rotate by taking the rotary shafts as the circle center, so that the rotary shafts and the material separating plates mounted on the rotary shafts are driven to rotate. The device is used for effectively separating and removing sand particles in sanding powder, so that the sanding powder is recycled, and raw material cost required for plate production is effectively reduced.

Owner:万华禾香生态科技股份有限公司

Method for reducing heavy metal residue in ganoderma lucidum polysaccharide by membrane method

The invention discloses a method for reducing a heavy metal residue in a ganoderma lucidum polysaccharide by a membrane method. The method comprises the following steps: step one: filtering ganoderma lucidum extracting solution by a first-level filter membrane, to obtain trapped fluid I and permeate, wherein the first-level filter membrane is a ceramic membrane of which a pore size is 10-20 nm; step two: filtering the permeate obtained in the step one by a second-level filter membrane, to obtain trapped fluid II, wherein the second-level filter membrane is a nanofiltration membrane of which a pore size is 0.5-2 nm; and step three: merging the trapped fluid I and the trapped fluid II, concentrating and drying, to obtain a ganoderma lucidum polysaccharide product. The method is capable of purifying the ganoderma lucidum polysaccharide through membrane filtration. The technology is capable of synchronously desalting as well as reducing the heavy metal residue, simple in process, simple in device structure, convenient for maintaining, and suitable for industrialization production.

Owner:华茂(湖州)保健品有限公司

Method for removing impurity in the process of air delivery of powdered materials

InactiveCN1827241AEffective separation and removalEfficient removalSievingConveyorsForeign matterEngineering

The invention relates to a method that removing foreign matters in the powder air feeding process, which adds a foreign matter removing device on the pipe that from the middle storage pot to the final storage post. Wherein, the foreign matters removing device comprises a case and a screen plate, while the left of case has a inlet, the right of case has a outlet, and the upper and lower parts of case have hand holes; the screen plate is arranged between the upper and lower cases, while it has screen holes with 30-45% hole percentage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for purifying and preparing poplar wood xylooligosaccharide by biological enzyme together with physical and chemical methods

ActiveCN110042133ARealize high-value utilizationReduce consumptionFermentationActivated carbonCalcium hydroxide

The invention discloses a method for purifying and preparing poplar wood xylooligosaccharide by a biological enzyme together with physical and chemical methods, and belongs to the technical field of biological refining. The preparation method simultaneously performs purification of pre-hydrolysis liquor and preparation of xylooligosaccharide, specifically treats the poplar wood pre-hydrolysis liquor by using a physical, chemical and biological combination method including calcium hydroxide treatment, laccase and xylanase treatment and activated carbon treatment; and, and separates and removessoluble impurities such as lignin and furfural in the pre-hydrolysis liquor to the maximum extent under the condition of ensuring high xylooligosaccharide yield and purity. The method solves the problems of long period, high energy consumption, complex process and high production cost in the process of producing xylooligosaccharide by traditional methods, improves the utilization value of the poplar wood pre-hydrolysis liquor, and realizes the high-value utilization of hemicellulose component of broad-leaf wood such as poplar wood. Therefore, the method has good practical application value.

Owner:QILU UNIV OF TECH

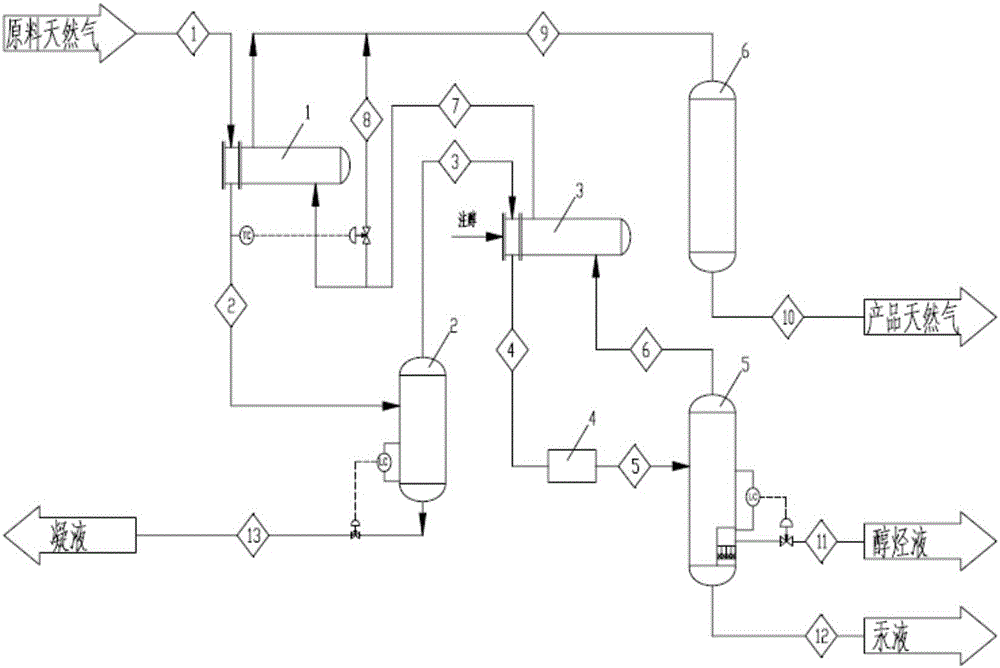

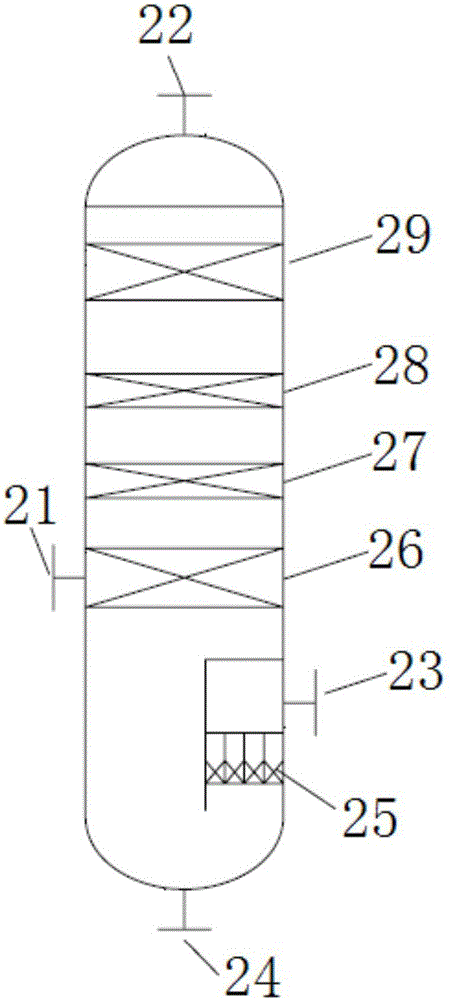

Natural gas demercuration device and method

ActiveCN105779055AEffective separation and removalEfficient separationGas treatmentGaseous fuelsAlcoholProcess engineering

The invention discloses a natural gas demercuration device and method. The device comprises a raw gas precooler, a raw gas separator, a raw gas aftercooler, a refrigerating facility, a low-temperature separator and the like which are connected in sequence. The natural gas demercuration device and method have the positive effects that an internal demercuration member is arranged by improving an internal structure of the low-temperature separator, such that an alcohol-hydrocarbon solution is extracted from the side surface instead of being extracted from the bottom by low-temperature separation, and low-temperature liquid mercury is discharged from the bottom of the low-temperature separator to be subjected to low-temperature demercuration, dehydration and dealkylation. Mercury, water and heavy hydrocarbons in raw gas are separated and removed effectively by the low-temperature separator through adopting a low-temperature separation, demercuration, dehydration and dealkylation system consisting of the raw gas precooler, the raw gas separator, the raw gas aftercooler, the refrigerating facility and the low-temperature separator.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

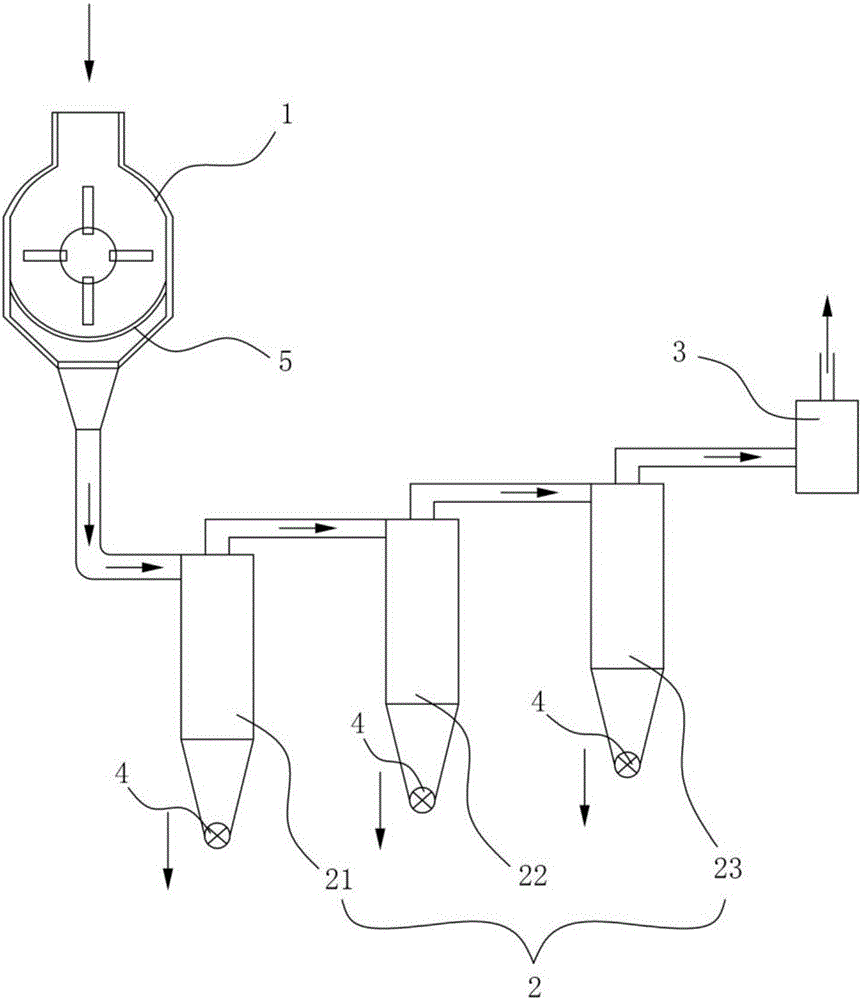

Crop straw crushing and sorting integrated device and method

The invention discloses a crop straw crushing and sorting integrated device and method. The device comprises a straw crusher and a sorting device. The straw crusher is connected with one end of the sorting device through an air pipe. The other end of the sorting device is connected with an induced draft fan through an air pipe. The sorting device is a centrifugal separator set. The centrifugal separator set comprises a first centrifugal separator, a second centrifugal separator and a third centrifugal separator which are connected in sequence. The straw crusher is connected with the first centrifugal separator through an air pipe. The third centrifugal separator is connected with the induced draft fan through an air pipe. By the adoption of the crop straw crushing and sorting integrated device, the production efficiency of crop straw artificial boards is greatly improved, the utilization rate of crushed aggregates is greatly increased, and the artificial boards made of the crushed aggregates obtained through the device are high in internal bond strength and good in surface quality.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for producing high-purity electronic titanium dioxide

ActiveCN111439781APlay a role in removing impuritiesMeet the requirements of high-end electronic grade titanium dioxideTitanium dioxideAluminium chlorideHydrolysate

The invention discloses a method for producing high-purity electronic titanium dioxide. Panzhihua titanium concentrate with the concentration larger than or equal to 80% is selected as a raw material,sulfuric acid is used for acidolysis of the titanium concentrate, a flocculating agent composed of a maleic anhydride-styrene sulfonic acid copolymer, sodium lignin sulfonate and polyaluminum chloride is added for impurity removal treatment, standing and filter pressing are conducted for solid-liquid separation, filter-pressed liquid enters a vacuum crystallization system, secondary filter pressing is conducted, and refined titaniferous solution is obtained; water is added into the refined titaniferous solution to adjust the concentration to 95-200g / L, heating and stirring are performed, anda crystal form control agent is added to react to obtain a hydrolysate; the hydrolysate is washed until the iron ion content is below 150ppm, then sulfuric acid is added for bleaching and washed for the second time until the iron ion content is below 50ppm to obtain slurry; squeezing is performed by a filter press, a filter cake is calcined in a rotary kiln and crushed to obtain the electronic titanium dioxide. The purity of the titanium dioxide product prepared by the method reaches 99.5% or above, the particle size distribution is 200-400 nm, the particle size distribution is narrow, the particle size distribution is uniform, the powder whiteness reaches 90% or above, and the requirements of middle-high-end electronic-grade titanium dioxide can be met.

Owner:GUANGXI JINMAO TITANIUM

Kaolin reagent quality control product and preparation method and application thereof

ActiveCN109541242AMeet quality control requirementsIncreased sensitivityPreparing sample for investigationBiological testingQuality controlBlood plasma

The invention discloses a kaolin reagent quality control product. The quality control product is lyophilized formulation, and the raw material of the lyophilized formulation includes platelet-deficient animal plasma. The R value of the quality control product is 6-8 min, the K value is 2-5 min, the Angle value is 60 DEG-80 DEG, and the MA value is 23-45 mm. The kaolin reagent quality control product is sensitive to the kaolin reagent reaction, so the accuracy of the quality detection is high, and the quality control requirements for the kaolin preparation in thromboelastography test are met. The quality control product has good reconstitution stability and can be stored for a long time under low temperature. The quality control product uses animal plasma as raw material, thus reducing thecost of the quality control and improving the safety of the quality control operations. The invention also discloses a preparation method of a kaolin reagent quality control product, which can preparethe kaolin reagent quality control product with accurate detection results and high stability. The preparation method is stable and reliable, the preparation process is simple and easy to operate, and the preparation method is suitable for the production and application of kaolin reagent quality control products.

Owner:中科精瓒(武汉)医疗技术有限公司

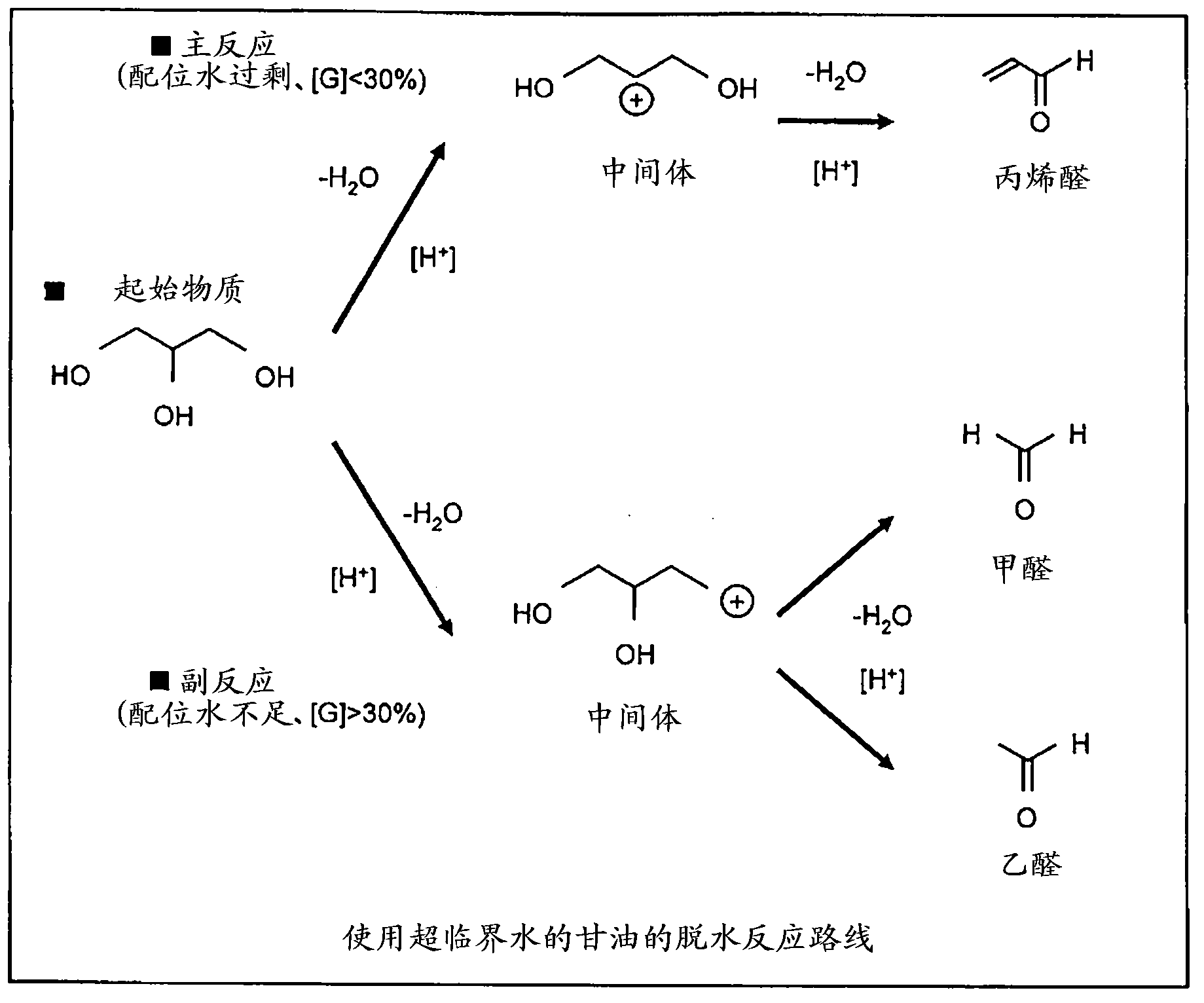

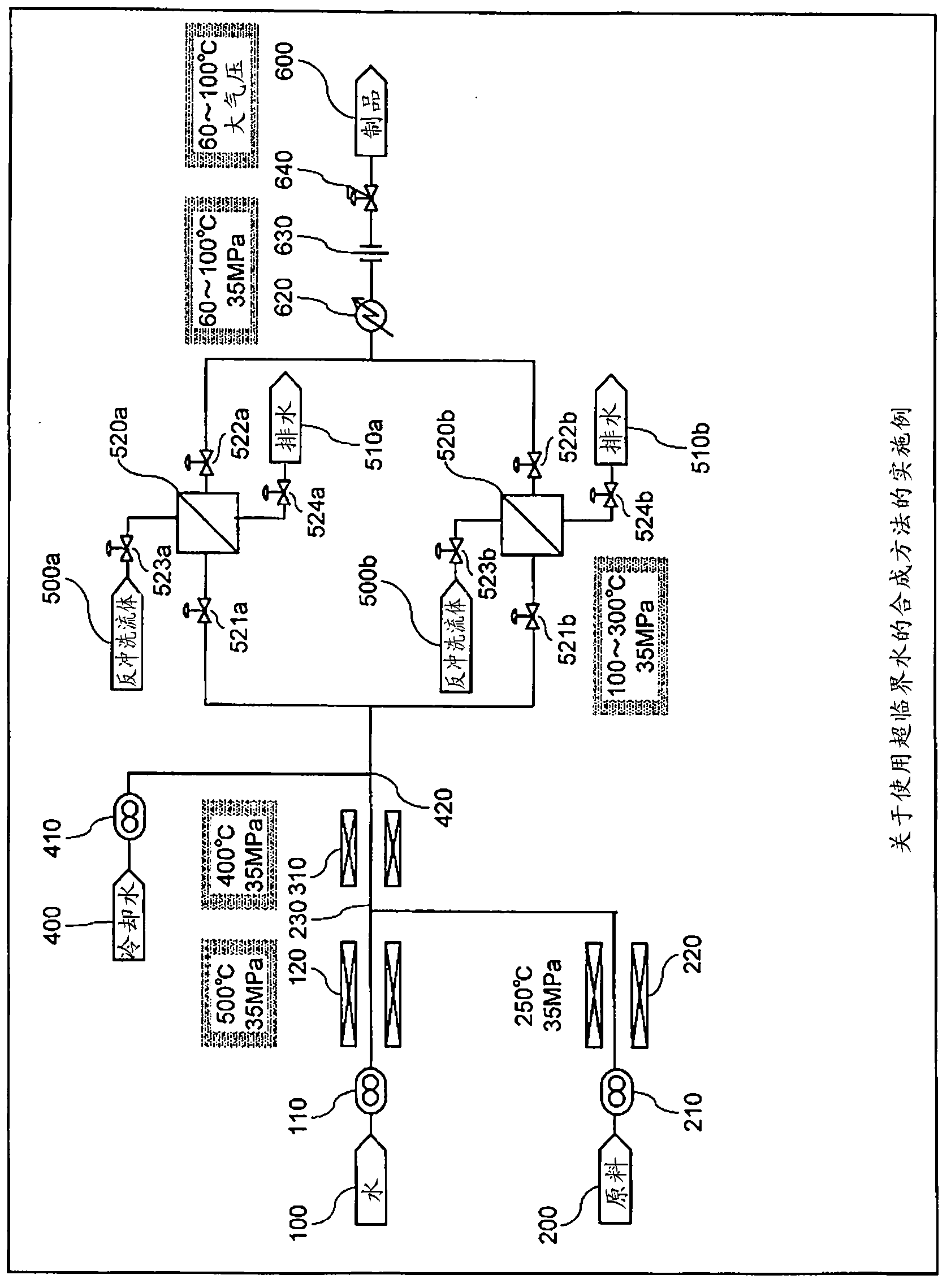

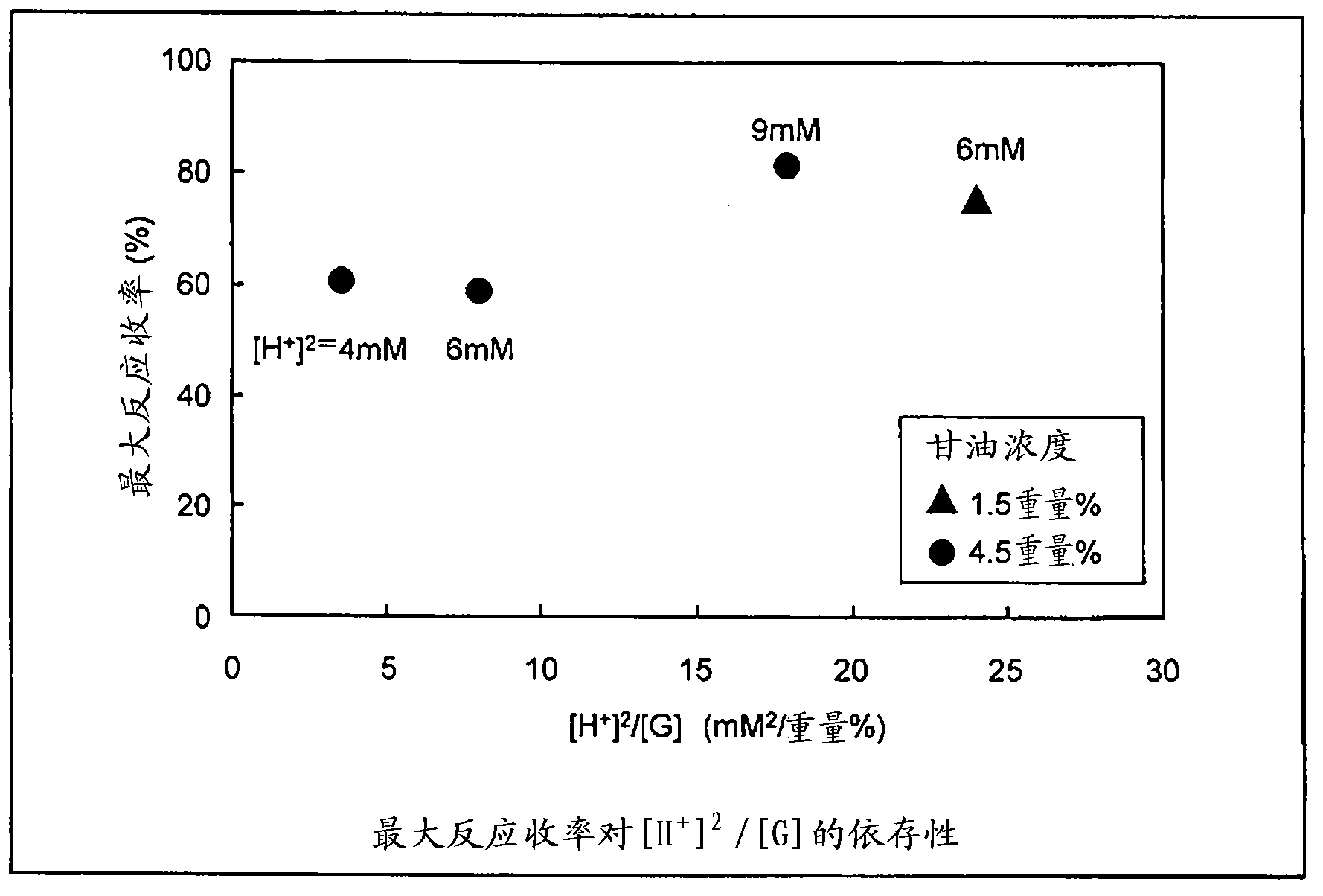

Process for synthesis of acrolein

InactiveCN102725256AReduce generationEffective separation and removalOrganic compound preparationCarbonyl compound separation/purificationBoiling pointAcrolein

Provided is a technique for a process for the synthesis of acrolein by reacting glycerol with supercritical water and an acid. In a case where a reaction fluid having a high glycerol concentration is employed to improve the energy efficiency, the technique makes it possible to protect pipes and devices from clogging and wear, which are caused by the generation of by-products, and thus enables the synthesis to proceed stably with high yield. In an embodiment of the technique, the reaction fluid is adjusted to a glycerol concentration of 30wt% or less. Further, the embodiment comprises: cooling the reaction fluid to a temperature that can stop the reaction and that can keep the tar contained in the reaction fluid at a sufficiently low viscosity, namely, a temperature of 100 to 300 DEG C; separating and removing carbon particles from the reaction fluid thus cooled; cooling the resulting reaction fluid to a temperature which is not higher than the boiling point of water and at which the tar contained in the reaction fluid does not stick to devices; and then evacuating the resulting system.

Owner:HITACHI LTD

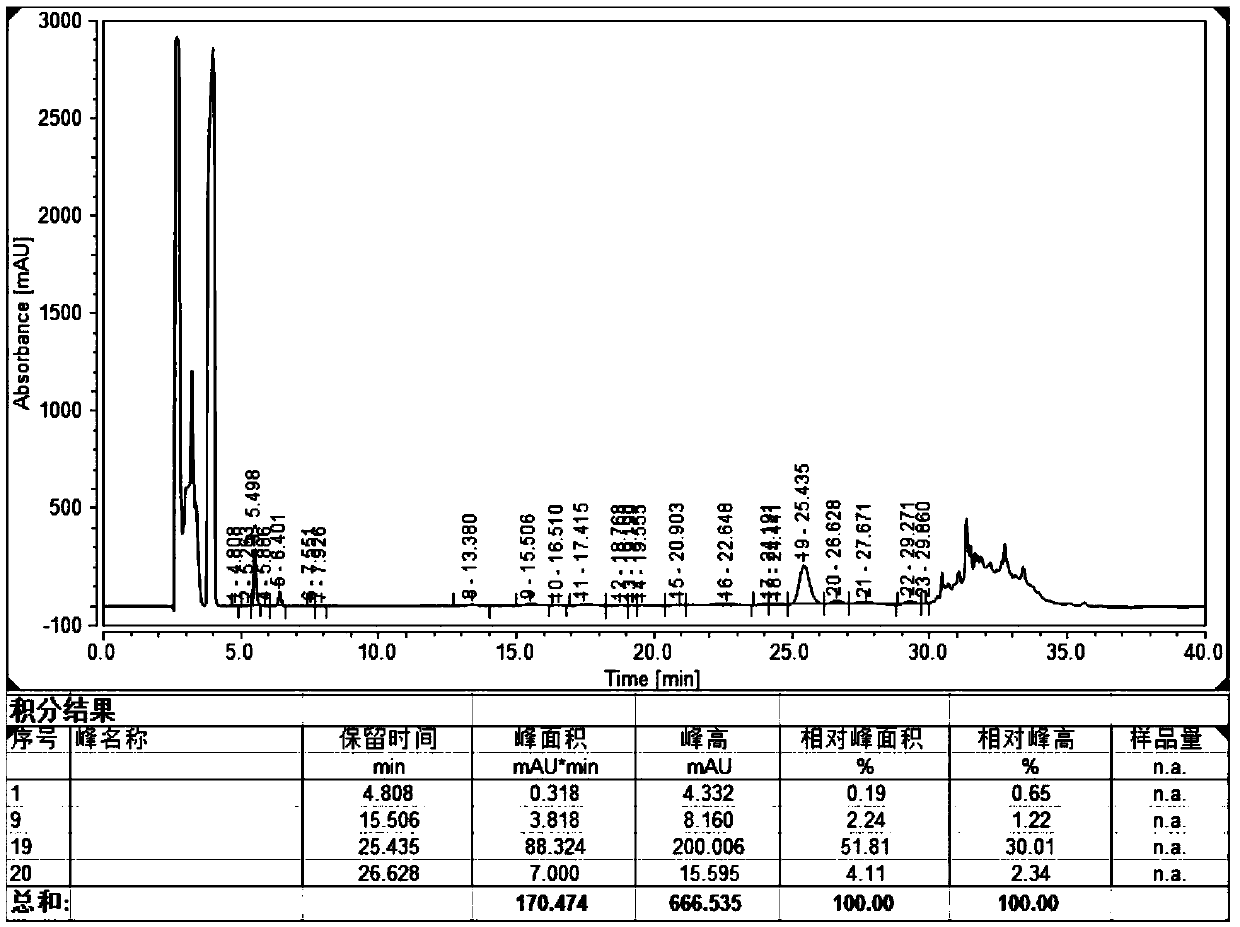

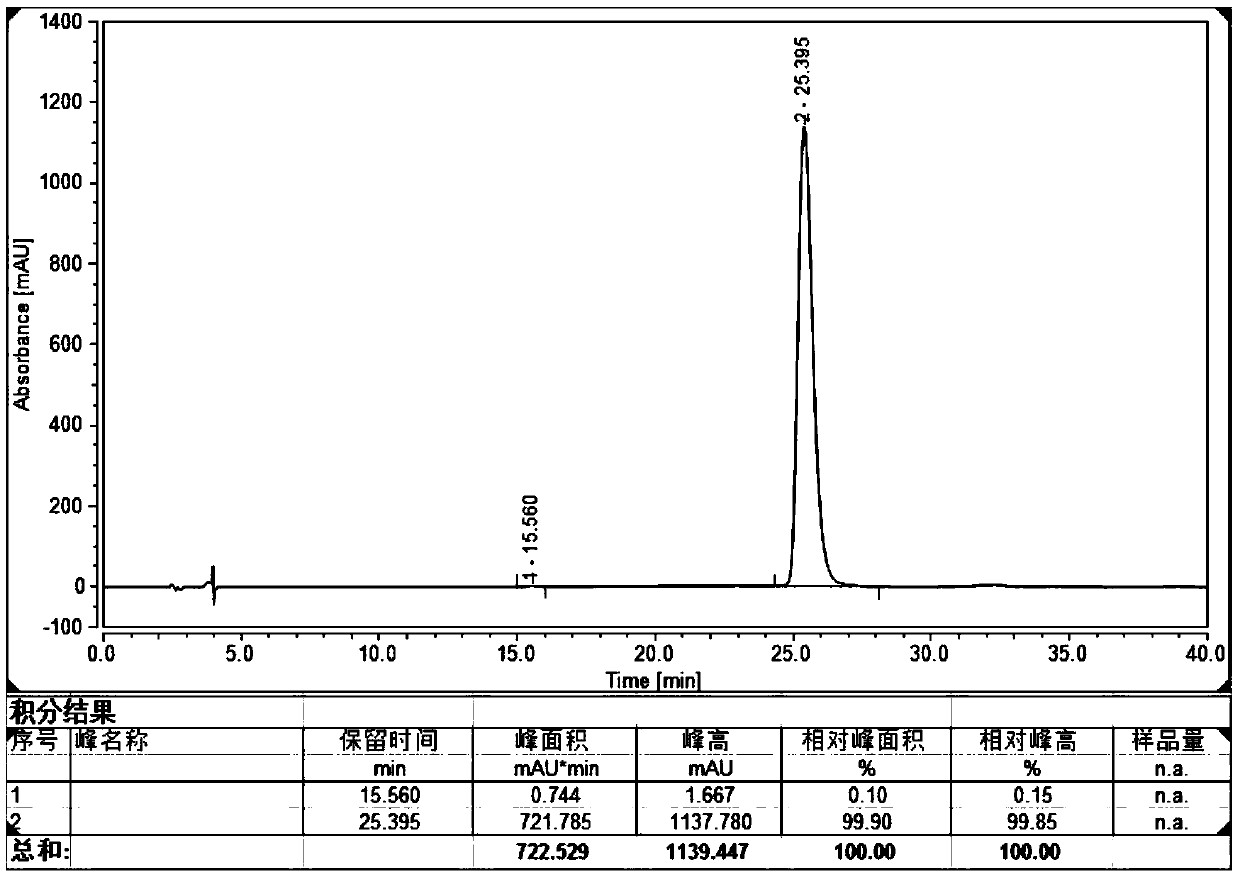

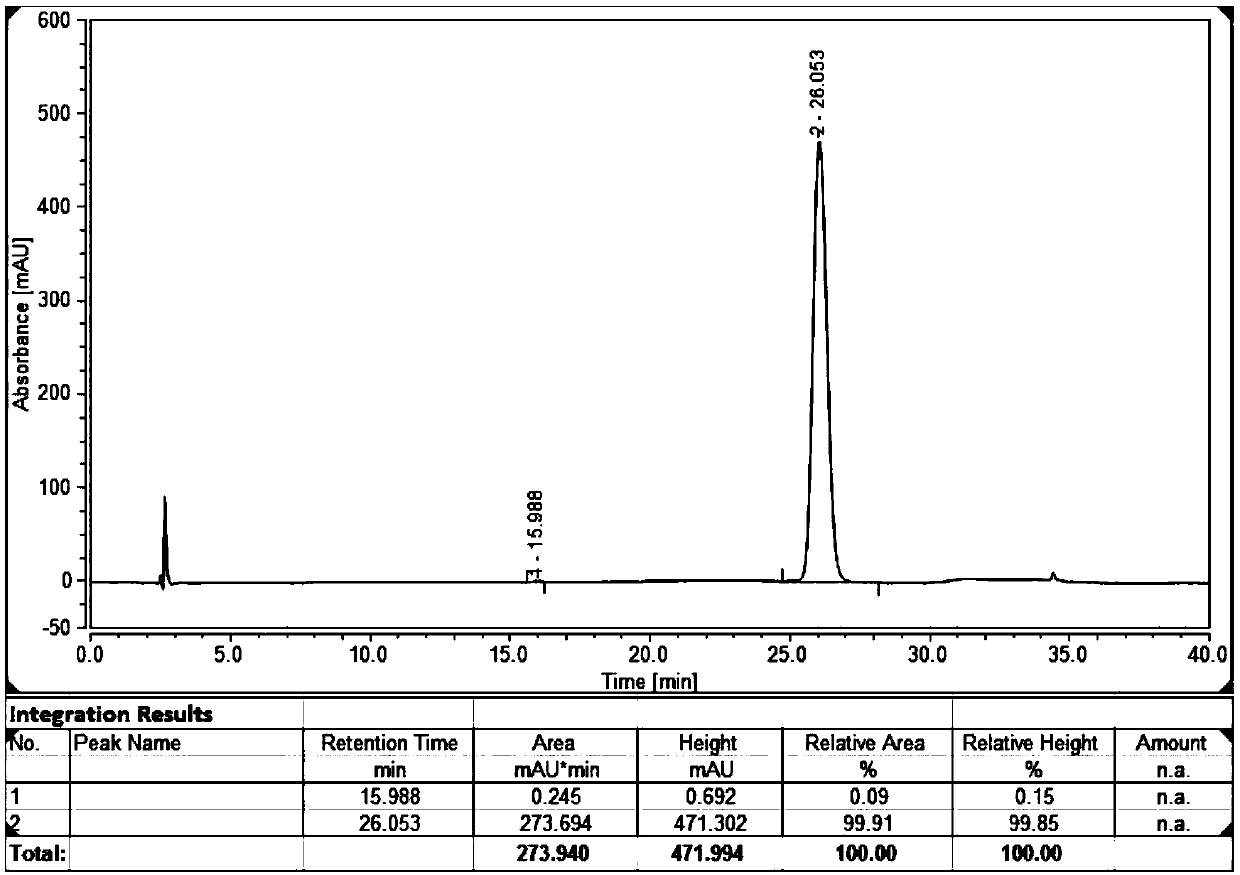

Method for preparing and purifying polypeptides

ActiveCN110845599AShorten the oxidation reaction timeEffective separation and removalGastrin releasing peptidePeptide preparation methodsMethionine biosynthesisOrganic chemistry

The invention belongs to the technical field of medicine, and particularly discloses a method for preparing and purifying polypeptides. A method for inhibiting methionine oxidation is used in the preparation and purification process of ularitide, so that the purity of the purified refined ularitide is as high as 99.90%, and methionine oxidation impurity peptides are controlled within 0.1%.

Owner:LUNAN PHARMA GROUP CORPORATION

Method for washing high-resistivity and low-resistivity silicon materials

InactiveCN102989723AEffective separation and removalMeet cleaning requirementsCleaning using liquidsWet separationHydrogen NitrateHigh resistivity silicon

The invention discloses a method for washing high-resistivity and low-resistivity silicon materials. The method comprises the following steps of: soaking the silicon material into hydrofluoric acid or a mixed solution of hydrofluoric acid and ammonium fluoride, after soaking, taking out the silicon material and washing the silicon material to be neutral with water; preparing the mixed solution of hydrofluoric acid and hydrogen nitrate, adding the silicon material into a plastic container, adding the prepared mixed solution, after reaction, lightly swashing the silicon material with clean water, enabling the low-resistivity silicon material to float on water surface, thereby realizing separation of high-resistivity silicon material and low-resistivity silicon material; mixing the mixed solution of hydrofluoric acid, hydrogen nitrate and glacial acetic acid, adding the separated high-resistivity material into the mixed solution, stirring and adding hydrogen peroxide at intervals, then, taking out the material and washing the material to be neutral with water; adding the high-resistivity material into an alkali wash basin, adding solid sodium hydroxide, adding a sodium hydroxide solution simultaneously, stirring for reaction, then, washing the alkali liquor away by the clean water; soaking the high-resistivity material into electronic grade hydrochloric acid, after soaking, washing the high-resistivity material to be clean with pure water; and finally, executing ultrasonic treatment with pure water, and then, fishing out the high-resistivity material, and drying.

Owner:嘉兴嘉晶电子有限公司

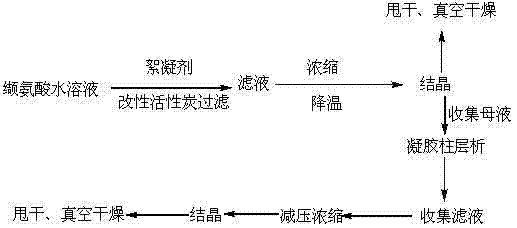

Production method for medical grade valine

ActiveCN102584611AEffective separation and removalSimple and fast operationOrganic compound preparationAmino-carboxyl compound preparationChromatographic separationFiltration membrane

The invention discloses a production method for high purity medical grade valine. Industrial valine raw material is prepared to be water solution higher than 5 percent under the temperature of 50 to 65 DEG C, flocculating agent is added, modified activated carbon is added after filtering, ultrafiltration is performed by using an ultra filtration membrane with molecular weight cutoff larger than 500, then vacuum concentration and cooling crystallization are performed to obtain the crystal product of medical grade valine, mother solution is added into a gel chromatography column for chromatographic separation, pure water with the temperature of 40 to 50 DEG C is taken as eluate, valine solution flowing out of the column is collected, after concentrated crystallization, the crystal product of medical grade valine is obtained, and finally, the removing rate of bacterial endotoxin and protein in the product can reach 99 percent, lactamic acid, aminocarproic acid and isoleucine can be effectively removed, the purity of the product can reach 99 percent, medical grade standards are met, the comprehensive yield of products can reach more than 96 percent, and large-scale production can be achieved.

Owner:汕头市佳禾生物科技有限公司

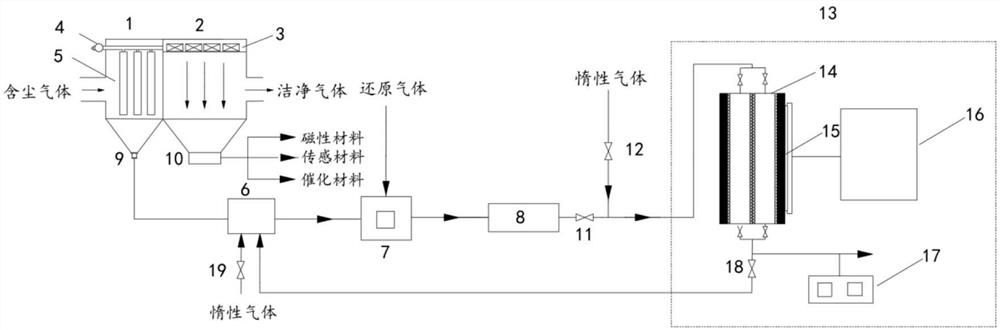

Iron oxidation product separation and reduction and reduction product storage and transportation system and method

The invention discloses an iron oxidation product separation and reduction and reduction product storage and transportation system and method. The system comprises a primary separator, a secondary separator and a storage and transportation system which are connected left and right. Micron-sized particles are removed from dust-containing flue gas with micron-sized alpha-Fe2O3 particles and nano-sized alpha-Fe2O3 and gamma-Fe2O3 polymer particles and generated after combustion of metal iron by virtue of the primary separator firstly, and then the nano-sized particles are removed from the dust-containing flue gas by virtue of the secondary separator; and after the collected micron-sized particles are conveyed to a powder reduction furnace for reduction by inert gas, the inert gas carries iron powder to enter a cooling section to be cooled to the room temperature, then the iron powder is adsorbed to the surface of a magnet pipe for storage when the inert gas passes through the storage and transportation system, and the inert gas is circulated to a powder bin. When the iron powder is transported, the inert gas enters a transporting system, a heating system and a sound wave vibration system are started at the same time, the magnet pipe is demagnetized through heating, the iron powder is conveyed along with the inert gas more easily through the sound wave vibration system, and the iron powder is effectively prevented from being oxidized in the transporting process.

Owner:XI AN JIAOTONG UNIV

Integrated super-gravity separation device

PendingCN110292810AReduce resistanceGood homogeneous mixing abilityCombination devicesGas phaseEngineering

The invention discloses an integrated super-gravity separation device. The device comprises a shell, a counter-current rotating packing layer and a cross-current rotating packing layer, wherein the shell is provided with an air inlet and an air outlet; the counter-current rotating packing layer and the cross-current rotating packing layer are rotationally arranged in the shell; the air inlet is communicated to the circumferential peripheral region of the counter-current rotating packing layer, and the axial central gas-phase outlet end of the counter-current rotating packing layer is communicated to the axial inlet end of the cross-current rotating packing layer; the axial gas-phase outlet end of the cross-current rotating packing layer is communicated with the air outlet. According to theintegrated type super-gravity separation device, a traditional counter-current rotating packing bed and a cross-current rotating packing bed are integrated into a whole, the structure is compact, theoccupied space is small, dust-containing gas is subjected to two-stage super-gravity separation treatment, the homogenization and mixing capacity is good, the flux is large, the resistance of the counter-current rotating packing layer is reduced under the same unit flux, the flooding point is increased, dust in the gas is effectively separated and removed, the dust removal efficiency is high, theeffect is good, and the cleanliness of the treated gas is improved.

Owner:成都市珑熙科技有限公司

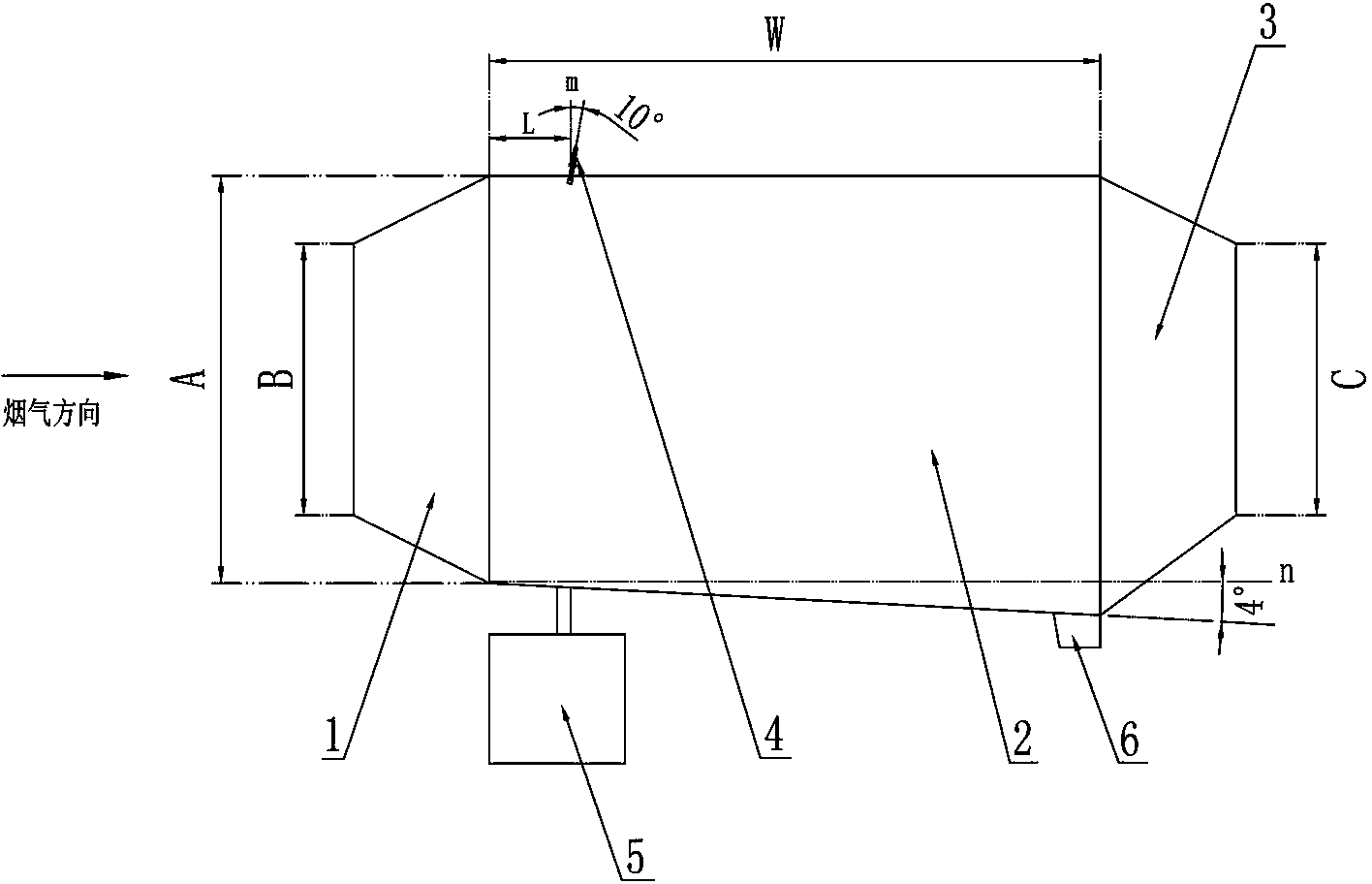

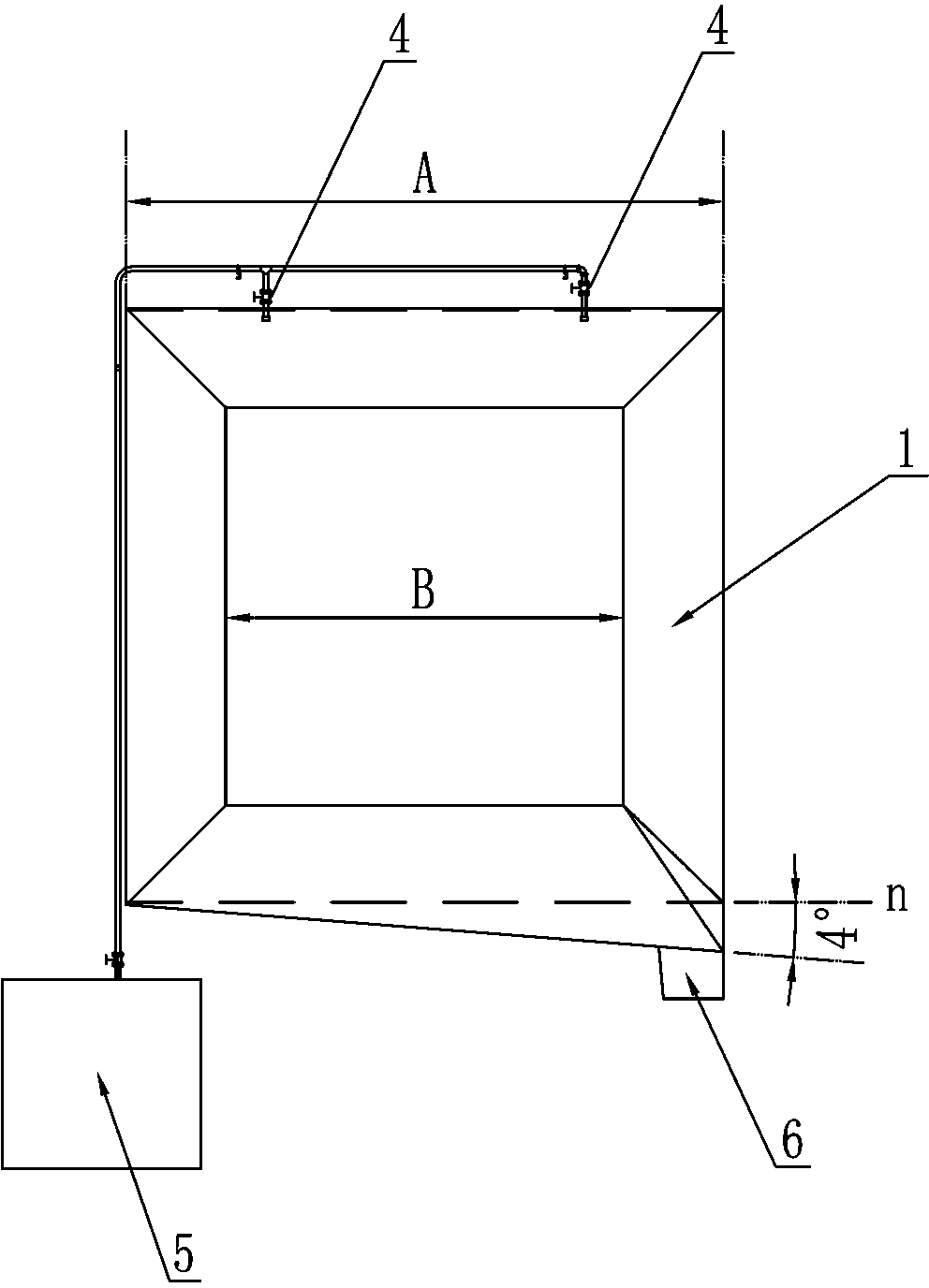

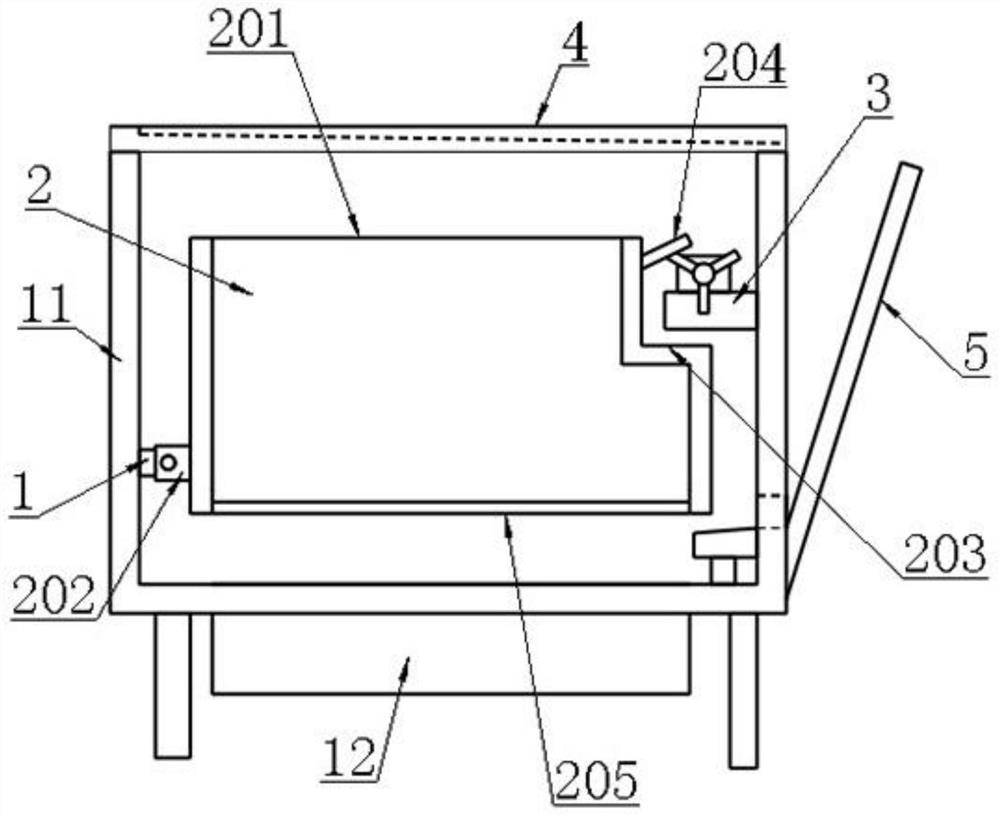

Device for absorbing and separating oil fouling of biomass boiler

InactiveCN104069709AEffective separation and removalSimple structureCombination devicesFlue gasBiomass boiler

The invention discloses a device for absorbing and separating oil fouling of a biomass boiler. The device comprises an oil fouling separation pipe body; the oil fouling separation pipe body is formed by a flue gas inlet pipe section, an oil fouling separation pipe section and a flue gas outlet pipe section which are sequentially communicated; the flue gas inlet pipe section is set into a horn shape, and the pipe diameter of the flue gas inlet pipe section is gradually increased along the forwarding direction of flue gas; the flue gas outlet pipe section is set into a horn shape, and the pipe diameter of the flue gas outlet pipe section is gradually decreased along the forwarding direction of the flue gas; the outer side wall of the oil fouling separation pipe section is evenly provided with a plurality of spray pipes; nozzles of the spray pipes extend into the oil fouling separation pipe section; the spray pipes are communicated with a storage tank at the same time, and oil fouling absorption powder is contained in the storage tank; the bottom surface of the oil fouling separation pipe section is arranged in a manner of gradually inclining towards the lower left side or lower right side along the forwarding direction of the flue gas; the lower end of the bottom surface has an ash discharge hole; an ash discharge valve used for opening and closing the ash discharge hole is arranged at the ash discharge hole. The device is capable of effectively separating and removing the oil fouling in the dust-containing flue gas.

Owner:JIANGSU NEW ENVIRONMENTAL CORP

Improved drilling fluid with high-strength wall protection effect and preparation method thereof, and equipment

The invention belongs to the technical field of horizontal directional drilling, and particularly relates to improved drilling fluid with a high-strength wall protection effect and a preparation method thereof, and equipment. According to the invention, the drilling fluid is prepared by stirring and compounding water, sodium carbonate, bentonite, a fluid loss agent, a suspension accelerator and aplugging agent, and the drilling fluid is matched with a vibrating screen in the use process to achieve the effect of effectively using the drilling fluid. The drilling fluid has the advantages of being simple and effective in preparation method, high in viscosity, low in water loss, high in gelling strength, good in suspension and chip conveying capacity, good in leaking stoppage effect and capable of forming a high-quality filter cake to be used for leakage prevention and collapse prevention; the vibrating screen can effectively separate and remove large-particle drilling chips and effectively recycle small-particle drilling cuttings and a drilling fluid filtrate, so resources are saved; and the vibrating screen is good in structural stability and easy and convenient to use, adjust, replace, disassemble, assemble and maintain in daily life.

Owner:河北省水利工程局集团有限公司

Domestic sewage solid greasy dirt condensation and separation device

ActiveCN111875137AEffective coagulationReduce entryFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSewageSewage treatment

The invention discloses a domestic sewage solid greasy dirt coagulation and separation device, and belongs to the technical field of sewage treatment. A plurality of greasy dirt separation balls are put into a sewage storage bin, greasy dirt on the surface of sewage enters an upper oil absorption hemisphere through a through hole, an adsorption pushing ball adsorbs greasy dirt to expand, and a pushing top block separates a pair of connecting magnetic blocks; meanwhile, under the elastic action of a compression spring, a pair of connecting magnetic blocks are far away from each other and are limited at the same time, so that a pair of butt joint plates are far away from each other, adjacent rectangular magnetic blocks are connected with each other, and water and oil stains are effectively separated; then barium hydroxide solution in the reaction bin is in contact with an ammonium chloride solution in the inner cavity to generate an endothermic reaction, and meanwhile, under the elasticaction of the elastic telescopic block and the pushing spring, the plugging block makes contact with the upper inner wall of the butt-joint plate, and the rising column stretches out of the butt-jointplate and the annular telescopic heat conduction column to transfer temperature, so that oil stains are solidified through heat absorption of the rising column and the annular conical block, and therefore the oil stains on the sewage surface are effectively solidified and separated.

Owner:怀化市全城污水处理有限公司

A kind of extraction method of heparin sodium crude product

Owner:湖南迪博制药有限公司

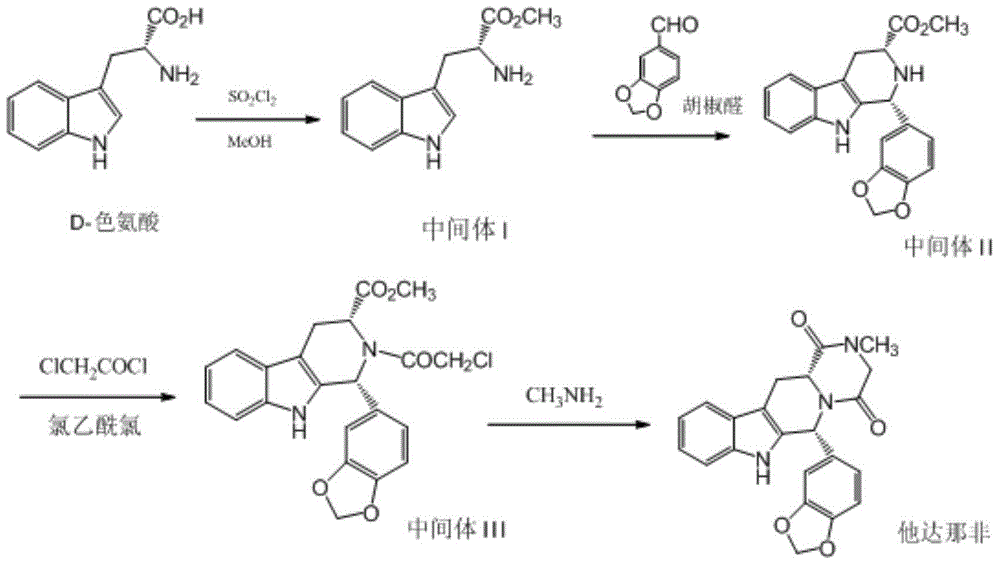

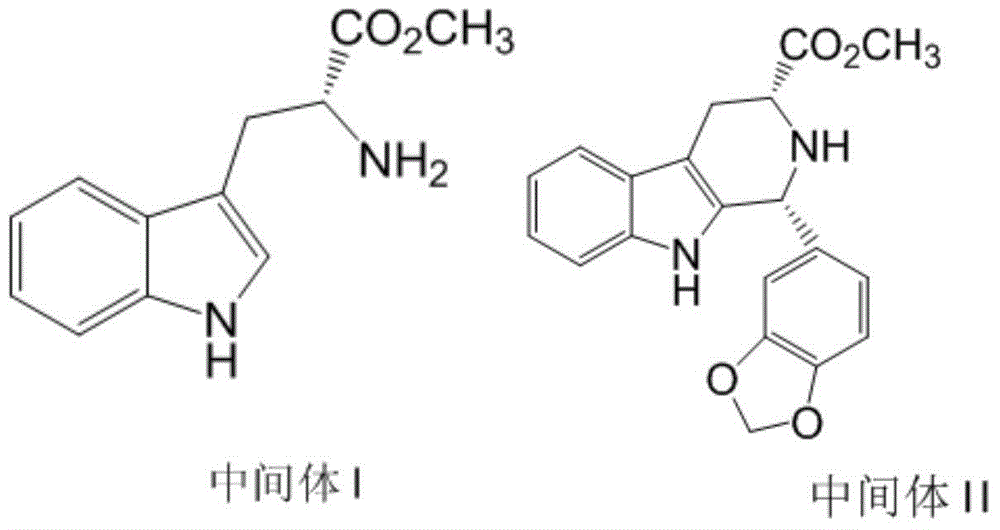

Preparing methods of Tadalafil intermediates

The invention provides preparing methods of two Tadalafil intermediates shown as I and II in a solvent that is dimethyl carbonate. The intermediate I is prepared without the existence of thionyl chloride. High-purity stereoisomer that is the intermediate II can be prepared in the dimethyl carbonate solvent.

Owner:GUANGZHOU PHARMACEUTICAL INDUSTRIAL RESEARCH INSTITUTE

Self-propagating pyrolysis system applied to solid waste treatment

A self-propagating pyrolysis system applied to solid waste treatment is composed of a chain belt type conveyor, a distribution device, a ventilation loosening device, a pyrolysis device composed of alow-temperature pyrolysis section, a self-propagating high-temperature pyrolysis section and a self-propagating pyrolysis section, a material collecting and returning device and the like. According tothe self-propagating pyrolysis system, air in the high-temperature pyrolysis section is heated through a gas combustion mode, flames do not make contact with a material, and the situation that the material is fused and subjected to caking due to the fact that the temperature of part of the material is too high is avoided; high-temperature air is subjected to self-propagating heating from the upper layer to the lower layer of the material, and the effect that organic matter in the material is sufficiently decomposed without stirring the material can be achieved. In the system, pyrolysis is divided into the low-temperature pyrolysis section, the self-propagating high-temperature pyrolysis section and the self-propagating pyrolysis section, the three sections adopt different structures, through the different heating modes, the pyrolysis temperature can be effectively adjusted and controlled, the self-propagating high-temperature pyrolysis section is shortened, it is ensured that the material are sufficiently decomposed through the self-propagating pyrolysis mode, and energy resource wasting is avoided.

Owner:重庆世银科技有限公司

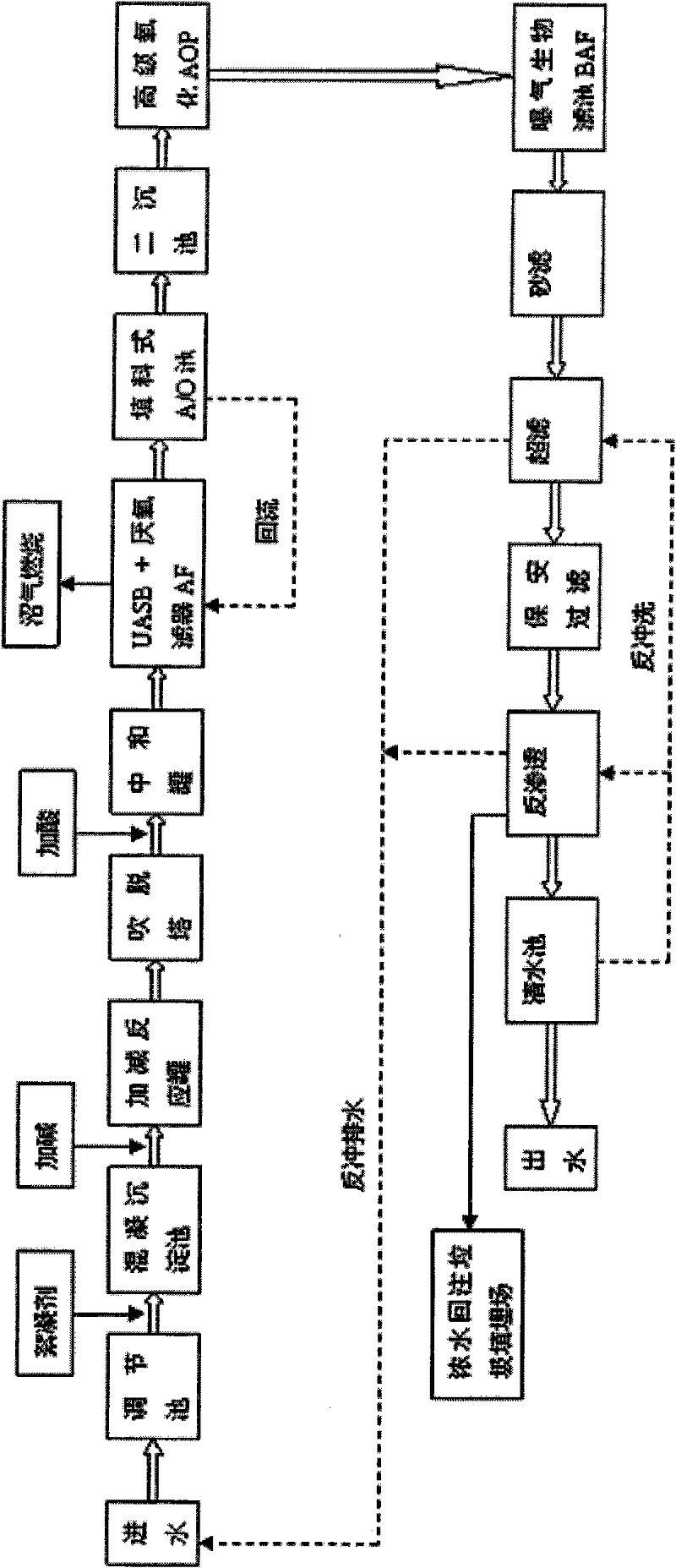

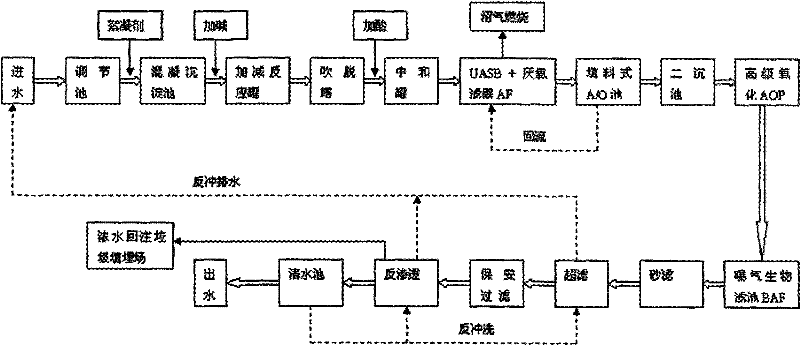

Garbage leachate treatment technique

ActiveCN101671095BEfficient separationEfficient degradationTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisLitterWater quality

Owner:UNIVERSTAR SCI & TECH SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com