Extraction method of heparin sodium crude product

An extraction method and heparin sodium technology, which are applied in the field of biopharmaceutical production, can solve the problems of high cost price of pig small intestine, unable to improve the purity, unable to develop rapidly, etc. Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Take fresh pig lungs or frozen pig lungs after natural thawing, peel off the trachea and fat, and twist them into a paste to obtain pig lung slurry. Take 10kg of pig lung slurry, add 5000ml of deionized water, and then add 15g of sorbic acid Potassium and 15g of hexadecyltrimethylammonium bromide, stirred at 25°C, the stirring speed was less than 50 rpm, once an hour, stirring for 30 minutes each time, stopping for 30 minutes, stirring and reacting for 4 hours, and the first pig was obtained. Lung slurry liquid, in the first pig lung slurry liquid, add the deionized water of 30000ml, get the second pig lung slurry liquid, add 1.8kg sodium chloride again, adjust pH to 9 with sodium hydroxide solution, at 25 Stir at ℃, the stirring speed is less than 50 rpm, stir once per hour, stir for 30 minutes each time, stop for 30 minutes, stir and react for 4 hours, and obtain the pig lung alkaline hydrolyzate;

[0042] 2) Slowly heat the pig lung alkaline hydrolysis solution ob...

Embodiment 2

[0049] 1) Take fresh pig lungs or frozen pig lungs after natural thawing, peel off the trachea and fat, and twist them into a paste to obtain pig lung slurry. Take 10kg of pig lung slurry, add 5000ml of deionized water, and then add 15g of benzoic acid and 15g of sodium dodecylsulfonate, stirred at 25°C, the stirring speed was less than 50 rpm, stirred once per hour, stirred for 30 minutes each time, stopped for 30 minutes, stirred and reacted for 4 hours, and the first porcine lung slurry was obtained Feed liquid, add 30000ml deionized water to the first porcine lung slurry liquid to obtain the second porcine lung slurry liquid, then add 2.0kg sodium chloride, adjust pH to 9 with sodium hydroxide solution, at 25°C Stirring, the stirring speed is less than 50 rpm, stirring once per hour, stirring for 30 minutes each time, stopping for 30 minutes, stirring and reacting for 4 hours, to obtain the pig lung alkaline solution;

[0050] 2) Slowly heat the pig lung alkaline hydrolysi...

experiment example

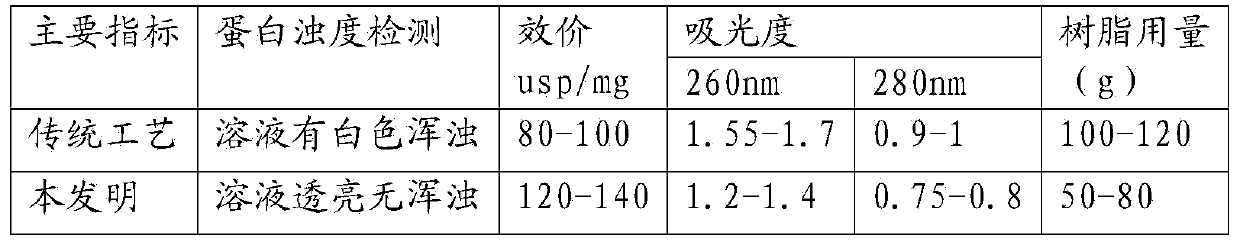

[0057] Contrast the effective yields of Examples 1 and 2 with the traditional process below. The traditional process refers to the method of removing impurities such as protein without centrifuge separation, and the results are as follows.

[0058] The present invention and traditional process effective yield comparative table

[0059]

[0060] 1. When using trichloroacetic acid method to titrate crude heparin sodium solution, protein impurities will make the solution turbid, and the higher the turbidity, the higher the protein content;

[0061] 2. Many impurities such as protein contained in the crude heparin sodium solution will be preferentially combined with the resin, resulting in an ineffective reaction of the resin, and at the same time increasing the amount of resin and reducing the service life of the resin;

[0062] 3. The extraction method of heparin sodium of the present invention effectively separates heparin sodium and protein impurities, improves potency and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com