Patents

Literature

69results about How to "Facilitate large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode material of composite silicate and preparation method thereof

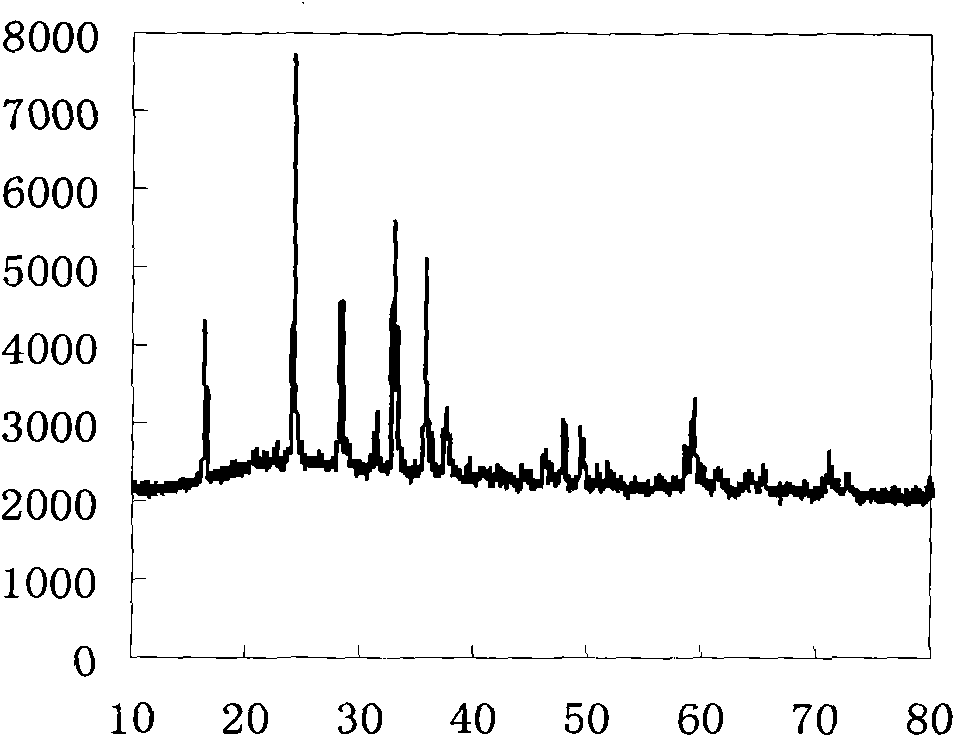

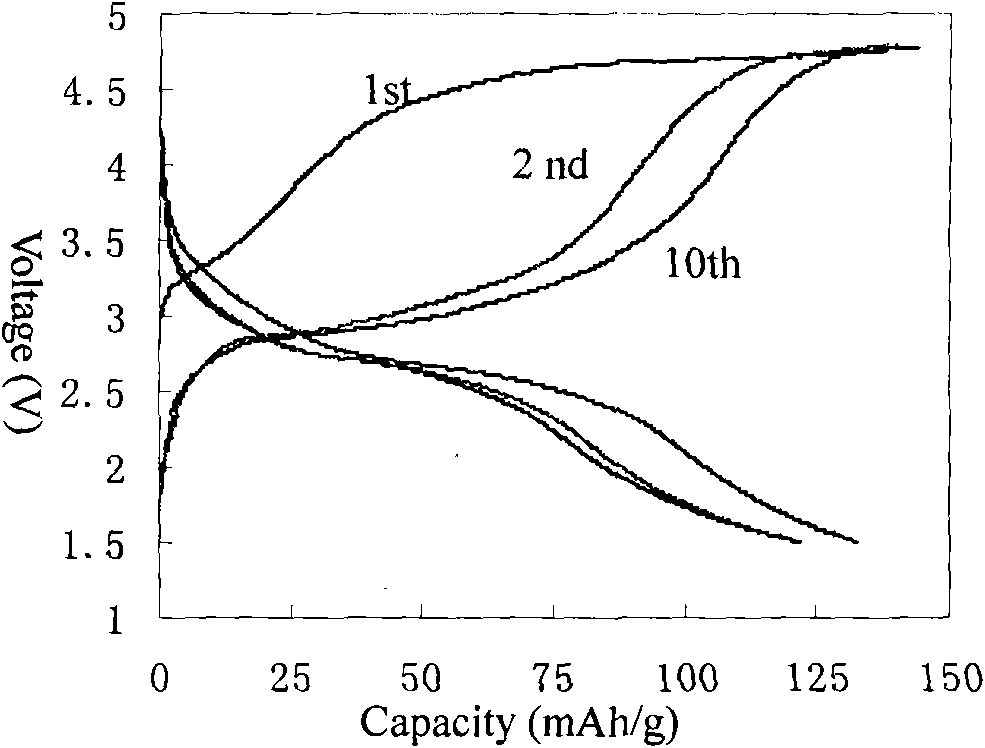

ActiveCN102088074AHigh densityImprove electrochemical performanceCell electrodesLithiumElectrochemistry

The invention discloses a solid phase method for synthesizing an anode material of a composite silicate (Li2-yMyFexMn1-xSiO4 / C, wherein 0<=x<=1, 0<=y<=0.02, and M is one or a plurality of transition state elements of IB-VIIIB) series, and an anode material of the composite silicate. Organic carbon source is added in iron source, manganese source, lithium source, silicon source and organic carbon source doped with metal compound for dispersing and ball milling for a plurality of hours, and the mixture is dried by spray, protected in a vacuum environment or by introduced non-oxide gas and sintered at the temperature of 600 to 950 DEG C for 5 to 24 hours, thus the anode material of the composite silicate with good electrochemical performance is obtained. The preparation method of the anode material has high technical adaptability and is easy to realize industrial production; and the product has extremely good electrochemical performance.

Owner:BTR NEW MATERIAL GRP CO LTD

High activity biological nutrition water-loss reducer and preparation method thereof

InactiveCN101215208AImprove biological activityImprove soil improvement effectOrganic fertilisersFertilizer mixturesForest industryCross linker

The invention provides a high activity bio-nutritive water retention agent, which adopts super absorbent resin as host crystal, uses 1-10% glycerin solution as surface cross linker, simultaneously compounds 10-20% humate / fulvic acid salt solution and 10% high activity biological bacteria (like EM bacterium fluid) to prepare high activity water retention agent. The invention has relatively high biological activity, and is applied to agriculture and forest industry, and improves production, strengthens effect, protects environment and greatly improves soil-improving ability. The invention adopts compounding biological agents with high activity under acidity condition, which is beneficial for survival and propagation of strains. The invention does not kill strains when dries at low temperature, and is beneficial for dormancy and storage of strains.

Owner:师进

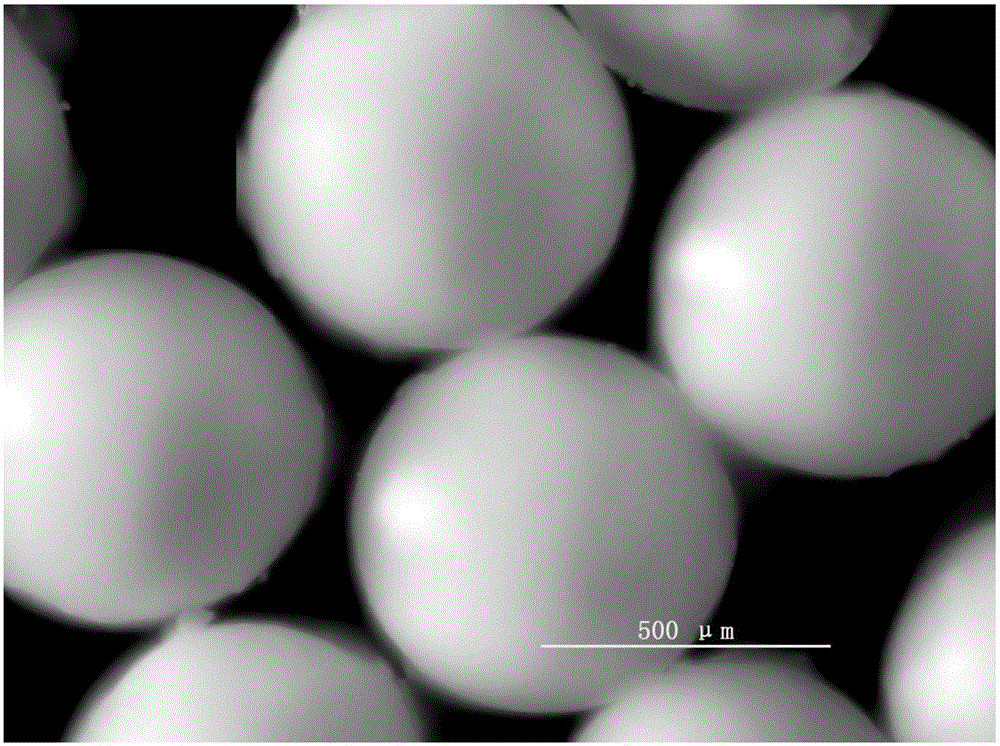

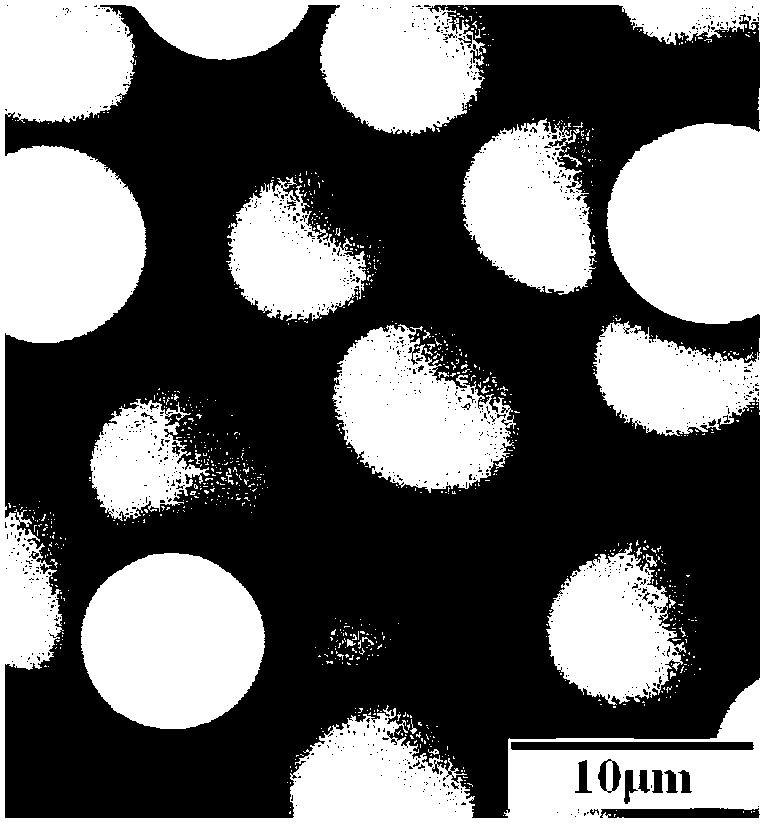

Preparation method for particle diameter controllable millimeter-scale polyurea monodisperse microsphere

InactiveCN104151516AMeet particle size requirementsNo pollutionMicroballoon preparationMicrocapsule preparationMicrospherePollution

The invention relates to a preparation method for a particle diameter controllable millimeter-scale polyurea monodisperse microsphere. The preparation method comprises the following steps: isocyanate compound is adopted as a monomer and is squeezed through syringe needles or capillary tubes to form liquid drops and the liquid drops are added into water or a polyamine aqueous solution for sedimentation and polymerization; during the settlement process of the liquid drops, the monomers on the surfaces of the liquid drops react with the water or the polyamine aqueous solution rapidly to form a gelatin layer or callus and the stability of particles is maintained. According to the method, as water is adopted as the dispersion medium, no pollution is generated; the polymerization reaction can be conducted under lower temperature, the equipment is simple and the manufacturing cost is low; the obtained microsphere is free from residual monomer and the post-processing is simple; no surface modified agent or pore-foaming agent is needed, porous polyurea microsphere with rich amino on the surface is prepared in one step; the method can be used in the fields of enzyme immobilization, chemocatalysis, dye, adsorption and separation of heavy metal ions and the like.

Owner:UNIV OF JINAN

Diffusion process in solar panel preparation

InactiveCN102315310AReduce pollutionSimple processFinal product manufactureSemiconductor devicesOxygenNitrogen gas

The invention provides a diffusion process in solar panel preparation, which comprises the steps of: a, carrying out heat treatment on a silicon chip in the nitrogen atmosphere at a low temperature; b, carrying out oxidation treatment on the treated silicon chip obtained in the step a in the atmosphere of C2H2C12, nitrogen and oxygen at 860 to 1200 DEG C; carrying out phosphorous diffusion treatment on the treated silicon chip obtained in the step b through inducing a phosphorous source in the atmosphere of nitrogen and oxygen; d, carrying out driving-in treatment on the treated silicon chip obtained in the step c in the mixed atmosphere of nitrogen and oxygen at 800 to 9000 DEG C; and e, carrying out annealing treatment on the treated silicon chip obtained in the step d in the nitrogen atmosphere. PN junctions with the perfect quality can be prepared, the photoelectric conversion rate of solar panels is higher, in addition, the reliability and the stability of the solar panels are improved, the compounding center of the silicon chip surface can also be reduced at higher quality, and the service life of few current carriers are prolonged. The diffusion process further improves the impurity removal effect of the diffusion process, and in addition, the process is simple and is easy to implement.

Owner:BYD CO LTD

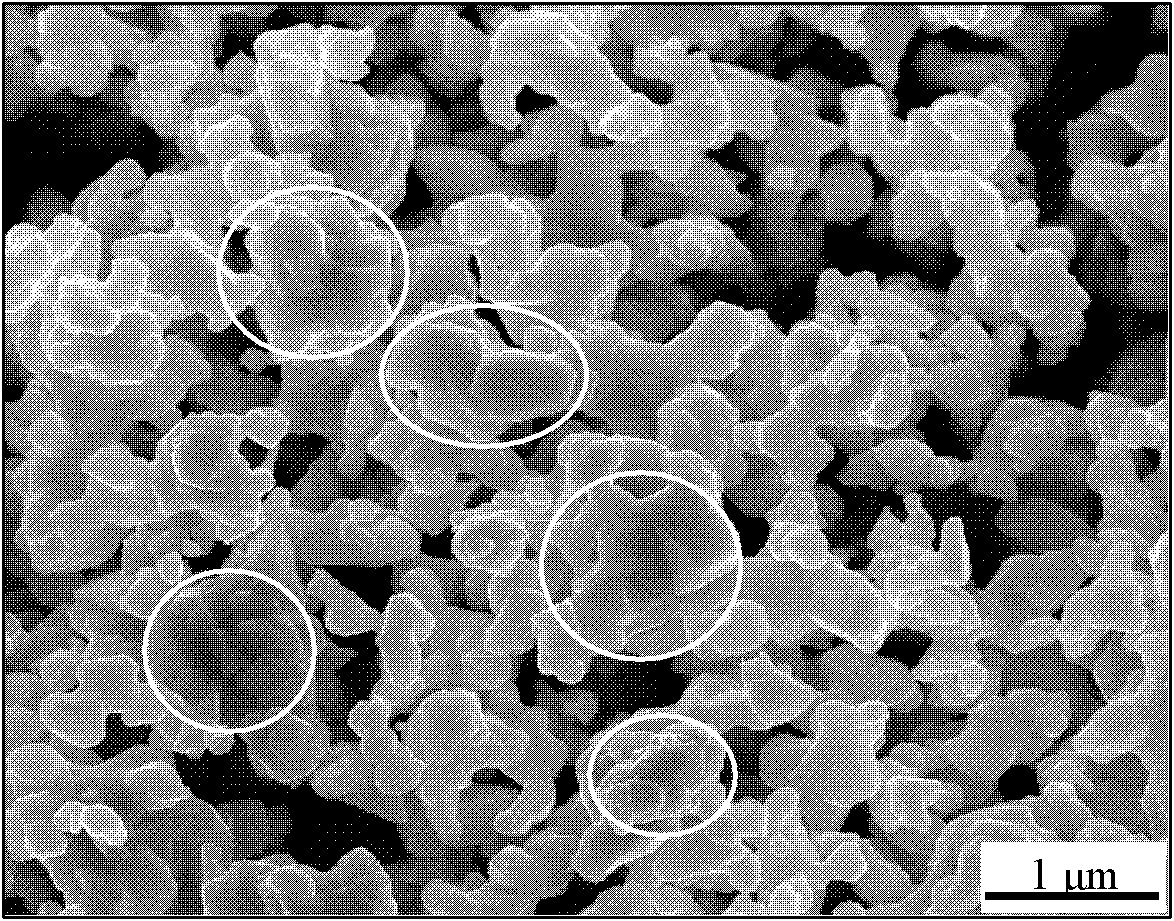

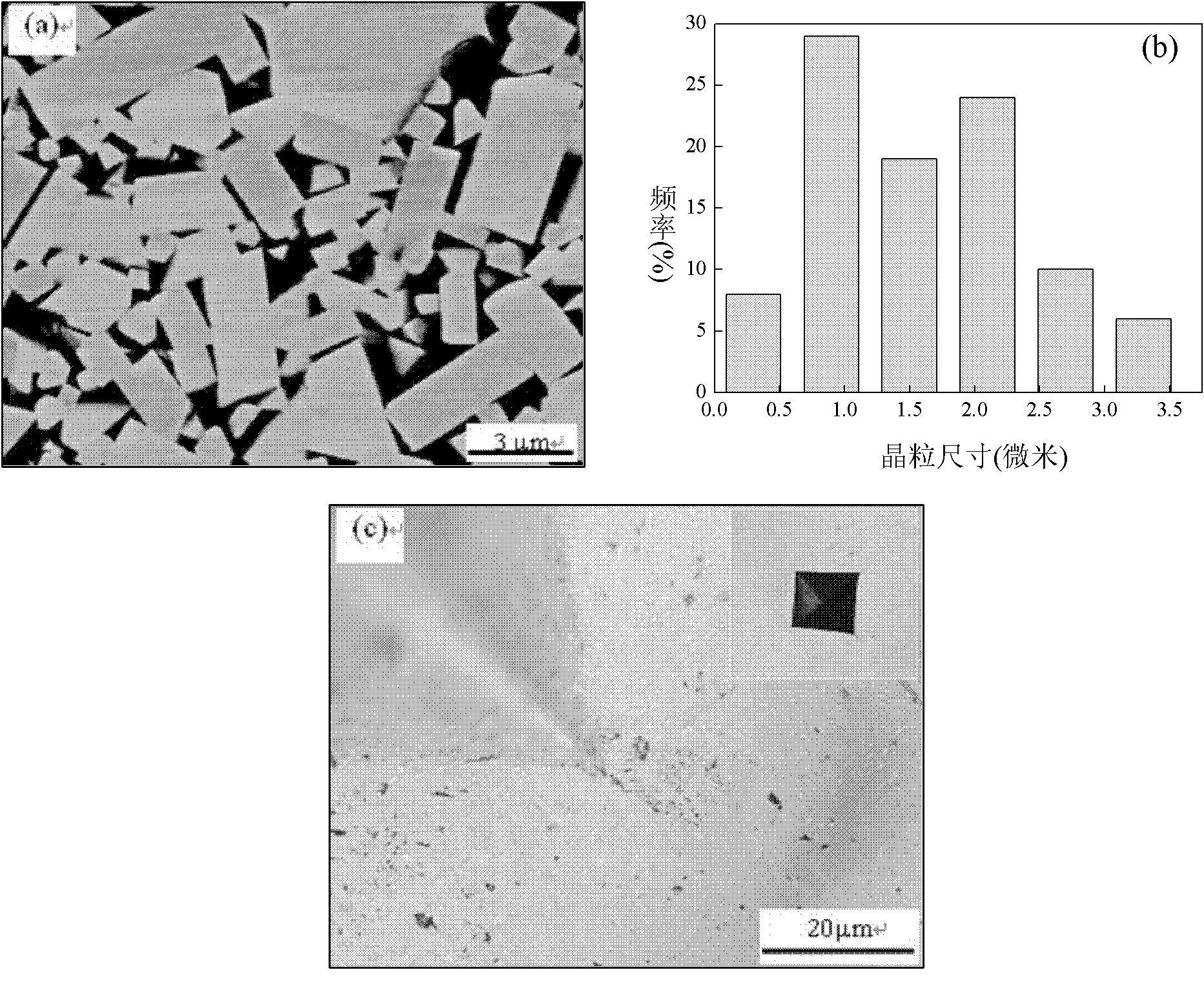

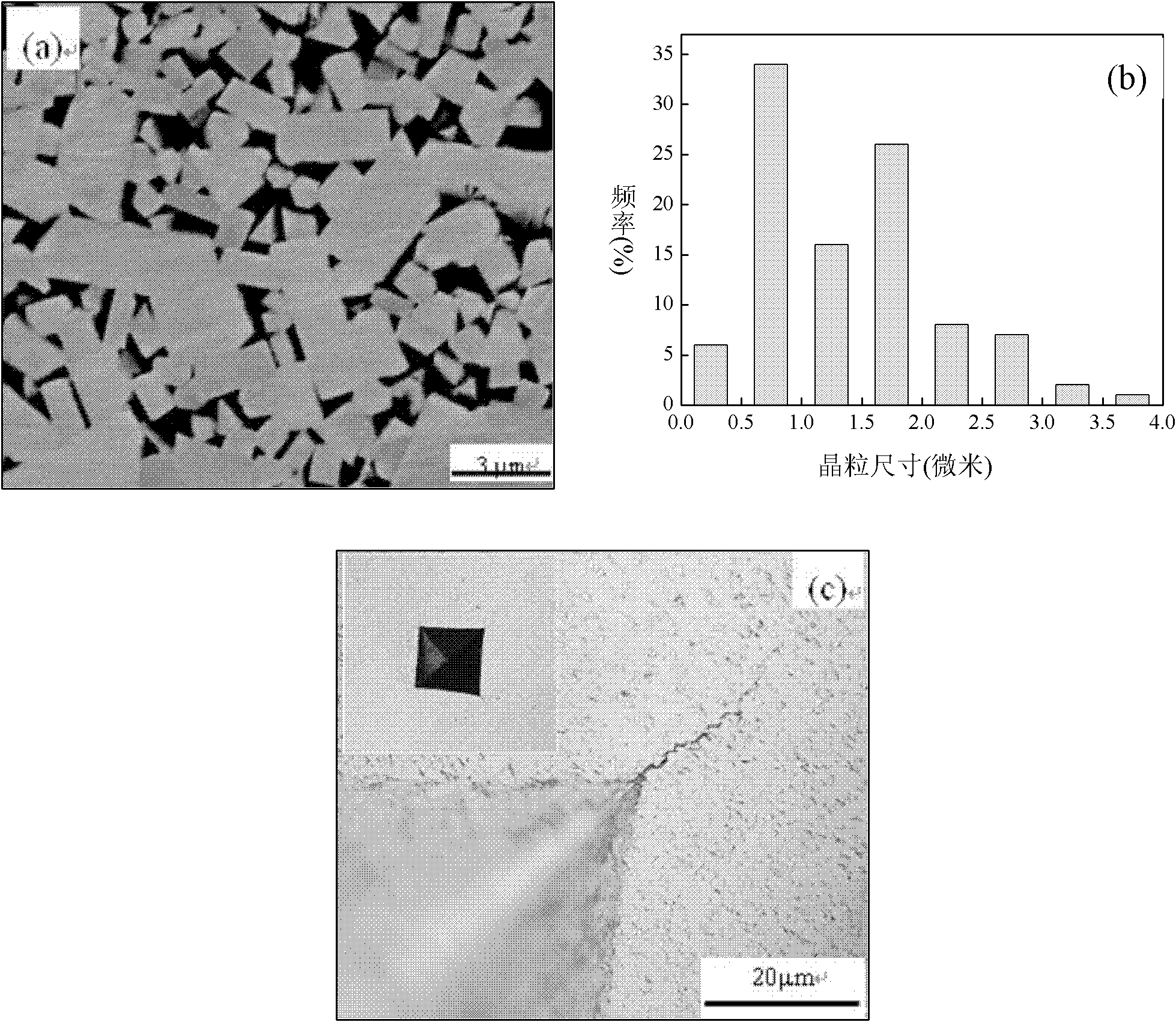

Method for industrially preparing dimorphic hard alloy with both high strength and high tenacity

The invention discloses a method for industrially preparing a dimorphic hard alloy with both high strength and high tenacity, belonging to the technical field of hard alloys. The method comprises the following steps of: according to the content of Co in the dimorphic hard alloy, ball-milling and mixing WO2.9, Co3O4 and carbon black; coldly pressing into a billet block; preparing WC-Co composite powder in a vacuum furnace; ball-milling by taking absolute ethyl alcohol or hexane as a medium; drying to obtain the WC-Co composite powder; under the protection of argon, performing powder aggregation pre-treatment; raising the temperature to 650-950 DEG C at a speed of 5-8 DEG C per minute; keeping the temperature for 30-60 min; adding 30-80 ml of polyethylene glycol forming agent to each kilogram of powder; moulding and forming; and sintering the moulded and formed powder billet in vacuum or at low pressure. The WC-Co dimorphic hard alloy prepared by the invention has both high strength andexcellent breakage tenacity. The method is an integral industrialization preparation technology route.

Owner:BEIJING UNIV OF TECH

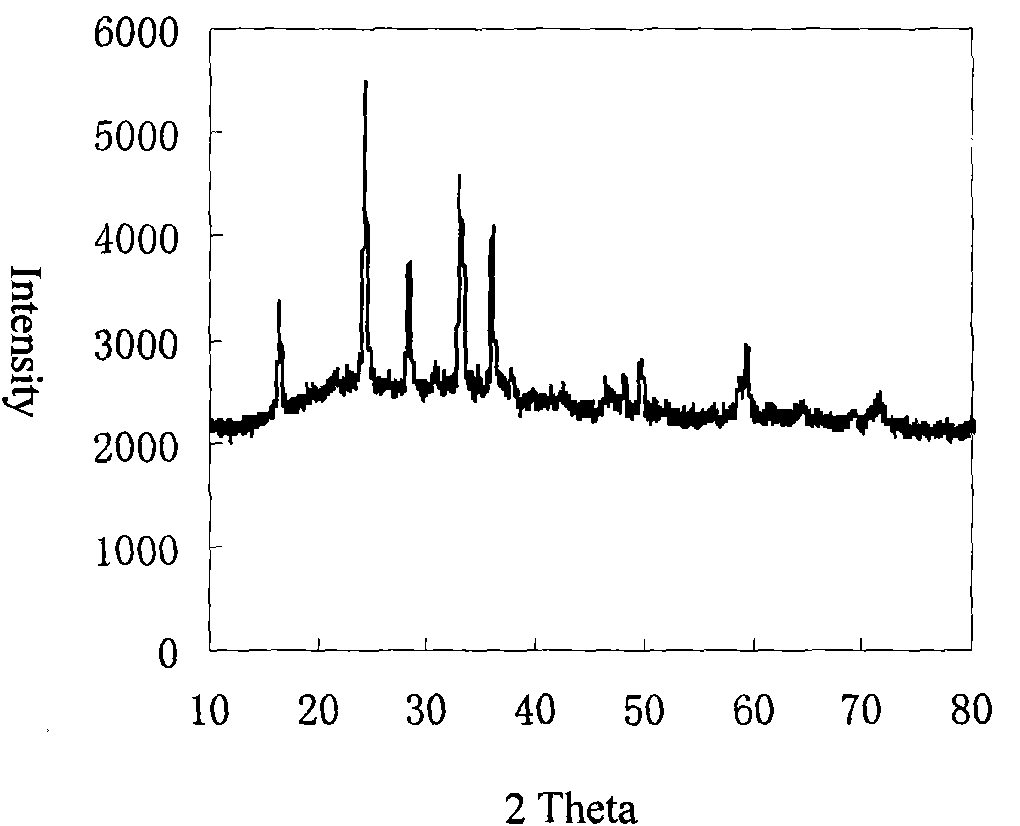

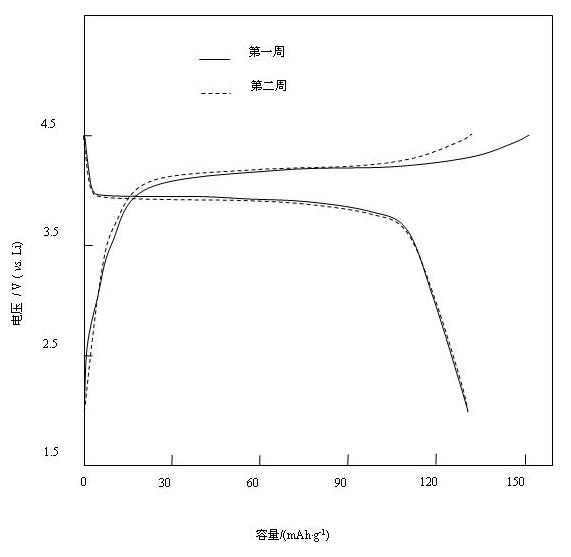

Zinc and fluorine-doped carbon-coated lithium manganese phosphate cathode material and preparation method thereof

InactiveCN102263263AReduce Ginger-Taylor EffectIncrease capacityCell electrodesRare earthCarbon coated

The invention discloses a zinc and fluorine doped carbon coating lithium manganese phosphate positive electrode material and a preparation method thereof, aiming at solving the problems of over low practical capacity and poor cycle performance in the traditional lithium manganese phosphate positive electrode material. A rare earth doped lithium manganese phosphate positive electrode materials of the invention is prepared from raw materials such as a lithium source compound, a zinc source compound, a manganese source compound, a phosphorus source compound, a fluorine source compound and a carbon source compound; the zinc and fluorine doped carbon coating lithium manganese phosphate positive electrode material is expressed by a chemical formula LiZnxMn1-x (PO4) (1-Y) F3y / C, wherein x is larger than 0 and is less than or equal to 0.2, and y is larger than 0 and is less than or equal to 0.05. The electrical conductivity of electrons and the migration rate of ions of the lithium manganese phosphate positive electrode material are obviously increased by doping zinc and fluorine, thereby the practical capacity and the cycle performance of the lithium manganese phosphate positive electrode material are increased.

Owner:NINGBO POLYTECHNIC

Biochemistry fulvic acid water-loss reducer and preparation method thereof

InactiveCN101215207AGuaranteed water retentionReduce manufacturing costOrganic fertilisersFertilizer mixturesCross linkerSwelling soils

The invention provides a process for preparing a water retention agent of fulvic acid. The process adopts acrylic acid / acrylamide, and inorganic mineral raw materials (such as attapulgite, swell soil, white sericite, kaolin and the like) as host crystals, uses aqueous solution of N, N-methylene-bisacrylamide as a cross linker, simultaneously is added with fulvic acid to be polymerized and prepared in aqueous phase condition. The invention adopts 1-10% of aqueous solution of N, N-methylene-bisacrylamide with low degree of cross linking as cross linker to be polymerized and prepared, has low consistency, is capable of directly spraying, and is convenient in use. owing to adding inorganic mineral raw materials of attapulgite and the like, the invention not only keeps the moisture retention of the water retention agent of the prior art, but also greatly reduces production costs, and owing to adding biochemistry fulvic acid, products are provided with biological nutrition and high fertilizer effect.

Owner:师进

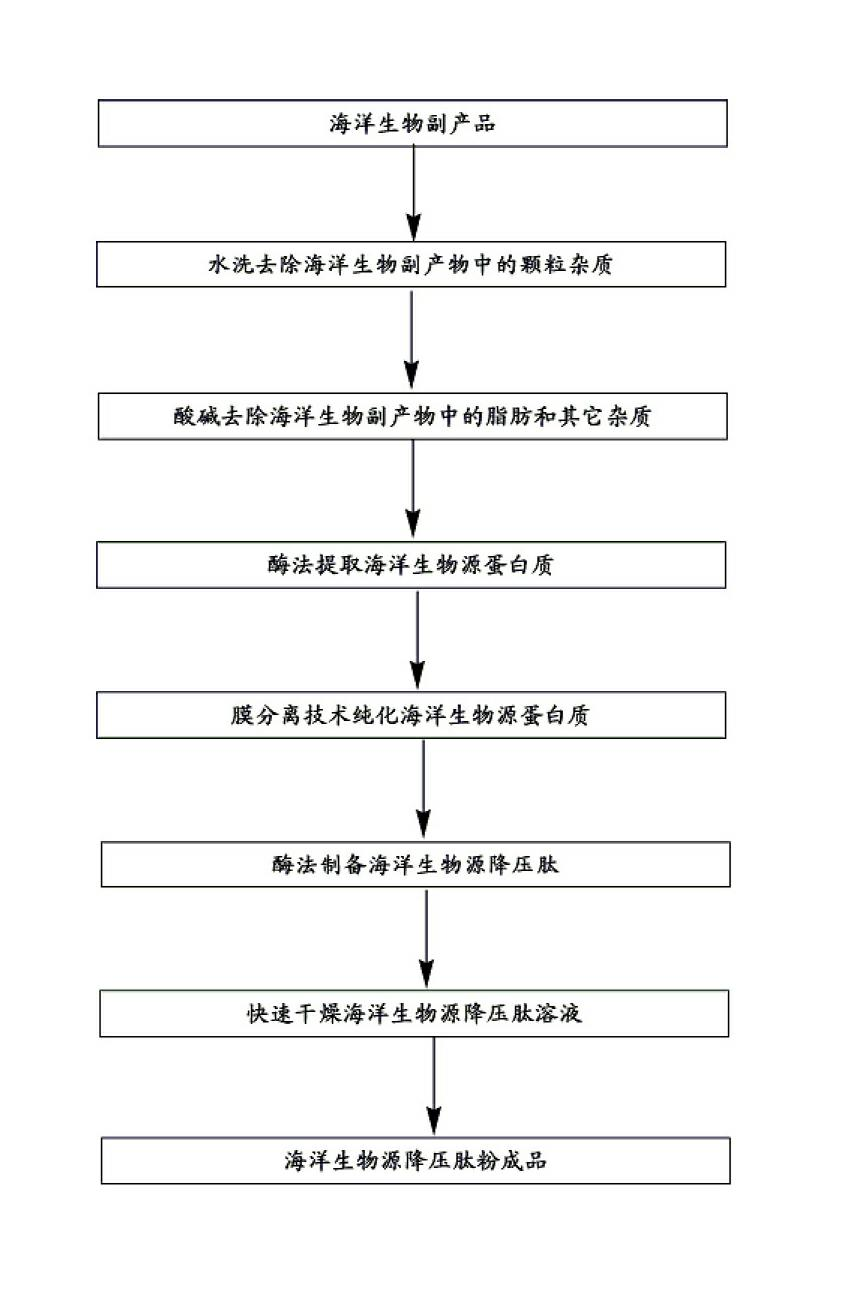

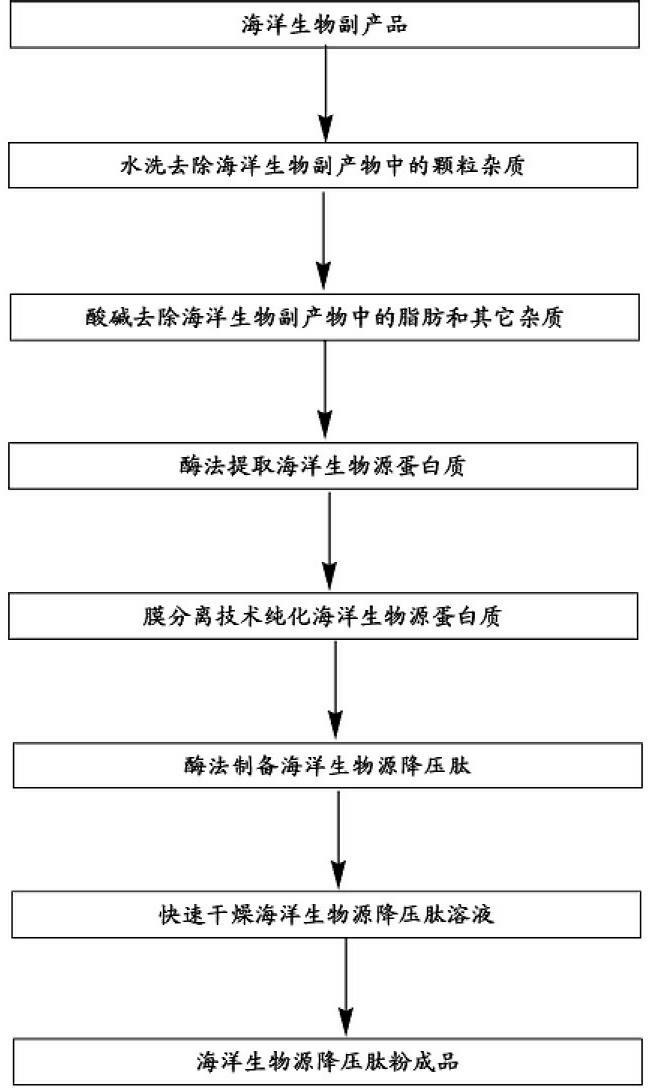

Preparation technique of marine-organism-derived antihypertensive peptides

ActiveCN102251003AChange the separation and purification process technologySimple processPeptide preparation methodsFermentationProteinase activityPre treatment

The invention discloses a preparation technique of marine-organism-derived antihypertensive peptides, which comprises the following steps: (1) pretreating a marine organism byproduct to remove surface impurities and fat on the marine organism byproduct; (2) extracting marine-organism-derived proteins by an enzyme method; (3) separating and purifying the extracting solution by a membrane separation technique to obtain the marine-organism-derived proteins; (4) decomposing the marine-organism-derived proteins with protease, and deactivating the protease after the enzymolysis finishes, thereby obtaining a marine-organism-derived antihypertensive peptide solution; and (5) quickly drying the marine-organism-derived antihypertensive peptide solution by spray drying to obtain the finished marine-organism-derived antihypertensive peptide powder product of which the protein content is higher than 90%. By adopting the technique, the marine-organism-derived antihypertensive peptides have the advantages of low cost, high antihypertensive activity, low average relative molecular weight and high purity, fully utilizes the marine organism byproduct, changes wastes into valuables, and is suitable for large-scale industrial production.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

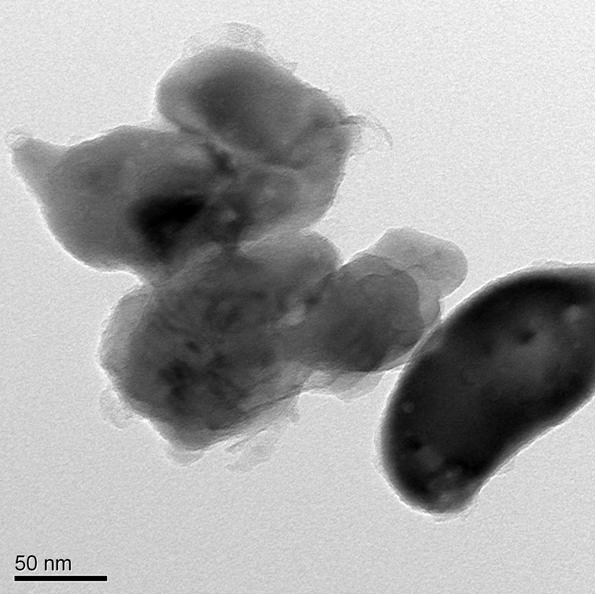

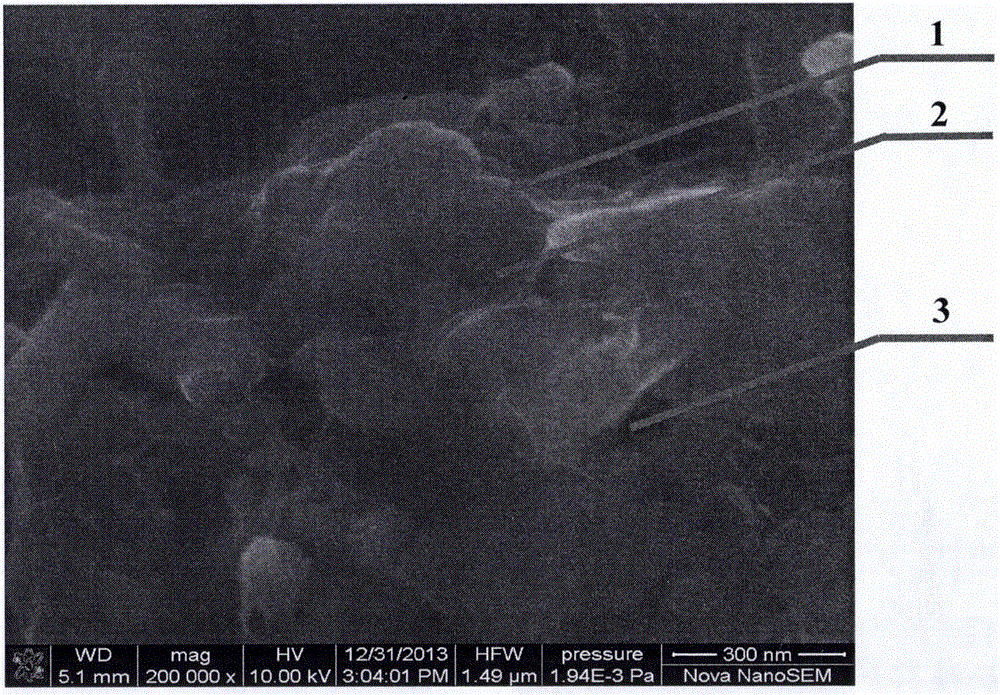

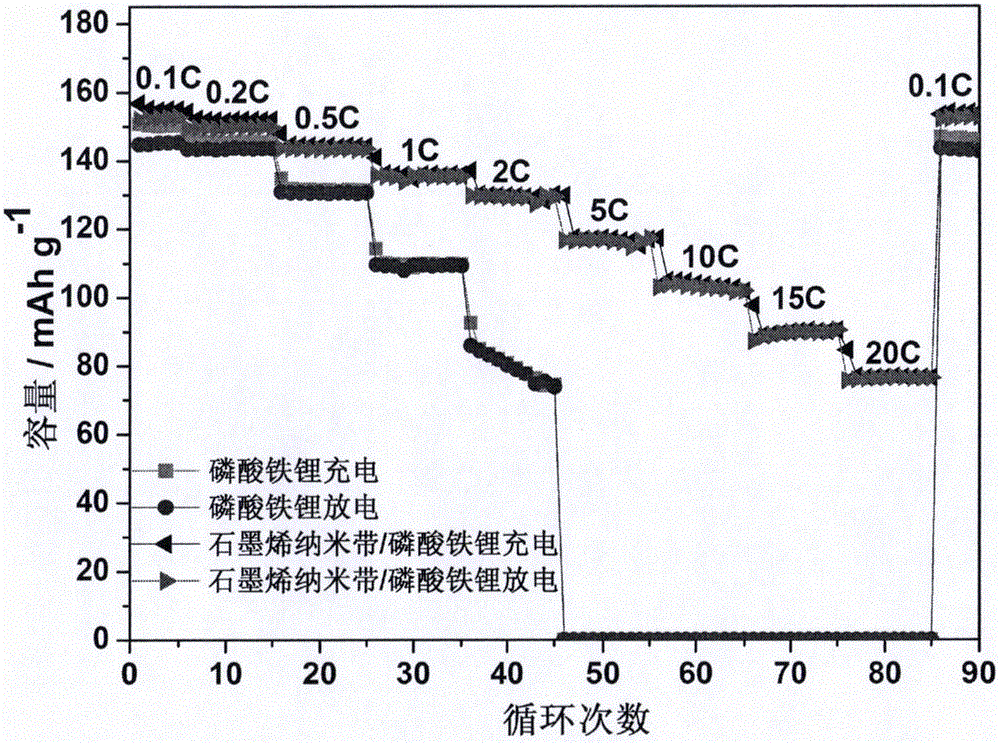

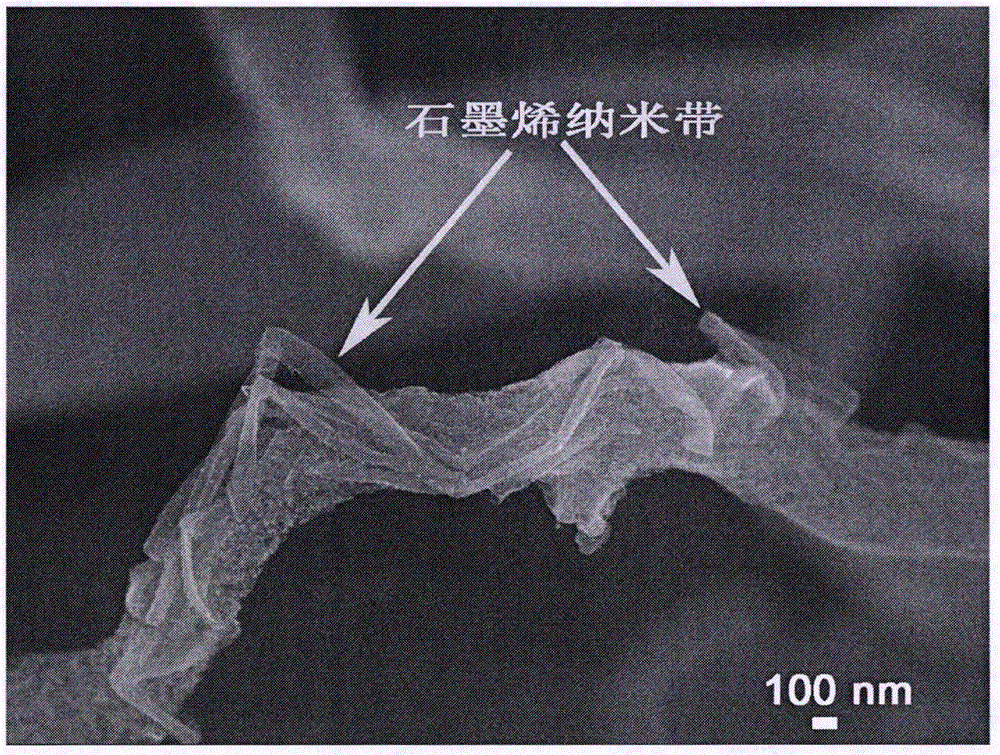

Preparation method for graphene nanobelt-lithium iron phosphate composite material

ActiveCN106450174ASimple processEasy to operateCell electrodesSecondary cellsHigh rateCarbon nanotube

The invention discloses a preparation method for a graphene nanobelt-lithium iron phosphate composite material, and belongs to the technical field of a lithium ion battery. A carbon nanotube is subjected to chemical cutting and ultrasonic peeling to prepare a graphene nanobelt; then commercial lithium iron phosphate is endowed with positive static charges through a surfactant; and next, the prepared graphene nanobelt and the lithium iron phosphate are ultrasonically-mixed and dried to prepare the graphene nanobelt-lithium iron phosphate composite material product. The preparation method has the characteristics of simple process, convenient operation, capability of promoting large-scale production, convenience in popularization and application, low energy consumption, low production cost, high production safety and the like; the product prepared by the preparation method has the characteristics of excellent conductivity, high ionic transport property, long cycle life, high rate charge-discharge performance and the like; the preparation method can be widely applied to the preparation of the graphene nanobelt-lithium iron phosphate composite material; and the product prepared by the preparation method can be widely used as a positive electrode material to be applied to the lithium ion battery which has high requirement on cycle performance and rate capability.

Owner:重庆锦添翼新能源科技有限公司 +1

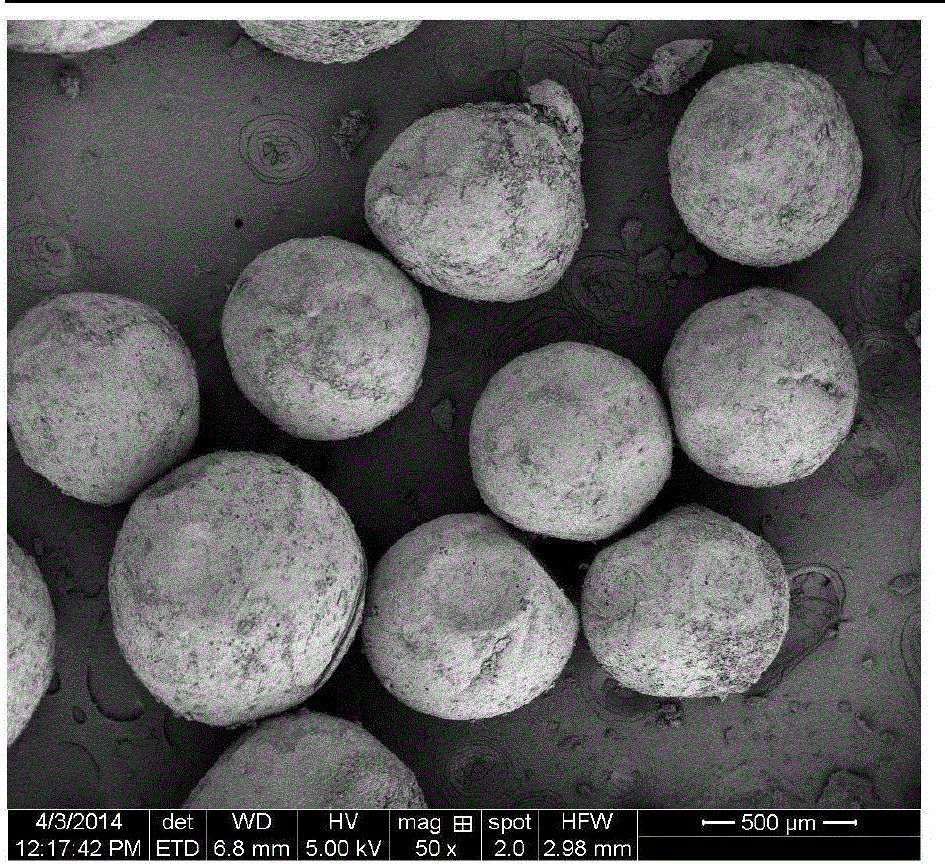

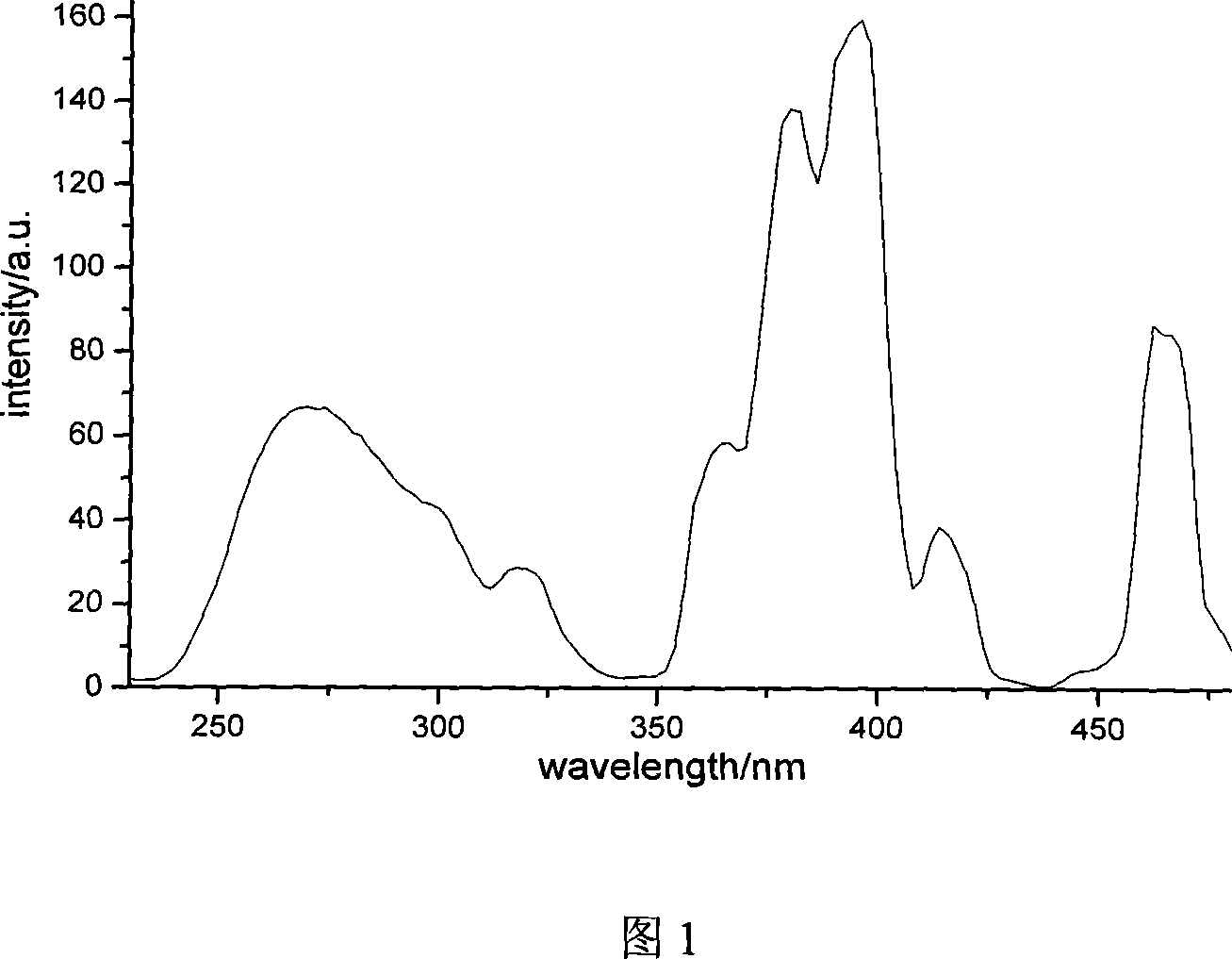

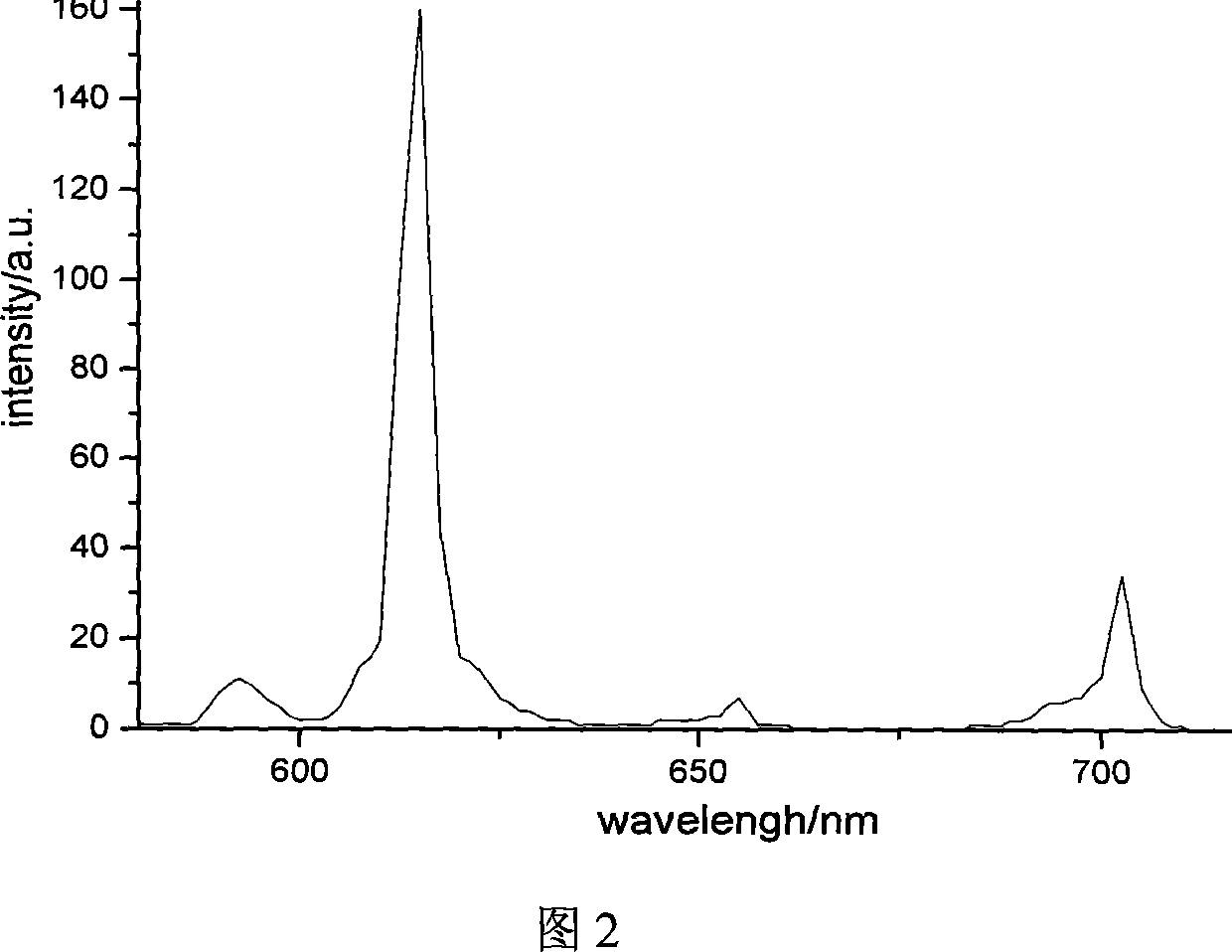

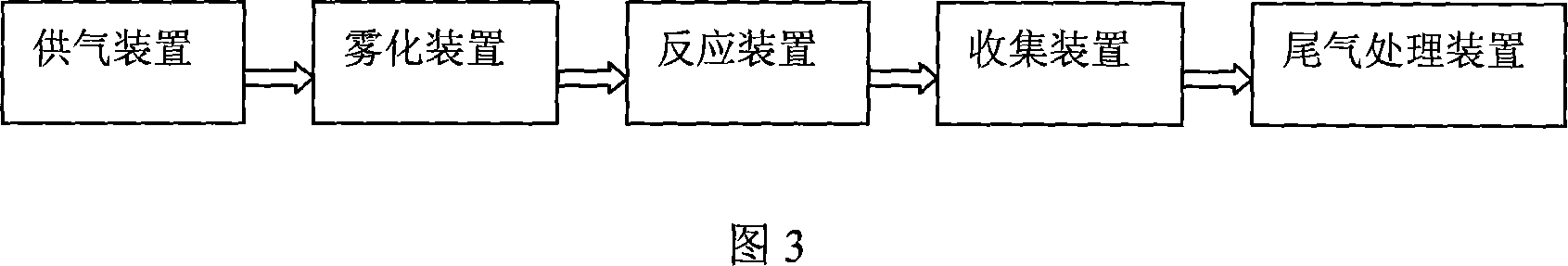

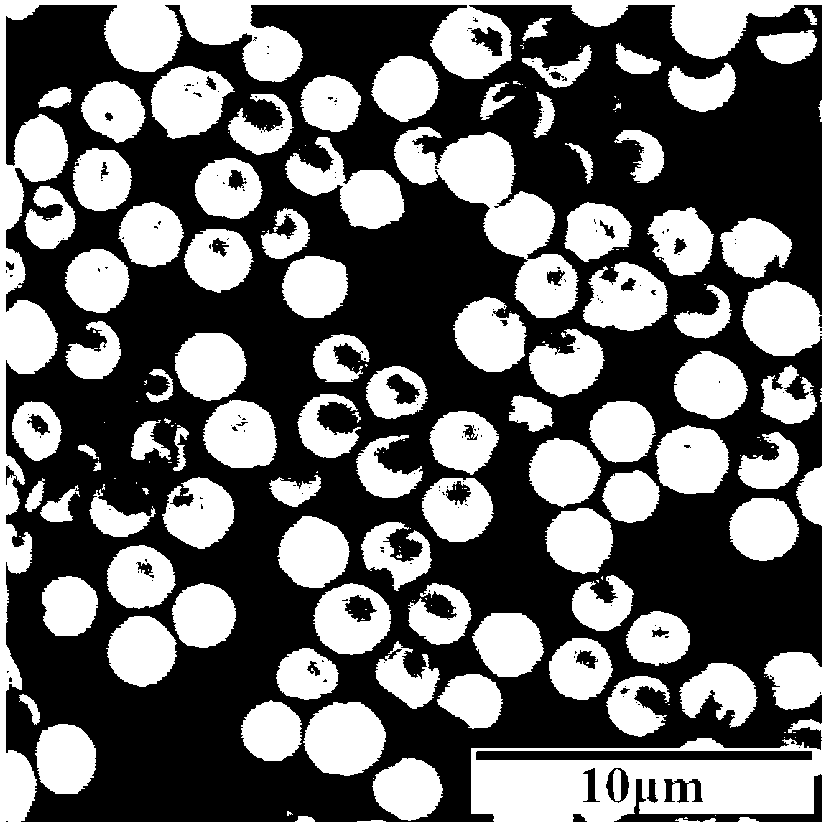

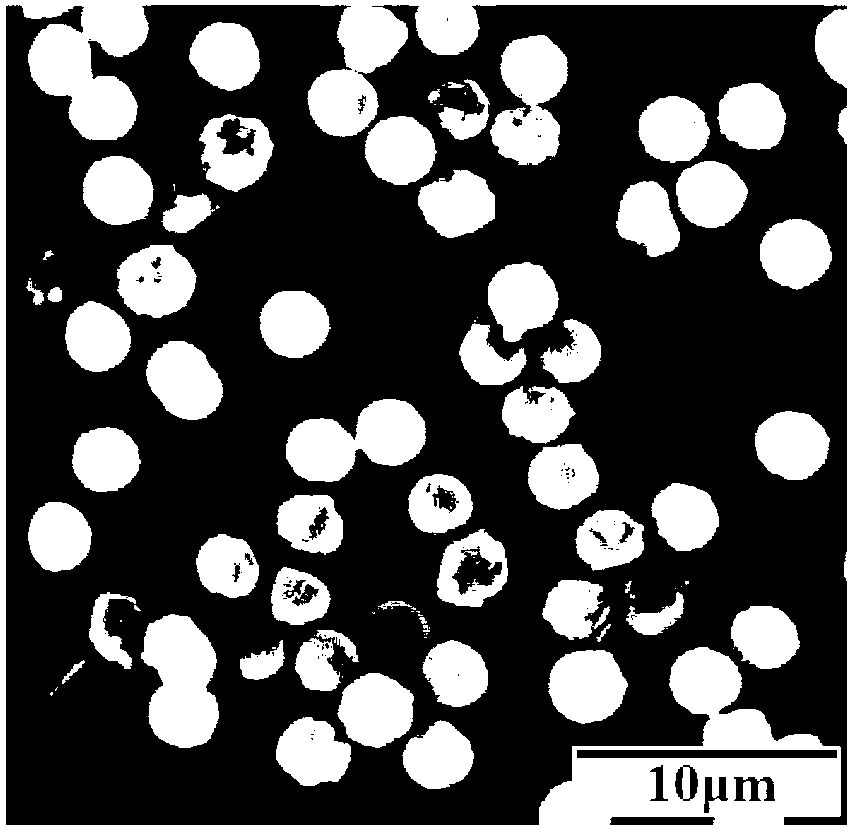

Red fluoresent material, and preparing technique

InactiveCN101050362ASimple processNovel preparation methodLuminescent compositionsSpray pyrolysisCrystallinity

This invention relates to a spray-pyrolysis process for preparing red fluorescent powder, whose chemical formula is (Li1-aNaa) (Eu1-b-c-dSmbYcGdd)(SiO2)1 / 6(W1-mMom)2O8, wherein, a is 0-0.8; b is 0-0.08; c is 0-0.08; d is 0-0.08; m is 0-1. The spray-pyrolysis process comprises: weighing soluble compounds of the cations according to the above chemical formula, preparing clear precursor solution, atomizing, reacting, and collecting the red fluorescent powder. The red fluorescent powder is approximately spherical, and has such advantages as high crystallinity, uniform particle size distribution, smooth particle surface, high luminescent efficiency, and high color purity. The spray-pyrolysis process has such advantages as simple process, easy operation, and high production efficiency, and is suitable for continuous production.

Owner:NANJING UNIV OF TECH

Method for preparing micro-sized monodisperse polyurea microsphere in static condition

The invention relates to a method for preparing micro-sized monodisperse polymer microspheres in static condition. The method comprises the steps that diisocyanate monomers and a water-acetone mixed solvent are added into a reaction bottle, wherein the mass ratio of water to acetone ranges from 20 / 80 to 60 / 40, and the diisocyanate compound accounts for 0.5-13.0% of the total mass of the polymerization system; after the reaction bottle is sealed and the mixed solvent is shaken up, the reaction bottle is placed in thermostatic waterbath of 20-80 DEG C for polymerization; after polymerization, the products are centrifugalized and dried to obtain the micro-sized monodisperse polyurea microspheres. The method for preparing micro-sized monodisperse polymer microspheres in static condition has the advantages that one monomer is used for precipitation polymerization completely in static condition without any stirring or oscillation, so that the reaction time is short, the monomer can be transformed completely, the yield of microspheres is high, and the operation is simple; the method is conducive to scale production of monodisperse microspheres; and the produced microspheres have clean surfaces and a large amount of amido, and can be used in various fields of protein adsorption and separation, enzyme immobilization, chromatographic analysis and the like..

Owner:UNIV OF JINAN

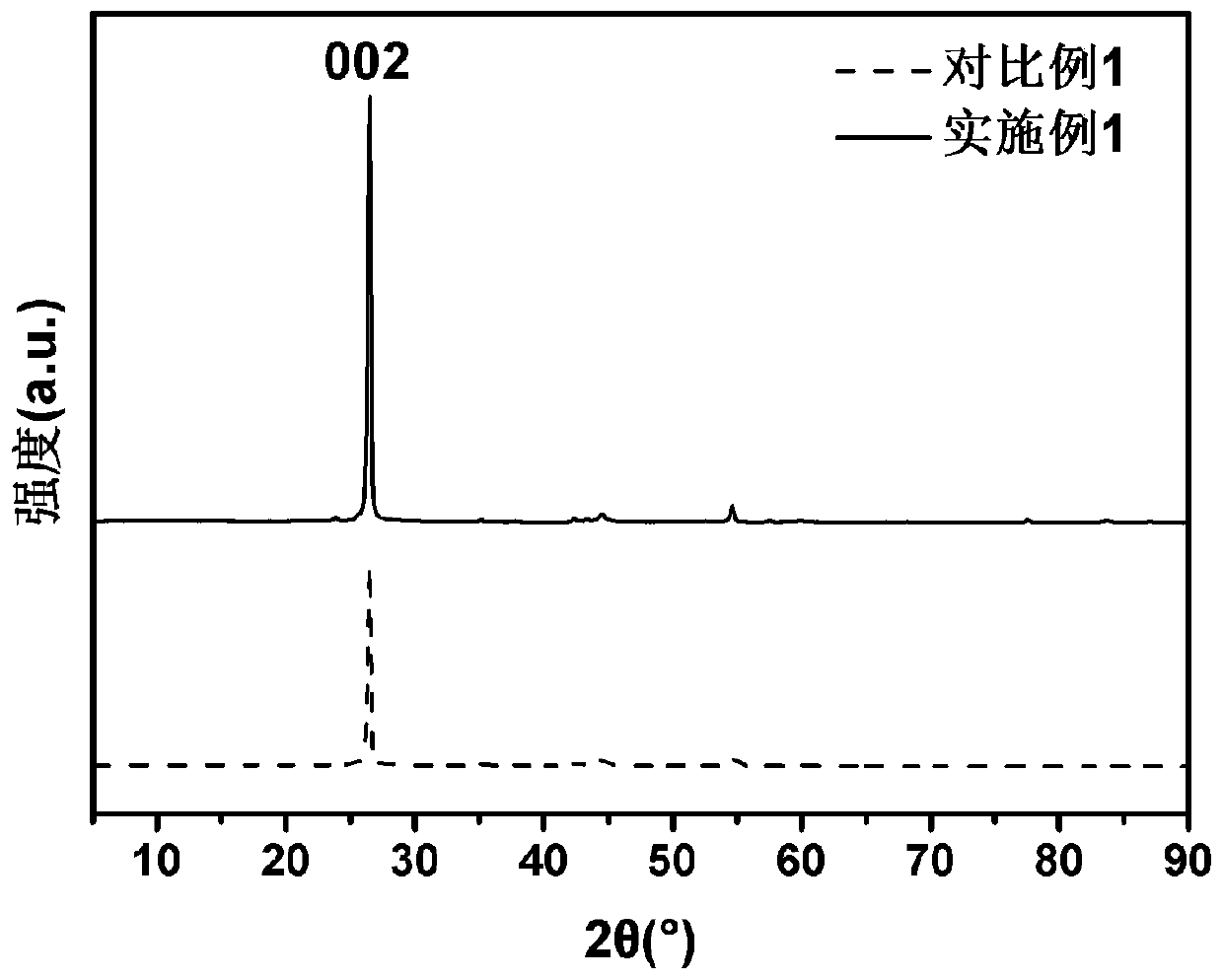

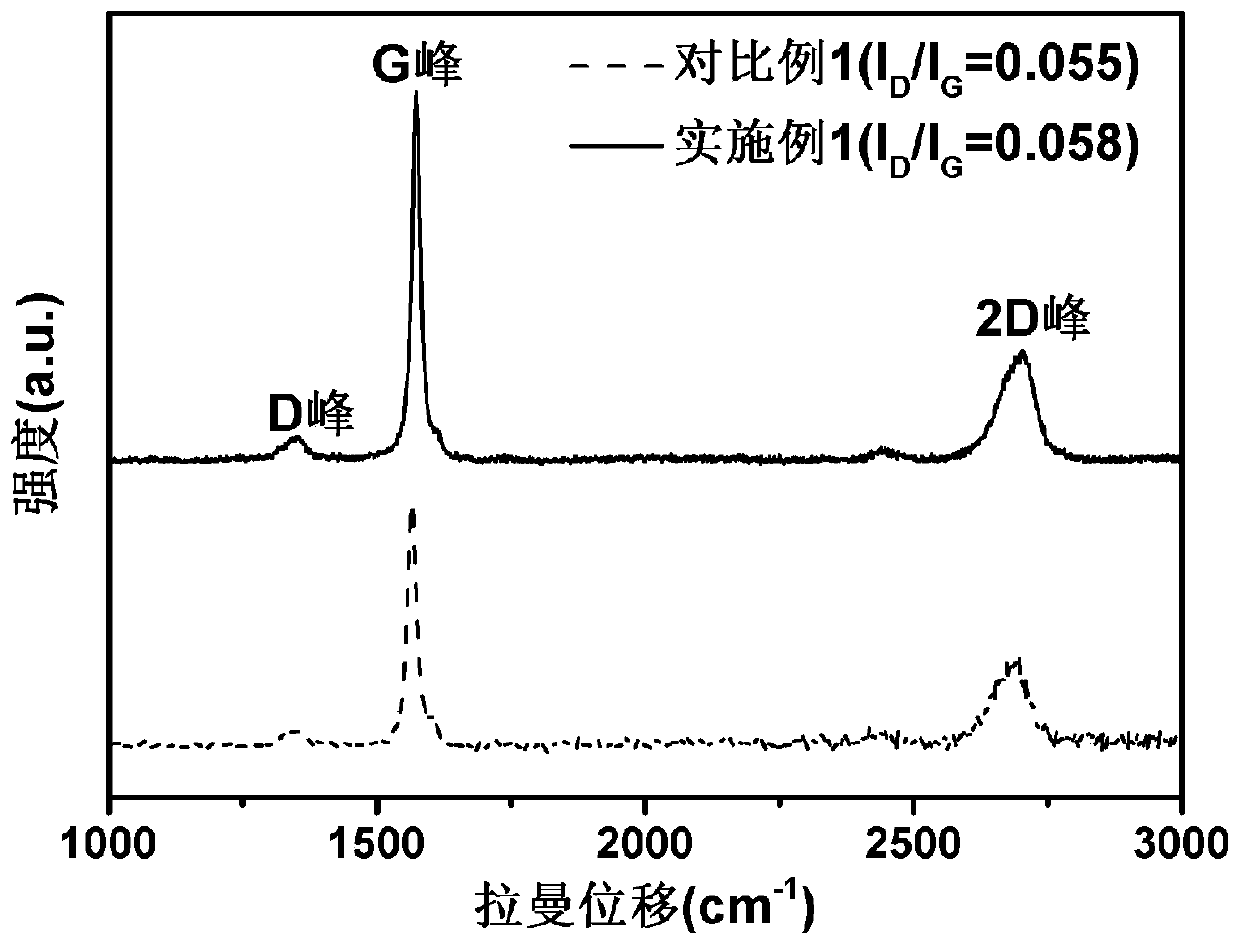

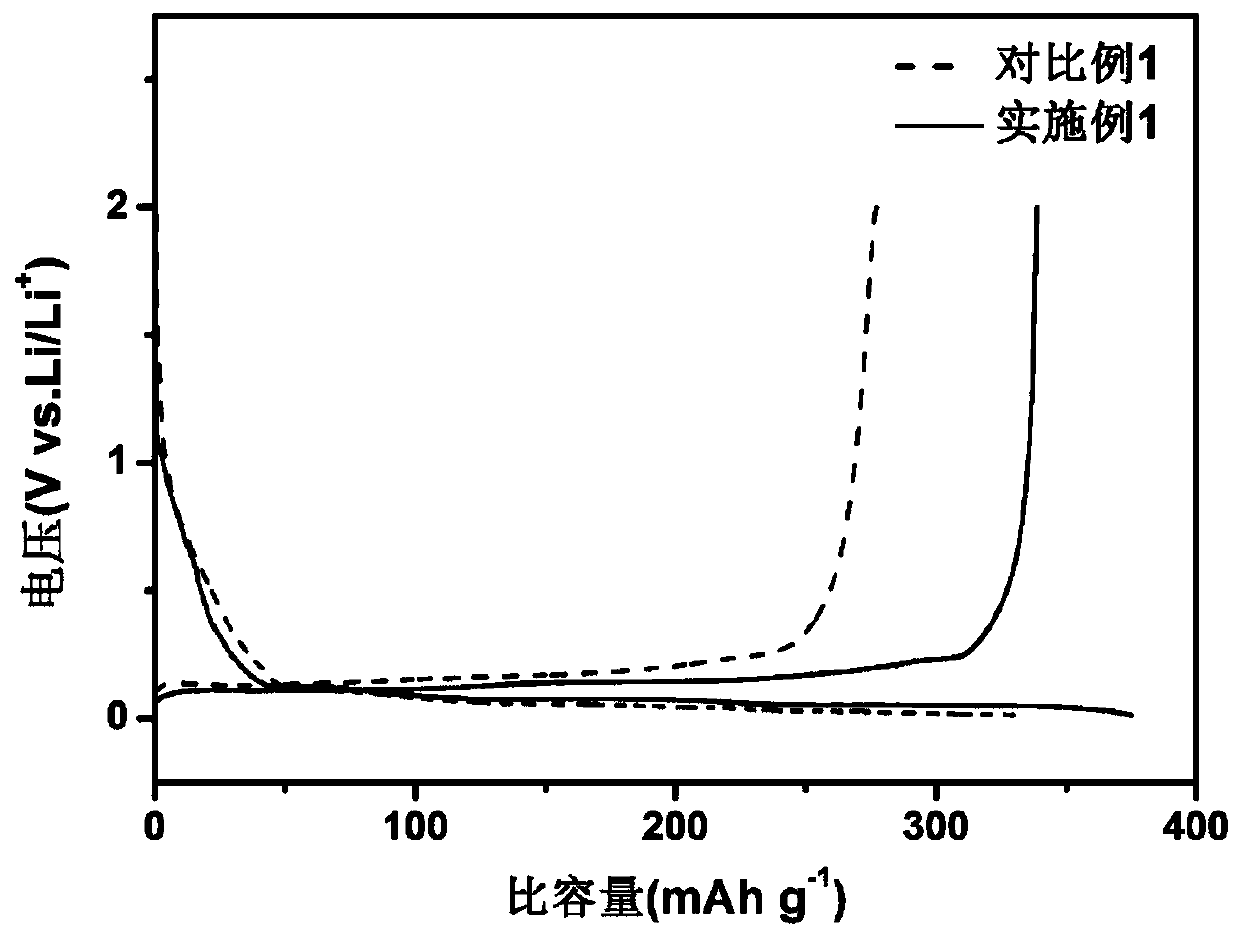

Regeneration method of lithium ion battery negative electrode graphite

InactiveCN111285366AEasy to operateLow costCarbon compoundsCell electrodesElectrical batteryHydrometallurgy

The invention belongs to the field of battery material recovery, and discloses a lithium ion battery negative electrode graphite regeneration method, wherein the method comprises the following steps:(1) carrying out discharging, crushing, hydrometallurgy and pyrometallurgy on waste battery negative electrodes to obtain graphite slag; (2) drying and sieving the graphite slag, and then carrying outheat treatment; (3) putting the graphite slag treated in the step (2) into an acid solution, and carrying out ultrasonic treatment to obtain a solution A; (4) performing solid-liquid separation on the solution A, collecting precipitates, adjusting the pH to 7-10, and adding a chelating agent to obtain a solution B; and (5) carrying out solid-liquid separation on the solution B, collecting precipitates, and washing and drying to obtain the graphite. According to the method, dilute acid and environment-friendly EDTA are used as metal complexing agents, operation is convenient, cost is low, large-scale production can be achieved easily, and application and popularization are convenient.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

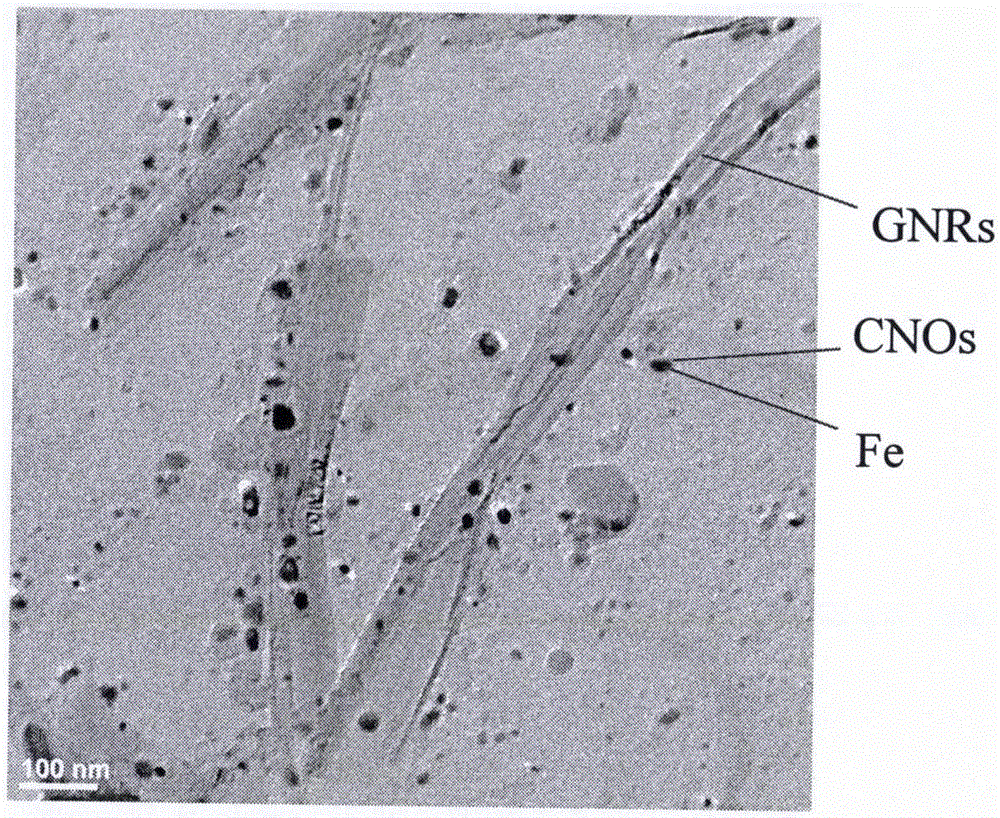

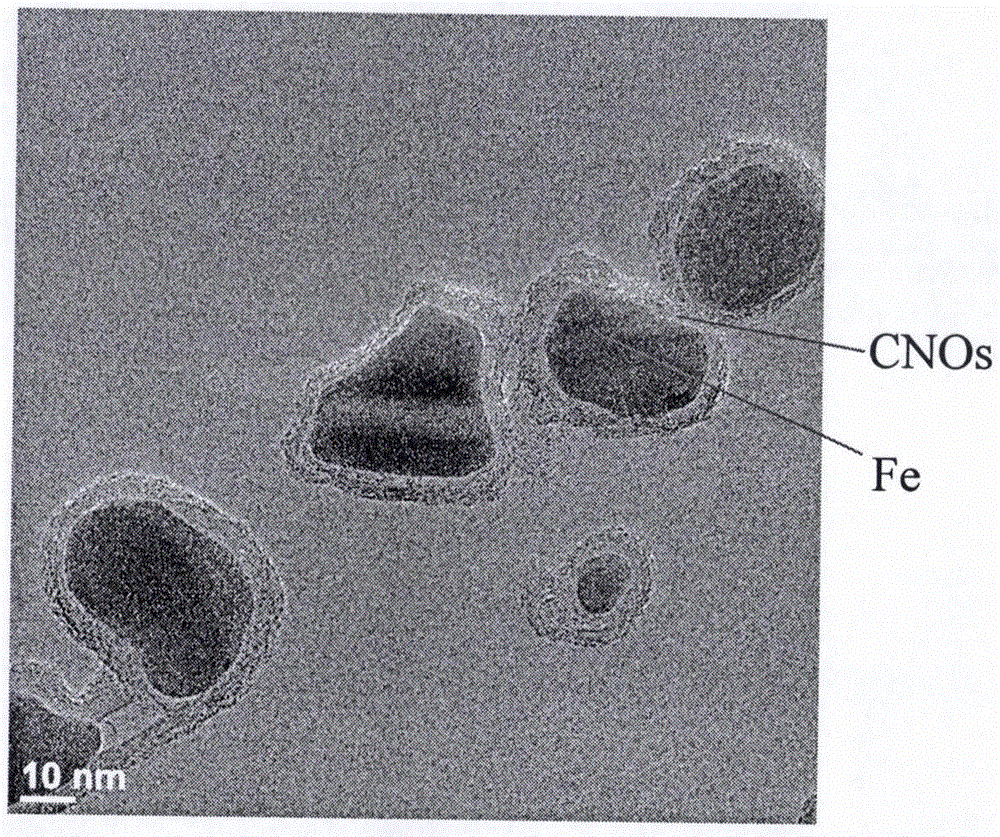

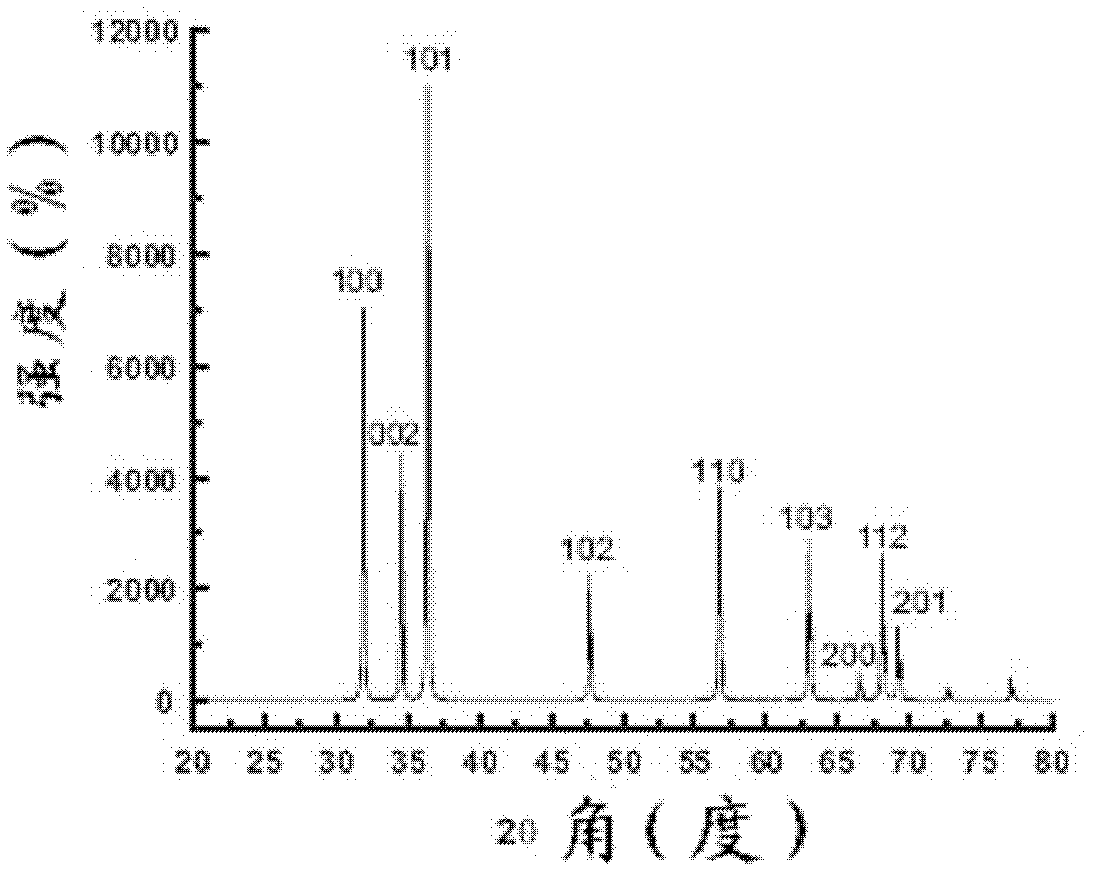

Preparation method for magnetic graphene nanobelt/graphene composite film

ActiveCN106191804ALow costSimple processLiquid/solution decomposition chemical coatingChemical vapor deposition coatingComposite filmOptical transparency

The invention provides a preparation method for a magnetic graphene nanobelt / graphene composite film. According to the preparation method, ferromagnetic metal nanoparticles wrapped with carbon nano onions grow on the surface of the graphene nanobelt and the surface of the graphene composite film in an in-situ growth manner through a two-step chemical vapor deposition method. The graphene composite film can be transferred to a target matrix without the assistance of a polymer during the transfer process and has the beneficial effects of strong in magnetism, high in optical transparency and high in hole / electron mobility. In addition, the ferromagnetic metal nanoparticles are wrapped with shells of the carbon nano onions so that oxidation, acidification, shedding and the like of the ferromagnetic metal nanoparticles can be avoided, so that the graphene composite film has high strength and good stability. By the adoption of the preparation method, the magnetic graphene composite film can be obtained through macroscopic preparation by the adoption of the two-step chemical vapor deposition method; by the adoption of the method, the technological process is simple, the cost is low, and large-scale production is facilitated; and the method can be widely applied to graphene spintronic devices, electromagnetic wave absorbing materials, flexible graphene film electronic devices and the like.

Owner:重庆锦添翼新能源科技有限公司

Preparation method of graphene nanoribbon in situ toughened nano carbon fiber

Belonging to the technical field of nano carbon fiber composite materials, the invention relates to a preparation method of a graphene nanoribbon in situ toughened nano carbon fiber. The method includes: firstly preparing an easily dispersible graphene nanoribbon, taking a macromoleclar polymer as the raw material, preparing a nano carbon fiber precursor solution, dispersing the graphene nanoribbon in the nano carbon fiber precursor solution, and conducting stirring dispersion, electrostatic spinning and heat treatment to obtain a graphene nanoribbon in situ toughened nano carbon fiber product. The method has the advantages of simple process, convenient operation, is conducive to realizing large-scale production, is convenient for popularization and application, and is low in cost. As the edge of the graphene nanoribbon and nano carbon fiber have in situ covalent interaction, the graphene nanoribbon in situ toughened nano carbon fiber prepared by the method has good electrical conductivity, good thermal conductivity and high mechanical strength, and can be widely applied to composite materials, conductive agents, heat conduction agents and mechanical enhancers, etc.

Owner:重庆锦添翼新能源科技有限公司

Tower-shaped layered zinc oxide nanometer rod, and preparation method and application thereof

InactiveCN103303967ALow priceSimple processZinc oxides/hydroxidesFluid pressure measurementVacuum pumpingTransducer

The invention relates to a preparation method for a tower-shaped layered zinc oxide nanometer rod. The method comprises the following steps: weighing and uniformly mixing zinc oxide and carbon powder with certain mass, putting an obtained mixture in a quartz boat, disposing a silicon chip above the quartz boat and putting the quartz boat and the silicon chip into a reacting furnace together; then carrying out vacuum-pumping, introducing nitrogen into the reacting furnace and heating the reacting furnace; and stopping introduction of nitrogen and heating when the reacting furnace is heated to a certain temperature and introducing oxygen into the reacting furnace for a reaction, wherein oxygen passes through cooling water and then enters into the reacting furnace, and a target product, i.e., the tower-shaped layered zinc oxide nanometer rod, is obtained after the reaction is ended. The preparation method has the advantages of simple process, safety and good versatility and operability and is favorable for large scale production. The invention further relates to the tower-shaped layered zinc oxide nanometer rod and application of the same in a high sensitivity gas sensor, a pressure transducer and a field emitter.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Comb type high-molecular sand fixation and water retaining agent and preparation method of same

InactiveCN103059231ANo pollution in the processThe production process is clean and environmentally friendlyOrganic fertilisersSoil conditioning compositionsCross-linkPolyethylene glycol

The invention provides a preparation method of a comb type high-molecular sand fixation and water retaining agent, comprising the following steps of: firstly, adding alkyl vinyl polyglycol ether, tetraethyl orthosilicate and catalyst p-toluenesulfonic acid into a reaction vessel, at the temperature of 50-150 DEG C, reacting for 2-10 hours, removing the solvent by vacuum evaporation to get the macromonomer; then, mixing vinyl acetate, butyl acrylate and acrylamide to get the polymerized small monomer; and finally, adding the macromonomer into the reaction vessel, adding the polymerized small monomer, water and emulsifying agent, heating up to 60-80 DEG C, dropping 40-100 parts of 5% ammonium persulfate water solution, finishing dropping within 180 minutes, preserving heat for reaction for 180-240 minutes, cooling, and obtaining the comb type high-molecular sand fixation and water retaining agent. For the comb type high-molecular sand fixation and water retaining agent, the production technology is clean and environment-friendly, and the production process is simple and convenient; the prepared comb type high-molecular sand fixation and water retaining agent forms cross-linked network with the sandy soil, and can realize higher sand fixation strength with low dosage; and the comb type high-molecular sand fixation and water retaining agent is high in strength and excellent in durability.

Owner:SHANXI UNIV

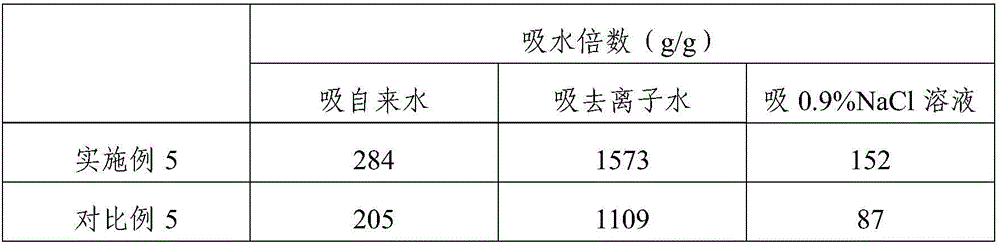

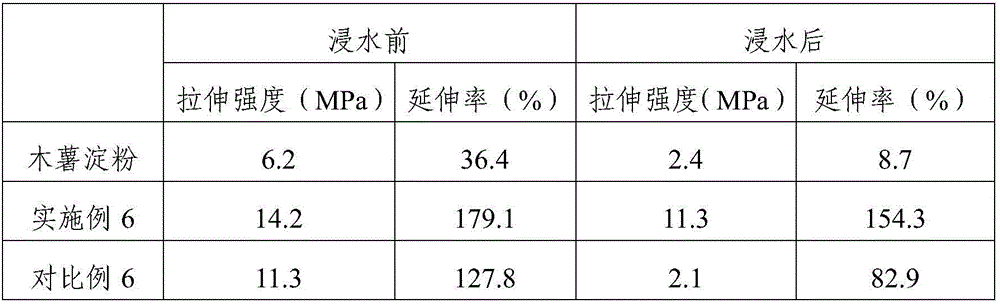

Preparation method and application of grafted starch

The invention relates to a preparation method of grafted starch. The preparation method comprises the following steps of firstly adopting an electrical Fenton method to pretreat a prepared starch milk suspension for breaking a starch crystalline region, so that molecular chains of starch molecules are stretched, and more reactive sites capable of being in graft polymerization are exposed; then dropwise adding grafting monomers in a pretreated system, continuously introducing oxygen and electrifiying, enabling generated hydroxyl radicals as an initiator to initiate a graft polymerization reaction of starch molecule free radials and the grafting monomers, and meanwhile avoiding the generation of homopolymers of the grating monomers as much as possible. Grafting treatment is carried out on starch by adopting the method, the grafting ratio can reach 69.2%, the grafting efficiency can reach 87.6%, and the content of the homopolymers is low; the grafted starch prepared by the method has a high water-absorbing quality or film-forming property; and besides, the method is simple in technological operation and post-treatment, mild in reaction condition, time-saving, efficient and little in environmental pollution, and is beneficial for expanding scale production.

Owner:北京颐方生物科技有限公司

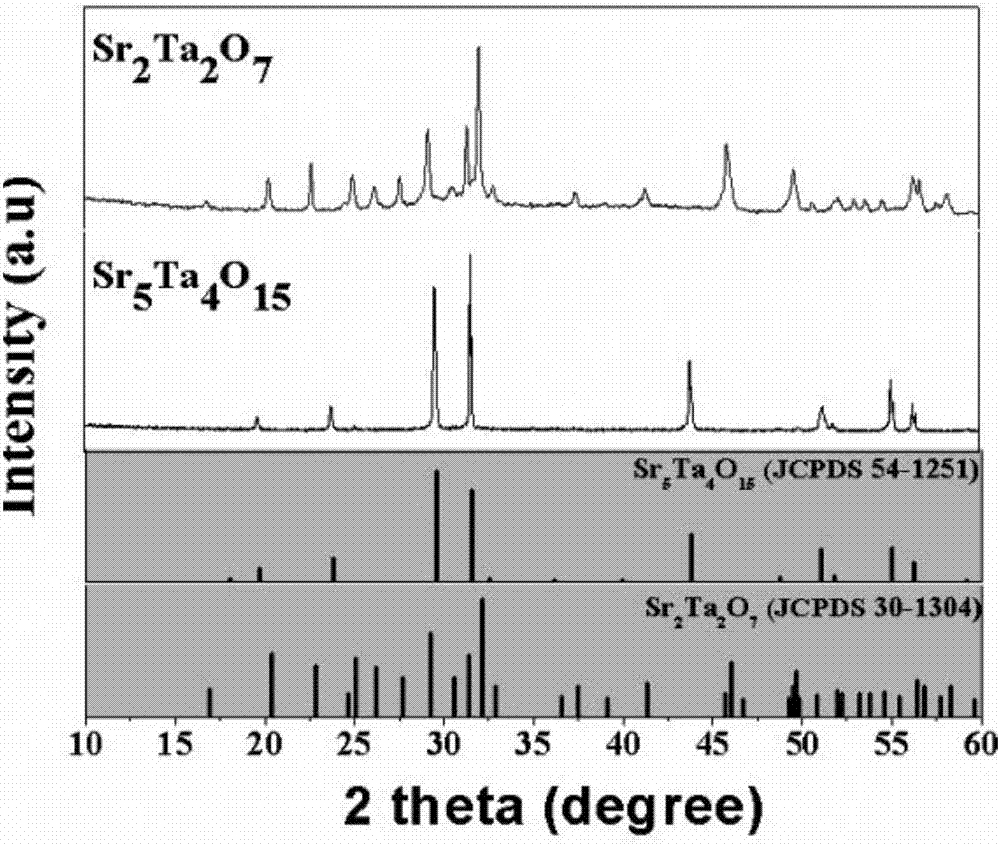

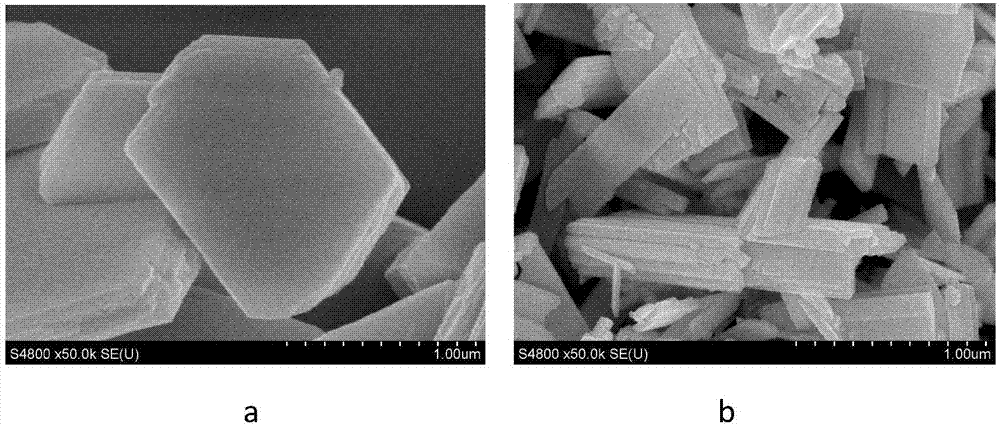

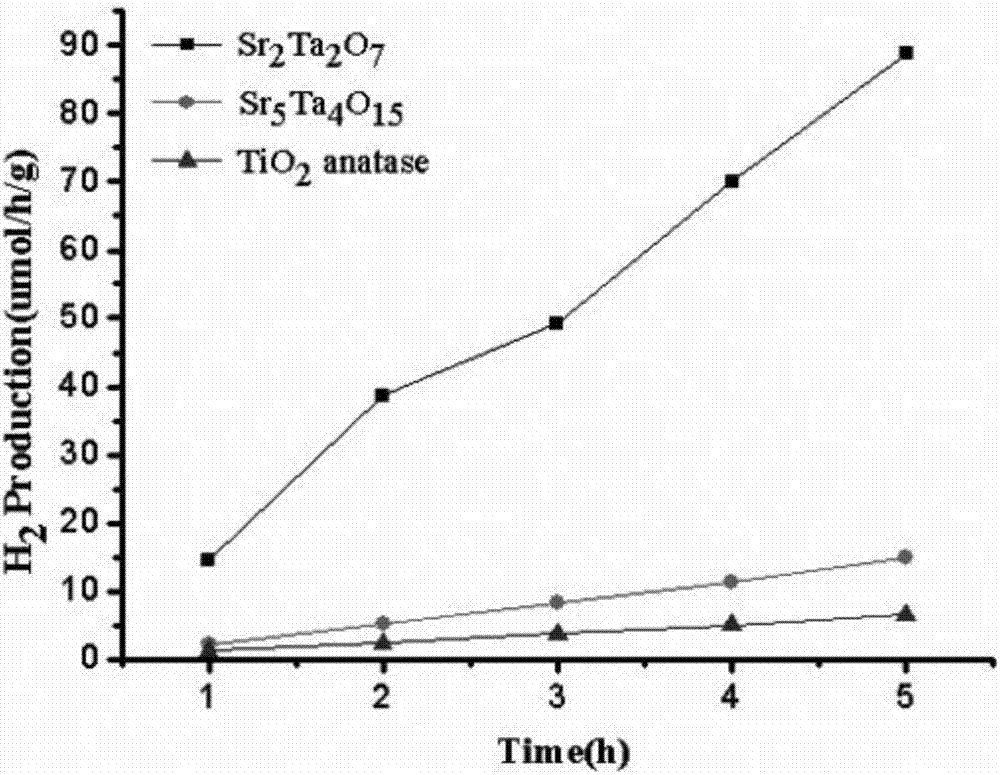

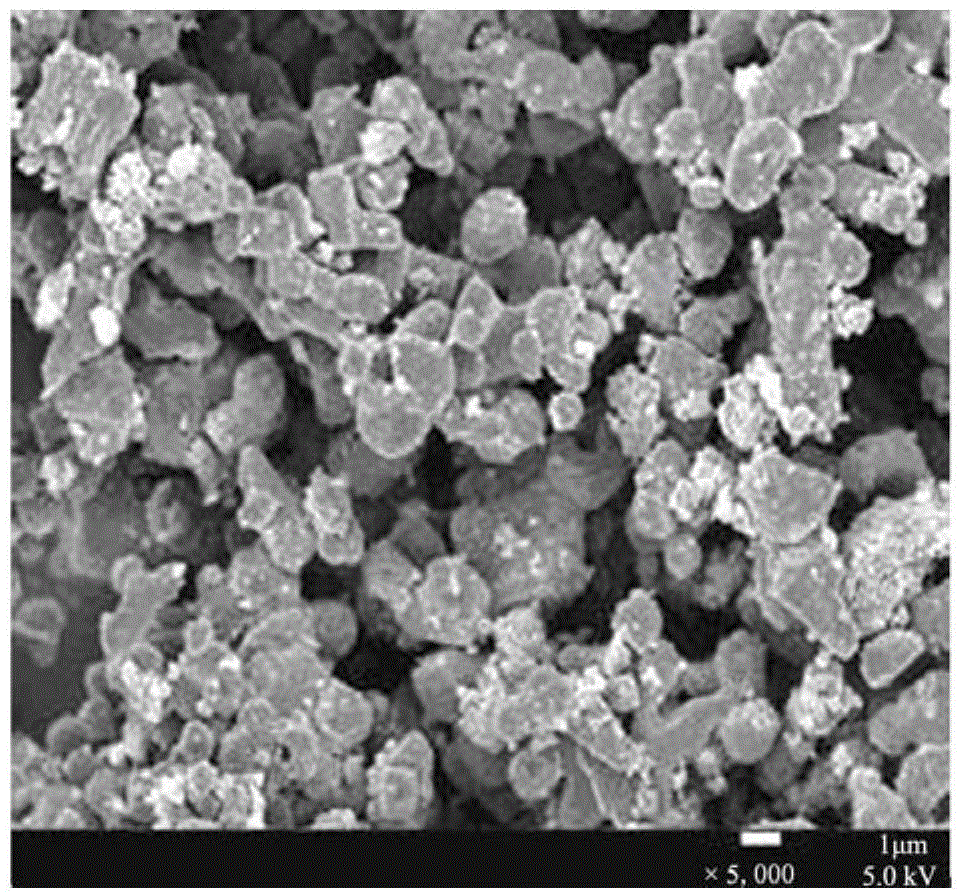

A method of preparing a layered perovskite type strontium- tantalum-based ternary oxide photocatalyst

ActiveCN106902804AExcellent water splitting performanceSimple processMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureStrontium

A method of preparing a layered perovskite type strontium- tantalum-based ternary oxide photocatalyst is provided. The method is characterized by including (1) a step of weighing Ta2O5 solid powder and SrCO3 solid powder, with the mole ratio of Ta / Sr is 1:1-1:1.4, mixing the Ta2O5 solid powder and the SrCO3 solid powder, and fully grinding the mixture to obtain mixed precursor powder; (2) a step of weighing a mixed salt consisting of NaCl and KCl, fully mixing and grinding the mixed salt and the mixed precursor powder to obtain a mixture, with the mass ratio of the mixed salt to the precursor powder being 1:1-1:0.1; (3) a step of calcinating the mixture at 750-850 DEG C for 2-24 h by adopting a high-temperature muffle furnace, and naturally cooling a reaction product to room temperature after the reaction is finished to obtain a mixture of a recrystallized salt and a strontium- tantalum-based oxide; and (4) a step of fully washing the mixture with deionized water, drying the washed mixture at 60 DEG C for 2-24 h by adopting a drying oven, and grinding the mixture to obtain sample powder of the photocatalyst.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for preparing graphene grade by grade by utilizing pulse ultrasonic stripping

The invention belongs to the technical field of preparation of graphene and provides a method for preparing graphene grade by grade by utilizing pulse ultrasonic stripping. The method comprises the following steps: dispersing natural flake graphite into water through a dispersion medium, applying high-frequency pulse ultrasonic waves and enabling graphite slurry to be subjected to high-frequency oscillation, so as to form cavitation bubbles in a liquid phase; generating a high-speed micro jet pointing to the surface of the graphite when the cavitation bubbles are broken, and partially breaking the surface of the graphite; gradually stripping the graphite from a bottom layer to an upper layer; finally, separating out the graphene on the upper layer. Compared with a traditional method, the method provided by the invention has a simple process and low cost; meanwhile, the defects that the stripping efficiency of the graphene is low, the time is long and continuous stripping is difficult to realize can be overcome.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Diagnostic kit for early liver cancer and use method thereof

ActiveCN104807998AReduce missed diagnosis rateSave time and costDisease diagnosisSialidaseTherapeutic effect

The invention relates to a diagnostic kit for early liver cancer. The diagnostic kit comprises the following components of G1: 5% of SDS (sodium dodecyl sulfate); G2: 2.2 microgram / muL glycanase; G3A: 100mM trisulphonate fluorescent marker; G3B: 1M organic matter reducing agent; G4: sialidase; GW: deionized water. The invention also discloses a use method of the diagnostic kit. The diagnostic kit has the advantages that the problem of high missed diagnosing rate of alpha fetoprotein on the liver cancer is solved; the liver cancer can be quickly, simply, conveniently and accurately detected, and the therapy effect of the liver cancer can be tracked.

Owner:JIANGSU XIANSIDA BIOTECH CO LTD

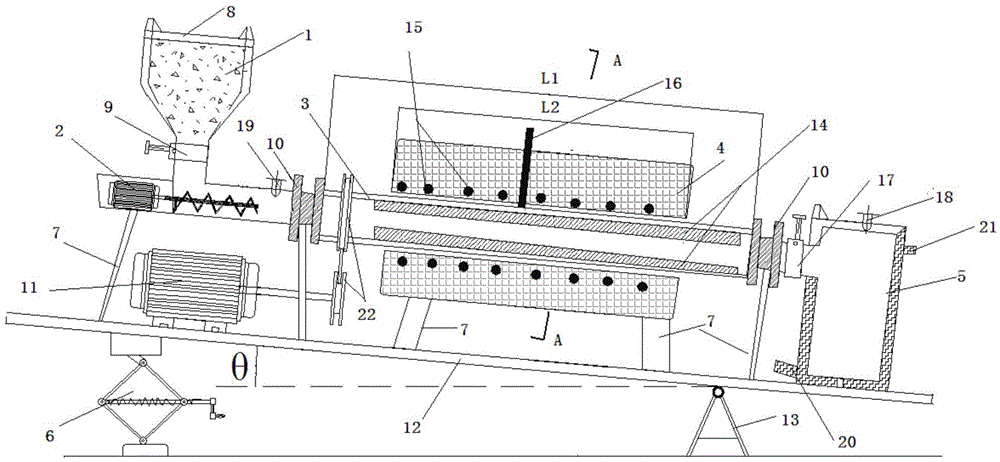

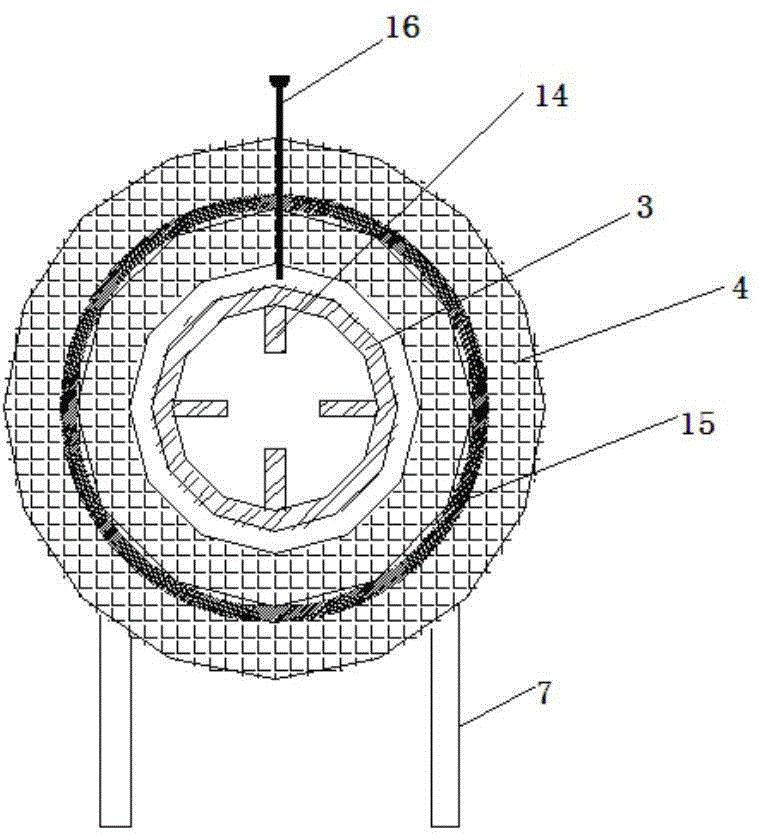

Rotation type dynamic continuous preparing method and device for (M1, M2)(CxN1-x) powder

ActiveCN104987075AImprove qualityEvenly heatedRotary drum furnacesCharge manipulationRare-earth elementLanthanide

The invention provides a rotation type dynamic continuous preparing method for (M1, M2)(CxN1-x) powder. In the chemical formula (M1, M2)(CxN1-x), M1 is one of Ti, V and Cr, M2 is at least one of Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Mn and an lanthanide series rare earth element, the mass of M1 accounts for 60%-90% of the sum of the mass of M1 and the mass of M2, M1 and M2 are not the same element, and x is larger than or equal to 0.1 but smaller than or equal to 0.9. Technological steps include that firstly, burdening is conducted; secondly, raw materials are put into a ball grinding mill, a grinding ball and a wet grinding medium are added for conducting wet grinding, and obtained mixed slurry is dried; thirdly, a dynamic continuous sintering device is used for conducting sintering in an open system or conducting sintering in a closed system, and the (M1, M2)(CxN1-x) powder is prepared. The invention further provides a rotation type dynamic continuous sintering device used in the method. According to the method, the single-phase high-quality (M1, M2)(CxN1-x) powder can be obtained, and continuous batched production is achieved.

Owner:SICHUAN UNIV

Composite filtering material fiber used for SCR dust removal and denitration and preparation method of same

ActiveCN107158799AImprove catalytic performanceEvenly dispersedGas treatmentDispersed particle filtrationFiberCerium

The invention discloses a preparation method of a composite filtering material fiber used for SCR dust removal and denitration. The preparation method includes the steps of: 1) dissolving manganese salt, cerium salt and zirconium salt in water to prepare a salt solution A; 2) preparing an alkaline solution B being 8-12 in pH value; 3) soaking fibers in the salt solution A for infiltration, during infiltration, performing ultrasonic wave treatment for assistance for a certain time, and draining the infiltrated fibers and soaking the fibers in the alkaline solution B for impregnation and precipitation for 15-70 min; 3) taking the impregnated and precipitated fibers out and aging the fibers, performing microwave thermal treatment to the aged fibers, and finally activating the aged fibers to prepare the composite filtering material fiber. The composite filtering material fiber can enable oxides of Mn, Ce and Zr to be firmly bonded to the fibers, and enables active metal oxides to be dispersed more uniformly in the fibers. A bifunctional composite filtering material woven by the fibers can not only capture granules but also remove NOx in coal-fired flue gas.

Owner:SHANDONG UNIV

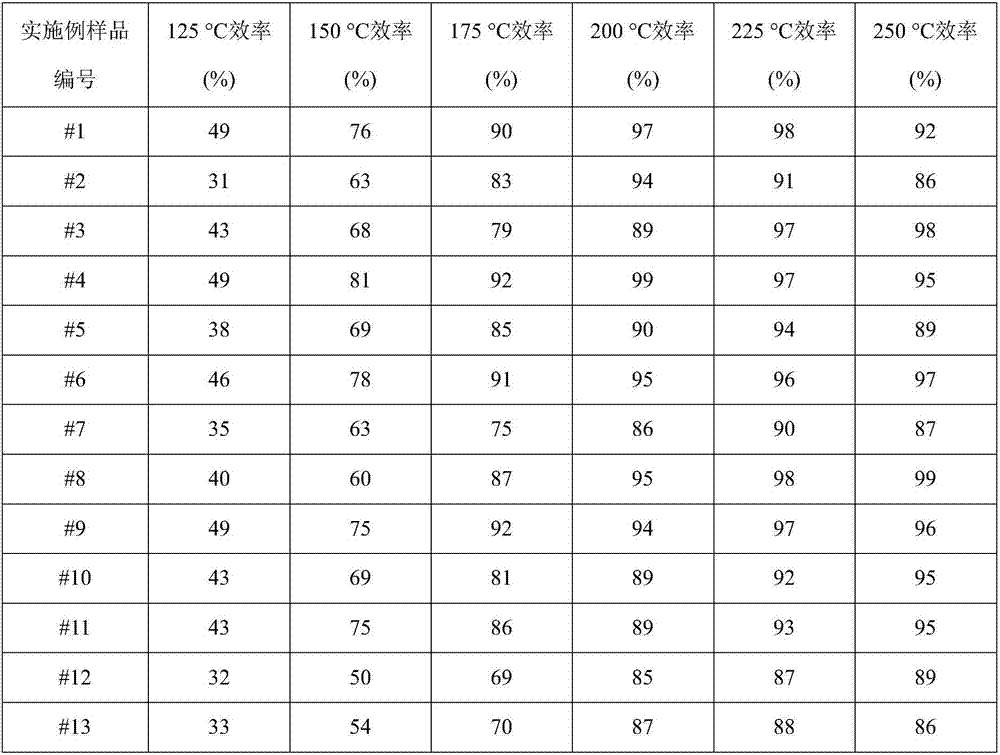

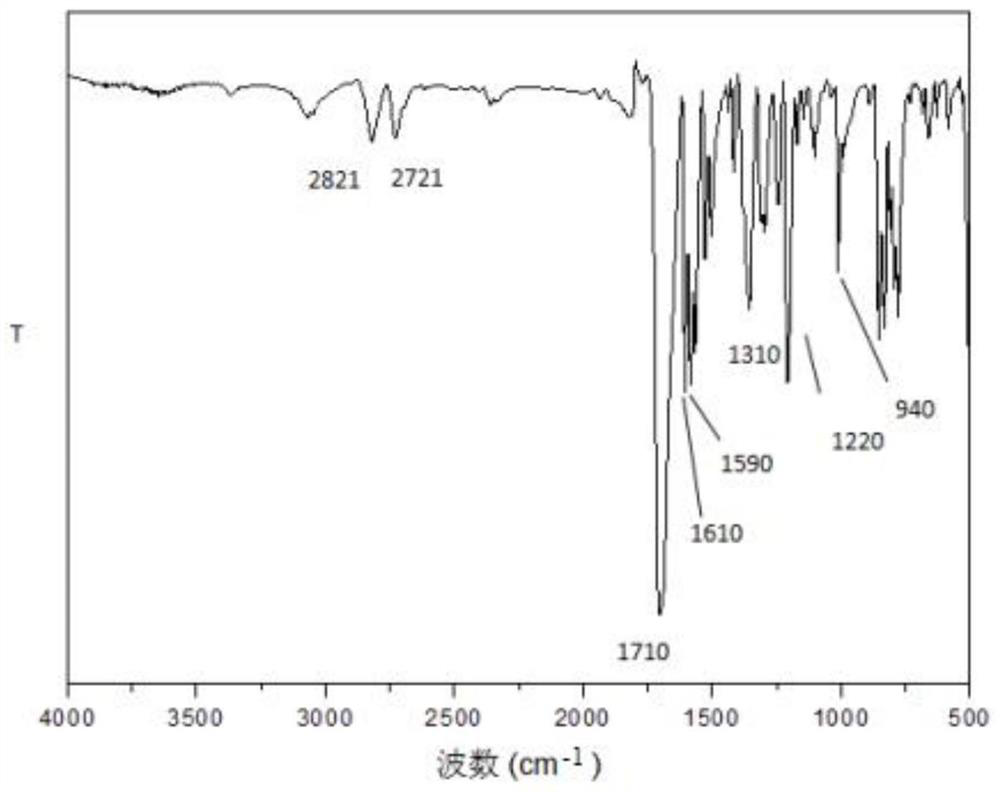

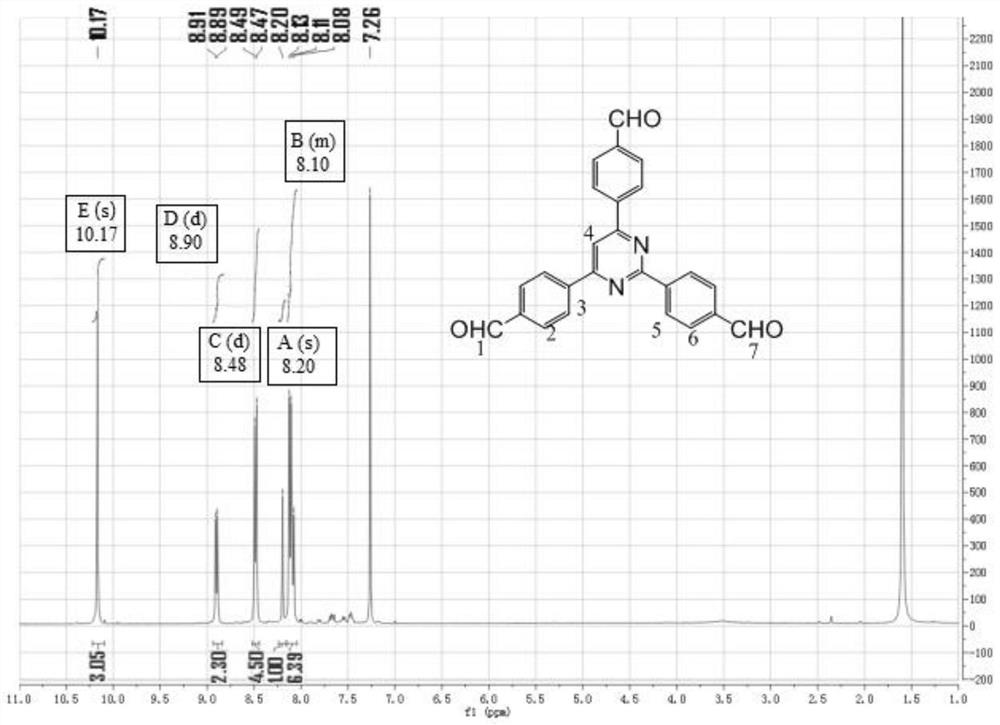

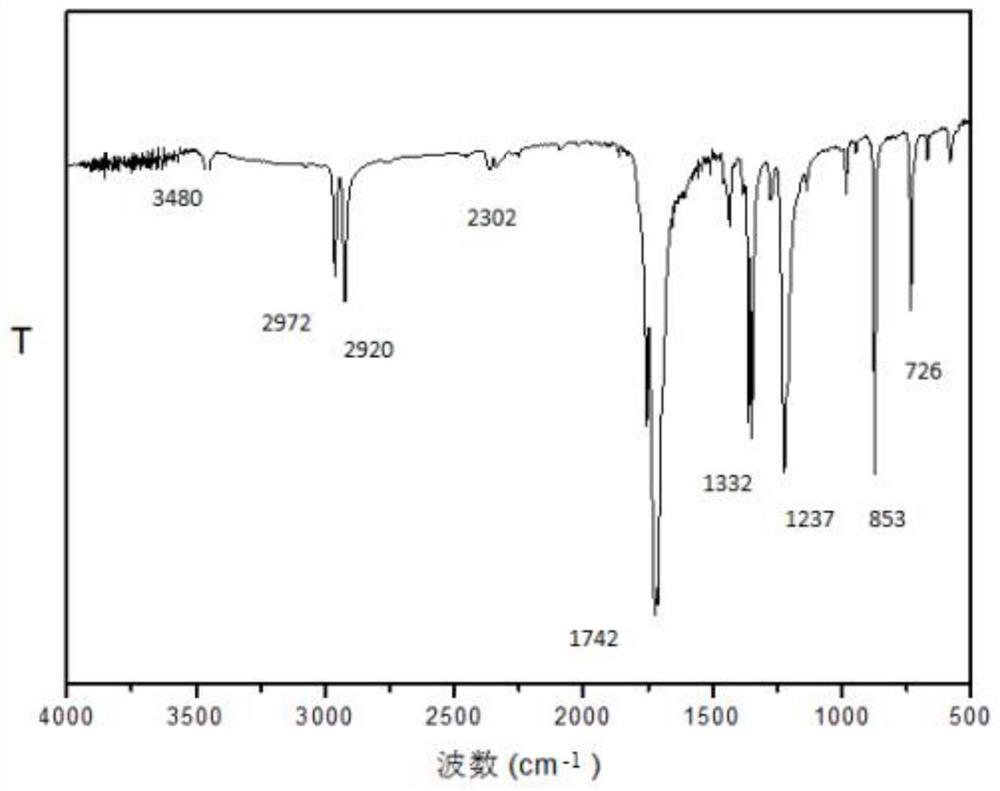

Conjugated microporous polymer based on 2,4,6-tri(4-formylphenyl)pyrimidine and preparation method of conjugated microporous polymer

PendingCN112574395ASimple manufacturing methodFacilitate large-scale productionOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceConjugated microporous polymer

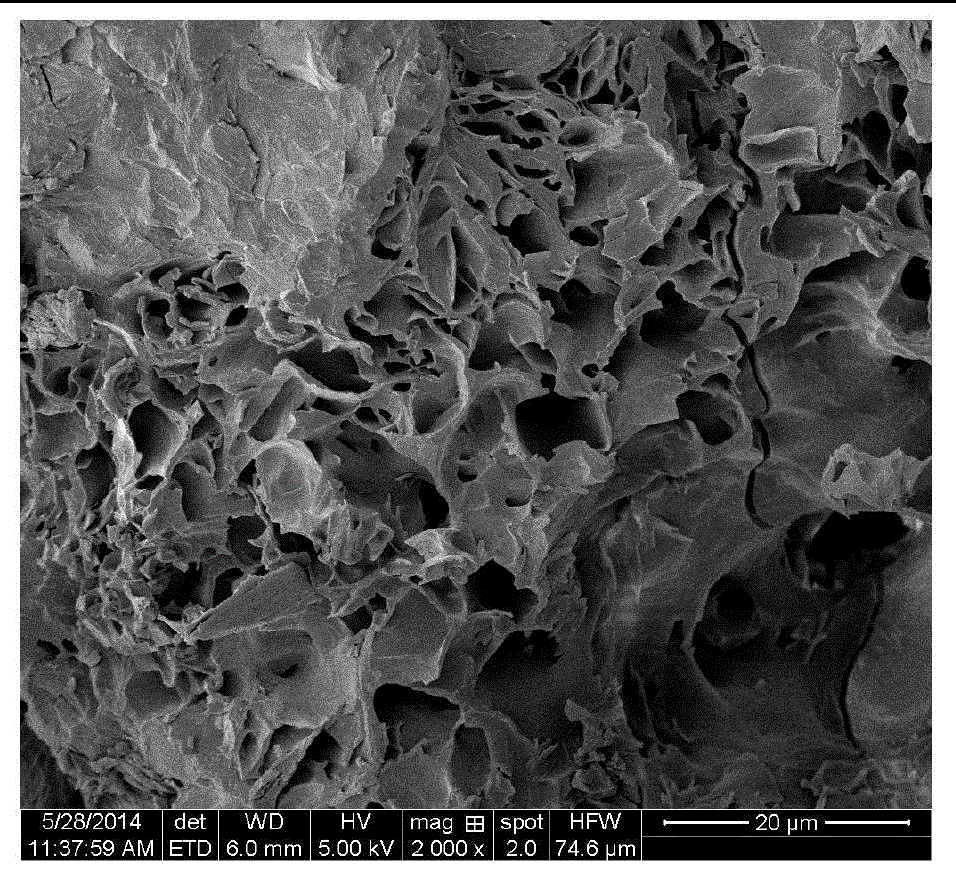

The invention provides a conjugated microporous polymer based on 2,4,6-tri(4-formylphenyl)pyrimidine and a preparation method of the conjugated microporous polymer, and belongs to the technical fieldof conjugated microporous polymers. S-indacene-1,3,5,7(2H,6H)-tetrone is introduced on the basis of 2,4,6-tris(4-formylphenyl)pyrimidine, and the prepared conjugated microporous polymer is a polymer with a sheet and amorphous structure, has a large conjugated structure and can be used as a photocatalyst.

Owner:TAIZHOU UNIV

Rice husk carbon-based water retention agent preparation method and rice husk carbon-based water retention agent

ActiveCN105131208ASimple production processEasy to operateOrganic fertilisersSoil conditioning compositionsCross-linkWater quality

The present invention relates to a rice husk carbon-based water retention agent preparation method. In the prior art, the preparation method of the rice husk carbon-based water retention agent having excellent adsorption capacity on wide pH value water does not exist. The preparation method comprises: diluting an acrylic acid monomer with deionized water to achieve a mass percent concentration of 50%, carrying out carbonization on rice husks, crushing, mixing the crushed rice husks and the water-soluble acrylic acid monomer in a reaction kettle, neutralizing with a NaOH aqueous solution, sequentially adding an additive, a cross-linking agent and an initiator, polymerizing for 30-45 min at a temperature of 70-80 DEG C, placing the polymer in an oven with a temperature of 85 DEG C, carrying out a polymerization reaction for 3 h, crushing, and screening with a 60 mesh sieve to obtain the grayish white rice husk carbon-based water retention agent, wherein the additive is acrylamide, the cross-linking agent is N,N'-methylene-bisacrylamide, and the initiator is ammonium persulfate. According to the present invention, the process is simple, and the prepared rice husk carbon-based water retention agent provides the excellent adsorption capacity on the wide pH value water, and can target the natural rain.

Owner:ZHEJIANG FORESTRY ACAD

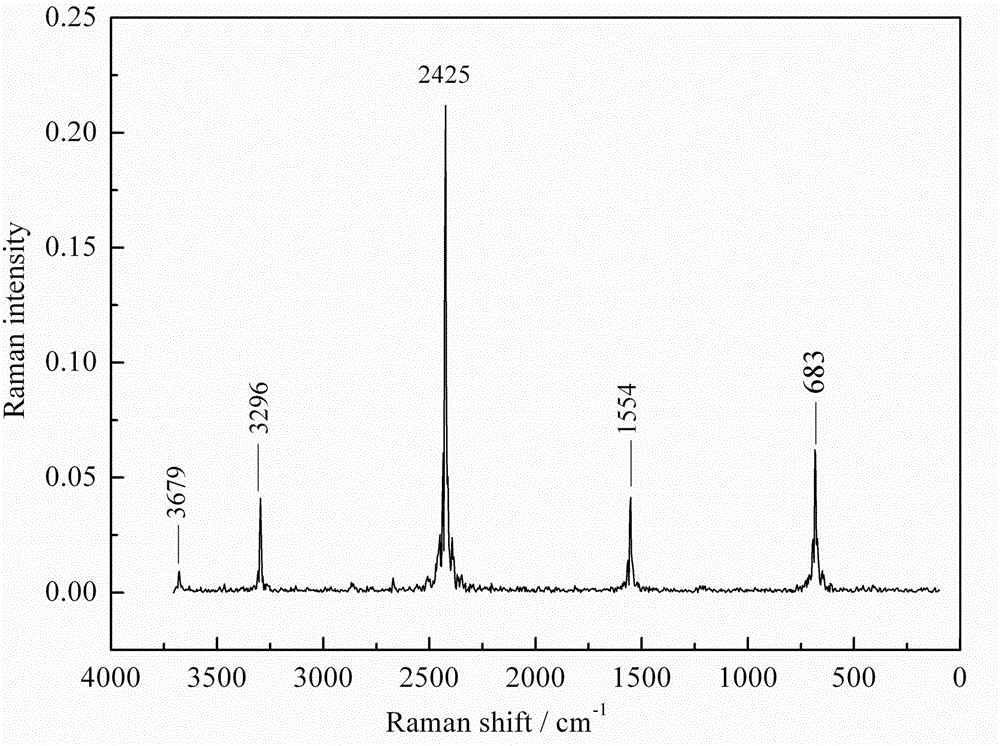

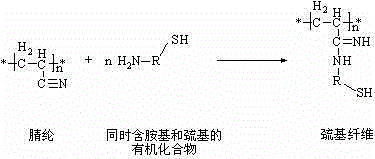

Thiol acrylic fiber material and synthesis method thereof

The invention discloses a thiol acrylic fiber material and a synthesis method thereof and belongs to the technical field of high polymer materials. The method comprises the following steps: taking an acrylic fiber as a raw material fiber, introducing a thiol through a chemical grafting reaction between the acrylic fiber and an organic compound (comprising cysteine, mercaptoethylamine, o-amido thiophenol and the like) containing amido and thiol, so as to obtain a novel functional fiber material. The functional fiber material is high in group content, keeps good form and strength and has application prospects in aspects such as functional textiles, water and air purification, chemical substance separation and extraction and the like. The synthesis method is simple in process, mild in conditions and easy to control, the used chemical raw materials are non-toxic or low-toxic, the raw material consumption is low in reaction process, no toxic by-product is generated, and the method is an environment-friendly synthesis method.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Method for preparing amide compounds through oxidation of amine under catalysis of manganese oxide

ActiveCN108610226AReduce manufacturing costFacilitate large-scale productionOrganic compound preparationCarboxylic acid amides preparationCatalytic oxidationReaction temperature

The invention relates to a method for preparing amide compounds through oxidation of amine under the catalysis of manganese oxide, belonging to the field of catalysts used for synthesis of amide compounds. The method comprises the following steps: adding an organic solvent, an organic amine substrate and a catalyst into a pressure vessel and carrying out uniform mixing; then introducing oxygen; and forming C=O double bonds on alpha carbon of the organic amine substrate through the catalytic oxidation of the catalyst in the process of a reaction, then preparing amido groups and eventually producing amide compounds. The catalyst used in the invention is cheap and easily available; the active component of the catalyst is manganese oxide, and no precious metal is used, so the preparation costof the catalyst is low, which is beneficial for large-scale production of the catalyst. The method is low in reaction temperature and does not need extra reaction aids in the process of synthesis, nopoisonous and harmful by-product is produced after the reaction, and the whole synthesis process is green and environment-friendly.

Owner:ZHEJIANG UNIV

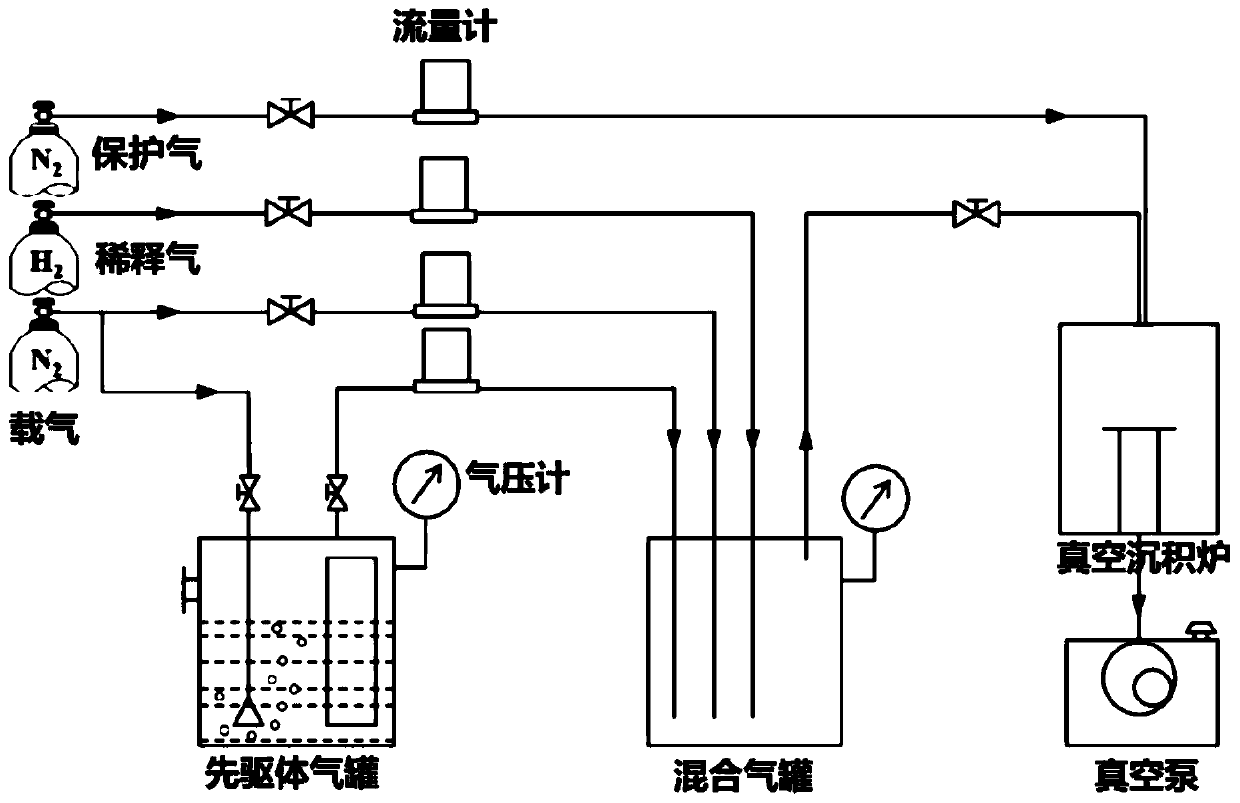

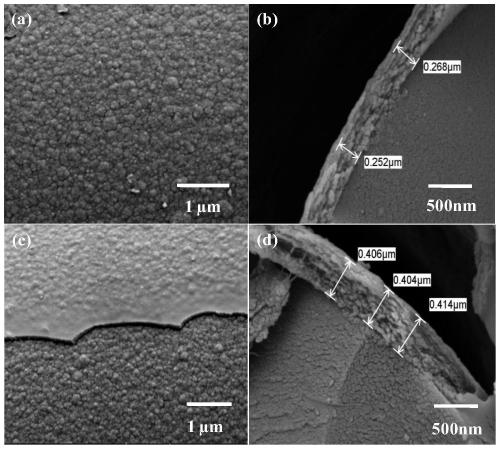

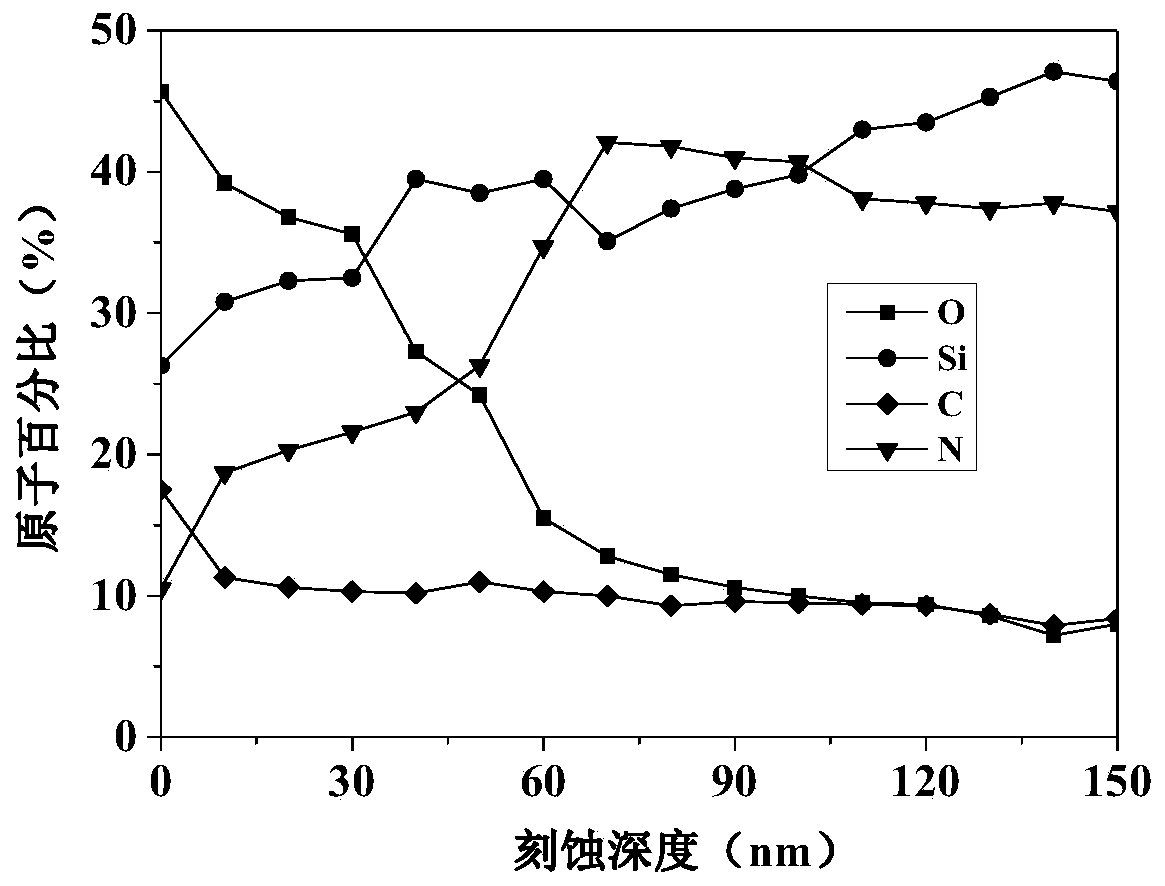

Fiber preform with double wave-transparent ceramic coating layer and preparation method of fiber preform

The invention discloses a preparation method of a fiber preform with a double-wave-transparent ceramic coating layer, wherein the preparation method comprises the following steps: by using borazine asa precursor, depositing a BN coating layer on the surface of nitride fibers by a chemical vapor deposition technique to obtain single-coating layer nitride fibers; and putting the obtained single-coating layer fiber into a perhydropolysilazane (PHPS) solution, completely dipping, taking out, volatilizing a solvent at room temperature, and transferring to a constant-temperature constant-humidity box for hydrolysis conversion, and thus obtaining the fiber preform with the double-wave-transparent ceramic coating layer. The method is simple in equipment, safe in process and low in cost, and the prepared wave-transparent fiber preform is resistant to high temperature, oxidation and moisture absorption and is expected to be applied to reinforcement bodies of oxide-based wave-transparent composite materials.

Owner:NAT UNIV OF DEFENSE TECH

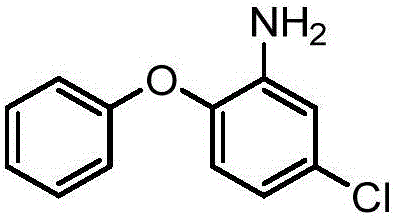

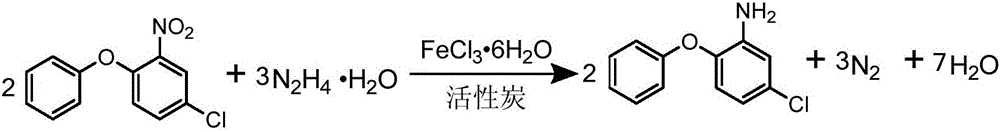

Method for preparing 2-amino-4-chlorodiphenyl oxide

ActiveCN106187787ALess side effectsHigh reaction yieldOrganic compound preparationChemical recyclingActivated carbonSolvent

The invention discloses a method for preparing 2-amino-4-chlorodiphenyl oxide. The method comprises the following steps: dispersing 2-amino-4-chlorodiphenyl oxide, ferric chloride hexahydrate and active carbon in ethanol, then adding alkali for adjusting the pH value to 7-9, under heating condition, dropping hydrazine hydrate for performing a reduction reaction, after the reaction is complete, and processing the material to obtain 2-amino-4-chlorodiphenyl oxide. The preparation method has the advantages of mild reaction condition, easy control, and simple reaction equipment, a catalyst and a solvent are repeatedly used, and the 2-amino-4-chlorodiphenyl oxide is friendly to environment, has the advantages of stable product quality, good purity, and high yield, and is in favor of realizing large-scale production.

Owner:ZHEJIANG RUNTU INST

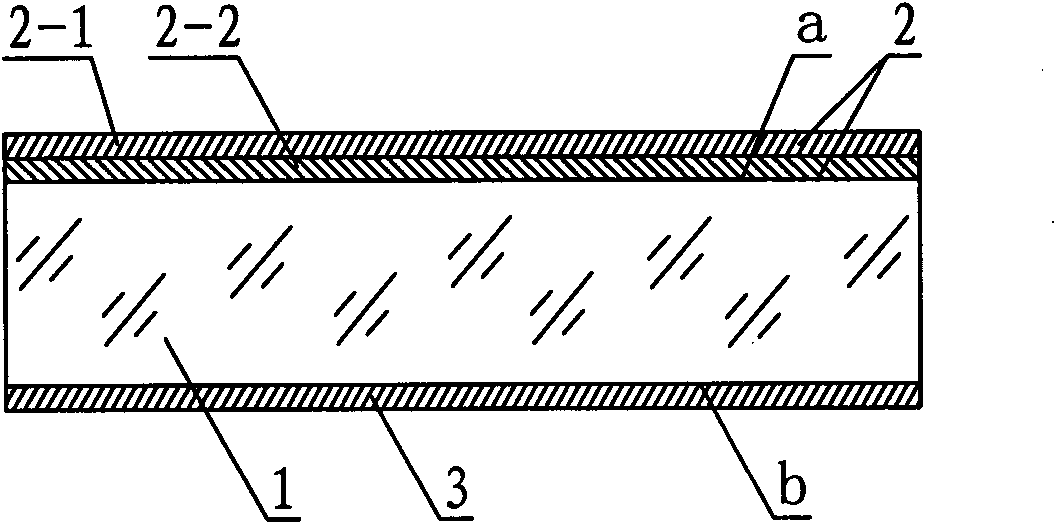

Ultra clear float glass with two sides coated with antireflection coatings for packaging solar battery assembly

The invention relates to a solar battery, in particular to ultra clear float glass with two sides coated with antireflection coatings for packaging a solar battery assembly, which is cover plate glass for packaging in a crystalline silicon solar battery assembly and is suitable for the production of the crystalline silicon solar battery assembly. The ultra clear float glass comprises an ultra clear flat glass substrate (1); the upper surface and the lower surface of the ultra clear floating glass substrate are both planes and are respectively provided with a light antireflection coating (2) and a light antireflection coating (3). The invention has the advantages of low cost, simple production process, high price performance, good weather resistance, good light transmission, easily obtained raw materials, low material cost, high hardness of the light antireflection coatings and firm adhesion to the ultra clear float glass substrate and can improve the power increment of the solar assembly to a higher degree. With higher price performance, the invention is convenient for industrial and mass production.

Owner:CHANGZHOU ALMADEN

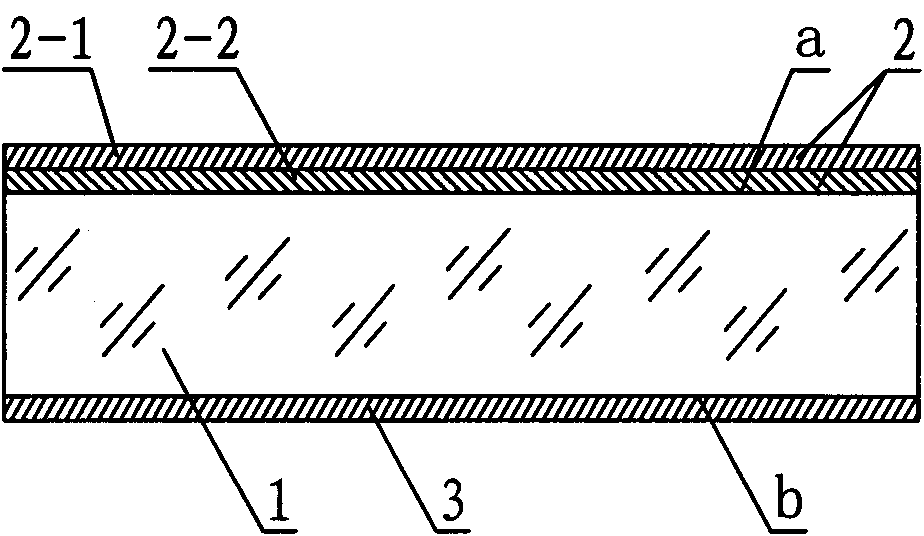

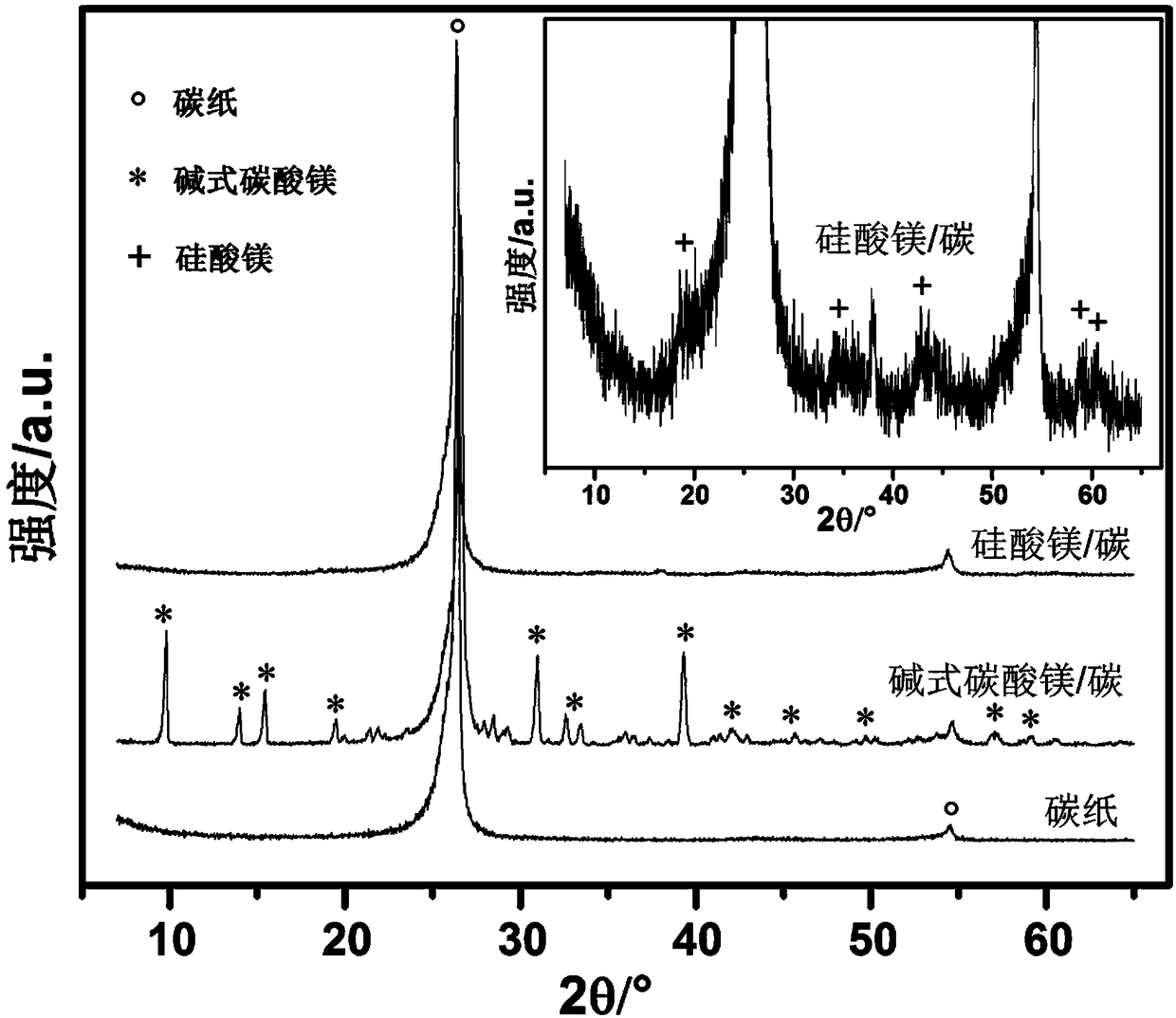

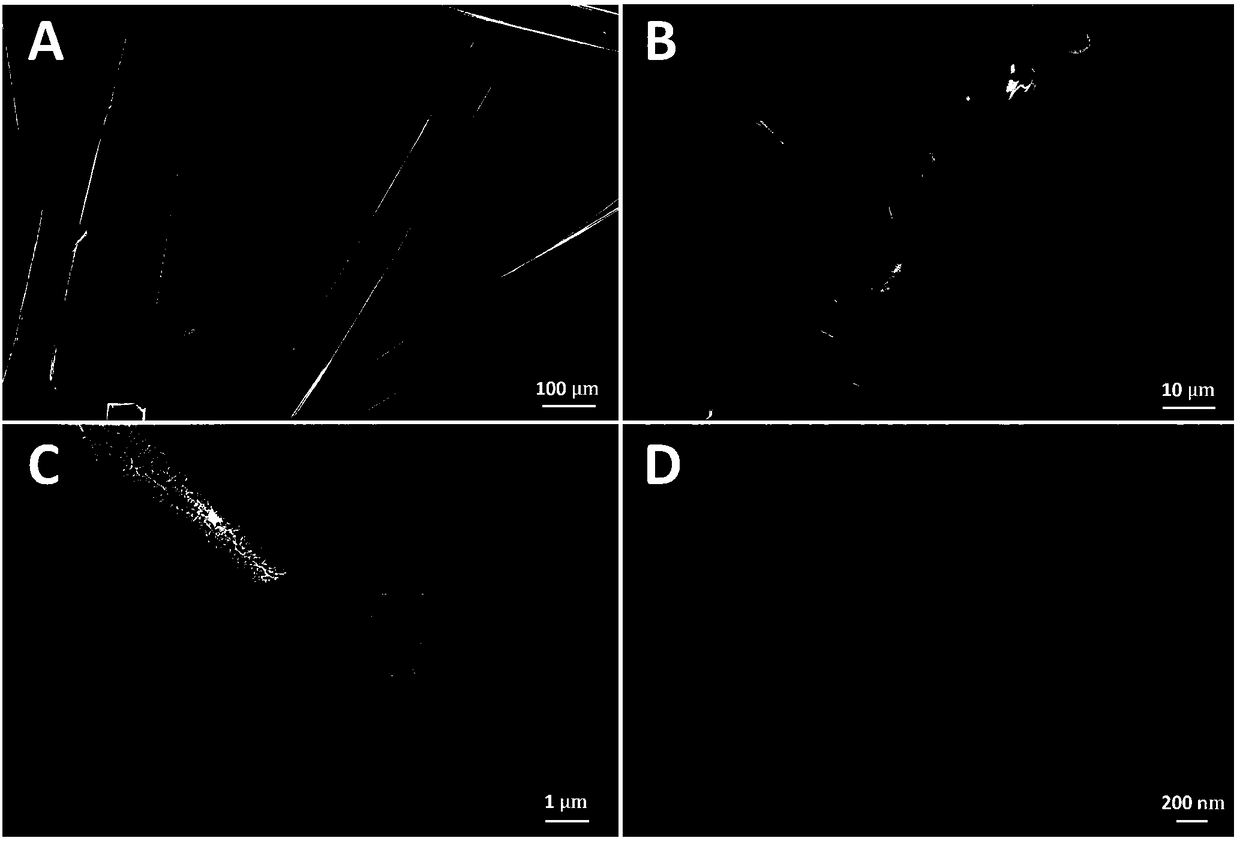

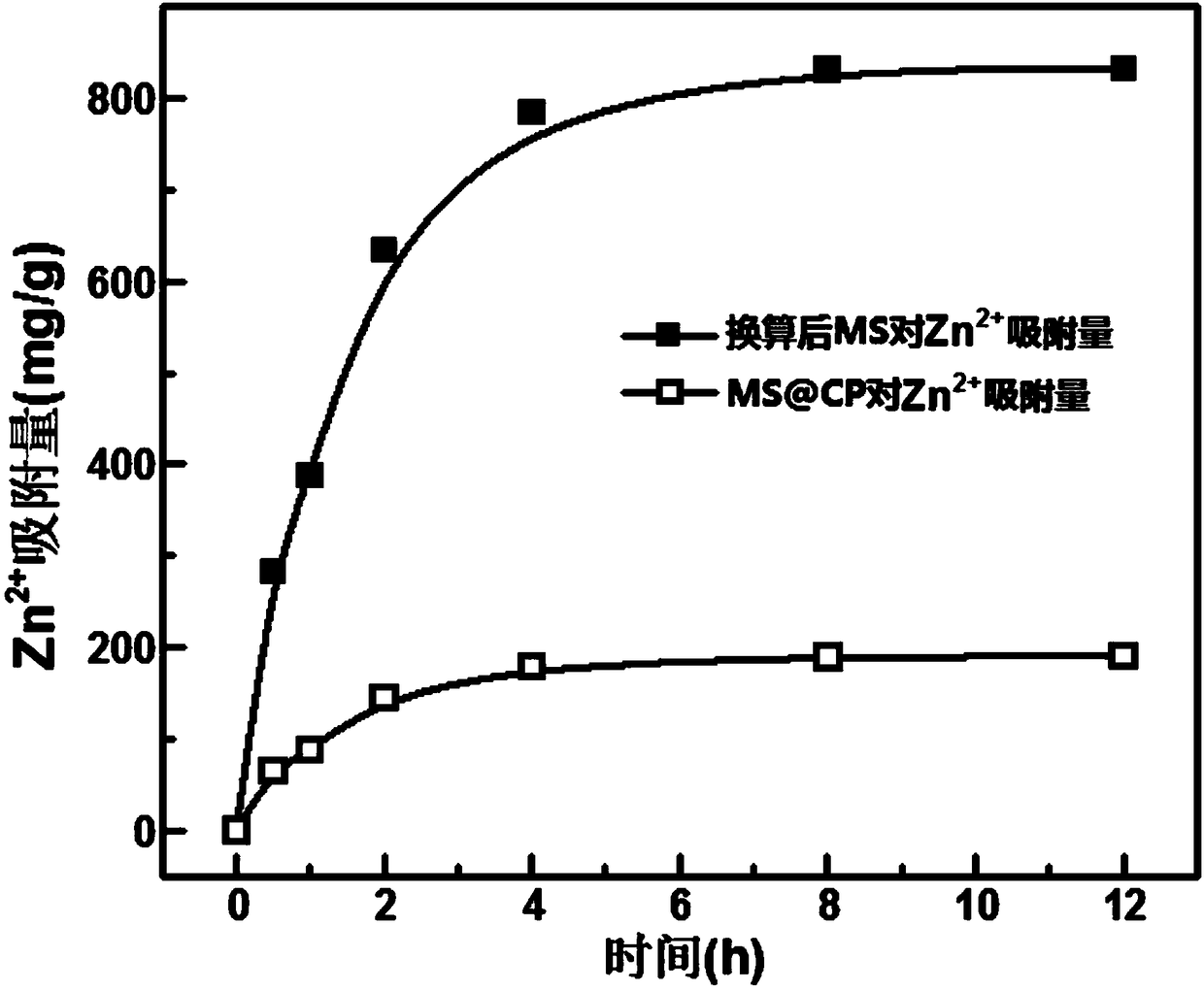

Porous magnesium silicate composite adsorption film and preparation method thereof

InactiveCN108067182AImprove adsorption capacityEasy to makeMagnesium silicatesOther chemical processesTwo stepSolvent

The invention provides a porous magnesium silicate composite adsorption film and a preparation method thereof. Firstly, a two-step hydrothermal method is used; a basic magnesium carbonate thin sheet grows on a substrate; then, the basic magnesium carbonate thin sheet is used as a magnesium source for preparing magnesium silicate; finally, the porous magnesium silicate composite adsorption film ofa hierarchical pore structure is obtained. Compared with a conventional Stober method which is shown in the description, the method provided by the invention has the advantages that the condition thatinflammable and explosive organic solutions such as ethanol are used as solvents is avoided; by using the method, more materials can be selected as substrates; meanwhile, the preparation process is simple and green; the large-scale production is favorably realized. Compared with a single powder adsorbing material, the composite adsorption film has the advantages that the operation is simple and convenient, and the separation and the recovery are easy; the adsorption performance on heavy metal ions is excellent; wide market application prospects are realized. The invention also provides the porous magnesium silicate composite adsorption film; the porous magnesium silicate composite adsorption film is of the hierarchical pore structure.

Owner:南京凯特莱斯环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com