Comb type high-molecular sand fixation and water retaining agent and preparation method of same

A comb-shaped polymer, water-retaining agent technology, applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of low strength, easy aging, small penetration depth, etc., and achieve simple production process, good durability, The effect of high sand-fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

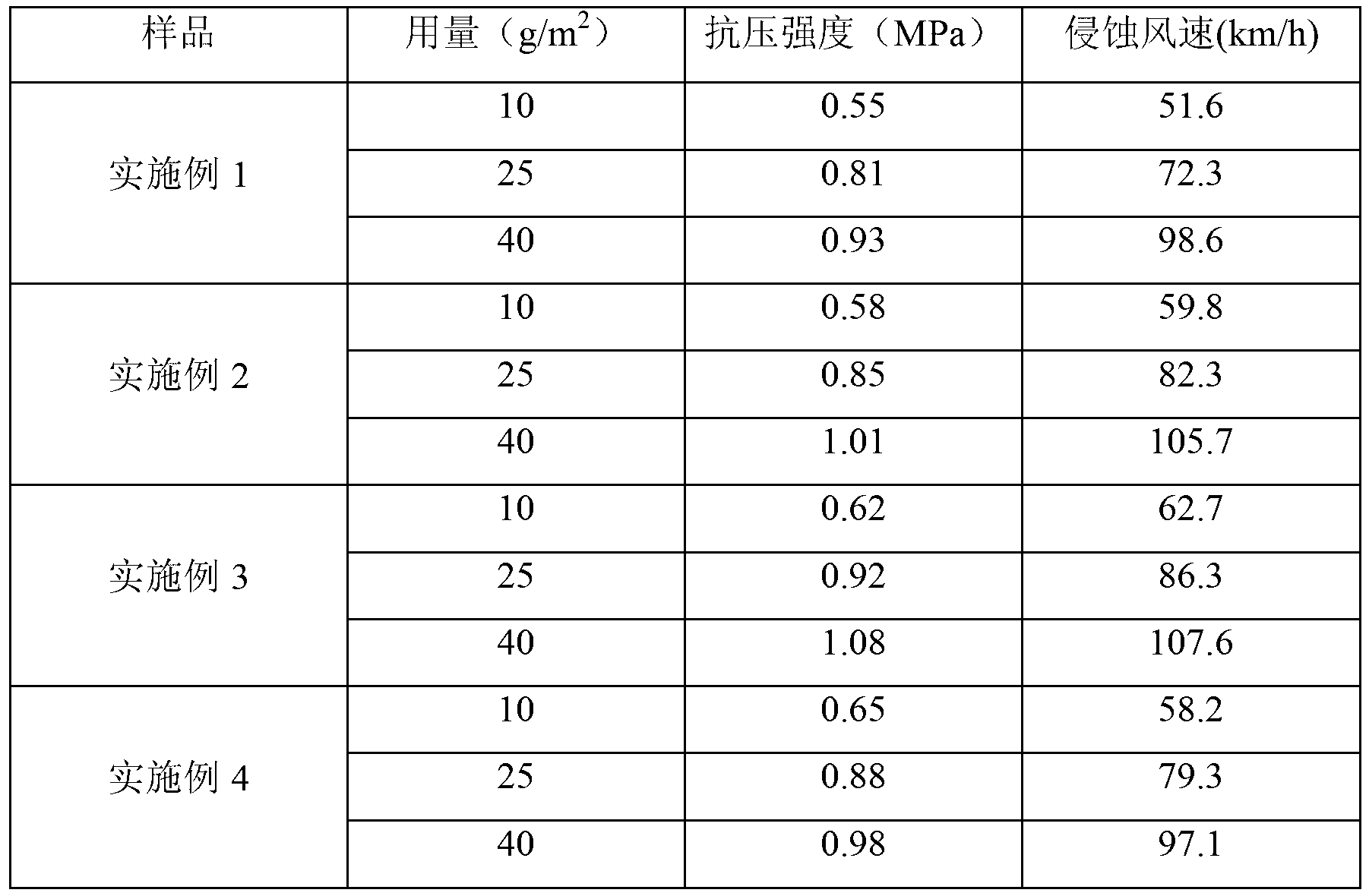

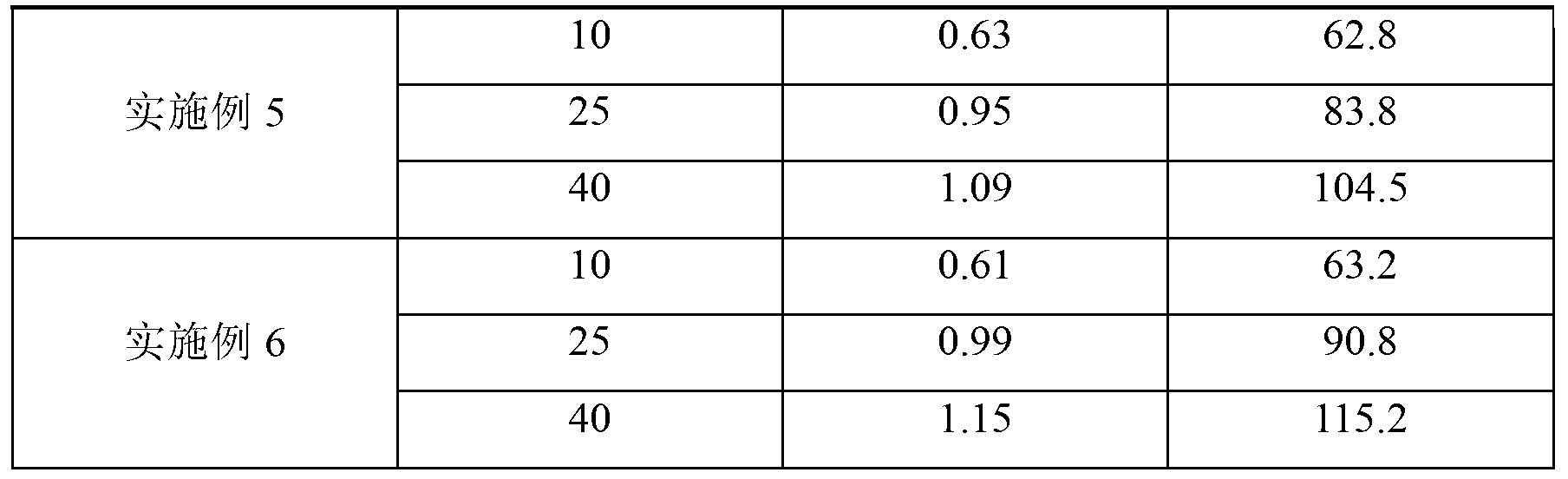

Examples

Embodiment 1

[0023] Heat 20 parts of APEG2400, 20 parts of tetramethoxysilane and 0.05 parts of p-toluenesulfonic acid to 100°C, react at this temperature for 4 hours, and distill off excess tetramethoxysilane and methanol produced by the reaction under reduced pressure. 21.3 parts of macromonomer were obtained.

[0024] Put 20 parts of the macromonomer obtained in the above steps into the reaction vessel, add 200 parts of water, 30 parts of vinyl acetate, 20 parts of butyl acrylate and 10 parts of acrylamide, add 0.1 part of emulsifier, and heat up to 80°C , add 40 parts of 5% ammonium persulfate aqueous solution dropwise, the dropwise addition is completed in 180 minutes, keep the reaction at 80°C for 240 minutes, and cool down to obtain a comb-shaped polymer sand-fixing and water-retaining agent.

Embodiment 2

[0026] Heat 20 parts of HPEG2400, 20 parts of tetramethoxysilane and 0.05 part of p-toluenesulfonic acid to 90°C, react at this temperature for 5 hours, and distill off excess tetramethoxysilane and methanol produced by the reaction under reduced pressure. 21.3 parts of macromonomer were obtained.

[0027] Put 20 parts of the macromonomer obtained in the above steps into the reaction vessel, add 200 parts of water, 30 parts of vinyl acetate, 20 parts of butyl acrylate and 10 parts of acrylamide, add 0.5 parts of emulsifier, and heat up to 70°C , add 40 parts of 5% ammonium persulfate aqueous solution dropwise, the dropwise addition is completed in 180 minutes, keep the reaction at 80°C for 210 minutes, cool down, and obtain a comb-shaped polymer sand-fixing and water-retaining agent.

Embodiment 3

[0029] Heat 20 parts of TPEG2400, 20 parts of tetramethoxysilane and 0.05 parts of p-toluenesulfonic acid to 80°C, react at this temperature for 6 hours, and distill off excess tetramethoxysilane and methanol produced by the reaction under reduced pressure. 21.3 parts of macromonomer were obtained.

[0030] Put 20 parts of the macromonomer obtained in the above steps into the reaction vessel, add 200 parts of water, 30 parts of vinyl acetate, 20 parts of butyl acrylate and 10 parts of acrylamide, add 1 part of emulsifier, and raise the temperature to 60°C , add 40 parts of 5% ammonium persulfate aqueous solution dropwise, the dropwise addition is completed in 180 minutes, keep the reaction at 80°C for 180 minutes, and cool down to obtain a comb-shaped polymer sand-fixing and water-retaining agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com