Ultra clear float glass with two sides coated with antireflection coatings for packaging solar battery assembly

A technology of ultra-white float glass and anti-reflection coating, applied in the field of solar cells, can solve the problems of low light transmittance of flat ultra-white float glass, inability to be popularized and applied, low power increase, etc., so as to reduce light reflection The effect of returning space, high cost performance and high power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

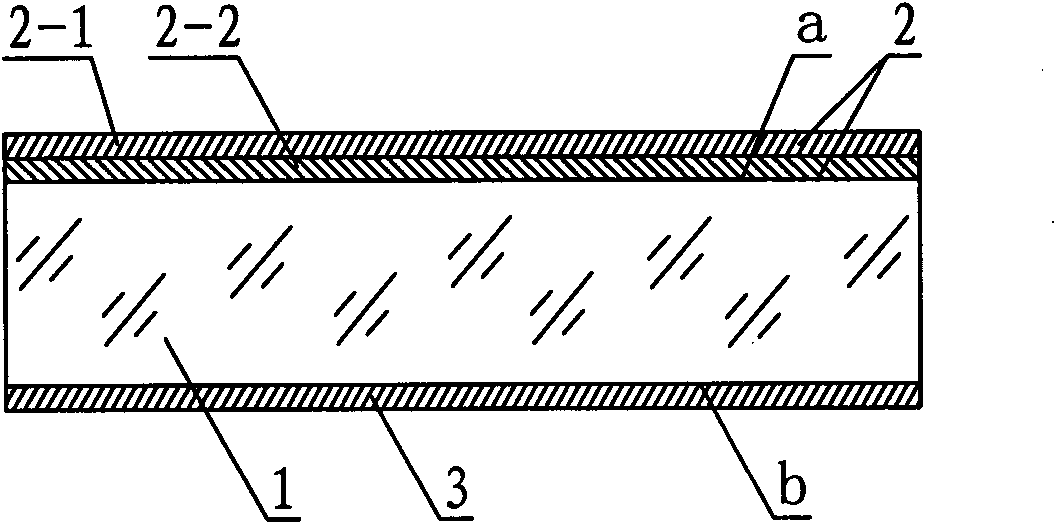

[0014] As shown in the accompanying drawings, an ultra-clear float glass with double-sided anti-reflection coating for solar cell module packaging includes an ultra-clear float glass substrate 1, the upper surface and the lower surface of the ultra-clear float glass substrate 1 are both It is a plane, and a light anti-reflection coating 2 is coated and fixed on the surface a of the upper surface of the ultra-clear float glass substrate 1, and a light anti-reflection coating 2 is also coated and fixed on the surface b of the lower surface of the ultra-clear float glass substrate 1. Coating 3, when installed, the upper surface a of the ultra-clear float glass substrate 1 faces the sunlight, and the lower surface b of the ultra-clear float glass substrate 1 faces the solar cells. The upper surface a of the ultra-clear float glass substrate 1 is coated with a fixed light anti-reflection coating 2 as a layer, the material is nano silicon dioxide, and the thickness is 80nm, because t...

Embodiment 2

[0016] As shown in the drawings, it is basically the same as the first embodiment, except that the light anti-reflection coating 2 provided on the upper surface a of the ultra-clear float glass substrate 1 has a thickness of 50 nm. The light anti-reflection coating 3 provided on the lower surface b of the ultra-clear float glass substrate 1 is made of nano-zirconia, and the thickness of the nano-zirconia is 180 nm.

Embodiment 3

[0018] As shown in the drawings, it is basically the same as the first embodiment, except that the light anti-reflection coating 2 provided on the upper surface a of the ultra-clear float glass substrate 1 has a thickness of 125 nm. The light anti-reflection coating 3 provided on the lower surface b of the ultra-clear float glass substrate 1 is a mixture of nano-titanium dioxide and nano-zirconia, and the thickness of the mixture of nano-titanium dioxide and nano-zirconia is 90nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com