Preparation method for graphene nanobelt-lithium iron phosphate composite material

A technology of graphene nanobelts and lithium iron phosphate, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of limited practical application, difficult practical operation, large energy consumption, etc., and achieves good ion transmission performance and convenient Promotion and application, good production safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The concrete steps of a kind of preparation method of graphene nanoribbon paper are as follows:

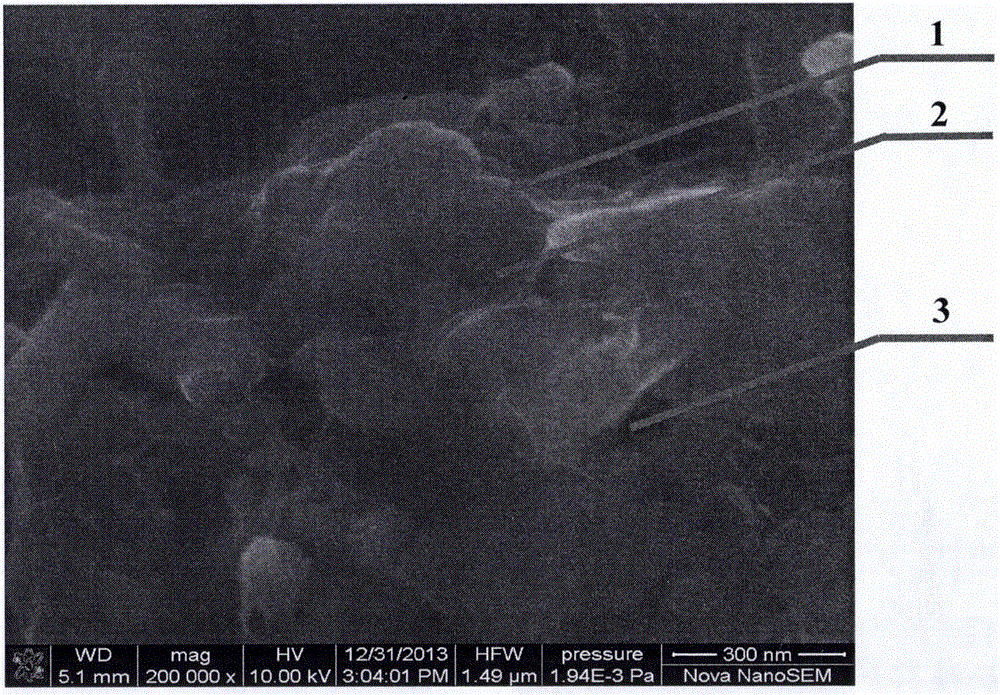

[0025] (1) Preparation of graphene nanoribbons

[0026] With carbon nanotube as raw material, potassium permanganate as oxidant, concentrated sulfuric acid as oxidizing acid, according to the quality (g) of the carbon nanotube: the oxidizing agent quality (g): the volume of the oxidizing acid ( mL) in a ratio of 1:5:400. First add the raw materials into the oxidizing acid and stir for 12 hours to prepare mixture 1, then add the oxidizing agent to the mixture 1, stir at room temperature for 1 hour, then transfer to a water bath, and then keep the mixture at a constant temperature of 80°C Stir for 5 hours to prepare mixture 2, then add hydrogen peroxide that can remove excess oxidant to mixture 2 to obtain mixture 3, and finally use hydrochloric acid and deionized water to repeatedly ultrasonically clean mixture 3 to neutrality (pH=7) After drying at 60°C for 12 hours, grap...

Embodiment 2

[0032] A preparation method of graphene nanoribbon paper, with embodiment 1, wherein:

[0033] In the 1st (1) step, oxidizing agent is concentrated nitric acid, and concentrated sulfuric acid is oxidizing acid, and the ratio of described raw material quality (g): described oxidizing acid quality (g): described oxidizing acid volume (ml) is 1: 1 : 50, the raw material is added to the oxidizing acid and the stirring time is 1h, the stirring time is 0.1h after adding the oxidizing agent into the mixture 1, the water bath temperature is 50°C, the stirring time in the water bath process is 1h, and the drying The temperature is 50°C and the drying time is 6h.

[0034] In the (2) step, the mass ratio of the lithium iron phosphate and the graphene nanoribbon prepared in the (1) step is 1: 0.1, and the surfactant cetyltrimethylammonium bromide, The ratio of the mass (g) of the lithium iron phosphate: the mass (g) of the surfactant: the volume of deionized water (mL) is 1:0.001:10, and...

Embodiment 3

[0037] A preparation method of graphene nanoribbon paper, with embodiment 1, wherein:

[0038]In the 1st (1) step, oxidizing agent is potassium permanganate, and perchloric acid is oxidizing acid, and described raw material quality (g): described oxidizing agent quality (g): the ratio of described oxidizing acid volume (ml) is 1:10:2000, the raw material is added to the oxidizing acid and the stirring time is 24 hours, the stirring time is 5 hours after adding the oxidizing agent to the mixture 1, the temperature of the water bath is 90°C, and the stirring time during the water bath is 10 hours , the drying temperature is 120°C, and the drying time is 24h.

[0039] In the (2) step, the mass ratio of the lithium iron phosphate and the graphene nanobelt prepared in the (1) step is 1:0.2, the surfactant polyetherimide, the lithium iron phosphate The mass (g): the mass (g) of the surfactant: the ratio of deionized water volume (mL) is 1:0.1:1000, and the mixing and stirring time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com