Method for industrially preparing dimorphic hard alloy with both high strength and high tenacity

A cemented carbide, high toughness technology, applied in the field of cemented carbide, can solve the problems of unreachable transverse fracture strength and fracture toughness of cemented carbide bulk, difficult to control the number and size of coarse WC, and small volume fraction of coarse grains. , to achieve the effects of low production cost, high phase purity and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

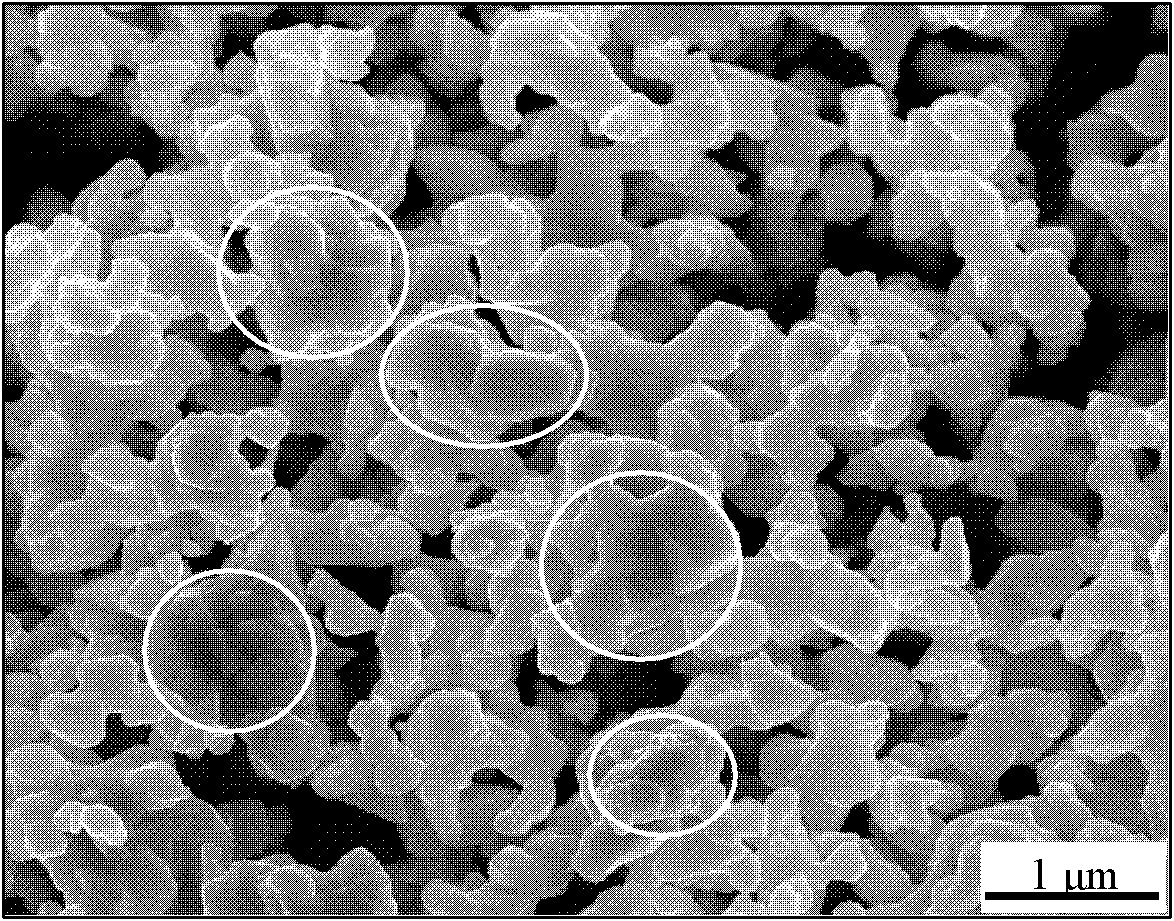

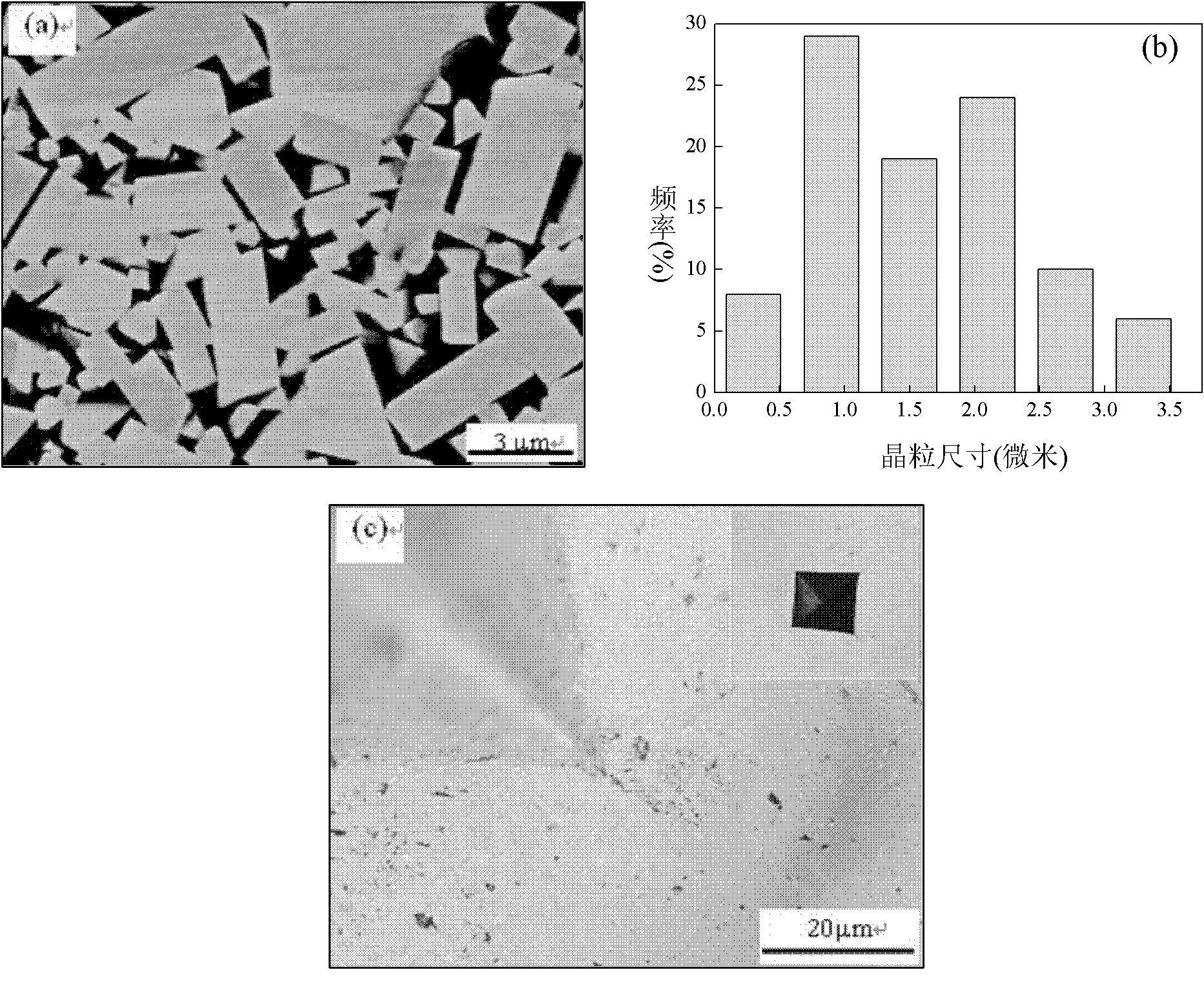

[0028] Example 1: The final product is WC-6wt.% Co (YG6) cemented carbide bulk material. with WO 2.9 、Co 3 o 4and carbon black powder as raw materials, according to the requirements of the Co content in the final prepared YG6 twin crystal cemented carbide, the ratio of the three raw materials is carried out and mixed by ball milling, and the powder after ball milling is cold-pressed and sent into a vacuum furnace. The WC-Co composite powder was prepared in a vacuum furnace using the following process parameters: the heating rate was 10°C / min, the holding temperature was 1050°C, and the holding time was 3 hours. The agglomerates of the prepared WC-Co composite powder were crushed by ball milling: using absolute ethanol as the grinding medium, the volume ratio of solid to liquid was 1:3; the ratio of ball to solid was 1:1; the speed of the ball mill was 300r / min; the milling time was 10 hours; after drying, WC-Co composite powder was obtained. The WC-Co composite powder afte...

example 2

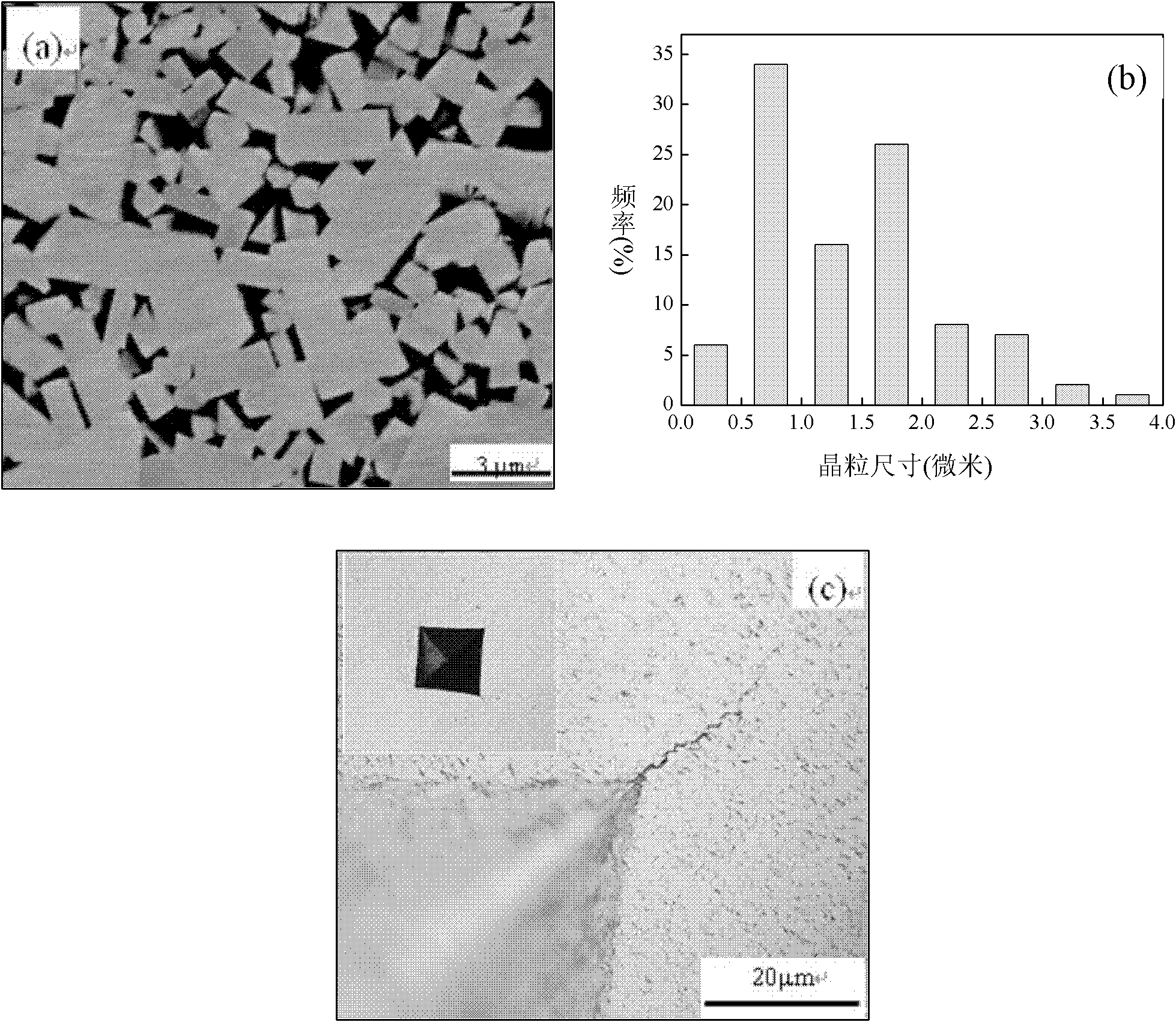

[0029] Example 2: The final product is WC-10wt.% Co (YG10) cemented carbide bulk material. with WO 2.9 、Co 3 o 4 and carbon black powder as raw materials, according to the requirements of the Co content in the final prepared YG10 twin crystal cemented carbide, the ratio of the three raw materials is carried out and mixed by ball milling, and the powder after ball milling is cold-pressed and sent into a vacuum furnace. The WC-Co composite powder was prepared in a vacuum furnace using the following process parameters: the heating rate was 8°C / min, the holding temperature was 1100°C, and the holding time was 3.5 hours. The prepared WC-Co composite powder agglomerate is ball milled: hexane is used as the grinding medium, the volume ratio of solid to liquid is 1:2; the ratio of ball to material is 1:1; the speed of the ball mill is 150r / min; the milling time is 15 Hours; WC-Co composite powder was obtained after drying. The WC-Co composite powder after ball milling was subjecte...

example 3

[0030] Example 3: The final product is WC-10wt.% Co (YG10) cemented carbide bulk material. with WO 2.9 、Co 3 o 4 and carbon black powder as raw materials, according to the requirements of the Co content in the final prepared YG10 twin crystal cemented carbide, the ratio of the three raw materials is carried out and mixed by ball milling, and the powder after ball milling is cold-pressed and sent into a vacuum furnace. The WC-Co composite powder was prepared in a vacuum furnace using the following process parameters: the heating rate was 8°C / min, the holding temperature was 1100°C, and the holding time was 3.5 hours. The prepared WC-Co composite powder agglomerates were ball milled and crushed: absolute ethanol was used as the grinding medium, the volume ratio of solid to liquid was 1:2, and the ratio of ball to material was 1:1; the rotational speed of the ball mill was 150r / min; the milling time was 15 hours; WC-Co composite powder was obtained after drying. The WC-Co com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com