A method of preparing a layered perovskite type strontium- tantalum-based ternary oxide photocatalyst

A strontium-tantalum-based ternary and perovskite-type technology, which is applied in the field of preparation of layered perovskite-type strontium-tantalum-based ternary oxide photocatalysts, can solve unfavorable large-scale production preparations, cumbersome photocatalyst synthesis methods, etc. problems, achieve excellent water splitting performance, realize large-scale production, and achieve the effect of low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of a layered perovskite-type strontium-tantalum-based ternary oxide photocatalyst of the present embodiment includes the following steps:

[0022] Step 1, take by weighing 0.5mmol (0.2209g) Ta respectively 2 O 5 Solid powder with 1mmol (0.1476g) SrCO 3 The solid powders are mixed and then ground uniformly to obtain a mixed precursor powder.

[0023] Step 2, weigh the mixed salt composed of NaCl and KCl, the total mass of which is twice that of the mixed precursor powder, and mix and grind with the precursor powder to obtain a mixture.

[0024] In step 3, the mixture is calcined at 850° C. for 4 hours in a high-temperature muffle furnace, and is naturally cooled to room temperature after the reaction to obtain a mixture of recrystallized salt and strontium-tantalum-based oxide.

[0025] In step 4, the mixture of recrystallized salt and strontium-tantalum-based oxide is fully washed with deionized water, and the washed mixture of recrystallized s...

Embodiment 2

[0032] In Embodiment 2, the same steps as those in Embodiment 1 are given the same symbols and the same explanations are omitted.

[0033] In this example, 1.4 mmol (0.2066 g) SrCO was weighed in step 1 3 solid powder, Ta 2 O 5 The solid powder is exactly the same as in Example 1, and the rest of the implementation steps and conditions are the same as those in Example 1.

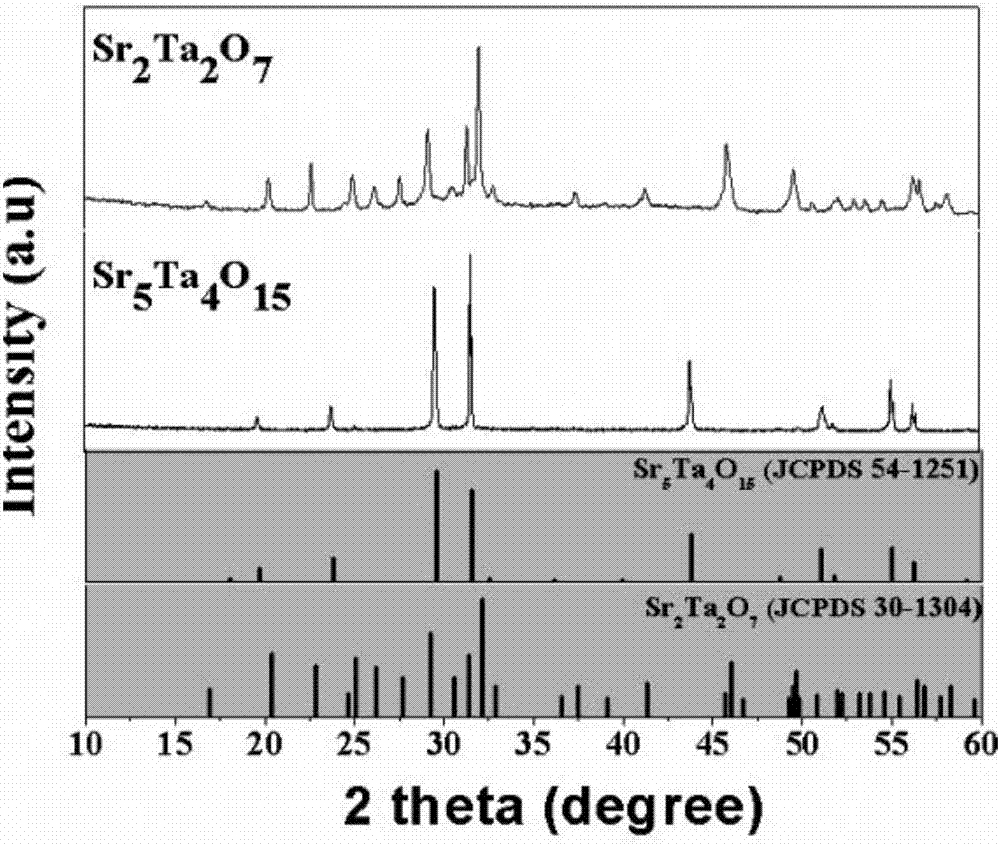

[0034] like figure 1 As shown, the sample powder of the layered perovskite-type strontium-tantalum-based ternary oxide photocatalyst prepared by the method of this example by X-ray diffraction is compared with the standard PDF card, and it is found that each peak shape position can match no other Peak formation, indicating that Sr was obtained 5 Ta 4 O 15 pure phase.

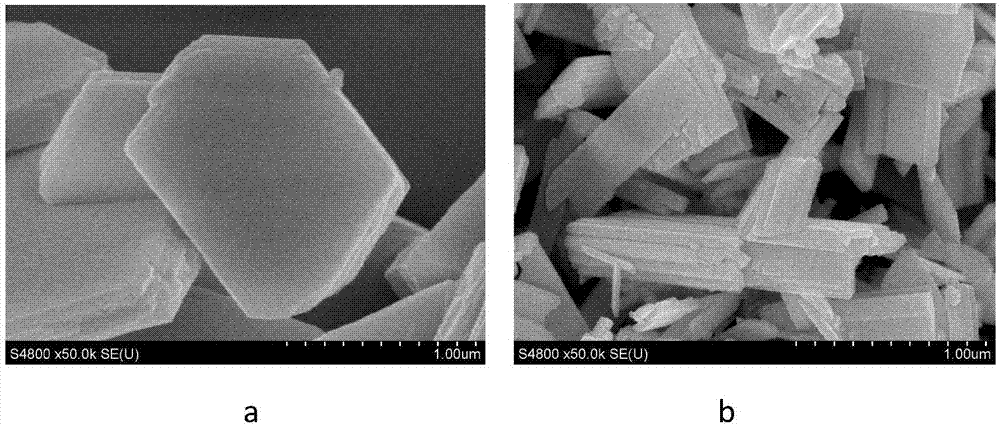

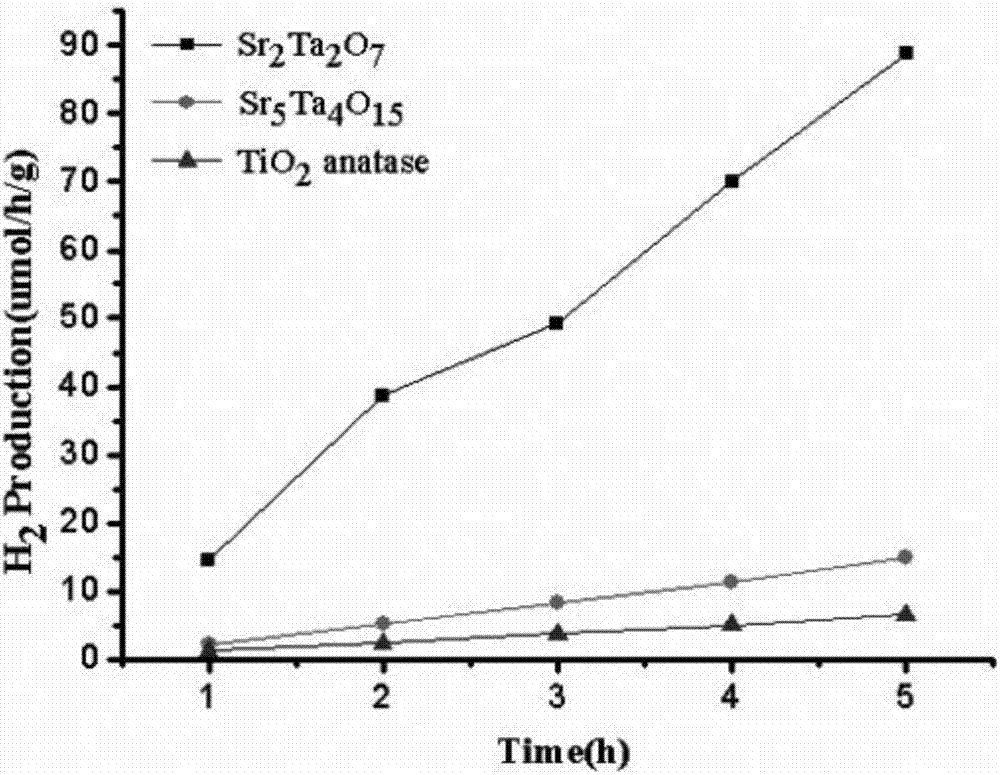

[0035] figure 2 (b) is the Sr obtained by the method for preparing the layered perovskite-type strontium-tantalum-based ternary oxide photocatalyst according to the embodiment of the present invention 5 Ta 4 O 15 SEM image of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com