Synthesis method and application of layered perovskite type photocatalyst

A synthesis method and perovskite-type technology are applied in the synthesis field of layered perovskite-type photocatalysts, which can solve the problems in the field of photocatalysis without application, and achieve excellent water splitting performance, strong morphology controllability, and synthesis Simple effects of routes and installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

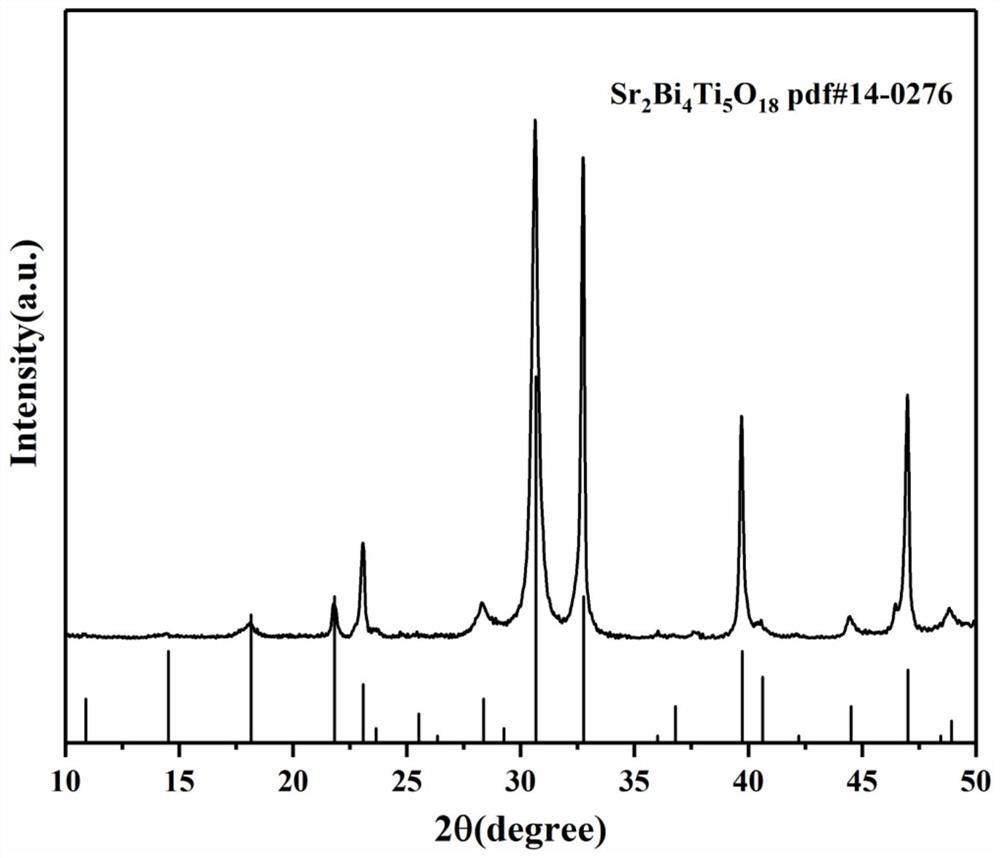

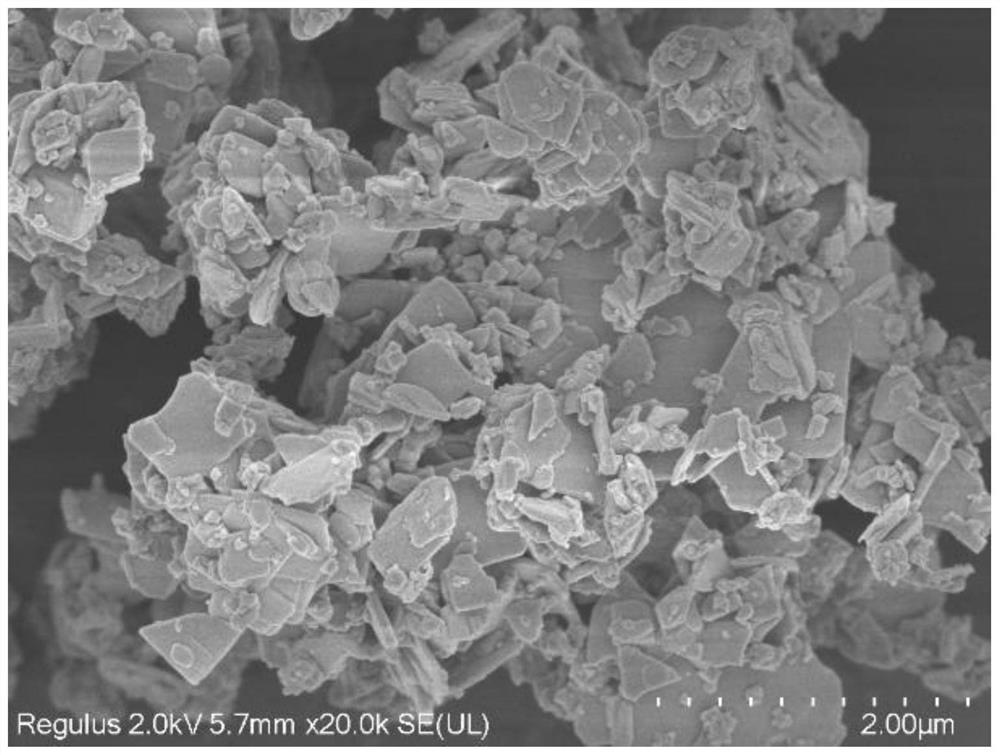

[0023] 1. Measure 30mL 4mol / L nitric acid solution and pour it into a beaker, press Sr 2 Bi 4 Ti 5 o 18 The stoichiometric ratio weighs 1.5mmol SrCl 2 ·6H 2 O, 1.5mmol Bi 2 (SO 4 ) 3 . 3.75 mmol of tetrabutyl titanate was dissolved in nitric acid solution and stirred for 10 min to obtain a raw material solution.

[0024] 2. Dissolve 7.2g of NaOH in 30mL of deionized water, stir for 5 minutes, and wait for it to cool to room temperature to obtain a sodium hydroxide solution.

[0025] 3. While stirring, use a dropper to drop the raw material liquid into the sodium hydroxide solution. After the dropwise addition is completed, stir for another 30 minutes to make it evenly mixed. After the reaction was completed, the reaction liquid was cooled to normal temperature, then centrifuged to collect the precipitate, washed with ethanol and deionized water three times, dried in an oven at 60°C for 10 h, and ground into powder to obtain Sr 2 Bi 4 Ti 5 o 18 Photocatalyst 1#.

[0...

Embodiment 2

[0029] 1. Measure 28.4mL 4.3mol / L nitric acid solution and pour it into a beaker, press Sr 2 Bi 4 Ti 5 o 18 The stoichiometric ratio weighs 1.5mmol SrCl 2 ·6H 2 O, 3mmol Bi(NO 3 ) 3 ·5H 2 O. 3.75 mmol of tetrabutyl titanate was dissolved in nitric acid solution, and stirred for 10 min to obtain a raw material solution.

[0030] 2. Dissolve 8.4g NaOH in 30mL deionized water, stir for 5min, and wait for it to cool to room temperature to obtain a sodium hydroxide solution.

[0031] 3. While stirring, use a dropper to drop the raw material liquid into the sodium hydroxide solution. After the dropwise addition is completed, stir for another 60 minutes to make it evenly mixed. After the reaction was completed, the reaction liquid was cooled to normal temperature, and then the precipitate was collected by centrifugation, washed three times with ethanol and deionized water, dried in an oven at 67°C for 9 hours, and ground into powder to obtain Sr 2 Bi 4 Ti 5 o 18 Photocata...

Embodiment 3

[0035] 1. Measure 26.7mL 4.6mol / L nitric acid solution and pour it into a beaker, press Sr 2 Bi 4 Ti 5 o 18 The stoichiometric ratio weighs 1.5mmol SrCl 2 ·6H 2 O, 1.5mmol Bi 2 (SO 4 ) 3 . 3.75 mmol of tetrabutyl titanate was dissolved in nitric acid solution and stirred for 10 min to obtain a raw material solution.

[0036] 2. Dissolve 9.6g NaOH in 30mL deionized water, stir for 5min, and wait for it to cool to room temperature to obtain a sodium hydroxide solution.

[0037] 3. While stirring, use a dropper to drop the raw material liquid into the sodium hydroxide solution. After the dropwise addition is completed, stir for another 90 minutes to make it evenly mixed. After the reaction was completed, the reaction liquid was cooled to normal temperature, and then the precipitate was collected by centrifugation, washed three times with ethanol and deionized water, dried in an oven at 73°C for 8 hours, and ground into powder to obtain Sr 2 Bi 4 Ti 5 o 18 Photocatalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com