Patents

Literature

309 results about "Ferroelectric ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferroelectric ceramics is a special group of minerals that have ferroelectric properties: the strong dependence of the dielectric constant of temperature, electrical field, the presence of hysteresis and others.

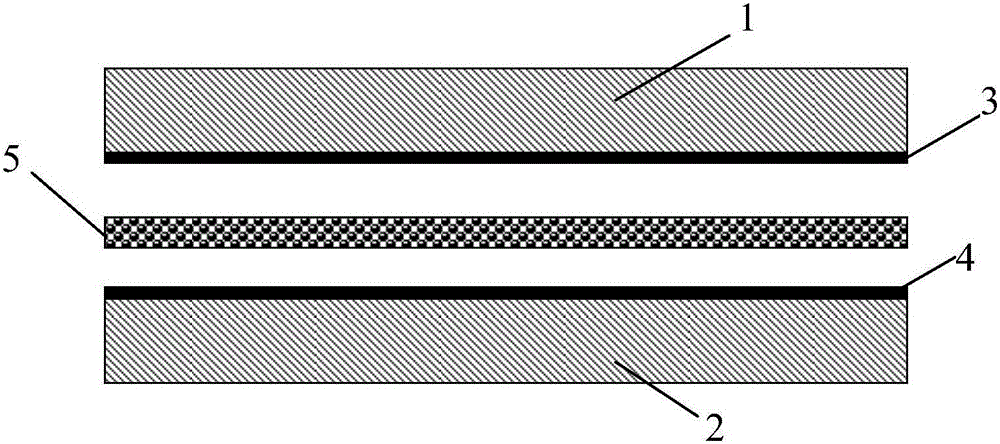

Capacitive flexible pressure sensor based on composite material dielectric layer and preparation method of capacitive flexible pressure sensor

ActiveCN106017748AHigh sensitivityIncrease rate of changeForce measurementPolymer resinElectrical conductor

The invention relates to a capacitive flexible pressure sensor based on a composite material dielectric layer and a preparation method of the capacitive flexible pressure sensor and belongs to the technical field of sensors. The flexible pressure sensor includes an upper flexible substrate and a lower flexible substrate, and an upper conducting layer attached to the inner surface of the upper flexible substrate and a lower conducting layer attached to the inner surface of the lower flexible substrate. The composite material dielectric layer is arranged between the upper conducting layer and the lower conducting layer. Compared with the prior art, doping is performed on dielectric layer polymer resin of the capacitive flexible pressure sensor. The doping material includes metal conductors, ferroelectric ceramics, carbon material and organic semiconductors. By adopting the above doping material, the flexibility of the capacitive flexible pressure sensor is improved effectively and the application and promotion of the sensor are facilitated.

Owner:XIAMEN ZHONGKE WISDOW MEDICAL TECH CO LTD

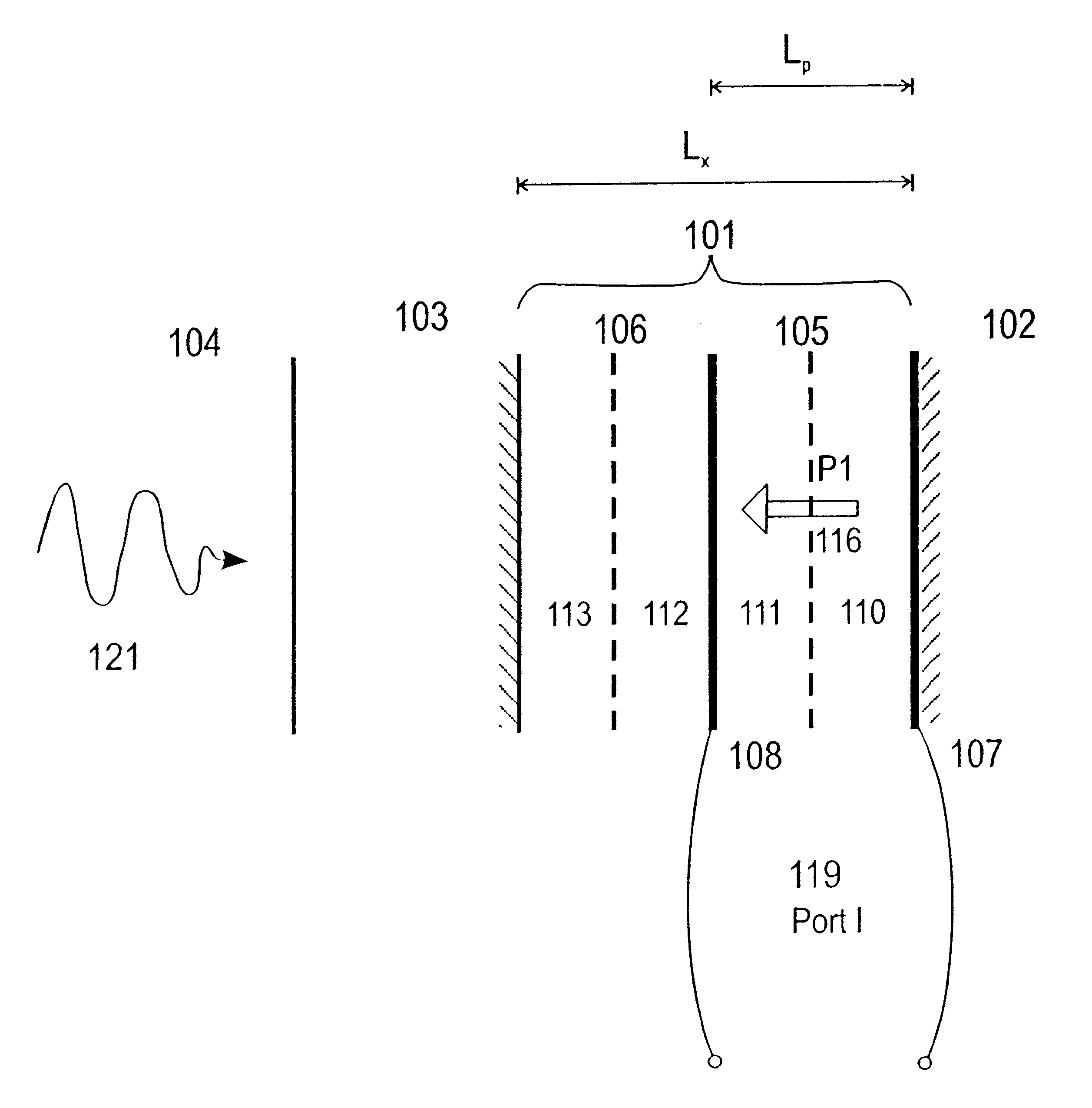

High frequency and multi frequency band ultrasound transducers based on ceramic films

InactiveUS6761692B2Maximizing electromechanical couplingImprove stabilityUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesMulti bandTransceiver

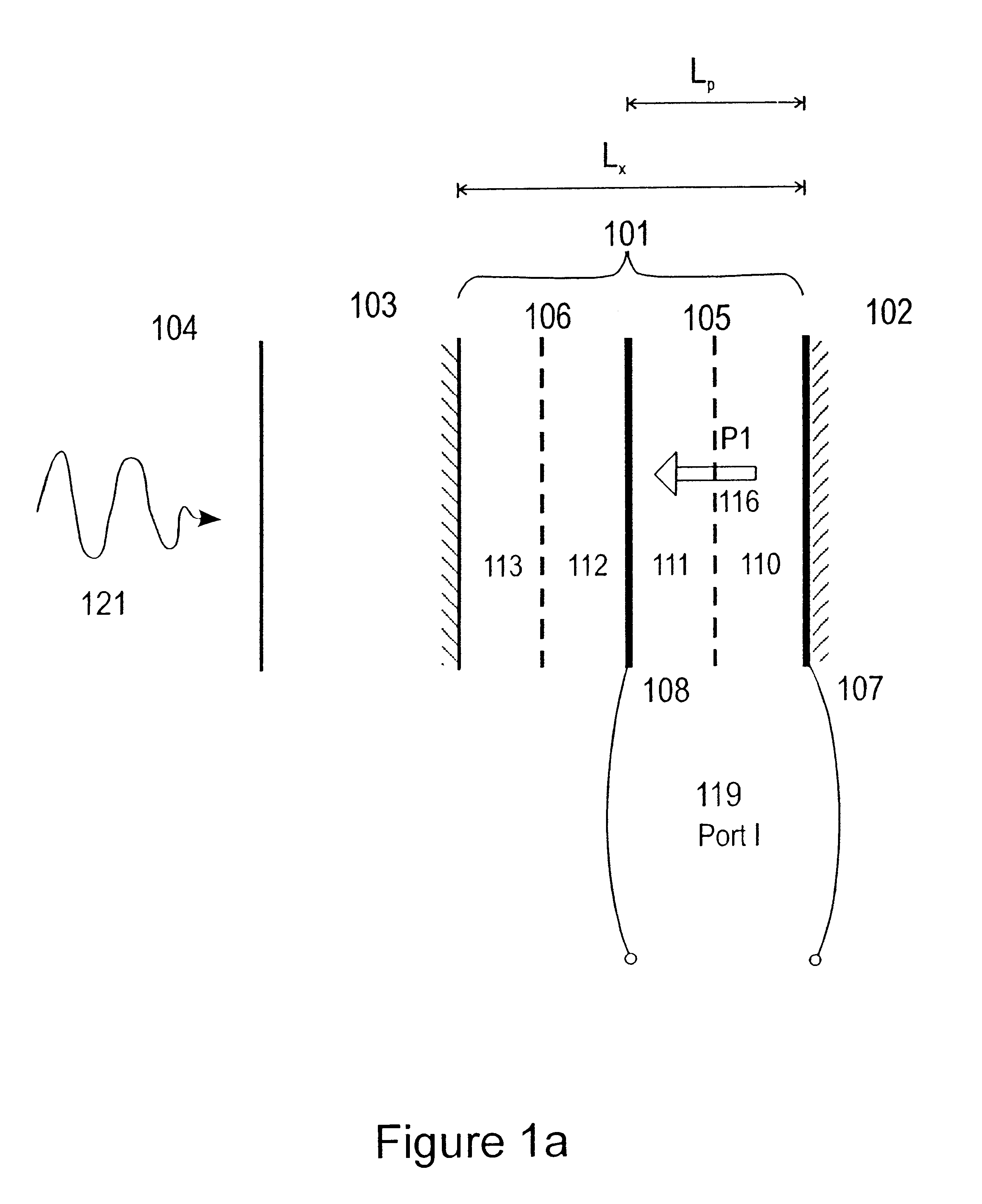

A design and a manufacturing method of ultrasound transducers based on films of ferro-electric ceramic material is presented, the transducers being particularly useful for operating at frequencies above 10 MHz. The designs also involve acoustic load matching layers that provides particularly wide bandwidth of the transducers, and also multiple electric port transducers using multiple piezoelectric layers, for multi-band operation of the transducers over an even wider band of frequencies that covers ~4 harmonics of a fundamental band. A transceiver drive system for the multi-port transducers that provides simple selection of the frequency bands of transmitted pulses as well as transmission of multi-band pulses, and reception of scattered signals in multiple frequency bands, is presented. The basic designs can be used for elements in a transducer array, that provides all the features of the single element transducer for array steering of the focus and possibly also direction of a pulsed ultrasound beam at high frequencies and multi-band frequencies. The manufacturing technique can involve tape-casting of the ceramic films, deposition of the ceramic films onto a substrate with thick film printing, sol-gel, or other deposition techniques, where manufacturing methods for load matching layers and composite ceramic layers are described.

Owner:PREXION

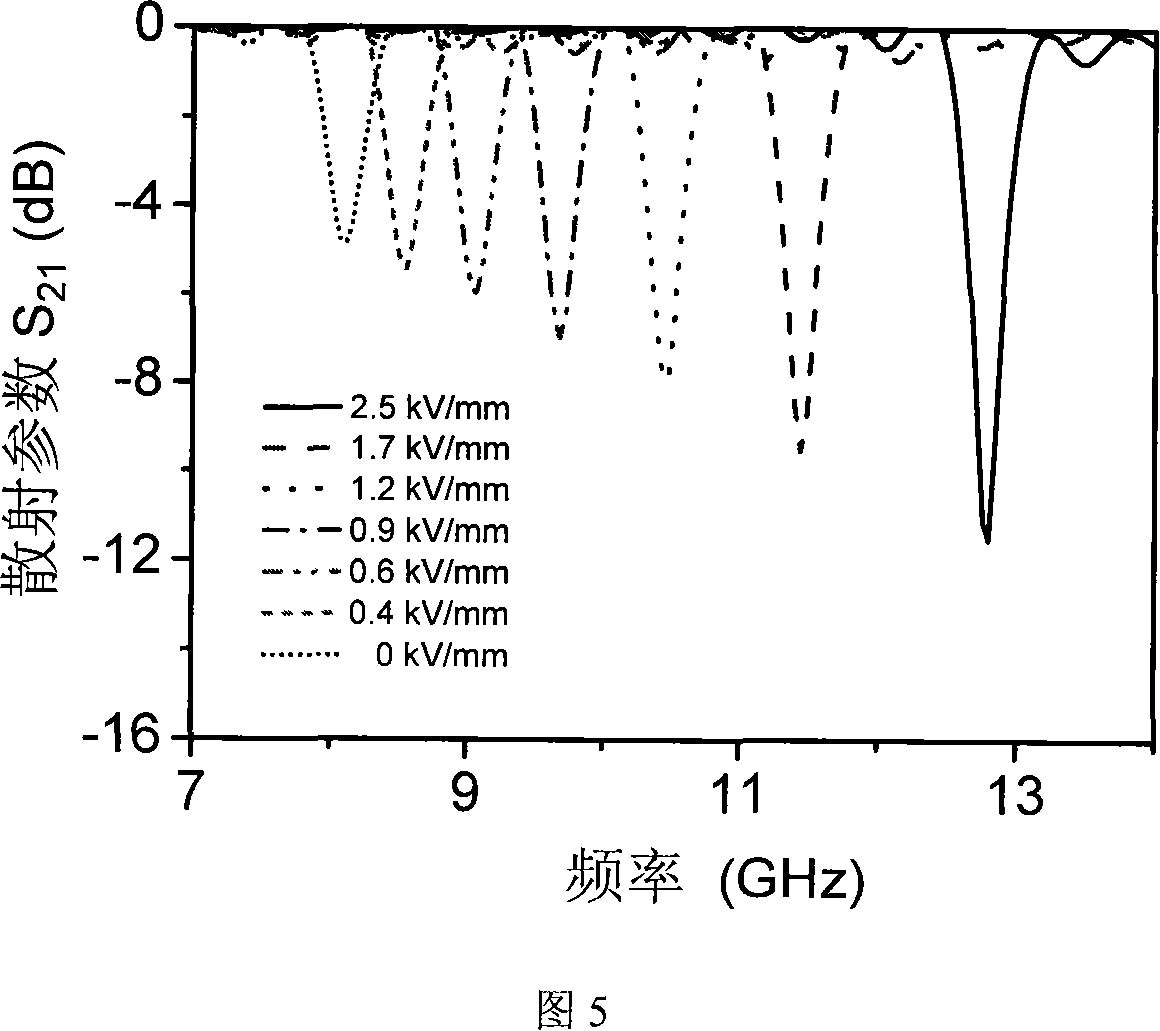

Electric field-tunable negative magnetic permeability part based on ferroelectric ceramic grain and its making method

InactiveCN101150217AStrong controllabilityStrong magnetic resonanceWaveguide type devicesDielectricBand-pass filter

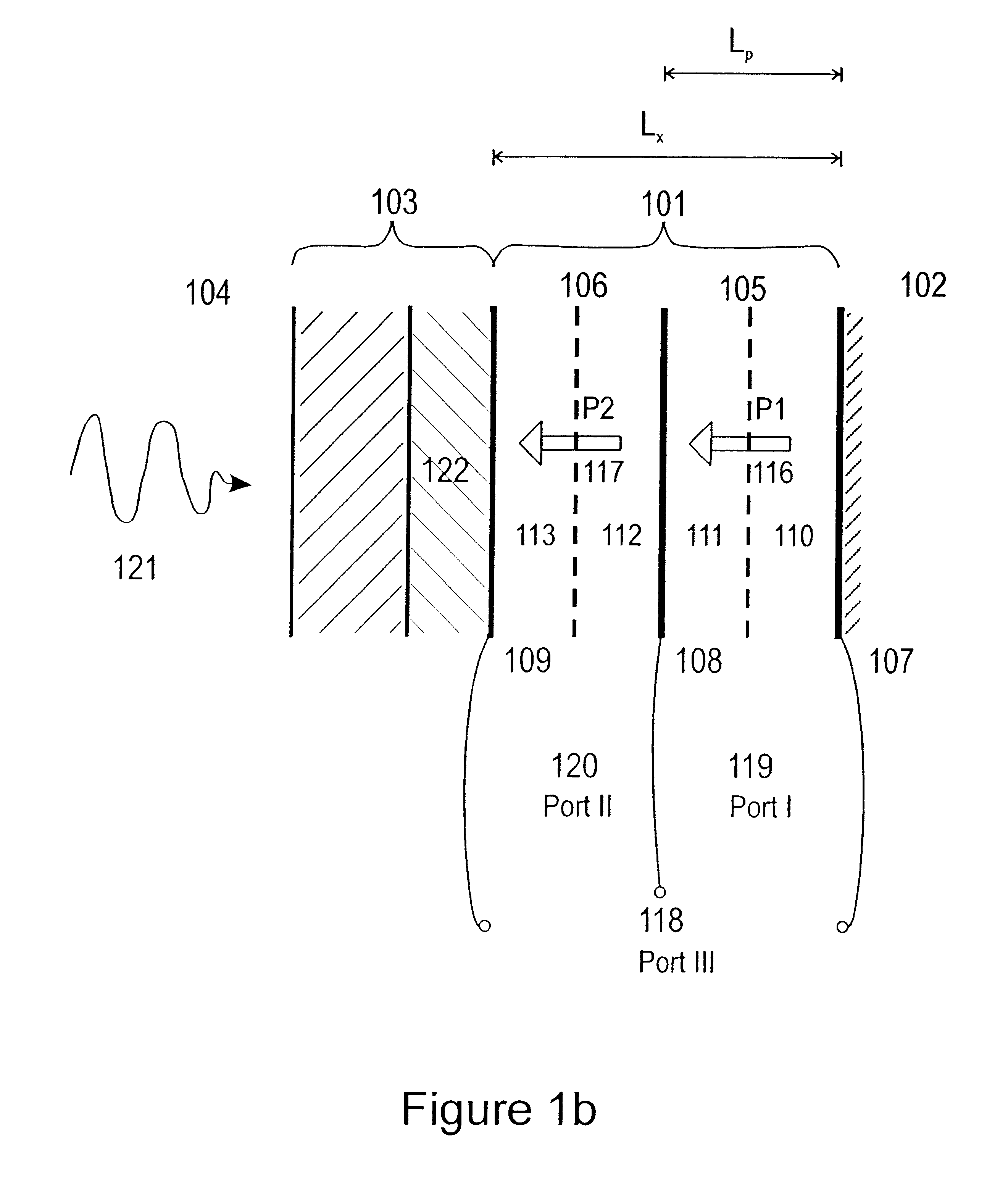

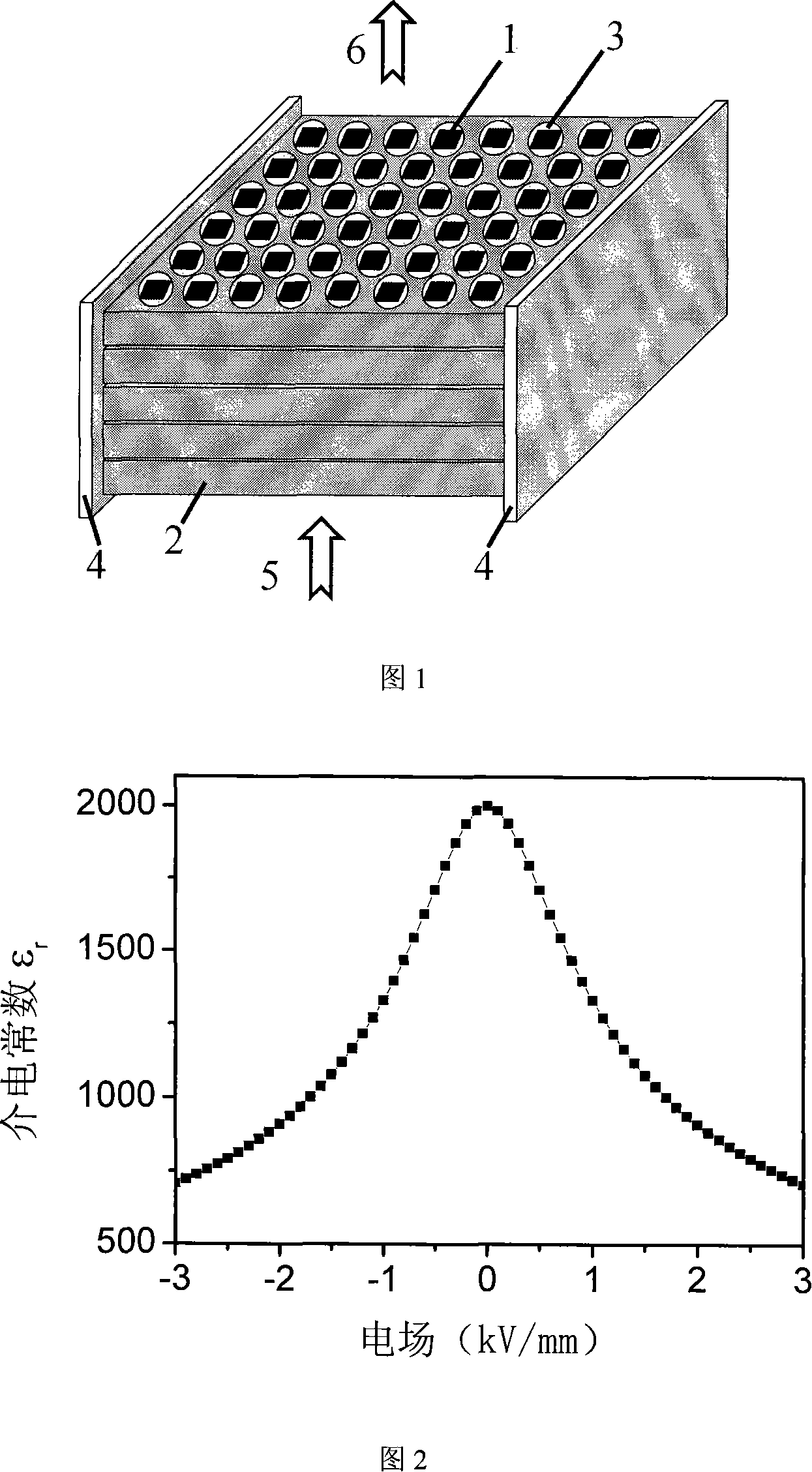

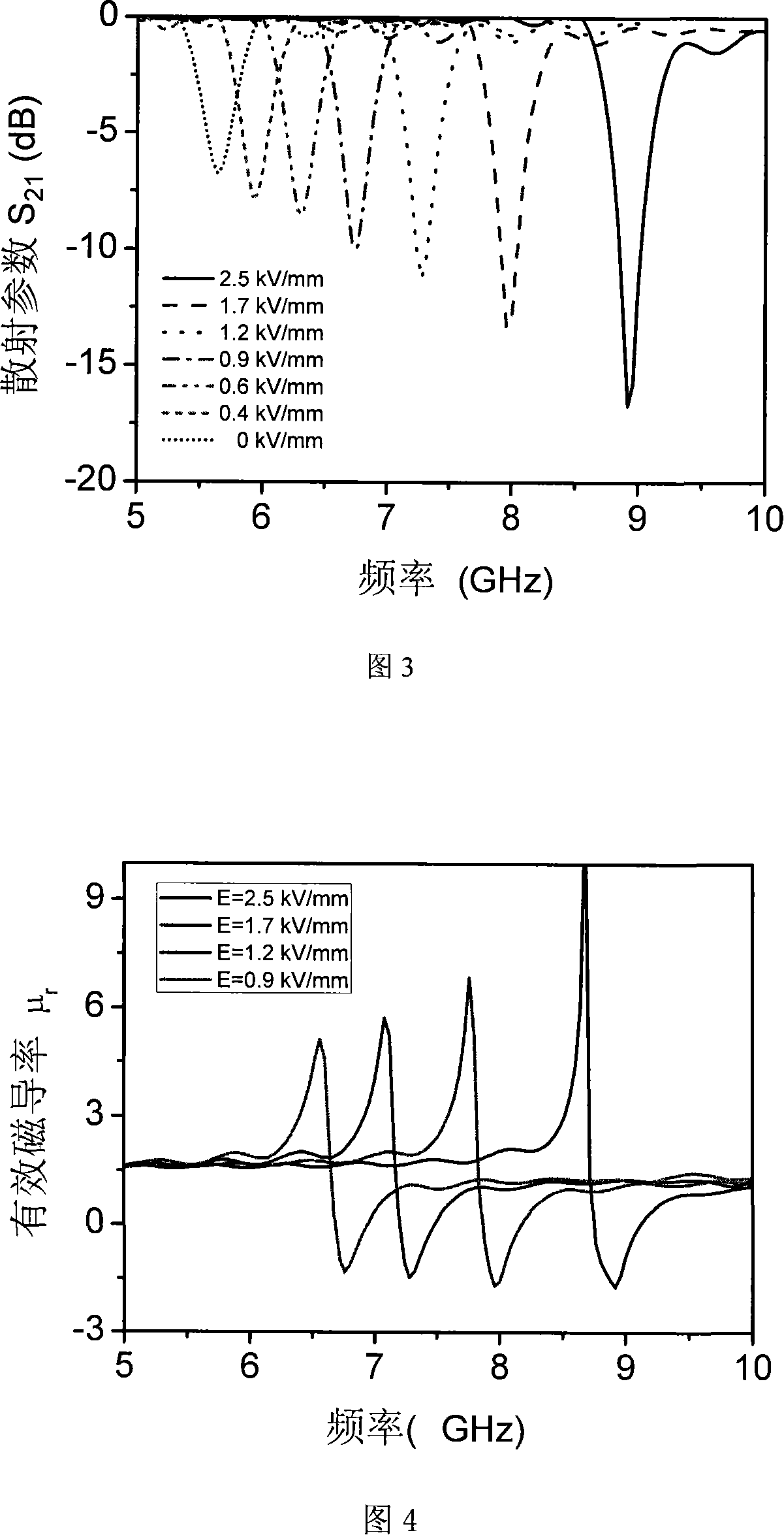

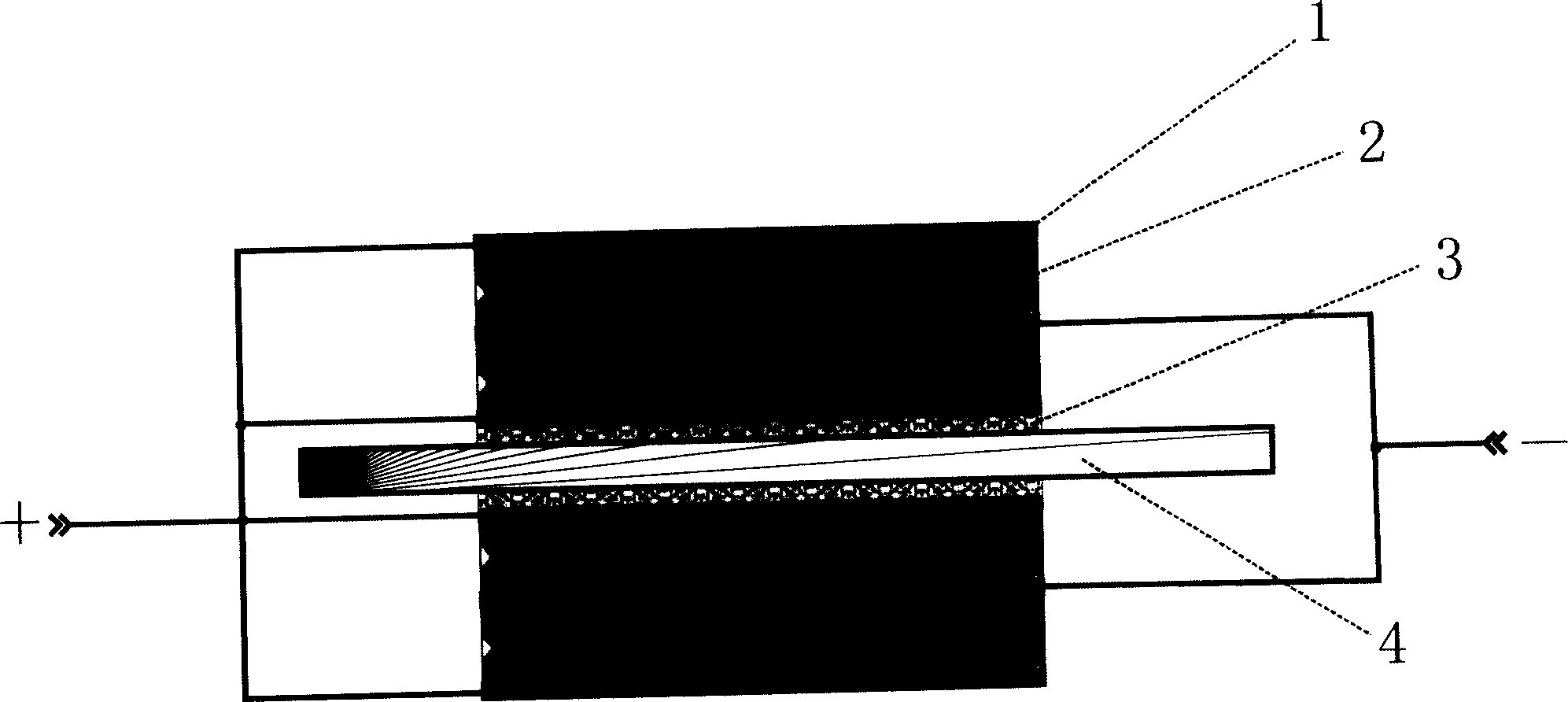

This invention relates to a negative permeability device with adjustable electric field based on ferroelectric ceramic particles and its preparation method, in which, the device is composed of two parallel metal pole plates, multiple laminated teflon templates set between the two pole plates, ferroelectric ceramic particles and DC supply, in which, a hole array is set on each teflon template filled with the particles, and the device can drive electromagnetic waves to generate strong magnetic resonance at a certain band and have isotropical negative permeability effect adjacent to the magnetic resonance to realize controlling negative magnetic conductivity and utilizes the adjustment property of field to dielectric constant of ferroelectric ceramic particles to realize controlling its negative permeability.

Owner:TSINGHUA UNIV

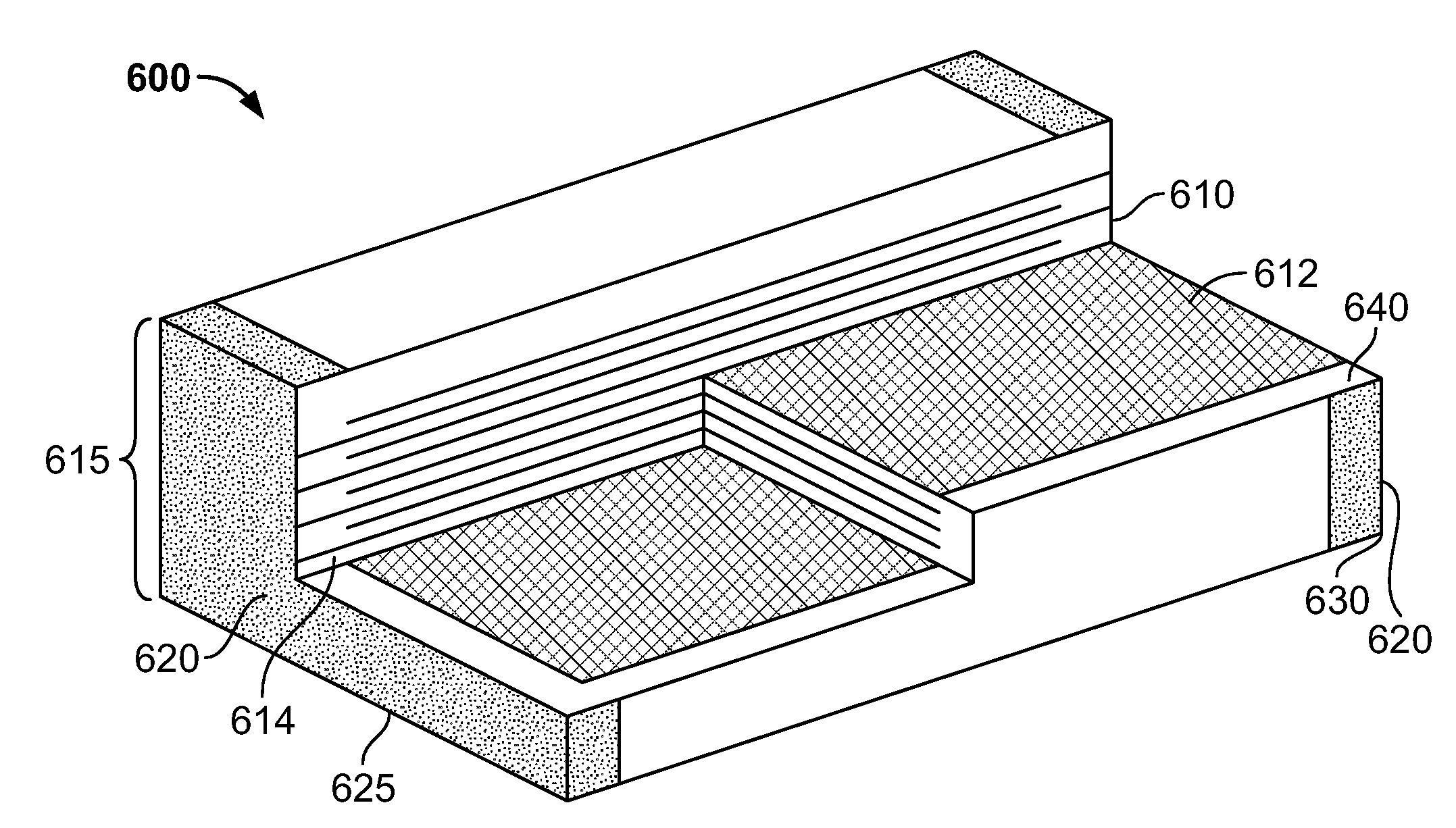

Antiferroelectric multilayer ceramic capacitor

InactiveUS20090207555A1Increase energy densityHigh materialFixed capacitor dielectricStacked capacitorsMetallurgyCeramic capacitor

Owner:TRS TECH

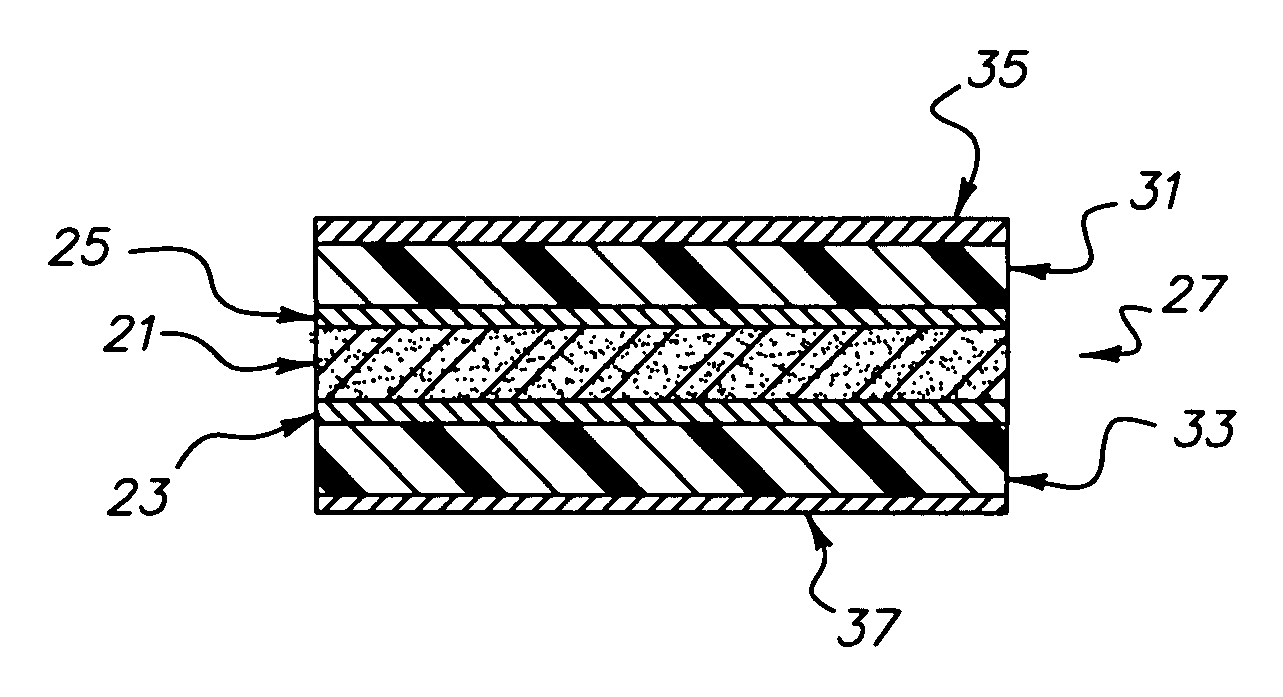

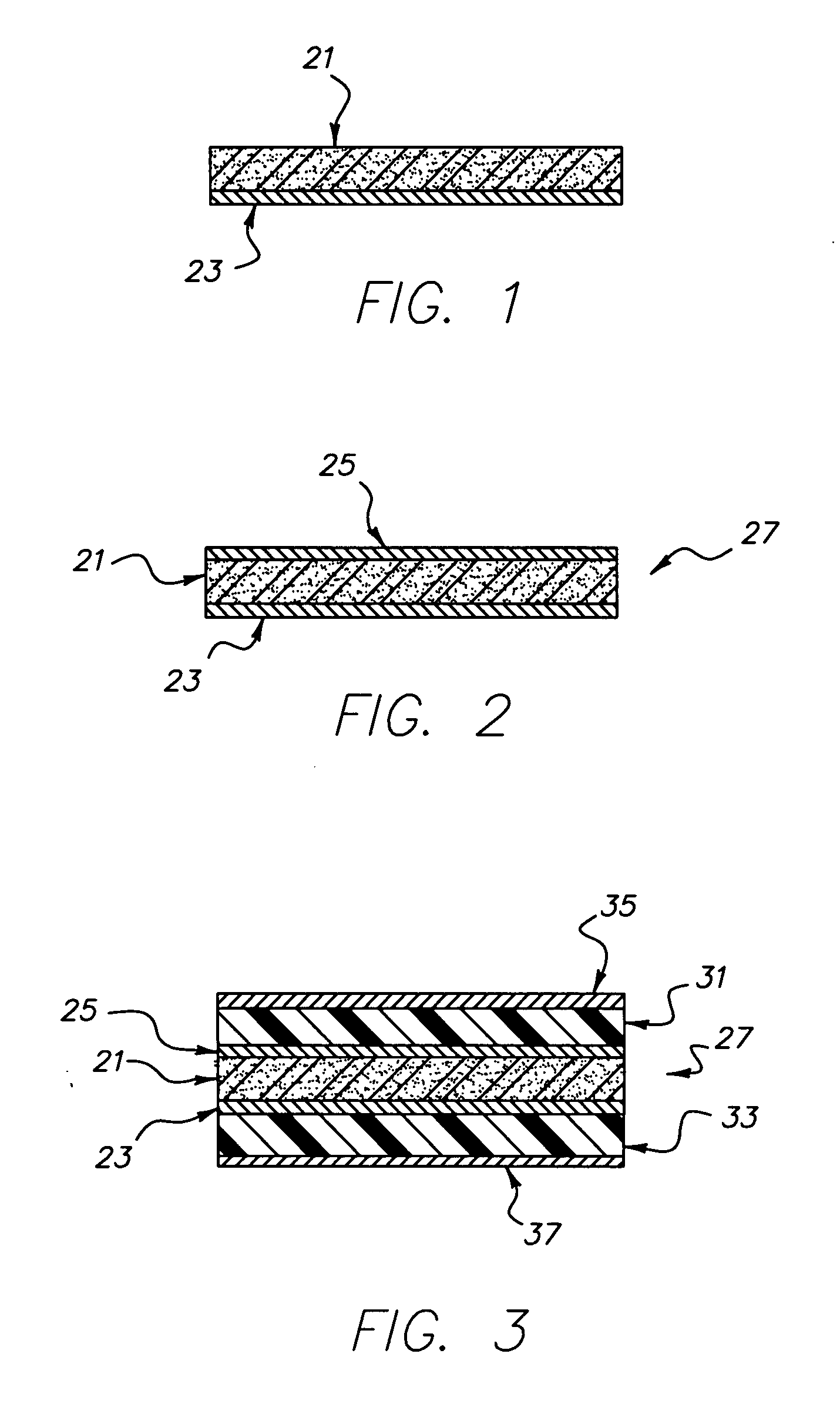

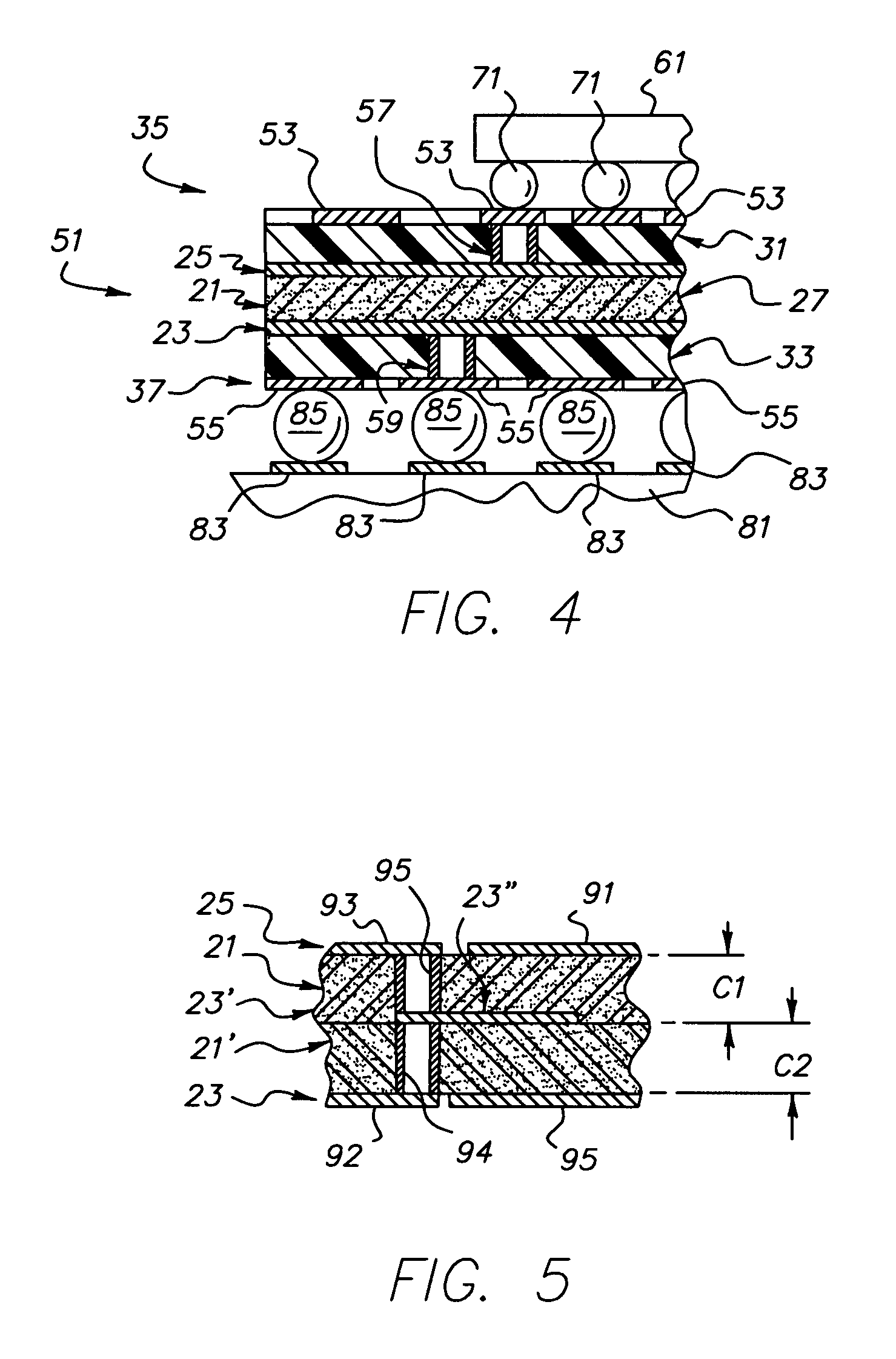

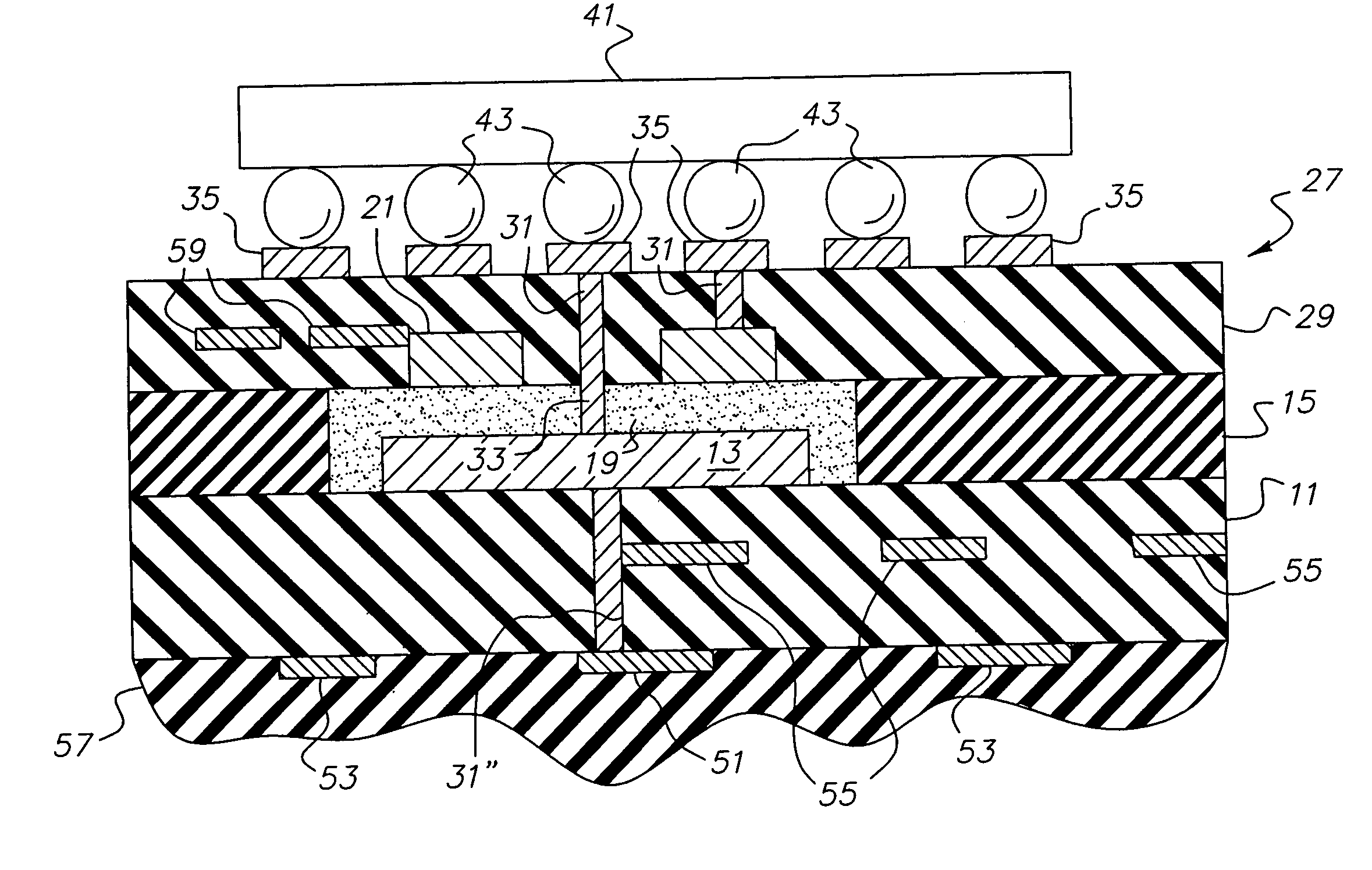

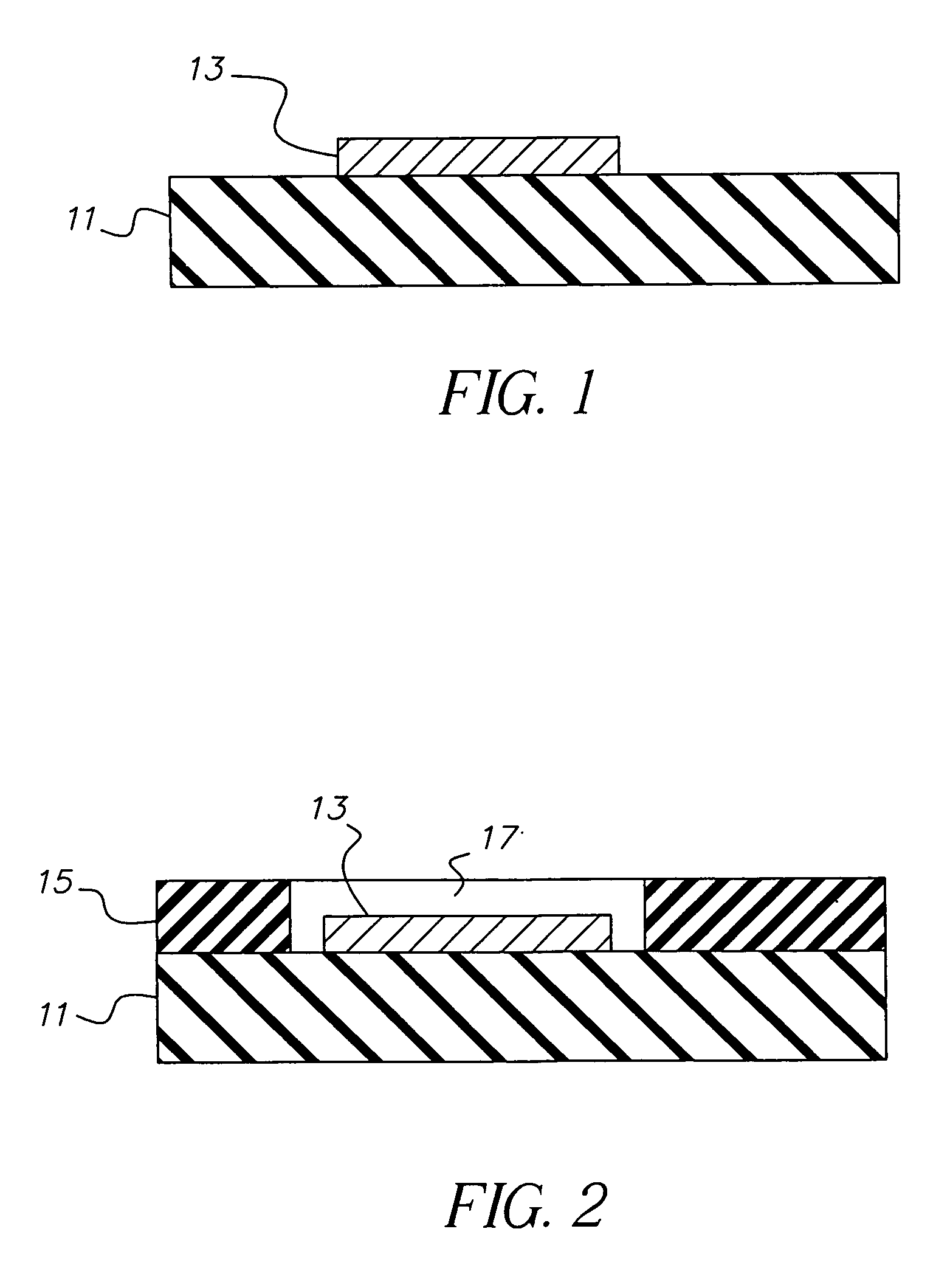

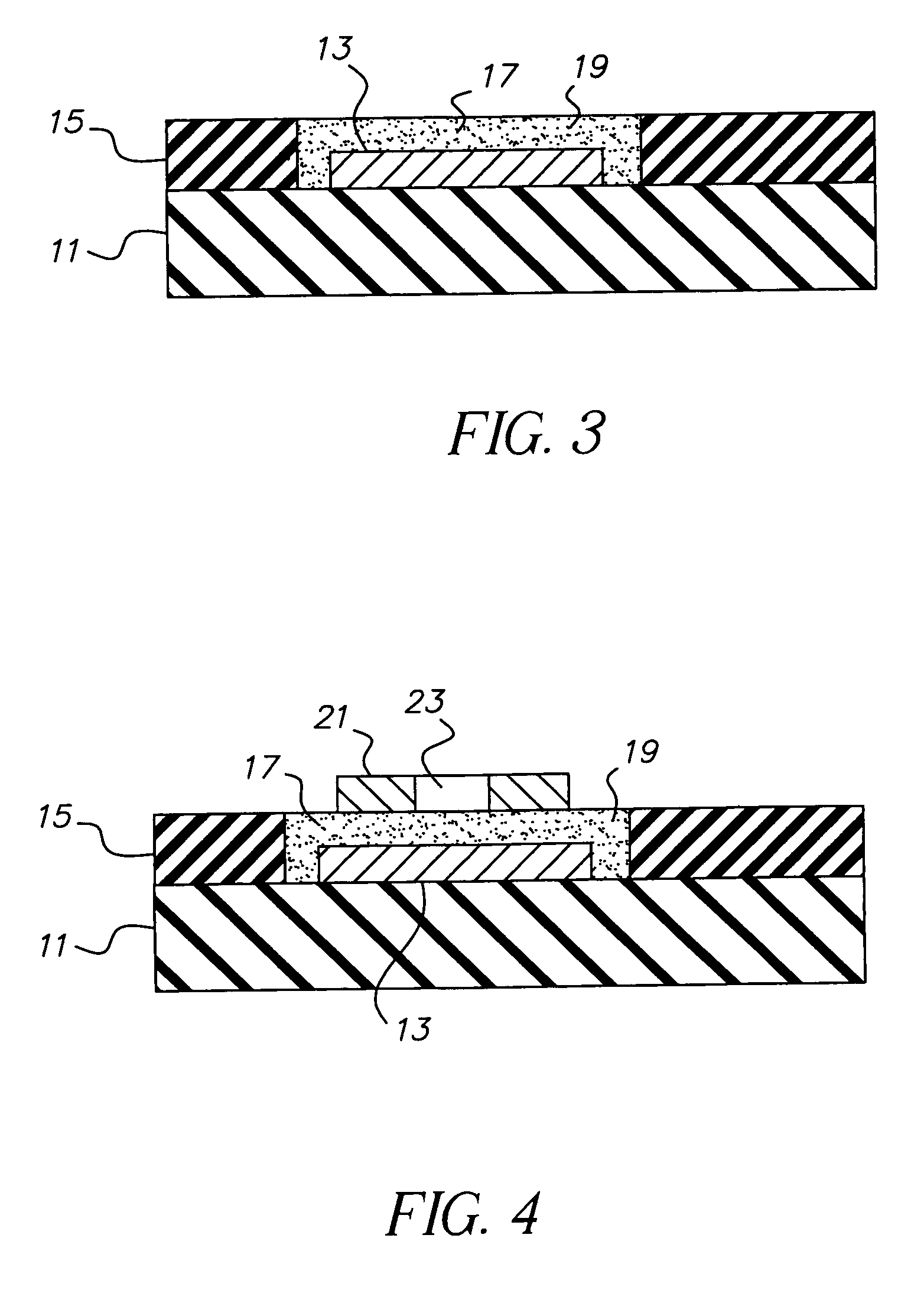

Non-flaking capacitor material, capacitive substrate having an internal capacitor therein including said non-flaking capacitor material, and method of making a capacitor member for use in a capacitive substrate

InactiveUS20070177331A1Enhance circuitized substrate artLow costThin/thick film capacitorPrinted circuit aspectsEpoxyCapacitance

A capacitor material including a thermosetting resin (e.g., epoxy resin), a high molecular mass flexibilizer (e.g., phenoxy resin), and a quantity of nano-particles of a ferroelectric ceramic material (e.g., barium titanate), the capacitor material not including continuous or semi-continuous fibers (e.g., fiberglass) as part thereof. The material is adapted for being positioned in layer form on a first conductor member and heated to a predetermined temperature whereupon the material will not possess any substantial flaking characteristics. A second conductor member may then be positioned on the material to form a capacitor member, which then may be incorporated within a substrate to form a capacitive substrate. Electrical components may be positioned on the substrate and capacitively coupled to the internal capacitor.

Owner:I3 ELECTRONICS

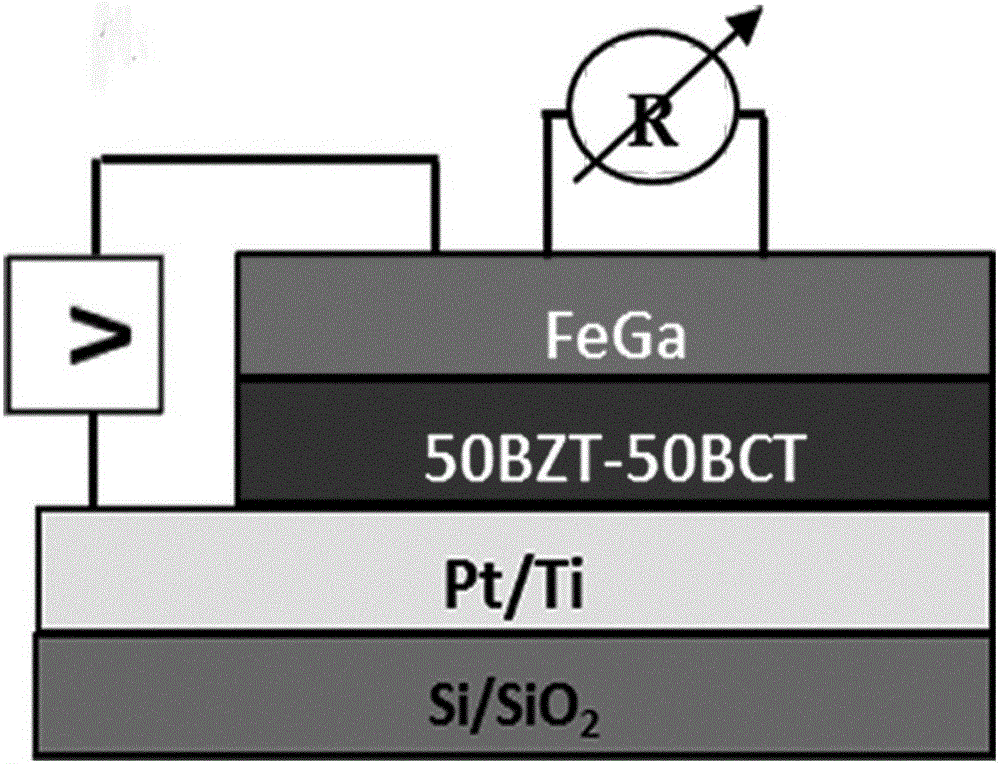

Magnetoelectric effect based magnetoelectric memory element of ferroelectric/ferromagnetic composite thin film

InactiveCN105720188AReduce power consumptionFast reading and writingMagnetic-field-controlled resistorsVacuum evaporation coatingVoltageFerroelectric ceramics

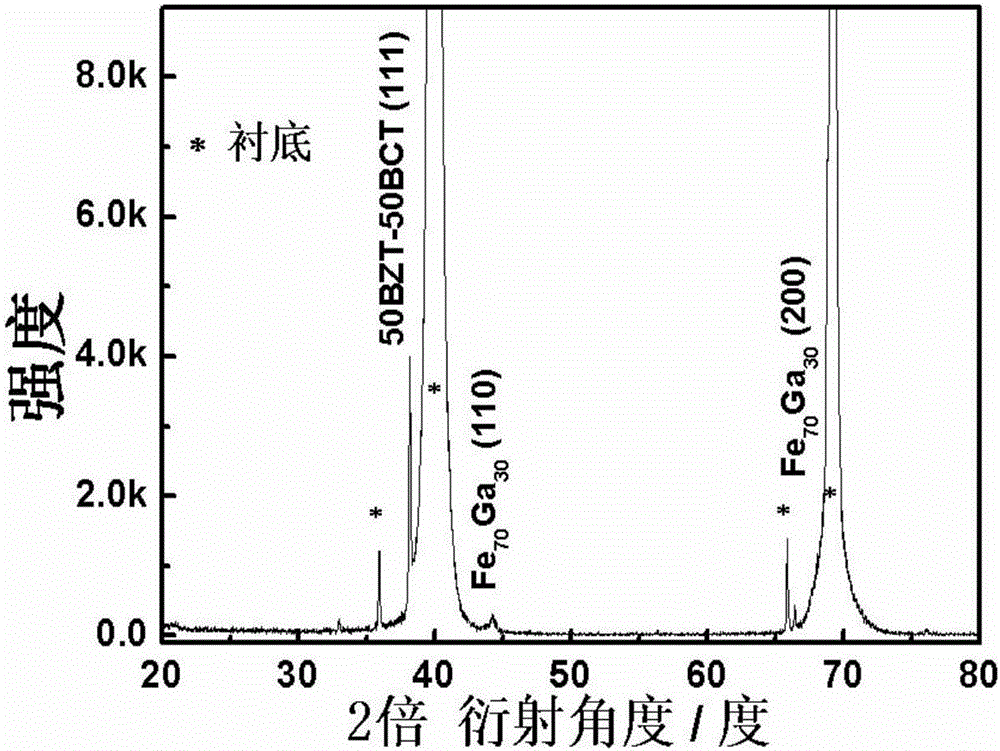

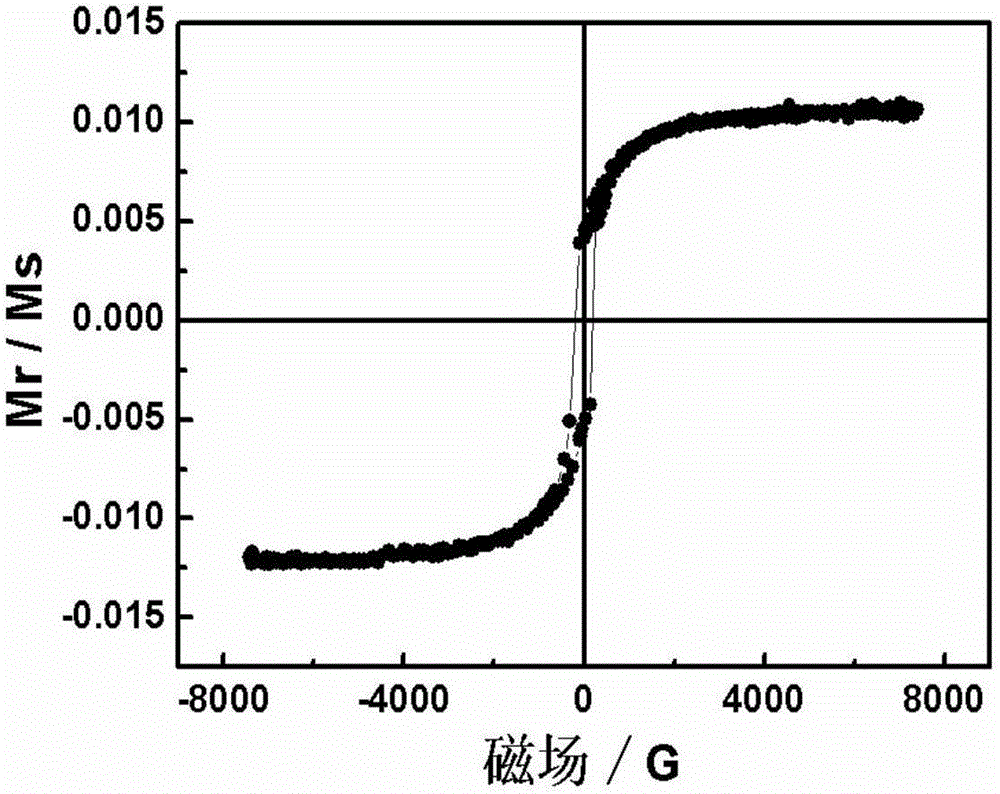

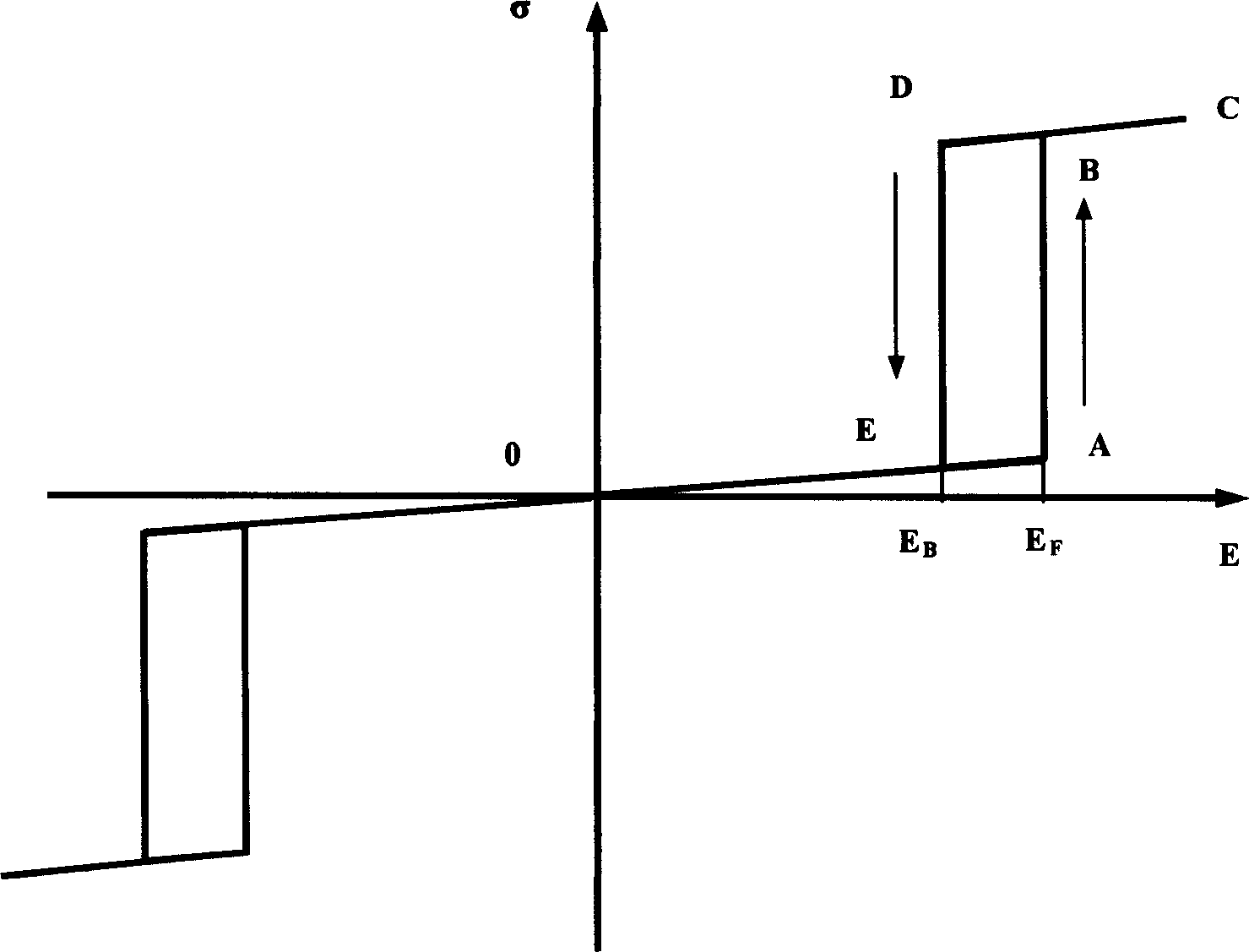

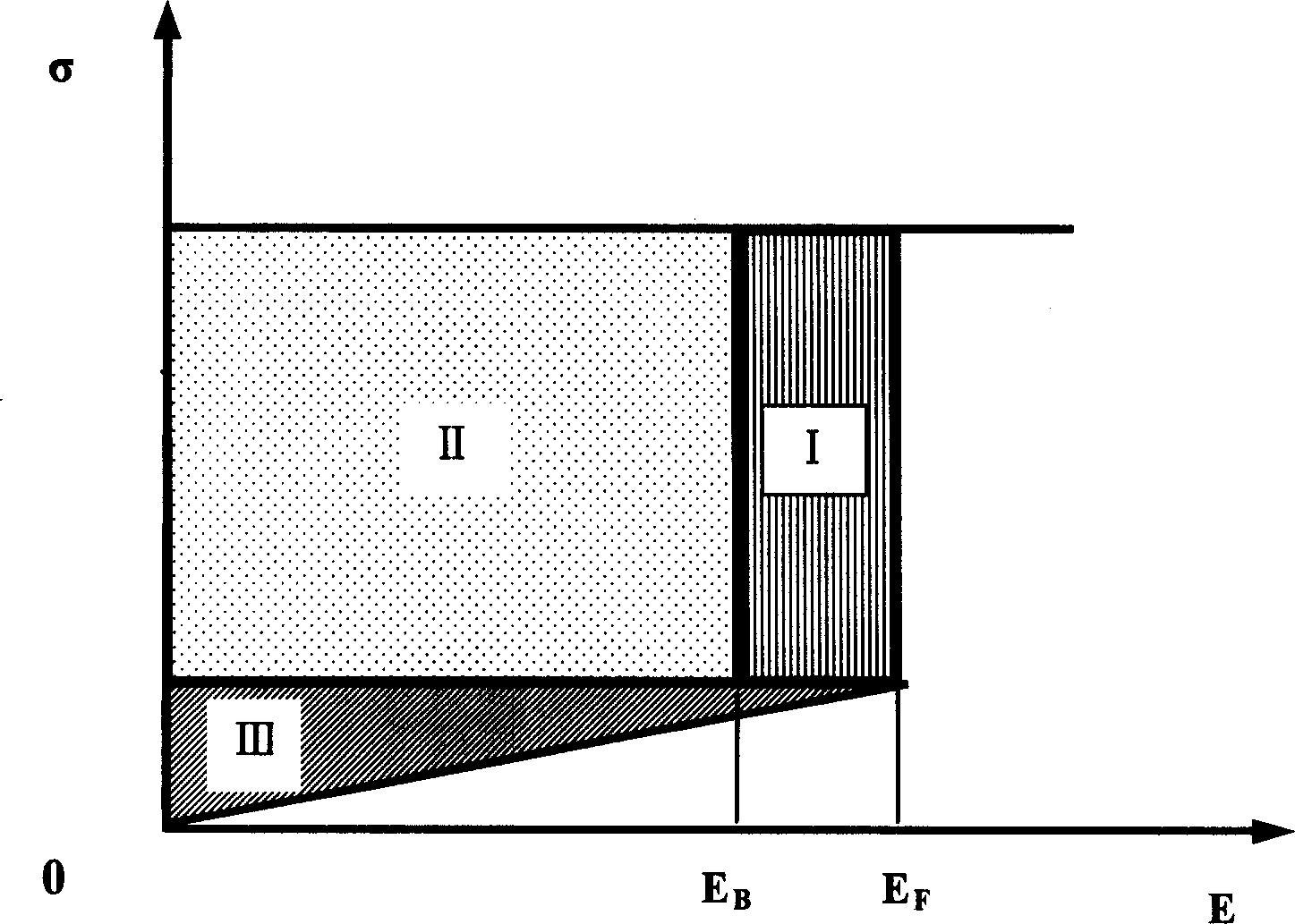

Disclosed is a magnetoelectric effect based magnetoelectric memory element of a ferroelectric / ferromagnetic composite thin film. Ferroelectric and ferromagnetic thin films are deposited on a Pt / Ti / SiO<2> / Si composite substrate in sequence to prepare a laminated structure; the chemical structural formula of the ferroelectric thin film with a piezoelectric effect is 0.5Ba(Zr<0.2>Ti<0.8>) O<3>-0.5(Ba<0.3>Ca<0.7>)TiO<3>(BZT-BCT); the thin film with a magnetostrictive effect is Fe<0.7>Ga<0.3>; the preparation method comprises the steps of preparing the ferroelectric ceramic thin film through radio frequency magnetron sputtering, and preparing the ferromagnetic thin film by direct current magnetron sputtering. The magnetoelectric effect based magnetoelectric memory element has the advantages as follows: the memory element is nonvolatile, capable of keeping the polarized and magnetized states under externally-applied voltage, and low in power consumption; the memory unit has good ferroelectric, piezoelectric and ferromagnetic performances at the room temperature; and the maximum electric field control magnetic resistance effect 6% is obtained when the externally applied bias voltage is 20V.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

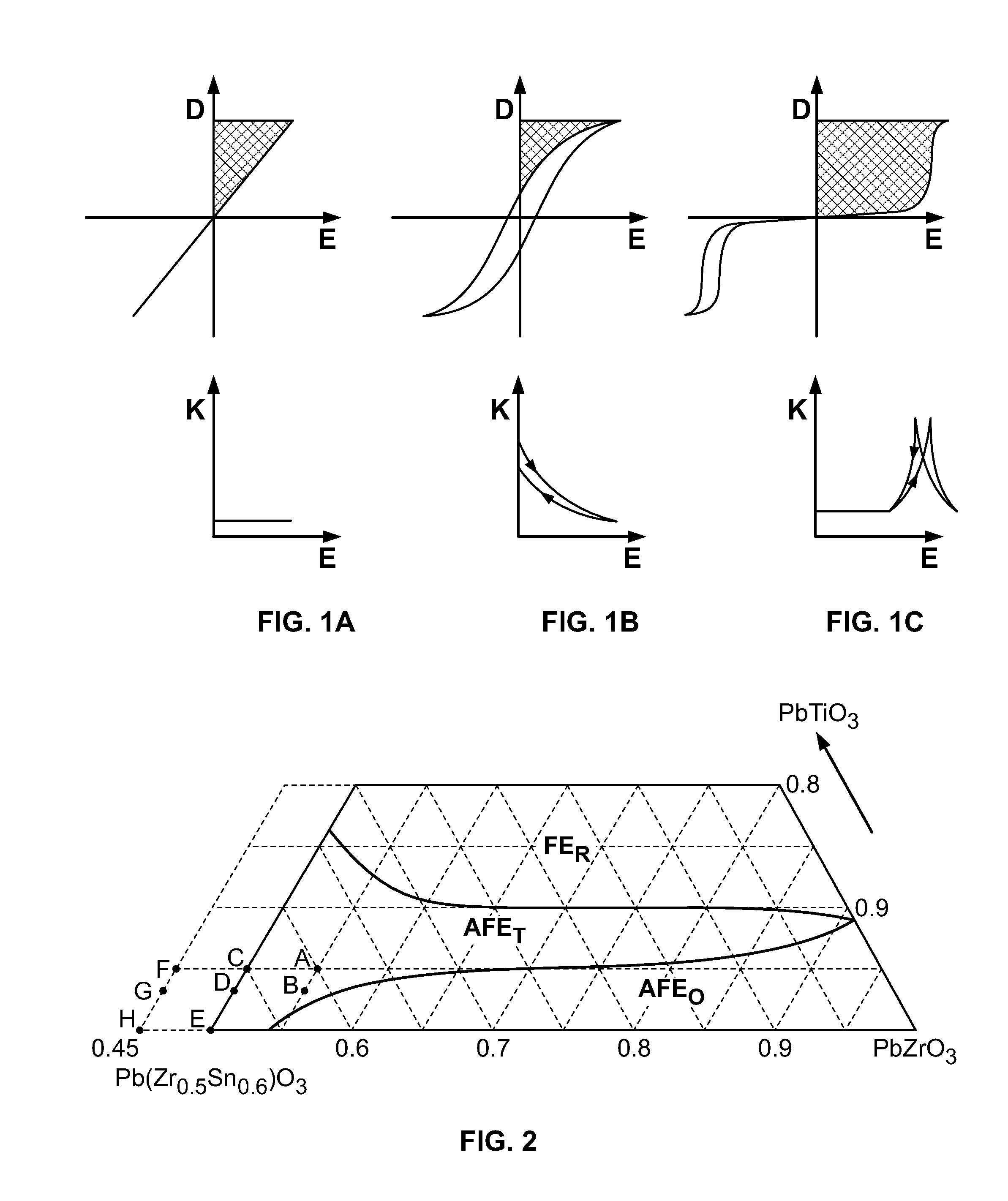

Dielectric nonlinear capacitor ceramic material and its making technique

InactiveCN1688004AHigh energy storage densityIncrease the number of cyclesFixed capacitor dielectricCeramicsLead zirconate titanateStrontium

This invention discloses an anti-ferroelectric ceramic capacitor material and its preparation technology, which applies Sn of positive four valency to replace Zr of positive 4 valency, applies the positive 3 valency La to replace 2 valency Pb in the compound of Pb(Zr, Ti) O3 to form a multi-component solid solution with Pb vacancy. The balanced formula of the charge and the valency is: (Pb1-3 2 / 2Laz)[(Zri-ysny)1-Tix]O3, in which, x varies between 0.06`0.20, y: 0.2010.40, z varies between 0.02-0.08, or positive 2 valency Sr or Ba is added to replace 2 valency Pb in Pb(zr, Ti) O3, the formula is [(Pb1-wBw)1-3z / 2Laz][Zr1-ySny]1-xTix ]O3, B expresses Sr or Ba of 2 valency, w varies between 0.02-0.12. A conventional electronic ceramic preparation method is applied in the method.

Owner:XI AN JIAOTONG UNIV

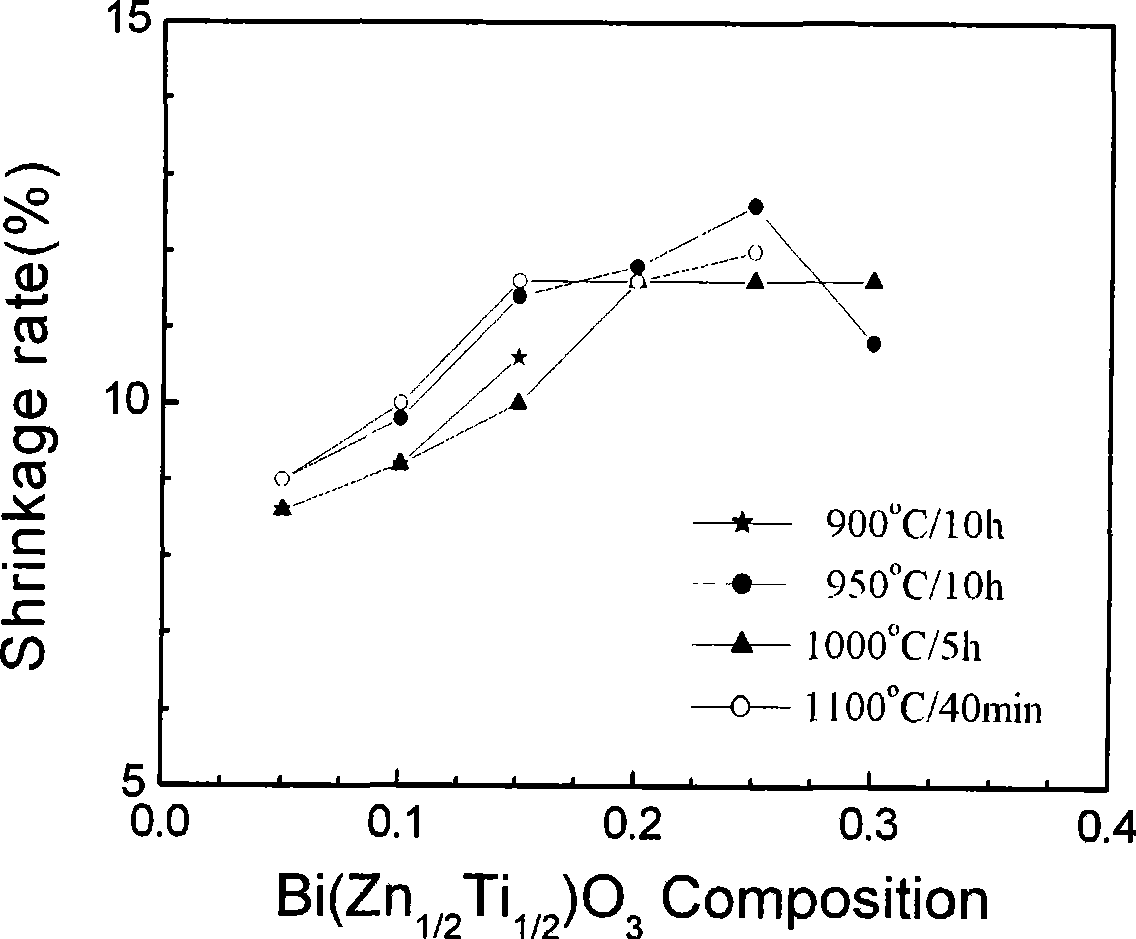

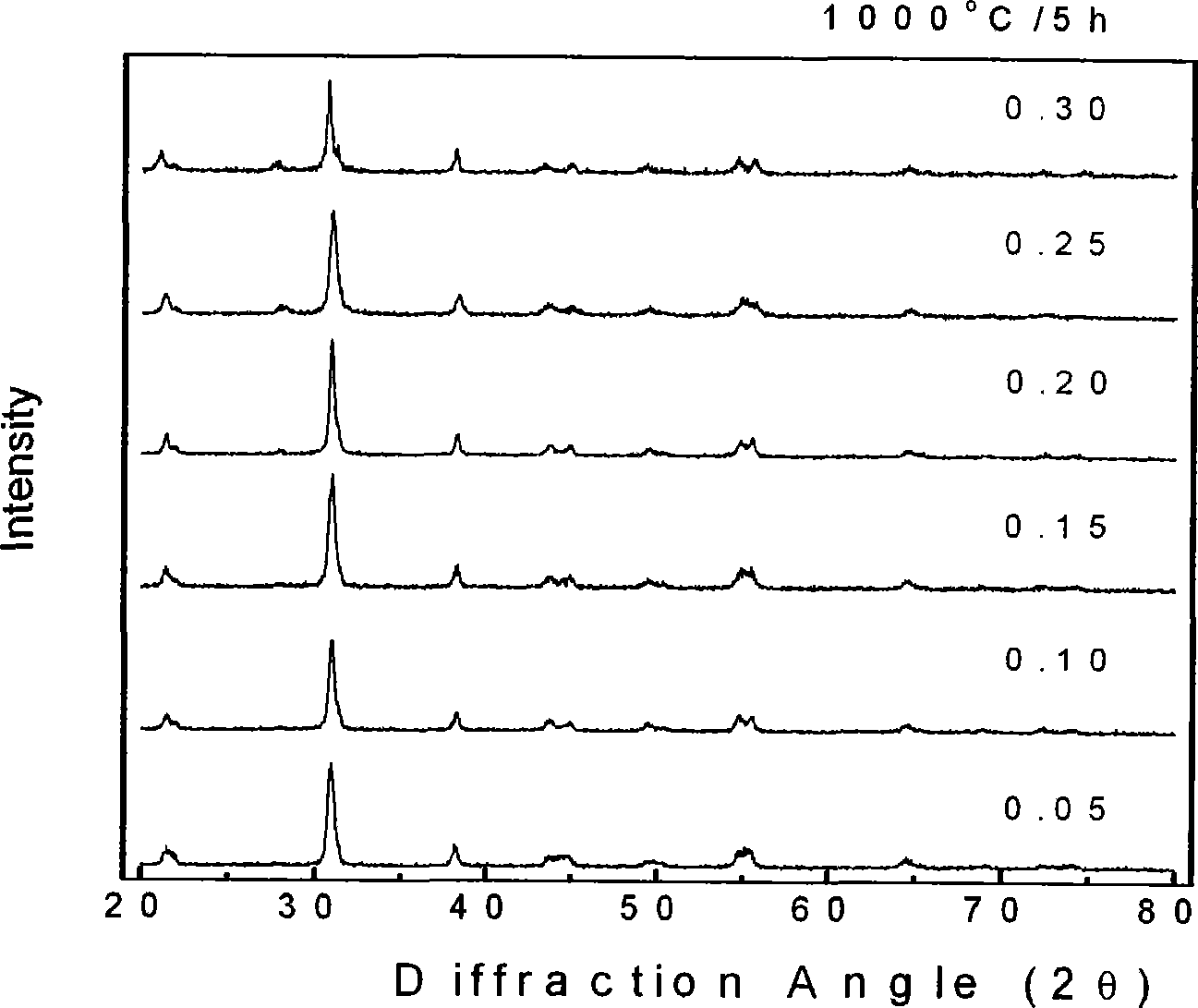

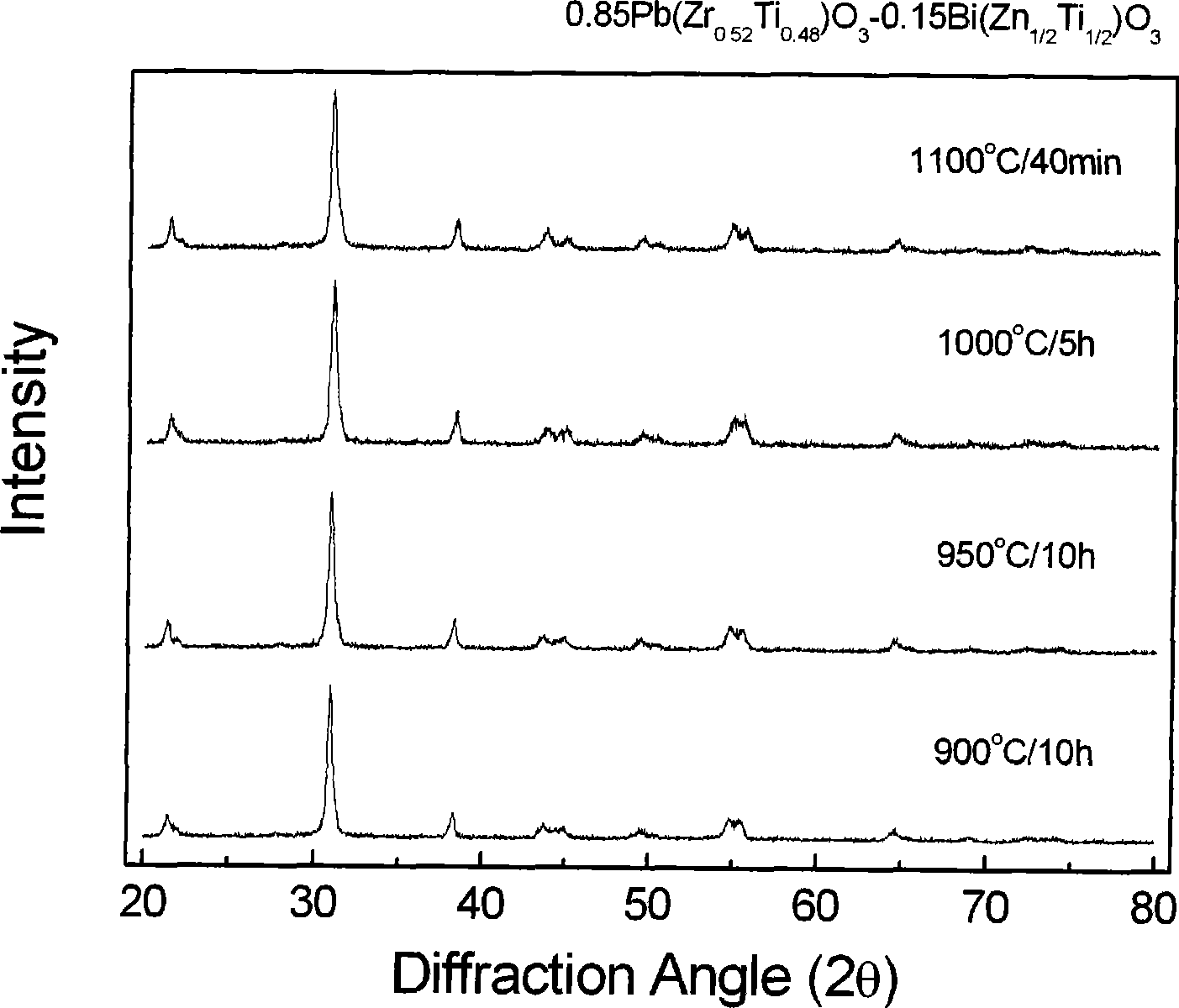

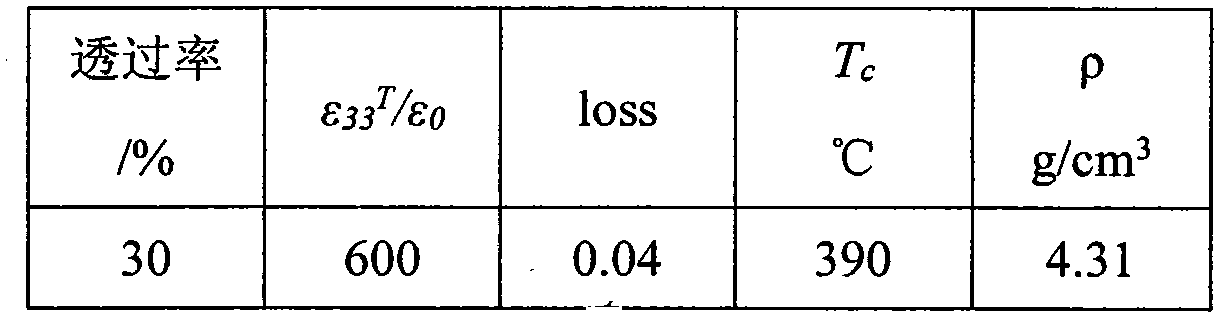

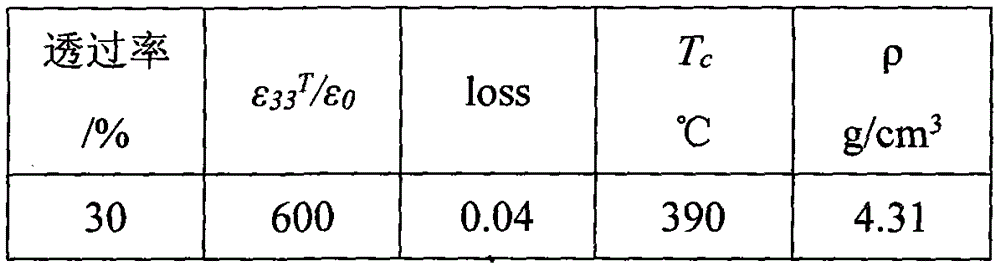

Ferro-voltage ceramic component with low sintering temperature character, production and uses thereof

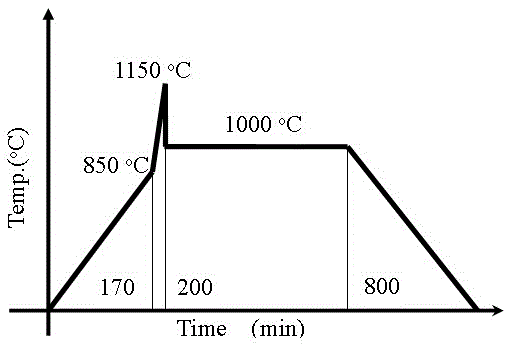

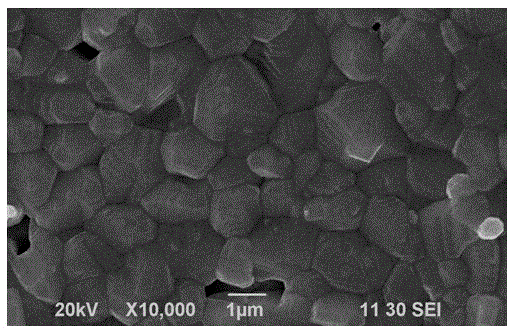

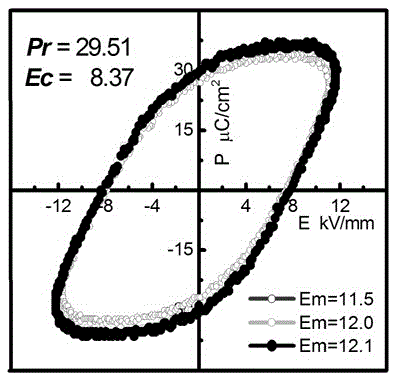

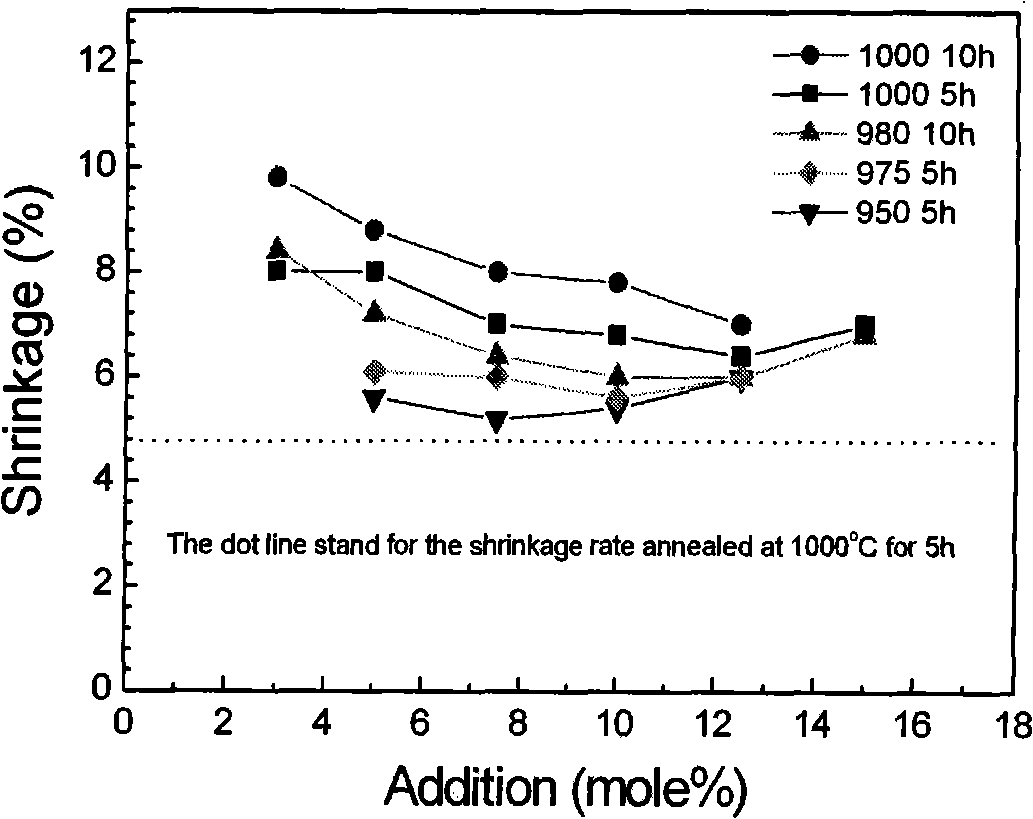

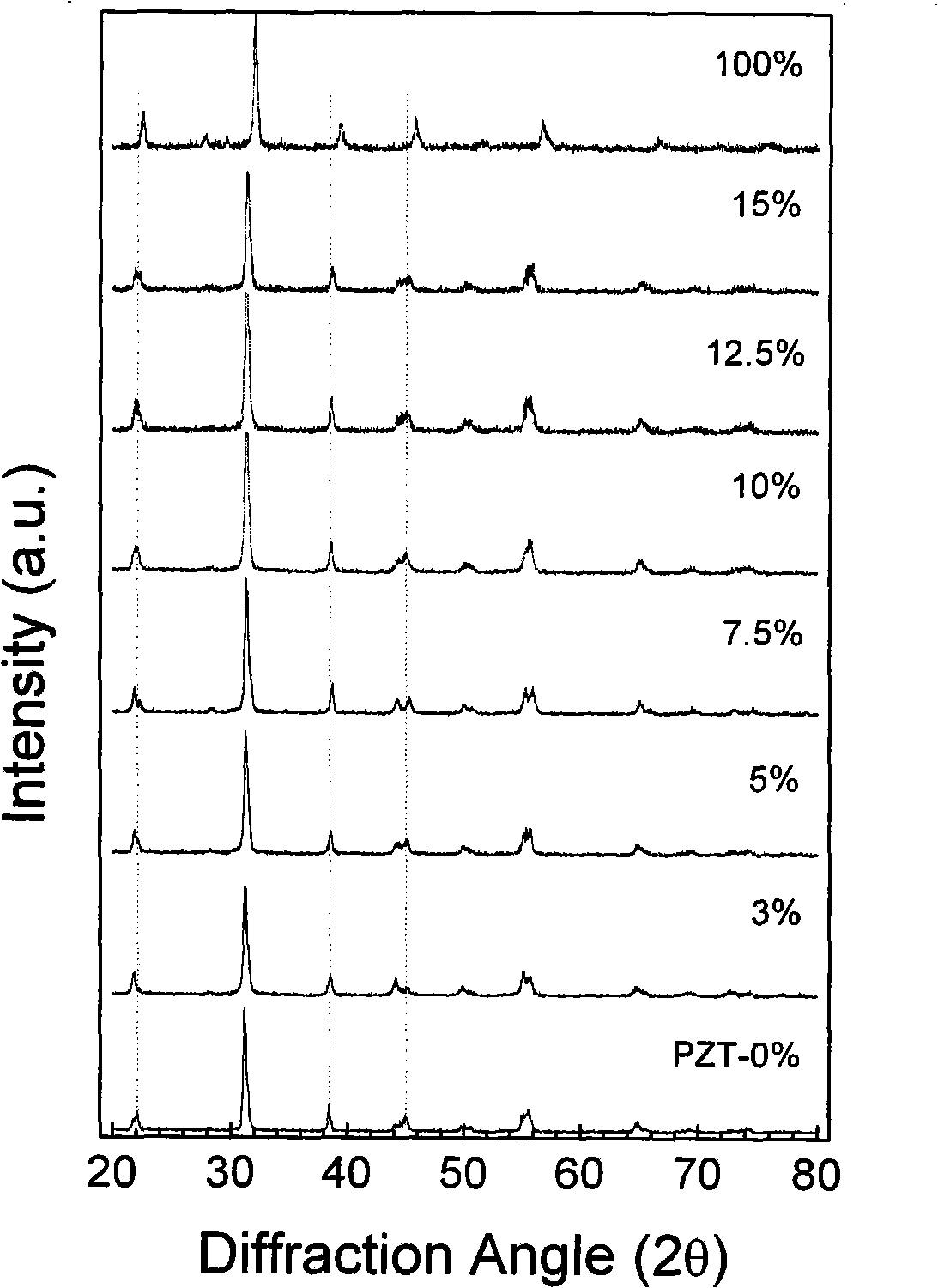

InactiveCN101429022ALower sintering temperatureReduce volatilityPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateElectricity

The invention relates to a ferroelectric piezoelectric ceramic with the characteristic of low sintering temperature. The compositions are (1-x-y)PbZrO3-xPbTiO3-yBi(Zn1 / 2Ti1 / 2)O3 and z weight percent of MnO2, wherein x is equal to between 0.30 and 0.50, y is equal to between 0.05 and 0.25, and z is equal to between 0.0 and 0.5. Oxide materials and the prior solid-state reaction electronic ceramic process are adopted to achieve the aim of sintering a compact piezoelectric ceramic chip at a low temperature between 900 and 1,000 DEG C. The PbZrO3-PbTiO3-Bi(Zn1 / 2Ti1 / 2)O3 ferroelectric piezoelectric ceramic is a single phase perovskite structure and has a 'hard' piezoelectric property. Presintering powder of the PbZrO3-PbTiO3-Bi(Zn1 / 2Ti1 / 2)O3 ferroelectric ceramic powder as a sintering auxiliary, and an electronic ceramic process of solid phase reaction are adopted so as to achieve the low temperature sintering of the strontium-doped lead zirconate titanate at a temperature of 1,050 DEG C as well as the modification of the piezoelectric property. The ferroelectric piezoelectric ceramic is particularly applicable to the manufactures of functional devices such as emission piezoelectric ceramic devices, low-temperature cofiring multi-layer ceramic piezoelectric drives, transformers, and transducers.

Owner:TONGJI UNIV

Dielectric elastomer material and method for preparing same

InactiveCN101250327AEasy to prepareEasy to operatePlastic/resin/waxes insulatorsElectricityPlasticizer

Owner:HARBIN INST OF TECH

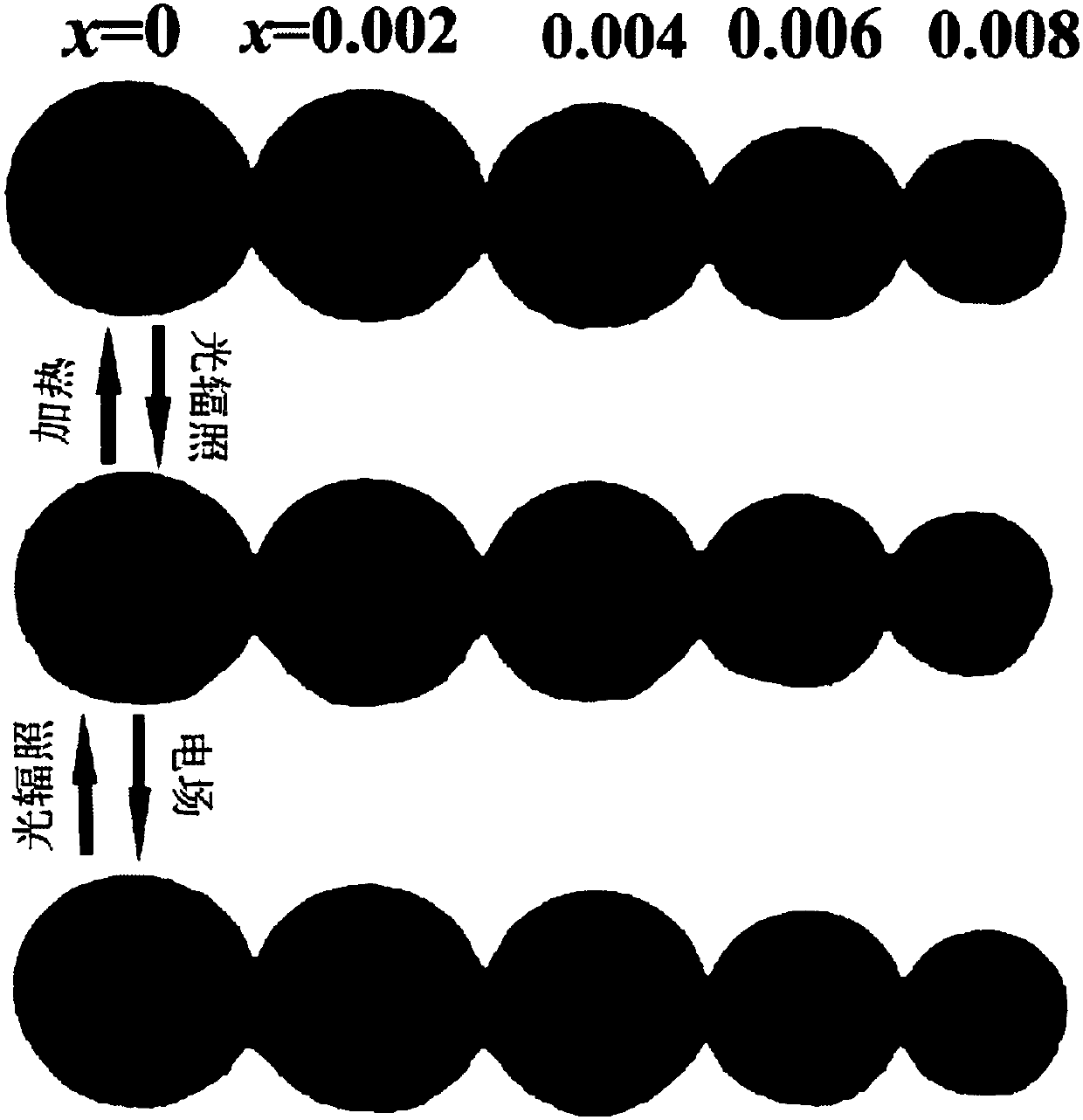

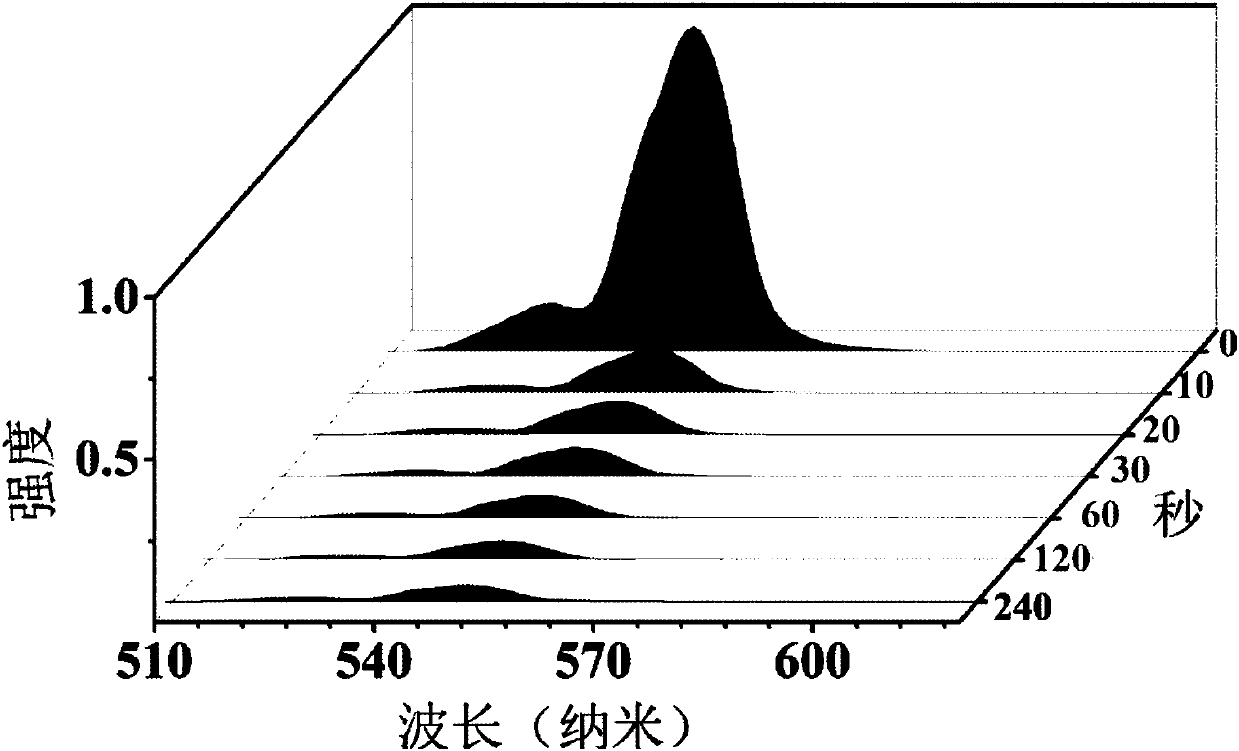

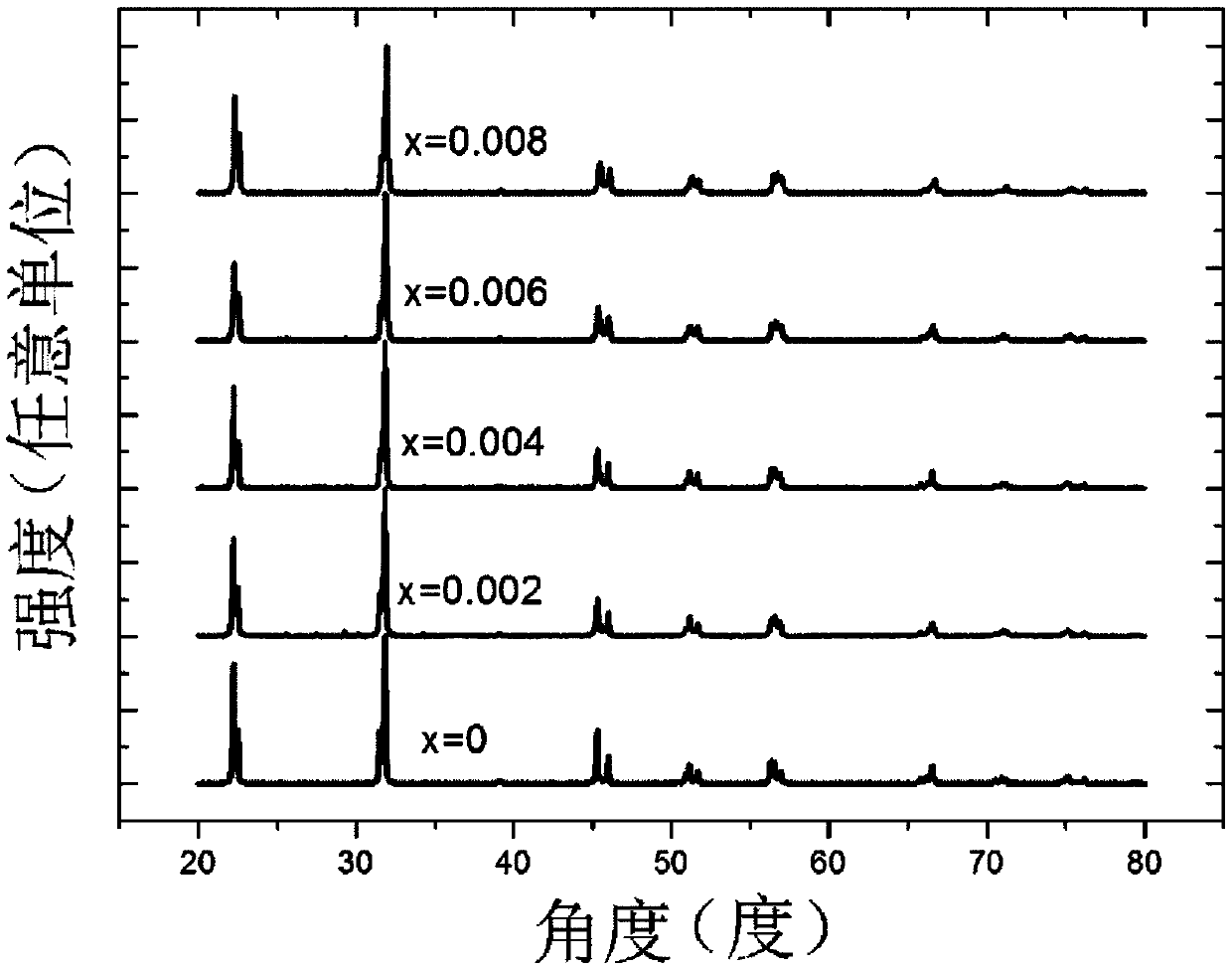

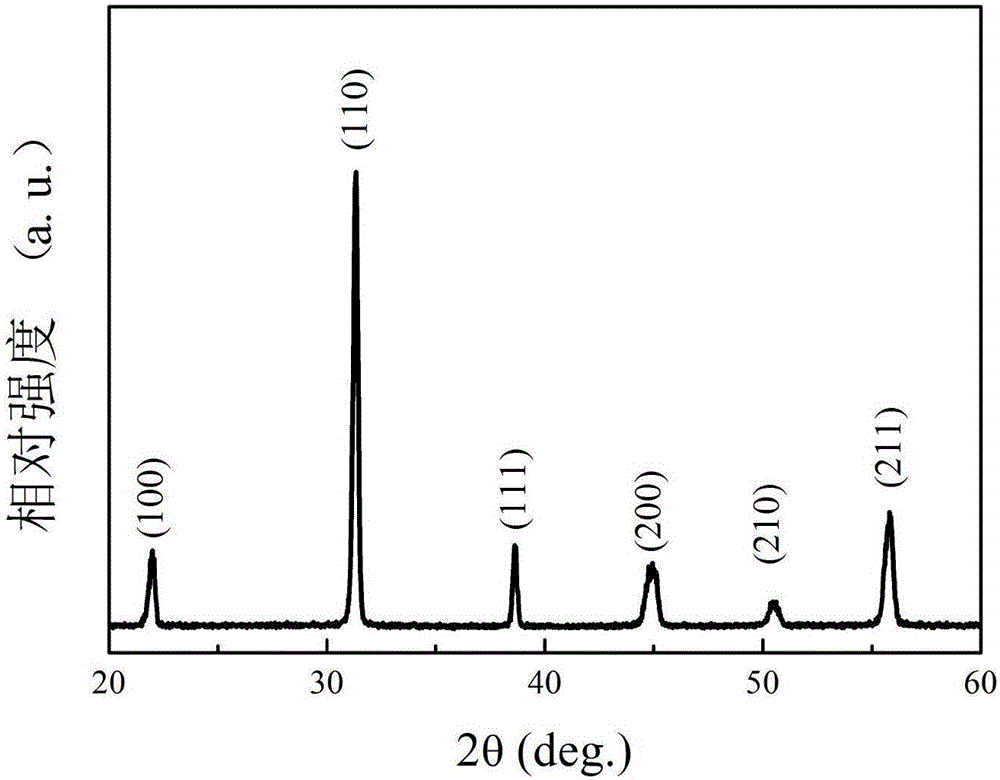

Lead-free ferroelectric photochromic material based on rare earth doping and preparation method and application thereof

ActiveCN108017390ALow costGood physical and chemical stabilityLuminescent compositionsRare-earth elementIon

The invention relates to a lead-free ferroelectric photochromic material. The material includes a lead-free ferroelectric ceramic material, wherein (K0.5Na0.5)NbO3 is as a matrix of the lead-free ferroelectric ceramic material, the material is characterized in that a chemical formula of the lead-free ferroelectric ceramic material is (K0.5Na0.5)0.998-xEr0.002YbxNbO3, wherein x is greater than 0.002 or equal to 0.002 and less than 0.008 or equal to 0.008, by adding rare earth element sensitizer Yb3+ at an A site and activating Er3 with rare earth element, K+ and N+ ions are replaced, and then up-conversion luminescence of the material is achieved. Compared with the prior art, the lead-free ferroelectric photochromic material has the advantages that the cost of raw materials for preparationof the matrix material is lower, the anti-fatigue performance of discoloration is good, the color change degree of inorganic photochromic material can be efficiently adjusted by the codoping of rare earth element so as to meet the needs of different applications.

Owner:东营睿港投资服务有限责任公司

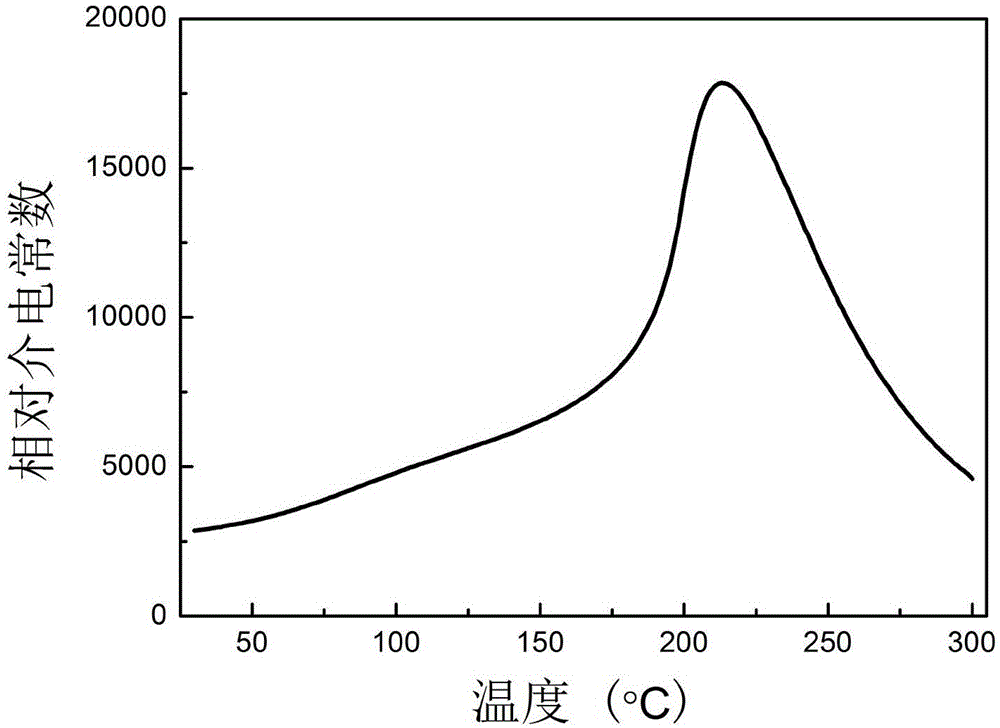

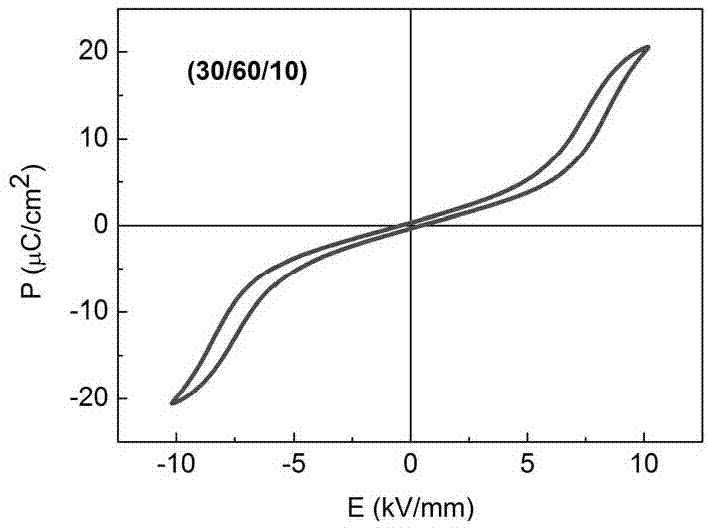

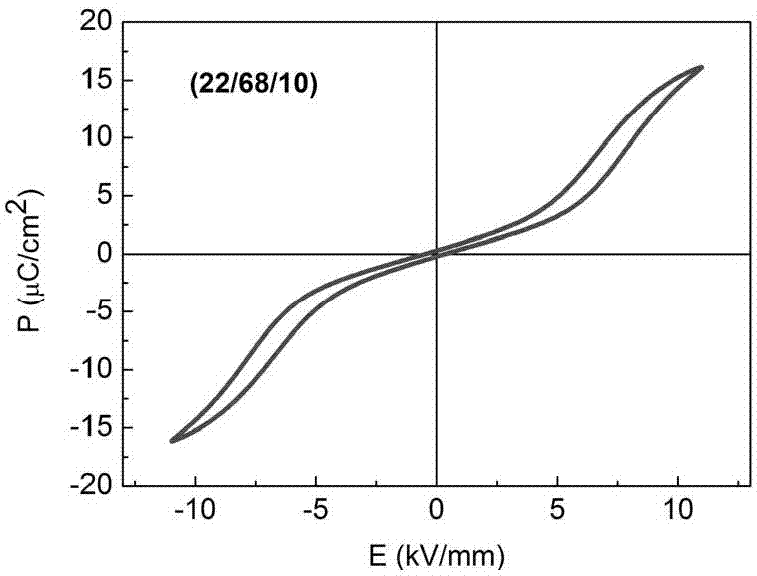

Low-temperature sintered ternary system relaxor ferroelectric ceramic material, preparation method and application of low-temperature sintered ternary system relaxor ferroelectric ceramic material

ActiveCN105084898AHigh curie temperatureImproved high-field piezoelectric performanceCeramic sinteringMetallurgy

The invention relates to a low-temperature sintered ternary system relaxor ferroelectric ceramic material, a preparation method and application of the low-temperature sintered ternary system relaxor ferroelectric ceramic material. The problems that existing PIN-PMN-PT ceramic sintering temperature is high, environmental pollution is caused by severe lead volatilization, the material performance is reduced, and the production cost is high are solved. The chemical general formula of the ceramic material is xPb(In1 / 2Nb1 / 2)O3-(1-x-y)Pb(Mg1 / 3Nb2 / 3)O3-yPbTiO3-awt.%CuO. The method includes the steps of firstly, conducting a solid-phase reaction to synthesize a precursor of MgNb2O6; secondly, conducting a solid-phase reaction to synthesize a precursor of InNbO4; thirdly, conducting a solid-phase reaction to synthesize matrix powder of PIN-PMN-PT; fourthly, preparing low-temperature sintered ternary system relaxor ferroelectric ceramic through the combination of the solid-phase synthesis technology and the curtain coating lamination process. The low-temperature sintered ternary system relaxor ferroelectric ceramic material, the preparation method and the application are used for preparing high-power piezoelectric buzzers and multi-layer piezoelectric devices.

Owner:HARBIN INST OF TECH

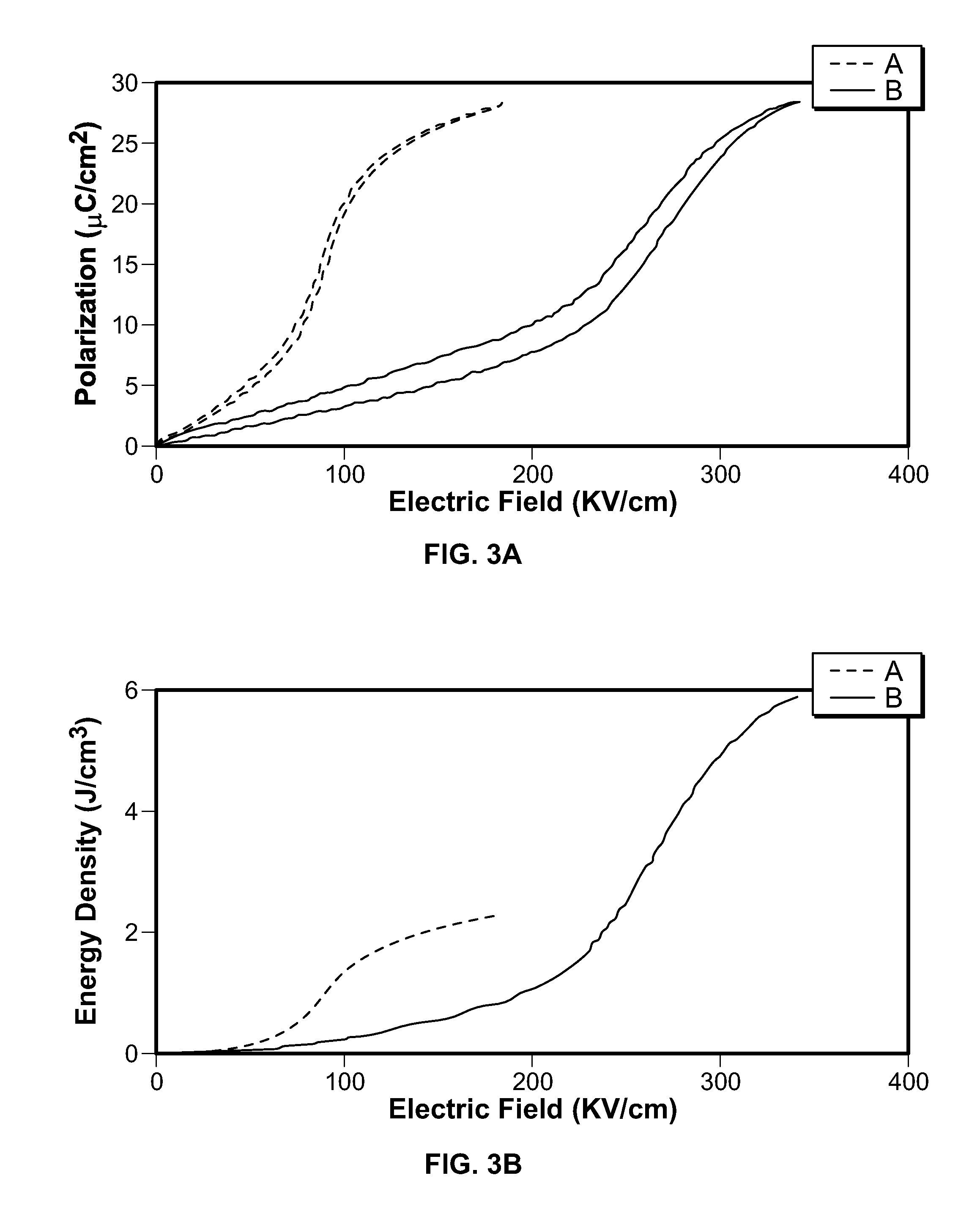

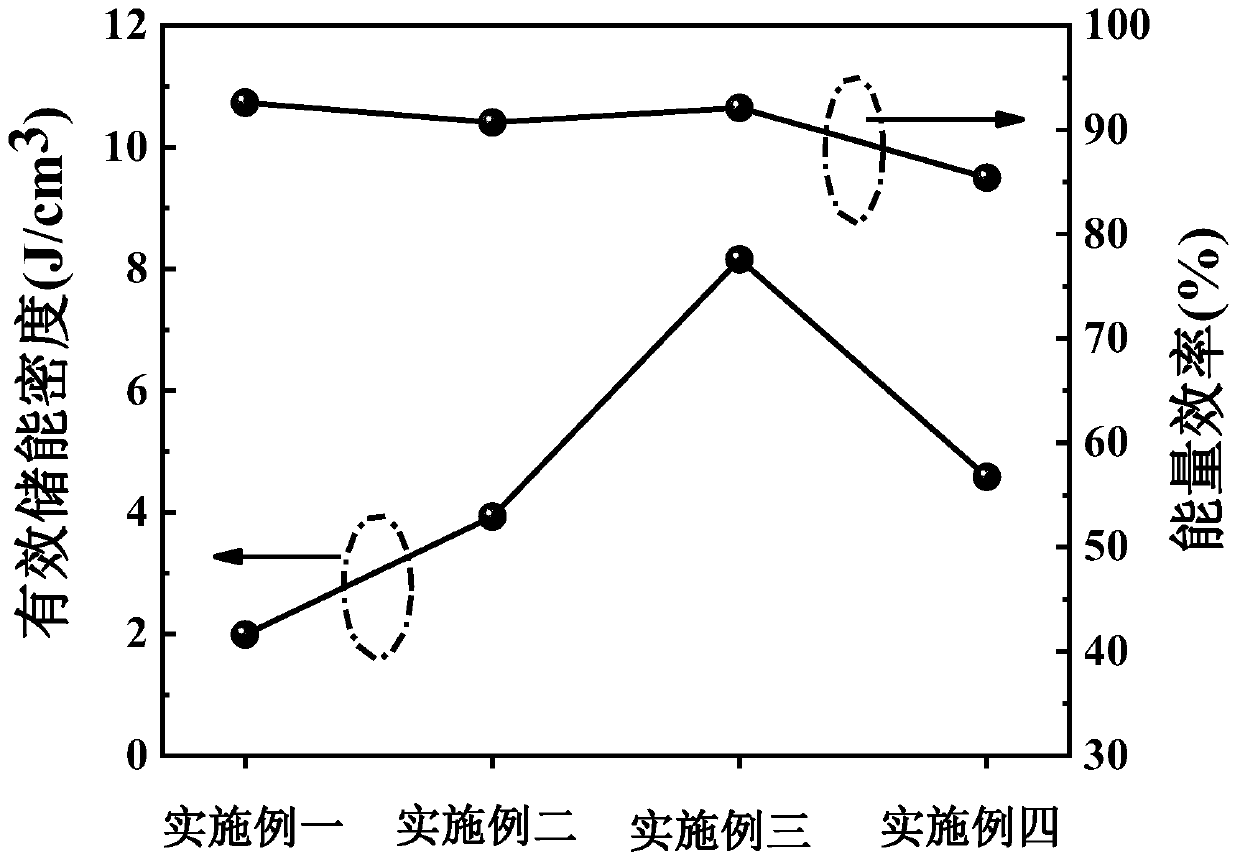

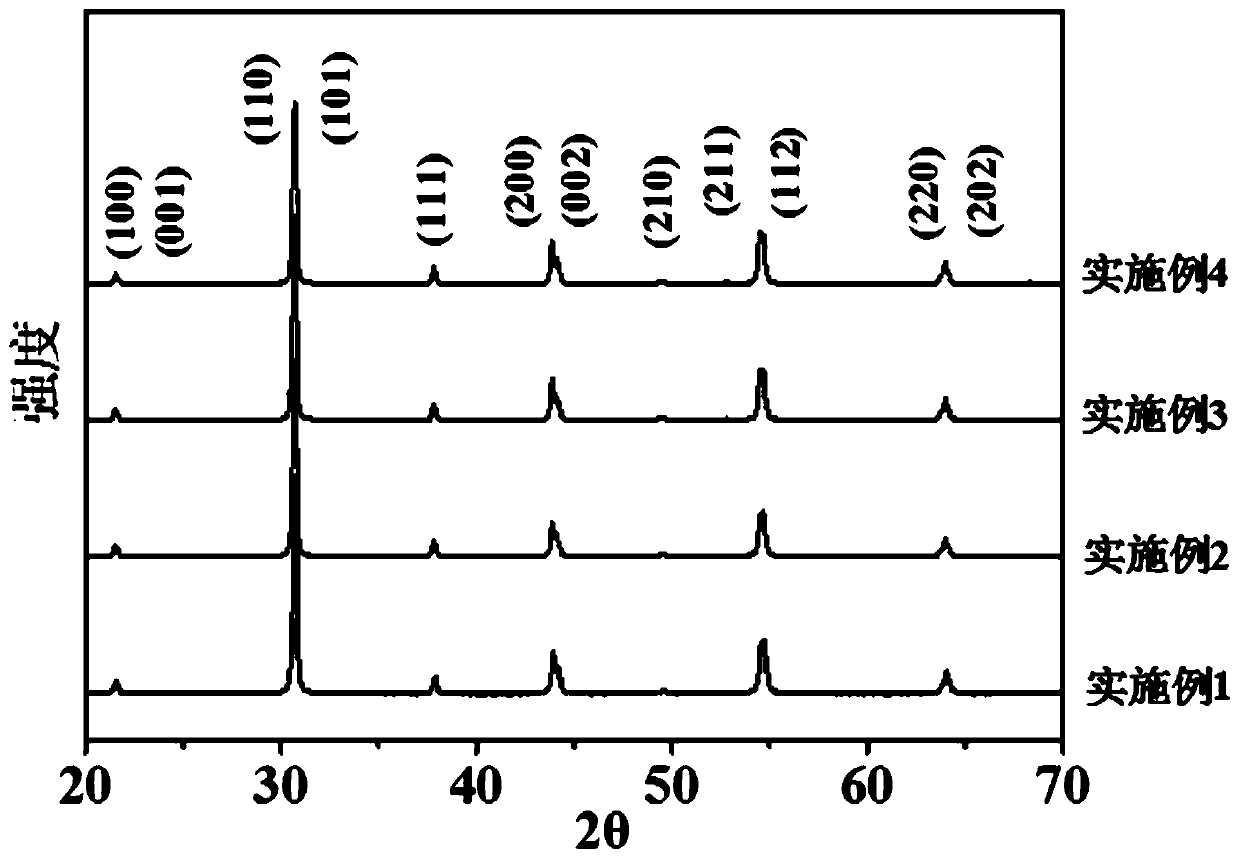

La-doped lead zirconate stannate titanate anti-ferroelectric ceramics with high energy storage efficiency and preparation method thereof

The invention relates to La-doped lead zirconate stannate titanate anti-ferroelectric ceramics with high energy storage efficiency and a preparation method thereof. The constitutional chemical formula of the anti-ferroelectric ceramics is (Pb1-1.5xLax)(ZrySn0.9-yTi0.1)O3, wherein x is greater than or equal to 0.02 and smaller than or equal to 0.04, and y is greater than or equal to 0.1 and smaller than or equal to 0.5. According to the preparation method, the anti-ferroelectric ceramics are prepared with a tradional preparation method of electronic ceramics, have the energy storage characteristics of small electric hysteresis and high energy storage efficiency, and have very important significance in developing a high-pressure impulse power capacitor with high energy storage density and high energy storage efficiency.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

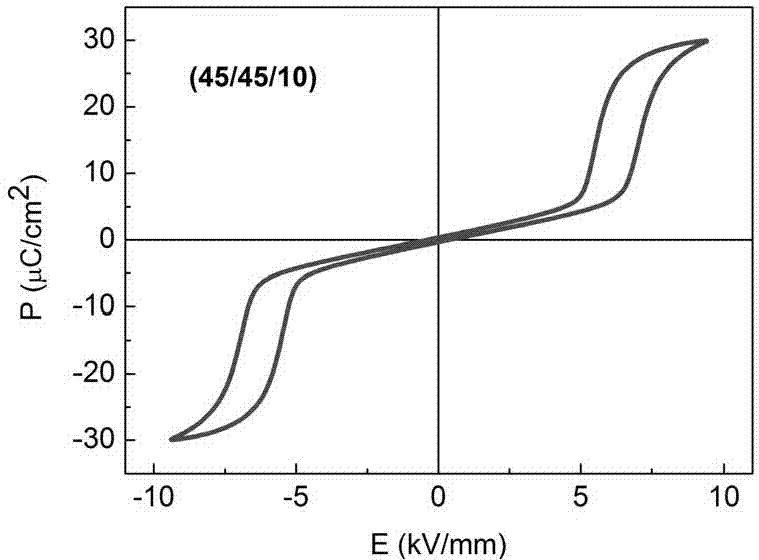

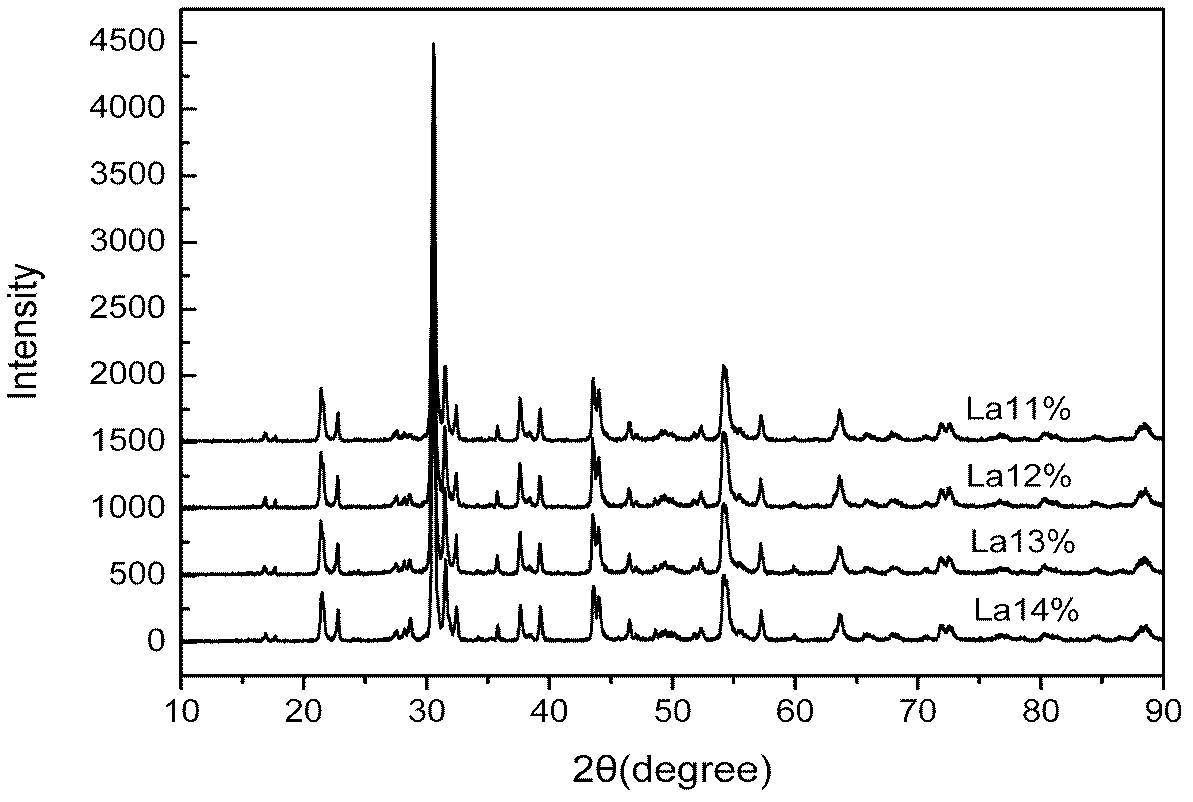

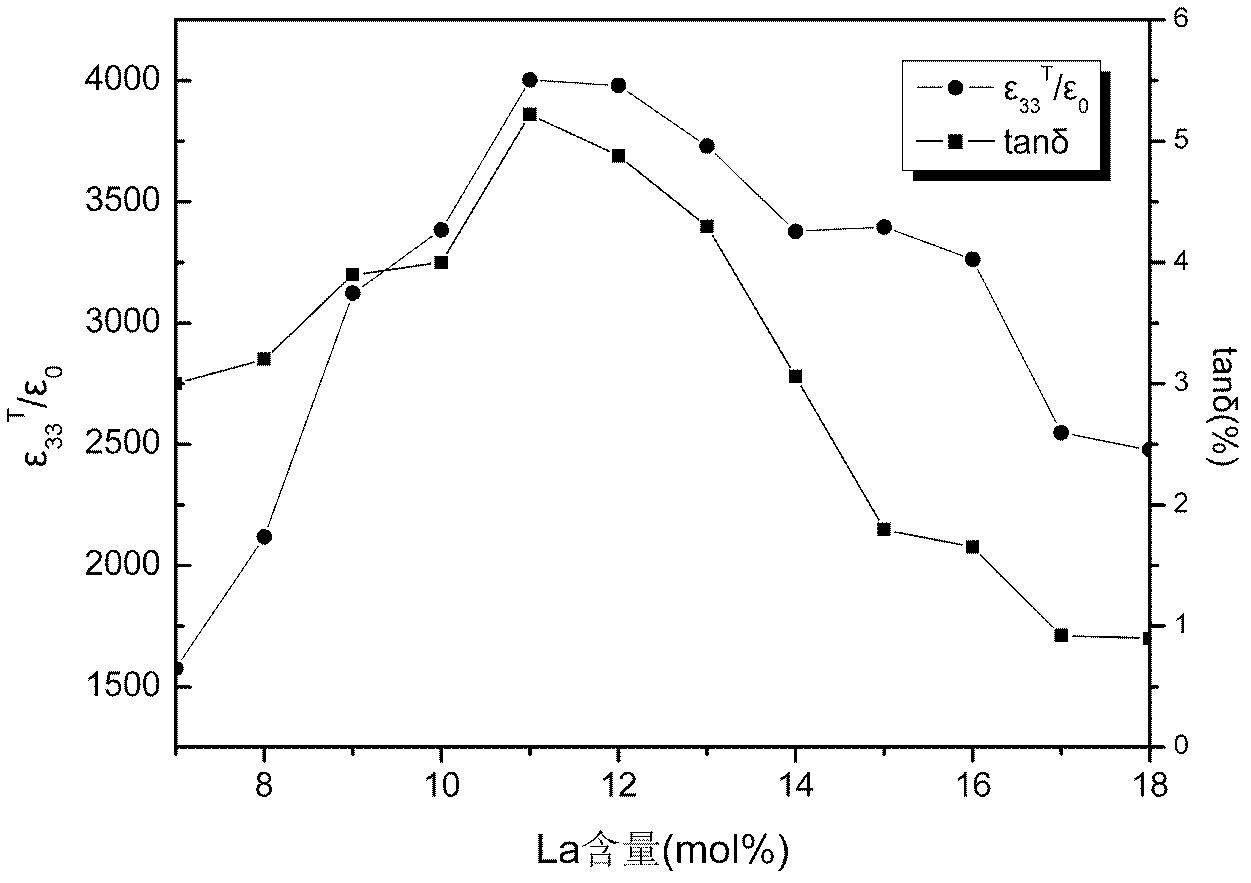

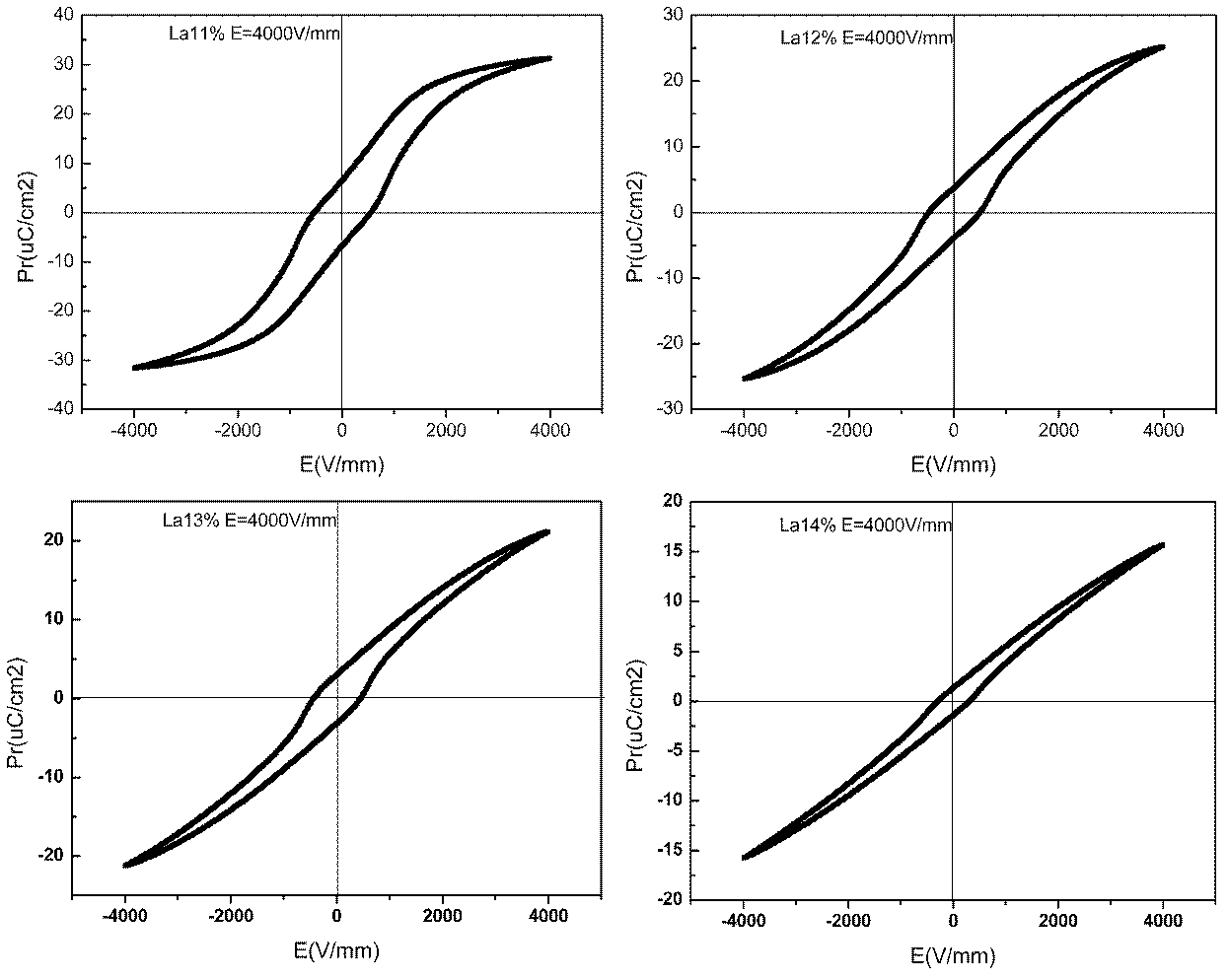

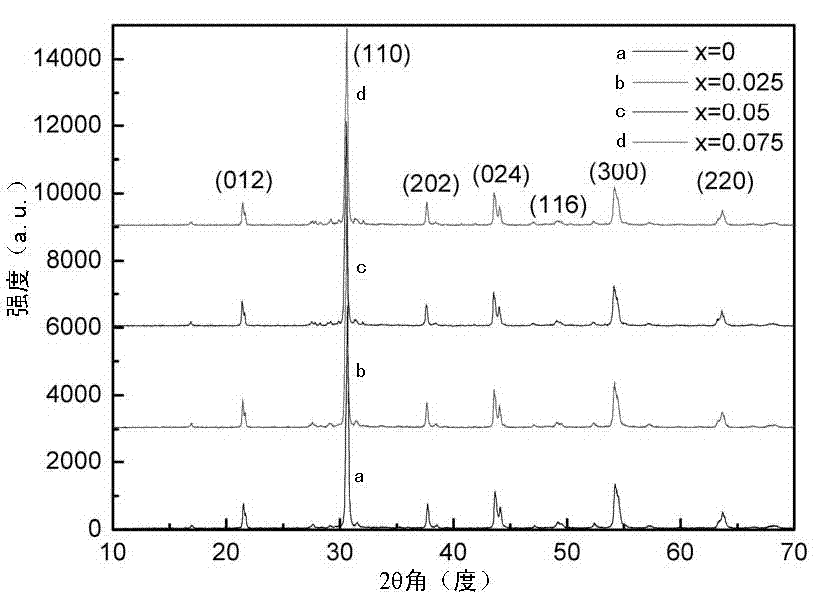

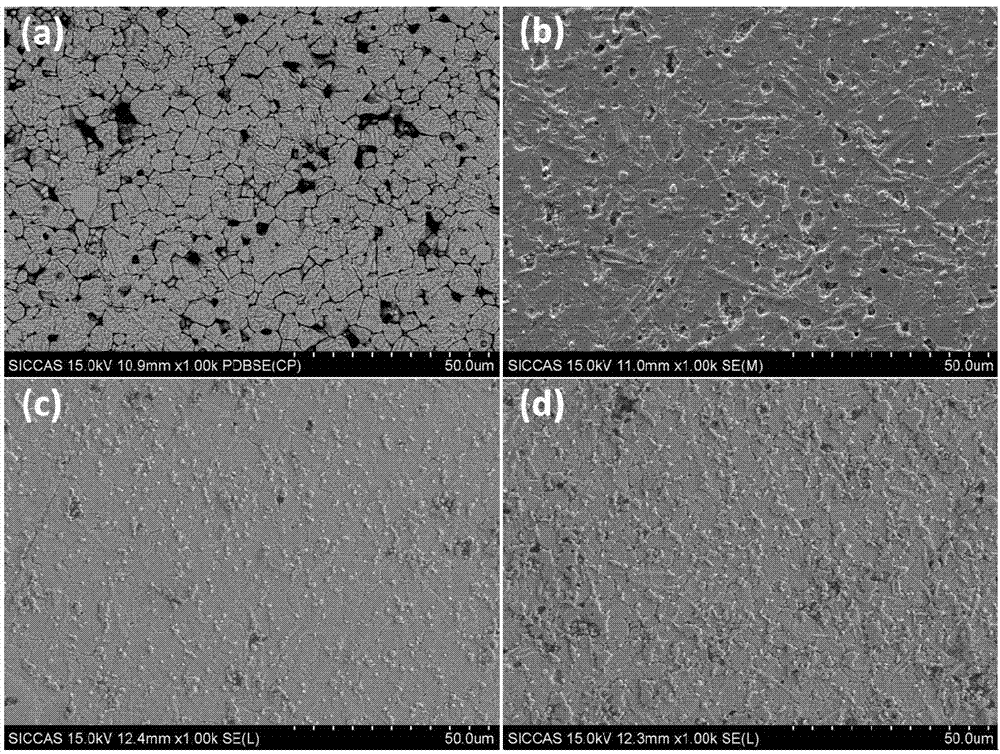

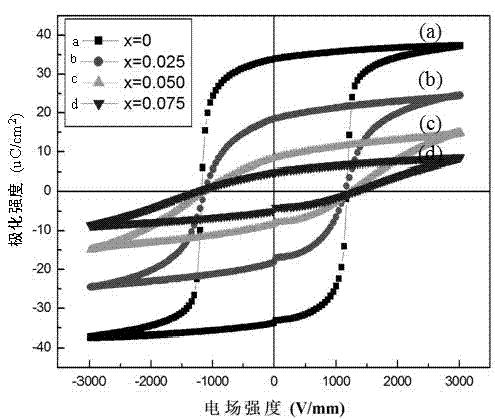

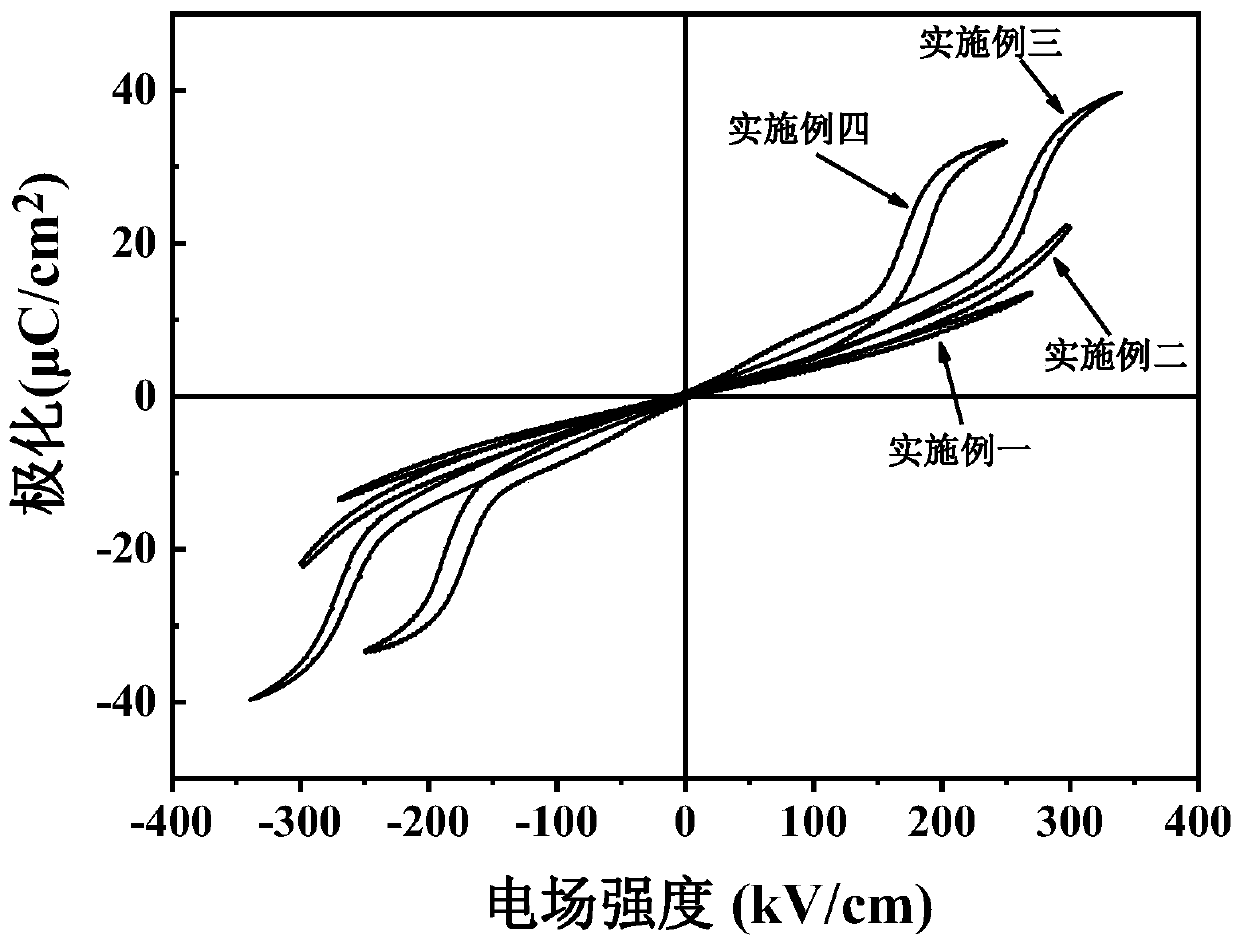

Lanthanum-doped lead zirconate titanate antiferroelectric ceramic and preparation method thereof

The invention discloses La2O3-doped lead zirconate titanate antiferroelectric ceramic. The components and the molar ratio of the components of the ceramic are represented by a formula of Pb1-xLax(Zr0.70Ti0.30)1-x / 4O3, wherein x=0.07-0.18. According to the invention, a traditional oxide mixing method is adopted, and sintering is carried out under a normal pressure, such that the antiferroelectric ceramic material is obtained. With the antiferroelectric ceramic provided by the invention, a double hysteresis loop can be displayed under room temperature, the loss is low, and the temperature coefficient is relatively small. The antiferroelectric ceramic is mainly applied in high-density energy-storage capacitors, large-displacement actuators, energy transducers, controllable switches, pyroelectric detectors, and the like.

Owner:TIANJIN UNIV

Anti-ferroelectric ceramic material which is sintered at low temperatures and has high energy storage density and method for preparing anti-ferroelectric ceramic material

ActiveCN105198416AHigh energy storage densityImprove energy storage efficiencyChemical compositionHigh energy

The invention relates to an anti-ferroelectric ceramic material which is sintered at low temperatures and has high energy storage density and a method for preparing the anti-ferroelectric ceramic material. Chemical components of the anti-ferroelectric ceramic material conform to a chemical general formula of Pb<0.97>La<0.02> (Zr<x>Sn<y>Ti<1-x-y>) O<3>+a*wt.% CuO, wherein the x is larger than or equal to 0.4 and is smaller than or equal to 0.6, the y is larger than or equal to 0.4 and is smaller than or equal to 0.6, the a is larger than or equal to 0.2 and is smaller than or equal to 1, the x and the y are mole numbers, and the a is a mass percent. The anti-ferroelectric ceramic material and the method have the advantages that appropriate sintering additives are chosen, and appropriate Zr / Sn / Ti ratios are adjusted, so that the PLZST anti-ferroelectric energy storage ceramic material sintered at the temperatures of 950-1000 DEG C can be obtained; the anti-ferroelectric ceramic material is high in energy storage density and energy storage efficiency, can be used for manufacturing energy storage multilayer ceramic capacitors and has an excellent application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

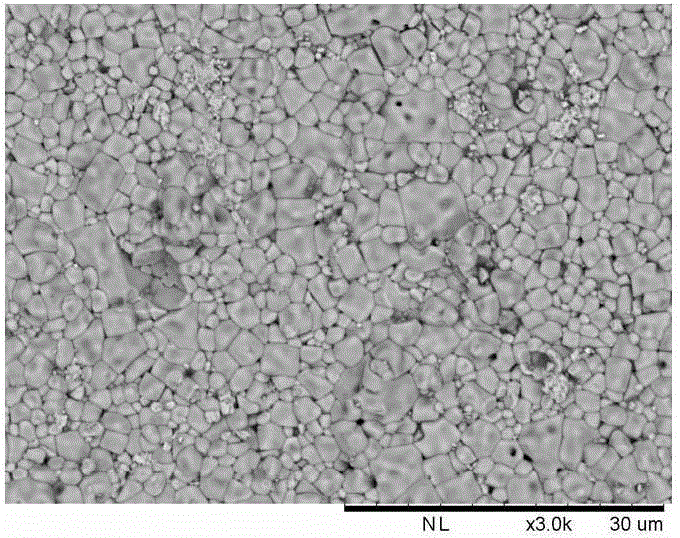

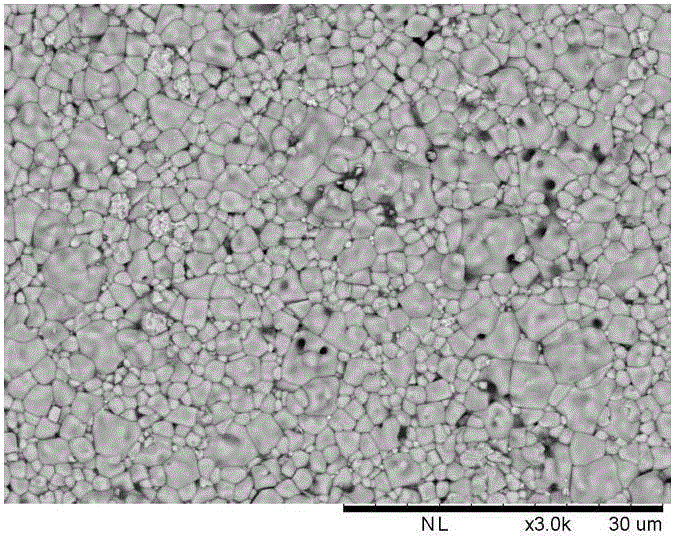

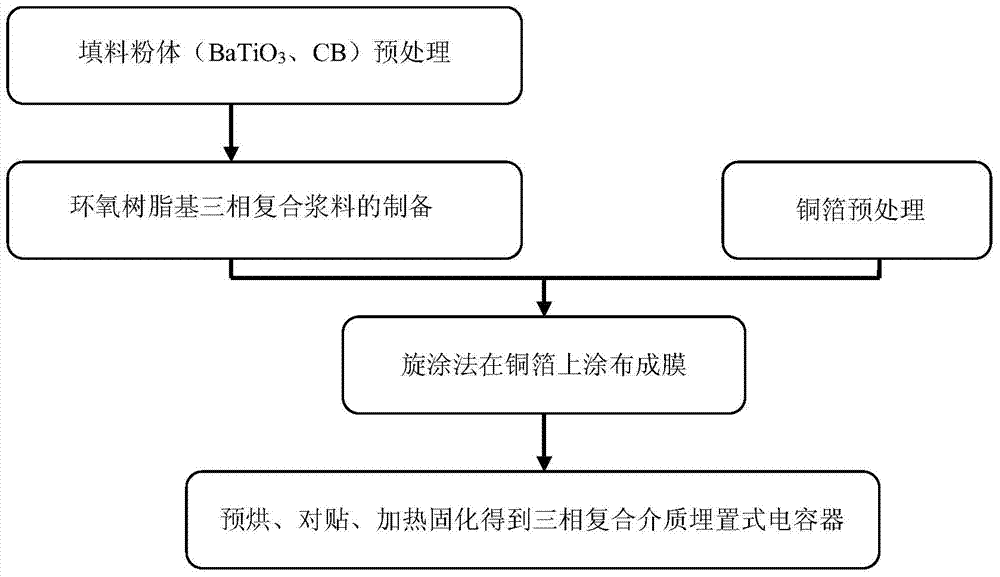

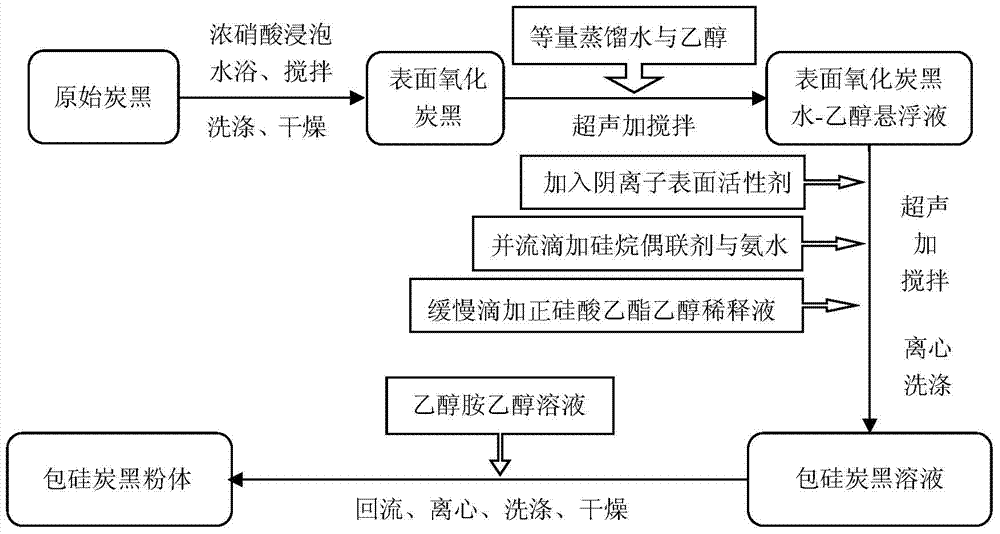

Three-phase composite high-dielectric-property material, manufacturing method and processing method

The invention provides a three-phase composite high-dielectric-property material, a manufacturing method and a processing method. The three-phase composite high-dielectric-property material comprises surface-activated barium titanate, silicon package carbon blank and epoxy resin. The three-phase composite high-dielectric-property material is manufactured according to the following steps of (1) preprocessing barium titanate, (2) preprocessing carbon blank, (3) reprocessing powdery surface-oxidized carbon blank, (4) preprocessing epoxy resin and (5) taking and adding surface-activated barium titanate and silicon package carbon blank into a epoxy resin butanone solution. The processing method includes the following steps of (1) material preprocessing, (2) curing agent preprocessing, (3) copper foil preprocessing, (4) surface coating and (5) solidifying. According to the three-phase composite high-dielectric-property material, the manufacturing method and the processing method, under the premise that dielectric loss is controlled, conductive particles are used for replacing a part of ferroelectric ceramics to manufacture a conductor / ceramics / a polymer three-phase composite dielectric material, wherein the conductor / the ceramics / the polymer three-phase composite dielectric material can effectively improve the dielectric constant of a polymer matrix composite material. Meanwhile, the problems that carbon blank is difficult to disperse in a polymer and dielectric loss is increased due to the fact that a conductive path is formed after the content of the carbon blank rises are effectively solved.

Owner:SOUTH CHINA UNIV OF TECH +1

Samarium-oxide-doped modified lead zirconate titanate ferroelectric ceramic and preparation method thereof

The invention relates to samarium-oxide-doped modified lead zirconate titanate ferroelectric ceramic and a preparation method thereof. The ferroelectric ceramic has a composition general formula as follows: Pb1-xSmx(ZryTi1-y)0.98Nb0.02O3, wherein x is more than 0 and not more than 0.1, and y is not smaller than 0.9 and not more than 0.97. The residual polarization strength Pr of the ferroelectric ceramic ranges from 4 mu C / cm<2> to 36 mu C / cm<2>, so that the energy storage density of the ferroelectric ceramic is regulated in a wider range, and the performance requirement of the output power design of a pulse power supply is met. According to the process, formula design, weighing, mixing, powder synthesizing and sintering are carried out according to design requirements; and the addition amount of Sm2O3 is low, and no extra process program is needed. Compared with the traditional process in which a pore-forming agent is added, the preparation method has the advantage that the use of the pore-forming agent and processes such as uniform dispersion are reduced. Accordingly, the invention is simple in process and suitable for scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

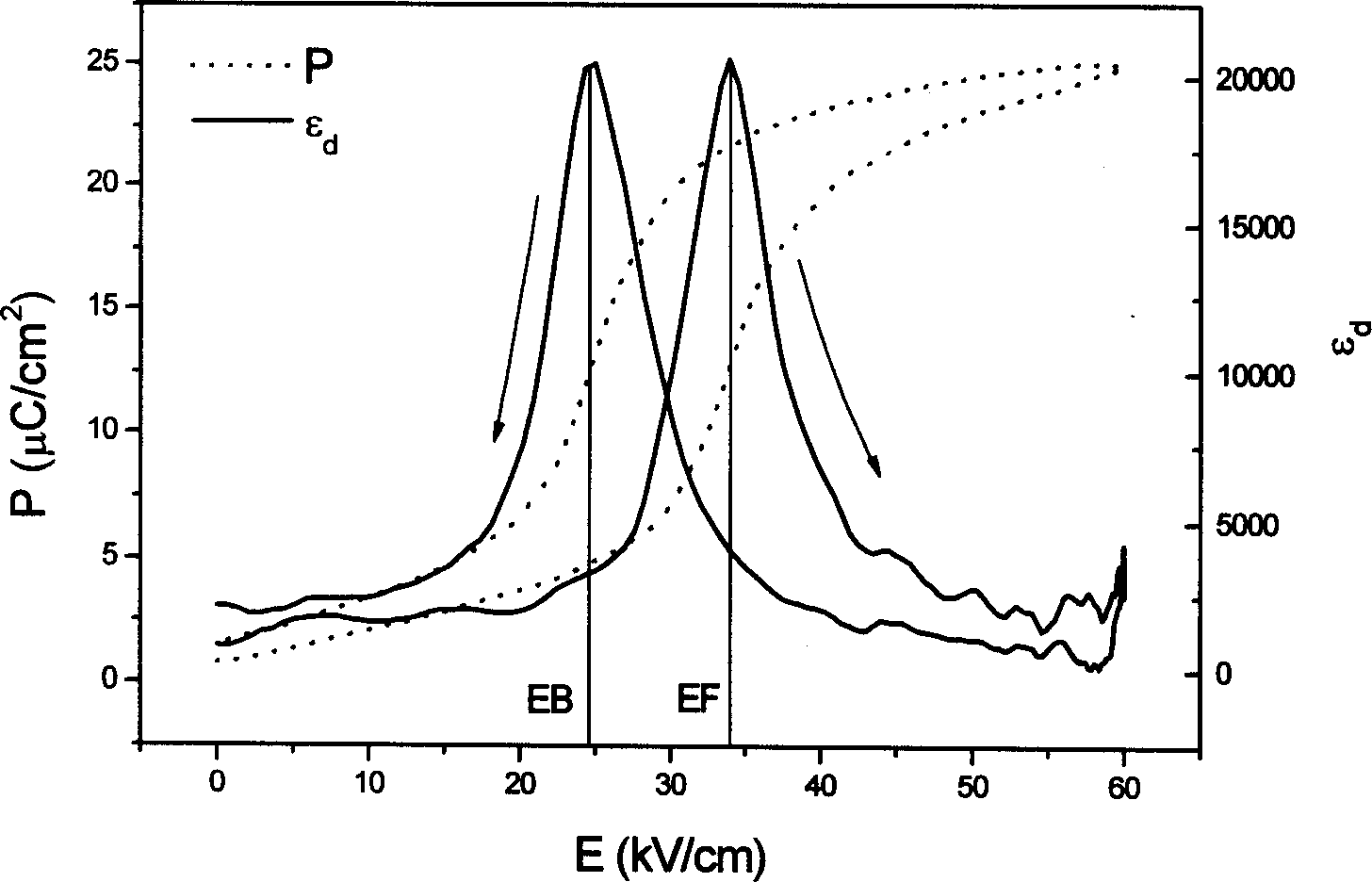

PZT (lead zirconate titanate)-based antiferroelectric ceramic material with low curie point and high bidirectional-adjustable dielectric electric field and preparation method thereof

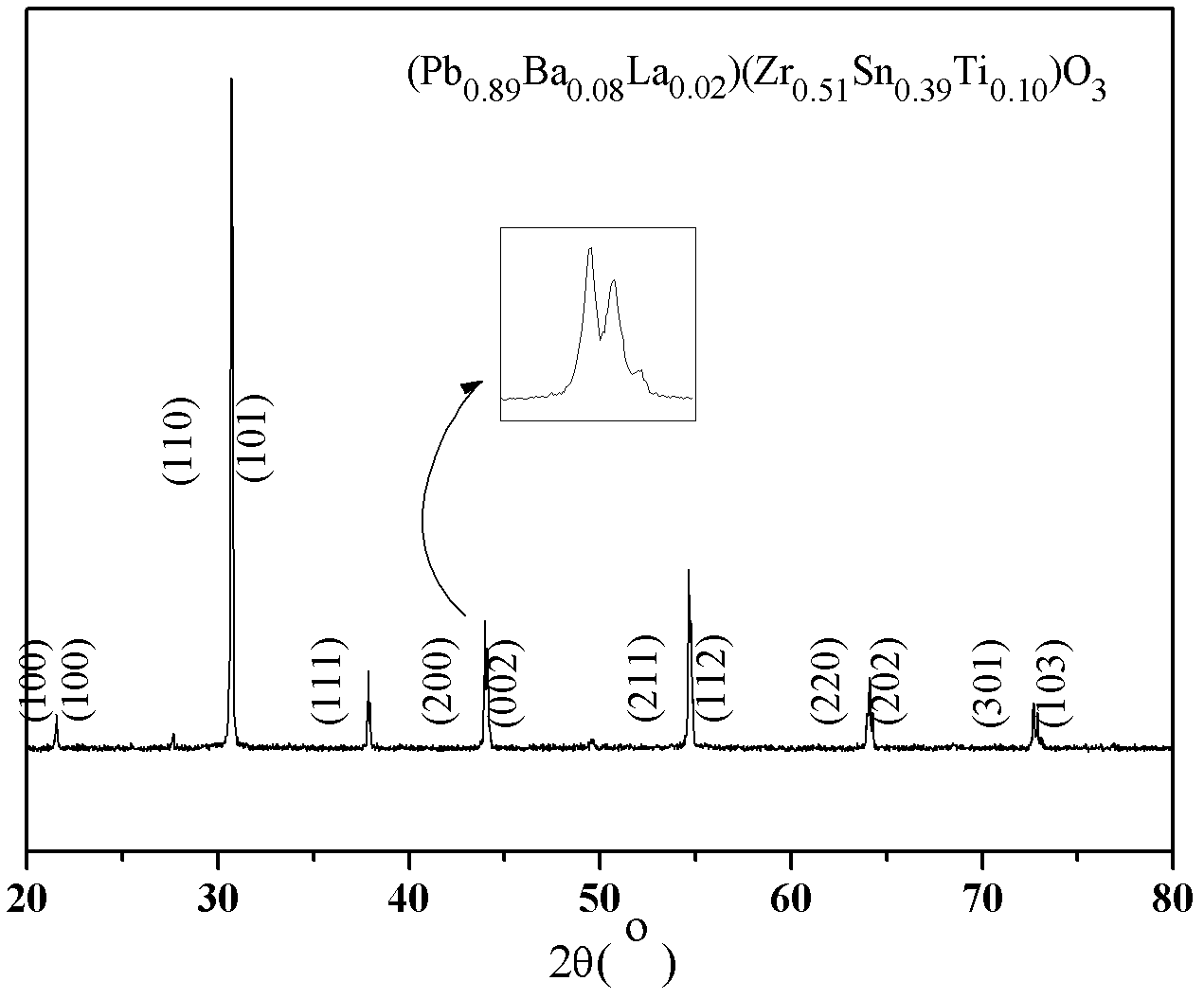

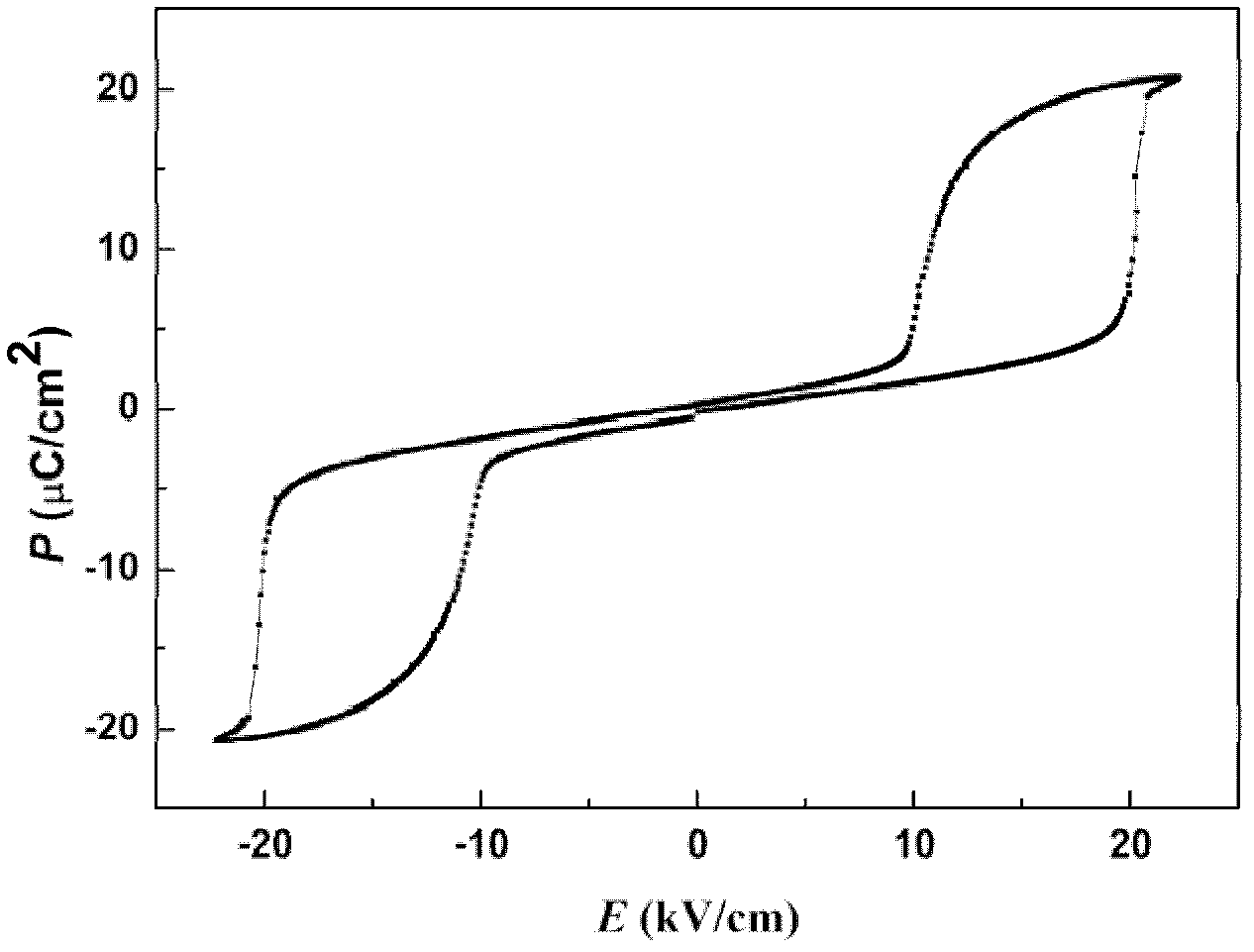

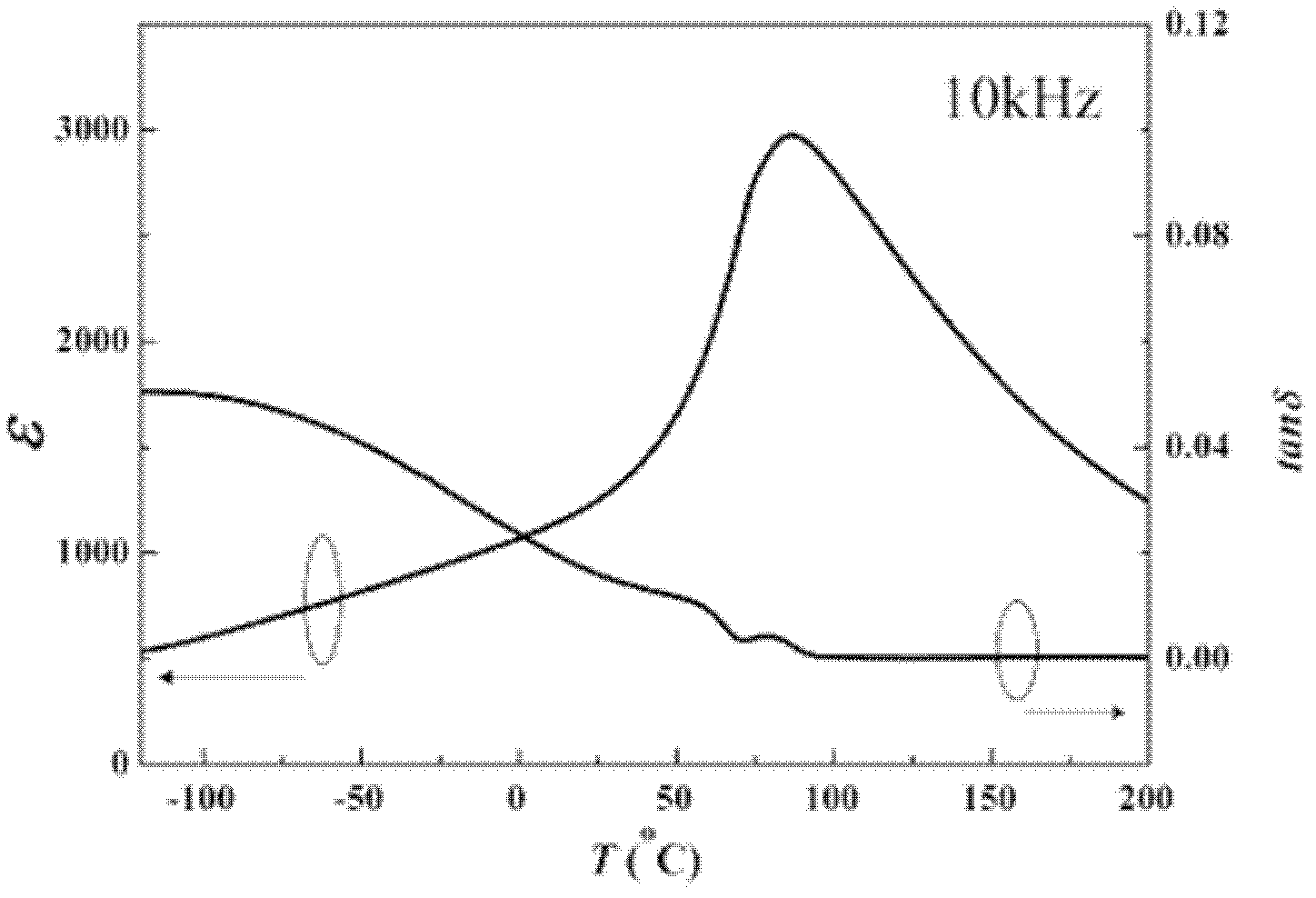

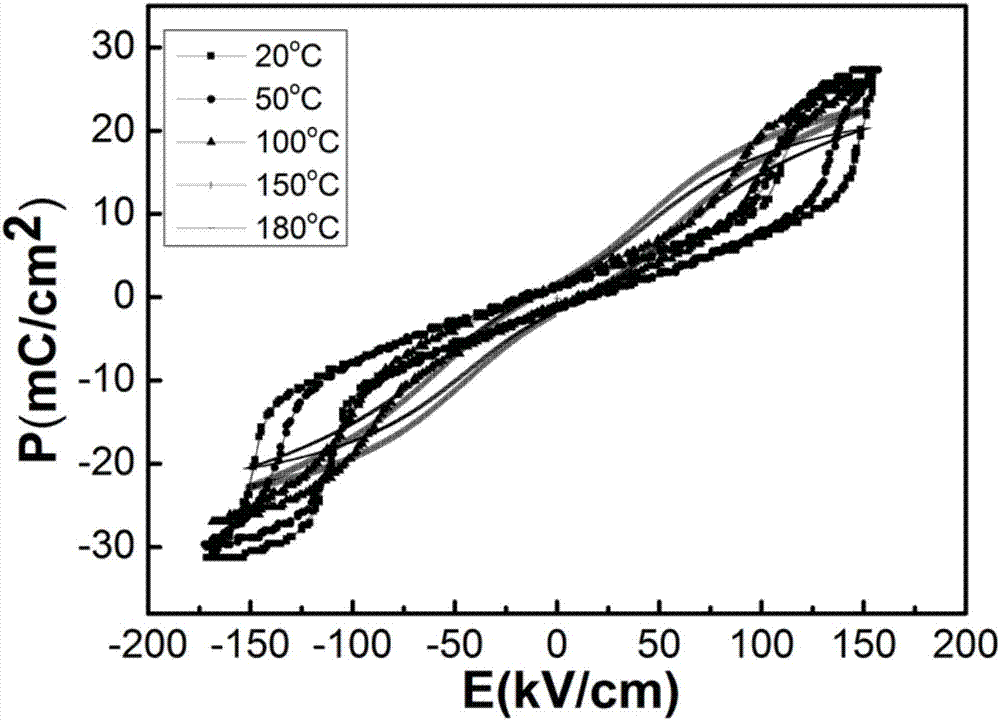

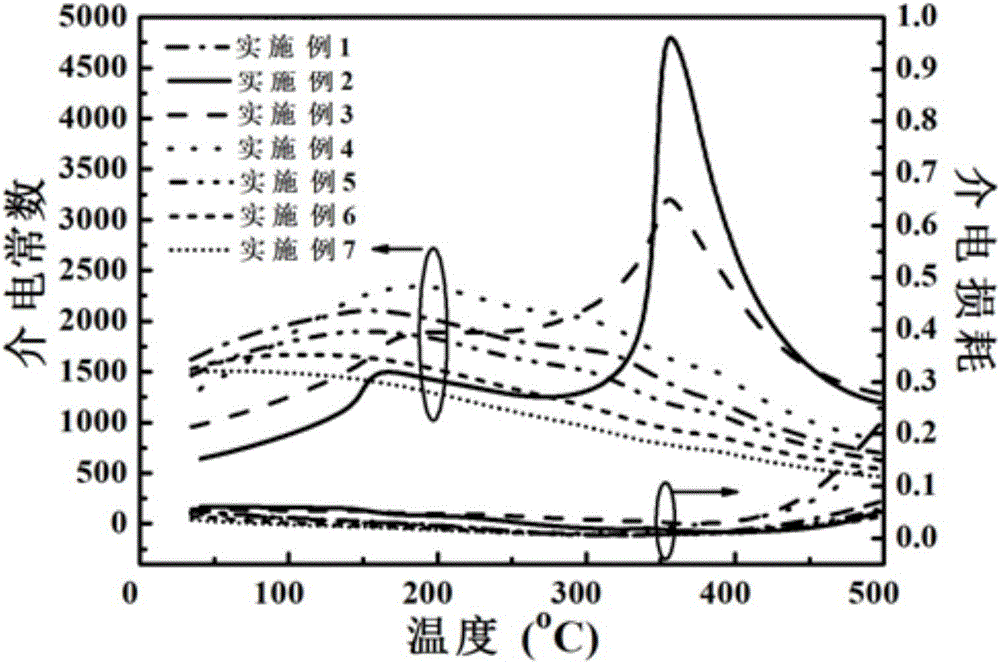

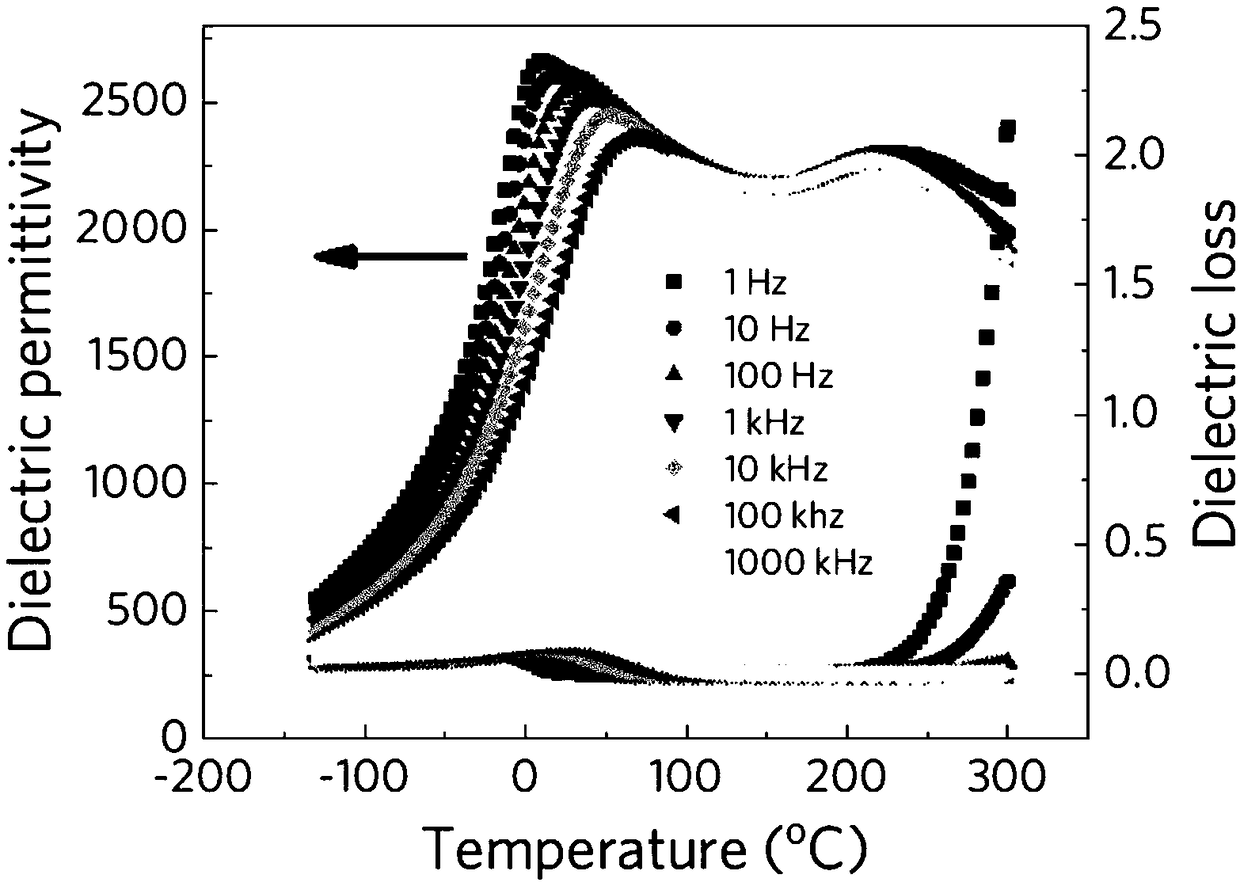

InactiveCN102643090AHigh dielectric constantHigh pyroelectric responseLead zirconate titanateElectron

The invention relates to a PZT (lead zirconate titanate)-based antiferroelectric ceramic material with low curie point TC and a high bidirectional-adjustable dielectric electric field and a preparation method thereof and belongs to the technical fields of electronic materials and devices. The chemical general formula of the PZT-based antiferroelectric ceramic material with bidirectional adjustability of a dielectric electric field is (Pb[0.99-x-y]BaxLay)(Zr0.51Sn 0.39Ti0.10)O3, wherein x is larger than 0 and less than or equal to 0.20, and y is larger than 0 and less than or equal to 0.06. The PZT-based antiferroelectric ceramic material with dielectric bidirectional adjustability has high dielectric coefficient and low dielectric loss under a certain bias voltage in the vicinity of low curie point TC, and the dielectric coefficient is increased and then decreased along with the increase of the bias voltage; the PZT-based antiferroelectric ceramic material has bidirectional dielectric adjustability, simultaneously has high pyroelectric coefficient and pyroelectric current, and can be widely used in the fields of microelectronics, computers, capacitors, sensors, aerospace technologies and the like.

Owner:TONGJI UNIV

Dielectric energy-storing anti-ferroelectric ceramic material and preparation method thereof

ActiveCN107459350ASolve the technical problem of poor temperature stabilityDielectricNegative temperature

Owner:HUAZHONG UNIV OF SCI & TECH

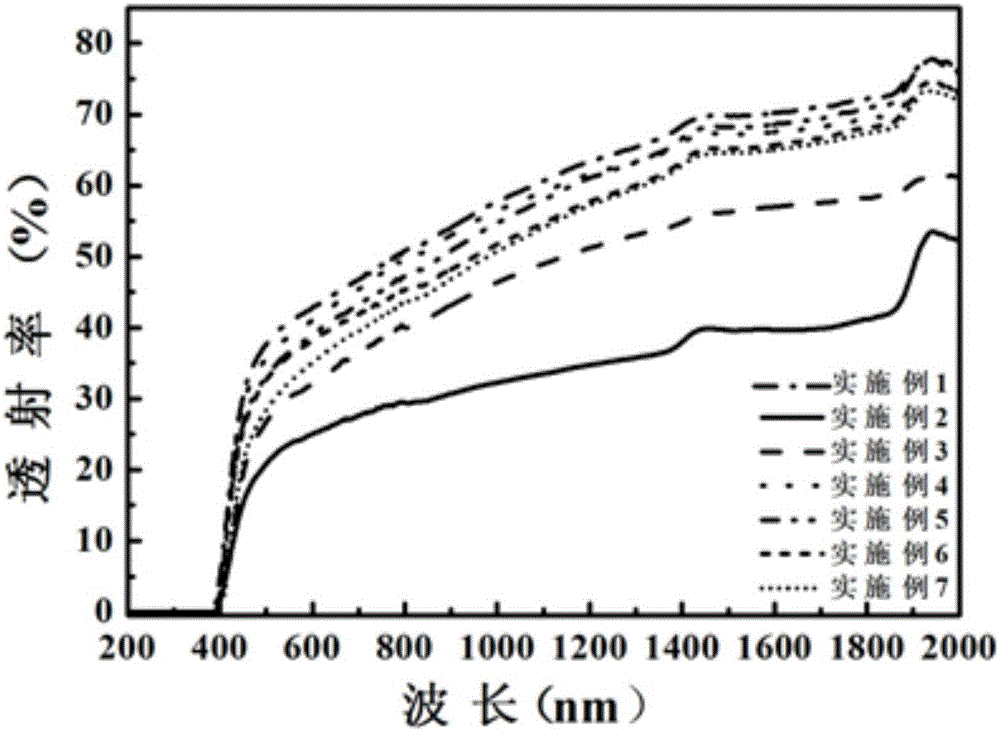

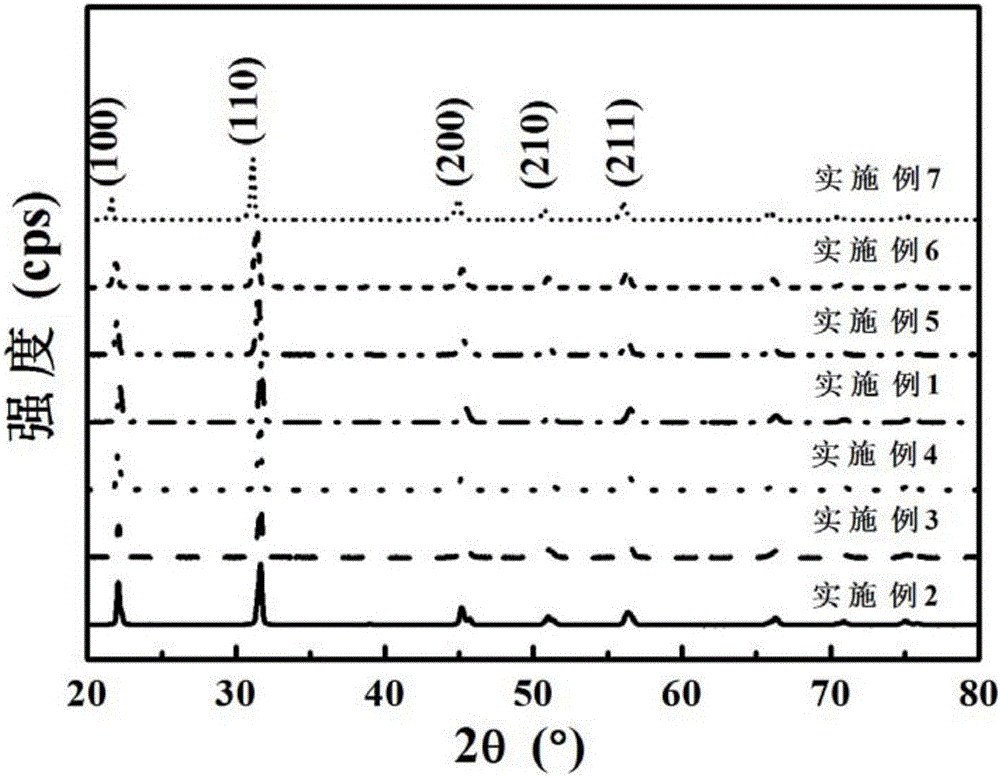

Potassium sodium niobate base lead free transparent ferroelectric ceramic material and preparation method thereof

InactiveCN105819856AGood light transmissionPracticalPiezoelectric/electrostrictive/magnetostrictive devicesSilver inkElectric properties

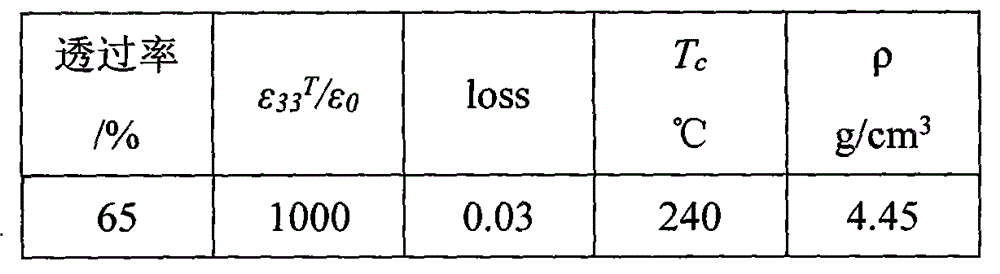

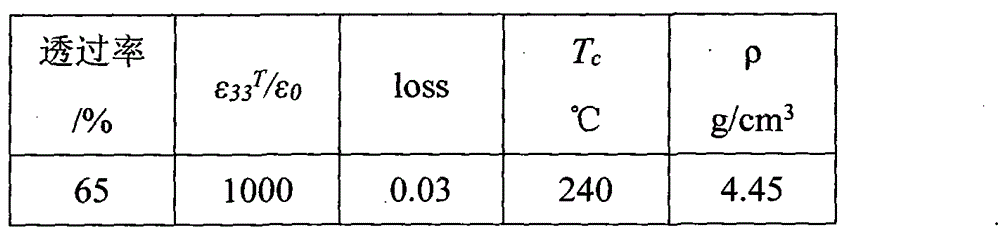

The invention discloses a potassium sodium niobate base lead free transparent ferroelectric ceramic material and a preparation method thereof. The formula of the ceramic material is (1-x)(K<0.5>Na<0.5>)Nb<3-x>Sr(Mg<1 / 3>Nb<2 / 3>)O3, and x represent the mole number of Sr(Mg<1 / 3>Nb<2 / 3>)O3 and is in a range of 0.02 to 0.08. The preparation method comprises steps of preparing raw materials, pre-burning, ball-milling, granulating, pressing, pressure-free sealed sintering, polishing, and silver ink firing; the ceramic material has the advantages of high light transmission, optical isotropy, strong practicality, and easy production, moreover, the preparation method is simple, the repeatability is good, and the yield is high. The test results show that when x is equal to 0.05, the optical transmission rate of the ceramic material is 60-70% in the near infrared area, at the same time, the ceramic material has good electric properties: the remnant polarization is 4.8 [mu]C / cm2, the coercive field is 7.4 kV / cm, the maximal dielectric constant is 2104, the dielectric loss is less than 0.03, and the piezoelectric constant d33 is 48 pC / N.

Owner:SHAANXI NORMAL UNIV

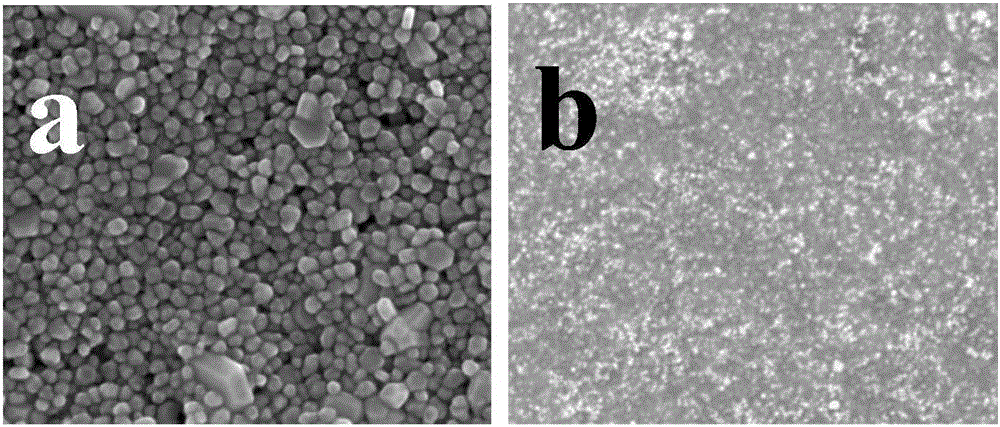

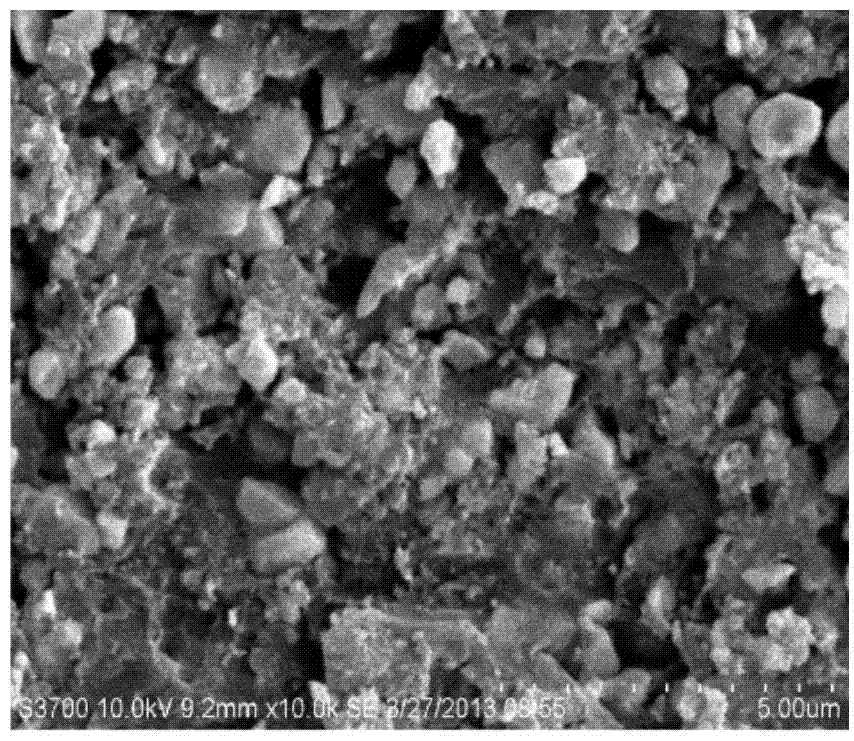

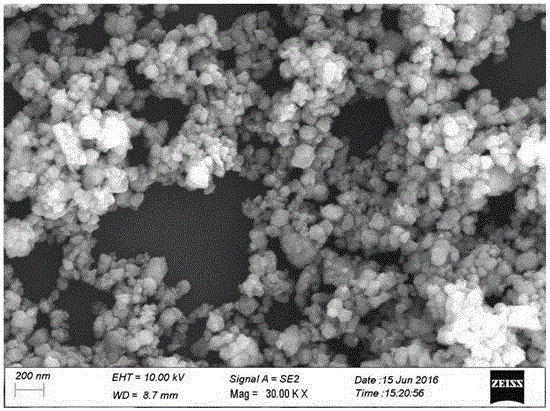

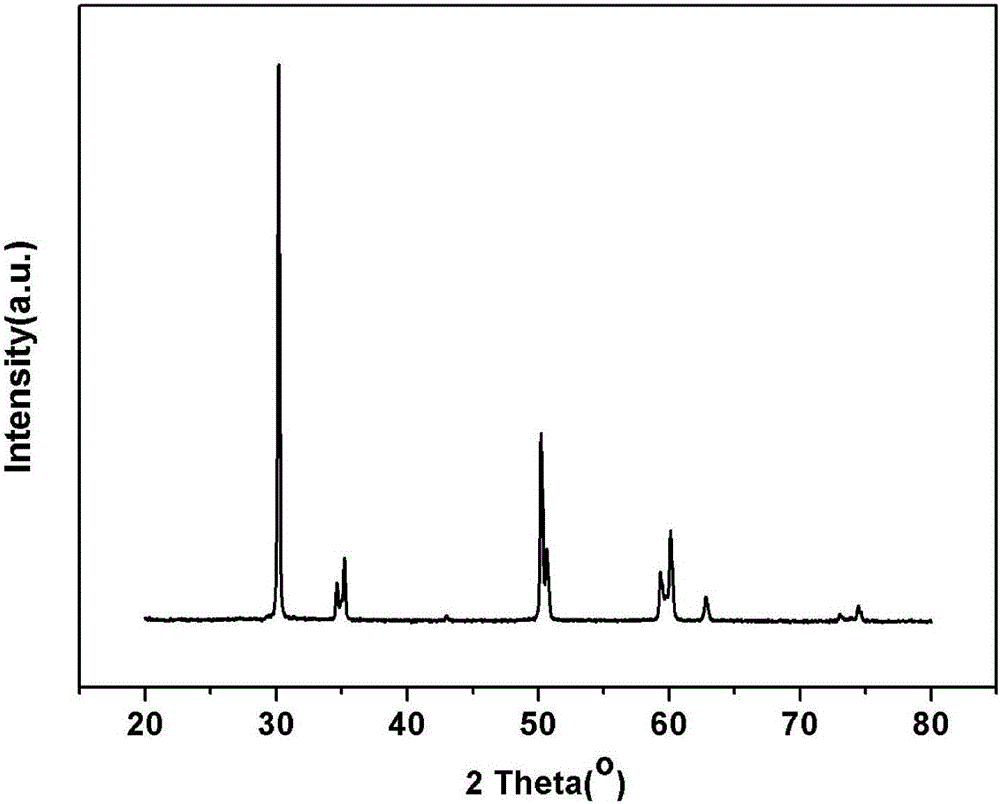

3 YSZ nano powder, preparation method and use thereof

InactiveCN106278255AThe process is simple and convenientShort cycleMaterial nanotechnologyFuel cellsFuel cellsOxygen sensor

The invention provides a preparation method of 3 YSZ nano powder. The preparation method comprises the following steps: mixing zirconium oxide and yttrium oxide, adding deionized water and a dispersing agent to form a slurry, stirring and ball milling the slurry, then carrying out sand grinding and spray drying to prepare the nano 3 YSZ powder, wherein the particle size range is less than or equal to 80 nm; the average particle size is less than 50 nm. The process for preparing the powder by the sand grinding technology is simple and convenient, the period is short and the repeatability is good. The deionized water is used as the grinding medium, the problems of high cost and large environmental pollution in the traditional powder preparation process are well solved, and the preparation method can be widely applied to the preparation of high-temperature solid fuel cells, piezoelectric ceramic, oxygen sensors and ferroelectric ceramic.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

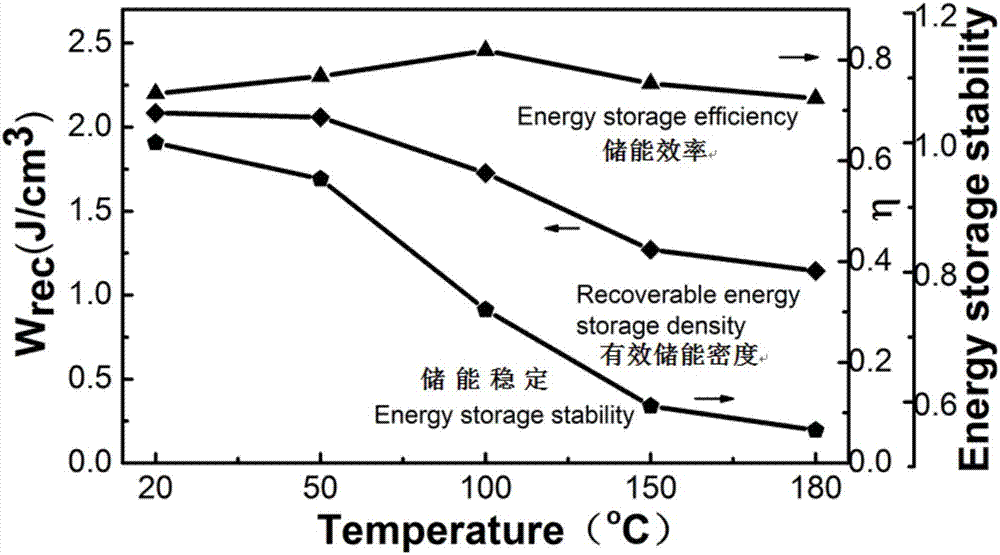

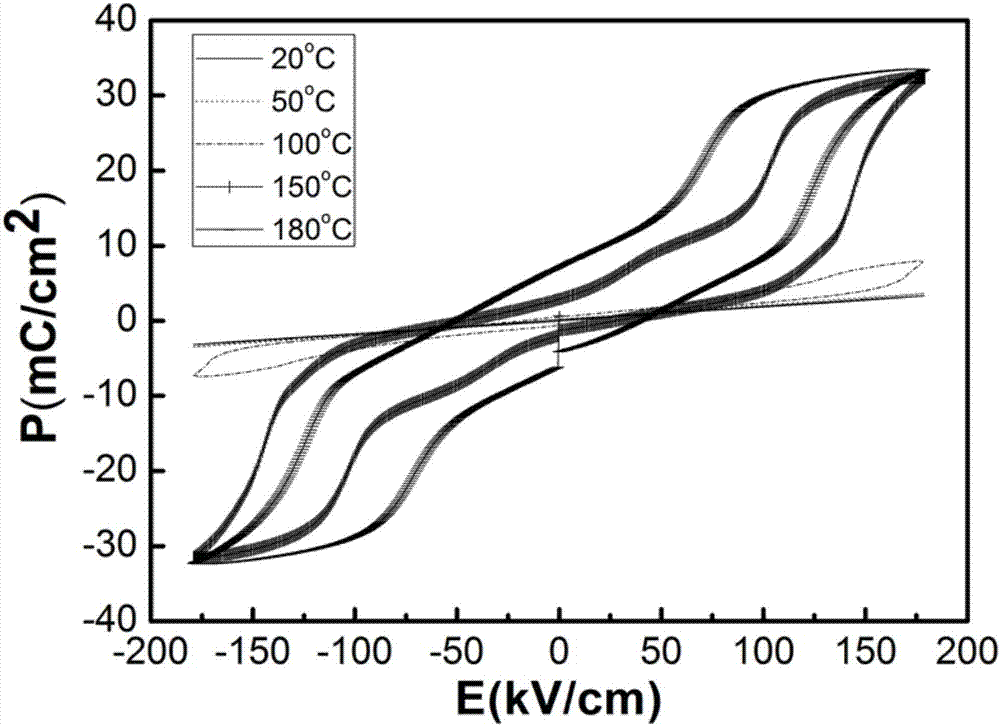

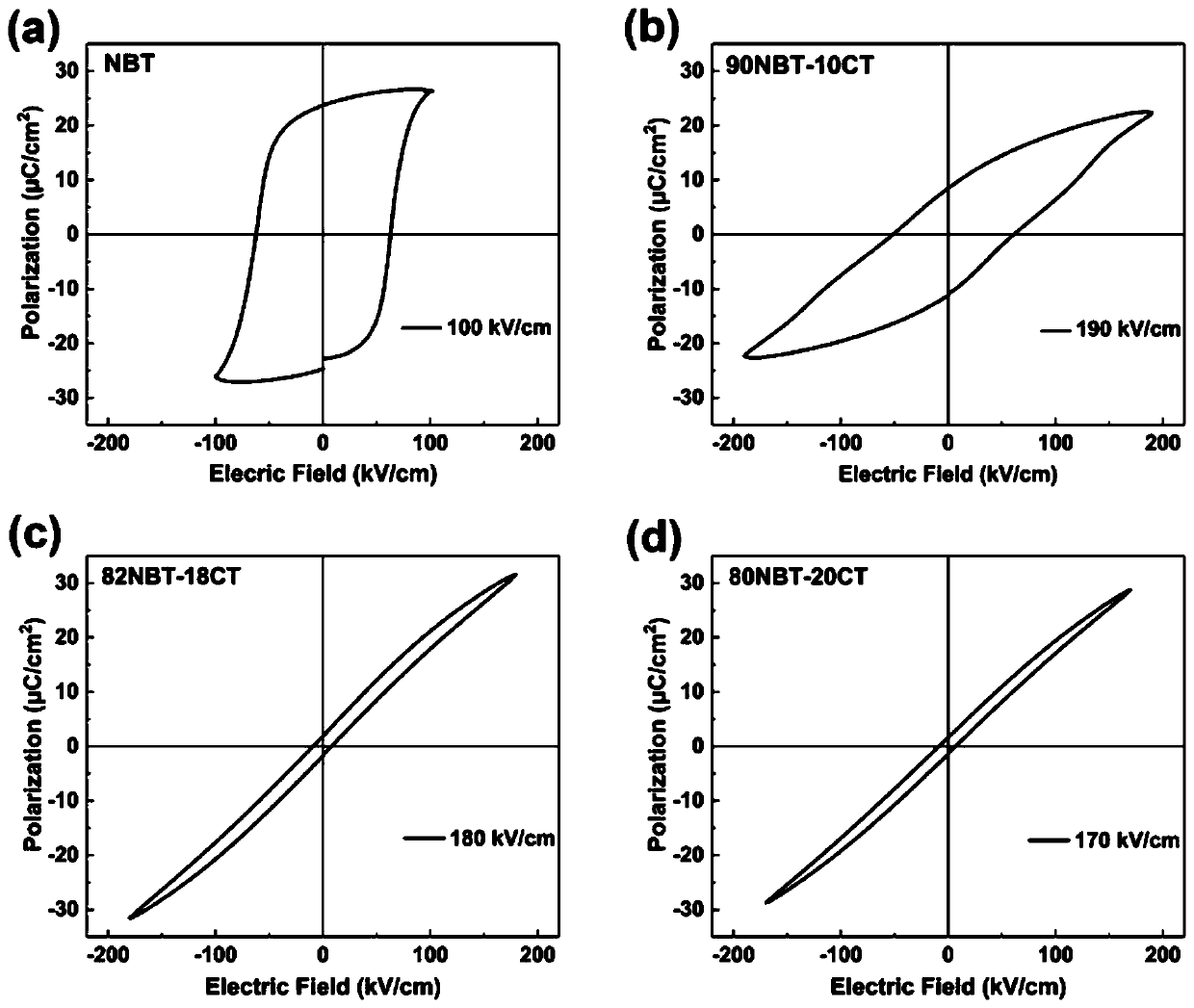

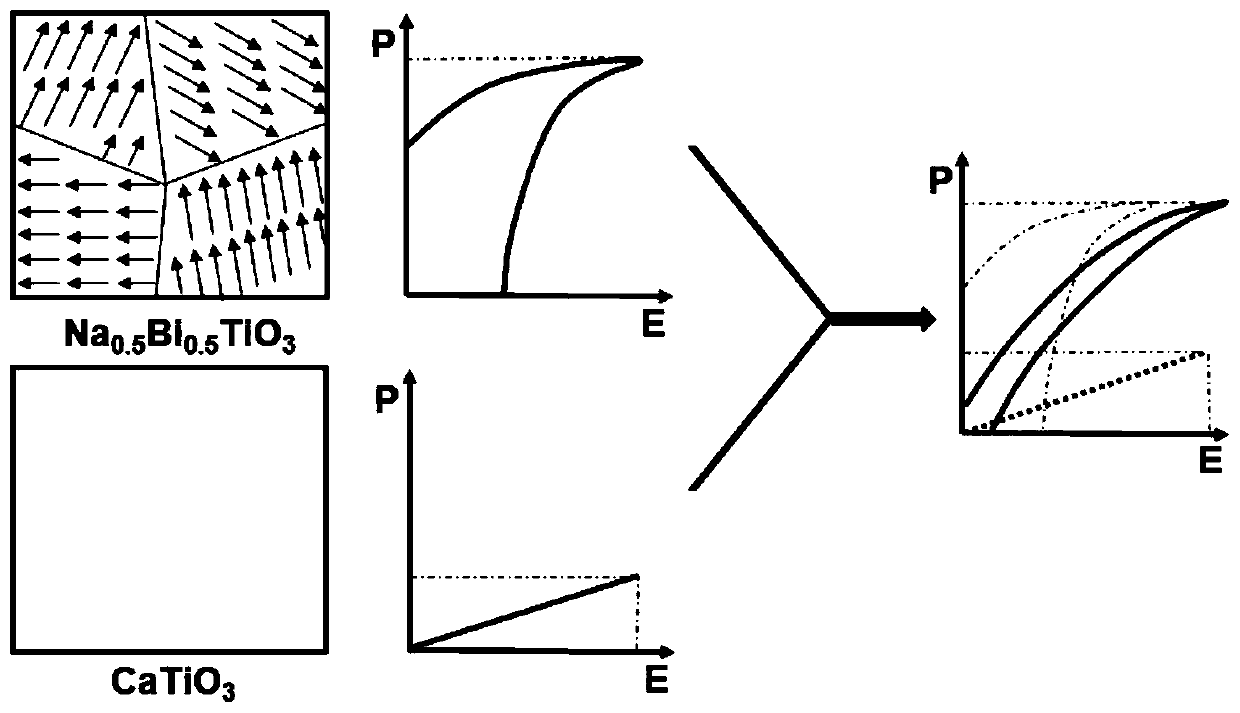

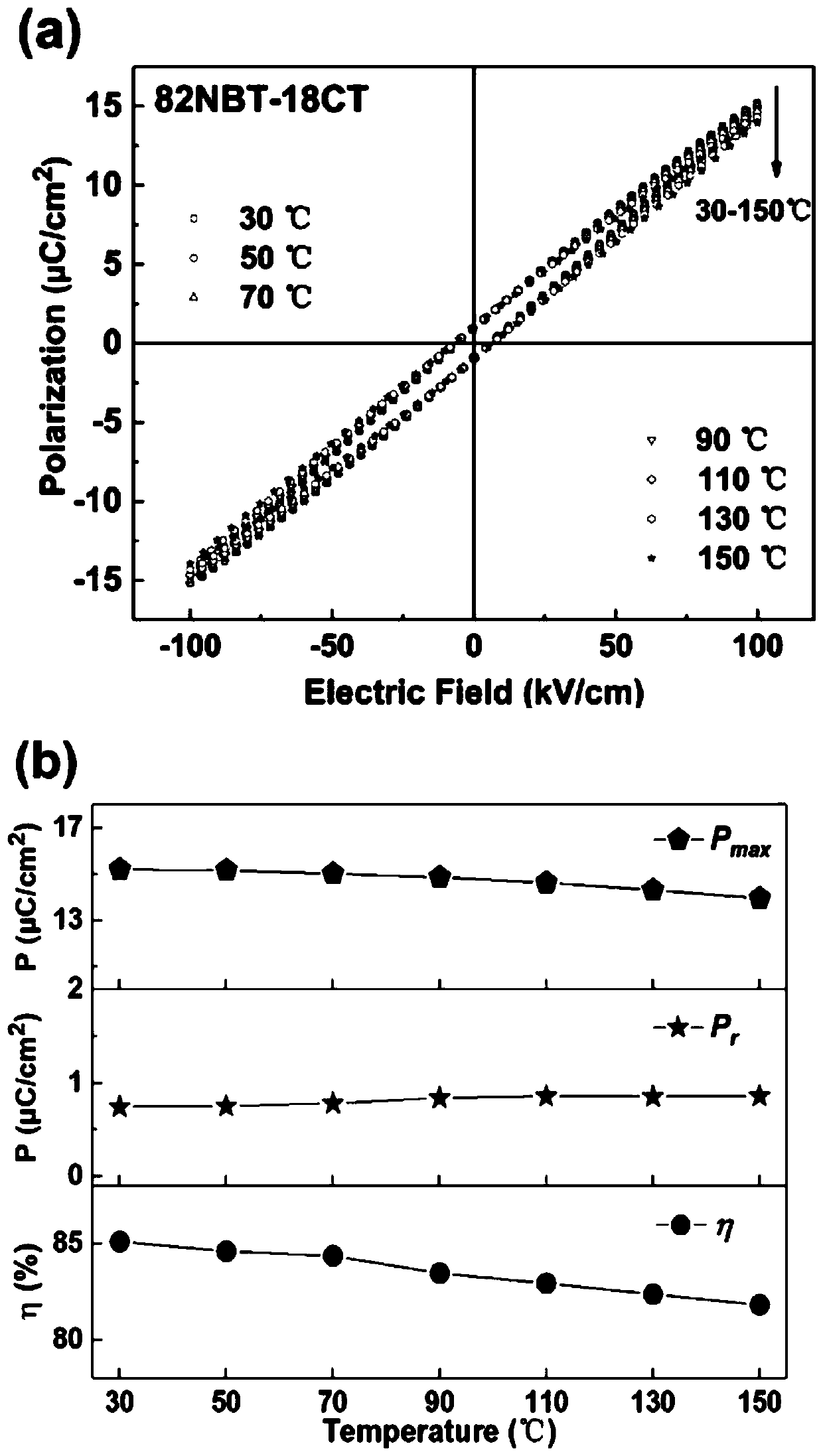

Similar linear lead-free relaxor ferroelectric ceramic material and preparation method thereof

InactiveCN110759728AStable energy storage densityEasy to prepareFixed capacitor dielectricElectrical field strengthHigh energy

The invention relates to a similar linear lead-free relaxor ferroelectric ceramic material and a preparation method thereof, and belongs to the field of dielectric capacitor material preparation. Thesimilar linear lead-free relaxor ferroelectric ceramic material has a chemical composition being 0.82Na0.5Bi0.5TiO3-0.18CaTiO3; when the electric field intensity of the material is 180kV / cm at the room temperature, the effective energy storage density is 2.34J / cm<3>, the total energy storage density is 2.87J / cm<3>, and the energy storage efficiency is larger than 80 percent; in addition, when a temperature stability test is conducted at 30 to 150 DEG C, the energy storage efficiency is maintained to be above 80 percent and is relatively stable, so that the similar linear lead-free relaxor ferroelectric ceramic material becomes an ideal material applied to high energy storage density; and meanwhile, the material is prepared and synthesized by adopting a traditional solid-phase reaction method, the preparation method is simple, the requirement on equipment is low, the sintering temperature is relatively lower (below 1180 DEG C), the reaction conditions are easily controlled, and the repeatability is good.

Owner:SOUTHWEST UNIV

Capacitor material for use in circuitized substrates, circuitized substrate utilizing same, method of making said circuitized substrate, and information handling system utilizing said circuitized substrate

InactiveUS7541265B2Enhance the circuitized substrate artLow costSemiconductor/solid-state device detailsPrinted circuit aspectsBarium titanatePersonal computer

A material for use as part of an internal capacitor within a circuitized substrate includes a polymer (e.g., a cycloaliphatic epoxy or phenoxy based) resin and a quantity of nano-powders of ferroelectric ceramic material (e.g., barium titanate) having a particle size substantially in the range of from about 0.01 microns to about 0.90 microns and a surface area for selected ones of said particles within the range of from about 2.0 to about 20 square meters per gram. A circuitized substrate adapted for using such a material and capacitor therein and a method of making such a substrate are also provided. An electrical assembly (substrate and at least one electrical component) and an information handling system (e.g., personal computer) are also provided.

Owner:TTM TECH NORTH AMERICA LLC

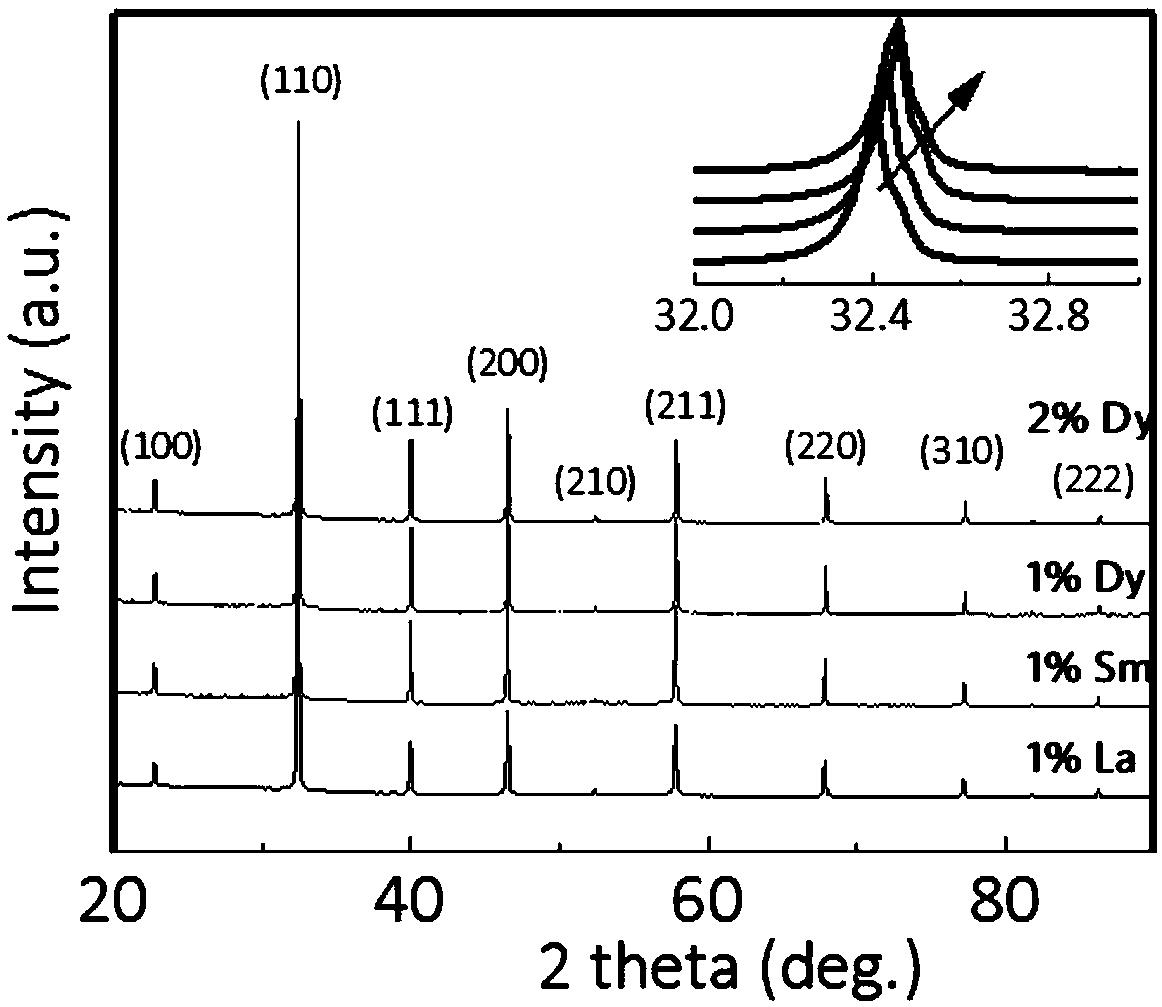

Lead-free relaxation antiferroelectric ceramic energy storage material, and preparation method thereof

ActiveCN109180181AImprove stabilityHigh energy storage densityEnergy storage efficiencyNanotechnology

The invention discloses a lead-free relaxation antiferroelectric ceramic energy storage material, and a preparation method thereof. The chemical formula is (1-x-y)(Na<0.5>Bi<0.5>)TiO<3-x>(Sr<0.7>Bi<0.2>)TiO<3-y>Me<2>O<3>, wherein Me is used for representing one or two elements selected from La, Sm, and Dy, x and y are used for representing molar fractions, 0.2<=x<=0.7, and 0.01<=y<=0.2. The lead-free relaxation antiferroelectric ceramic energy storage material is relatively in energy storage density, energy storage efficiency, and possesses relaxation characteristics, and the preparation method is simple.

Owner:XI AN JIAOTONG UNIV

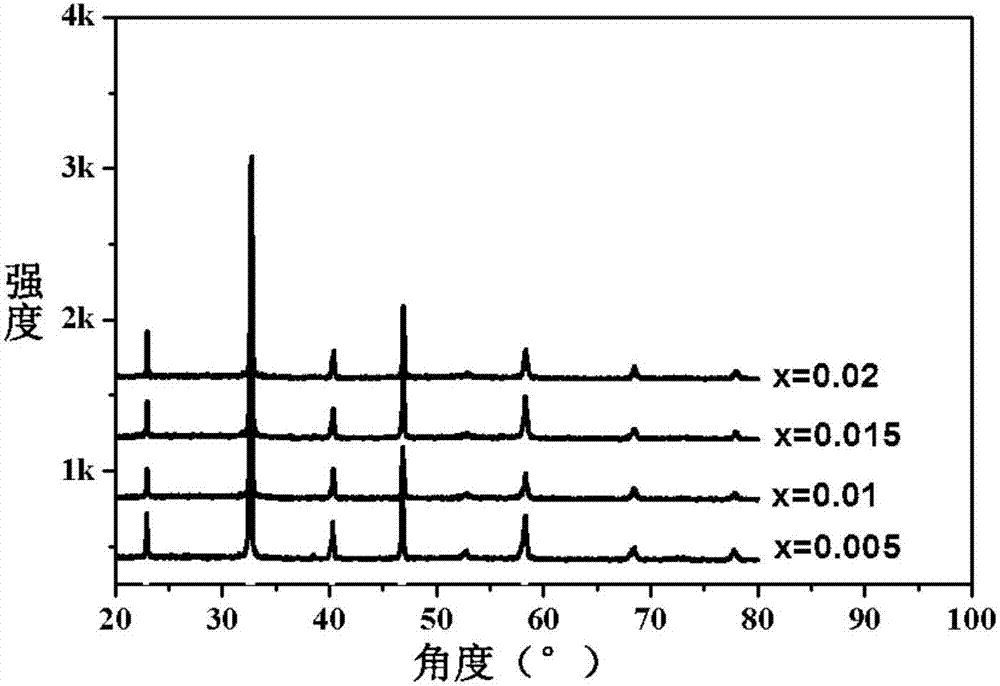

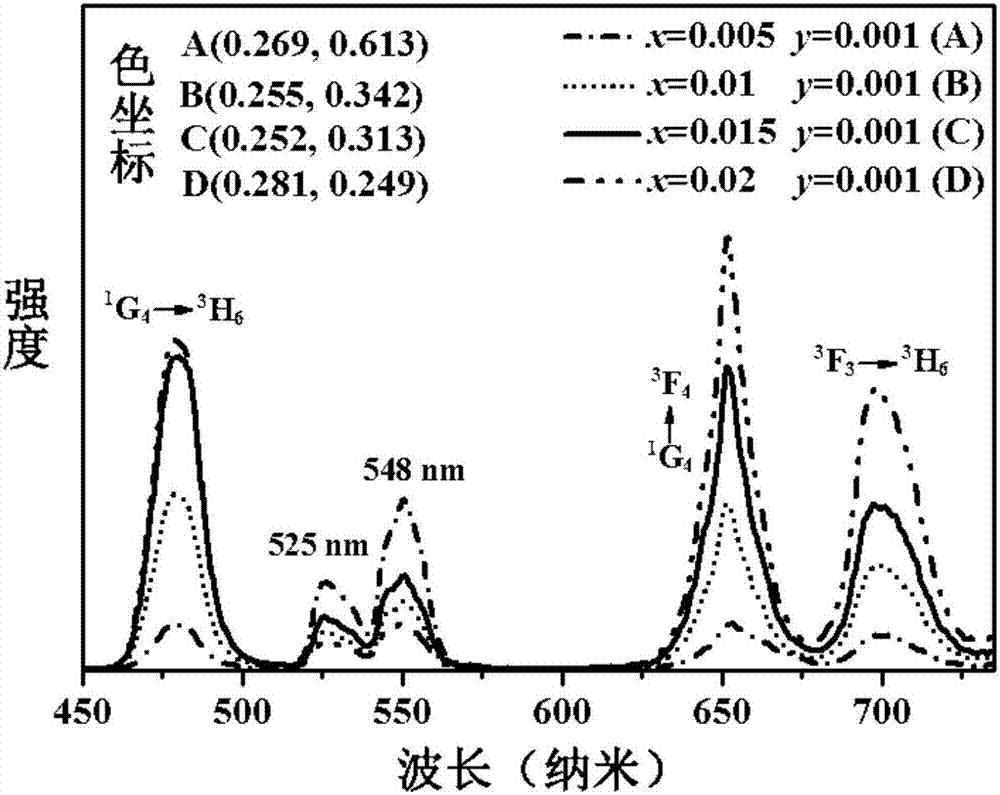

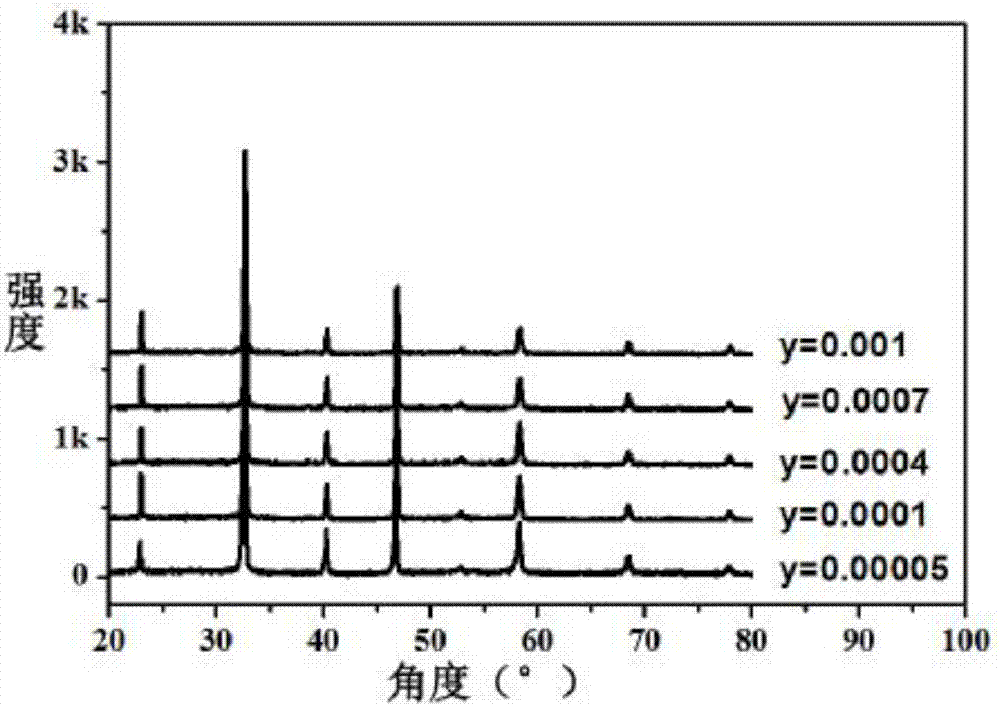

Unleaded ferroelectric upconversion fluorescence material as well as preparation method and application thereof

ActiveCN107057699ARealize color controlHigh luminous intensityThermometers using physical/chemical changesLuminescent compositionsUpconversion luminescenceRare-earth element

The invention relates to an unleaded ferroelectric upconversion fluorescence material. The unleaded ferroelectric upconversion fluorescence material comprises a perovskite unleaded ferroelectric ceramic material with the structure of ABO3, and is characterized in that the chemical formula of the unleaded ferroelectric ceramic material is Na0.5Bi0.5-x-yYbxTmyTiO3, wherein x is greater than or equal to 0.005 and smaller than or equal to 0.02, y is greater than or equal to 0.00005 and smaller than or equal to 0.001, and then defect-based upconversion fluorescence is realized by adding a rare earth element sensitizer Yb<3+> and a rare earth element activator Tm<3+> to substitute Bi<3+> on A sites. The invention also discloses a preparation method of the material. Inherent point defects are used for replacing green rare earth ions emitted in the unleaded ferroelectric ceramic material, so that the adjustment of ceramic components is realized, and then the upconversion fluorescence color and performance of the ceramic material are adjusted; and meanwhile, the invention also provides a preparation method and application of the unleaded ferroelectric upconversion fluorescence material, so that the production cost can be greatly reduced, and the rare earth resources are protected to a great extent.

Owner:东营睿港投资服务有限责任公司

Ferroelectric ceramic micro refrigerator and producing method thereof

InactiveCN1710355AReduce weightReduce volumeMachines using electric/magnetic effectsSustainable buildingsSolid solutionDouble stage

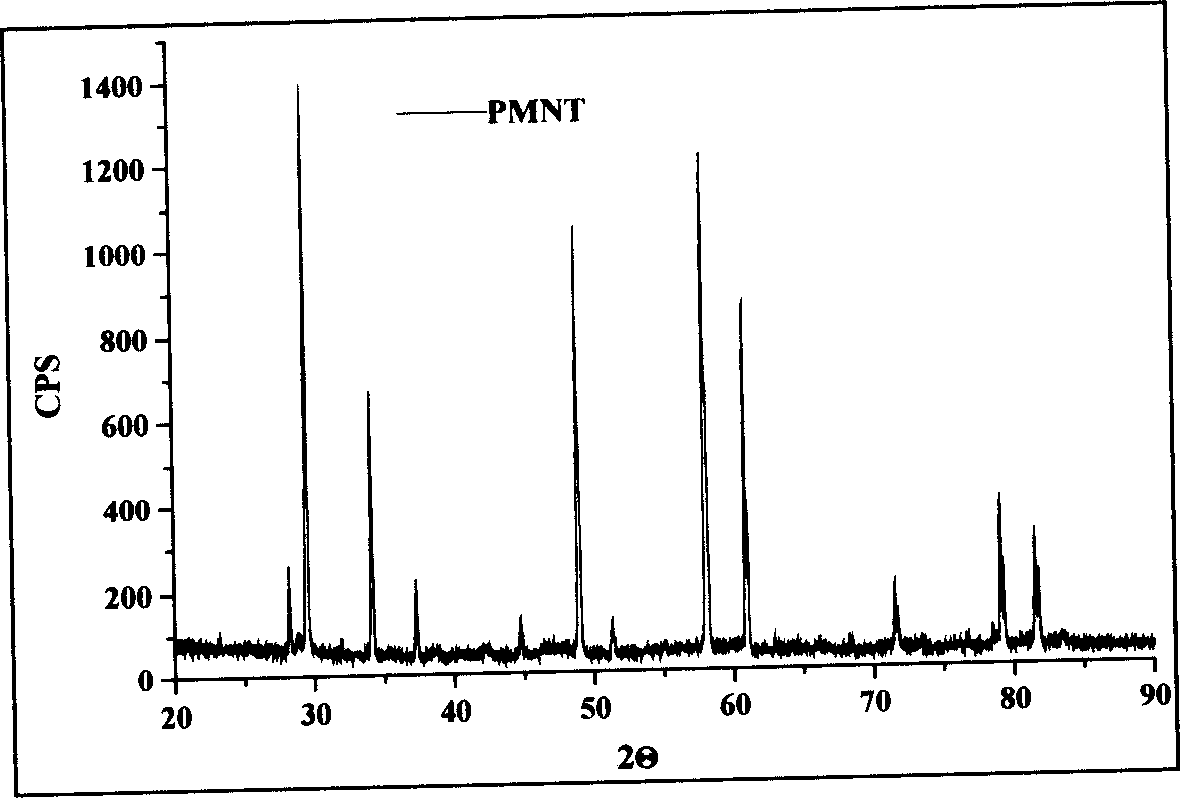

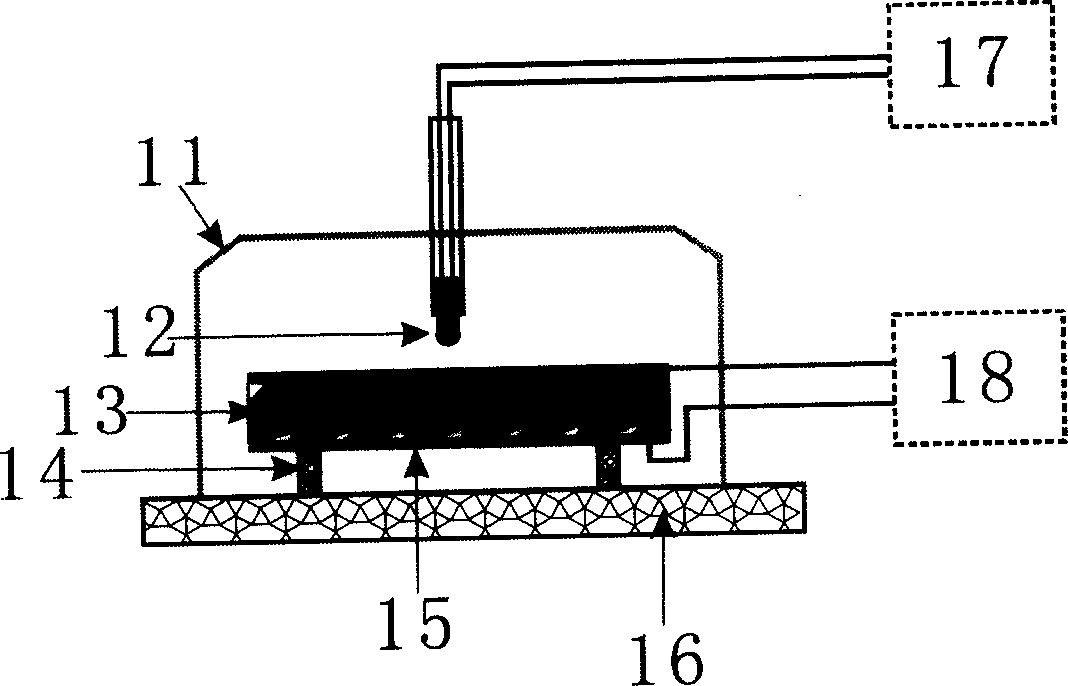

A micro refrigerator of ferroelectric ceramics applies ' double stage - overlap' refrigerating structure and it is prepared adapting relaxation and solid solution of PMNT with high electro biological heat effect under wet preparation method of sol - gel . In said method, new mode of physical-chemical thickness reduction and new detecting means of electro biological heat property are applied.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

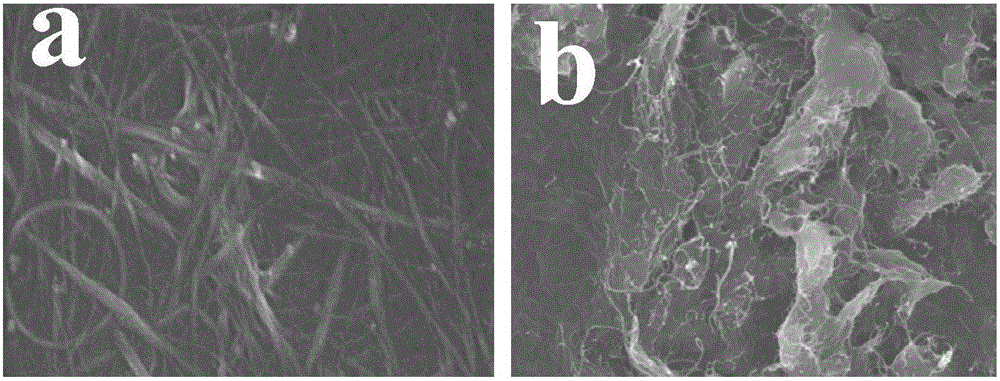

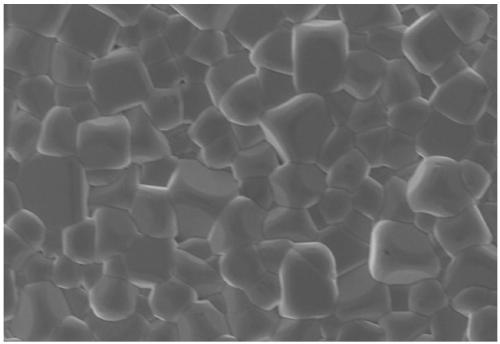

Preparation method of leadless antiferroelectric sodium niobate piezoelectric ceramic

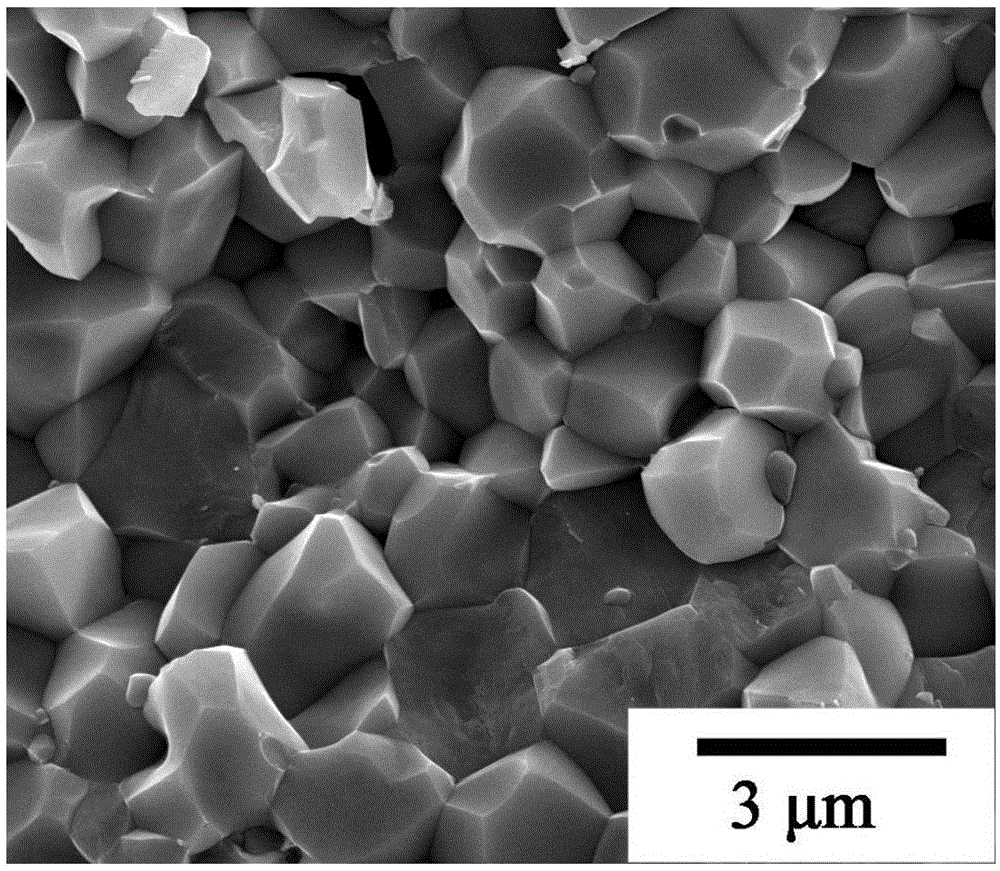

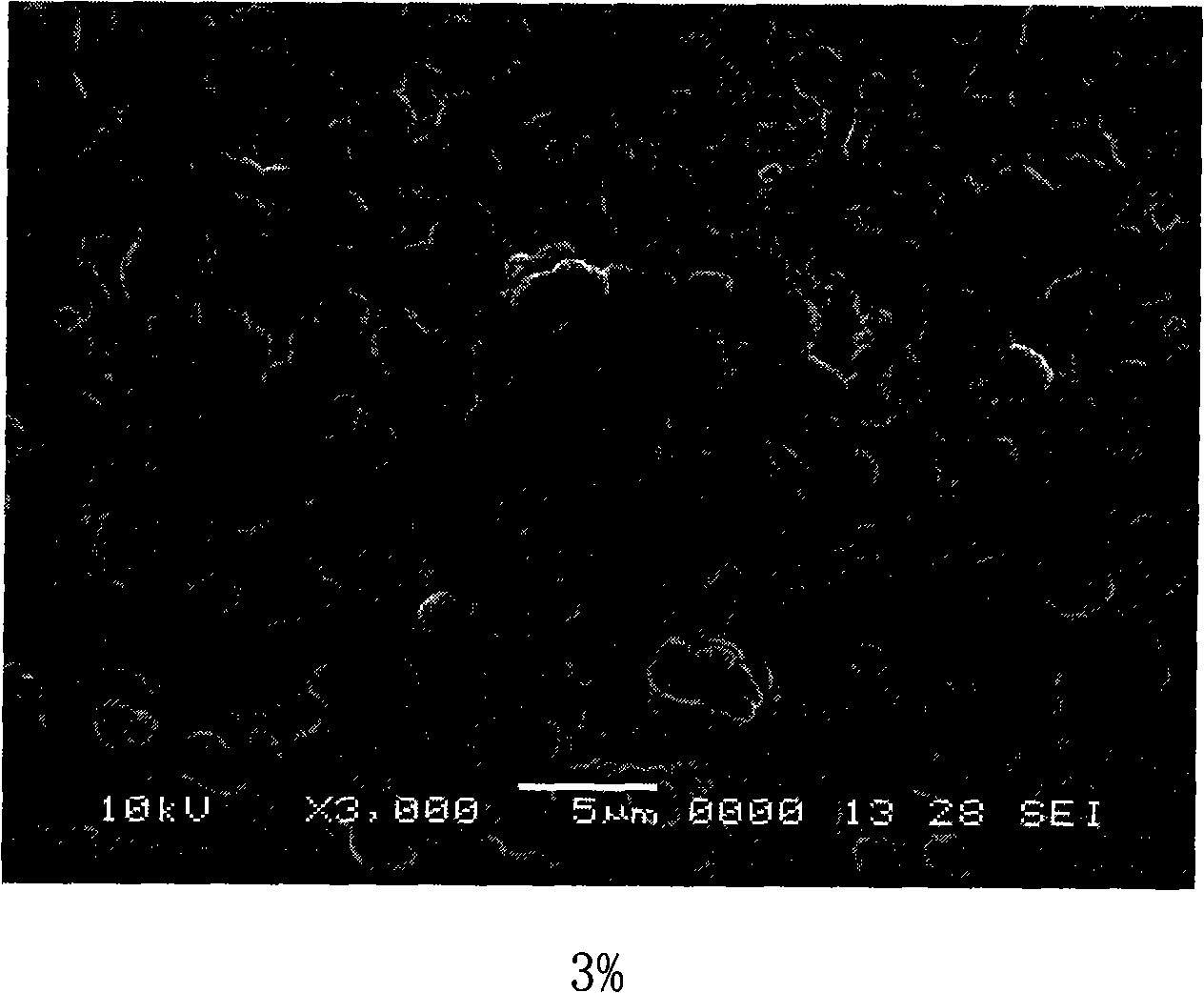

The invention relates to a preparation method of sodium niobate ceramic with a diamond-shaped crystal grain morphology, and belongs to the field of leadless antiferroelectric piezoelectric ceramic crystal grain regulation and control. The chemical formula of the sodium niobate ceramic is NaNbO3 (called NN for short), the crystal grain morphology of the ceramic has a diamond shape, and the crystal grain has gradient anisotropy. The preparation method comprises the following steps: carrying out ball milling to prepare mixed raw material powder, processing the mixed raw material powder through an appropriate technology to prepare a mixing precursor, and carrying out a solid phase reaction through appropriate technology regulation and control in order to prepare the antiferroelectric piezoelectric ceramic with uniform micrometer crystal grain size. The dimension effect of the crystal grain makes the ceramic have an excellent ferroelectric performance not antiferroelectric performance. The ceramic has a strong demonstration effect in the crystal grin regulation and control field, so the ceramic has bright prospect; and the high-performance leadless antiferroelectric sodium niobate ceramic prepared through the method has wide application values in high voltage ceramic energy storage capacitors and electro-mechanical energy transducers.

Owner:CHINA JILIANG UNIV

Ferroelectric ceramic with low-temperature sintering characteristic and its technique and application

InactiveCN101265081AForming and sintering temperature decreasedReduce volatilityImpedence networksPiezoelectric/electrostrictive devicesLead zirconate titanateTransformer

The invention relates to a ferroelectric ceramic with low-temperature sintering property, utilizes ferroelectric ceramic materials with low-temperature sintering property as sintering additives, employs the conventional solid-phase ceramic process, and realizes the non-pressure low-temperature (100 DEG C) sintering of lead zirconate titanate piezoelectric ceramics for commercial purpose and modification in piezoelectric property. The non-pressure low-temperature sintered piezoelectric ceramic sheet, PbZr1-xTixO3-BiCrO3-BiFeO3-PbTiO3, has a single-phase perovskite structure and exhibits 'hardness' piezoelectric property compared with the piezoelectric ceramic powder for commercial purpose and the ceramic sheet made by the conventional sintering process. The inventive ferroelectric ceramic is particularly suitable for the fabrication of functional devices such as emission piezoelectric ceramic devices, low-temperature cofired multi-layer piezoelectric ceramic drivers, transformers, transducers.

Owner:TONGJI UNIV

Anti-ferroelectric ceramic material and preparation method thereof

The invention relates to an anti-ferroelectric ceramic material and a preparation method thereof. The chemical general formula of the anti-ferroelectric ceramic material is (Pb<0.91>Ba<x>La<0.06-2x / 3>) (Zr<y>Sn<1-y>) O<3>, wherein 0<x<0.09, and 0<y<1. Compared with the prior art, the anti-ferroelectric ceramic material prepared by a traditional electronic ceramic preparation process has the characteristics of high energy storage density, small hysteresis, high energy storage efficiency and excellent charge discharge performance, and is of great significance for the development of pulse power capacitors with high energy storage density and high energy storage efficiency with long cycle charge discharge life.

Owner:TONGJI UNIV

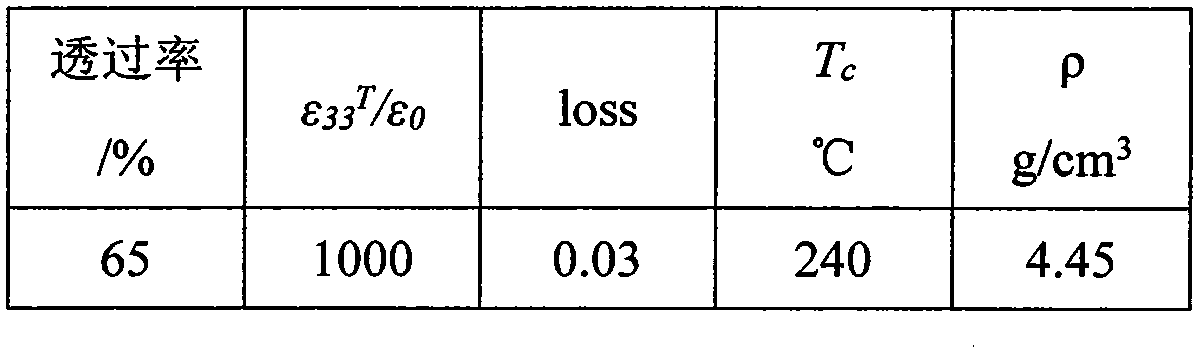

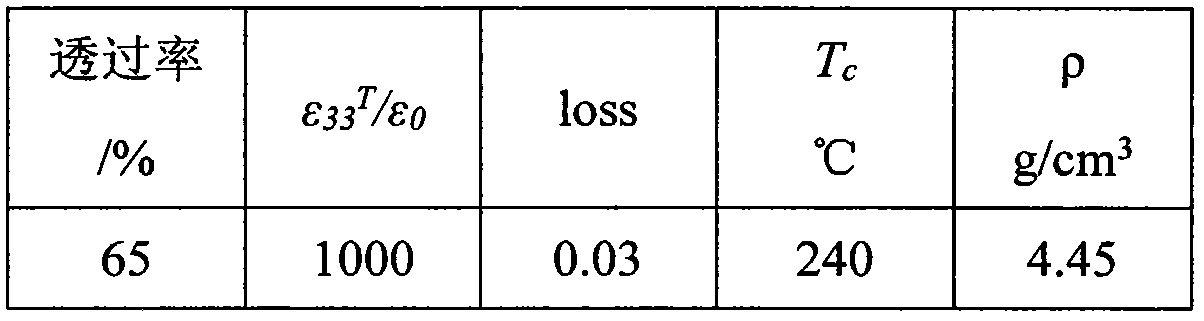

(K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 leadless transparent ferroelectric ceramic material and preparation method thereof

InactiveCN104030683ASimple preparation processReduce manufacturing costSilver electrodeOptical transmittance

The invention discloses a (K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 leadless transparent ferroelectric ceramic material and a preparation method thereof. Through adding Sr(Sc0.5Nb0.5)O3, the grain size of (K0.5Na0.5)NbO3-based ceramics can be up to hundreds of nanometers which are basically same as the wavelength of visible light, and a ceramic sample has the transmittance of 60-70% within the ranges of visible light and near infrared rays and also has relatively high curie temperature and ferroelectric performance. The (K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 leadless transparent ferroelectric ceramic material has the stoichiometric ratio of (1-x), wherein 0.02<=x<=0.4. The preparation method of the (K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 leadless transparent ferroelectric ceramic material comprises the steps: proportioning; drying and grinding; carrying out secondary presintering; granulating; forming; sintering; and grinding and sintering a silver electrode to obtain the leadless transparent ferroelectric ceramic material with high optical transmittance, wherein the leadless transparent ferroelectric ceramic material can be used for improving the compact degree and optical transmittance of ceramics. The (K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 leadless transparent ferroelectric ceramic material has the advantages of simple preparation process and low preparation cost and is strong in practicability.

Owner:AIR FORCE UNIV PLA

(K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 lead-free transparent ferroelectric ceramic material and preparation method thereof

InactiveCN104098333ASimple preparation processReduce manufacturing costSilver electrodeOptical transmittance

The invention discloses a (K0.5Na0.5)NbO3-Sr(Sc0.5Nb0.5)O3 lead-free transparent ferroelectric ceramic material and a preparation method thereof. By adding Sr(Sc0.5Nb0.5)O3, (K0.5Na0.5)NbO3 based ceramic can have a grain size up to hundreds of nanometers, which is basically the same with the wavelength of visible light. In the range of visible light and near infrared, a ceramic sample has 60-70% transmittance, and high Curie temperature and ferroelectric properties. The lead-free transparent ferroelectric ceramic has a stoichiometric ratio of (1-x)(K0.5Na0.5)NbO3-xSr(Sc0.5Nb0.5)O3, wherein x is greater than or equal to 0.02 and smaller than or equal to 0.4. By means of the processes of proportioning, drying and grinding, twice pre-sintering, granulation, forming, sintering, grinding and silver electrode coating, the lead-free transparent ferroelectric material with high optical transmittance can be obtained, and the densification degree and optical transmittance of the ceramic are improved. The lead-free transparent ferroelectric ceramic material provided by the invention has the advantages of simple preparation process and low preparation cost, and has strong practicability.

Owner:AIR FORCE UNIV PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com