Magnetoelectric effect based magnetoelectric memory element of ferroelectric/ferromagnetic composite thin film

A magnetoelectric storage and composite thin film technology, applied in the manufacture/processing of electromagnetic devices, information storage, static memory, etc., to achieve the effect of good ferroelectricity, simple process, and fast reading and writing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

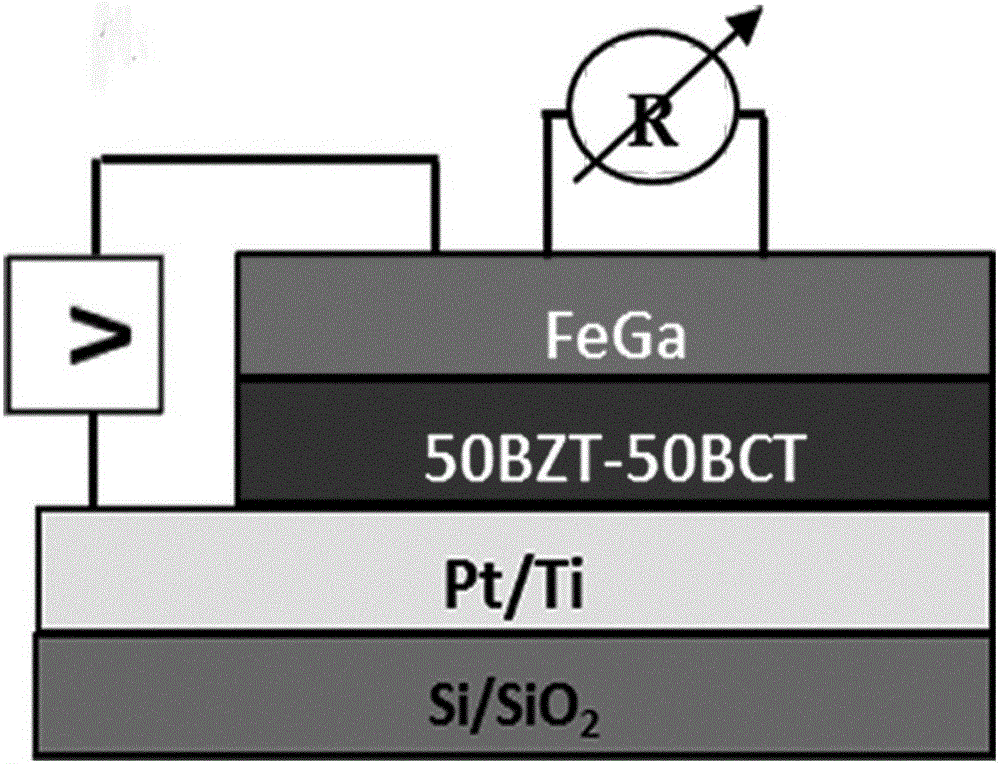

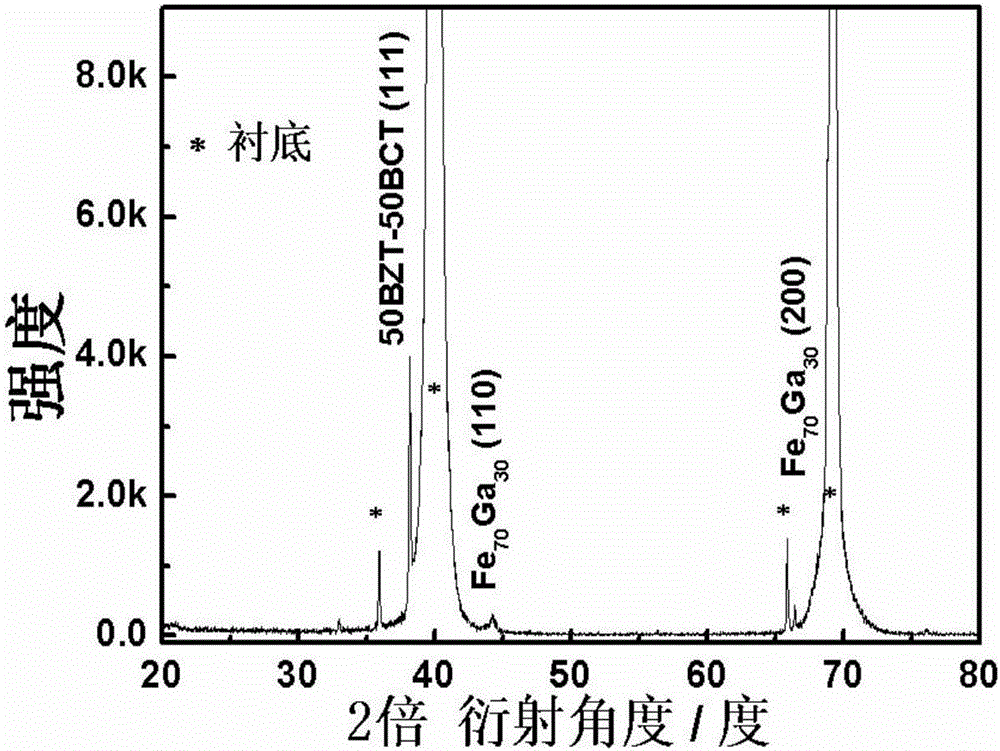

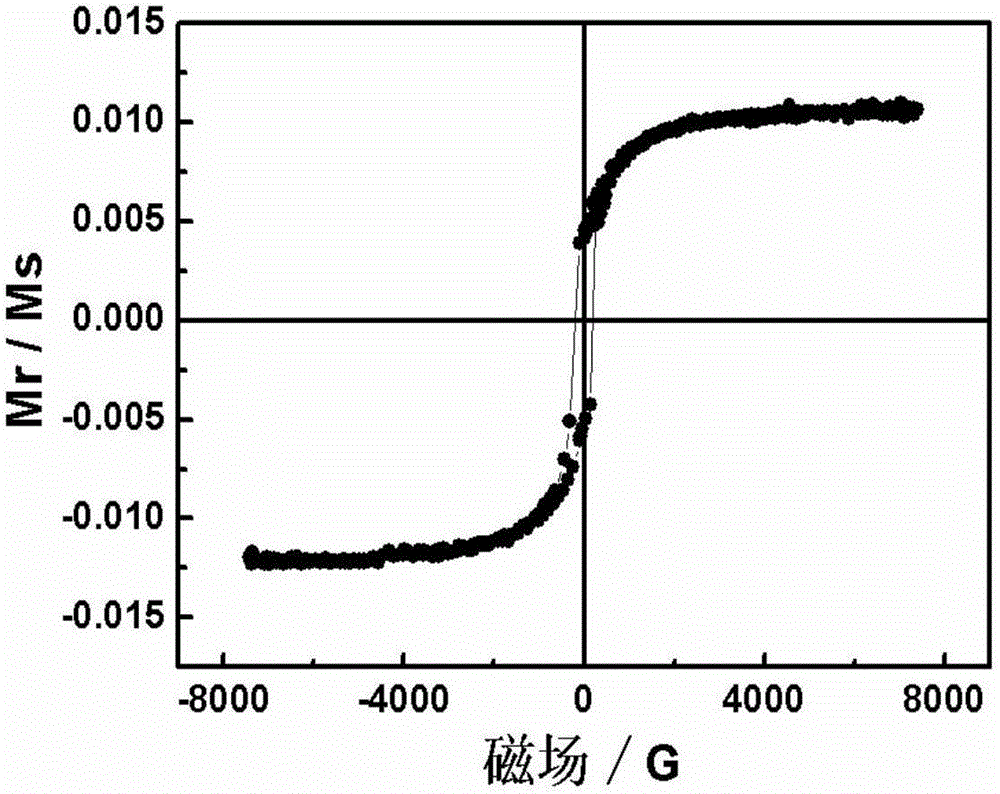

[0021] A magnetoelectric storage element based on magnetoelectric effect ferroelectric / ferromagnetic composite thin film, in Pt / Ti / SiO 2 The ferroelectric and ferromagnetic thin films are sequentially deposited on the / Si composite substrate to form a laminated structure, in which the composite substrate is Si, SiO 2 , Ti and Pt bottom electrodes, the chemical structure of ferroelectric thin film with piezoelectric effect is 0.5Ba(Zr 0.2 Ti 0.8 )O 3 -0.5(Ba 0.3 Ca 0.7 )TiO 3 (BZT-BCT), the thickness is 200nm, the film with magnetostrictive effect is Fe 0.7 Ga 0.3 , with a thickness of 200nm.

[0022] The preparation method of the magnetoelectric storage element based on the ferroelectric / ferromagnetic film structure of the magnetoelectric effect, wherein the ferroelectric ceramic film is prepared by radio frequency magnetron sputtering, and the ferromagnetic film is made of Fe 0.7 Ga 0.3 The alloy target is prepared by DC magnetron sputtering, the steps are as follows...

Embodiment 2

[0031] A magnetoelectric storage element based on magnetoelectric effect ferroelectric / ferromagnetic composite thin film, in Pt / Ti / SiO 2 The ferroelectric and ferromagnetic thin films are sequentially deposited on the / Si composite substrate to form a laminated structure, in which the composite substrate is Si, SiO 2 , Ti and Pt bottom electrodes, the chemical structure of ferroelectric thin film with piezoelectric effect is 0.5Ba(Zr 0.2 Ti 0.8 )O 3 -0.5(Ba 0.3 Ca 0.7 )TiO 3 (BZT-BCT), the thickness is 250nm, the film with magnetostrictive effect is Fe 0.7 Ga 0.3 , with a thickness of 250nm.

[0032] The preparation method of the magnetoelectric storage element based on the ferroelectric / ferromagnetic film structure of the magnetoelectric effect, wherein the ferroelectric ceramic film is prepared by radio frequency magnetron sputtering, and the ferromagnetic film is made of Fe 0.7 Ga 0.3 The alloy target is prepared by DC magnetron sputtering, the steps are as follows...

Embodiment 3

[0037] A magnetoelectric storage element based on magnetoelectric effect ferroelectric / ferromagnetic composite thin film, in Pt / Ti / SiO 2 The ferroelectric and ferromagnetic thin films are sequentially deposited on the / Si composite substrate to form a laminated structure, in which the composite substrate is Si, SiO 2 , Ti and Pt bottom electrodes, the chemical structure of ferroelectric thin film with piezoelectric effect is 0.5Ba(Zr 0.2 Ti 0.8 )O 3 -0.5(Ba 0.3 Ca 0.7 )TiO 3 (BZT-BCT), the thickness is 300nm, the film with magnetostrictive effect is Fe 0.7 Ga 0.3 , with a thickness of 300nm.

[0038] A method for preparing a magnetoelectric storage element based on the ferroelectric / ferromagnetic film structure of the magnetoelectric effect, wherein the ferroelectric ceramic film is prepared by radio frequency magnetron sputtering, and the ferromagnetic film is made of Fe 0.7 Ga 0.3 The alloy target is prepared by DC magnetron sputtering, the steps are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com