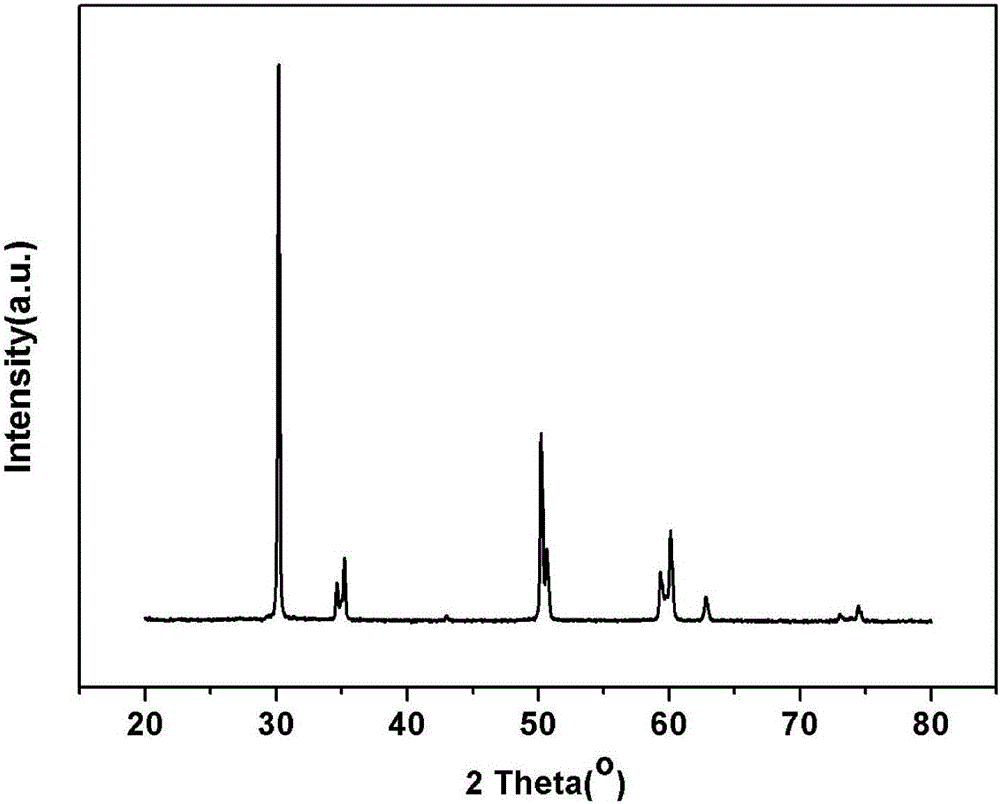

3 YSZ nano powder, preparation method and use thereof

A nano-powder and zirconia technology, applied in the field of material science, can solve the problems of pollution, long ball milling time, high cost, etc., and achieve the effect of good repeatability, simple and convenient process, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Ingredients: Accurately weigh zirconia and yttrium oxide raw materials according to the stoichiometric ratio, and calculate based on a total mass of 1000 parts, of which 945 parts are zirconia and 55 parts are yttrium oxide;

[0028] (2) Stirring ball milling: place zirconia and yttrium oxide in a stirring ball mill, add deionized water and 0.30% by weight dispersant ammonium polyacrylate, adjust to a slurry with a solid content of 30% by weight, stir ball mill for 1 hour, and grind It is a zirconia ball with a particle size of 3mm;

[0029] (3) Sand milling: the slurry after stirring ball milling is introduced into the sand mill, and it is sanded at 800r / min for 6 hours. The grinding body is zirconia beads with a particle size of 0.7-0.8mm. The material is sanded once every 5 minutes;

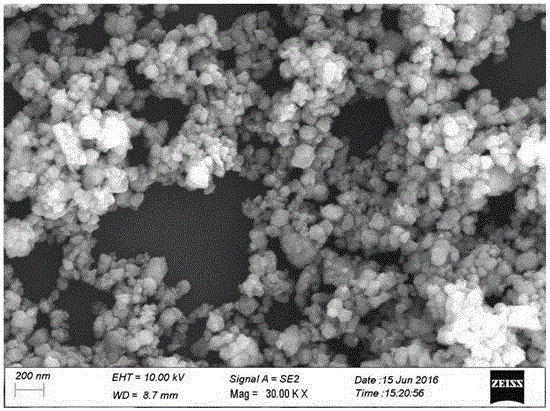

[0030] (4) Drying: The sanded slurry is introduced into the spray drying equipment for spray drying to obtain the final powder with an average particle size of less than 80nm. The ...

Embodiment 2

[0032] (1) Ingredients: Accurately weigh zirconia and yttrium oxide raw materials according to the stoichiometric ratio, and calculate based on a total mass of 1000 parts, of which 945 parts are zirconia and 55 parts are yttrium oxide;

[0033] (2) Stirring ball milling: place zirconia and yttrium oxide in a stirring ball mill, add deionized water and 0.40% by weight dispersant sodium tripolyphosphate, adjust to a slurry with a solid content of 55% by weight, stir ball mill for 2 hours, and grind The body is a zirconia ball with a particle size of 3mm;

[0034] (3) Sand milling: the slurry after stirring ball milling is introduced into the sand mill, and it is sanded for 5 hours at 900r / min. The grinding body is zirconia beads with a particle size of 0.5-0.6mm. The material is sanded once every 6 minutes;

[0035] (4) Drying: The sanded slurry is introduced into the spray drying equipment for spray drying to obtain the final powder with an average particle size of less than 7...

Embodiment 3

[0037] (1) Ingredients: Accurately weigh zirconia and yttrium oxide raw materials according to the stoichiometric ratio, and calculate based on a total mass of 1000 parts, of which 945 parts are zirconia and 55 parts are yttrium oxide;

[0038] (2) Stirring ball milling: place zirconia and yttrium oxide in a stirring ball mill, add deionized water and 0.45% by weight dispersant PEG2000, adjust to a slurry with a solid content of 62.5% by weight, stir ball mill for 3 hours, and the grinding body is granular Zirconia balls with a diameter of 3mm;

[0039] (3) Sand milling: the slurry after stirring ball milling is introduced into the sand mill, and it is sanded for 4 hours at 950r / min. The grinding body is zirconia beads with a particle size of 0.3-0.4mm. The material is sanded once every 7 minutes;

[0040] (4) Drying: The sanded slurry is introduced into the spray drying equipment for spray drying to obtain the final powder with an average particle size of less than 60nm. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com