Patents

Literature

427 results about "Yttria-stabilized zirconia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yttria-stabilized zirconia (YSZ) is a ceramic in which the cubic crystal structure of zirconium dioxide is made stable at room temperature by an addition of yttrium oxide. These oxides are commonly called "zirconia" (ZrO₂) and "yttria" (Y₂O₃), hence the name.

Corrosion control for chamber components

Owner:APPLIED MATERIALS INC

Corrosion control for chamber components

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

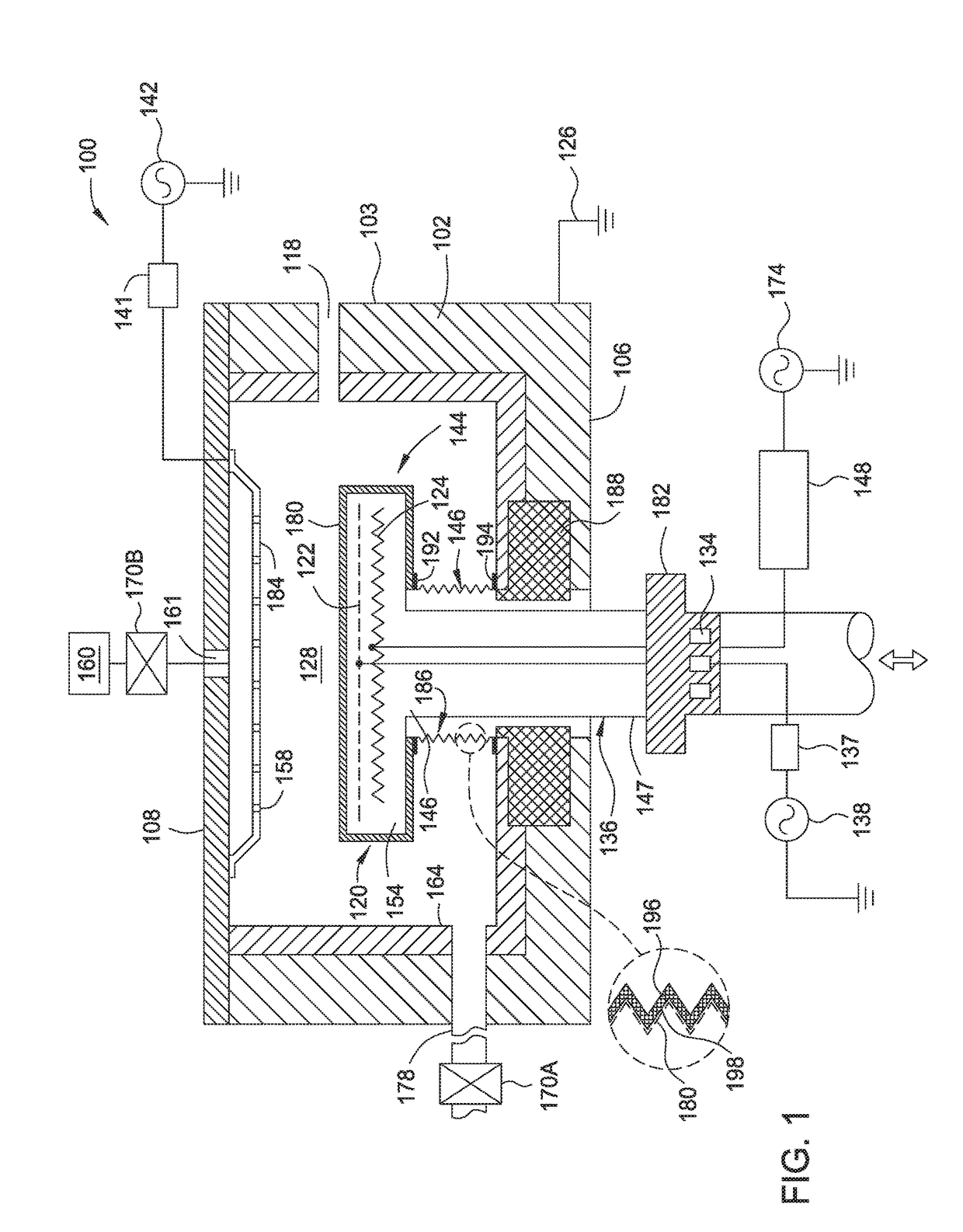

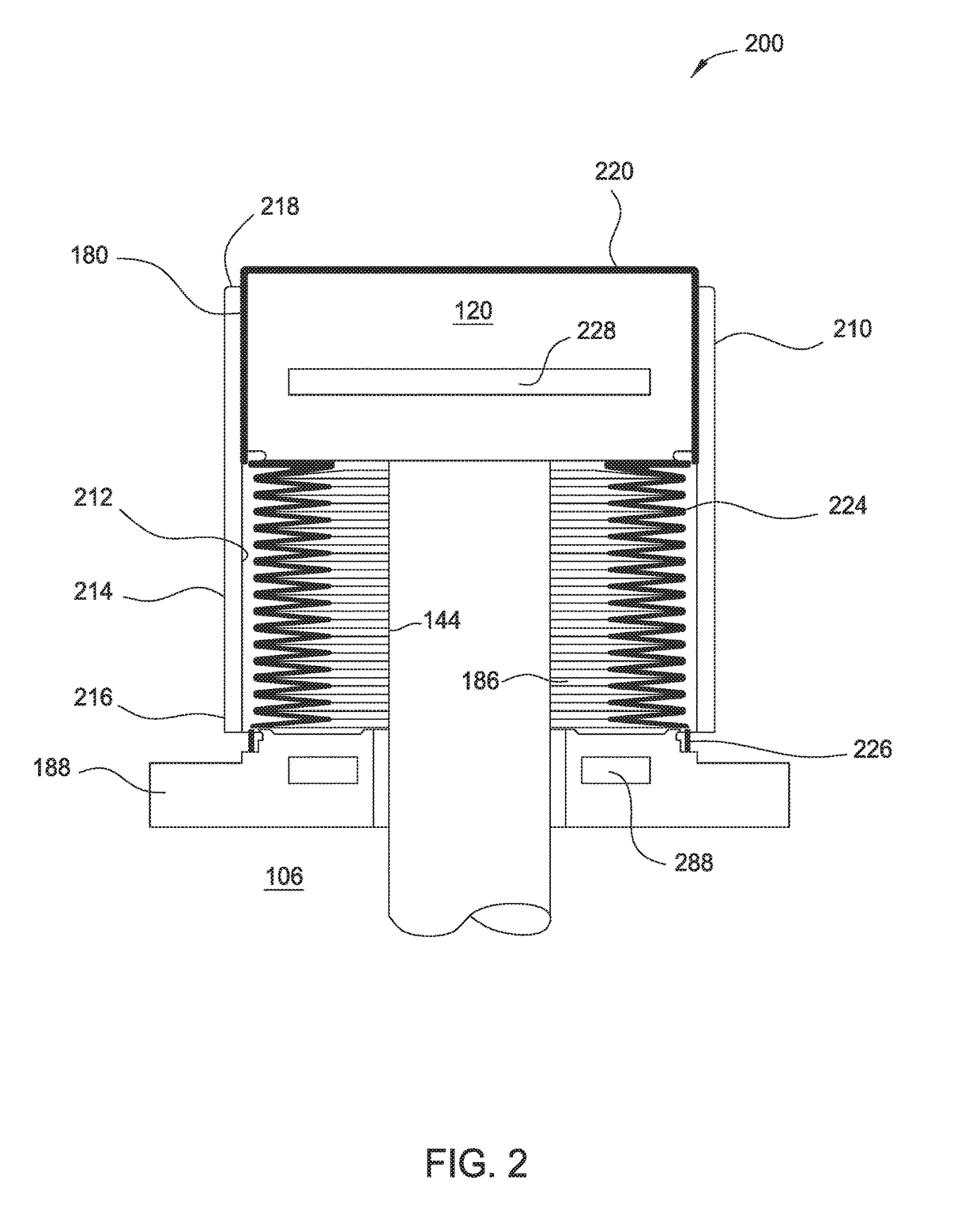

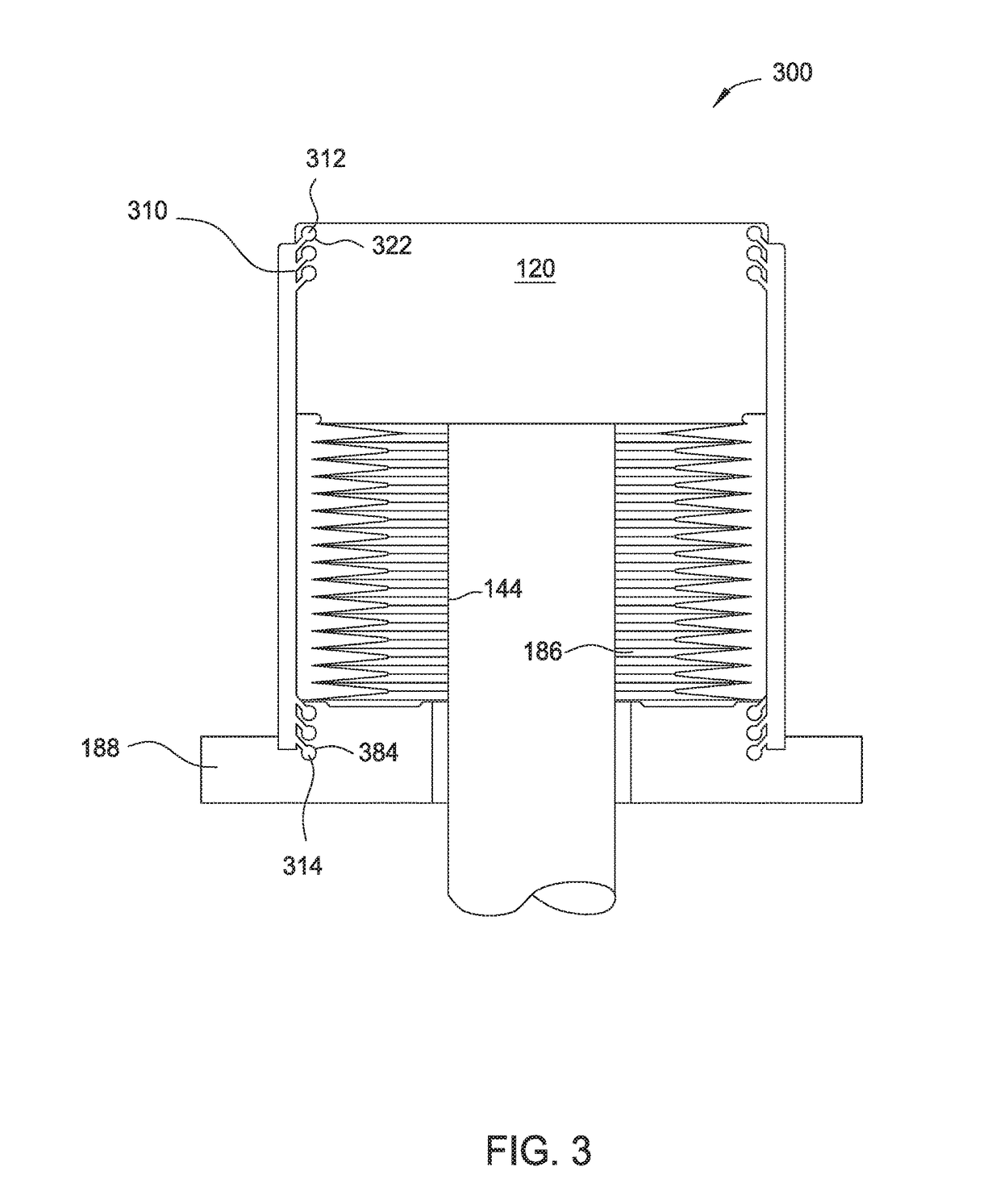

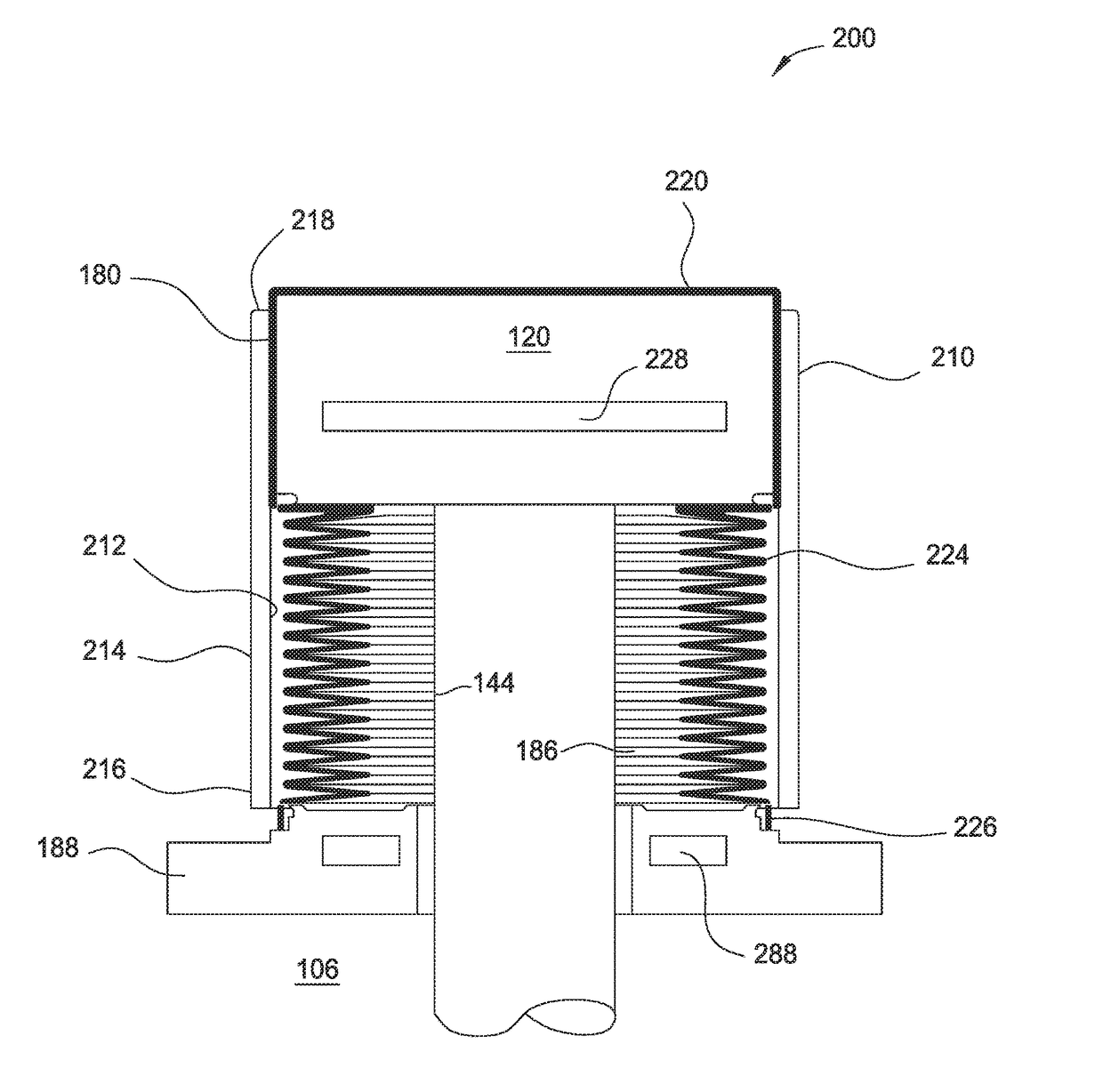

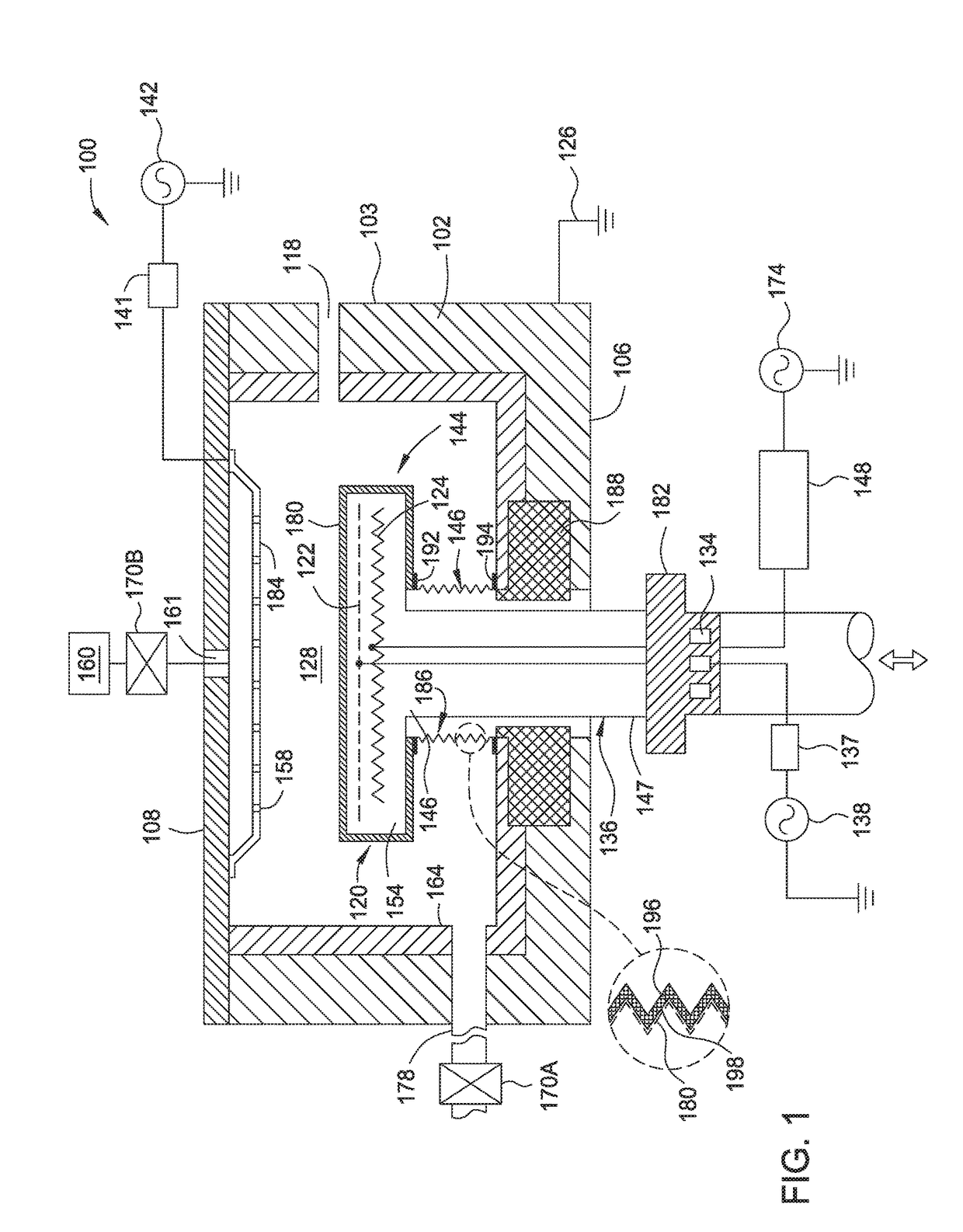

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

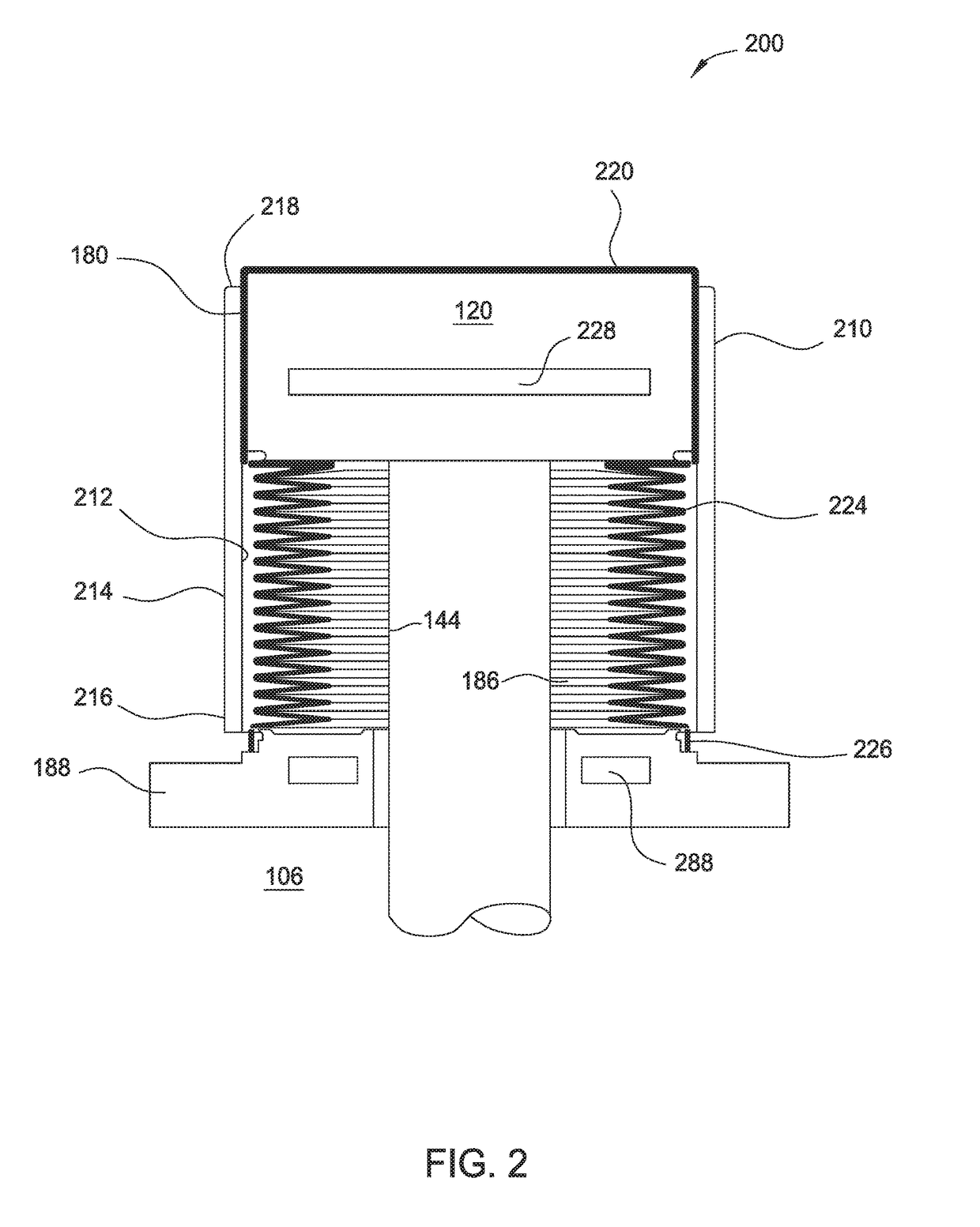

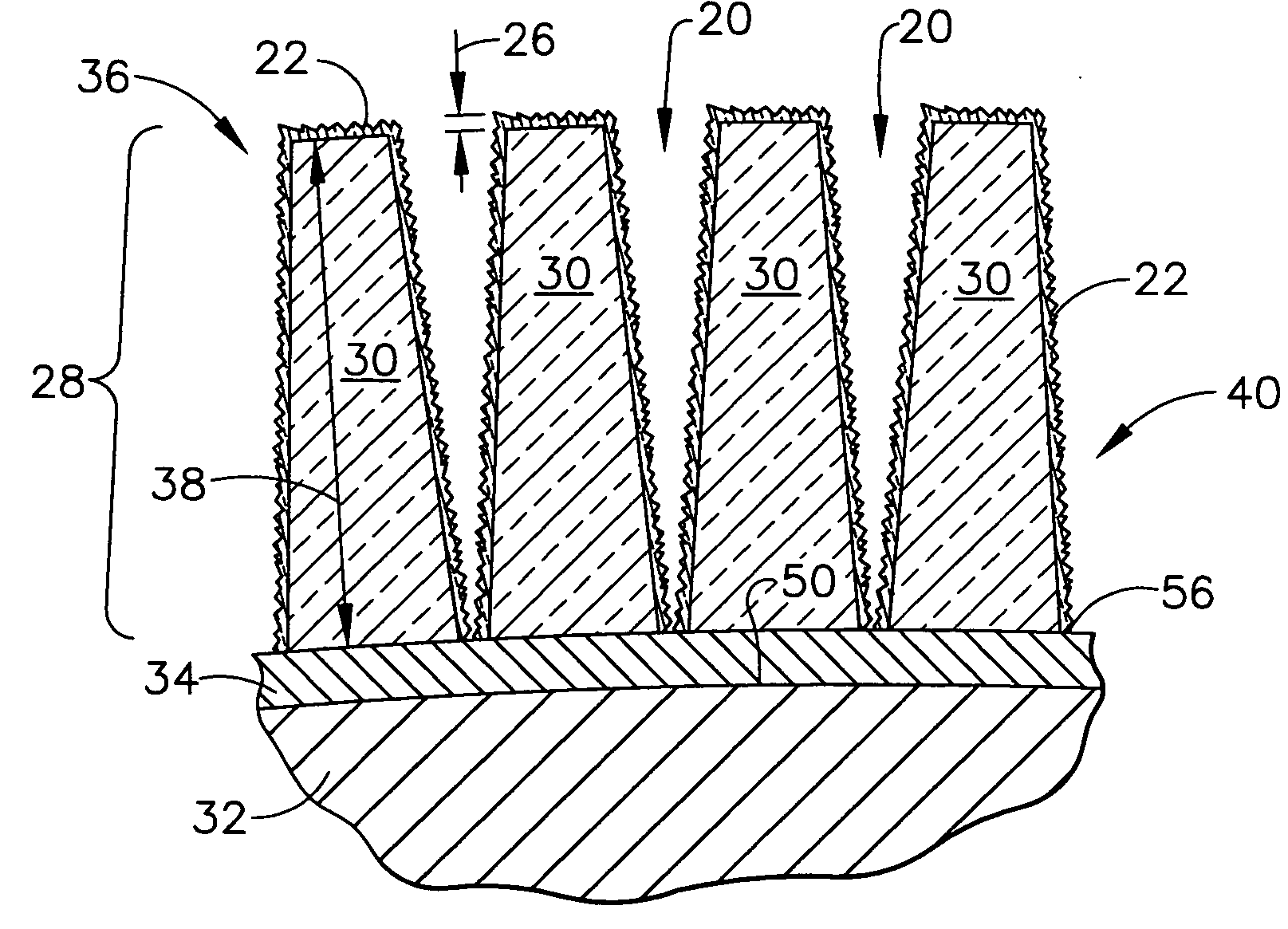

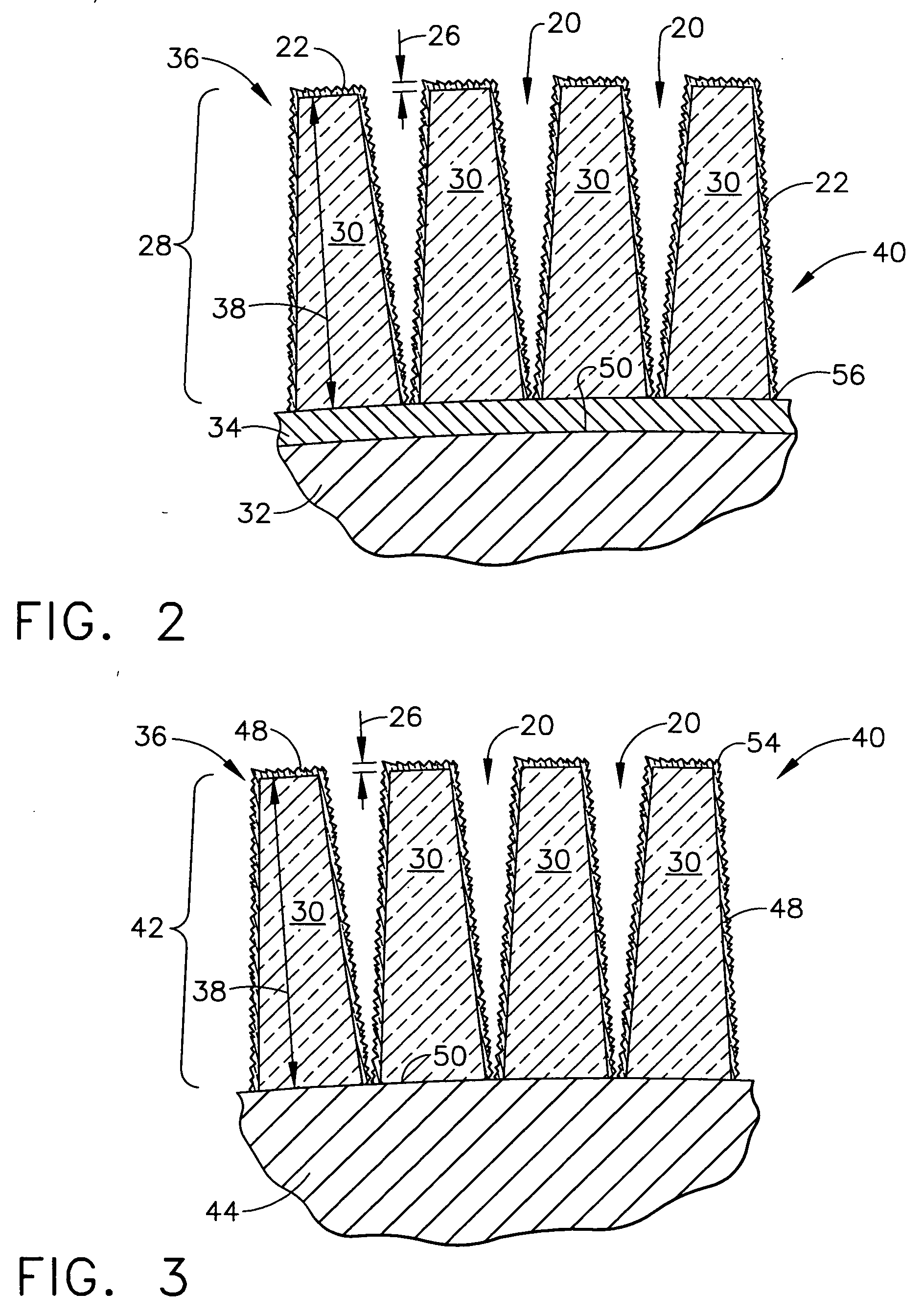

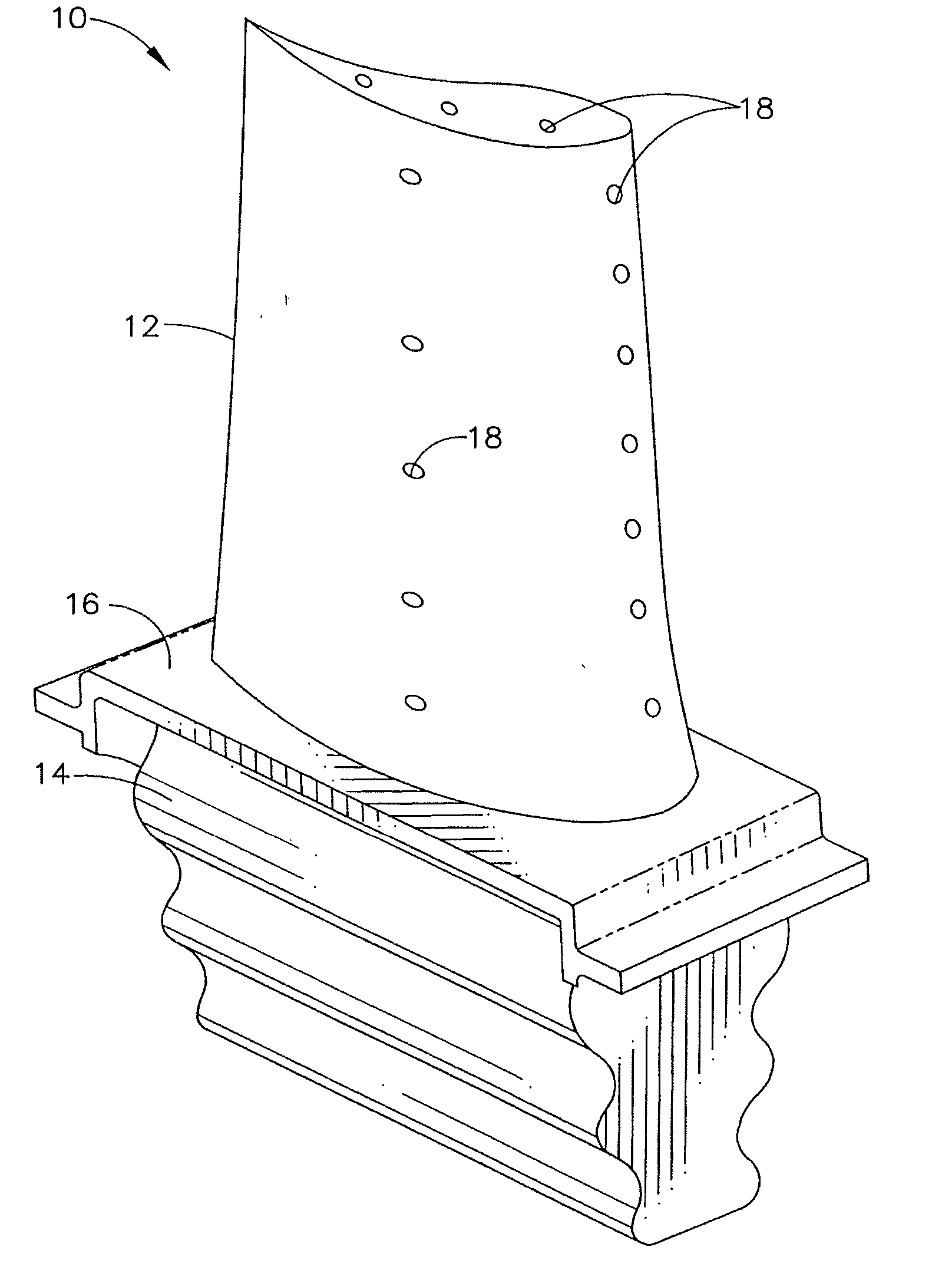

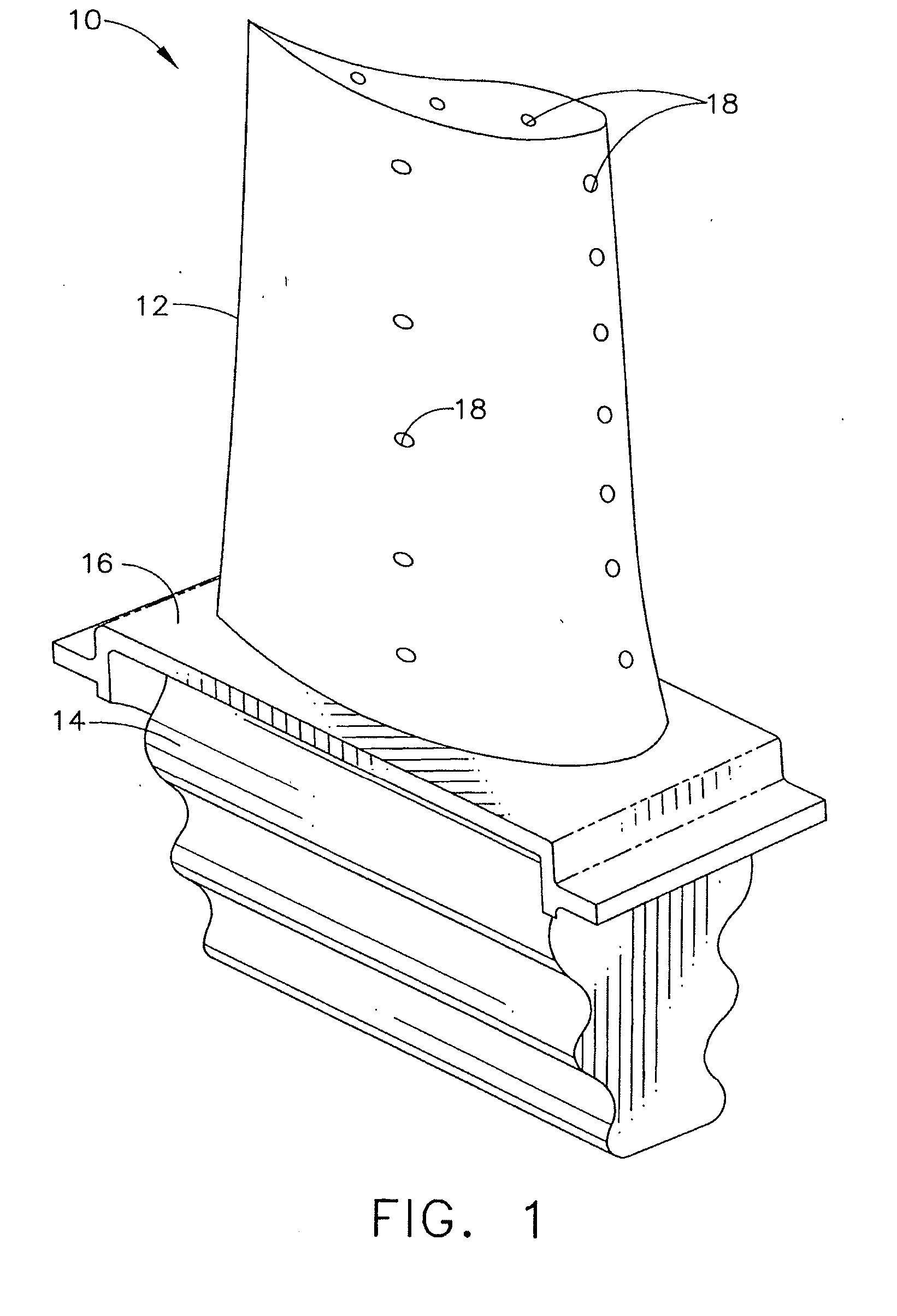

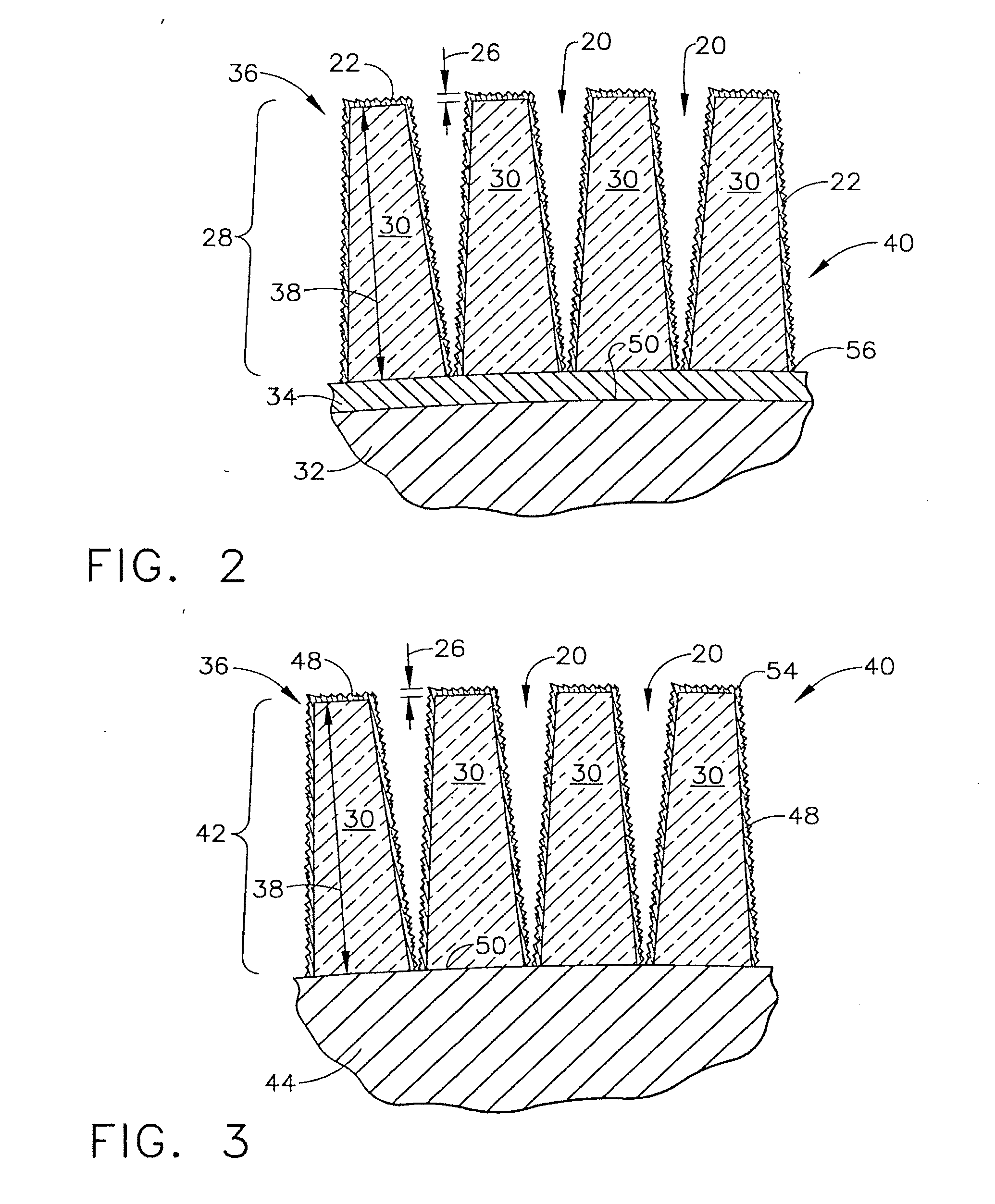

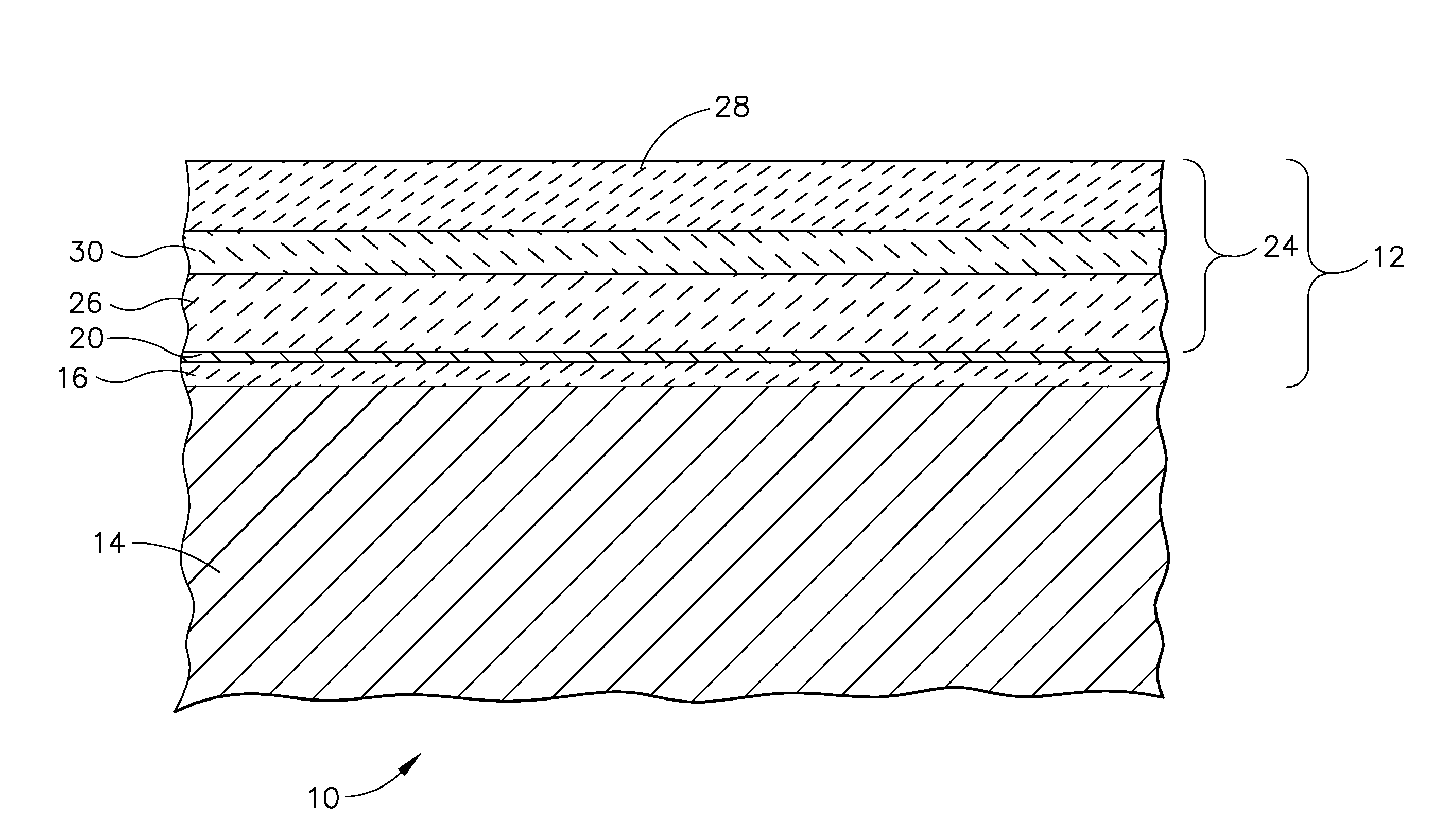

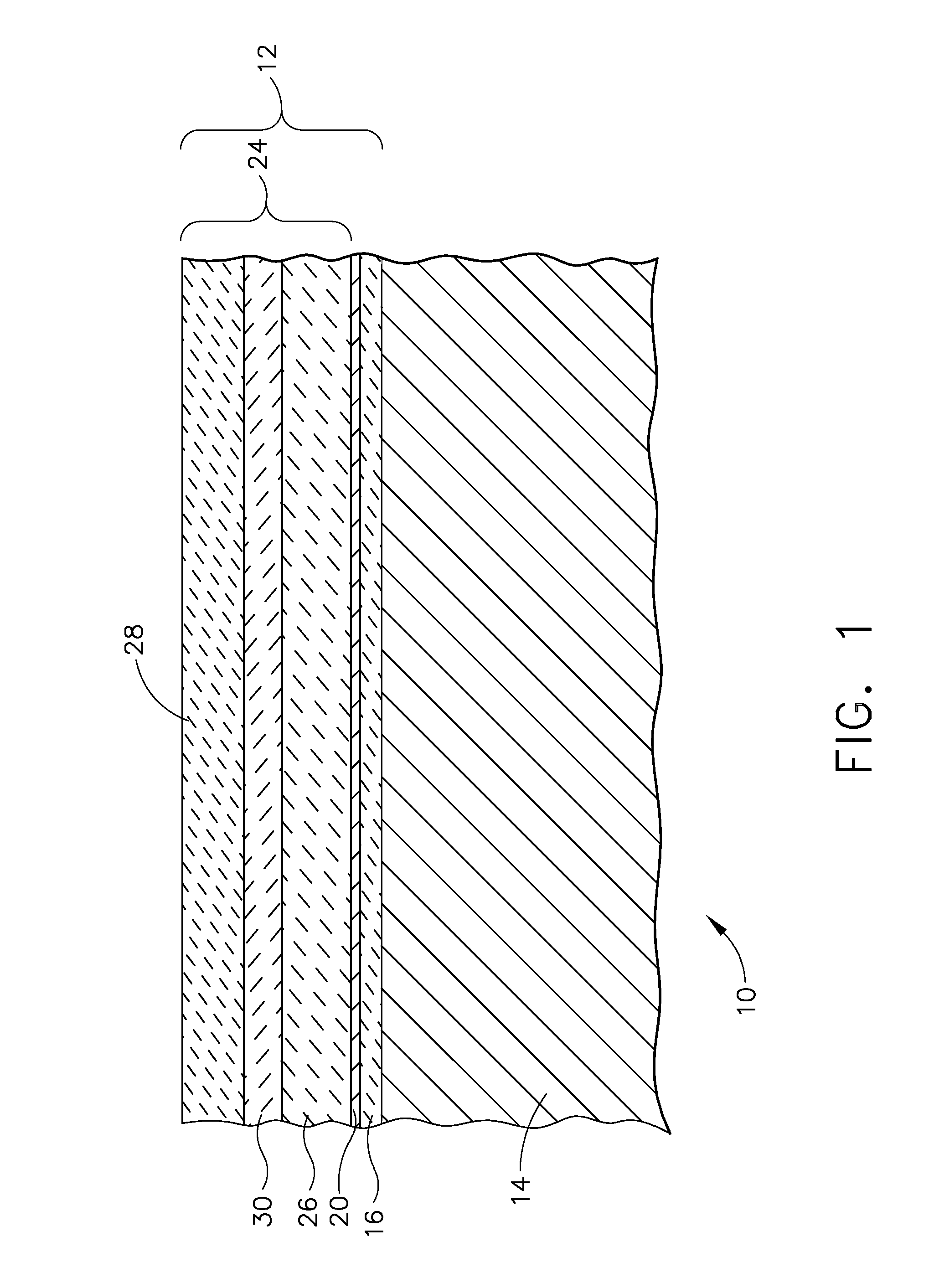

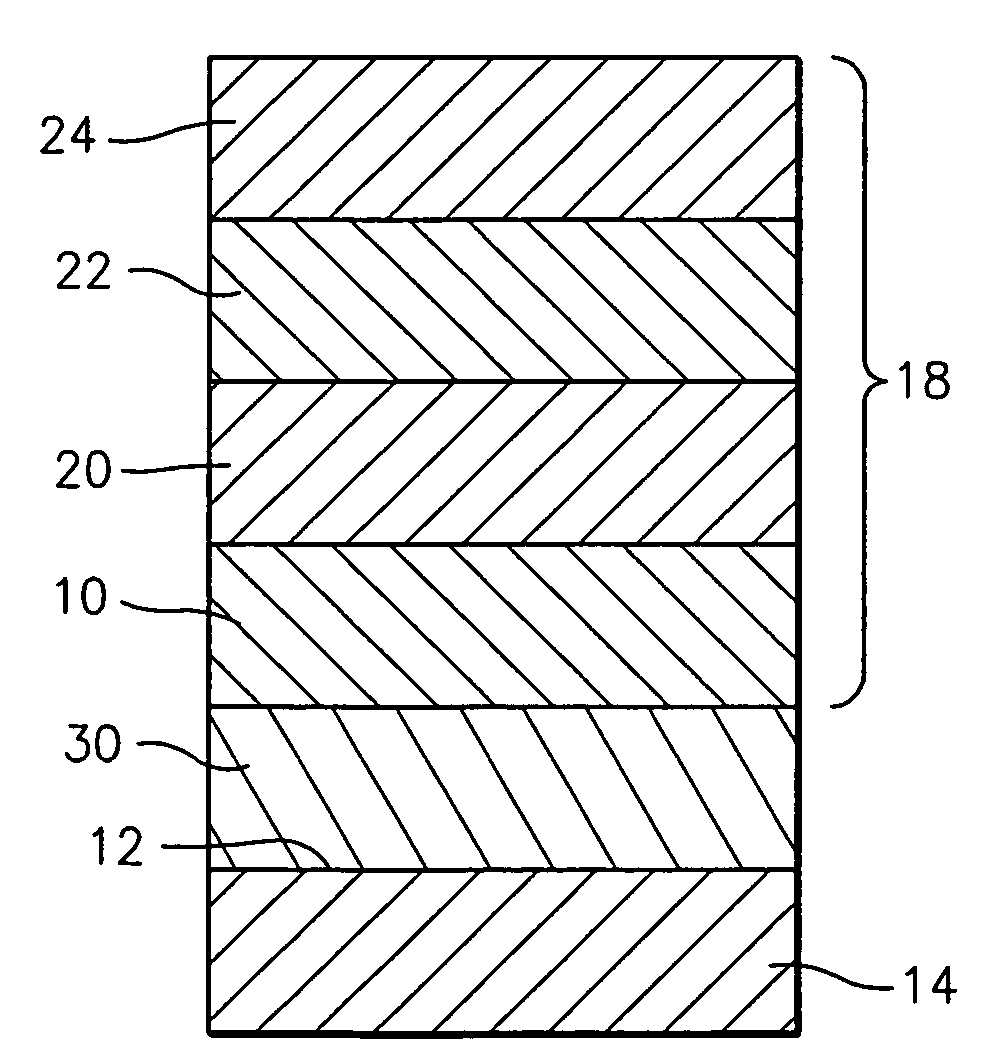

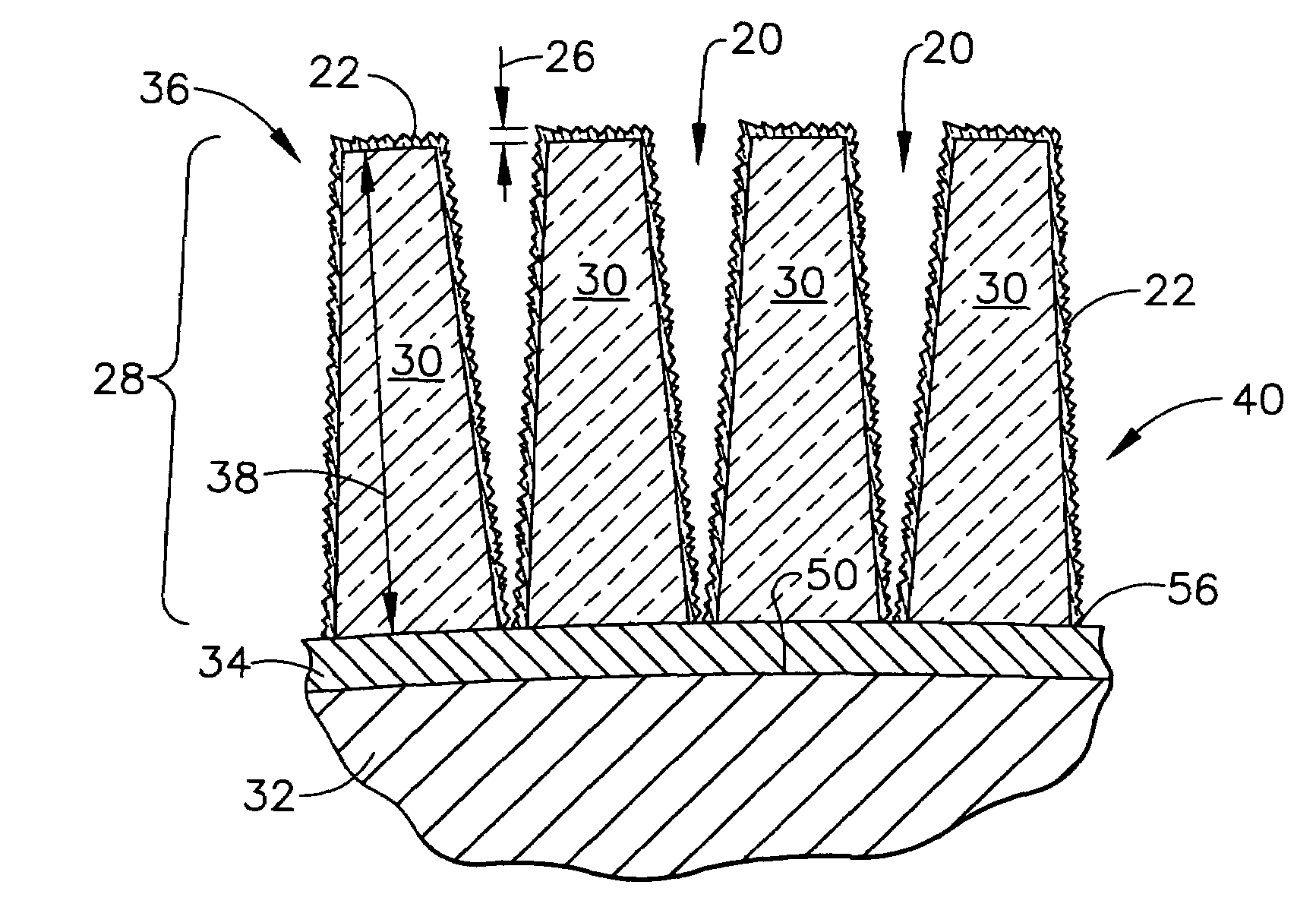

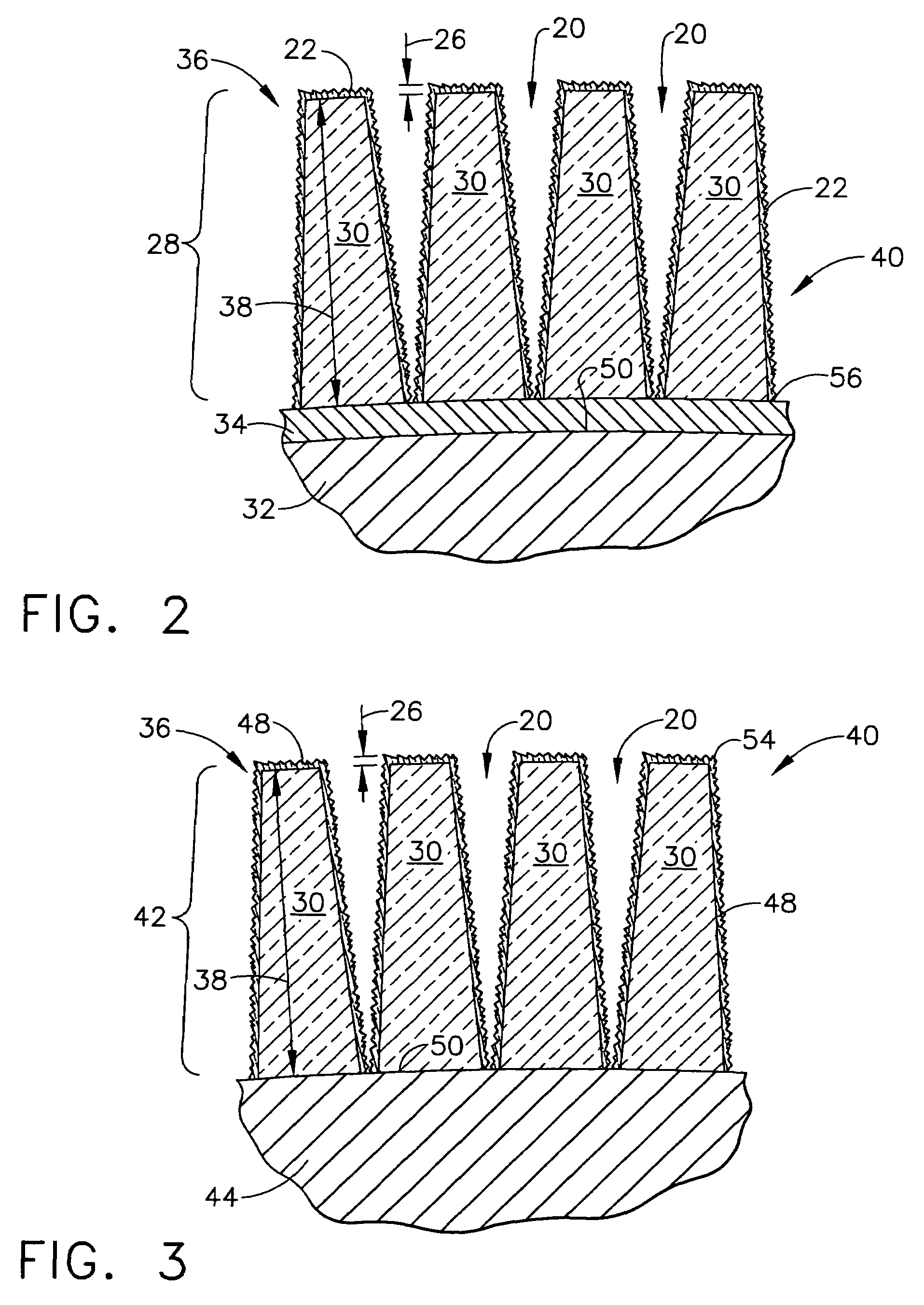

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

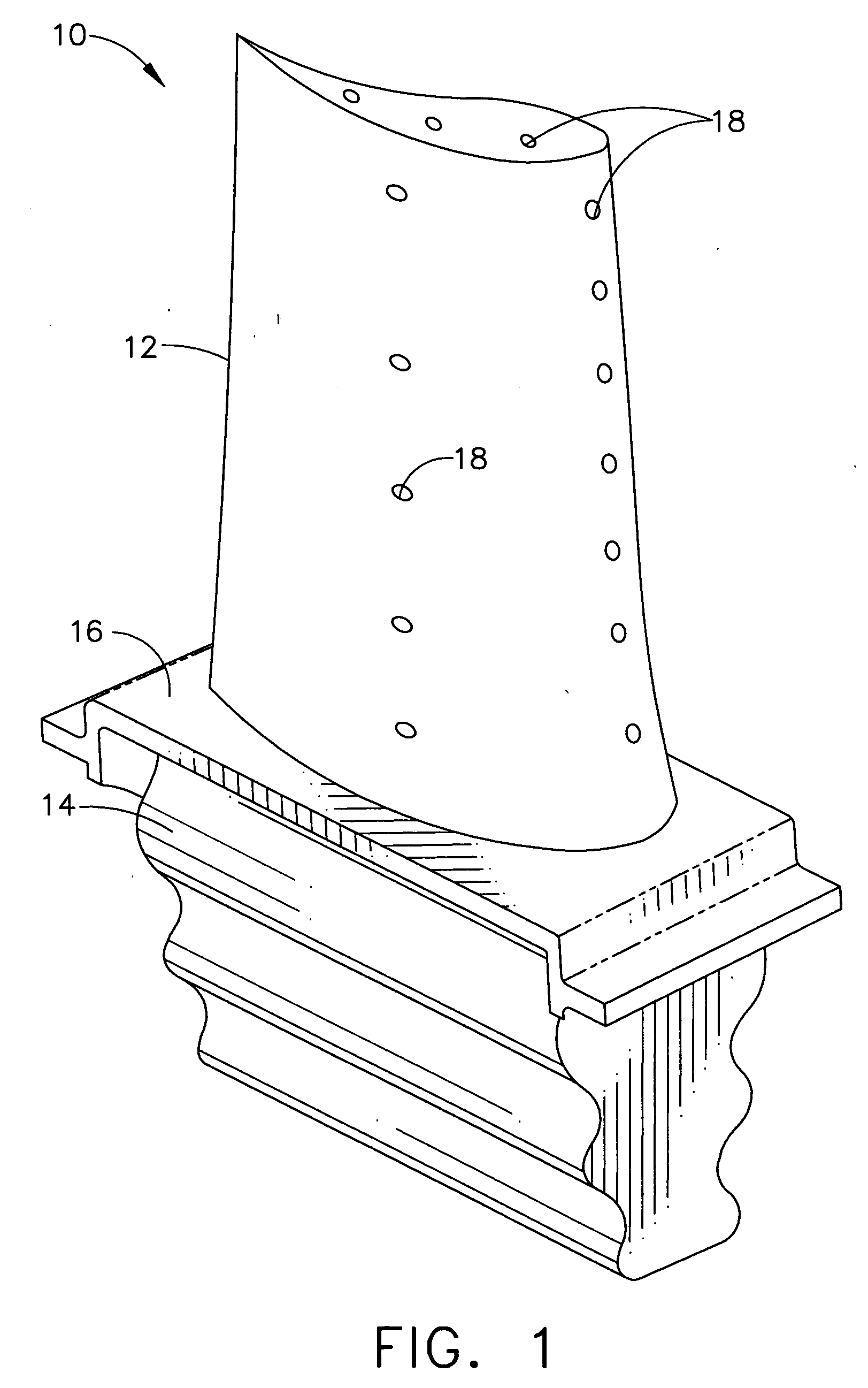

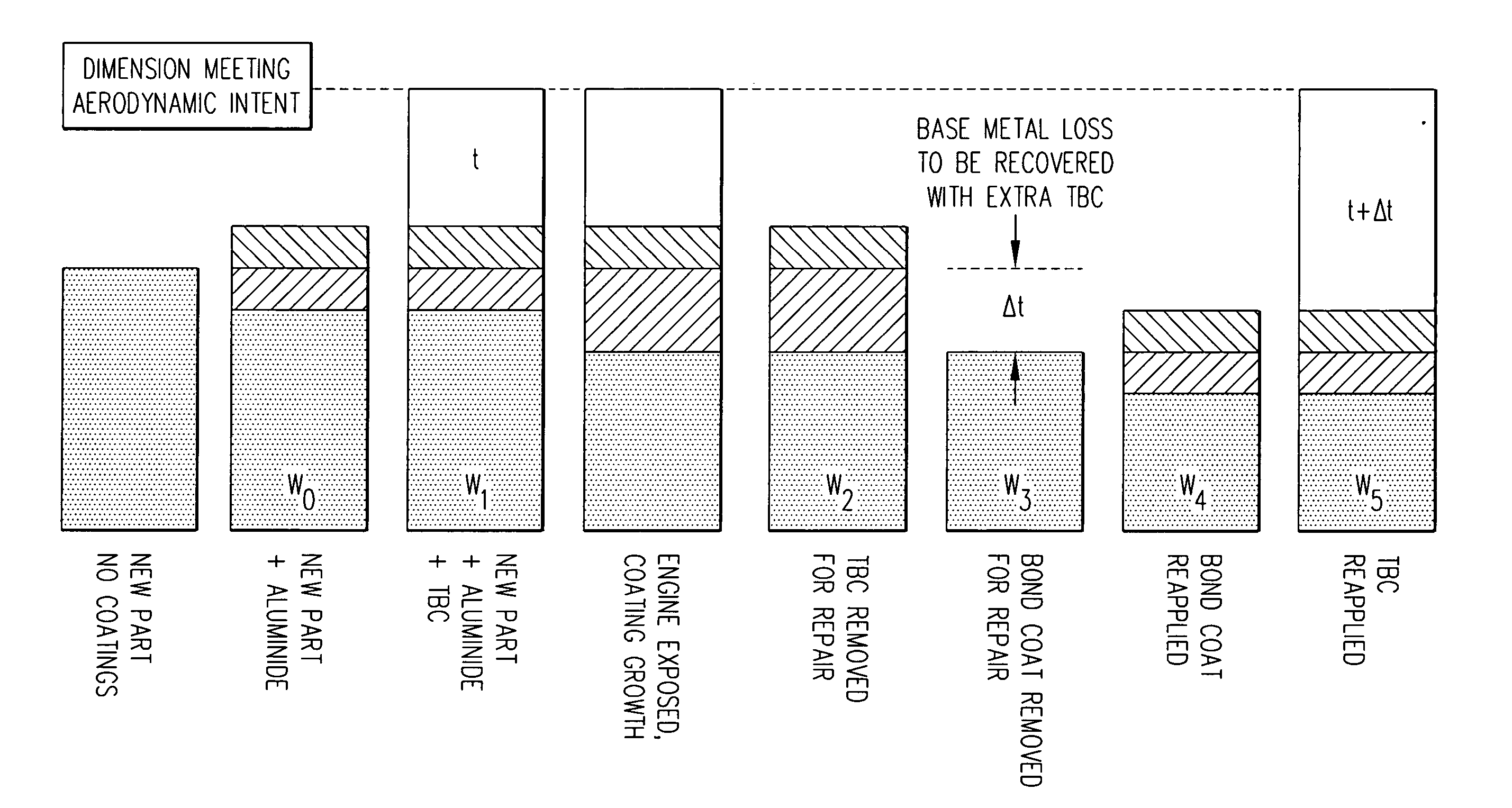

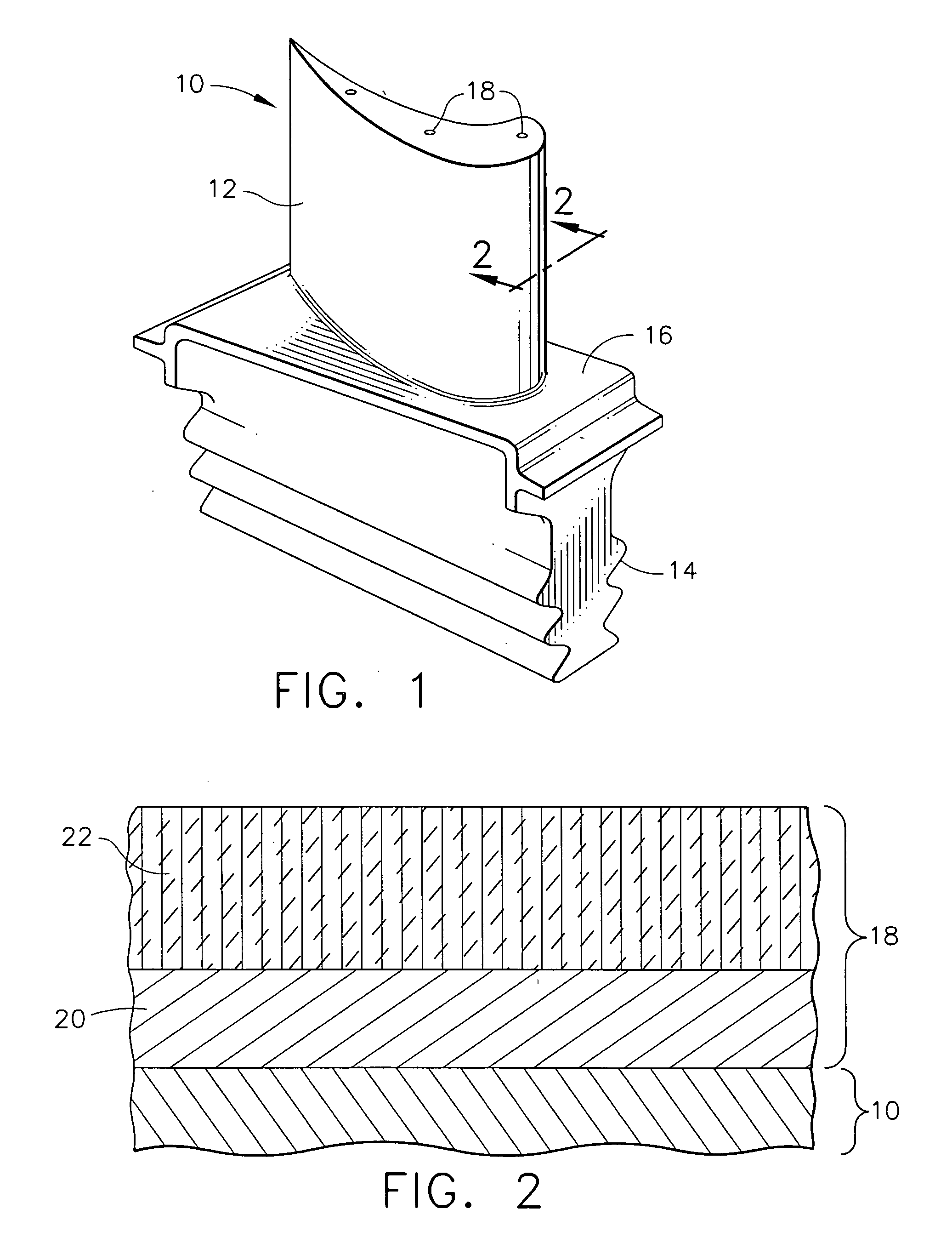

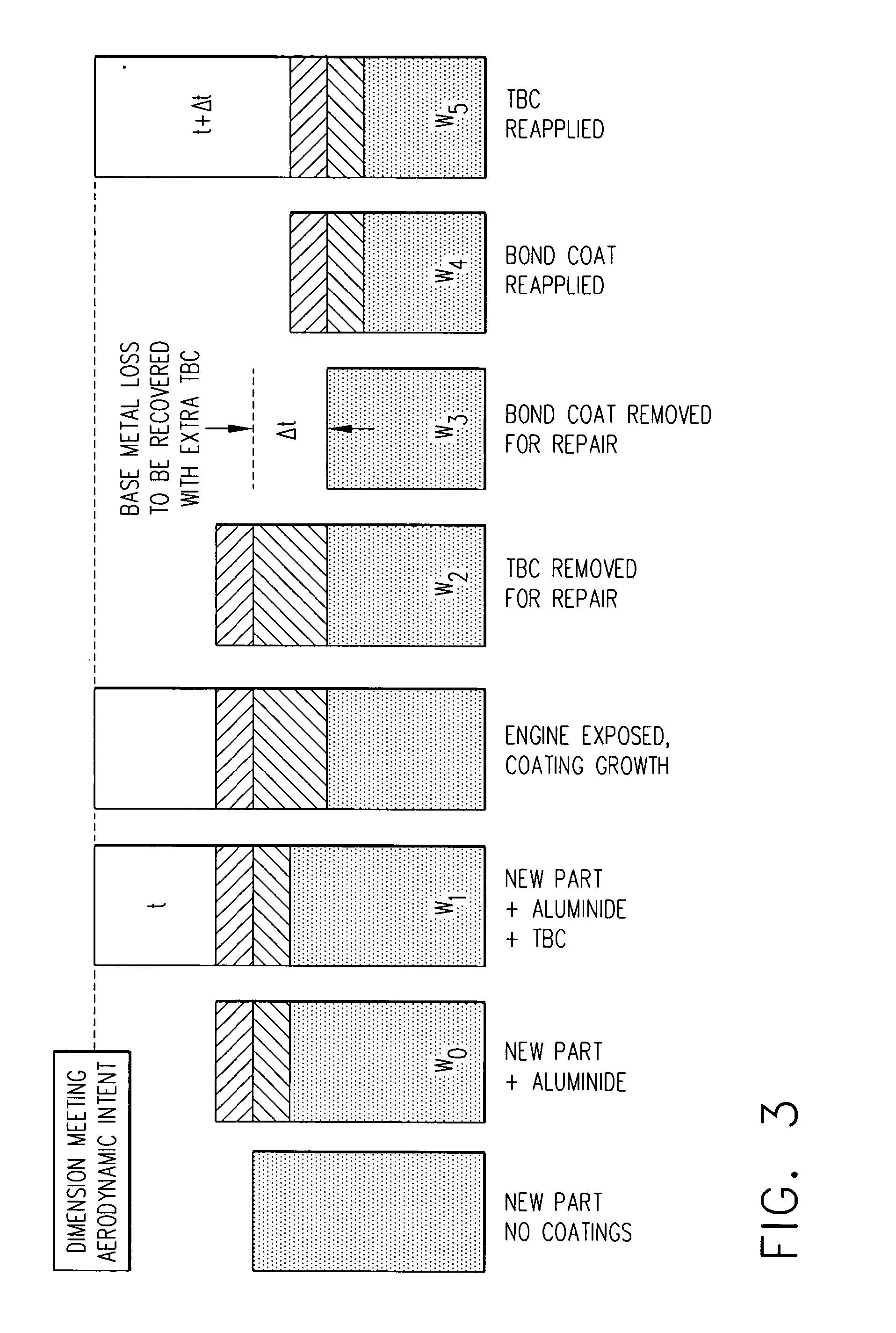

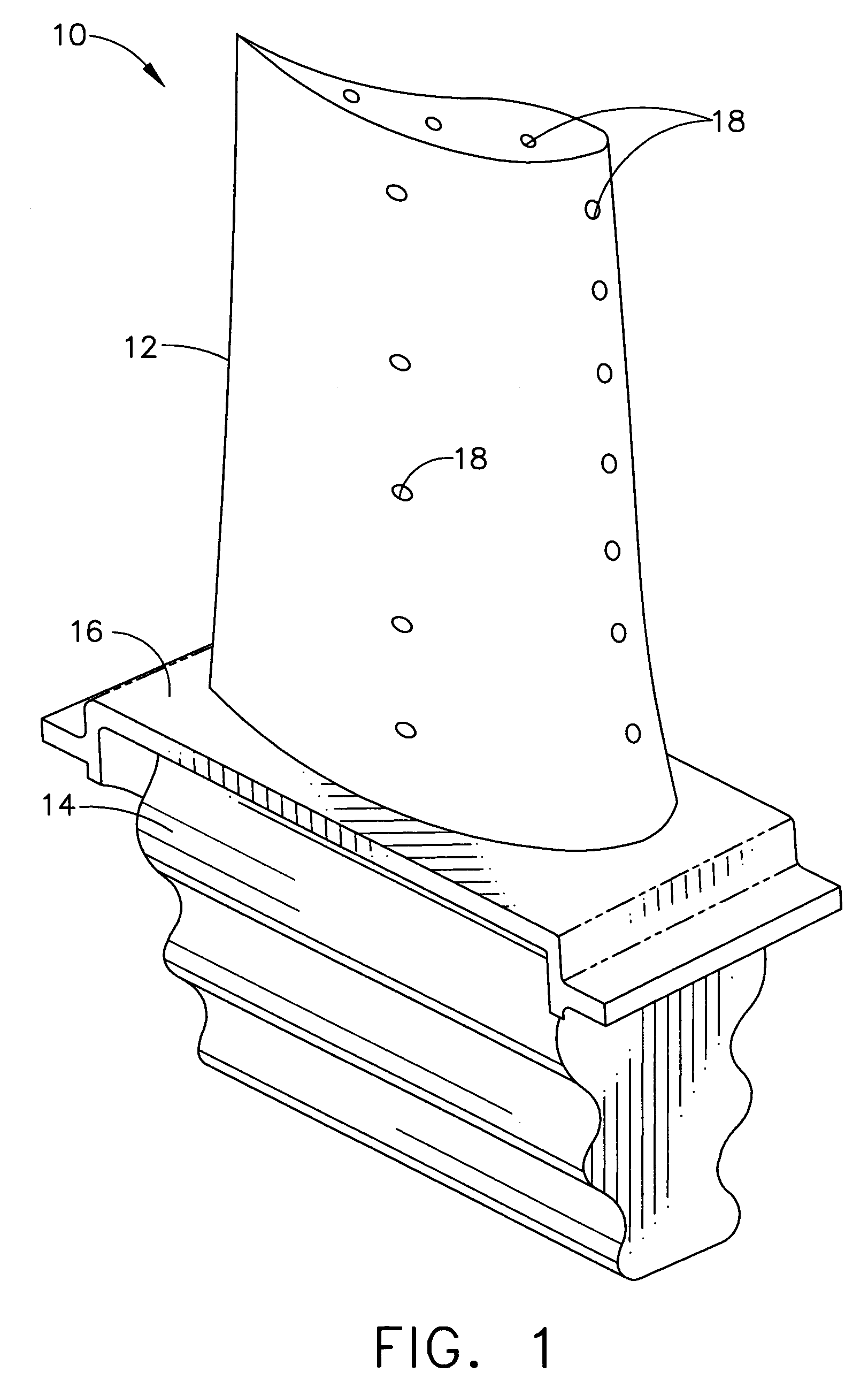

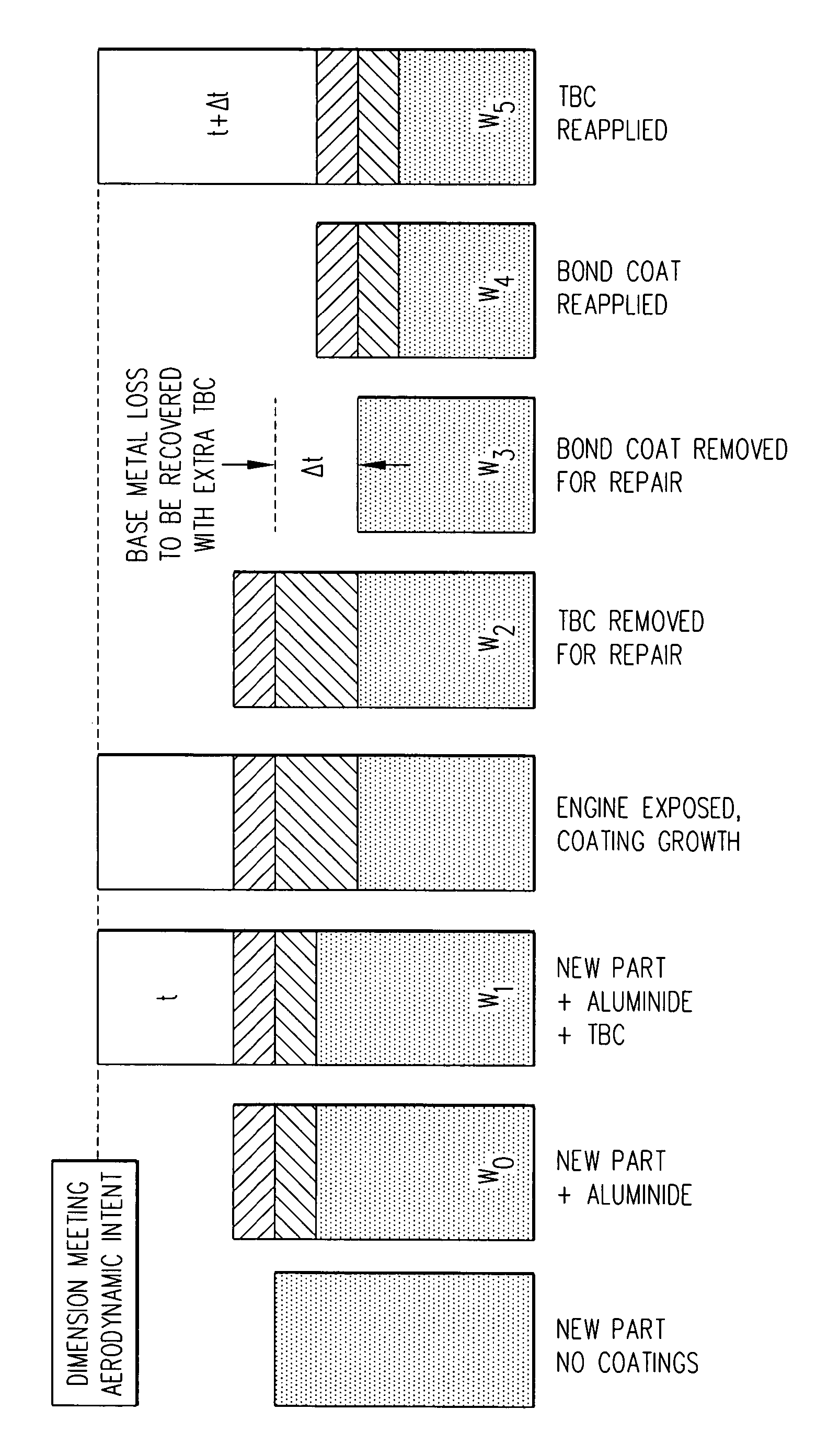

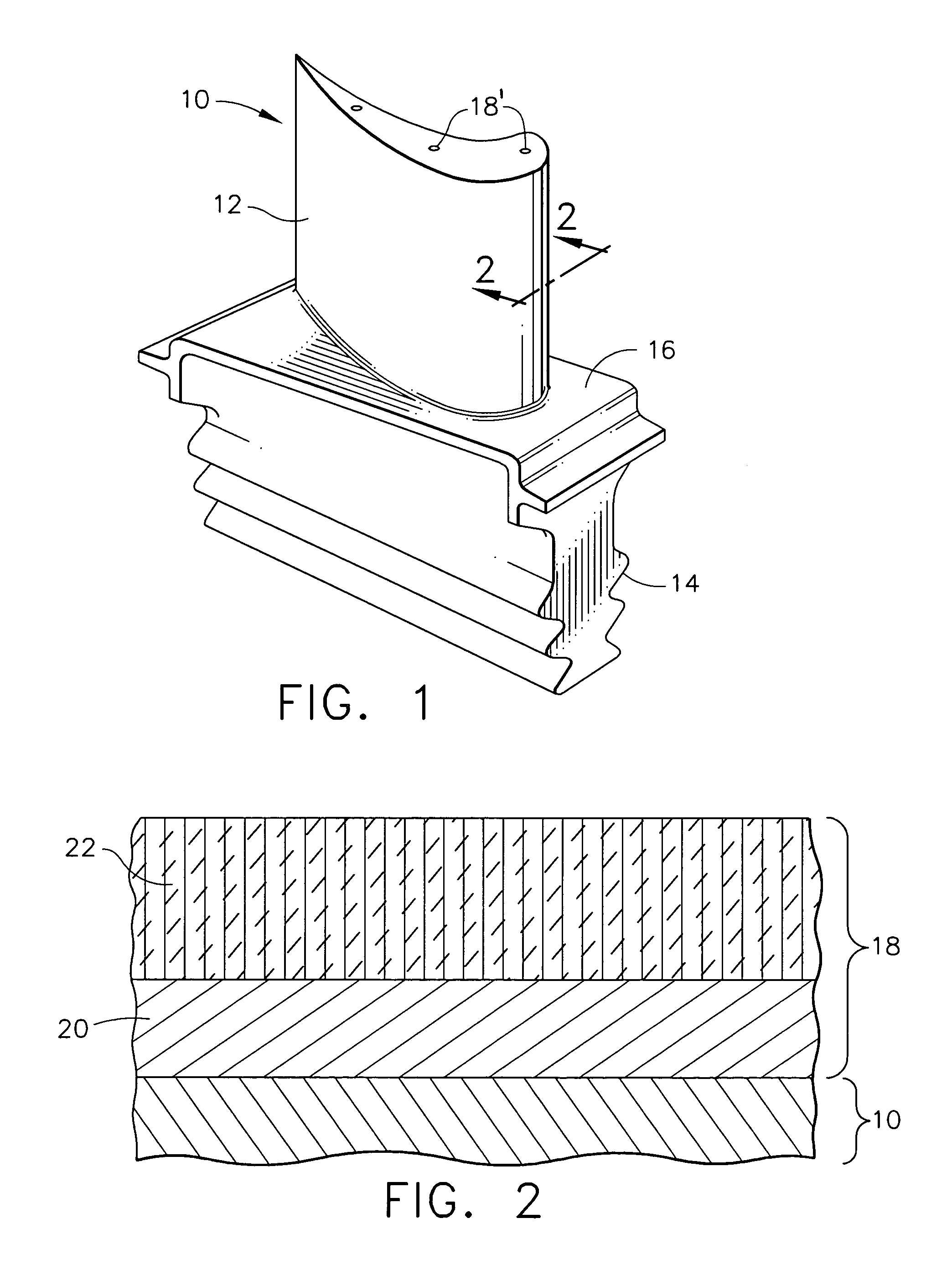

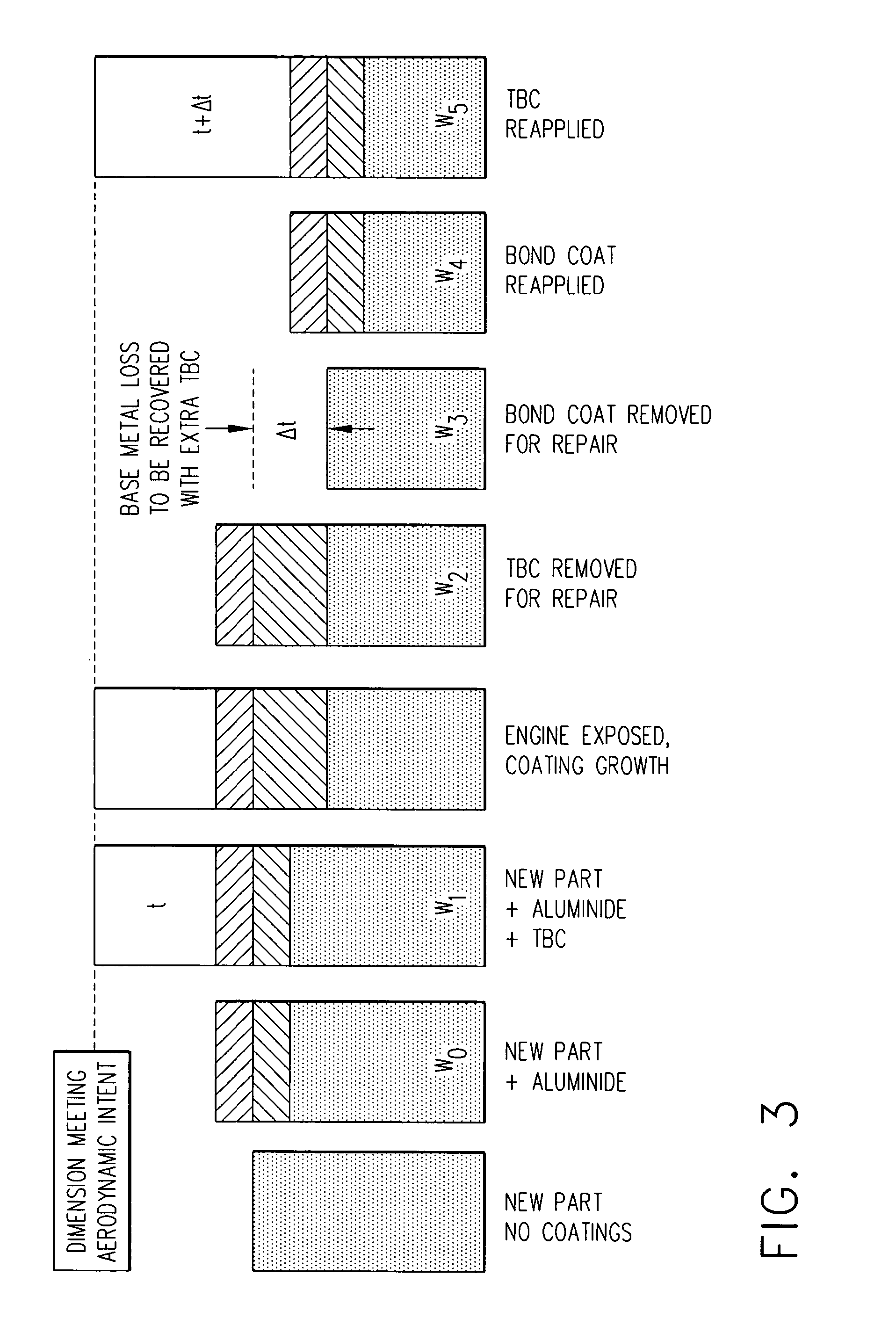

Method for repairing coated components

ActiveUS20050106316A1Increase ceramic spallation lifeReduce coatingMolten spray coatingLayered productsTurbine bladeAlloy

According to an embodiment of the invention, a method for repairing a coated high pressure turbine blade, which has been exposed to engine operation, to restore coated airfoil contour dimensions of the blade, is disclosed. The method comprises providing an engine run high pressure turbine blade including a base metal substrate made of a nickel-based alloy and having thereon a thermal barrier coating system. The thermal barrier coating system comprises a diffusion bond coat on the base metal substrate and a top ceramic thermal barrier coating comprising a yttria stabilized zirconia material. The top ceramic thermal barrier coating has a nominal thickness t. The method further comprises removing the thermal barrier coating system, wherein a portion of the base metal substrate also is removed, and determining the thickness of the base metal substrate removed. The portion of the base metal substrate removed has a thickness, Δt. The method also comprises reapplying the diffusion bond coat to the substrate, wherein the bond coat is reapplied to a thickness, which is about the same as applied prior to the engine operation; and reapplying the top ceramic thermal barrier coating to a nominal thickness of t+Δt, wherein Δt compensates for the portion of removed base metal substrate. Advantageously, the coated airfoil contour dimensions of the high pressure turbine blade are restored to about the coated dimensions preceding the engine run.

Owner:GENERAL ELECTRIC CO

Thermal spray coatings for semiconductor applications

InactiveUS20100272982A1Erosion is goodImproved corrosion resistant coatingLiquid surface applicatorsMolten spray coatingThermal sprayingIntegrated circuit manufacturing

This invention relates to thermal spray coatings on a metal or non-metal substrate. The thermal spray coating comprises a partially or fully stabilized ceramic coating, e.g., yttria stabilized zirconia coating, and has sufficiently high thermodynamic phase stability to provide corrosion and / or erosion resistance to the substrate. This invention also relates to methods of protecting metal and non-metal substrates by applying the thermal spray coatings. The coatings are useful, for example, in the protection of integrated circuit manufacturing equipment, internal chamber components, and electrostatic chuck manufacture.

Owner:PRAXAIR ST TECH INC

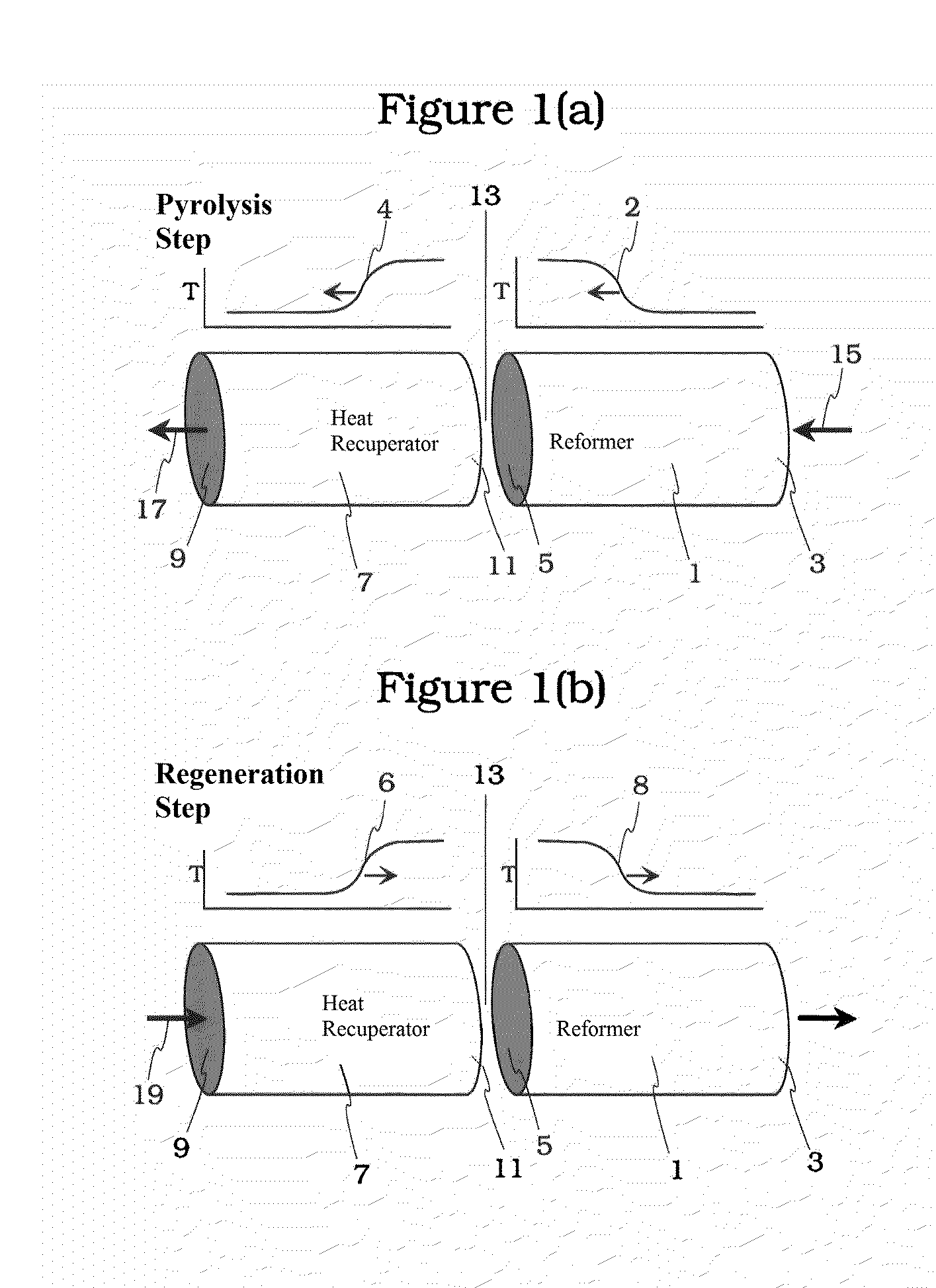

Pyrolysis Reactor Materials and Methods

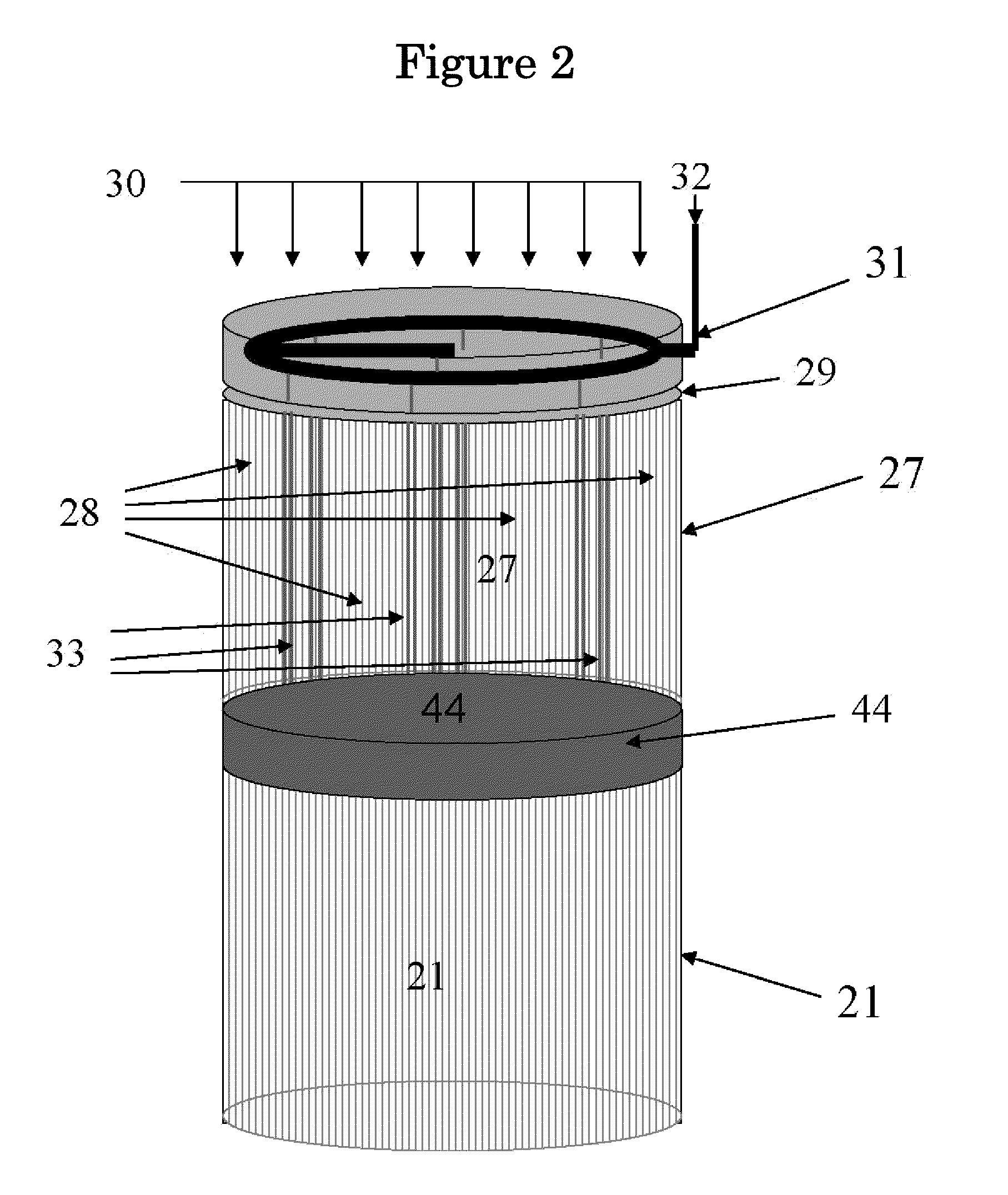

ActiveUS20100290978A1Reduce corrosionChemical/physical/physico-chemical processesRare earth metal compoundsPorosityReactor system

In one aspect, the invention includes a refractory material for a pyrolysis reactor for pyrolyzing a hydrocarbon feedstock, the refractory material comprising an yttria stabilized zirconia, the refractory material comprising at least 21 wt. % yttria based upon the total weight of the refractory material. In another aspect, this invention includes a method for mitigating carbide corrosion while pyrolyzing a hydrocarbon feedstock at high temperature using a pyrolysis reactor system comprising the steps of: (a) providing a pyrolysis reactor system comprising stabilized zirconia in a heated region of the reactor, the stabilized zirconia including at least 21 wt. % yttria and having porosity of from 5 vol. % to 28 vol. %; (b) heating the heated region to a temperature of at least 1500° C.; and (c) pyrolyzing a hydrocarbon feedstock within the heated region.

Owner:EXXONMOBIL CHEM PAT INC

Light emitting diode and semiconductor laser

InactiveUS20030132449A1Desirable crystallinityImprove luminous efficiencyLaser detailsSolid-state devicesUltraviolet lightsSingle crystal substrate

An ultraviolet-light-emitting semiconductor diode comprising an n-type ZnO layer with luminous characteristics formed on a transparent substrate, and a p-type semiconductor layer selected from the group consisting of SrCu2O2, CuAlO2 and CuGaO2, which is formed on the n-type ZnO layer to provide a p-n junction therebetween. The transparent substrate is preferably a single crystal substrate having atomically flat yttria-stabilized zirconia (YSZ) (III) surface. The n-type ZnO layer is formed on the transparent substrate having a temperature of 200 to 1200° C., and the p-type semiconductor layer selected from the group of SrCu2O2, CuAlO2 and CuGaO2 is formed on the n-type ZnO layer. The n-type ZnO layer may be formed without heating the substrate, and then the surface of the ZnO layer may be irradiated with ultraviolet light to promote crystallization therein.

Owner:HOYA CORP

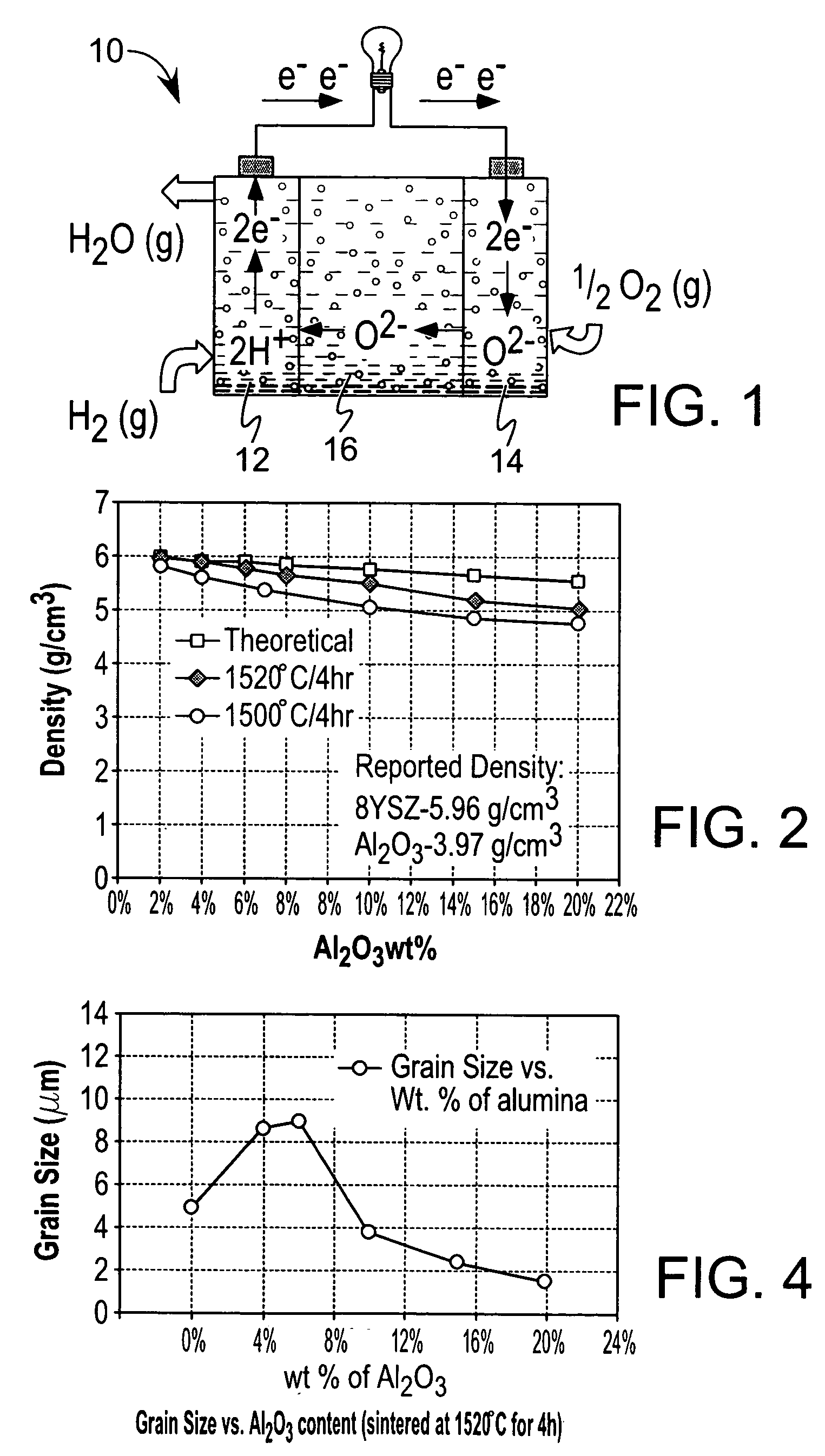

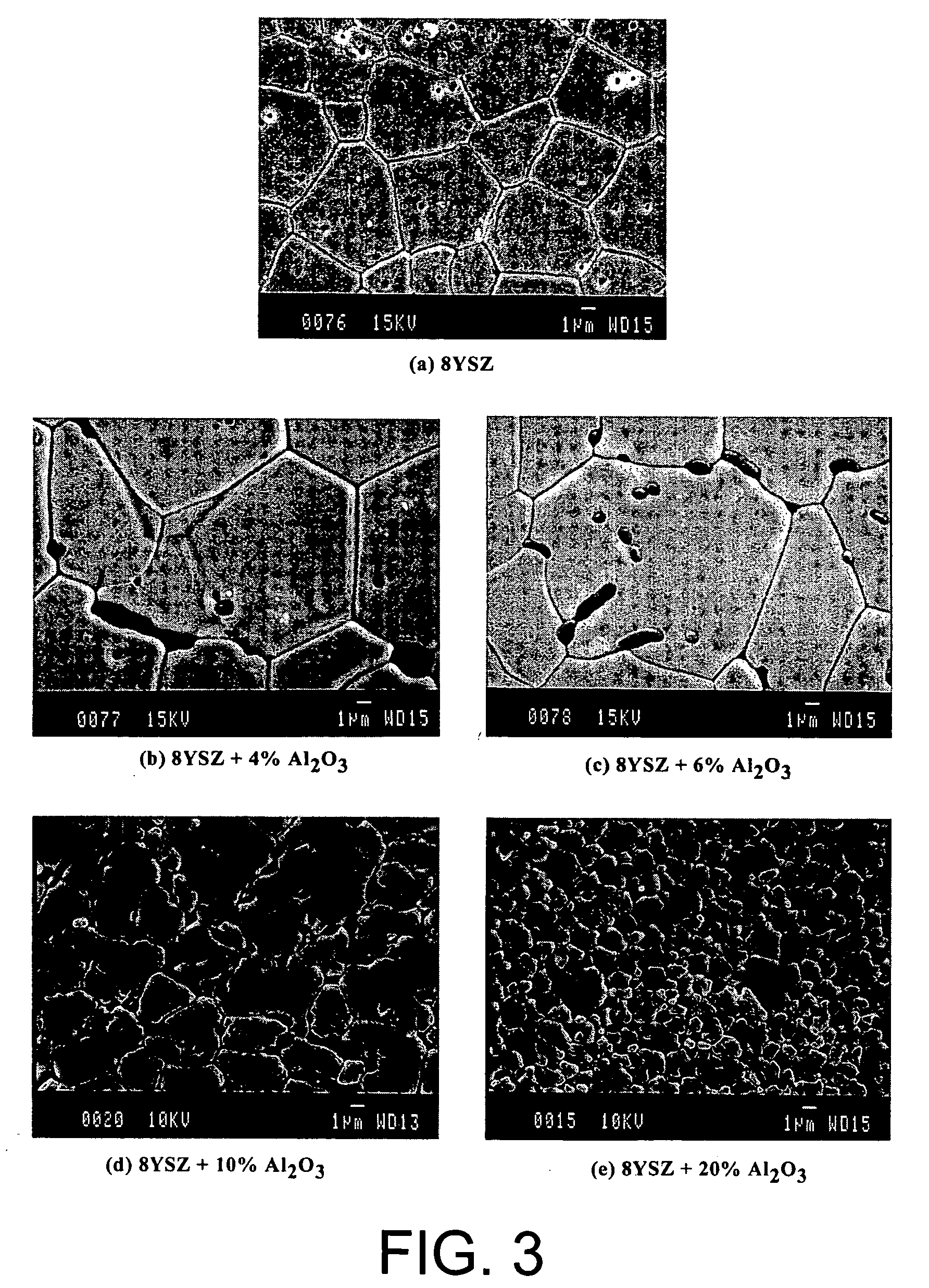

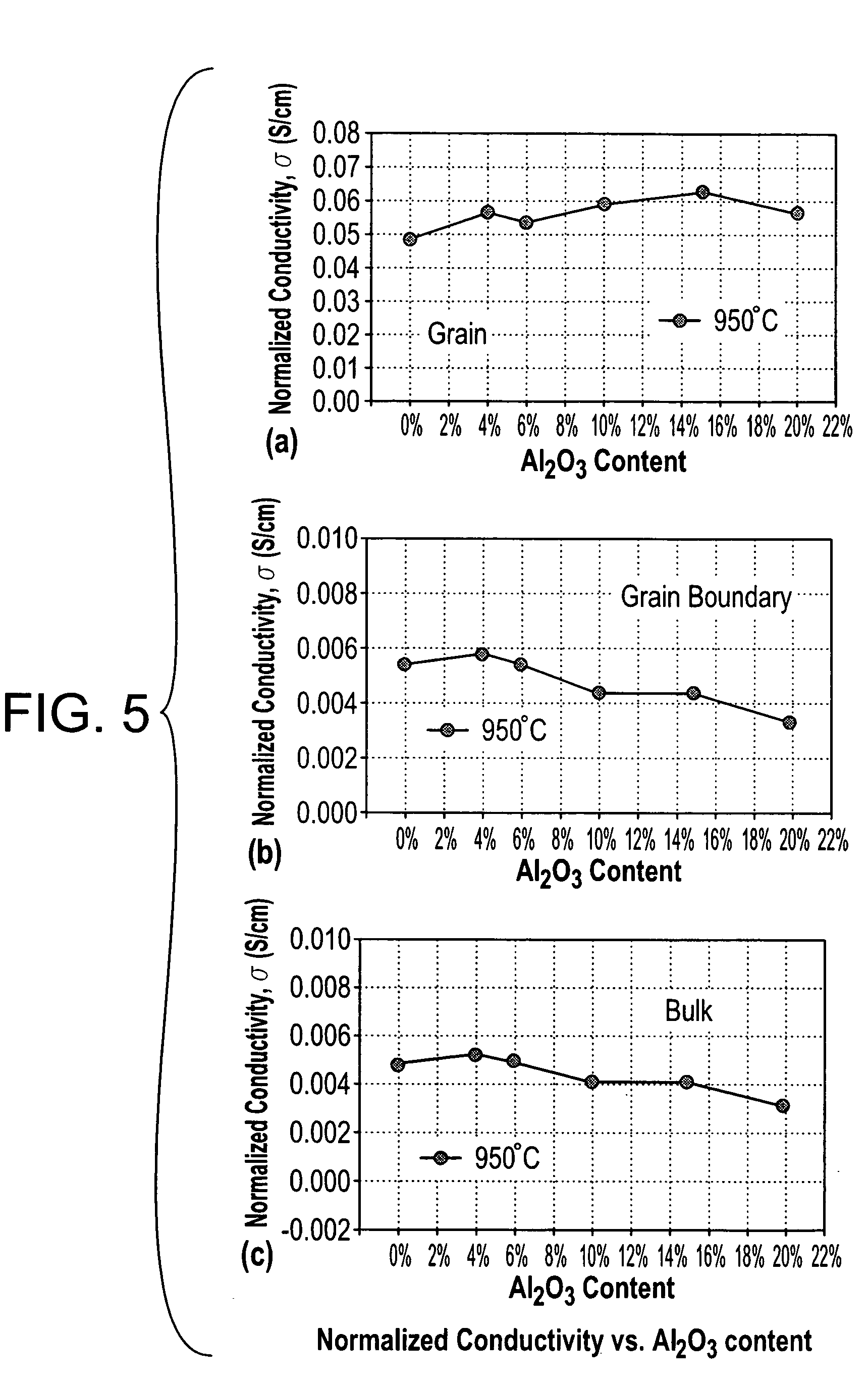

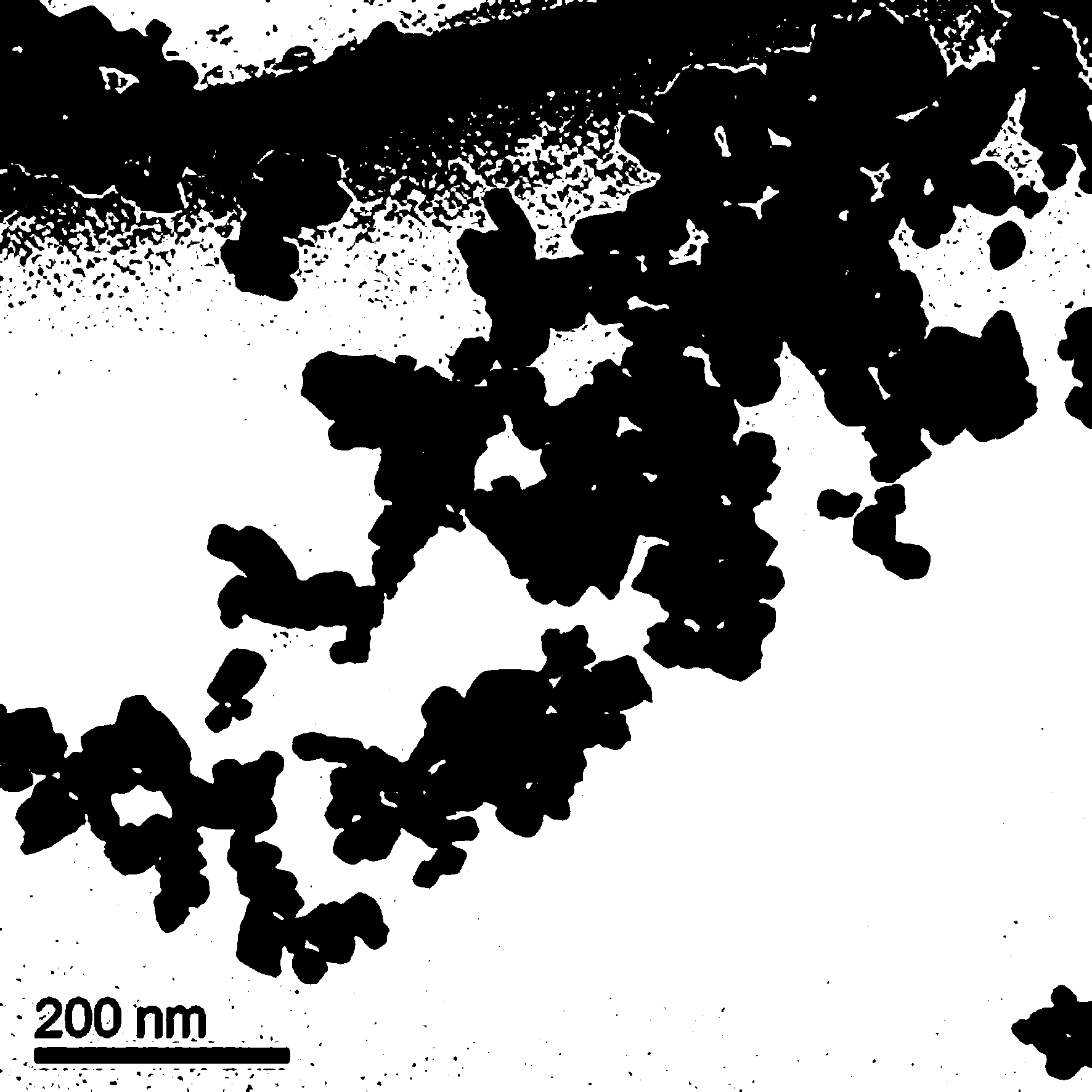

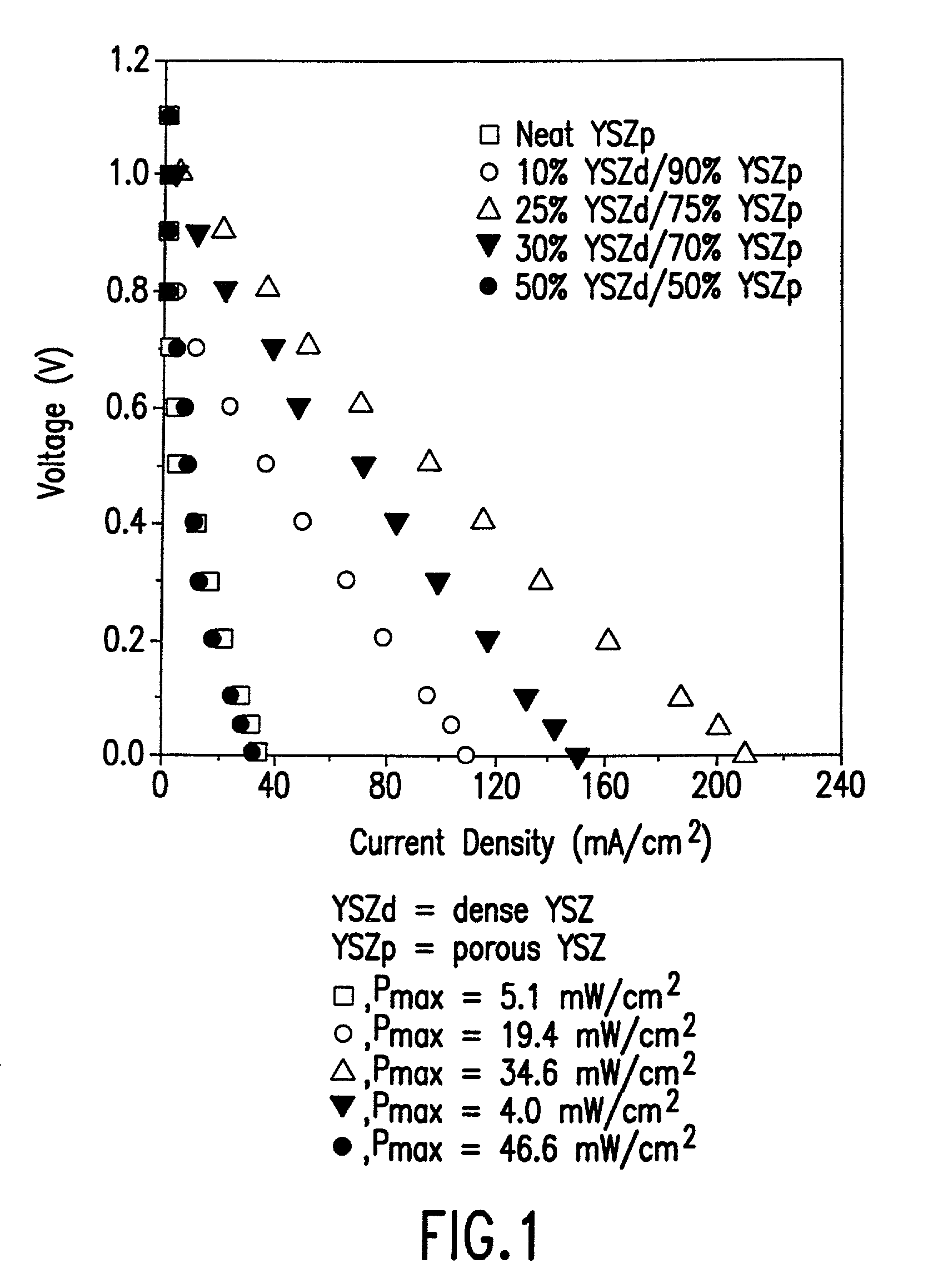

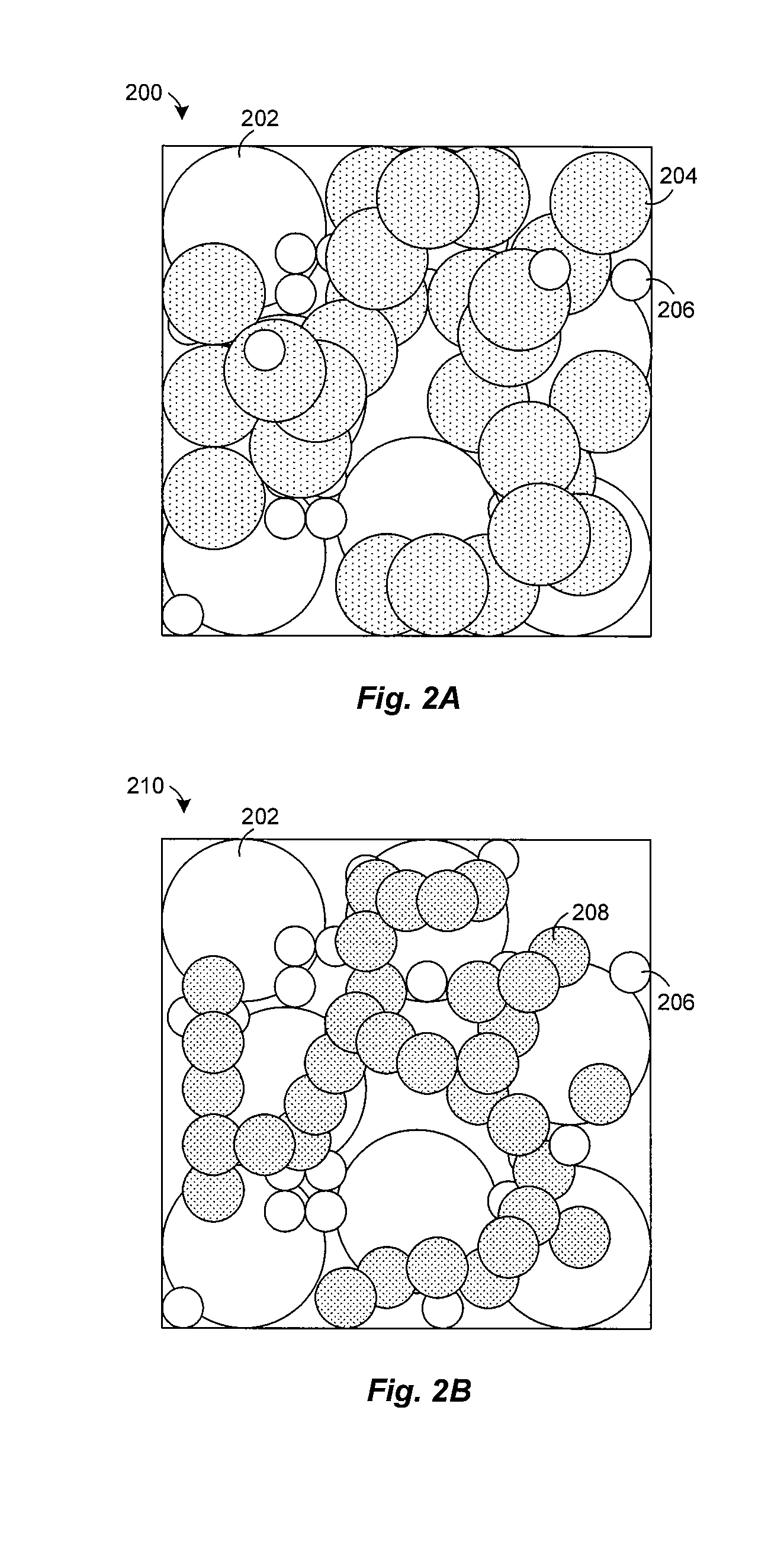

Ceramic-ceramic nanocomposite electrolyte

ActiveUS20050214616A1Improve conductivityImprove ionic conductivityMaterial nanotechnologyFinal product manufactureDopantComposite electrolyte

A ceramic-ceramic nanocomposite electrolyte having enhanced conductivity is provided. The nancomposite electrolyte is formed from chemically stabilized zirconia such as yttria stabilized zirconia or scandia stabilized zirconia and a heterogeneous ceramic dopant material such as Al2O3, TiO2, MgO, BN, or Si3N4 The nanocomposite electrolyte is formed by doping the chemically stabilized zirconia with the ceramic dopant material and pressing and sintering the composite. The resulting electrolyte has a bulk conductivity of from about 0.10 to about 0.50 S / cm at about 600° C. to about 900° C. and may be incorporated into a solid oxide fuel cell.

Owner:UNIV OF DAYTON

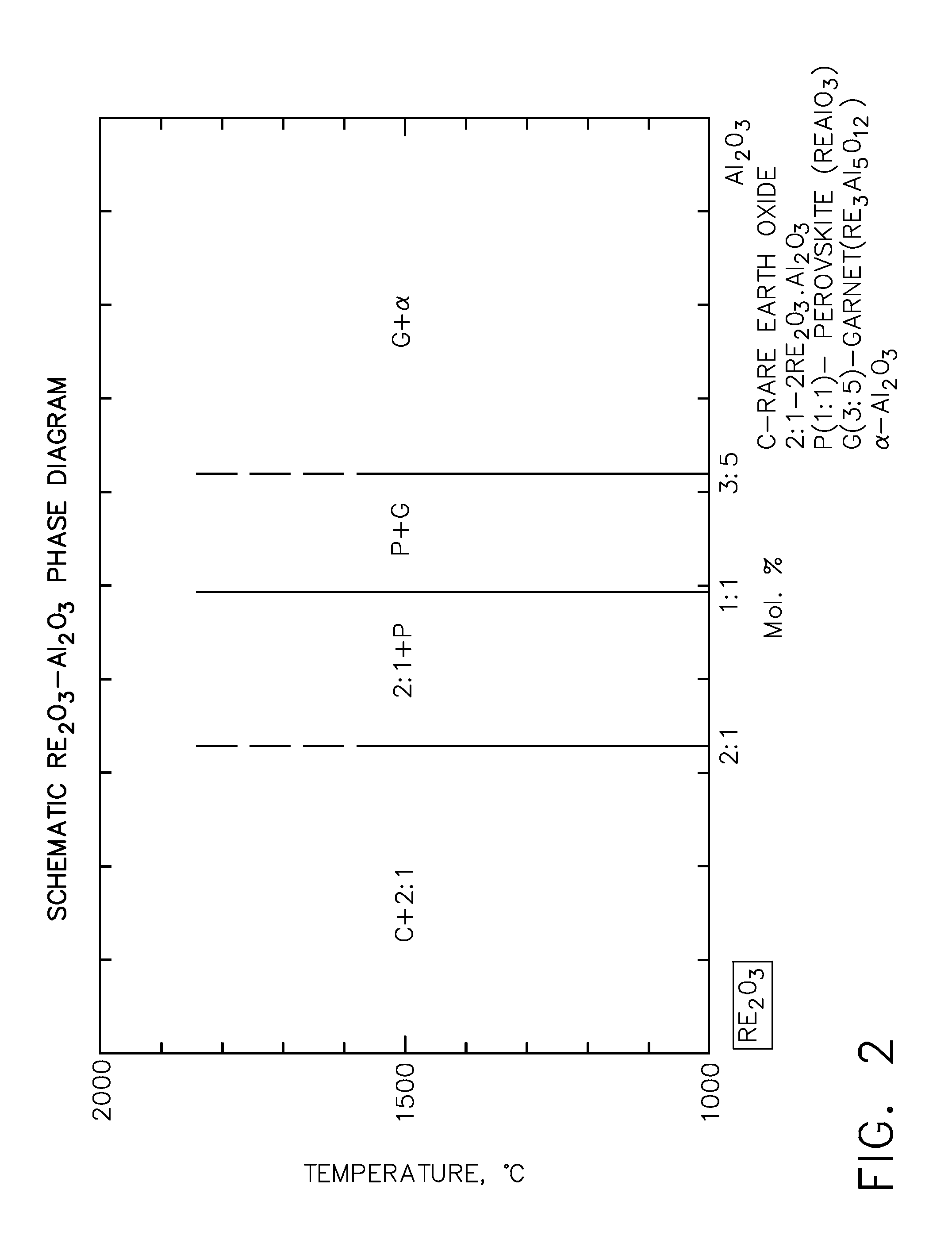

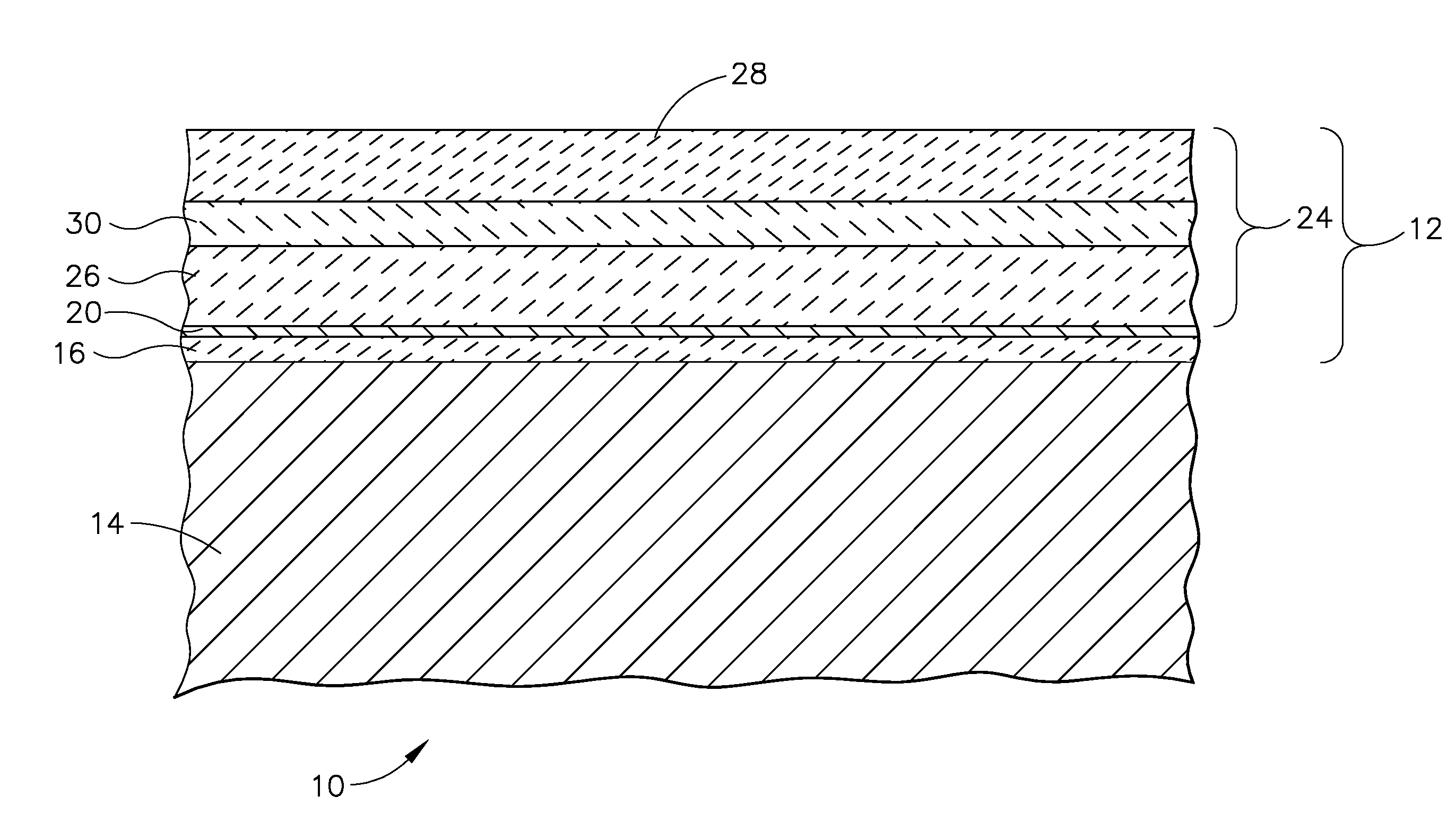

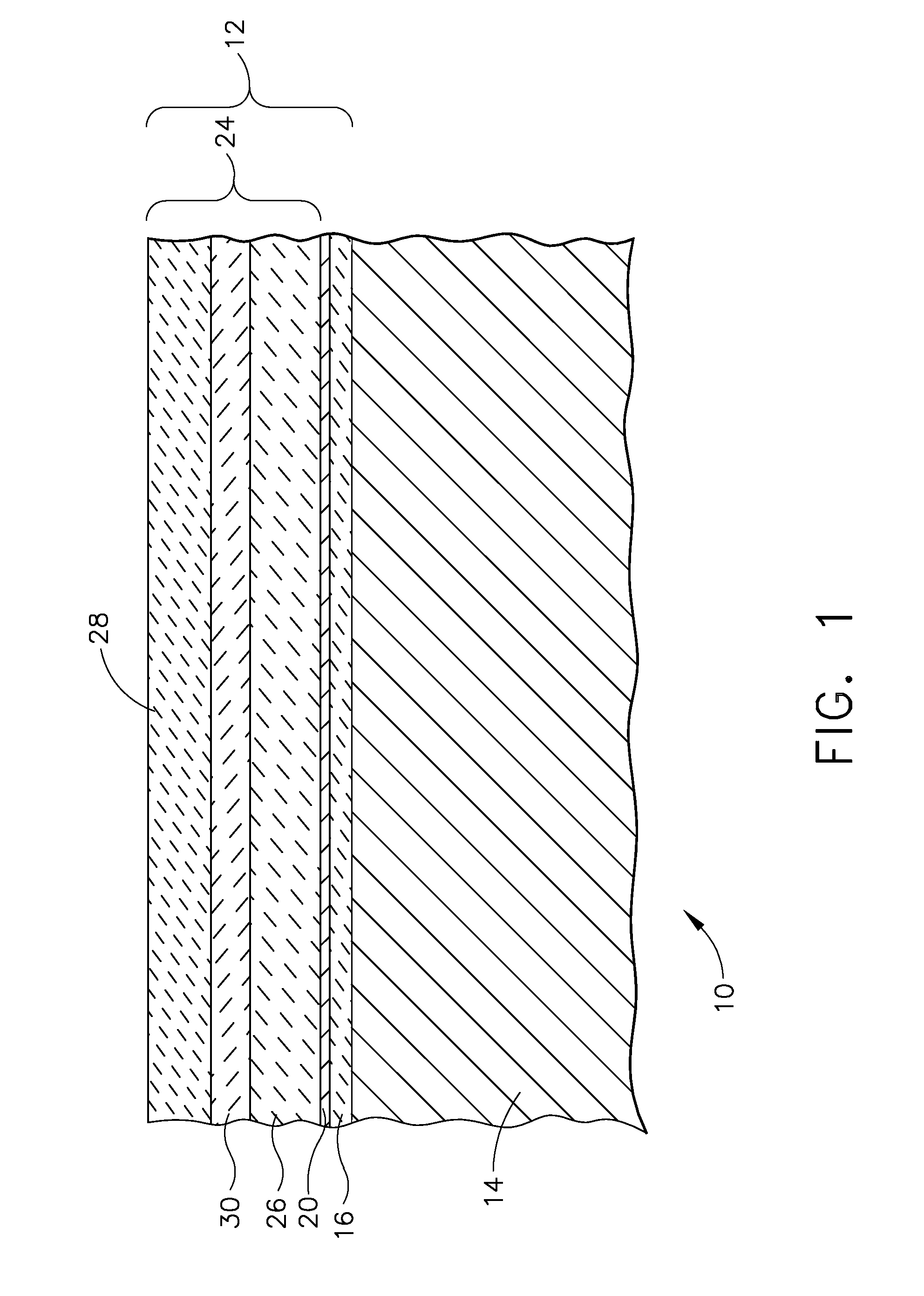

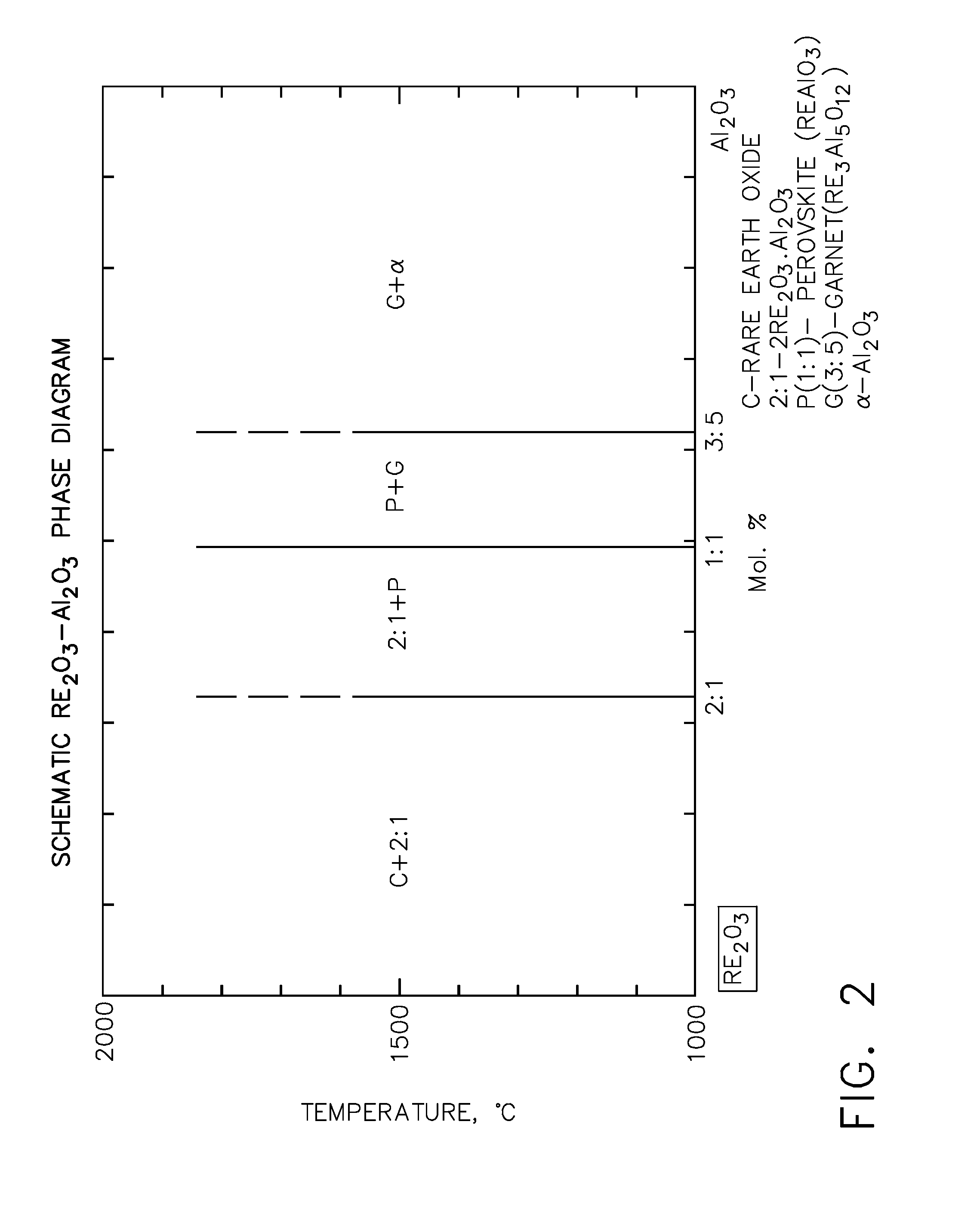

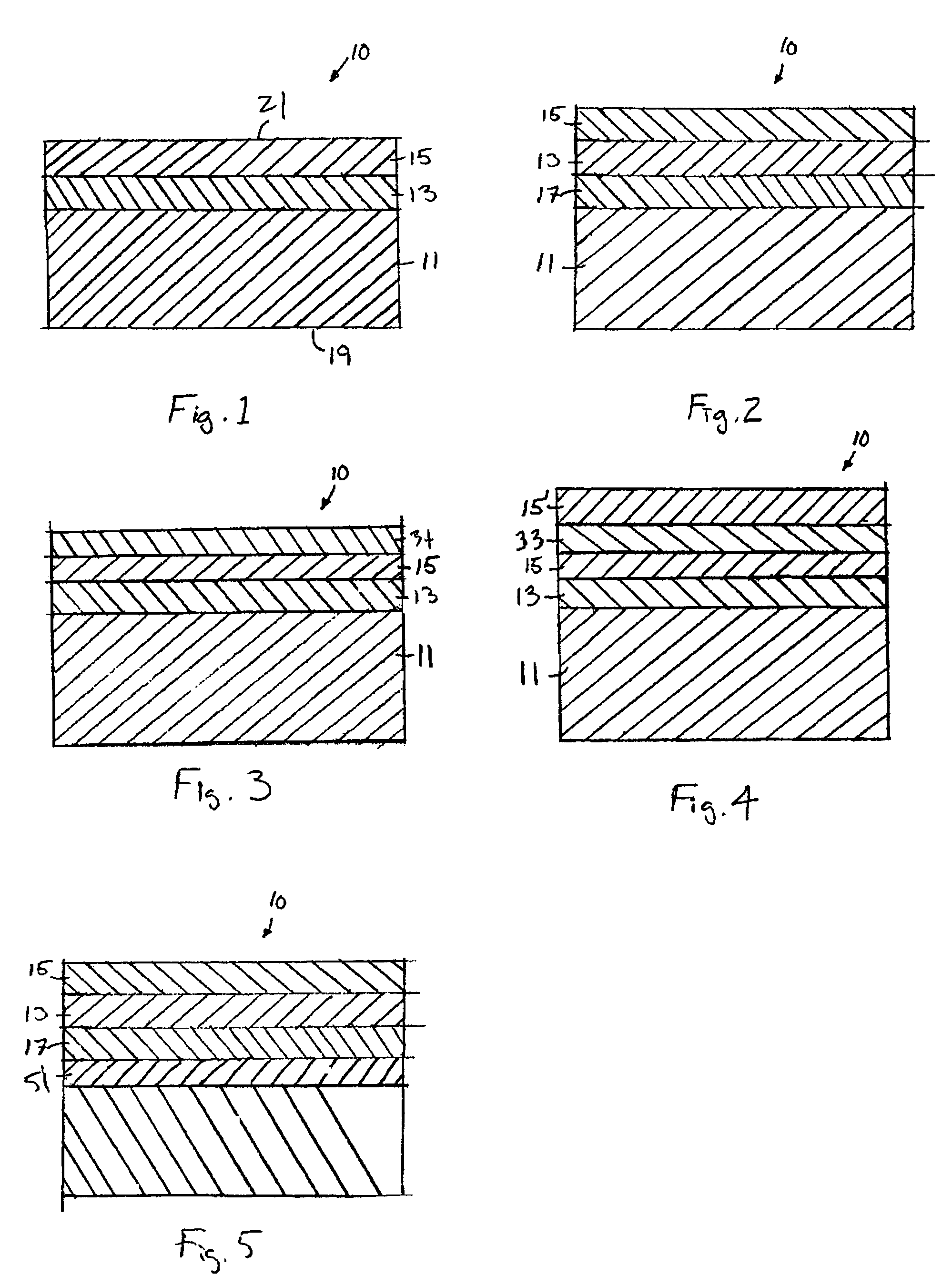

Thermal Barrier Coating Systems Including a Rare Earth Aluminate Layer for Improved Resistance to CMAS Infiltration and Coated Articles

ActiveUS20090169914A1Efficient propulsion technologiesNatural mineral layered productsRare earthBond coat

Thermal barrier coating systems for use with hot section components of a gas turbine engine include an inner layer overlying a bond coated substrate and a top layer overlying at least a portion of the inner layer. The inner layer includes a thermal barrier material such as yttria-stabilized zirconia. The top layer includes a rare earth aluminate. The thicknesses and microstructures of the layers may be varied depending on the type of component to be coated. Articles incorporating the thermal barrier coating system exhibit improved resistance to CMAS infiltration

Owner:GENERAL ELECTRIC CO

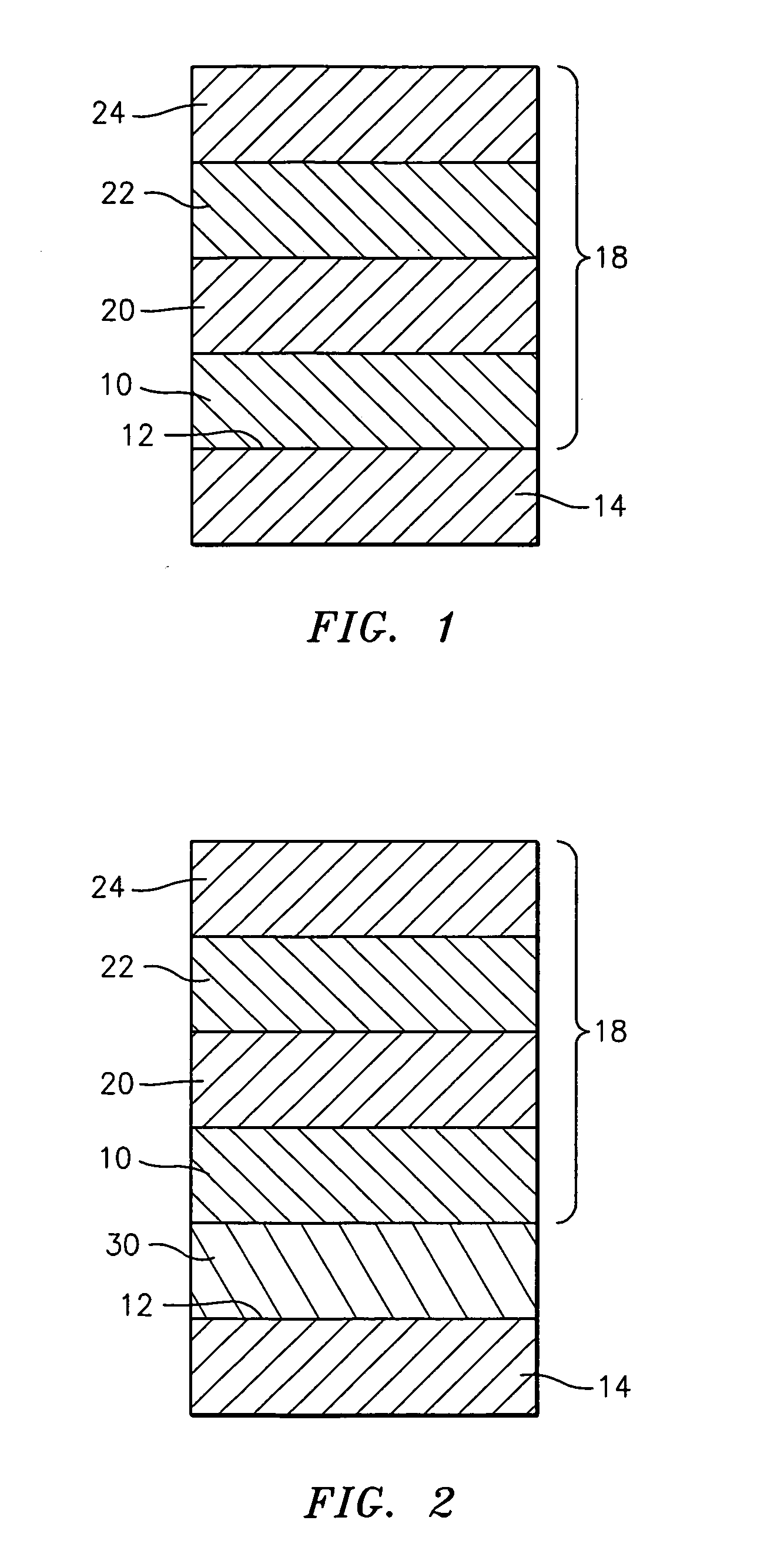

CMAS resistant thermal barrier coating

ActiveUS20070172703A1Reduce componentsReduces sand related distressMolten spray coatingBlade accessoriesIndiumCerium

A turbine engine component is provided which has a substrate and a thermal barrier coating applied over the substrate. The thermal barrier coating comprises alternating layers of yttria-stabilized zirconia and a molten silicate resistant material. The molten silicate resistant outer layer may be formed from at least one oxide of a material selected from the group consisting of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, indium, zirconium, hafnium, and titanium or may be formed from a gadolinia-stabilized zirconia. If desired, a metallic bond coat may be present between the substrate and the thermal barrier coating system. A method for forming the thermal barrier coating system of the present invention is described.

Owner:RTX CORP

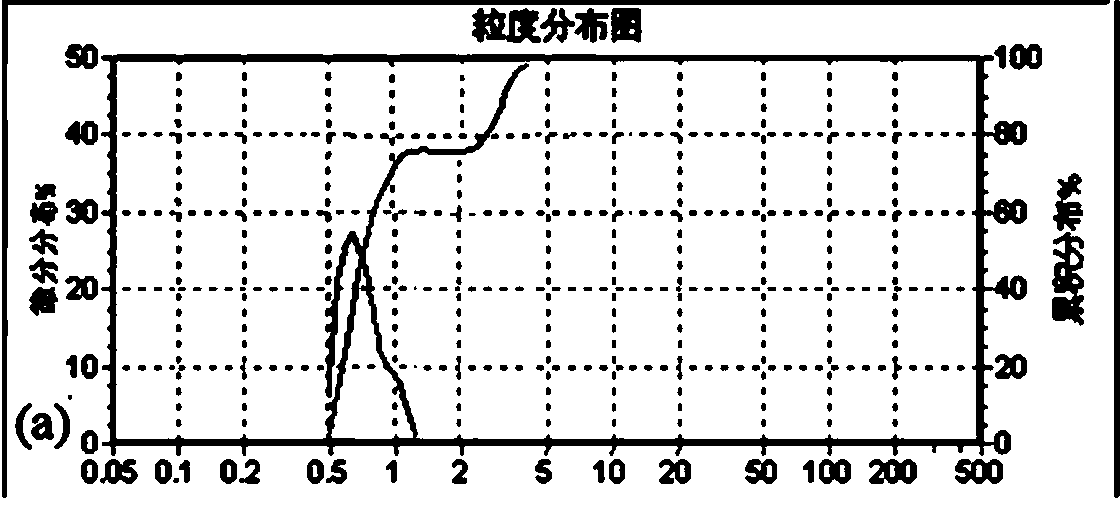

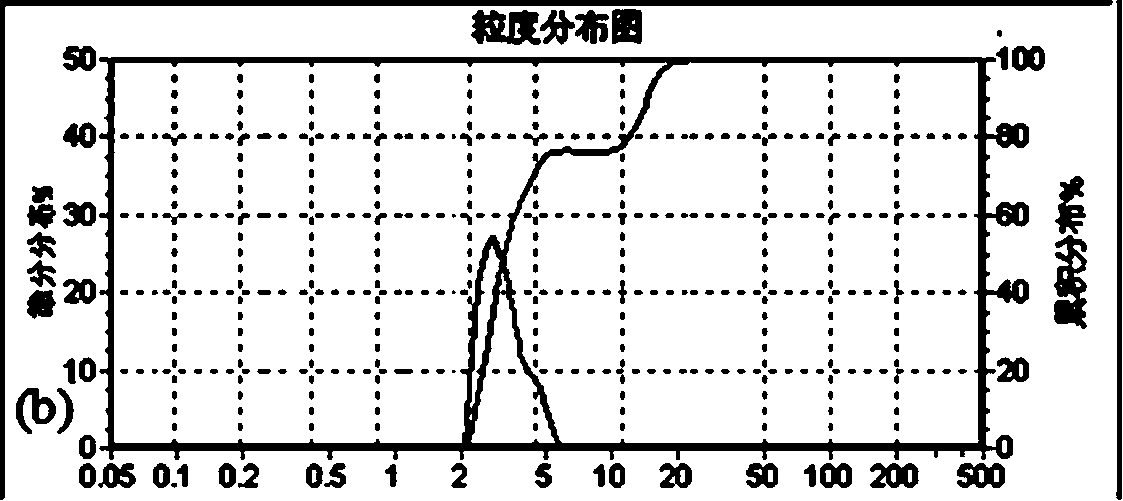

Yttria-stabilized zirconia powder and preparation method thereof

The invention relates to yttria-stabilized zirconia powder and a preparation method thereof. The yttria-stabilized zirconia powder has the composition characteristics that yttria is taken as a stabilizer of a zirconia material; the powder comprises a doping system formed by one or more following third components: alumina, ceria, lanthana, copper oxide, magnesium oxide and calcium oxide, wherein the weight of the yttria is 2-8mol%, and the total doping weight of the alumina, the ceria, the lanthana, the copper oxide, the magnesium oxide and the calcium oxide is 0-5wt%. According to the yttria-stabilized zirconia powder and the preparation method, the deficiencies of an existing liquid phase preparation process of nanometer zirconia powder are overcome, and the prepared nanometer ZrO2 composite powder has the performance of uniformity in dispersion of components, uniform grain size, super-fineness, high sintering activity, good liquidity and the like. Furthermore, the preparation method is simple in process and low in cost and is easy to industrialize.

Owner:YAAN YUANCHUANG CERAMIC

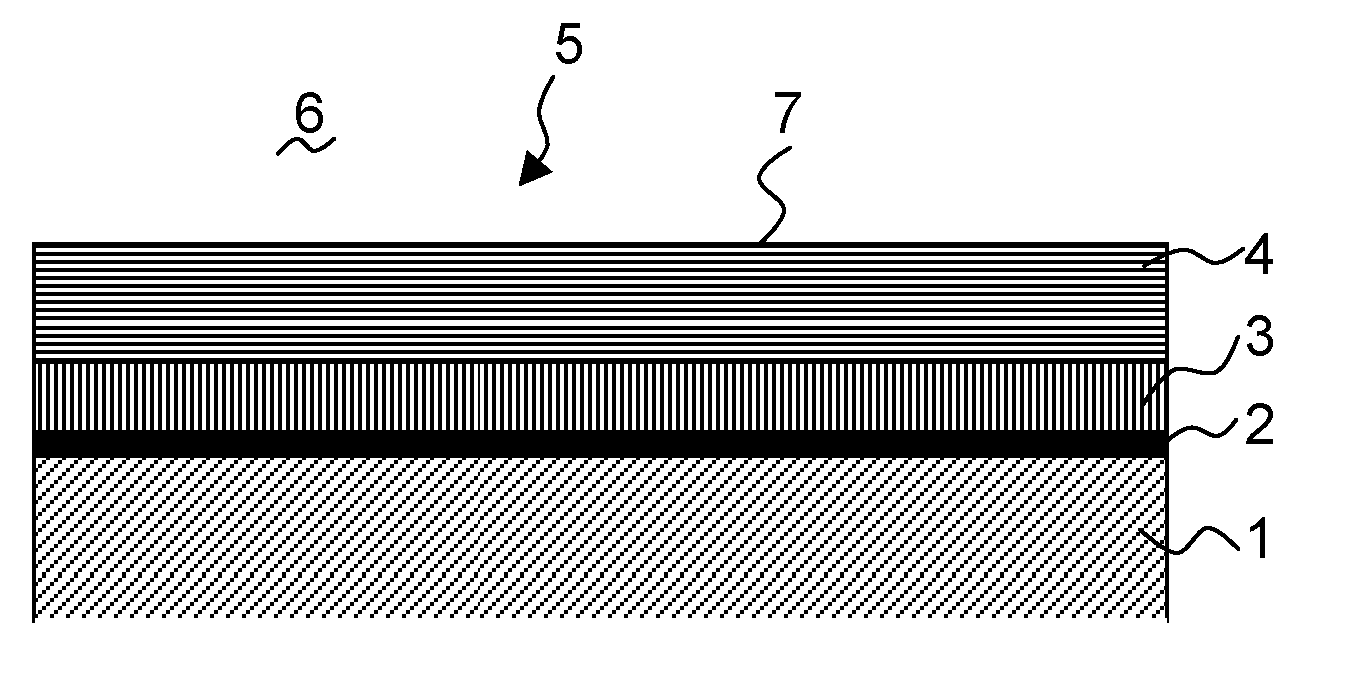

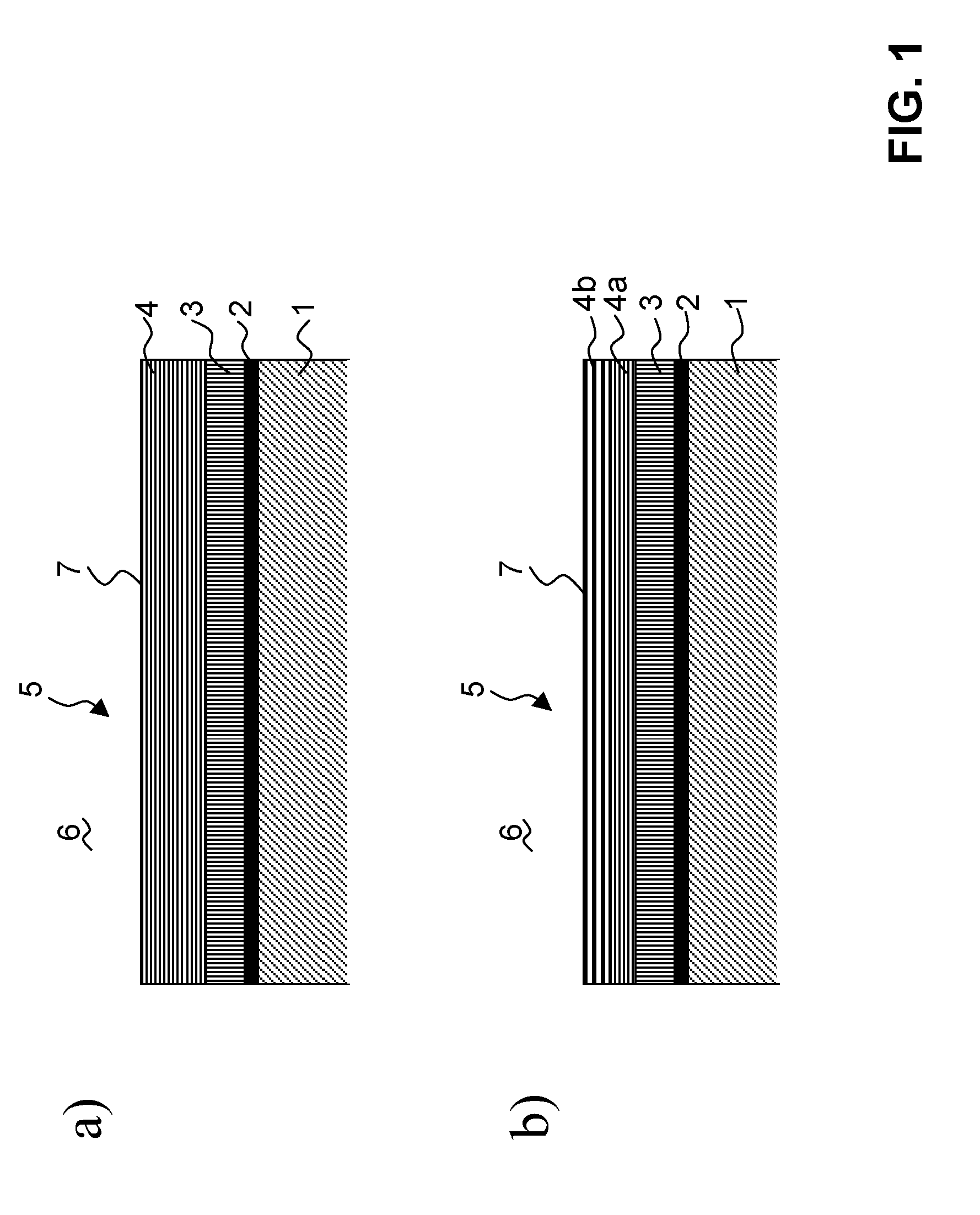

Thermal barrier coating system, components coated therewith and method for applying a thermal barrier coating system to components

A thermal barrier coating system on a base material includes a bond coat layer with a lower face in direct contact with the base material and an upper face, a first ceramic layer in direct contact with the upper face of the bond coating layer and a second ceramic layer disposed on an outermost surface of the coating system and configured to be exposed to hot gas. The first ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of yttria-stabilized zirconia with a yttria content in a range of 6-8 wt-%, YTaO4 doped zirconia, and titania doped zirconia. The second ceramic layer includes a layer, combination, mixture, alloy, blend or multilayer structure of at least one of YTaO4 doped zirconia, titania doped zirconia, scandia stabilized zirconia, ceria containing perovskite material, yttrium aluminium garnet material, Monazite material, and spinel material. A material of the second ceramic layer is different from a material of the first ceramic layer.

Owner:ANSALDO ENERGIA SWITZERLAND AG

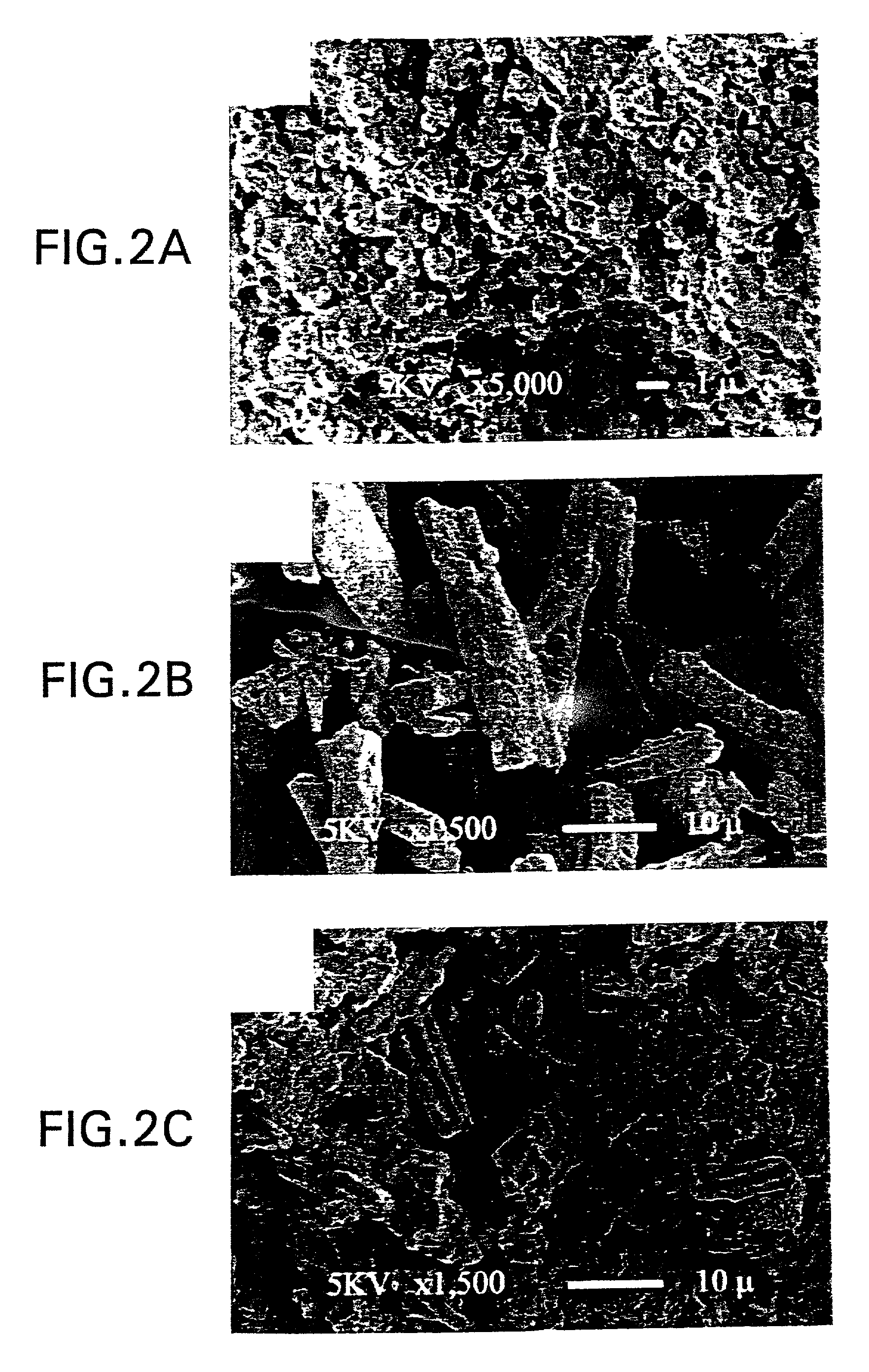

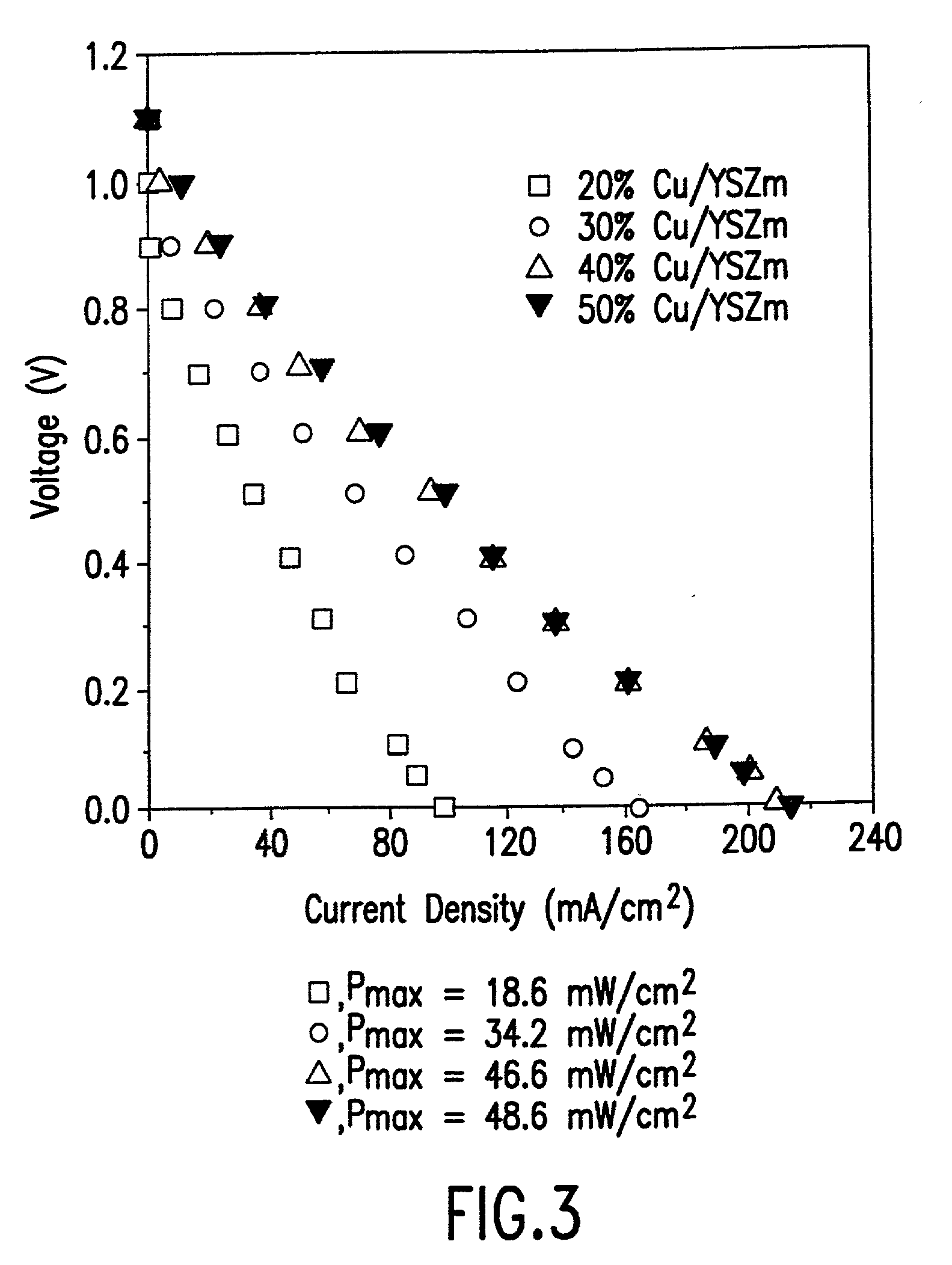

Method for solid oxide fuel cell anode preparation

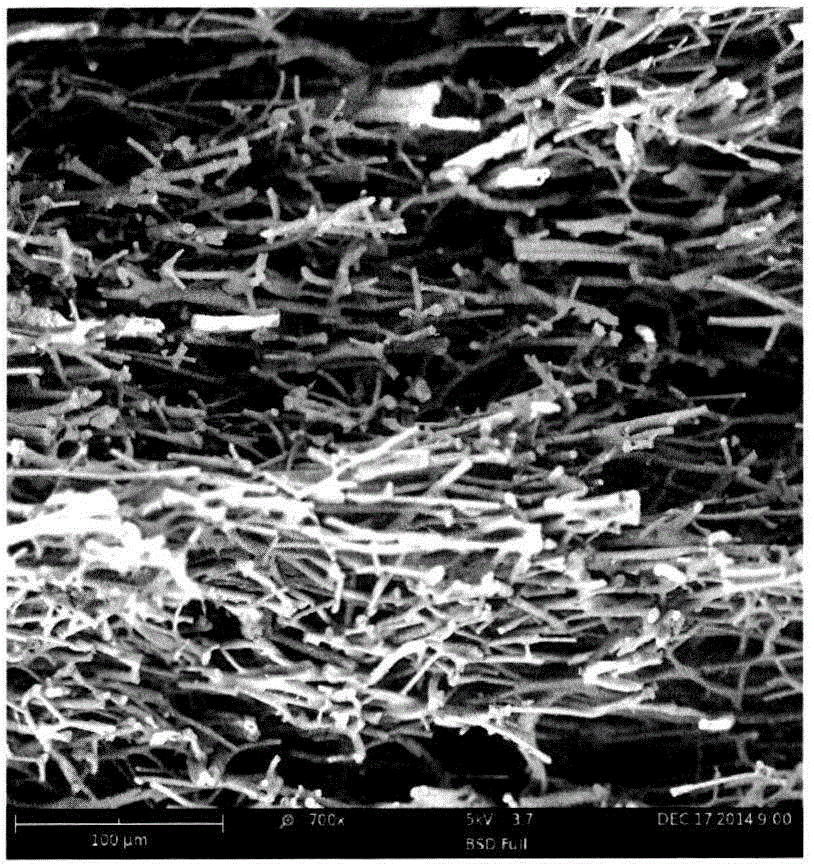

InactiveUS20010029231A1Easy to operateLower performance requirementsFinal product manufacturePrimary cellsFiberPowder mixture

A method for preparation of an anode for a solid oxide fuel cell in which a plurality of zircon fibers are mixed with a yttria-stabilized zirconia (YSZ) powder, forming a fiber / powder mixture. The fiber / powder mixture is formed into a porous YSZ layer and calcined. The calcined porous YSZ layer is then impregnated with a metal-containing salt solution. Preferred metals are Cu and Ni.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

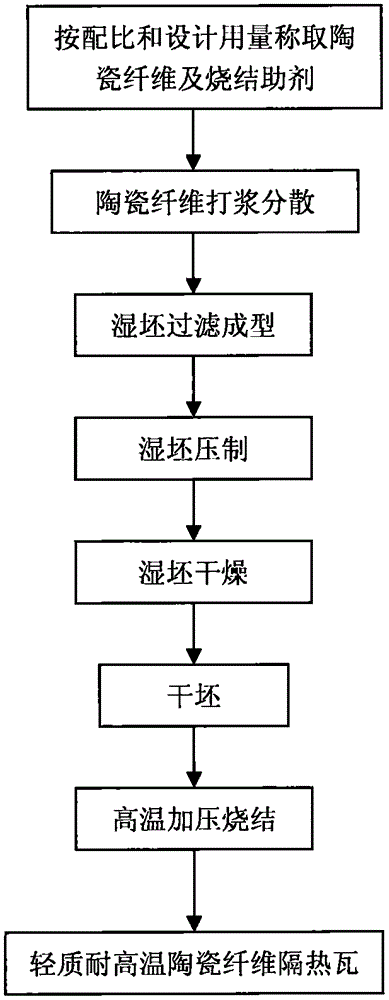

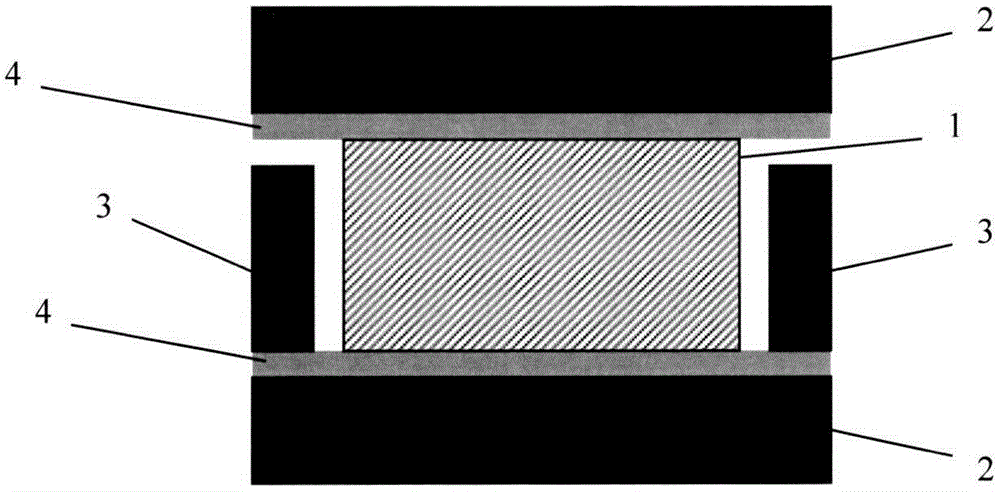

Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

ActiveCN105272322AOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

The invention relates to a light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and a making method thereof. The heat insulation tile comprises ceramic fibers and boron oxide, wherein the ceramic fibers comprise quartz fibers, alumina fibers and yttrium oxide stabilized zirconia fibers. The making method of the light-weight, high temperature-resistance and heat-insulation ceramic fiber tile comprises the following steps: preparing a sintering aid suspension, preparing a ceramic fiber slurry, carrying out wet green body molding, drying the obtained wet green body, and carrying out pressurization sintering. The heat insulation tile has good heat insulation effect and mechanical performances, has light weight and resists high temperature; the density is controllable between 0.10g / cm<3> and 0.90g / cm<3>; the lowest apparent heat conduction coefficient at room temperature reaches 0.033W / (m.K); the compressive strength at room temperature is greater than 3.0Mpa; and the long-time use temperature can reach 1350DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

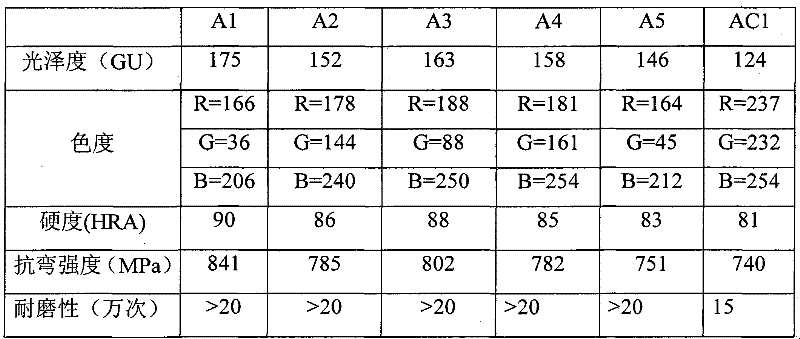

A kind of zirconia ceramic and its preparation method

The invention, belonging to the technical field of zirconia ceramic, discloses a zirconia ceramic and a preparation method thereof. The ceramic comprises matrix, sintering aid, neodymium oxide and additive, wherein, the matrix is yttria stabilized zirconia, the additive is selected from one or more of zinc oxide, barium carbonate and calcium fluoride, and the diffraction peak of the XRD appears when the 2 theta is 34.8-36.2 degrees. The zirconia ceramic has stable and beautiful purple. The preparation method comprises the following steps: adding neodymium oxide particles in a diethanolamine solution for soaking, then carrying out solid-liquid separation; carrying out ball mill mixing of the matrix, processed neodymium oxide particles, sintering aid and additive, then carrying out die forming and high temperature sintering. The preparation method provided by the present invention is simple and easy, and is suitable for large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Atomic layer deposition for turbine components

A method and superalloy component for depositing a layer of material onto gas turbine engine components by atomic layer deposition. A superalloy component may have a ceramic thermal barrier coating on at least a portion of its surface, comprising a superalloy substrate and a bonding coat; and aluminum oxide (Al2O3) layer may be deposited on top of an yttria-stabilized zirconia layer and form a bonding coat by atomic layer deposition. The yttria-stabilized zirconia layer may have a plurality of micron sized gaps extending from the top surface of the ceramic coating towards the substrate and defining a plurality of columns of the yttria-stabilized zirconia layer. Also, atomic layer deposition may be used to lay an aluminum oxide (Al2O3) layer over a tantalum oxide (Ta2O5) layer on a silicon-based substrate. Using atomic layer deposition to coat the gas turbine engine components permits conformal coating of the columnar surface to permit gap expansion and contraction without sintering of the columnar surface or spalling of the coating, and form an oxidation resistant bonding coat.

Owner:HONEYWELL INT INC

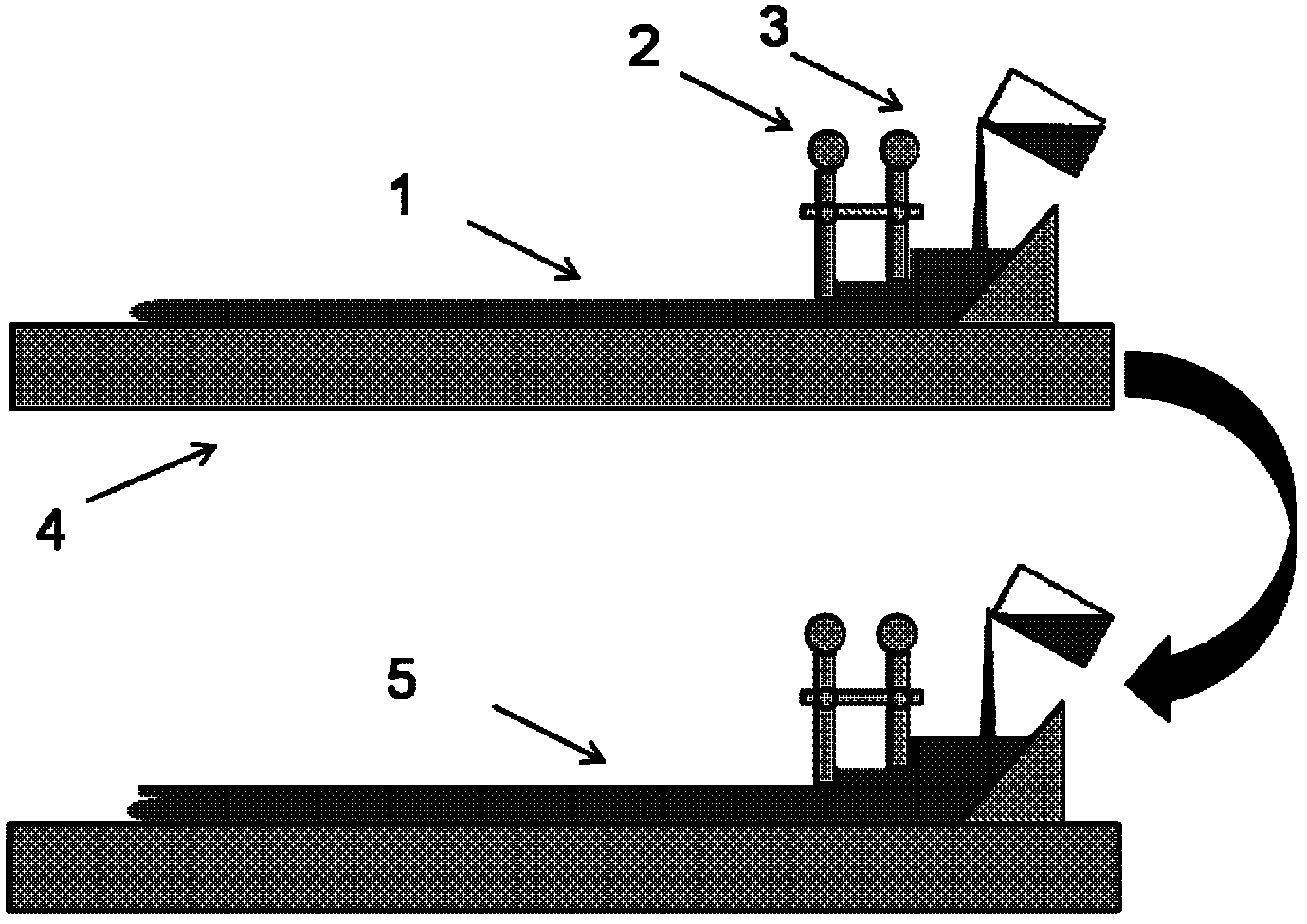

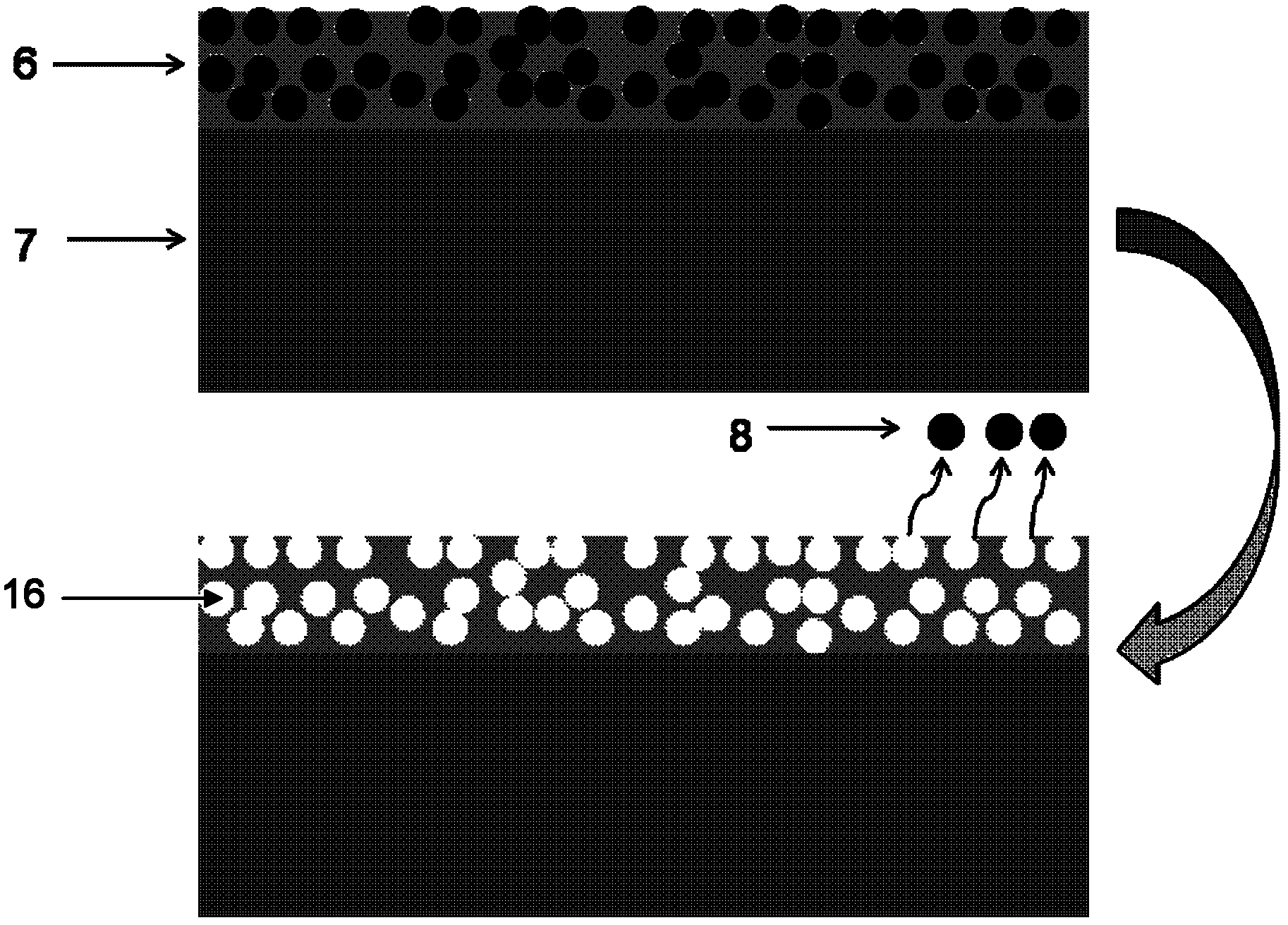

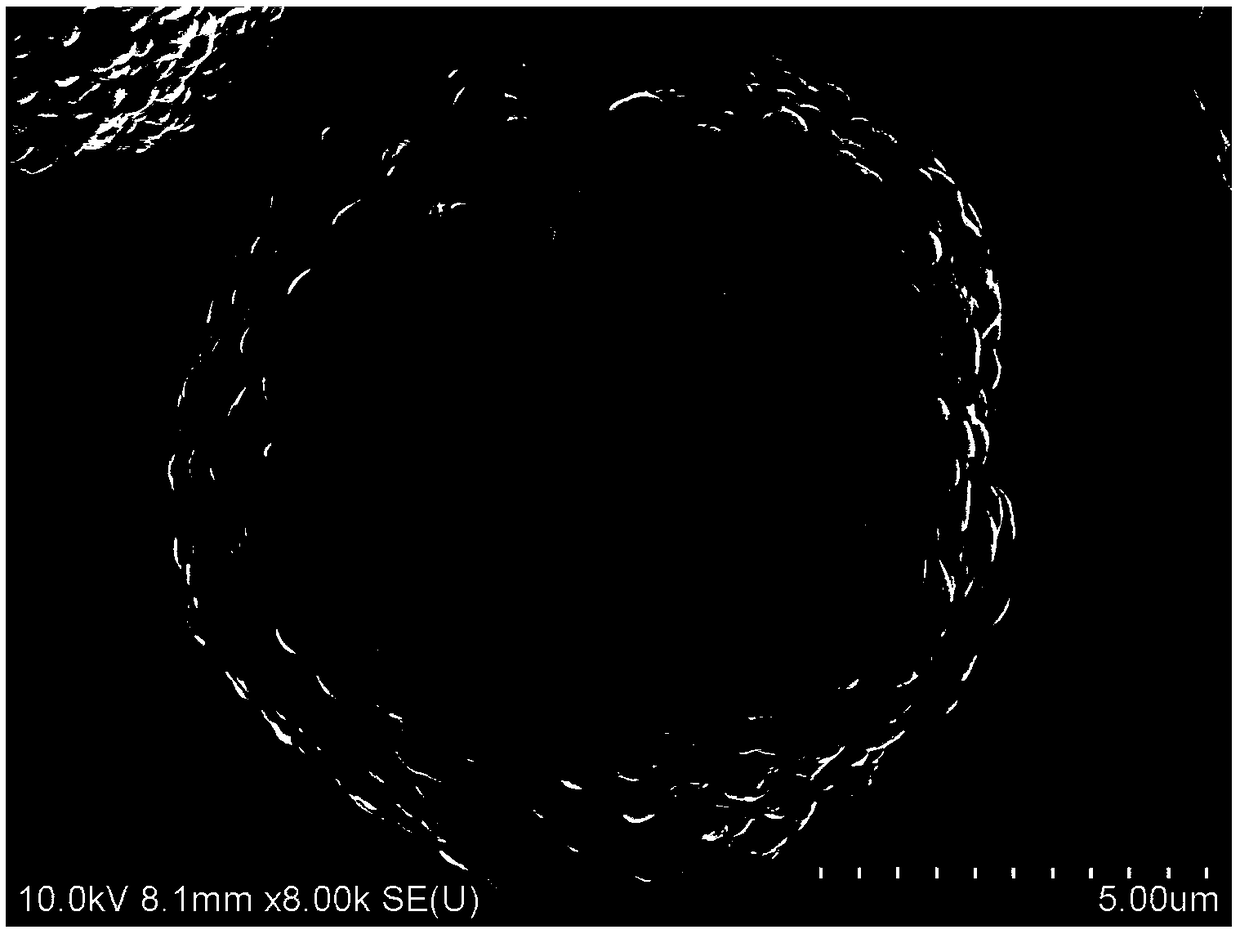

Mixed-potential nitrogen dioxide sensor based on porous YSZ (yttria stabilization zirconia) substrate and preparation method for sensor

ActiveCN102495122AIncreased sensitivityLow costMaterial analysis by electric/magnetic meansSlurryYttria-stabilized zirconia

The invention belongs to the technical field of gas sensors, and particularly relates to a mixed-potential nitrogen dioxide sensor with an efficient three-phase interface based on a porous YSZ (yttria stabilization zirconia) substrate and a preparation method for the sensor. The sensor is mainly used for detecting automobile exhaust, and sequentially comprises an Al2O3 ceramic plate, the porous YSZ substrate, a Pt (platinum) reference electrode and an MnCr2O4 sensitive electrode, wherein the Al2O3 ceramic plate is provided with a Pt heating electrode, one side of the porous YSZ substrate is provided with a pore-forming surface, both the reference electrode and the sensitive electrode are bar-shaped and symmetrically positioned at two ends of the pore-forming surface of the porous YSZ substrate close to a boundary, the porous YSZ substrate is provided with a planar double-layer structure, the surface of the porous YSZ substrate is rough and porous, and the porous YSZ substrate is prepared by casting YSZ slurry added with pore-forming agent starch on a YSZ cast biscuit after low-temperature degreasing and high-temperature sintering. By using MnCr2O4 as the sensitive electrode and adding the three-phase interface of the mixed-potential NO2 sensor, sensitivity of the sensor is enhanced.

Owner:JILIN UNIV

Method for Improving Resistance to CMAS Infiltration

InactiveUS20090169752A1Improve the immunityMolten spray coatingPretreated surfacesMetallurgyRare earth

Methods for providing improved resistance to CMAS infiltration for hot section components of a gas turbine engine. Exemplary methods include coating a substrate with a thermal barrier coating system by overlying a bond coated substrate with an inner thermal barrier layer comprised of a thermal barrier material such as yttria-stabilized zirconia. A top layer, including a rare-earth aluminate, is deposited so as to overlie at least a portion of the inner layer. Deposition processes and coating thicknesses may be tailored to the type of component to be coated.

Owner:GENERAL ELECTRIC CO

Alumina ceramic and preparation method thereof

The invention provides alumina ceramics and a manufacturing method of the alumina ceramics. The main materials of the alumina ceramics are as follows: alumina micro mist or a superfine alumina micro mist which is formed by Gamma alumina and an Alpha alumina with an particle diameter of between zero point one to three point five micron and a purity of ninety-nine point nine percent or more than ninety-nine point nine percent according to certain proportion. One or a mixture of a small quantity of magnesia, yttria, lanthana, thulia and yttria stabilized zirconia is added into the micro mist as sinter accessory ingredient and is subject to dry pressing, grouting and isostatic cool pressing after being even mixed evenly, thus ceram green pressing is obtained. Only a little organic addition agent is needed to be added. After drying, the green pressing body does not need to be roasted and can be directly introduced to an ordinary high temperature si-mo rod resistance furnace or a continuous type si-mo rod electrothermal tunnel kiln to be sintered for one to three hours at a temperature below one thousand six hundred and seventy Celsius system. Therefore, the alumina ceramics can be obtained with high tightness, mechanical property and good dielectric property and with a nonconventional structure and a placode the size of which is zero point two to two hundred millimeter and a purity of ninety nine to ninety-nine point nine percent.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

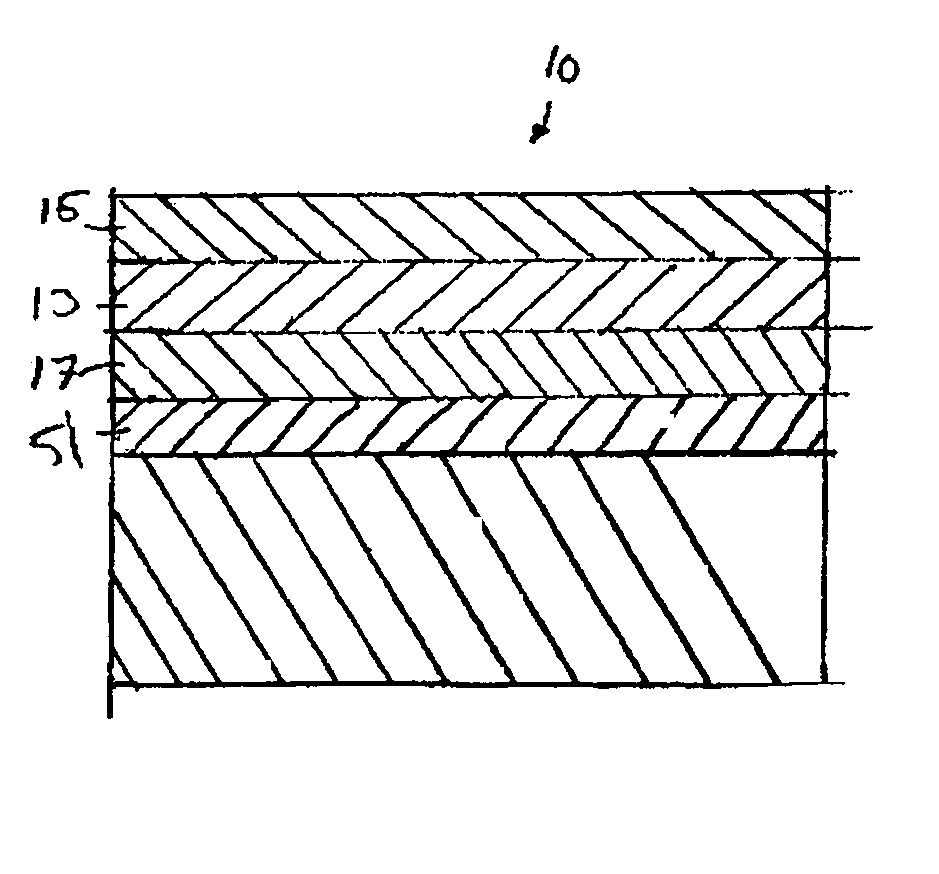

Thin 7YSZ, interfacial layer as cyclic durability (spallation) life enhancement for low conductivity TBCs

A spallation resistant metallic article comprising a metallic substrate, at least one ceramic thermal barrier coating comprising a zirconia base and at least one other element selected from the group consisting of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc, In, Y, Mo and C, rare earth oxides, scandium, and indium, and a ceramic bond coat located on at least a portion of the substrate and between the metallic substrate and the at least one ceramic thermal barrier coating wherein the ceramic bond coat is composed of yttria stabilized zirconia (YSZ).

Owner:RTX CORP

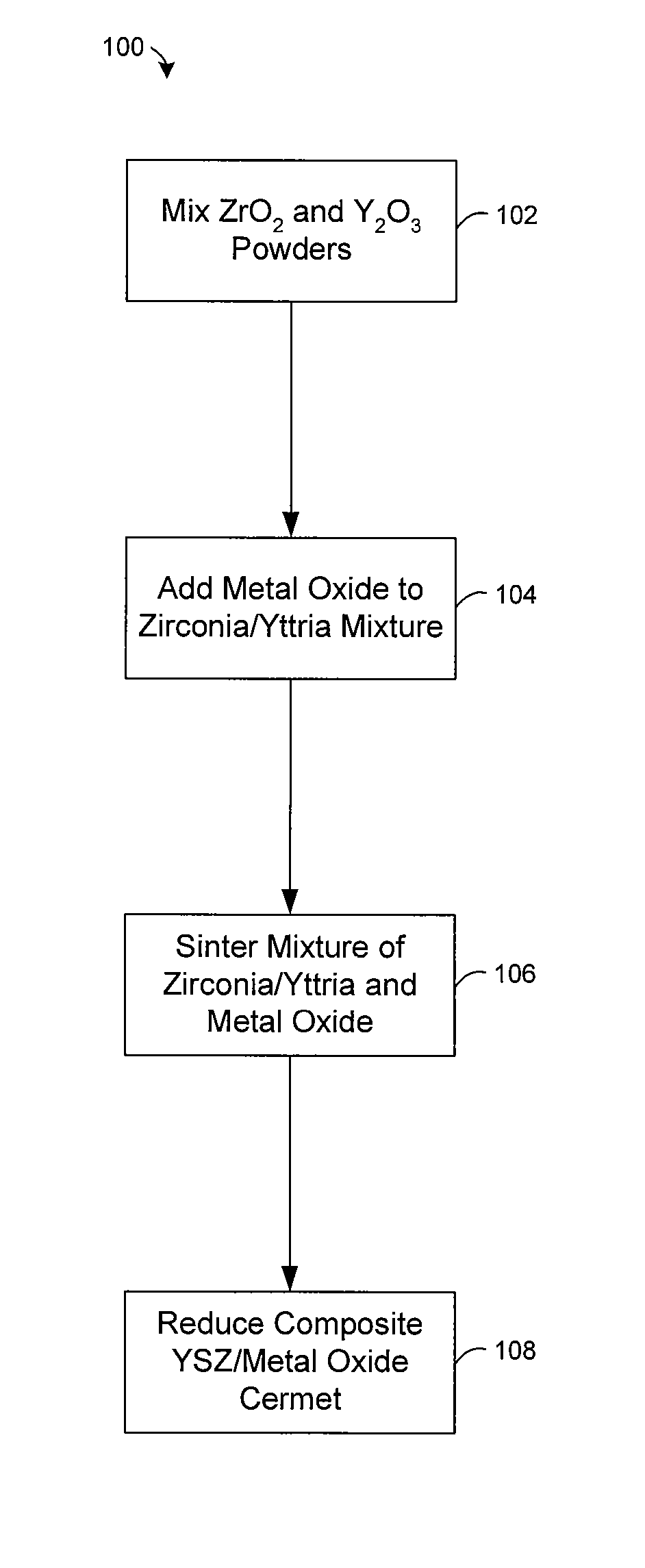

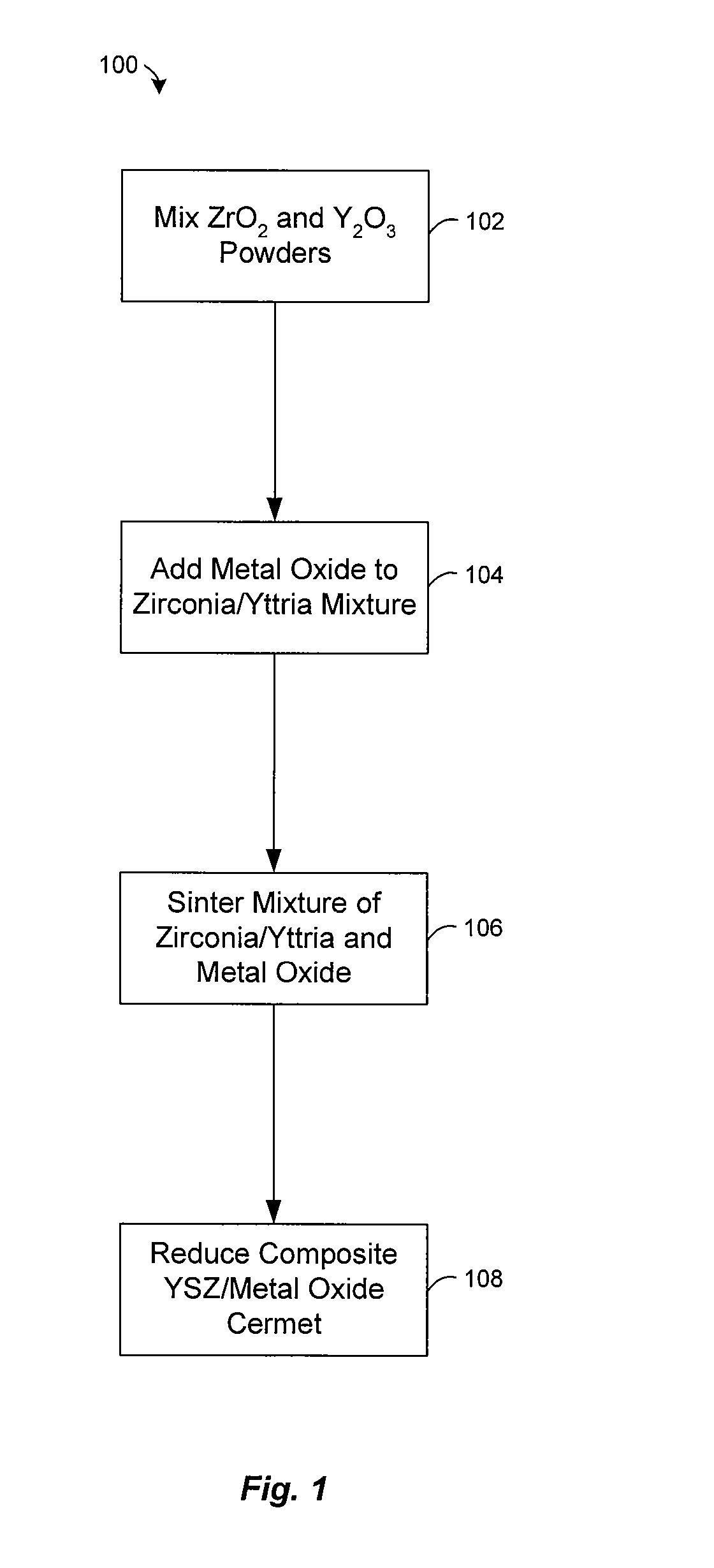

Preparation of yttria-stabilized zirconia reaction sintered products

A method of making a solid electrolyte-YSZ product, where the method includes the step of providing a powdered mixture of zirconia, yttria and about 2%, by wt., or less of a metal oxide, where yttria-stabilized zirconia is not added to the mixture. The method also includes sintering the powdered mixture at about 1500° C. or less, for about 5 hours or less, to form a reaction sintered YSZ. Also, a method of making a fuel cell electrolyte that includes the step of forming a green body that includes zirconia, yttria and about 2%, by wt., or less of a metal oxide, where yttria-stabilized zirconia is not added to the green body. The method also includes shaping the green body into a form of the electrolyte, and sintering the green body at about 1500° C. or less to form a reaction sintered yttria-stabilized zirconia and metal oxide electrolyte.

Owner:COORSTEK INC

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

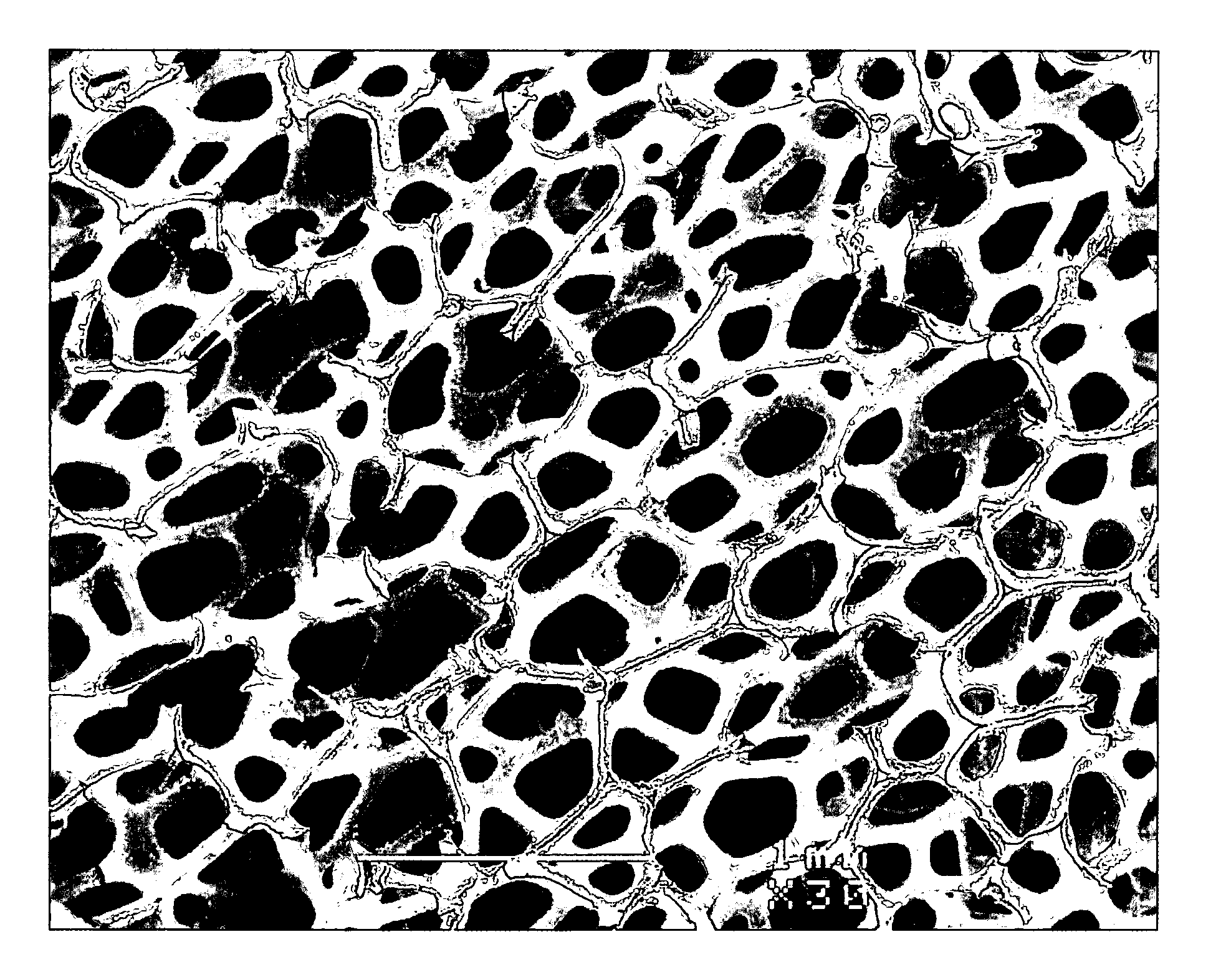

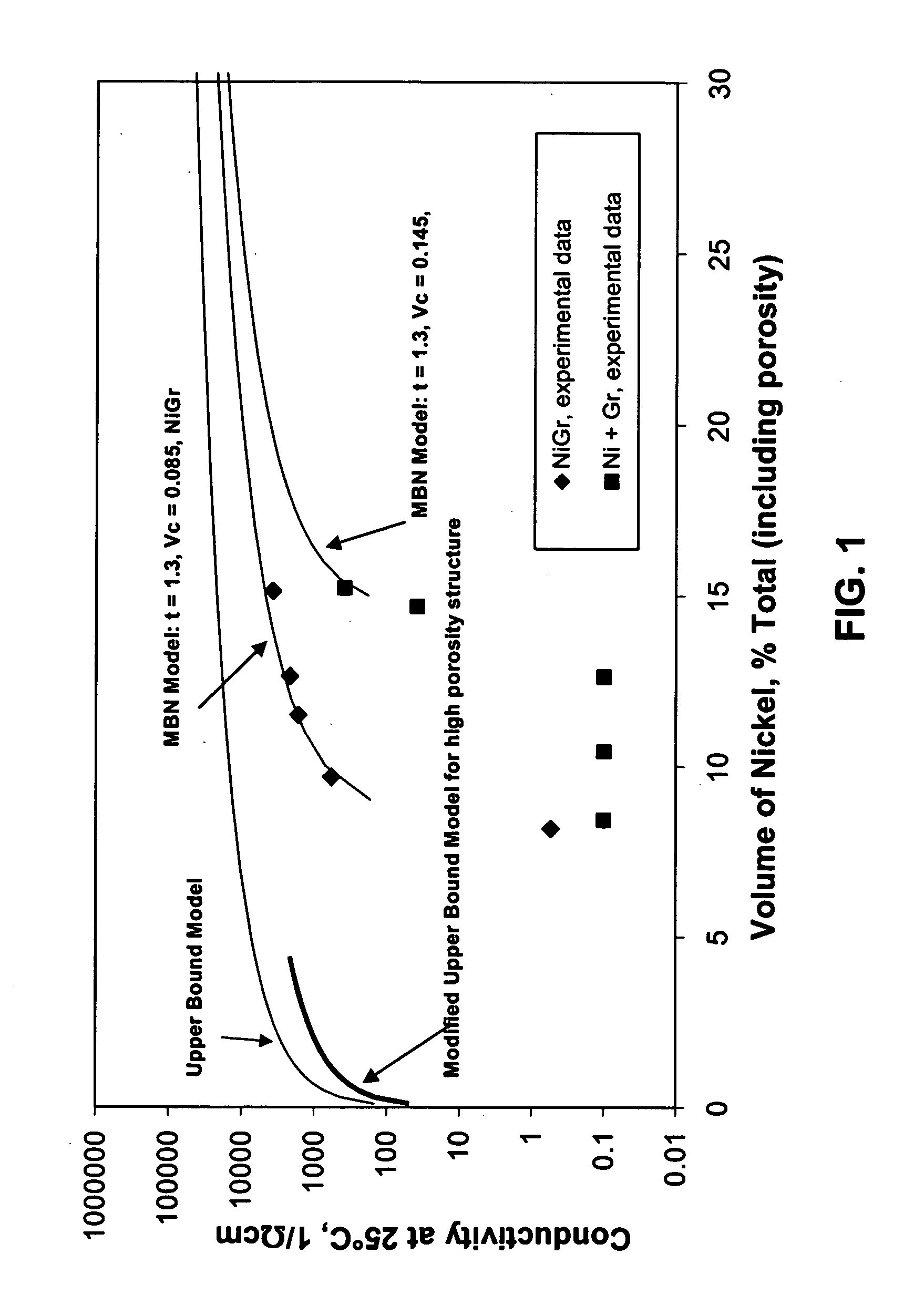

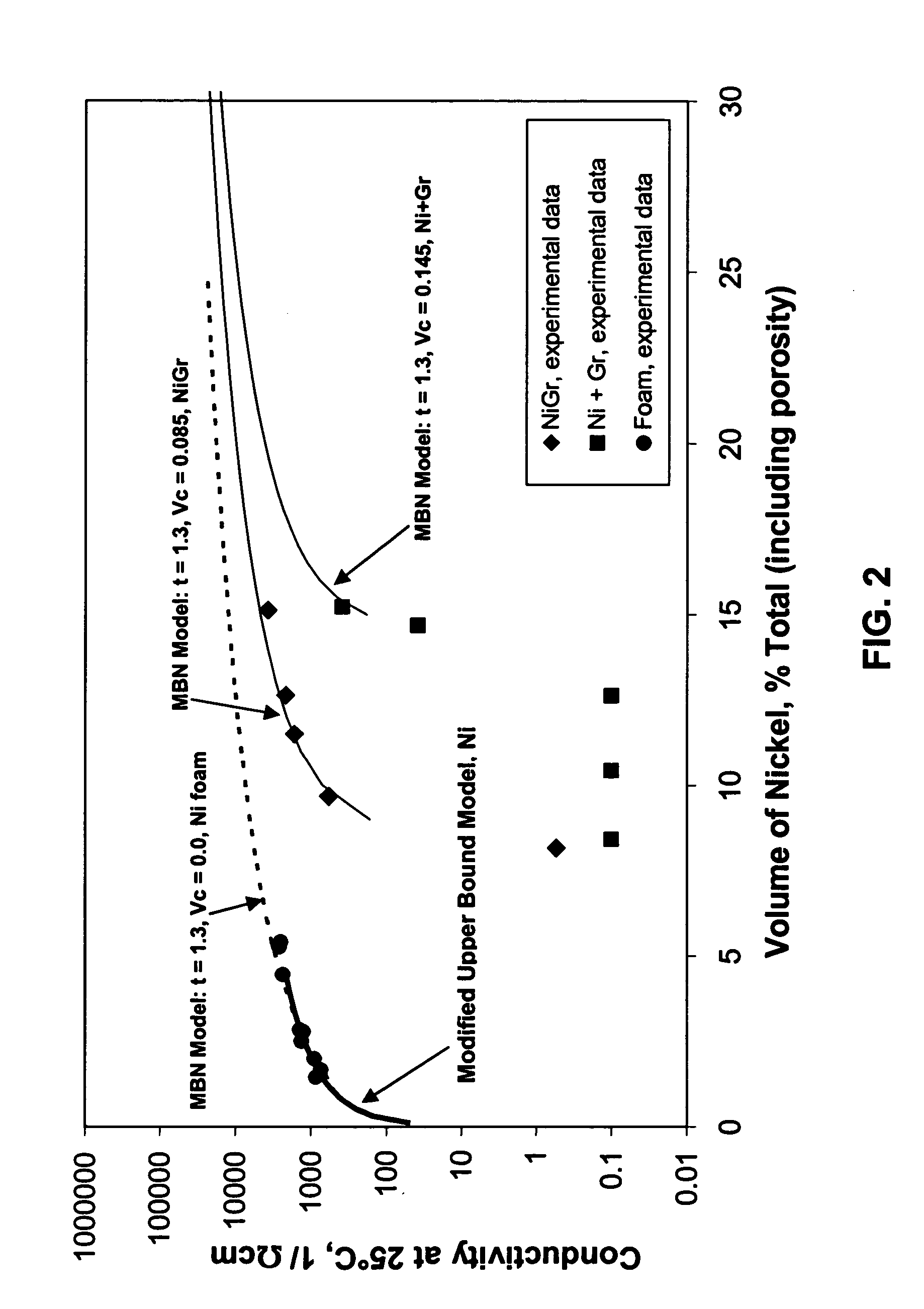

Nickel foam and felt-based anode for solid oxide fuel cells

InactiveUS20050221163A1Improve conductivityReduce in quantityPhotography auxillary processesVacuum evaporation coatingFuel cellsThermal expansion

A solid oxide fuel cell anode is comprised of a nickel foam or nickel felt substrate. Ceramic material such as yttria stabilized zirconia or the like is entrained within the pores of the substrate. The resulting anode achieves excellent conductivity, strength and low coefficient of thermal expansion characteristics while effectively reducing the overall quantity of nickel contained in the fuel cell. Equivalent or better fuel cell anode characteristics result in the present invention as compared to conventional anode designs while simultaneously employing significantly less nickel.

Owner:INCO

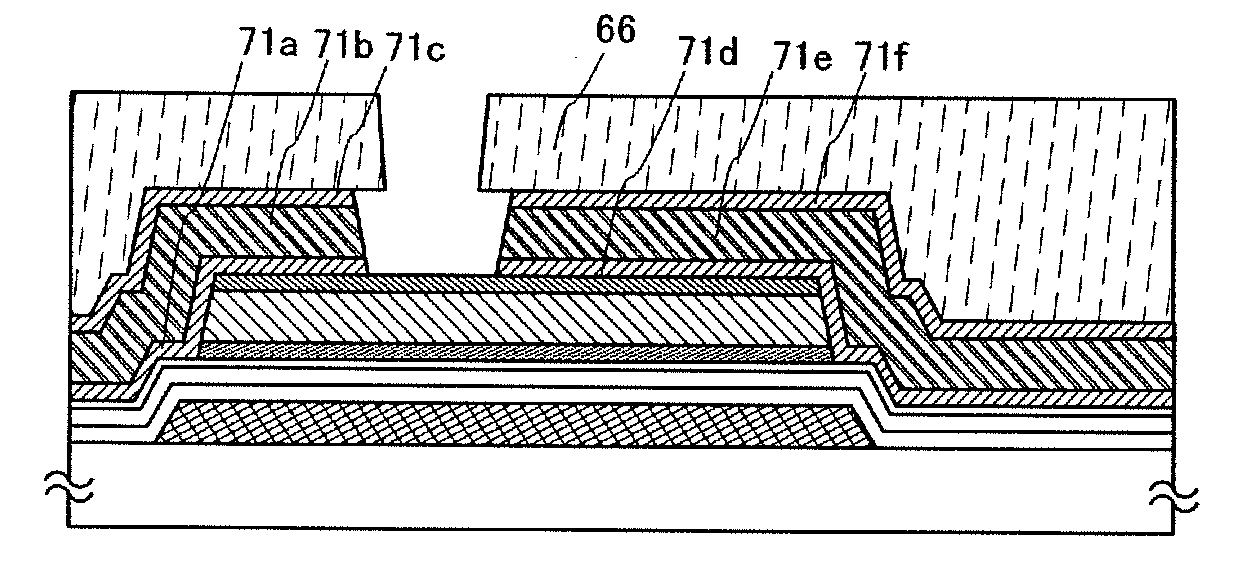

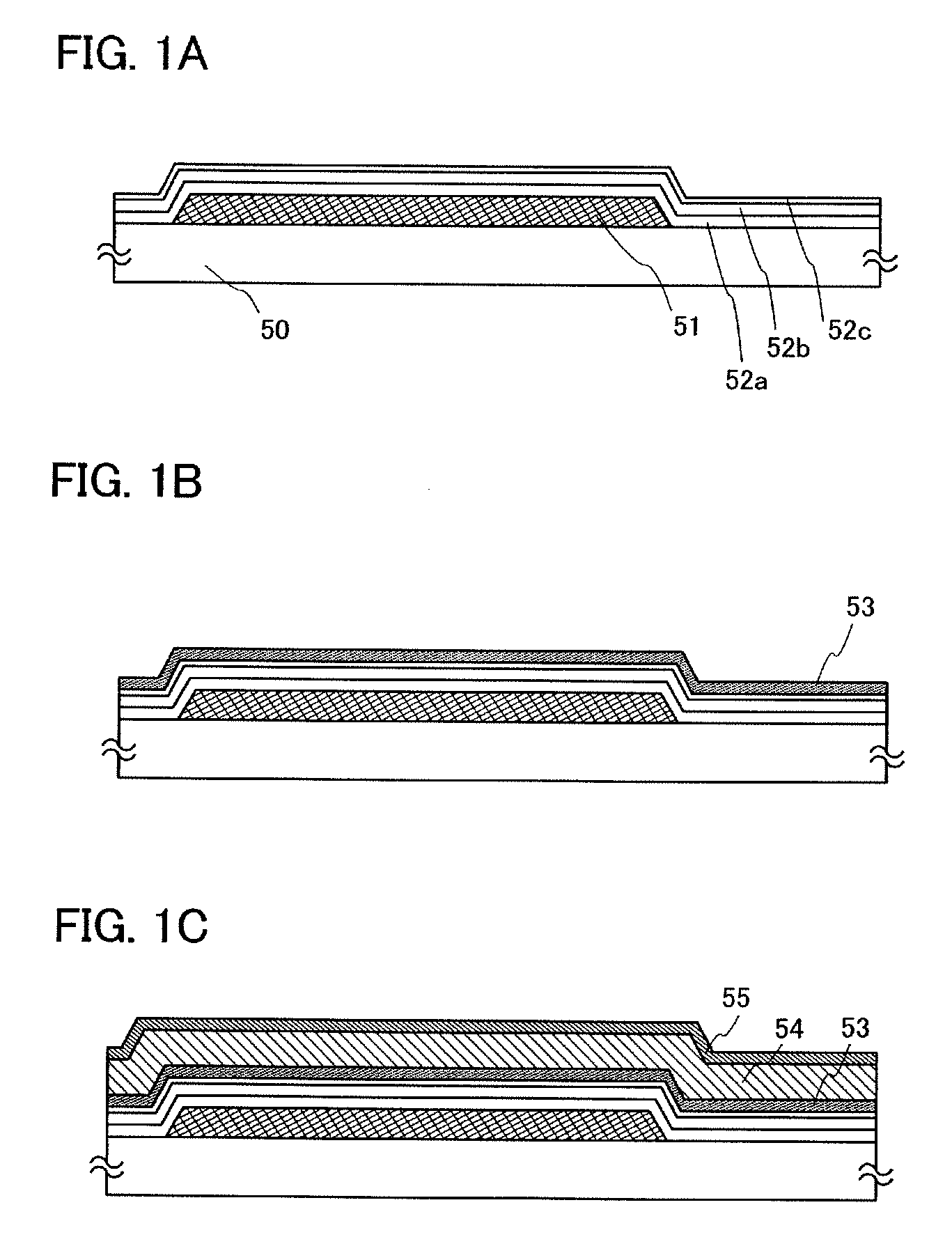

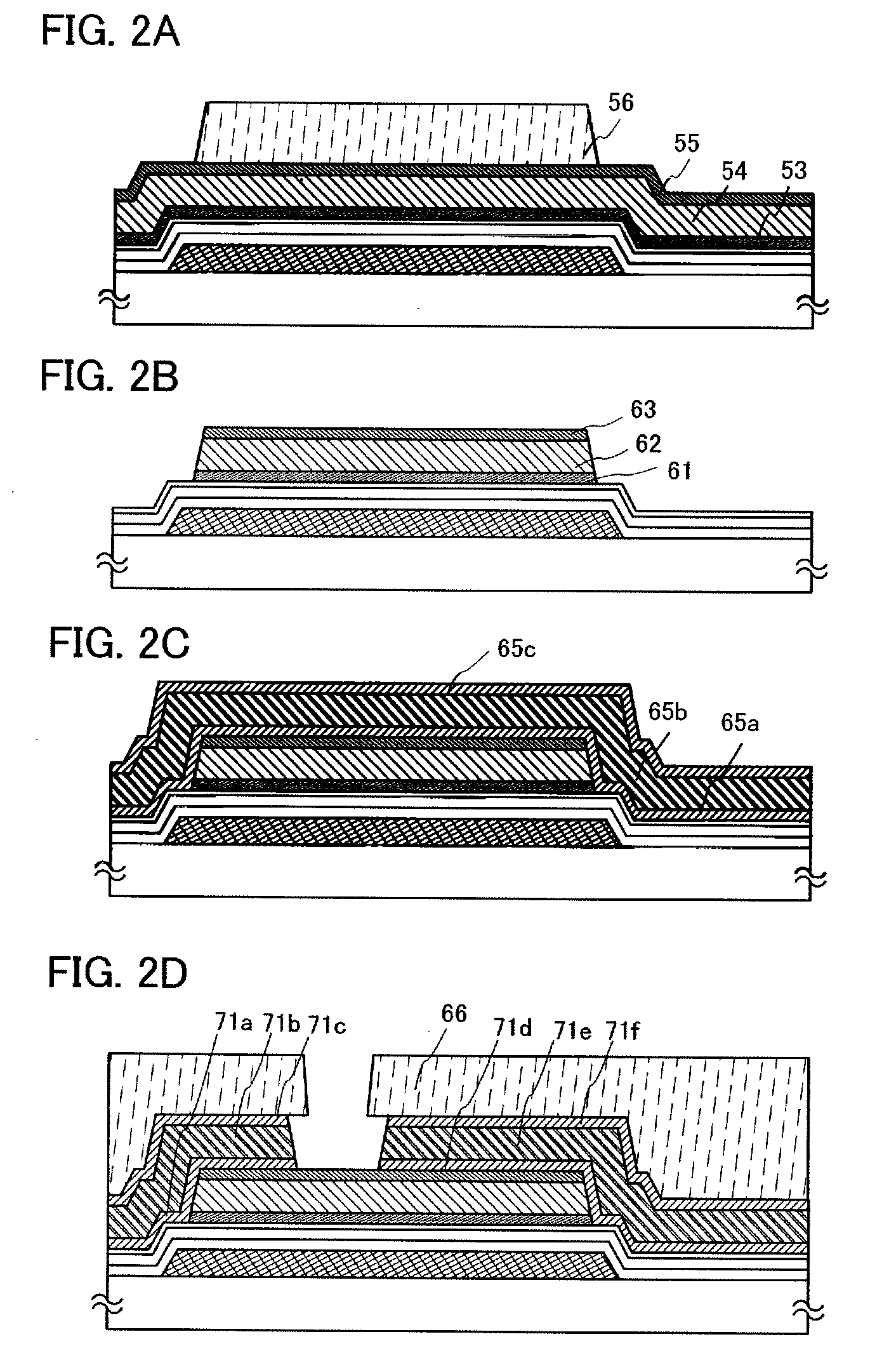

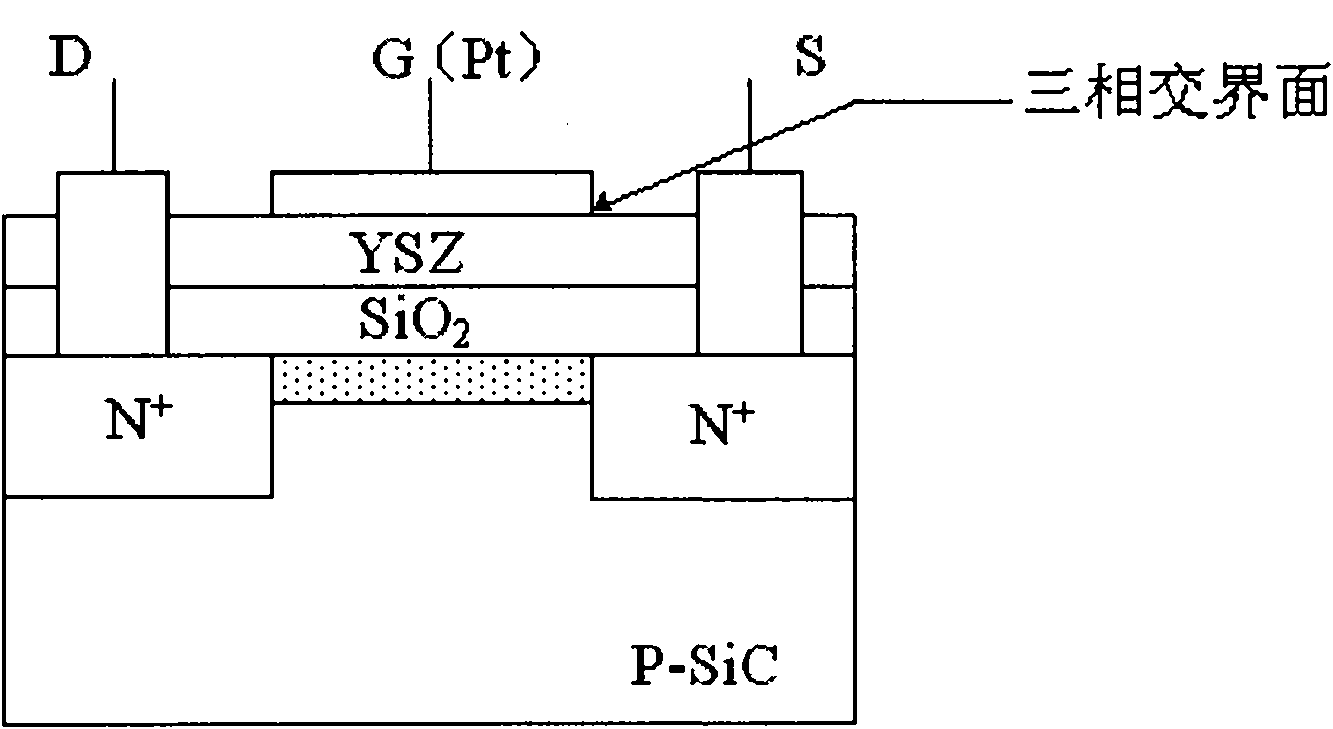

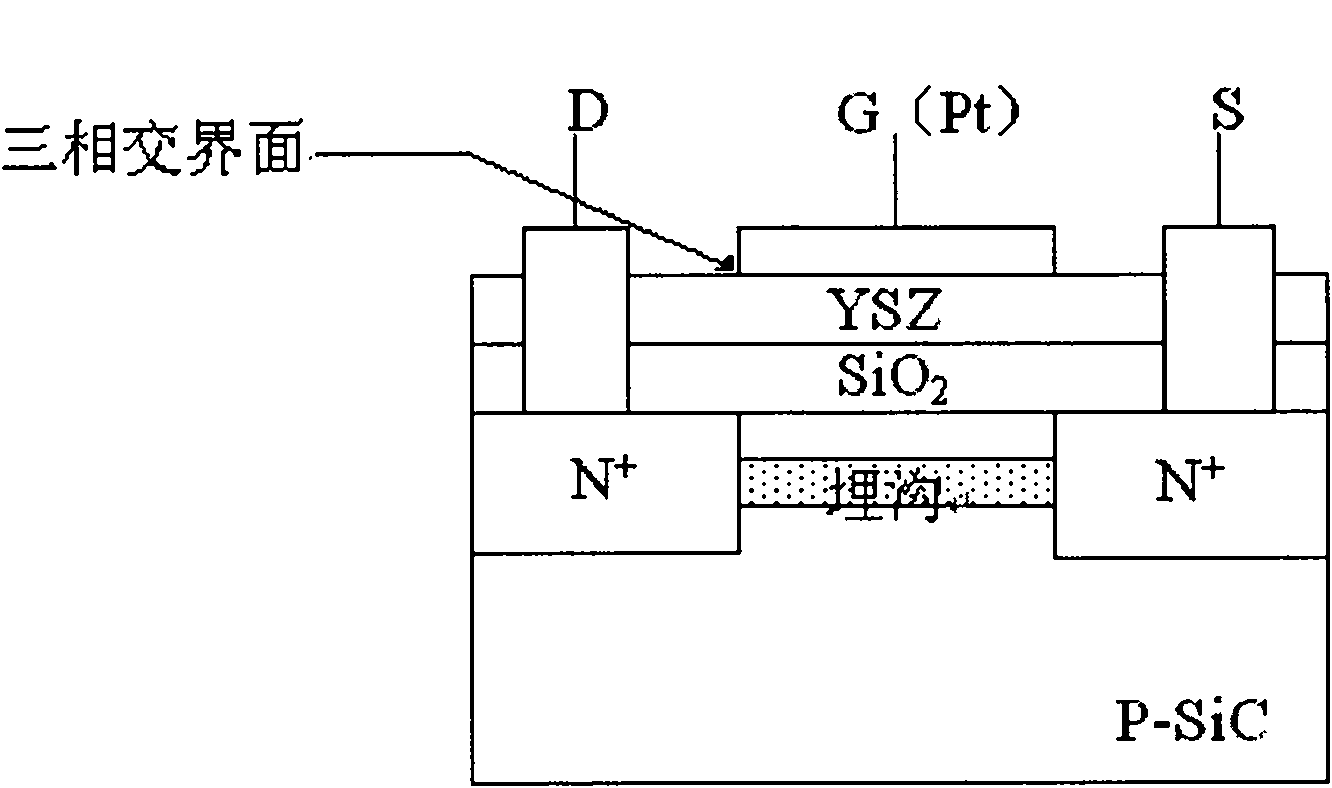

Semiconductor device and method for manufacturing semiconductor device

InactiveUS20090152550A1Improve responseIncrease speedTransistorSemiconductor/solid-state device manufacturingDevice materialCrystallinity

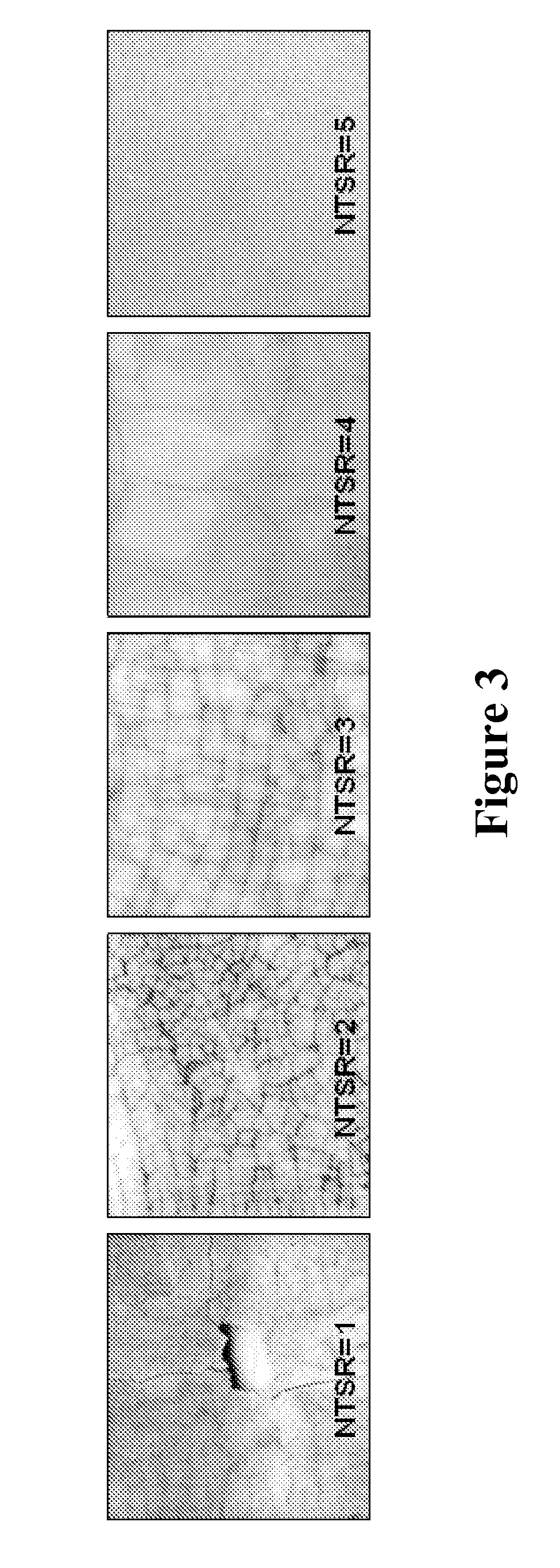

An object is to provide a semiconductor device including a microcrystalline semiconductor film with favorable quality and a method for manufacturing the semiconductor device. In a thin film transistor formed using a microcrystalline semiconductor film, yttria-stabilized zirconia having a fluorite structure is formed in the uppermost layer of a gate insulating film in order to improve quality of a microcrystalline semiconductor film to be formed in the initial stage of deposition. The microcrystalline semiconductor film is deposited on the yttria-stabilized zirconia, so that the microcrystalline semiconductor film around an interface with a base particularly has favorable crystallinity while by crystallinity of the base.

Owner:SEMICON ENERGY LAB CO LTD

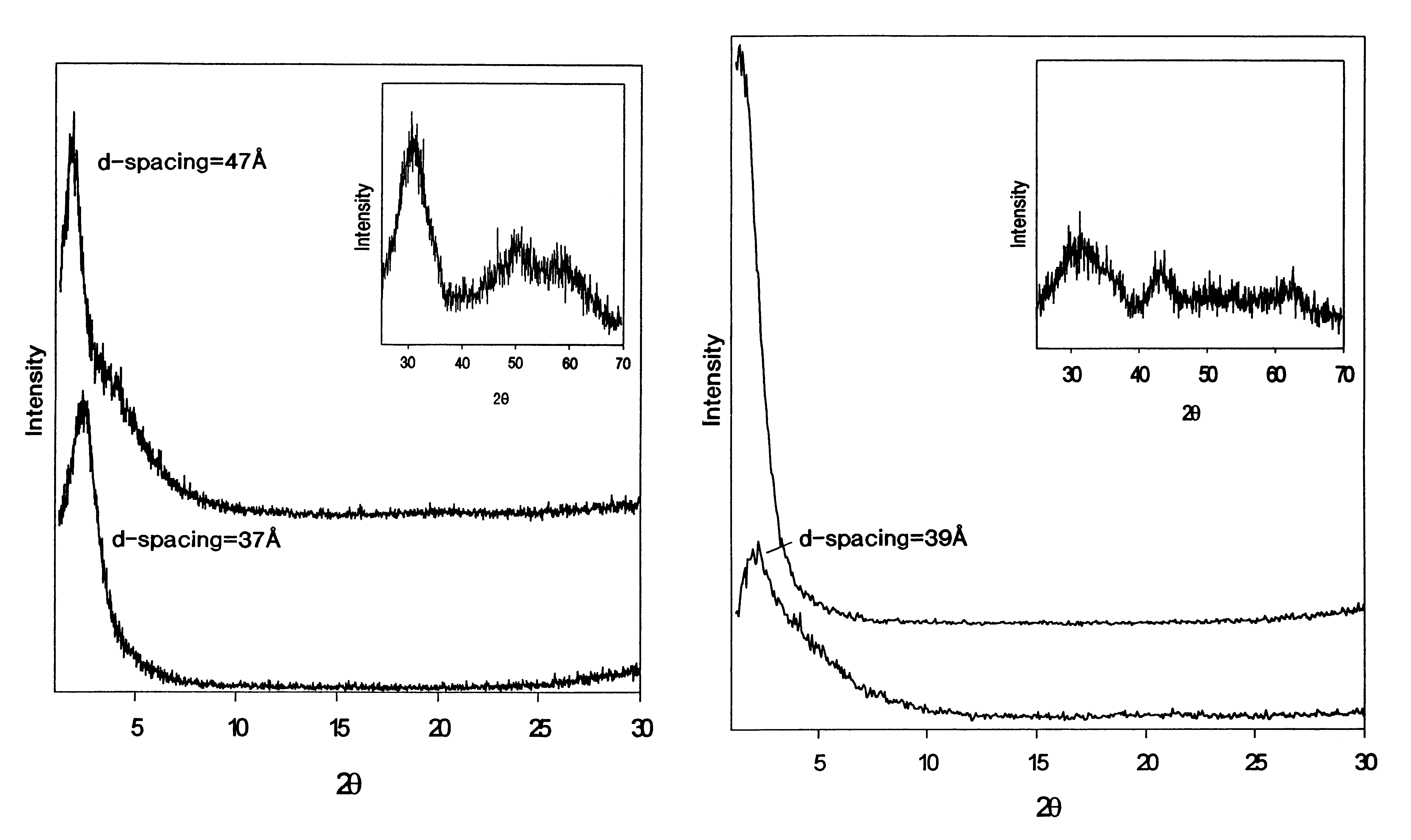

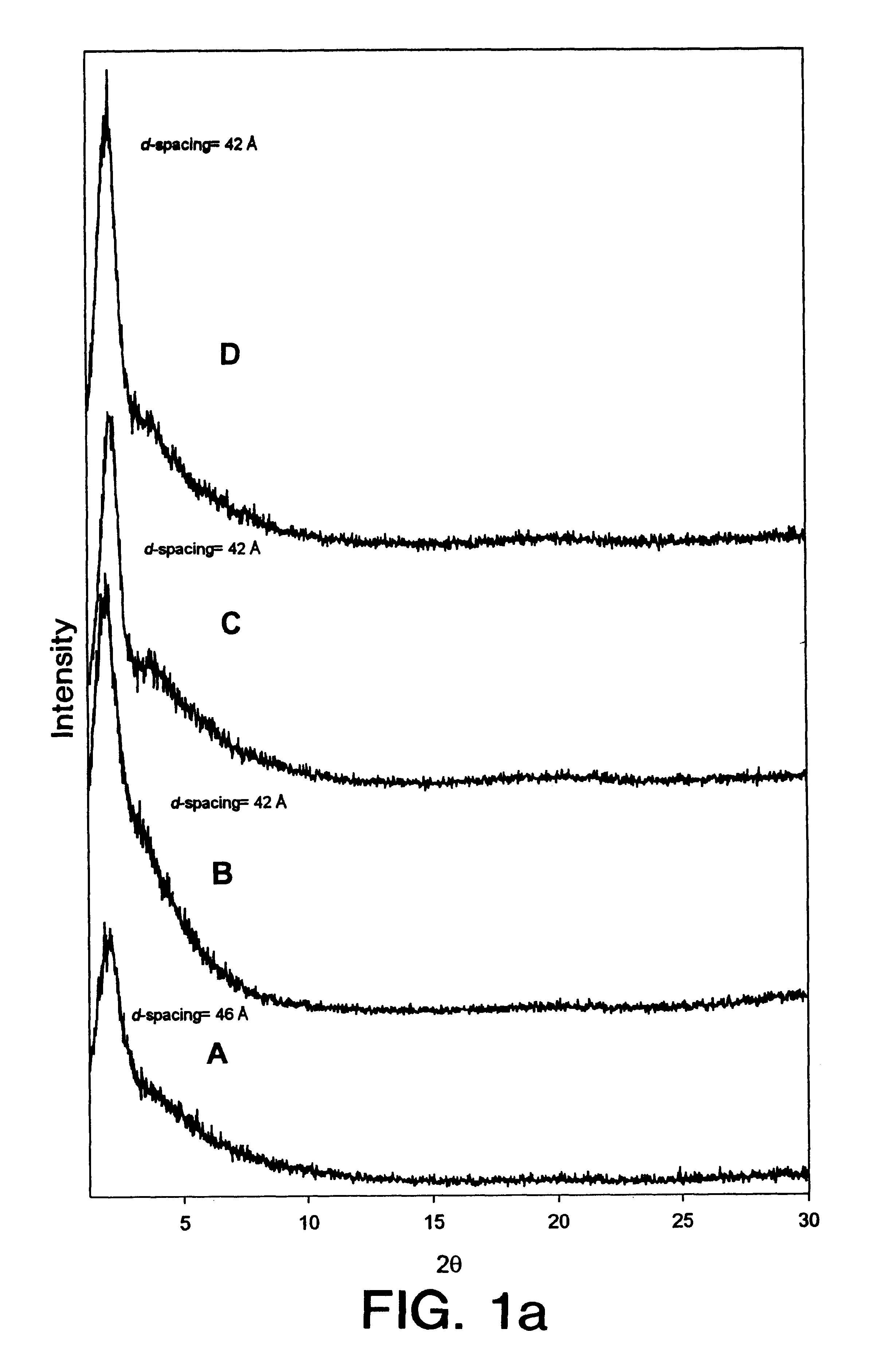

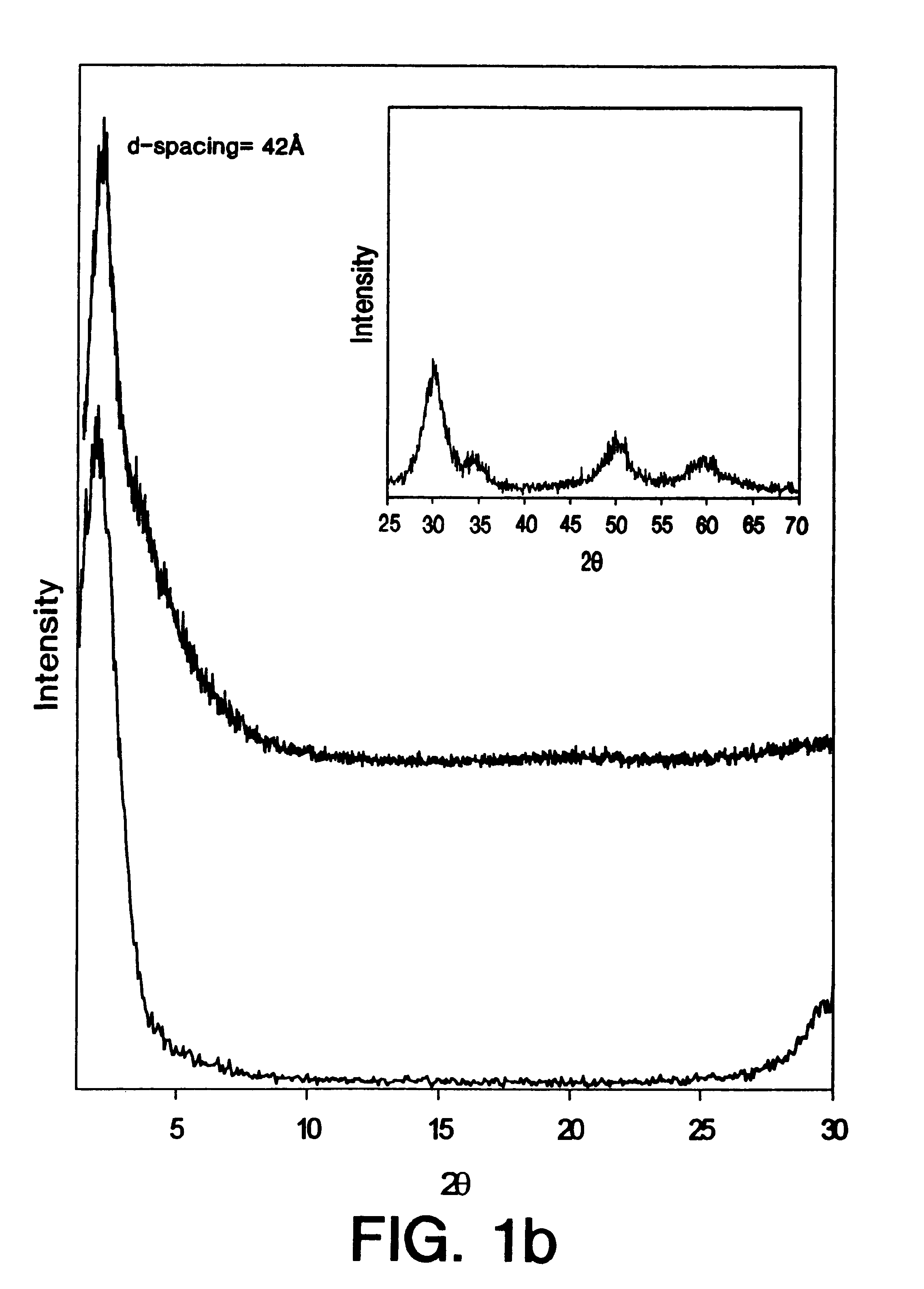

Mesoporous oxide compositions and solid oxide fuel cells

InactiveUS6420063B1Oxide/hydroxide preparationZirconium compoundsYttria-stabilized zirconiaPt element

The invention discloses methods of producing thermally stable mesoporous transition metal oxide compositions by aqueous co-assembly of glycometallates and metal complexes with a surfactant template, without the necessity of the use of stabilizers. Mesoporous (nickel / platinum)-yttria-zirconia materials are also disclosed for use as electrode materials in solid oxide fuel cells. These materials display the highest surface area of any form of (metal)-yttria-stabilized-zirconia, thereby providing significant improvement in the efficiency of solid oxide fuel cells.

Owner:EXXON RES & ENG CO

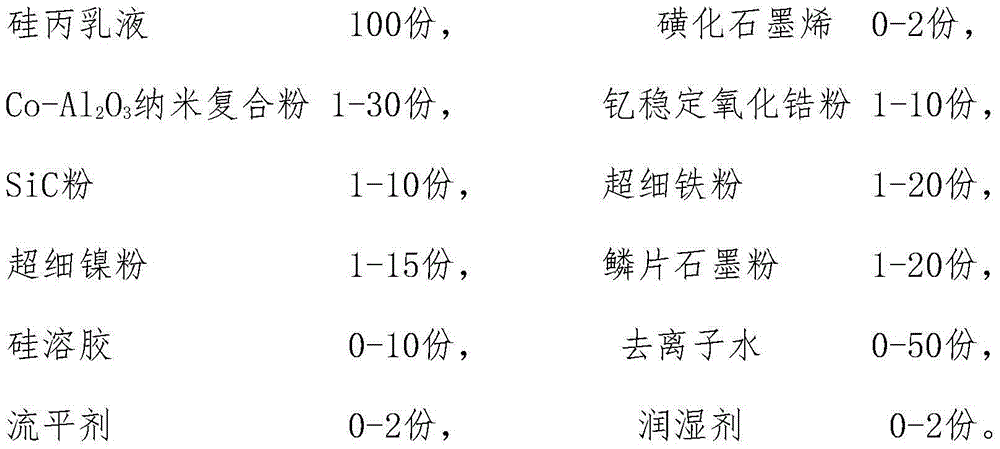

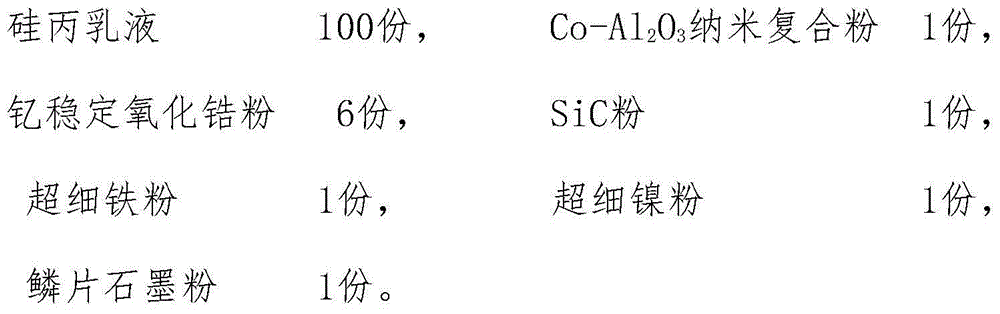

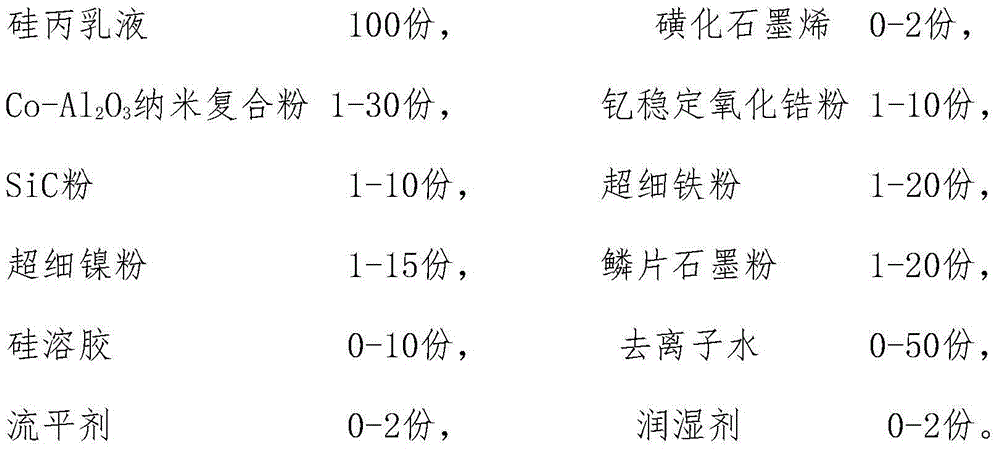

Aqueous solar energy heat-absorbing coating

ActiveCN104387880AImprove absorption rateImprove thermal conductivityRadiation-absorbing paintsRoom temperatureYttria-stabilized zirconia

The invention discloses an aqueous solar energy heat-absorbing coating. The uniformly mixed aqueous solar energy heat-absorbing coating is prepared by carrying out defibrination on an organosilicone-modifed acrylic emulsion (silicone-acrylic emulsion), sulfonated graphene, Co-Al2O3 nano-composite powder, yttria-stabilized zirconia powder, SiC powder, superfine iron powder, superfine nickel powder, flake graphite powder, silica sol, deionized water, a flatting agent and a wetting agent in a sand grinding machine at the room temperature in a certain proportion. The aqueous solar energy heat-absorbing coating has the properties that the absorptivity is 0.90-0.94, the emissivity is 0.18-0.20, the coating adhesive force is 4B-5B level, the pencil hardness is H, and the stability and the environmental protection property are high; the aqueous solar energy heat-absorbing coating is simple in preparation process, low in cost, suitable for industrial production and especially applicable to solar energy heat-absorbing coatings of a solar heat absorber.

Owner:ZHONGSHAN TAILAI PAINT CHEM

Method for repairing coated components

According to an embodiment of the invention, a method for repairing a coated high pressure turbine blade, which has been exposed to engine operation, to restore coated airfoil contour dimensions of the blade, is disclosed. The method comprises providing an engine run high pressure turbine blade including a base metal substrate made of a nickel-based alloy and having thereon a thermal barrier coating system. The thermal barrier coating system comprises a diffusion bond coat on the base metal substrate and a top ceramic thermal barrier coating comprising a yttria stabilized zirconia material. The top ceramic thermal barrier coating has a nominal thickness t. The method further comprises removing the thermal barrier coating system, wherein a portion of the base metal substrate also is removed, and determining the thickness of the base metal substrate removed. The portion of the base metal substrate removed has a thickness, Δt. The method also comprises reapplying the diffusion bond coat to the substrate, wherein the bond coat is reapplied to a thickness, which is about the same as applied prior to the engine operation; and reapplying the top ceramic thermal barrier coating to a nominal thickness of t+Δt, wherein Δt compensates for the portion of removed base metal substrate. Advantageously, the coated airfoil contour dimensions of the high pressure turbine blade are restored to about the coated dimensions preceding the engine run.

Owner:GENERAL ELECTRIC CO

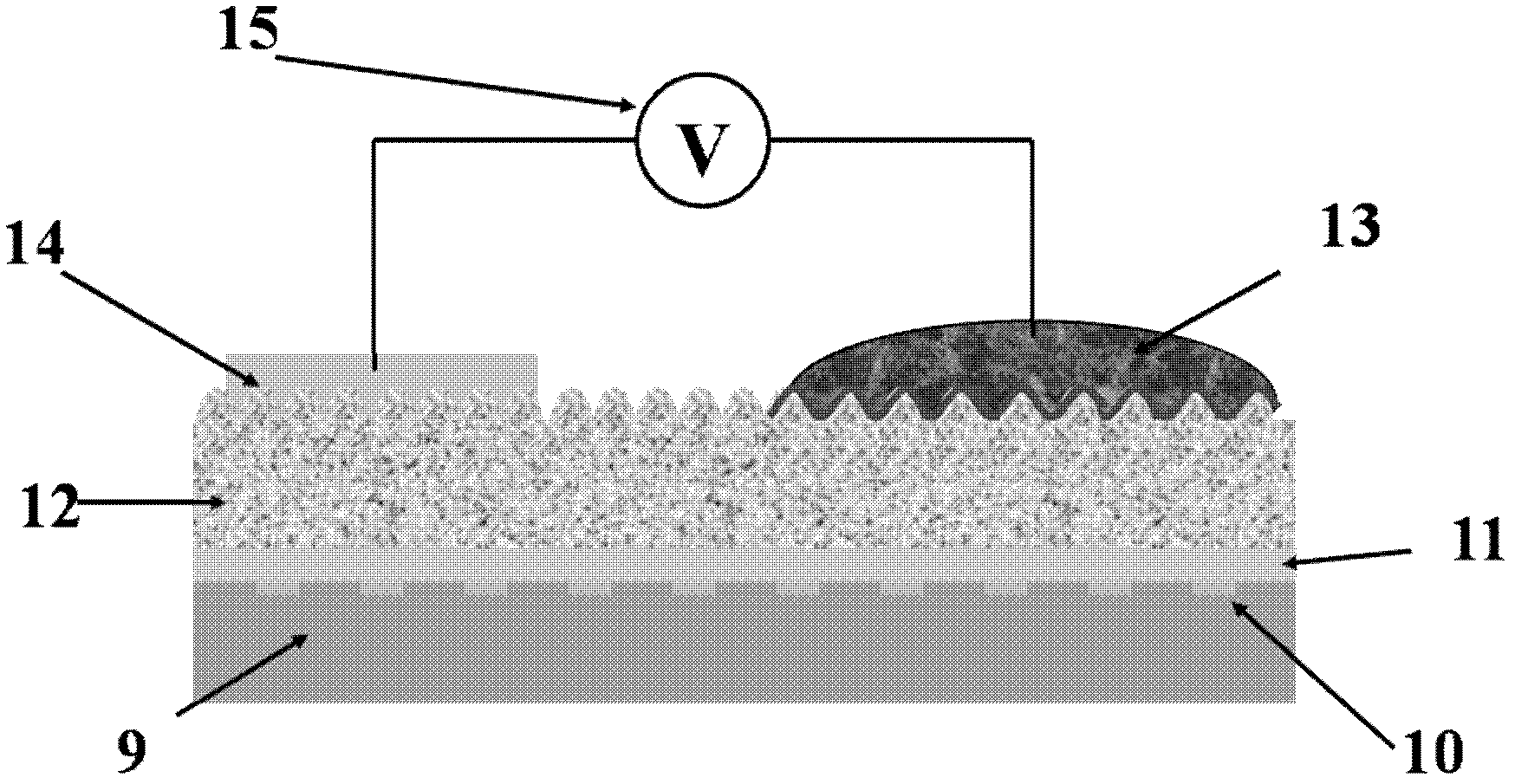

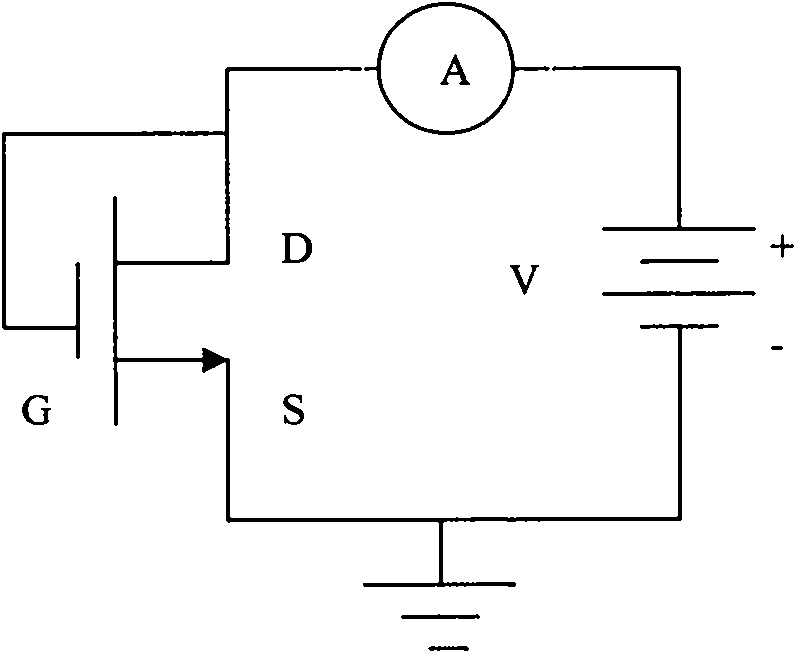

SiC-based MOSFET (metal-oxide -semiconductor field effect transistor) oxysensible sensor for automobile engine

InactiveCN102169104AReduce weightReduce volumeInternal combustion piston enginesMaterial analysis by electric/magnetic meansCapacitanceMOSFET

The invention discloses a SiC-based MOSFET (metal-oxide -semiconductor field effect transistor) oxysensible sensor for an automobile engine and a manufacturing method thereof. Silicon carbide material with the excellent characteristics of wide energy gap, high breakdown electric field, high electron saturated drifting velocity, high heat conductivity and the like is used as a P-type substrate of an N-type channel MOSFET, thereby meeting the requirement of high-temperature working. In the MOSFET structure, a layer of oxysensible film material (such as YSZ: yttria stabilized zirconia) grows on an original gate oxide layer, wherein metal Pt is adopted as a metal gate electrode, and the channel of a MOSFET type oxysensible sensor can be a surface channel and an embedded channel. In the sensor, the change of oxygen concentration can be converted into the change of capacitance of the gate oxide layer in unit area, thereby causing the change of a threshold voltage. Besides, the invention also discloses a method for manufacturing the MOSFET type oxysensible sensor.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

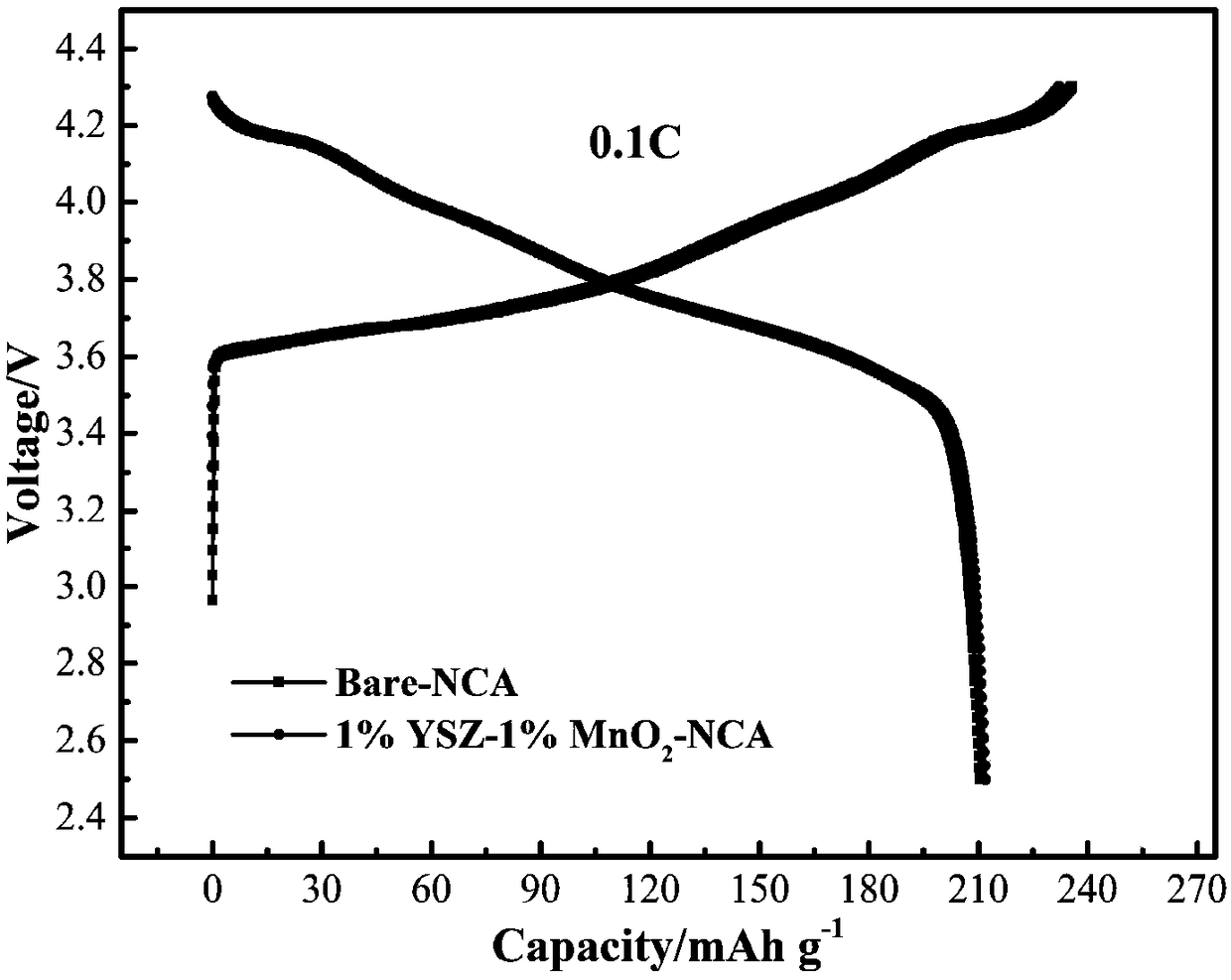

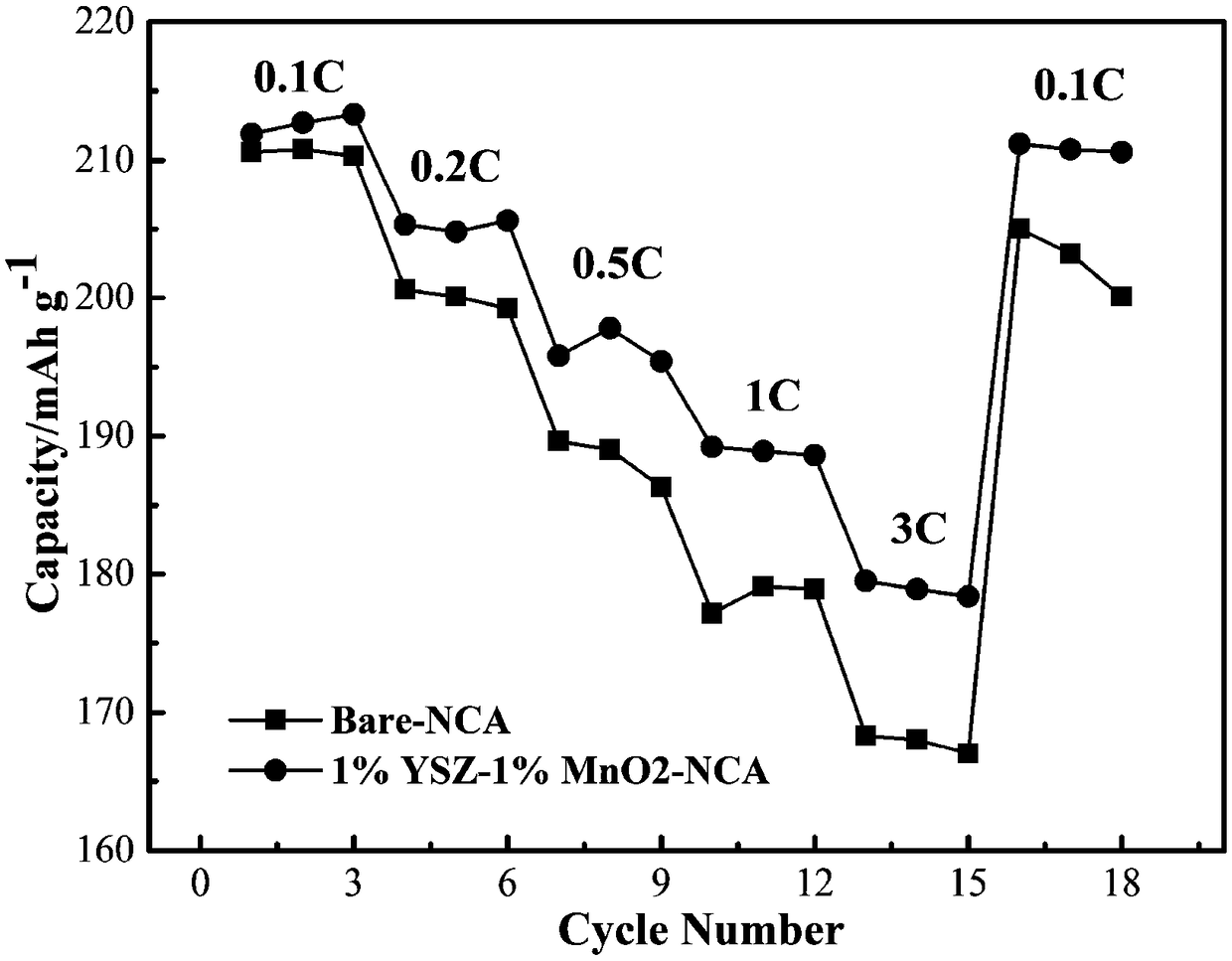

Surface-modified high-nickel ternary positive material, preparation thereof, and battery prepared from surface-modified high-nickel ternary positive material

InactiveCN108777296ASuppression of irreversible capacity lossLess side effectsCell electrodesSecondary cellsCapacity lossPhosphate

The invention provides a surface-modified high-nickel ternary positive material. A surface modification layer is covered on an inner core of a high-nickel ternary positive material; the inner core ofthe high-nickel ternary positive material is Li1 plus kNixCoyMzO2, wherein k is larger than or equal to -0.1 and smaller than or equal to 0.1, x is larger than 0 and smaller than 1, y is larger than 0and smaller than 1, and z is larger than 0 and smaller than 1. The surface modification layer is formed by two surface modification matters, wherein one is yttria-stabilized zirconia, and the other one is selected from one or more of metal oxide MeOx, metal fluoride MeFx, metal phosphate Me(PO4)x or C. The invention also provides a preparation method of the surface-modified high-nickel ternary positive material, and a battery prepared from the surface-modified high-nickel ternary positive material. According to the surface-modified high-nickel ternary positive material provided by the invention, the surface modification matters are covered on the surface of the body material, so that the side reaction of the high-nickel ternary positive material and an electrolyte is reduced, the irreversible capacity loss of the material is inhibited, and the cycle performance is improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com