Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

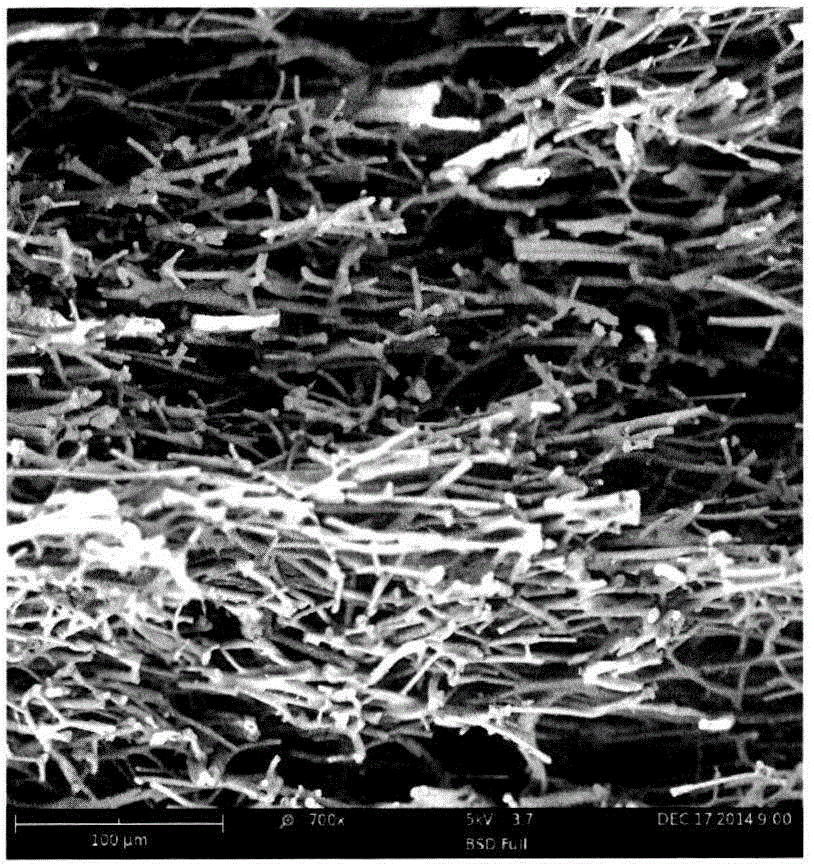

A technology of high-temperature-resistant ceramics and ceramic fibers, which is applied in the field of lightweight high-temperature-resistant ceramic fiber rigid heat insulation tiles and their manufacturing fields, can solve the problems of high thermal conductivity, poor mechanical properties, and poor temperature resistance of rigid heat insulation tiles, and achieves improved performance. The effect of mechanical properties, small dispersion and uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

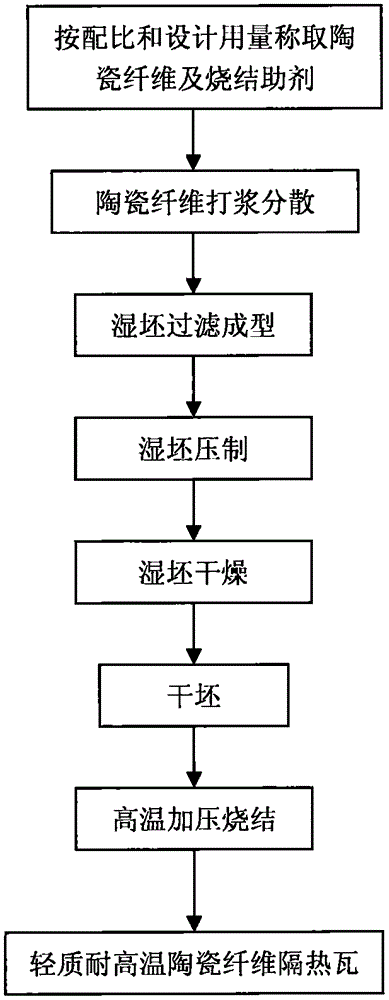

[0082] (1) Weigh 15.0 grams of boron nitride powder and 50 grams of soluble starch, add 5000 milliliters of deionized water and 5000 milliliters of absolute ethanol, and stir well to obtain a sintering aid suspension.

[0083] (2) Take by weighing 670 grams of fused silica glass fiber, 220 grams of alumina fiber, 110 grams of yttrium oxide stabilized zirconia fiber, the suspension in (1) and 500 liters of deionized water and mix, use a high-speed shear mixer to mix the fiber in Uniformly disperse in deionized water to obtain a slurry.

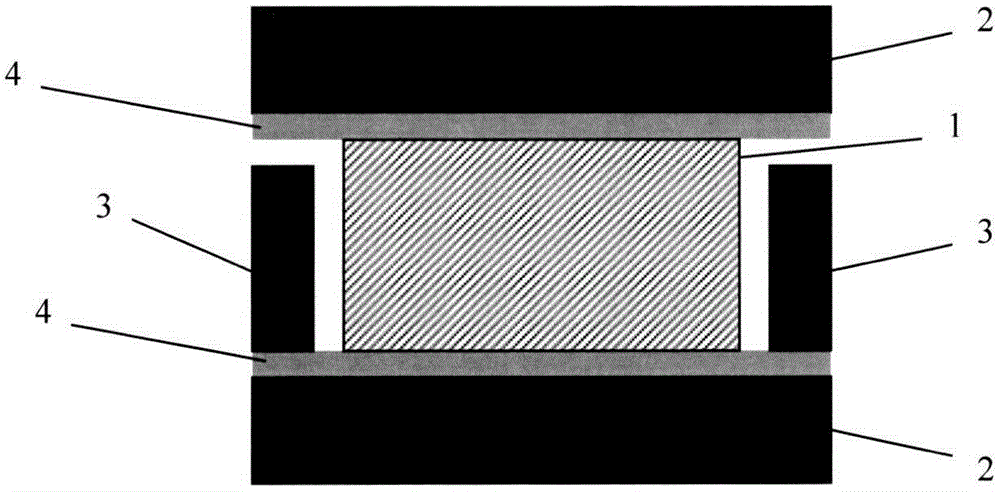

[0084] (3) The above-mentioned slurry is poured into the forming mold, and the target density of the final product obtained by adjusting the height of the mold is 0.14g / cm 3 . Use suction filtration to filter out most of the water until it stops dripping when standing under normal pressure. Then the mold is transferred to a pressure forming machine, and a pressure of 2.5 MPa is applied to obtain a ceramic fiber heat-insulating tile wet body. ...

Embodiment 2

[0088] (1) Weigh 15.0 grams of boron nitride powder, 30 grams of silicon carbide powder, and 50 grams of soluble starch, add 5000 milliliters of deionized water and 5000 milliliters of absolute ethanol, and stir well to obtain a sintering aid suspension.

[0089] (2) Weigh 850 grams of quartz fiber, 150 grams of mullite (3Al 2 o 3 2SiO2 2 ) fibers are mixed with the suspension in (1) and 500 liters of deionized water, and the fibers are uniformly dispersed in the deionized water using a high-speed shear mixer to obtain a slurry.

[0090] Subsequent molding and sintering procedures are exactly the same as in Example 1.

Embodiment 3

[0092] (1) Weigh 15.0 grams of boron nitride powder, 30 grams of silicon carbide powder, and 50 grams of soluble starch, add 5000 milliliters of deionized water and 5000 milliliters of absolute ethanol, and stir well to obtain a sintering aid suspension.

[0093] (2) Weigh 780 grams of quartz fibers, 220 grams of alumina fibers, mix the suspension in (1) and 500 liters of deionized water, and use a high-speed shear mixer to uniformly disperse the fibers in the deionized water to obtain a slurry.

[0094] Subsequent molding and sintering procedures are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com