Patents

Literature

35results about How to "Precise Density Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

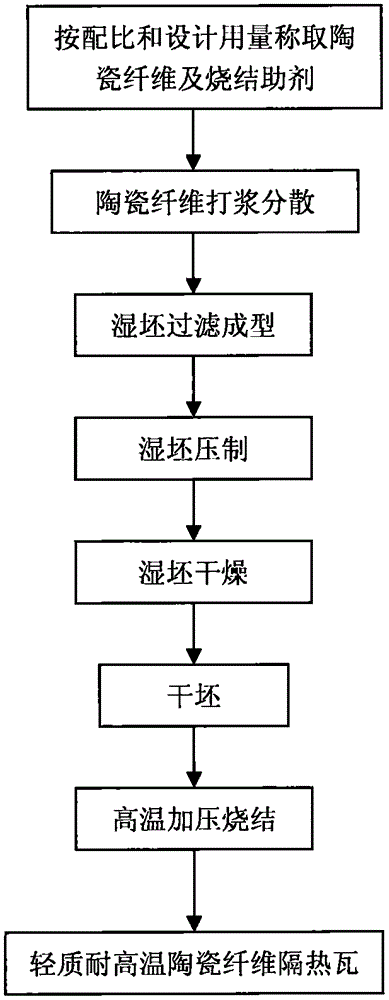

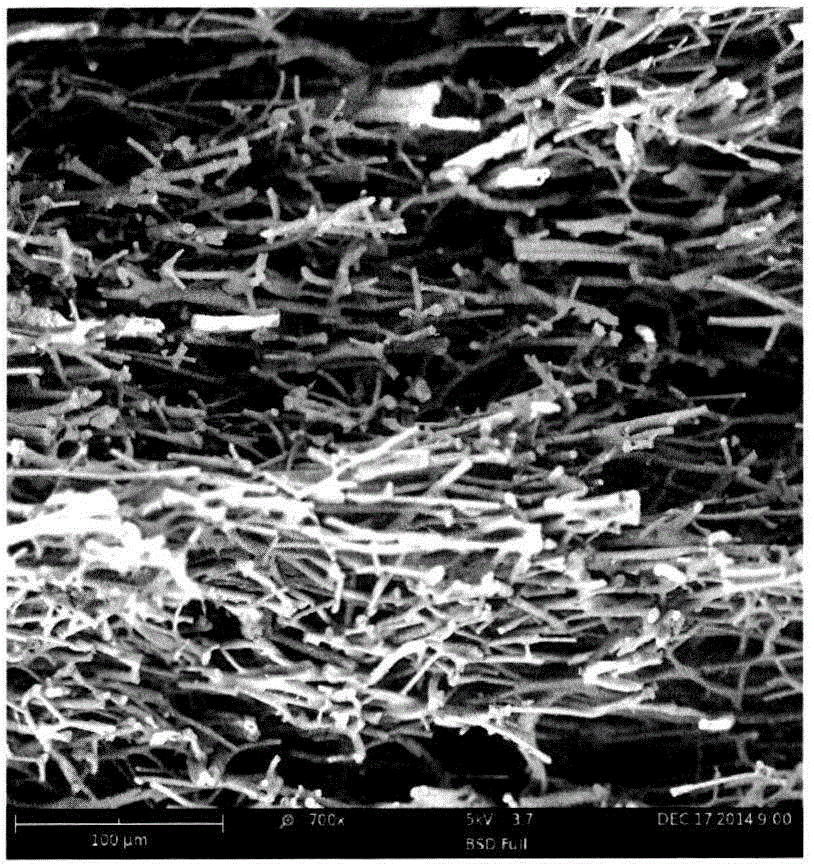

Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

ActiveCN105272322AOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

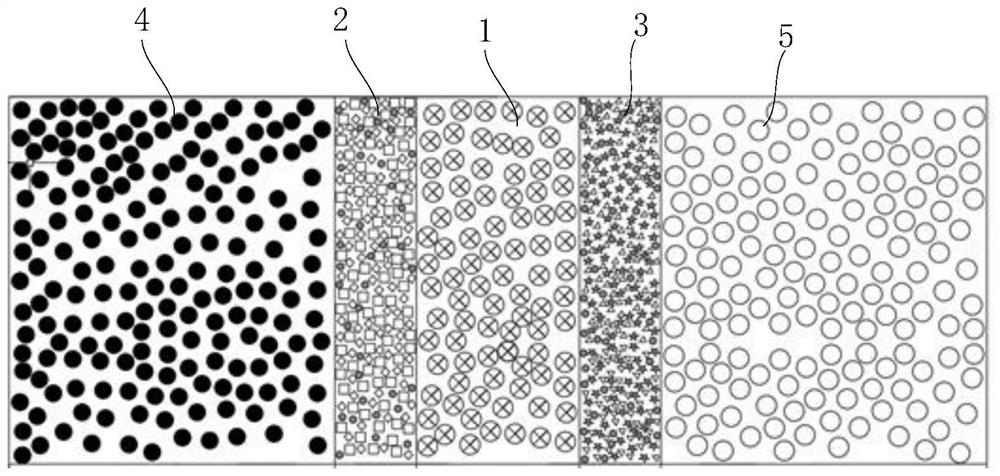

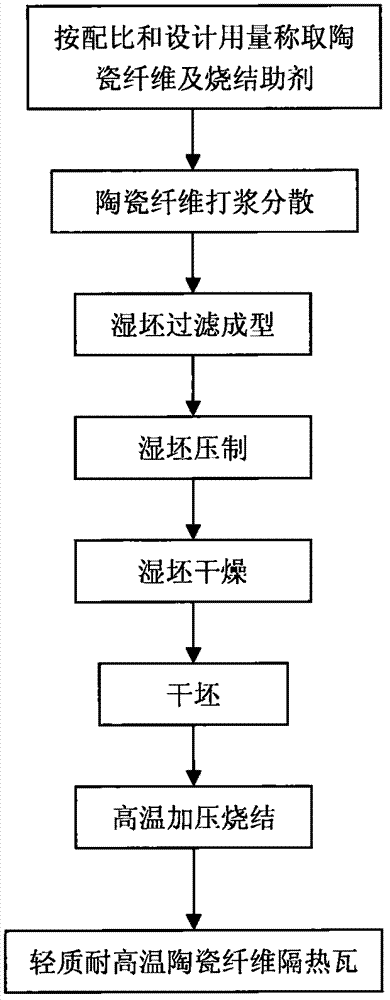

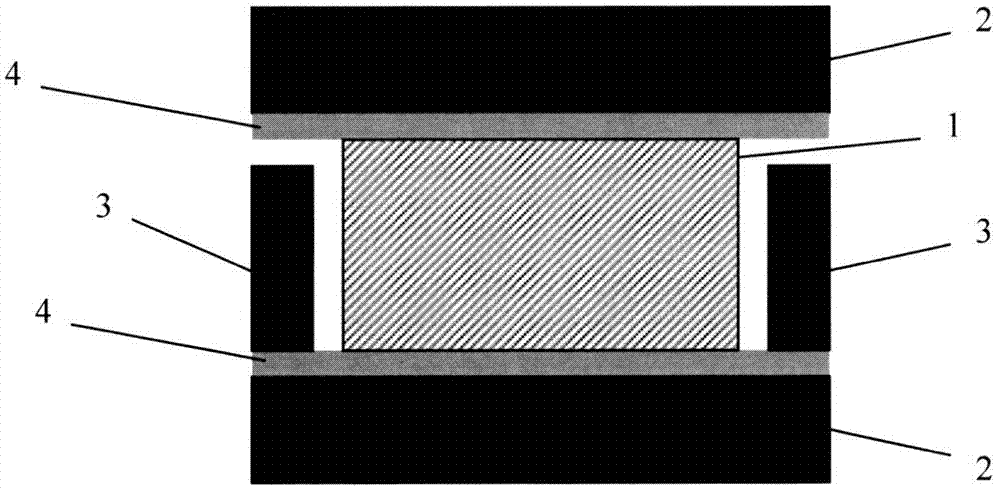

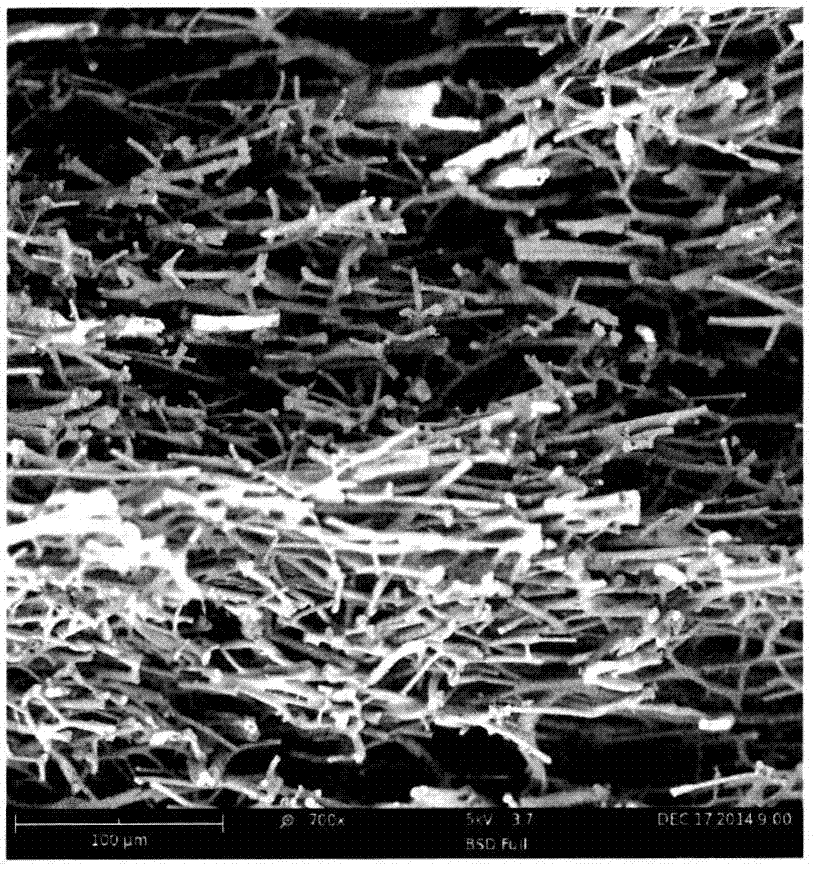

The invention relates to a light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and a making method thereof. The heat insulation tile comprises ceramic fibers and boron oxide, wherein the ceramic fibers comprise quartz fibers, alumina fibers and yttrium oxide stabilized zirconia fibers. The making method of the light-weight, high temperature-resistance and heat-insulation ceramic fiber tile comprises the following steps: preparing a sintering aid suspension, preparing a ceramic fiber slurry, carrying out wet green body molding, drying the obtained wet green body, and carrying out pressurization sintering. The heat insulation tile has good heat insulation effect and mechanical performances, has light weight and resists high temperature; the density is controllable between 0.10g / cm<3> and 0.90g / cm<3>; the lowest apparent heat conduction coefficient at room temperature reaches 0.033W / (m.K); the compressive strength at room temperature is greater than 3.0Mpa; and the long-time use temperature can reach 1350DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

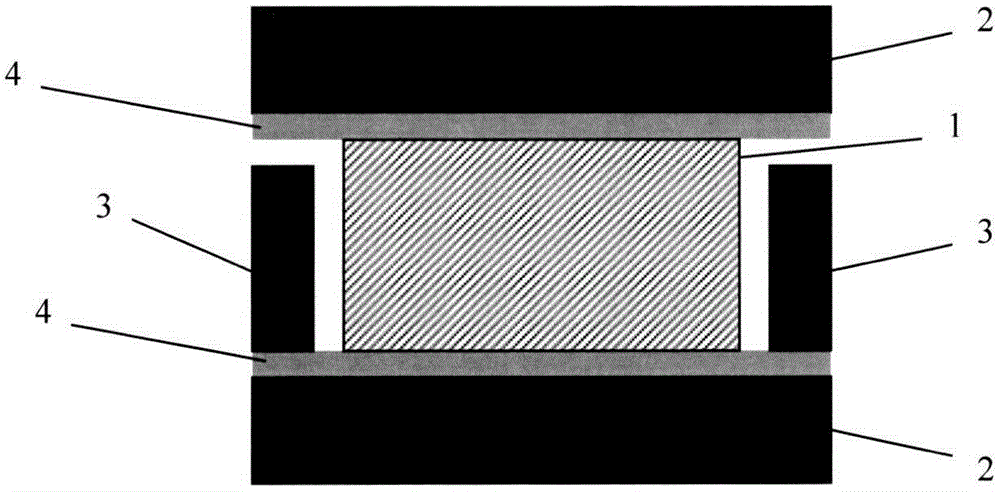

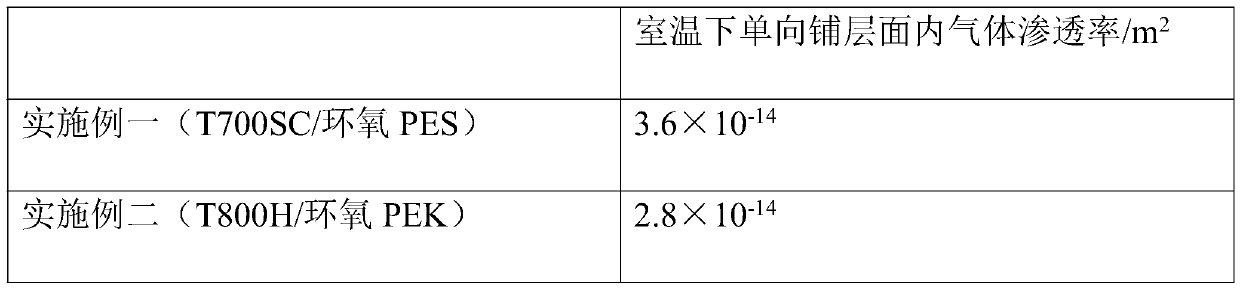

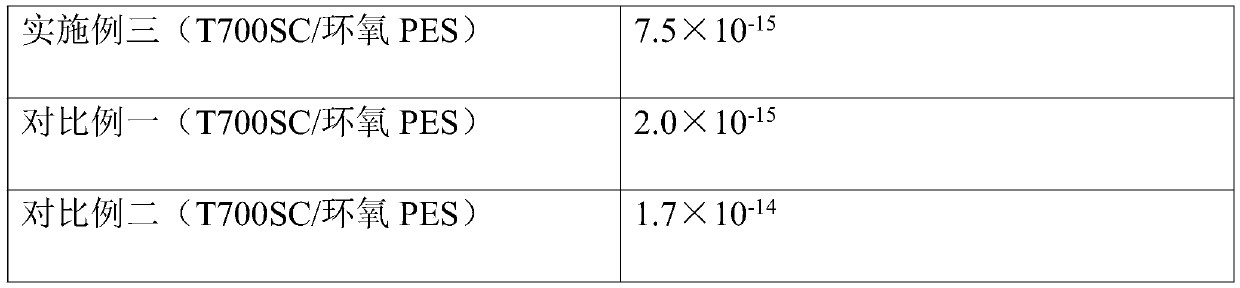

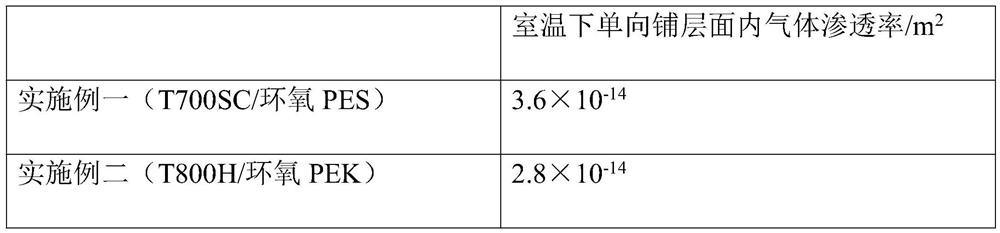

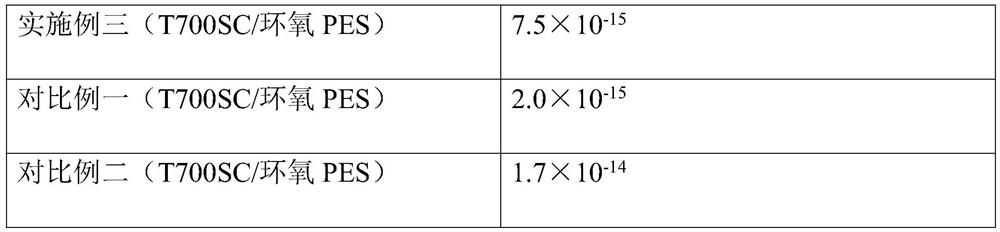

Preparation method of carbon fiber/toughened epoxy resin prepreg for vacuum bag forming process

The invention discloses a preparation method of a carbon fiber / toughened epoxy resin prepreg for a non-autoclave vacuum bag forming process. According to the method, the dissolution degree and the particle size of a curing agent and a toughening agent in epoxy resin are controlled by controlling a resin formula, the particle sizes of the curing agent and the toughening agent and process conditionsfor resin system configuration, and meanwhile, two modification effects are achieved: 1, the resin system is toughened; and 2, the requirements of a non-autoclave process on the viscosity of the resin in the prepreg and a room-temperature storage period are met. The prepared epoxy resin system is prepared into a rubber film, the carbon fiber / epoxy resin prepreg is further prepared by adopting a rubber film calendering method, and the semi-impregnated prepreg (unsaturated impregnated prepreg) is obtained by controlling the pressure and temperature during compounding of the rubber film and carbon fibers.

Owner:BEIHANG UNIV

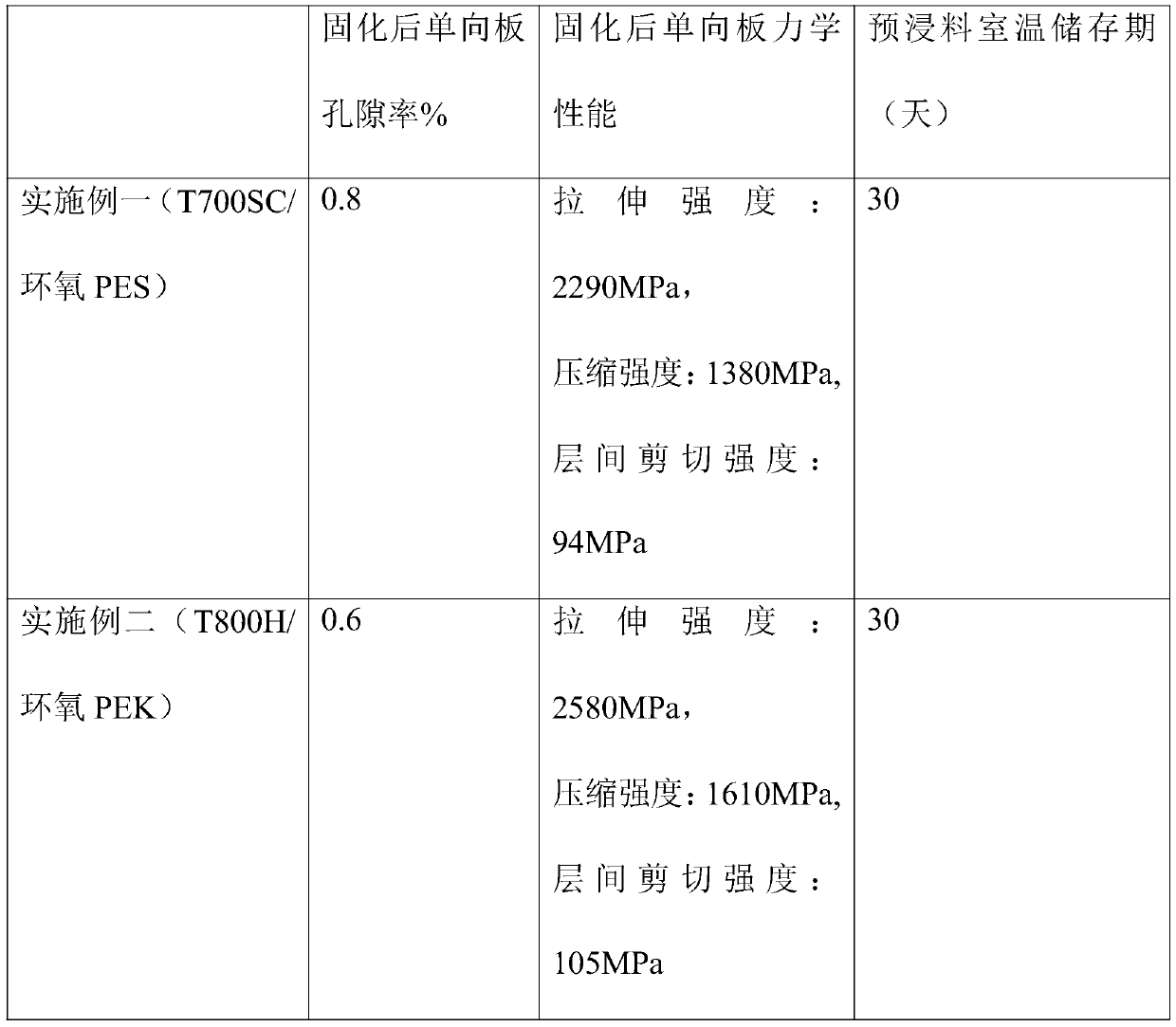

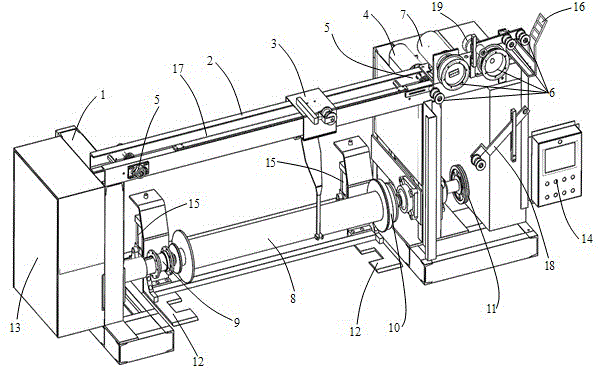

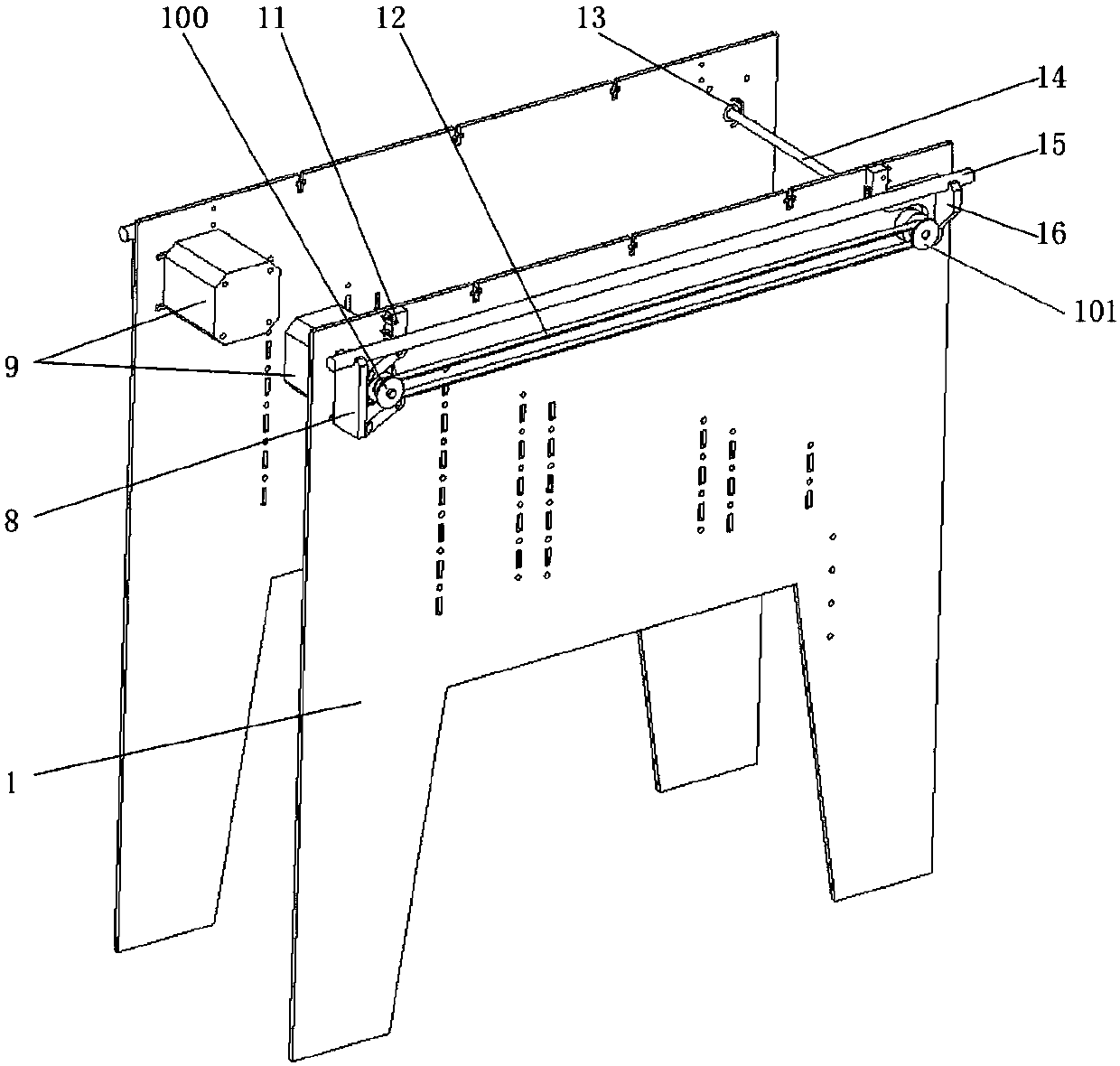

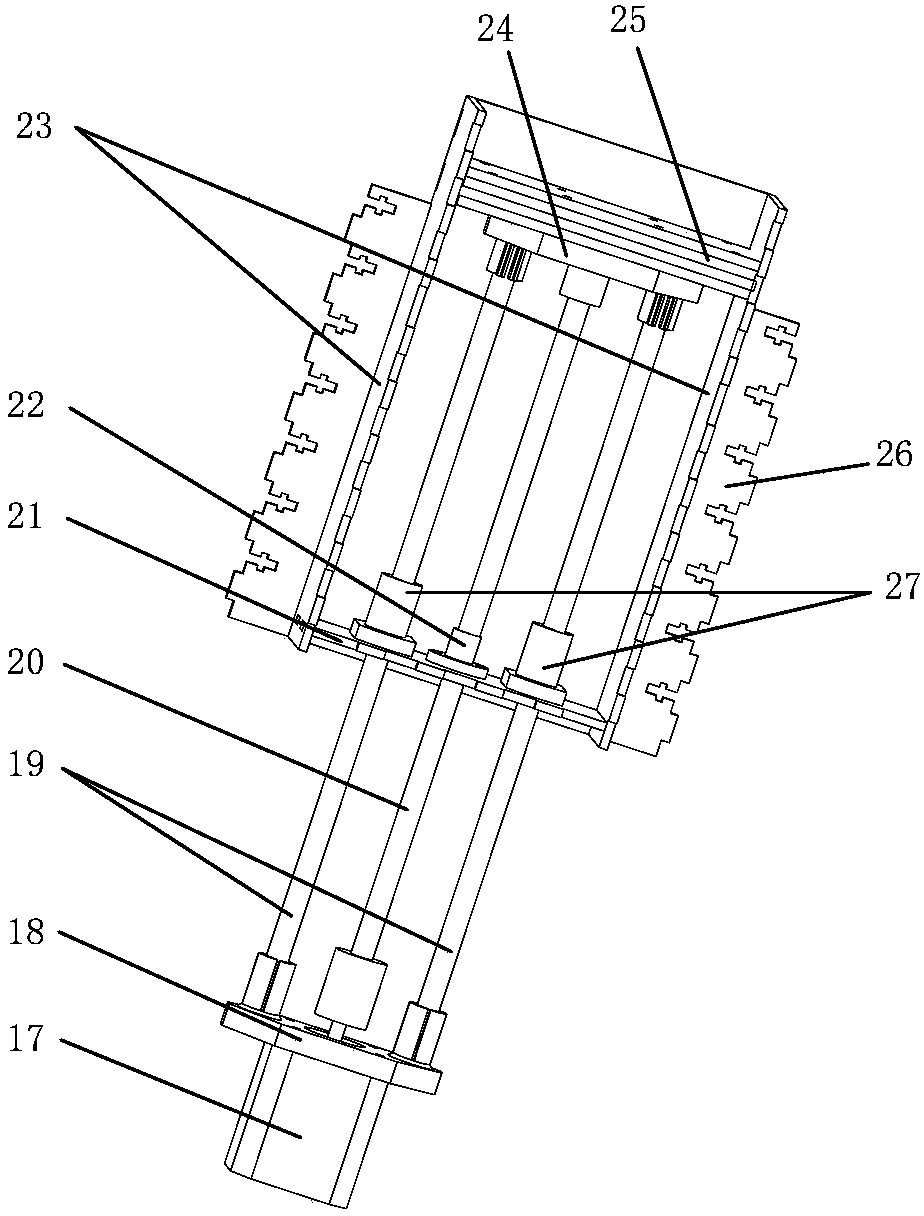

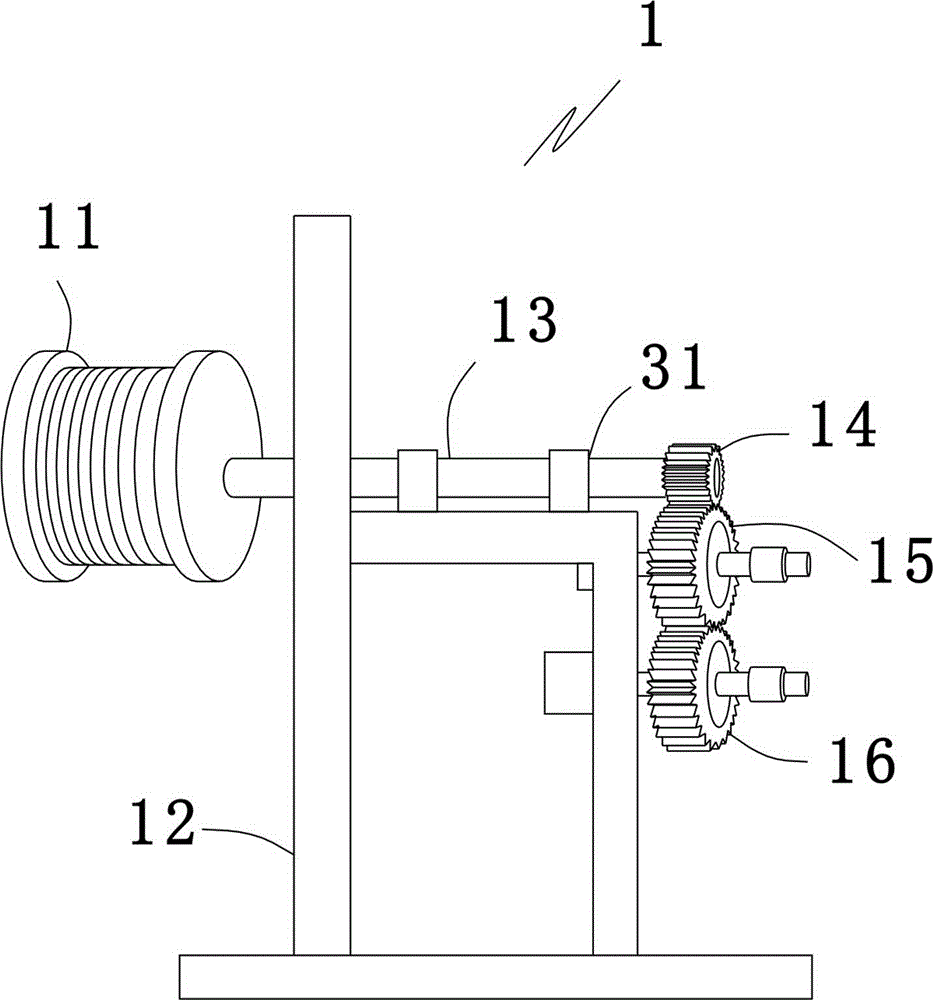

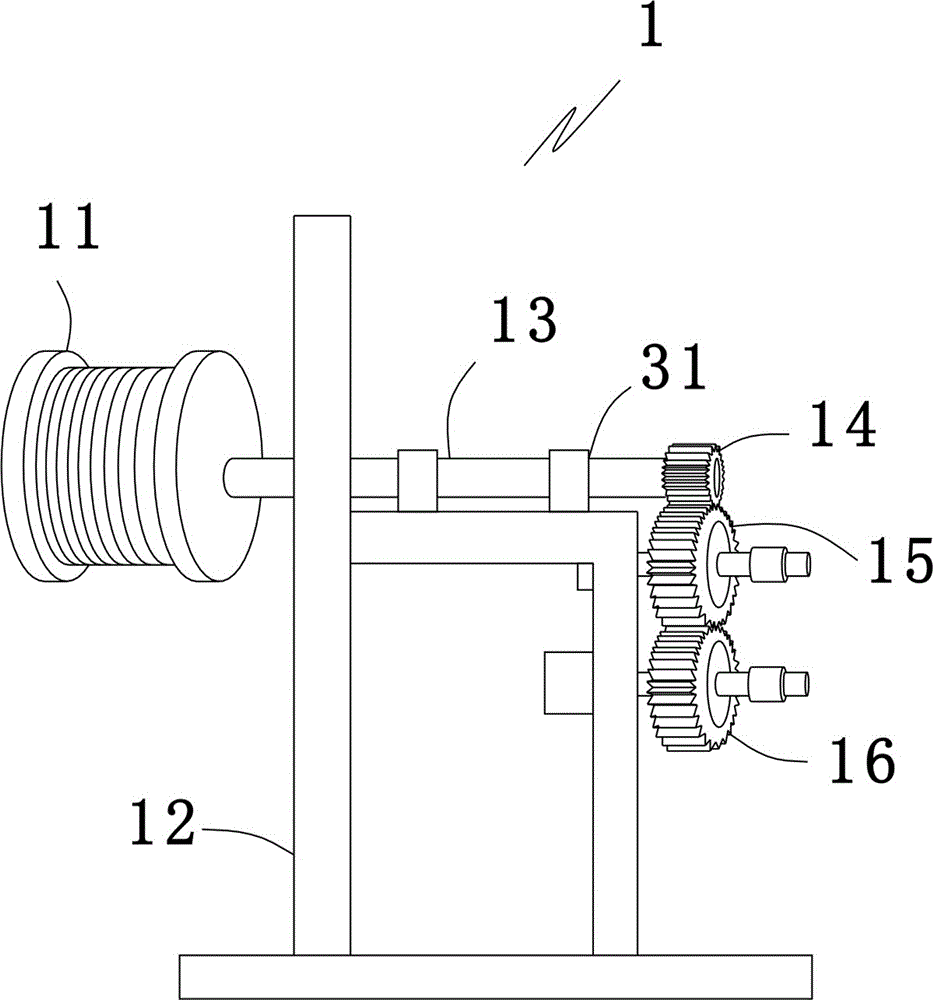

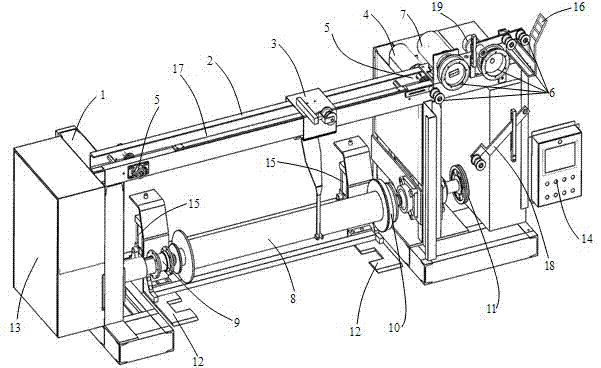

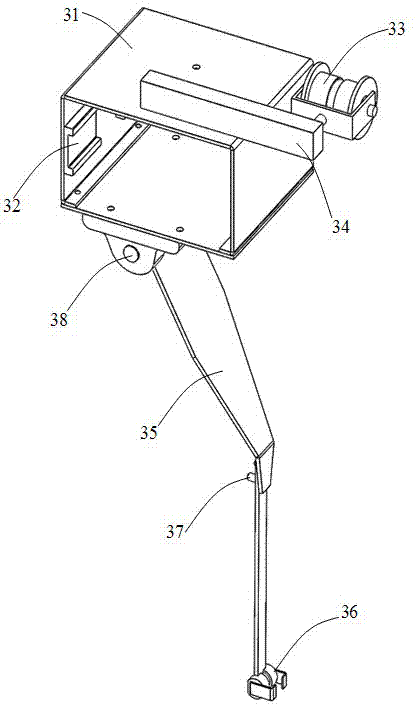

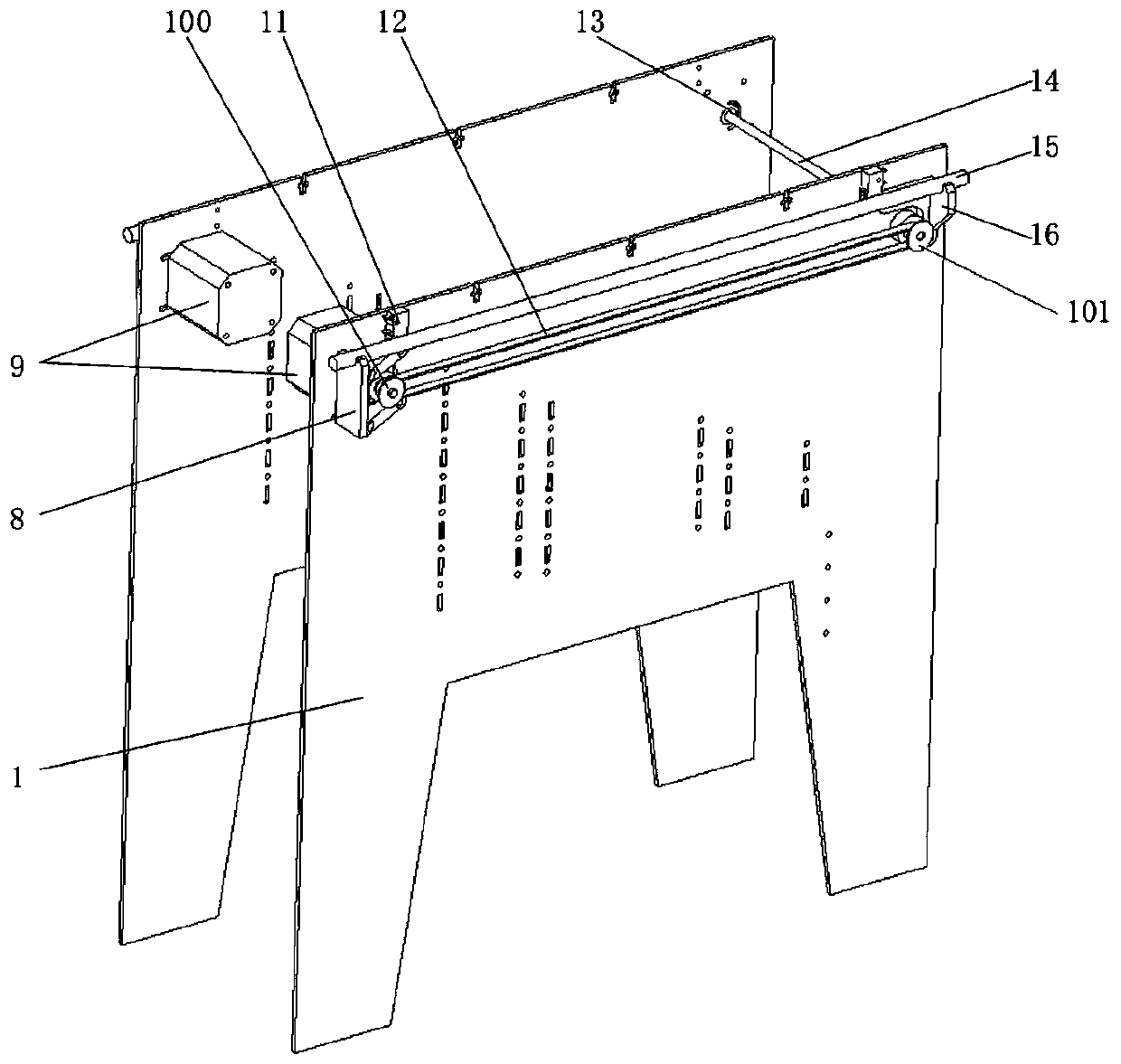

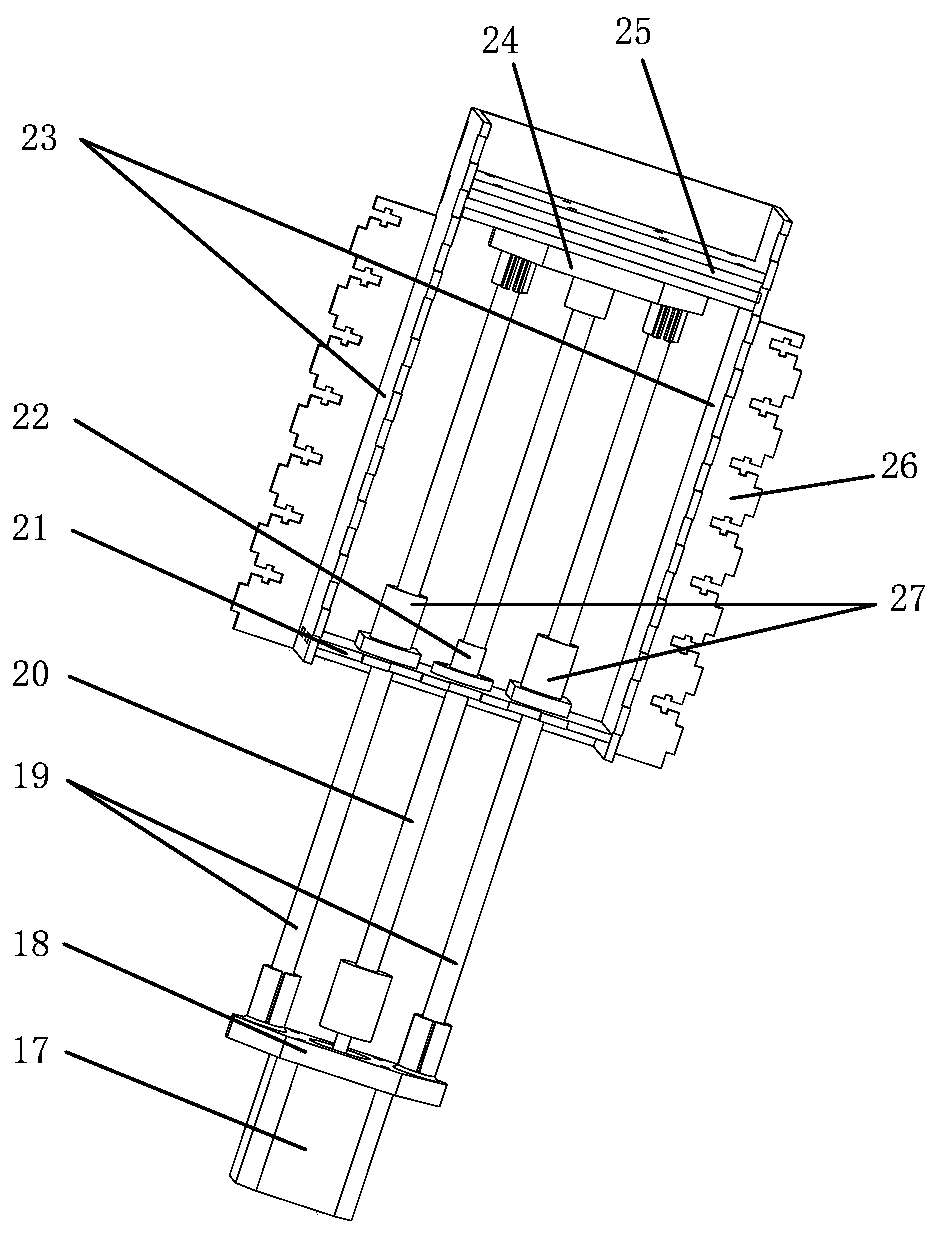

Precise intelligent winding machine and winding control method thereof

InactiveCN103552884ASimple control methodPrecise Density ControlFilament handlingWinding machineDyeing

The invention discloses a precise intelligent winding machine and a winding control method thereof. The precise intelligent winding machine mainly comprises a support, a guide rail, a pressing arm component, a roller set, a belt feeding servo motor, a winding shaft and pneumatic equipment thereof, a central controller, a winding shaft belt pulley and a motor thereof, and the like. Wound fabric is wound on all rollers in the roller set sequentially through a feeding support, passes a guide roller on the pressing arm component, and then is wound on the winding shaft through a guide head. The pressing arm component is mounted on the guide rail and driven through a synchronous belt. The central controller controls rotational motion of a synchronizing wheel driving motor so as to control position and stepping speed of the pressing arm component, and controls rotational speeds of the belt feeding servo motor and the winding shaft so as to adjust and control tensile stress for winding the fabric. Density, the tensile stress and winding shape for fabric winding can be precisely controlled, the control method is simple and feasible, and a powerful guarantee is provided for smooth proceeding of subsequent dyeing.

Owner:萧振林

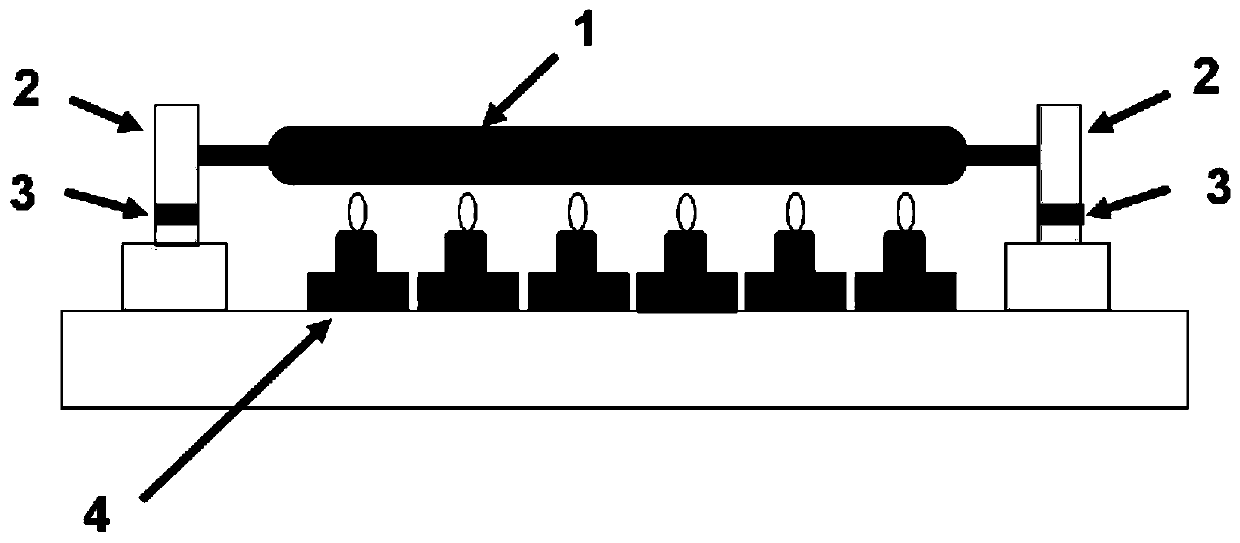

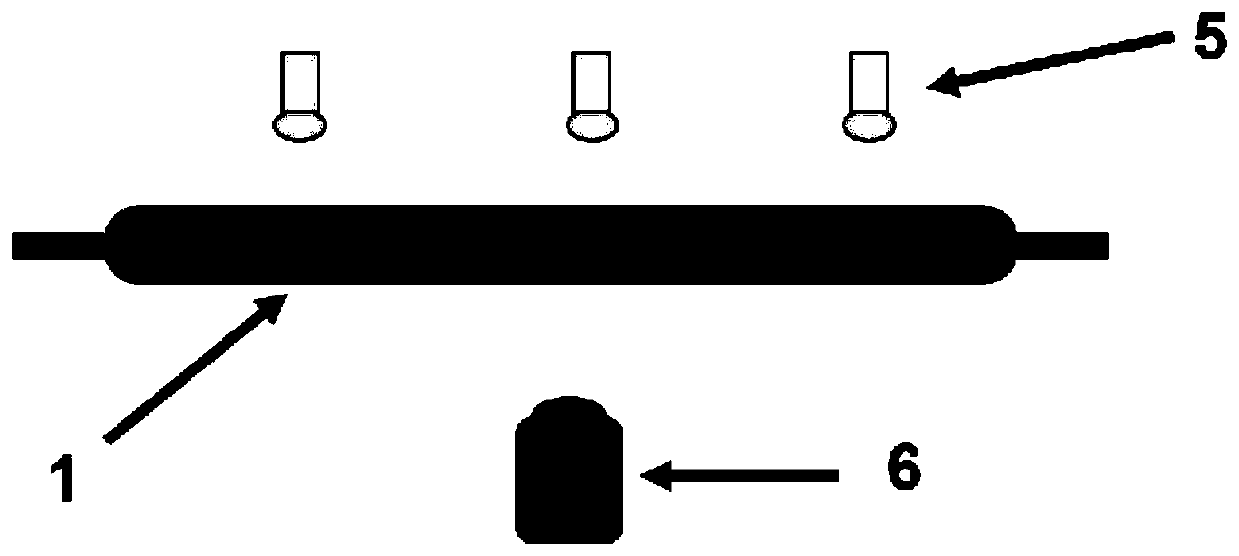

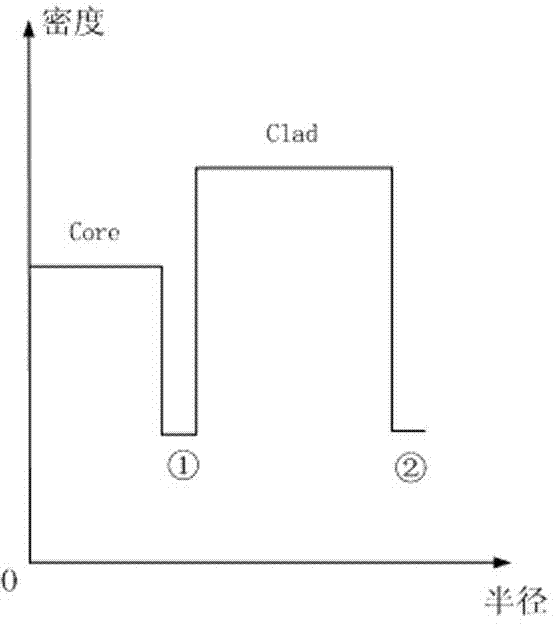

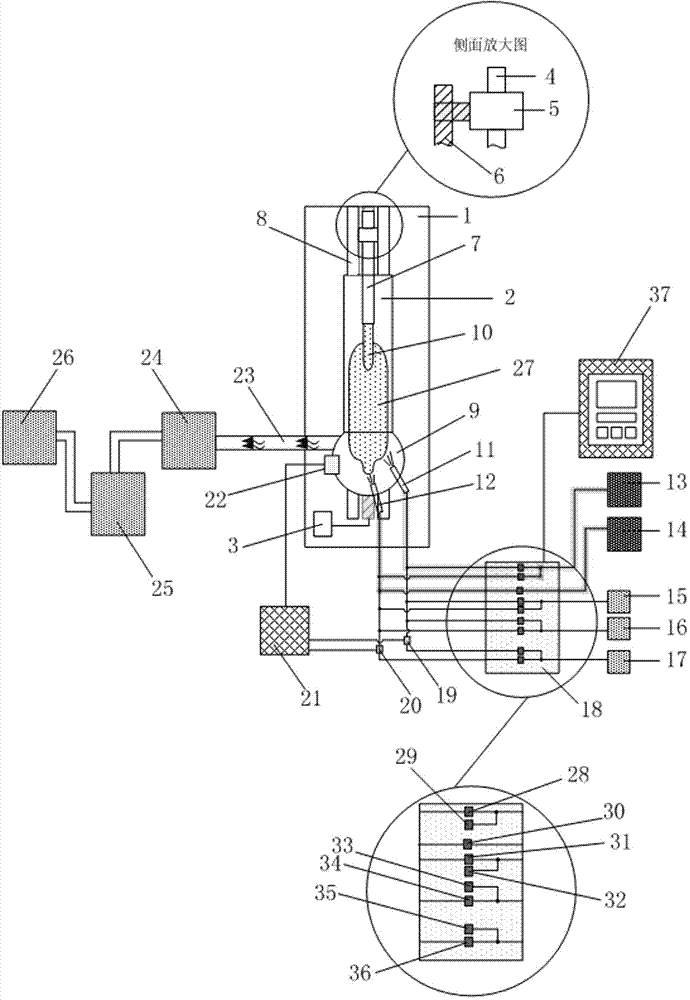

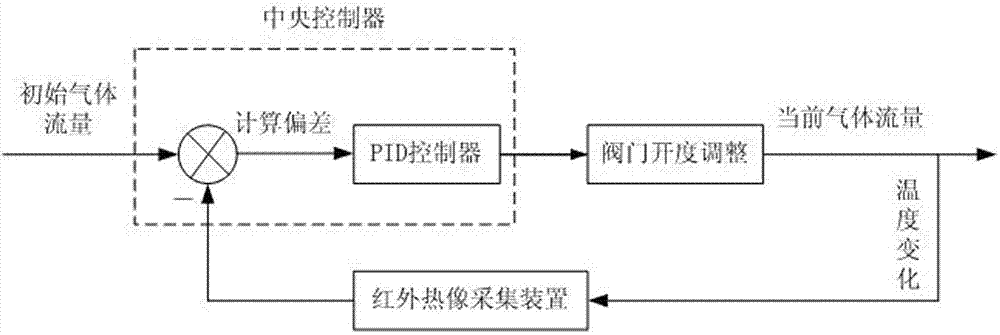

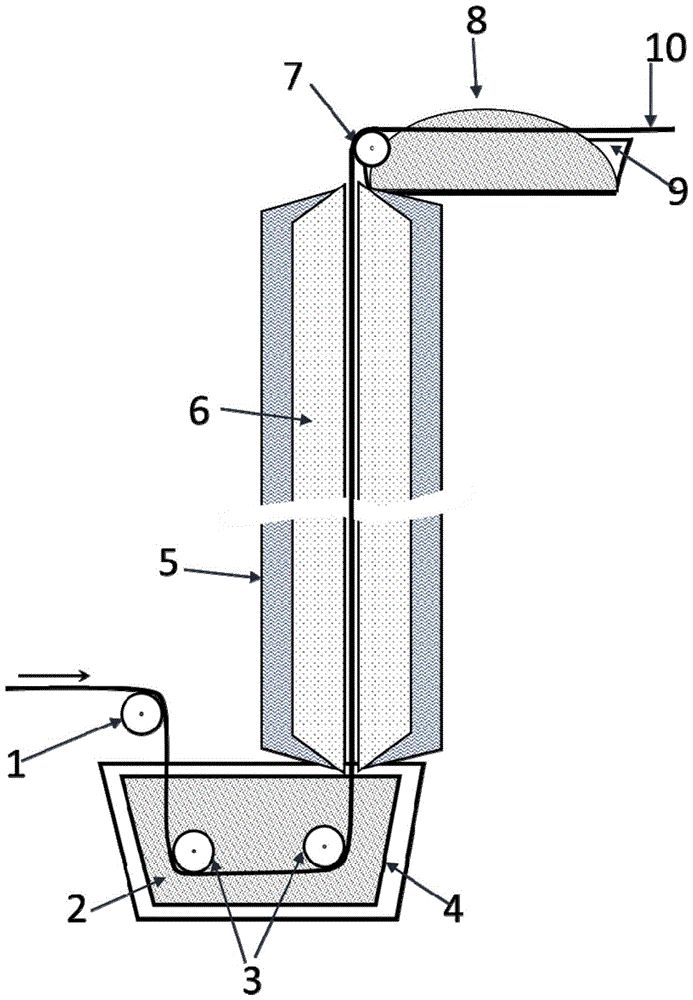

Manufacturing method and manufacturing equipment of optical fiber prefabricated rod

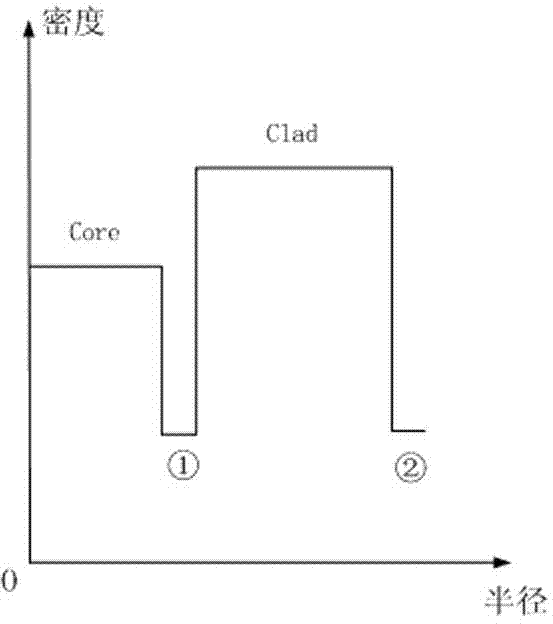

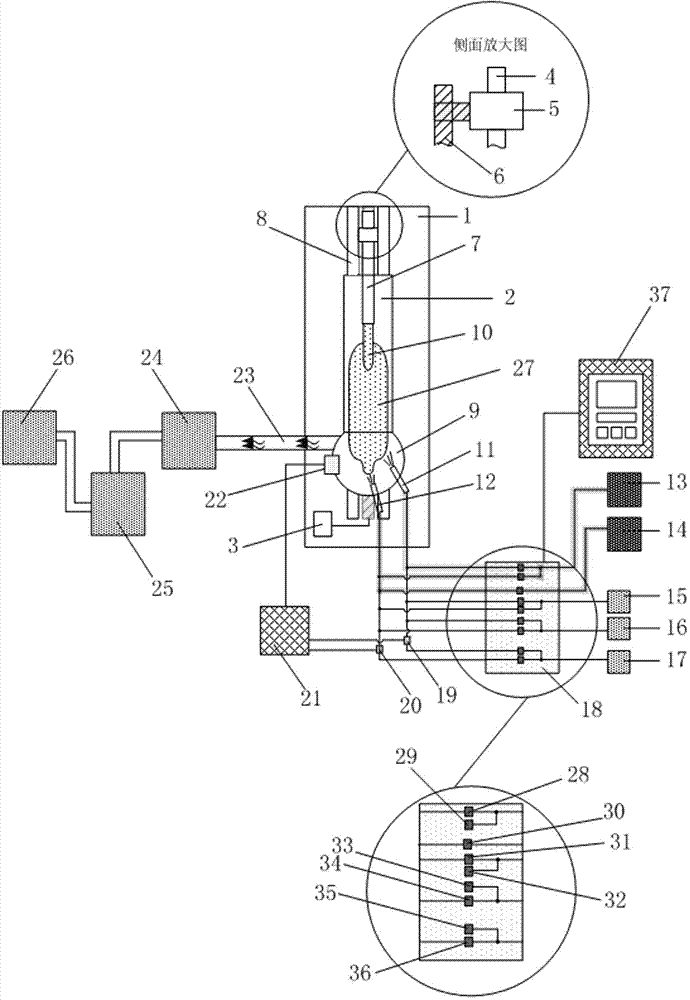

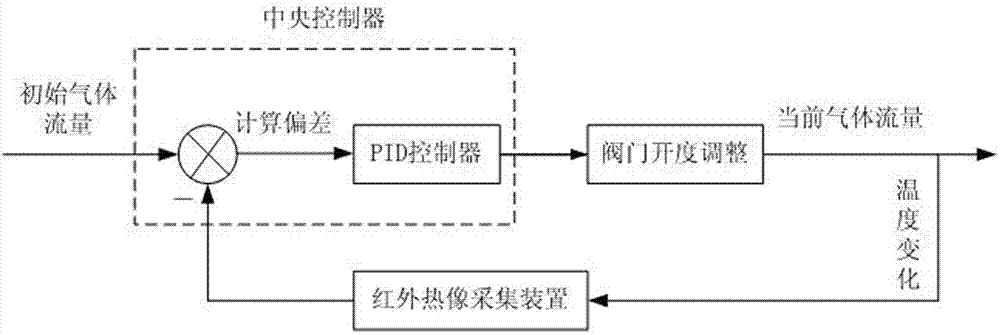

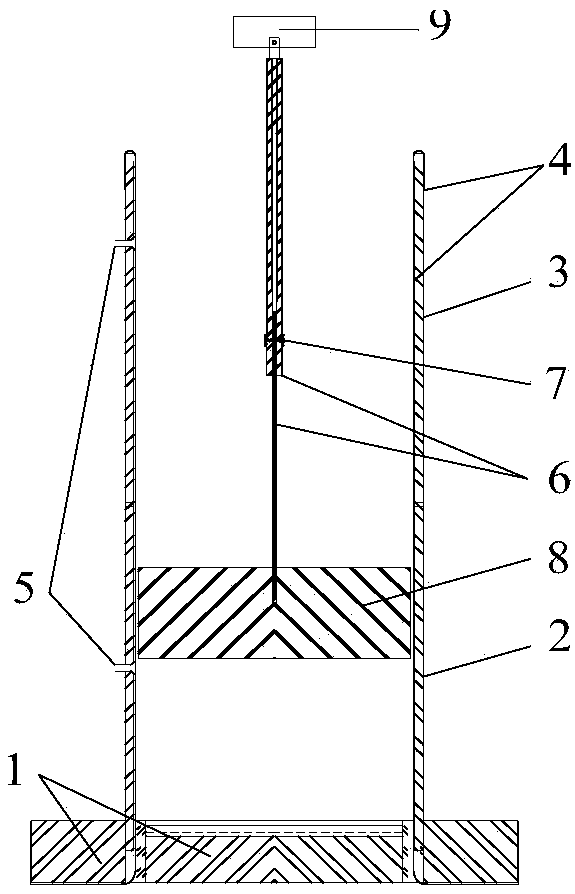

ActiveCN103241938AReasonable designPrevent powder sticks from crackingGlass making apparatusElectric machineryChemistry

The invention relates to a manufacturing method and manufacturing equipment of an optical fiber prefabricated rod, belongs to the field of manufacturing of an optical fiber prefabricated rod, and in particular relates to the method and the equipment which are used for collecting the surface temperature of a powder rod head by utilizing the infrared thermal imaging technology and participate in the controlling of the gas flow. By utilizing the method, the gas flow can be adjusted in real time, so that the density of the powder rod can be controlled accurately; and thus the cracking of the powder rod, caused by the large density gradient, is avoided. Therefore, the product quality is improved. The equipment comprises a tower body, a prefabricated rod depositing cavity body, a motor 1, a motor 2, a clamping disk, a lead screw, a metal hanging rod, a guiding rail, a quartz cavity body, a quartz target rod, a quartz spraying lamp 1, a quartz spraying lamp 2, a SiCl4 raw material tank, a GeCl4 material jar, a liquid Ar storage tank, a liquid O2 storage tank, a H2 storage tank, a gas control cabinet, an electromagnetic valve 1, an electromagnetic valve 2, a CPU (Central Processing Unit), a thermal infrared imager, an exhaust duct, a front treating tower, an electric dust-removing tower and a washing tower.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

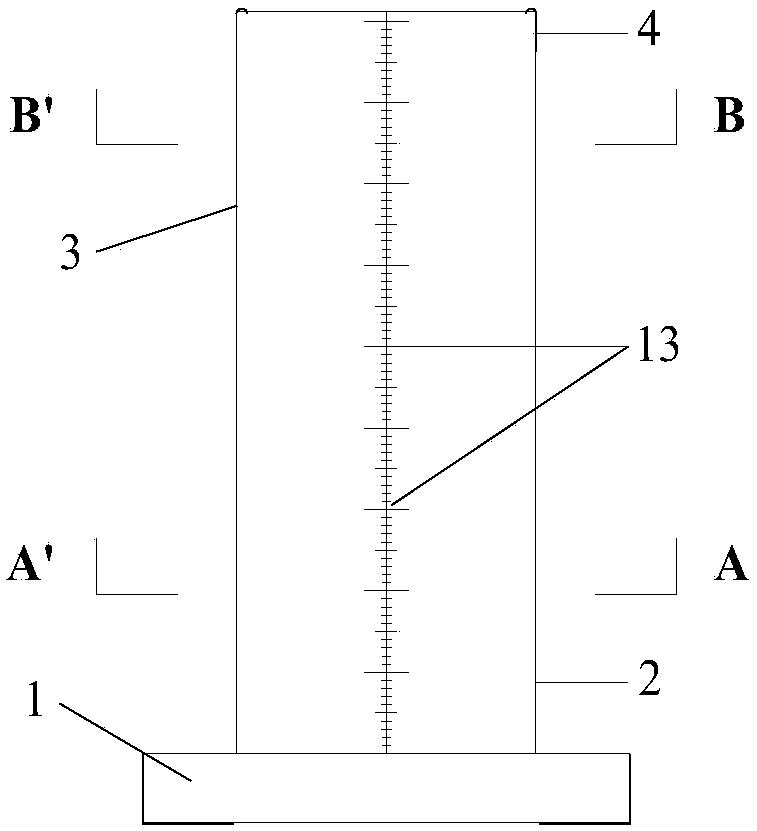

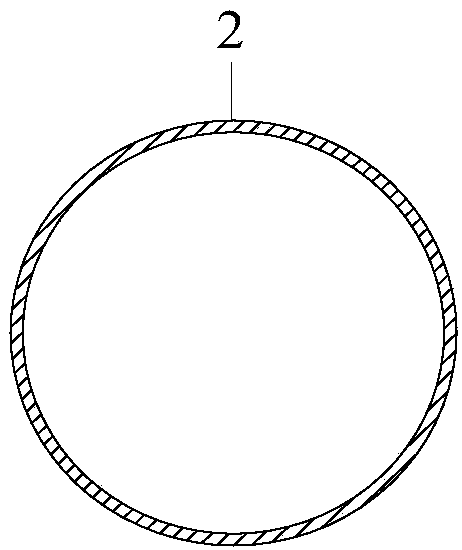

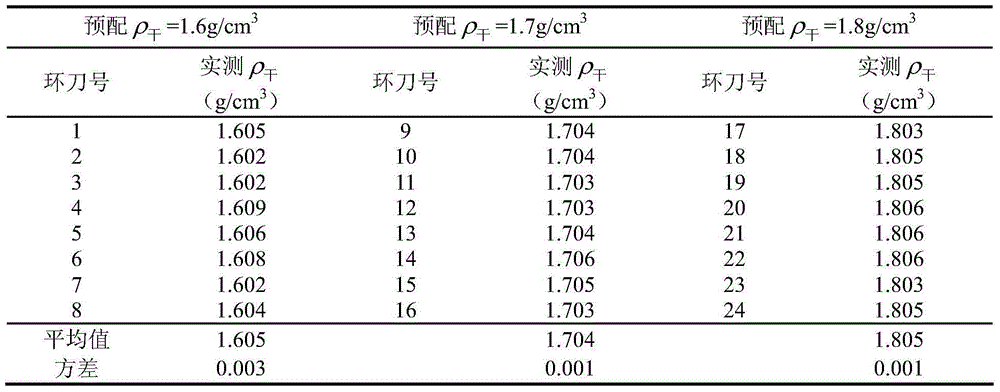

Sample production method for disturbed soil for conventional triaxial test, and method thereof

PendingCN108663242AEliminate the effects of rigid constraintsUniform sample preparationPreparing sample for investigationDiameter ratioGeotechnical engineering

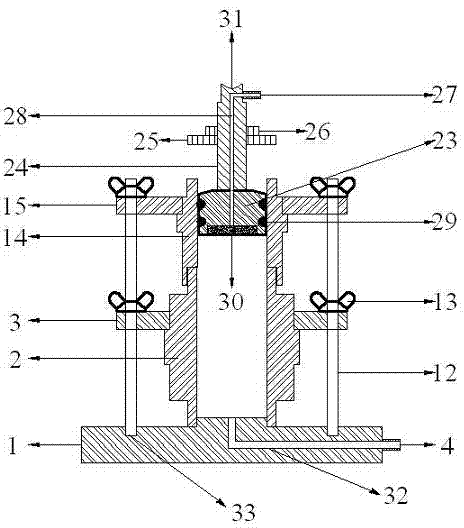

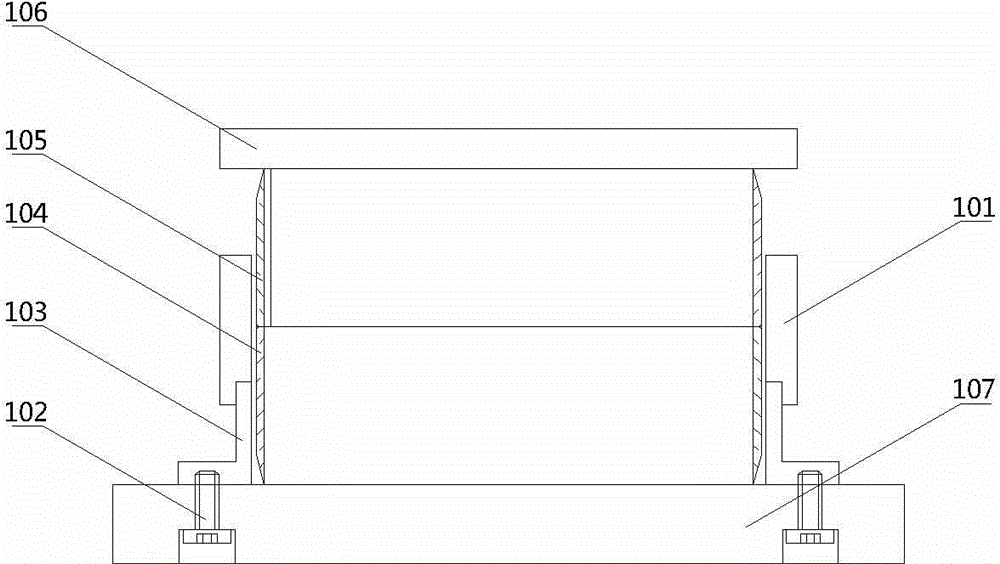

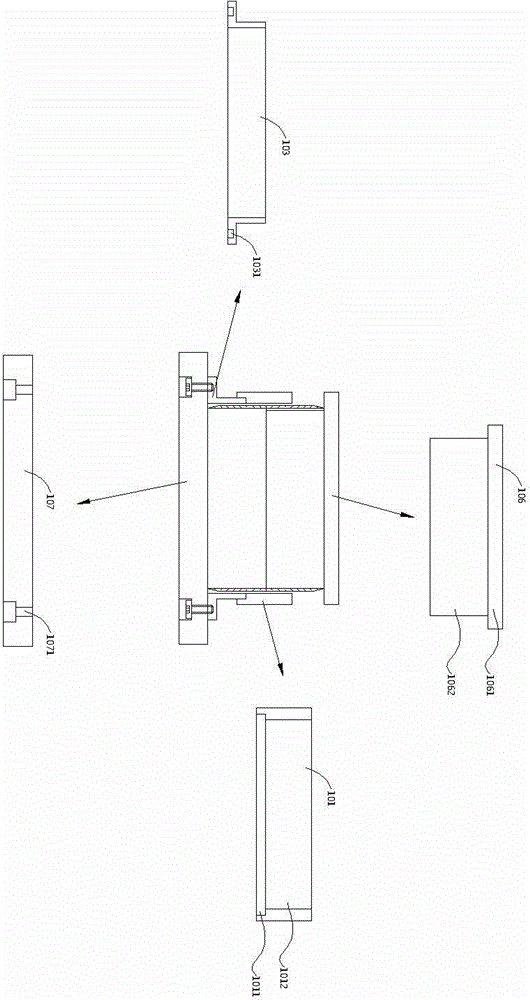

The invention belongs to the technical field of geotechnical engineering indoor test apparatuses, and particularly relates to a ample production method for disturbed soil for conventional triaxial test, and a method thereof. The apparatus comprises a sample production cylinder and a compacting device, the sample production cylinder comprises a base, an upper protection cylinder and a lower protection cylinder, the upper protection cylinder can be telescoped along the lower protection cylinder to adjust the total height of the upper protection cylinder and the lower protection cylinder, the outer wall of each of the upper protection cylinder and the lower protection cylinder is provided with is a uniform scale line, the sample production cylinder is made of transparent tempered glass, a rubber mold goes through the protection cylinders and then cling to to the inner walls of the cylindrical shells of the protection cylinders, two ends of the rubber mold sleeve the outer walls of the protection cylinders and the base, and the wall of every protection cylinder is provided with vent holes to realize vacuumizing of a gap between the inner walls and the rubber mold. The compacting deviceis made of a stainless steel, and includes a force transmitting rod, a compacting hammer and a shaving blade, the lower solid rod of the force transmitting rod can be telescoped in the upper hollow rod of the force transmitting rod, and the total length of the force transmitting rod can be adjusted by a stopper. The apparatus and the method have the advantages of flexibility in adjustment of theheight-diameter ratio of a soil sample during sample production, visualization of the whole process, accuracy in control of soil sample paving and compacting, and simple test operation process, and can be promoted in the technical field of geotechnical test.

Owner:ZHEJIANG UNIV +1

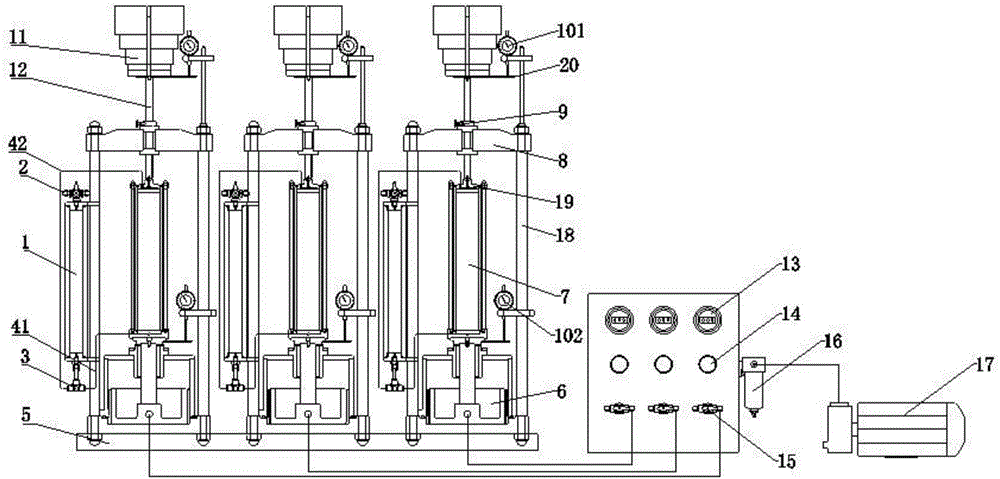

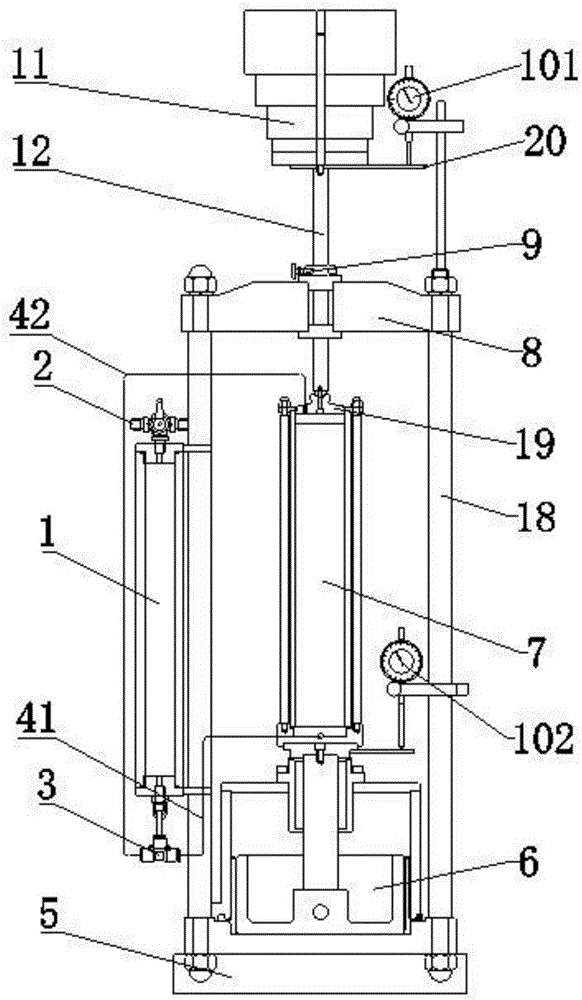

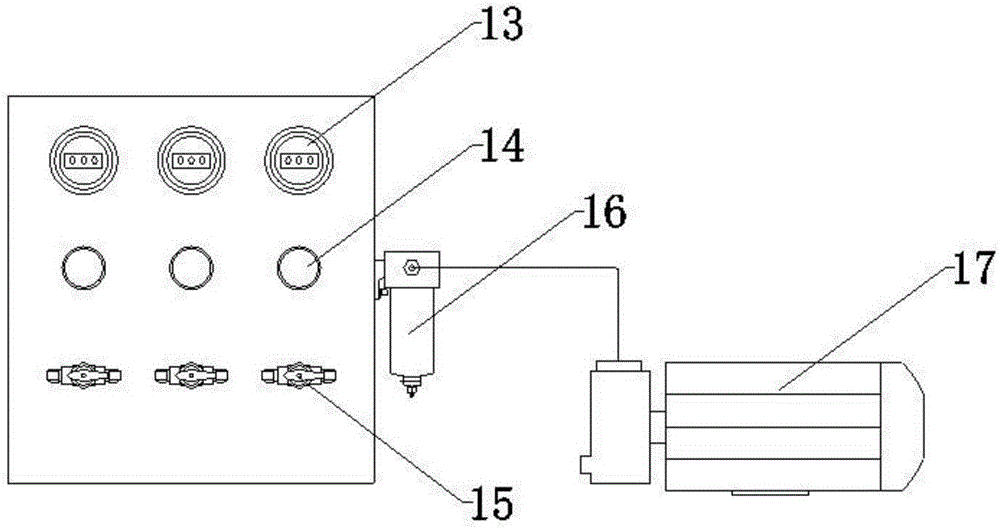

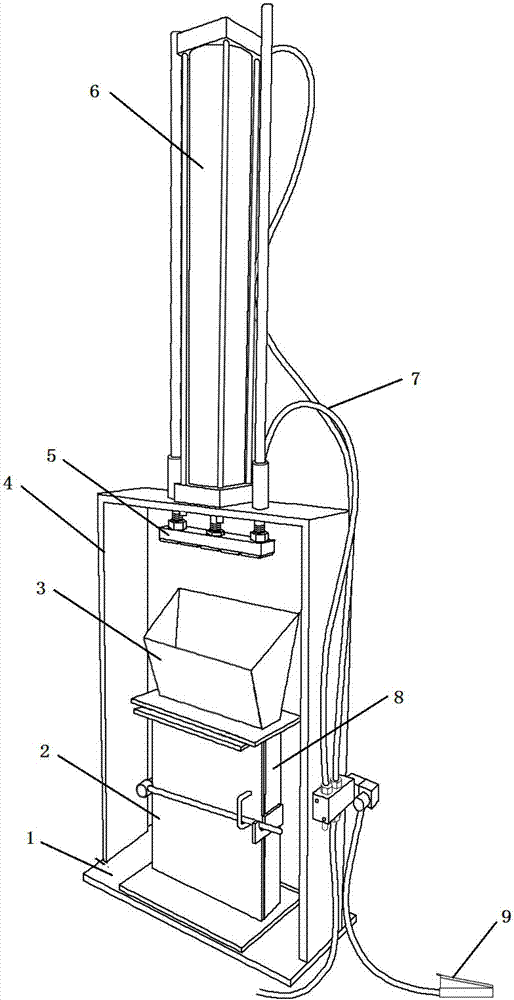

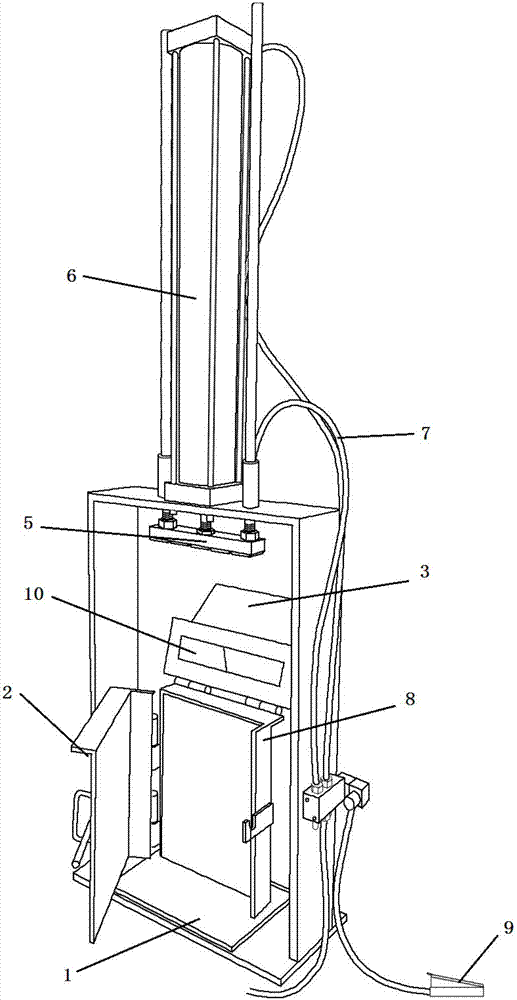

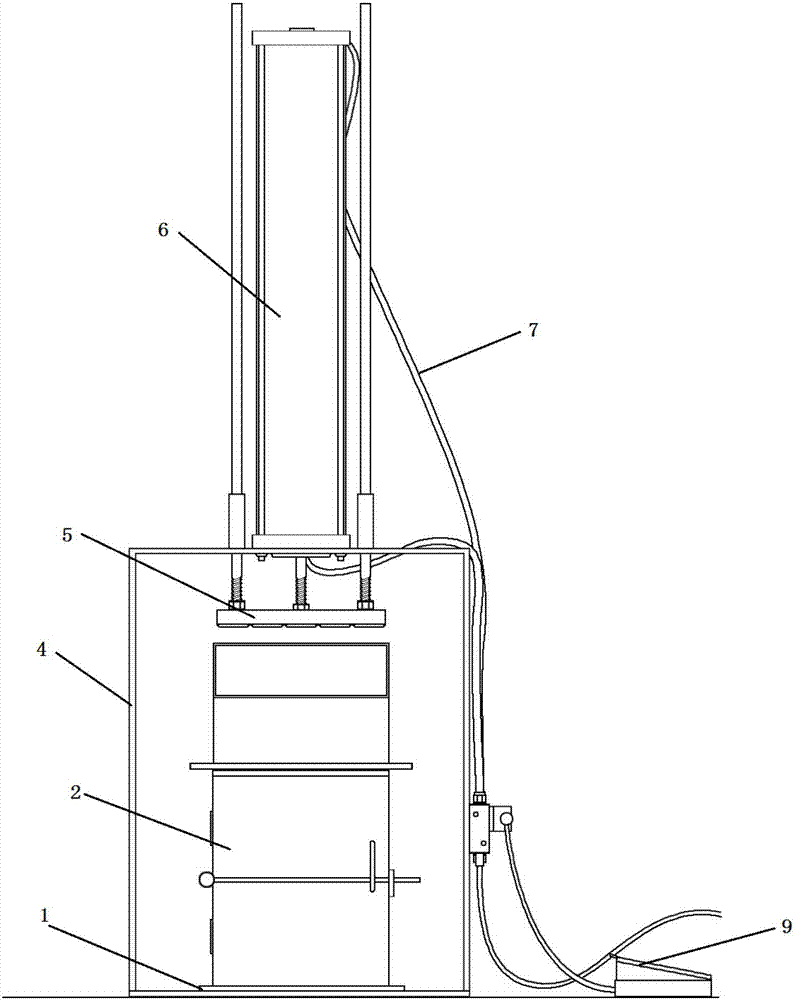

Remolded soil sample preparation device capable of controlling density through weight and air pressure combined loading

ActiveCN106680051APrecise Density ControlImprove reliabilityPreparing sample for investigationEngineeringAtmospheric pressure

The invention discloses a remolded soil sample preparation device capable of controlling density through weight and air pressure combined loading. The remolded soil sample preparation device comprises an air pressure raising device part and a sample preparation tube part, wherein the sample preparation tube part comprises a vertically arranged sample tube; the top of the sample tube is connected with a weight through a pressure bar; the weight is arranged on a tray on the top of the pressure bar; the bottom of the pressure bar is provided with a pressing plate for pressing a soil sample in the sample tube; and the pressing plate extends into the sample tube. After weight loading is performed by using the device, pressurization is performed through an air compressor, so that the purpose of accurately controlling the density of a remolded soil sample is achieved, the sample preparation period is greatly shortened, and the remolded soil sample having a given water content or given density can be prepared according to requirements; the prepared soil sample is uniform, thereby greatly improving the reliability of experimental results; and instruments are used to realize quantitative control of the air pressure and the sample height, thereby greatly reducing various operation errors caused by artificial operation.

Owner:CHANGAN UNIV

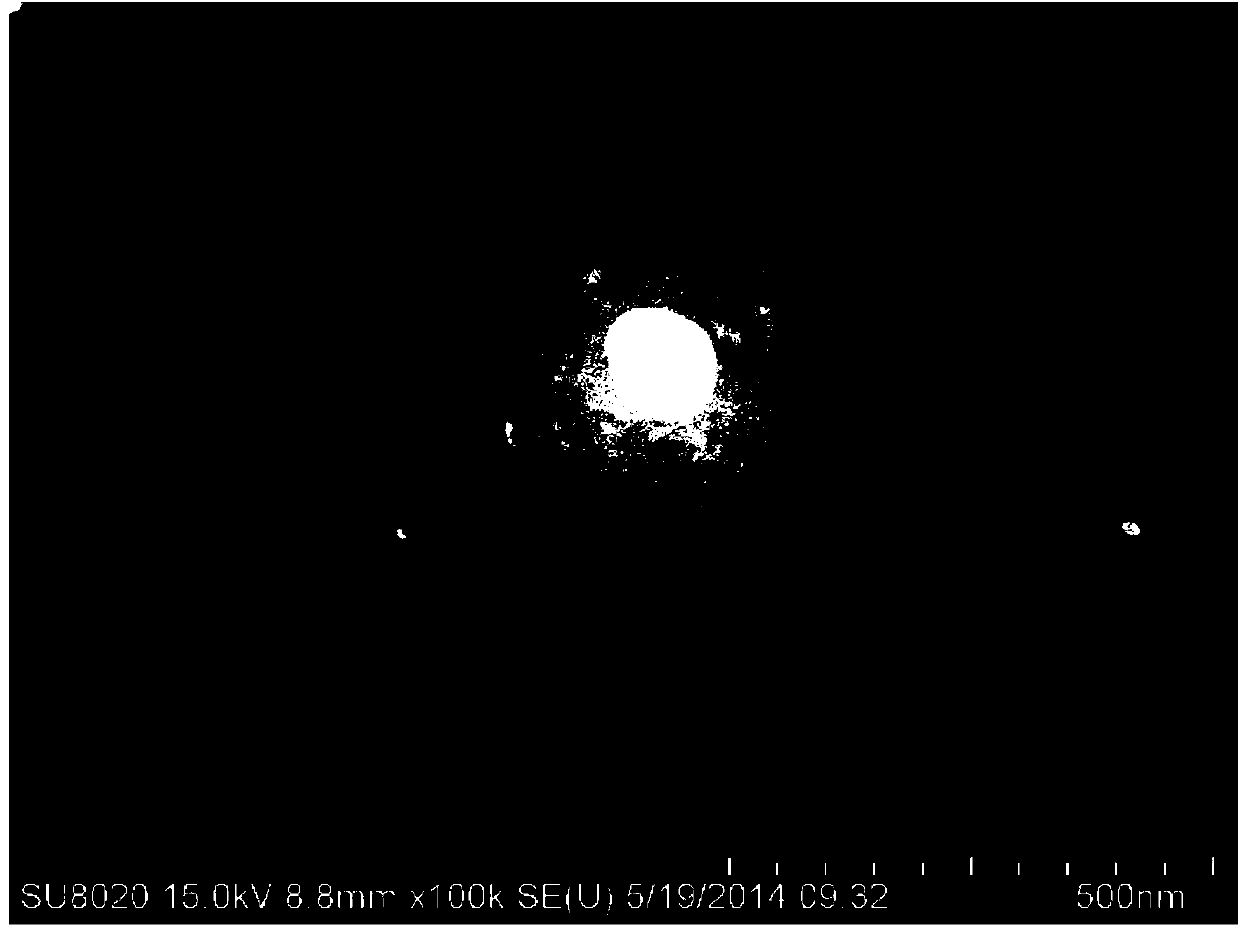

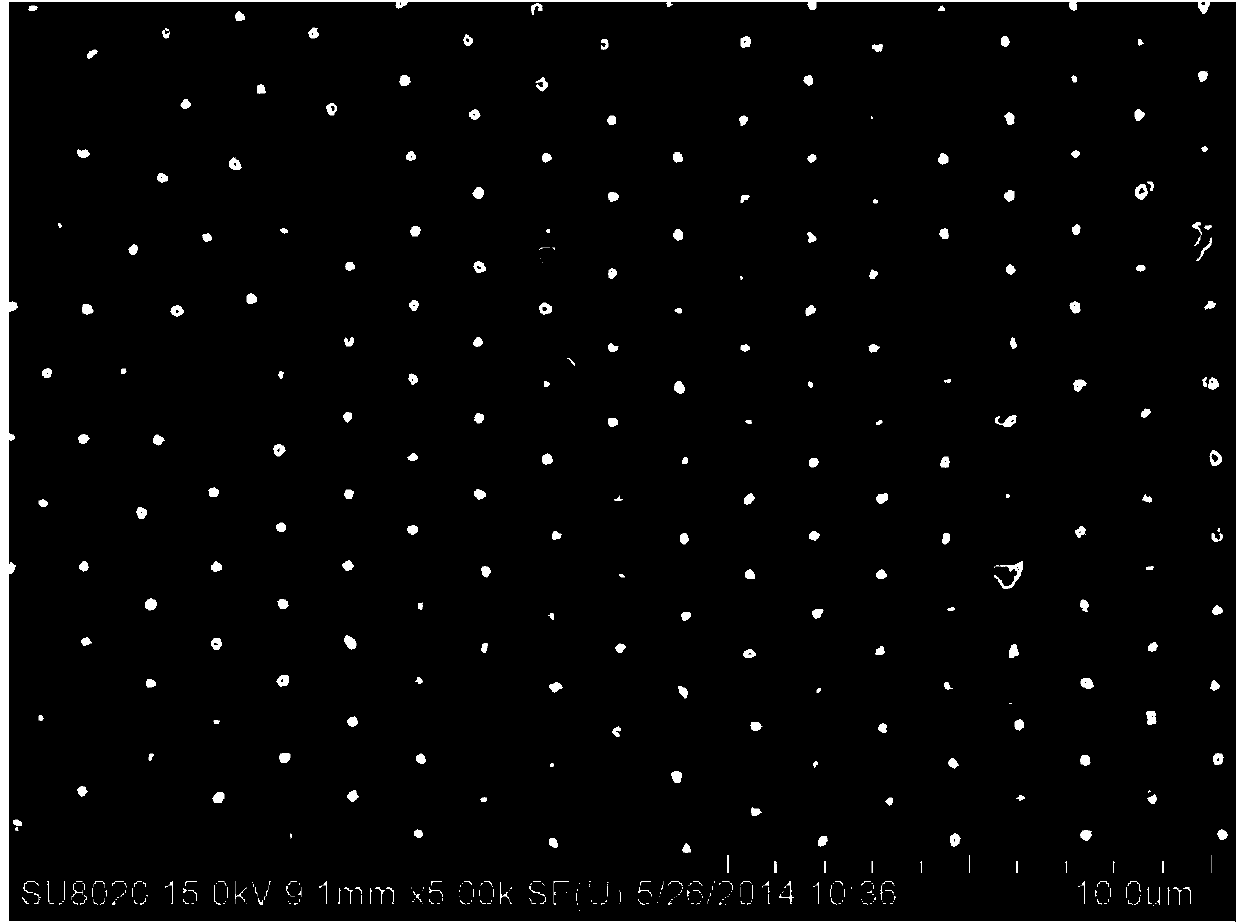

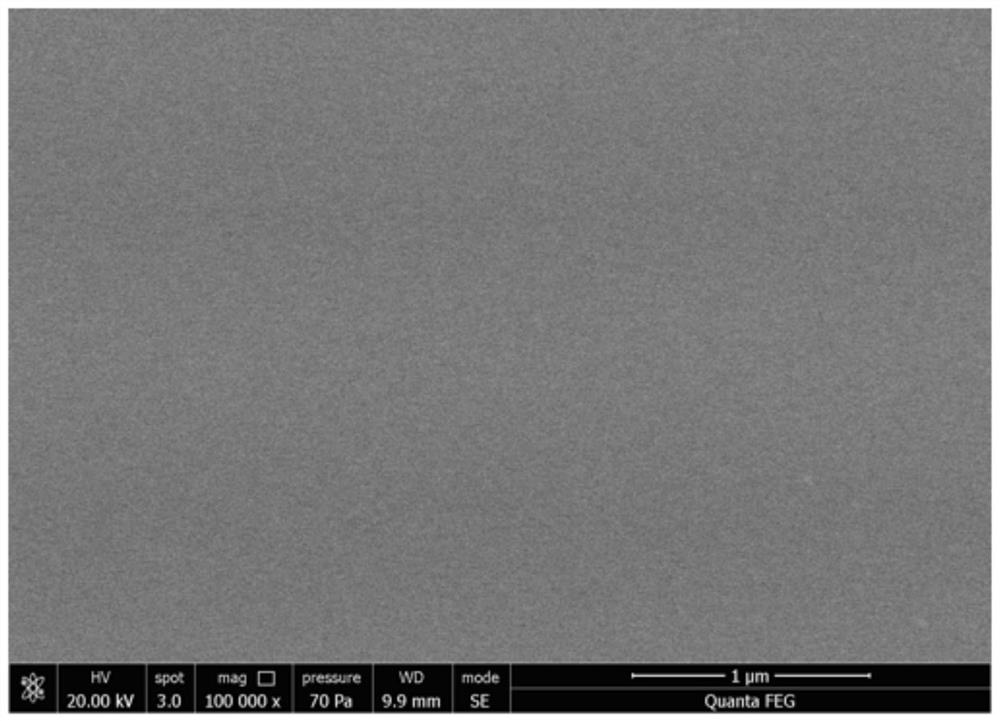

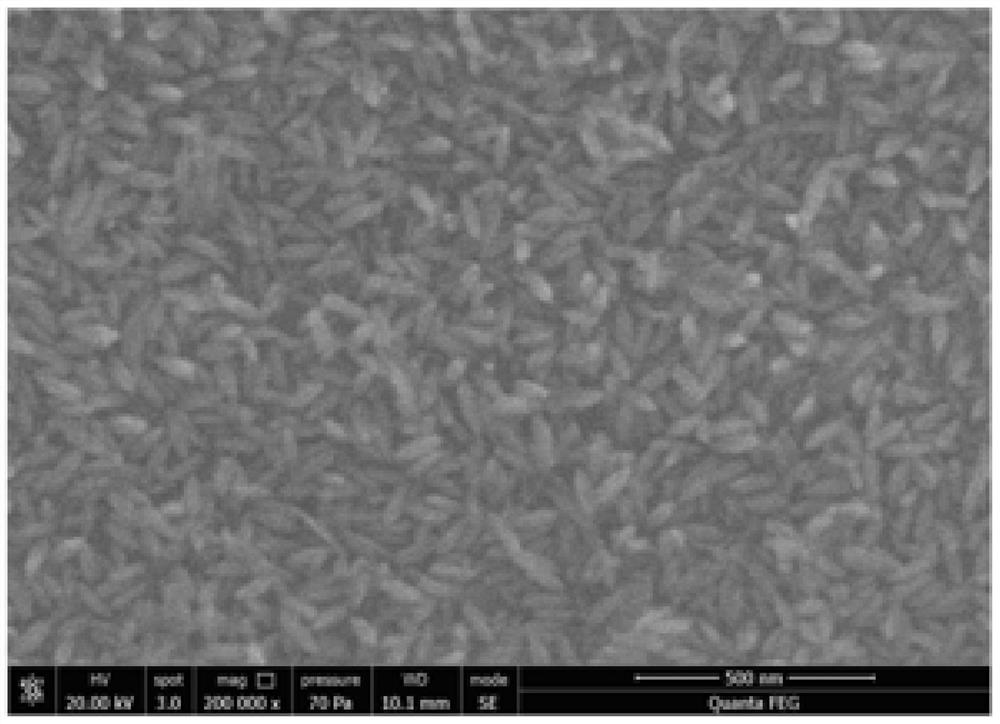

Laser-chemical preparation method of monocrystal silicon substrate sub-micron pyramid structure

ActiveCN104195644APrecise positioningPrecise control of densityPolycrystalline material growthAfter-treatment detailsWater bathsMicro structure

The invention discloses a laser-chemical preparation method of a monocrystal silicon substrate sub-micron pyramid structure, belonging to the field of crystalline silicon surface micro-structure preparation. The preparation method comprises the following steps: firstly, performing pretreatment on monocrystal silicon, and covering periodically close-packed microspheres on the surface of monocrystal silicon; performing irradiation by adopting a 248nm laser, wherein the single pulse energy density is 100-400mJ / cm<2>; performing certain treatment on a monocrystal silicon sample after irradiation, and removing the residual microspheres on the surface; after removal ends, dipping the monocrystal silicon sample into a sodium hydroxide aqueous solution containing ethanol under the environment that the water bath temperature is 70-80 DEG C, eroding for 10-30 seconds, taking out the monocrystal silicon sample, and washing by using deionized water to obtain a monocrystal silicon piece with a normal pyramid array. The laser-chemical preparation method disclosed by the invention exerts the laser controllability, can be used for rapidly and simply preparing the pyramid array with periodicity and uniformity, has high controllability in pyramid forming, can be used for adjusting the separation distance and morphology features of the pyramid array, also is low in raw material cost, and has relatively high practicability.

Owner:BEIJING UNIV OF TECH

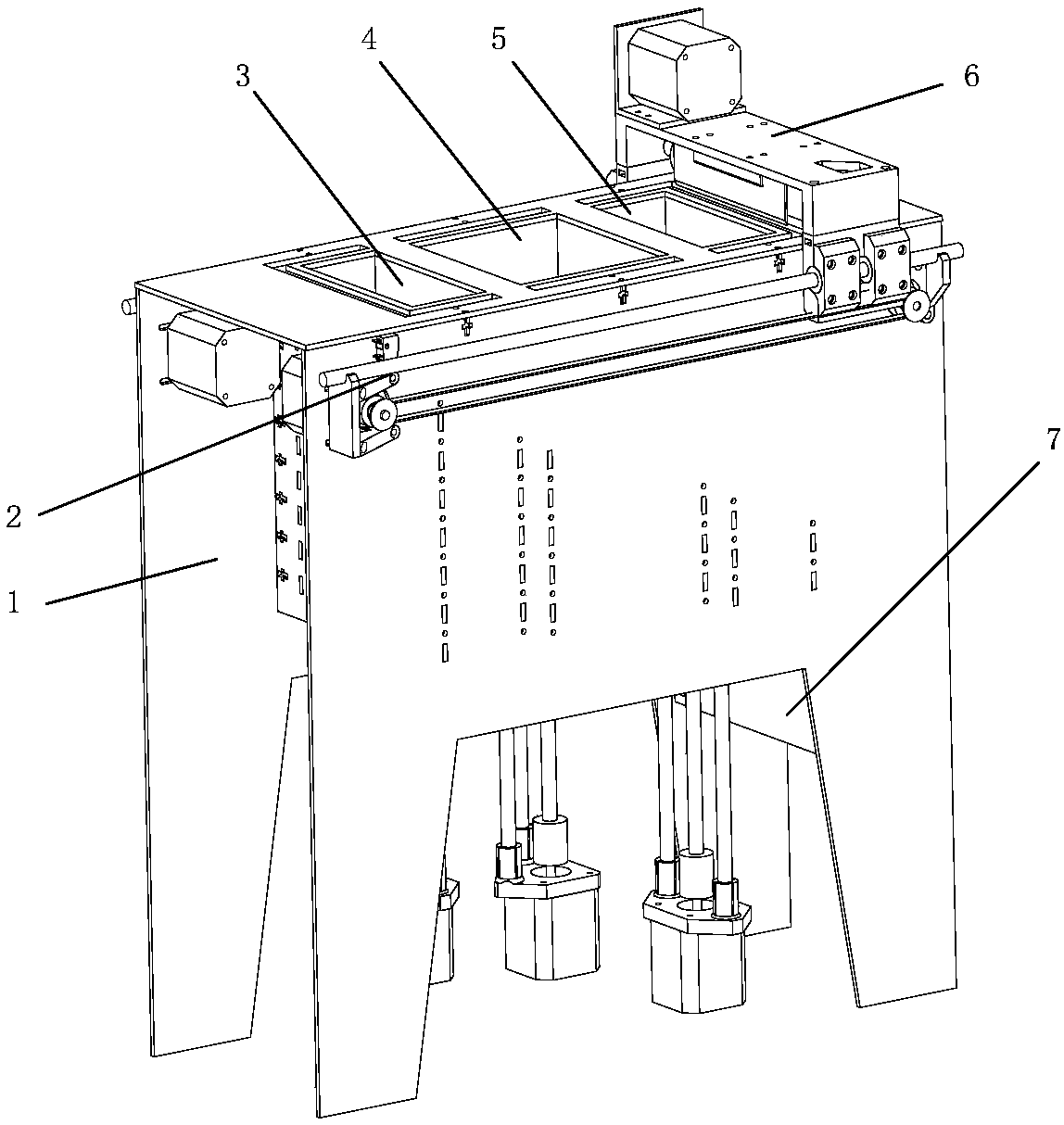

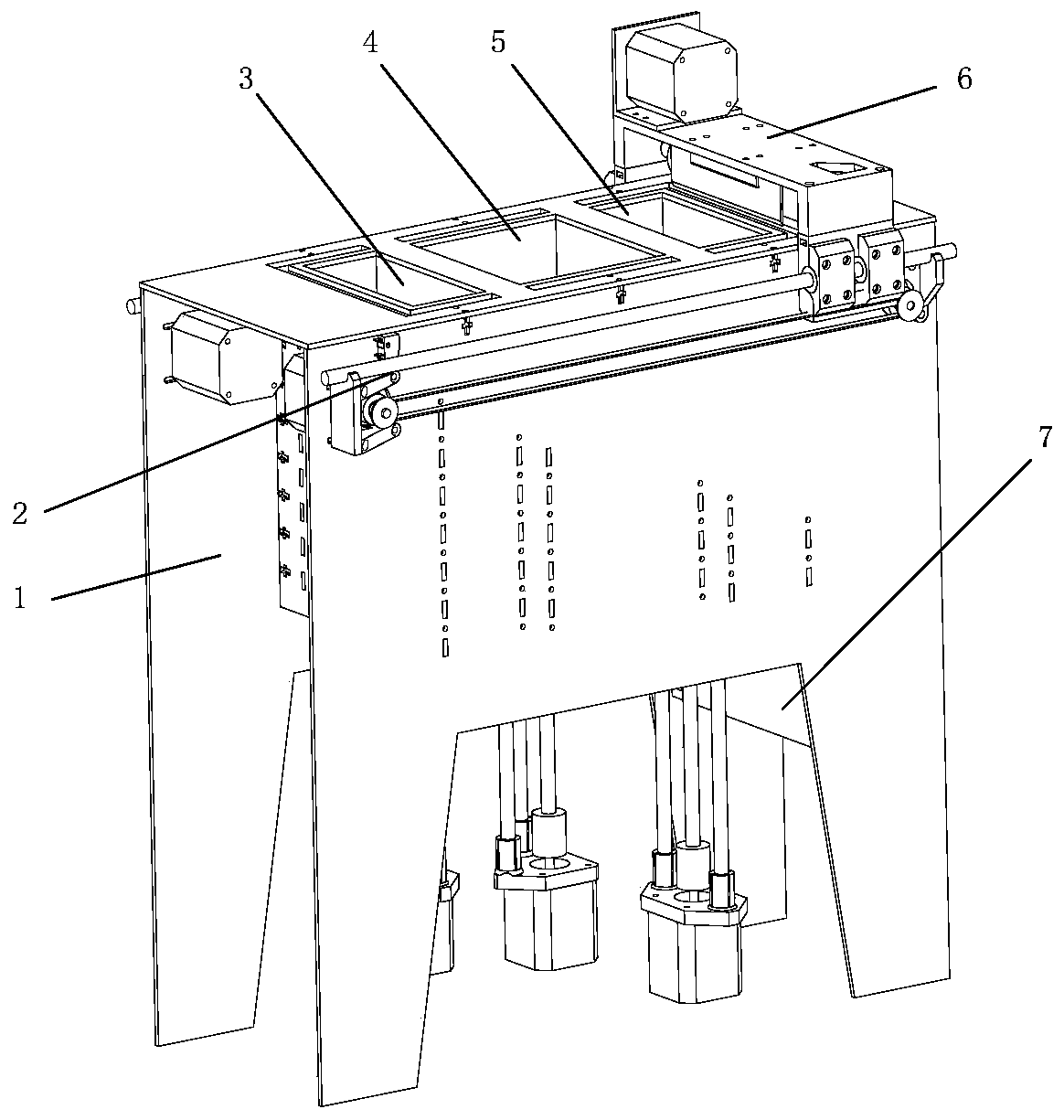

Laser powder rapid sintering and powder spreading device

ActiveCN107855525APrecisely control the amount of powder fedPrecise Density ControlAdditive manufacturing apparatusIncreasing energy efficiencyControl systemLaser

The invention discloses a laser powder rapid sintering and powder spreading device which comprises a foundation mounting frame, a powder spreading guide device, a powder spreading guide device controlsystem, a first powder spreading cylinder, a first powder spreading cylinder control system, a forming cylinder, a forming cylinder control system, a second powder spreading cylinder, a second powderspreading cylinder control system, a powder spreading roller reciprocating traveling device, a powder spreading roller reciprocating traveling device control system, and a powder recovery cylinder system. By adoption of the laser powder rapid sintering and powder spreading device disclosed by the invention, the continuous powder spreading operation can be completed on a laser sintering machine, and meanwhile, fallen raw material powder can be recovered. Compared with the prior art, the laser powder rapid sintering and powder spreading device has the advantages that the positions of the powderspreading cylinders are symmetrically set, so that not only can the structural compactness of a powder spreading device be guaranteed, but also the idle stroke of the powder spreading roller reciprocating traveling device during a motion process can be eliminated, and then the working efficiency of a laser powder sintering machine can be greatly improved.

Owner:HUBEI UNIV OF TECH

Acid-free external formation method of lead-acid storage battery and lead-acid storage battery

ActiveCN105280963AExtended service lifeGuaranteed capacityFinal product manufactureCell electrodesWastewaterEngineering

The invention provides an acid-free external formation method of a lead-acid storage battery and the lead-acid storage battery. During formation, a sulfuric acid electrolyte is substituted by a neutral electrolyte, acid mist pollution is prevented, and lead-containing wastewater generated during washing of the traditional external formation pole plate is avoided; meanwhile, the formation efficiency and the pole plate quality are superior to those of an internal formation process; and moreover, no waste acid is generated like the internal formation process, and the purposes of saving energy, reducing emission and also improving product quality are achieved.

Owner:江西力之奇新能源科技有限公司

Intelligent control system and method for manufacturing optical fiber prefabricated rod by using OVD (optical variable device)

InactiveCN110526573AImprove intelligent productionPromote OVD method to prepare optical fiber preform to realize intelligent productionGlass making apparatusEngineeringOptical variable device

The invention discloses an intelligent control system and a method for manufacturing an optical fiber prefabricated rod by using an OVD (optical variable device) and relates to the field of optical fiber manufacturing. The intelligent control system comprises a support device, at least one blowtorch, a diameter measuring device and a control device, wherein the support device is used for clampinga core rod to be processed; a weighing sensor is arranged on the support device; the weighing sensor is used for measuring the weight of a loosened body on the core rod in real time; the at least oneblowtorch is arranged on the support device; the diameter measuring device is used for measuring the outer diameter of the loosened body in real time; and the control device is used for receiving weight data transmitted from the weighing sensor and outer diameter data transmitted from the diameter measuring device, and used for adjusting the flow of the blowtorch according to the weight data and the outer diameter data, and thus the outer diameter and the density of the loosened body are both within preset ranges. By adopting the intelligent control system, the outer diameter size, the weightand the density of the loosened body can be precisely controlled.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

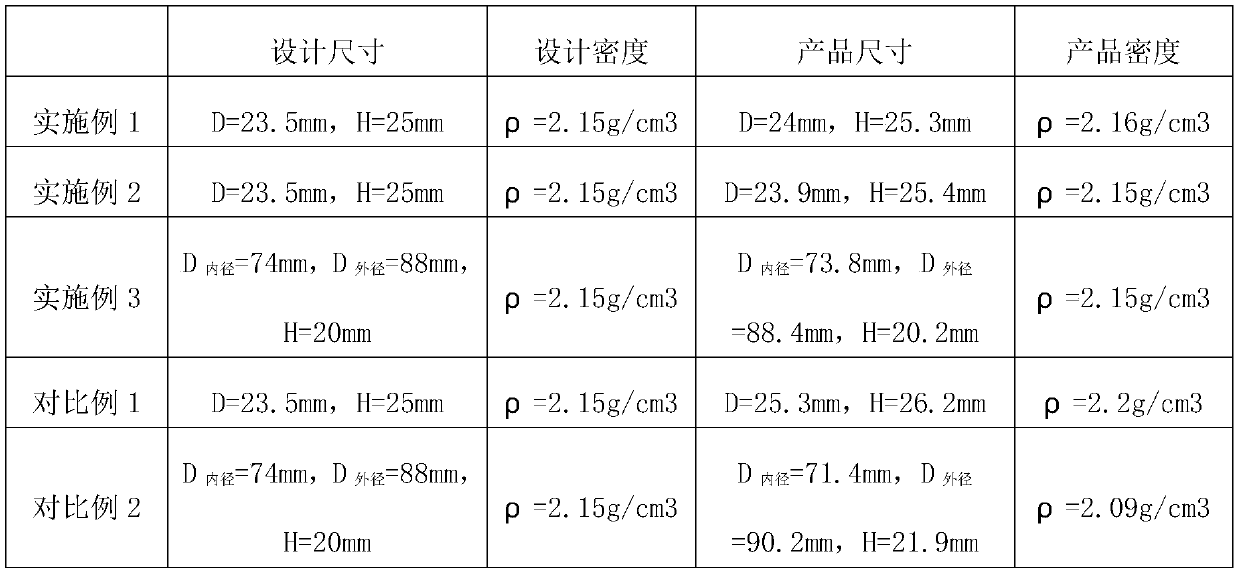

Preparation method of density-controllable B10-rich boron carbide ceramic

The invention discloses a preparation method of density-controllable B10-rich boron carbide ceramic. The preparation method comprises the following steps: 1) drying B10-rich boron carbide powder; 2) weighing a certain amount of dried B10-rich boron carbide powder according to the designed density; 3) putting the weighed B10-rich boron carbide powder into a specially-made high-strength and high-density graphite mold cavity, heating the powder to 2100-2250 DEG C under a vacuum condition, and carrying out hot pressed sintering; and 4) performing pressurization after the pressure maintaining temperature is reached, wherien the pressure ranges from 10 MPa to 90 MPa and the heat preservation and pressure maintaining time ranges from 1 h to 2.5 h, and demolding the material after furnace coolingis conducted. The B10-rich boron carbide ceramic prepared by the preparation method disclosed by the invention solves the problem of low neutron absorption capacity; accurate control over the densityand the size of the boron carbide ceramic can be achieved through the hot-pressing mold by adopting the hot-pressing sintering process, the percent of pass of the boron carbide ceramic is increased, the machining and production cost is reduced, and the method is simple, effective and easy for industrial production.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

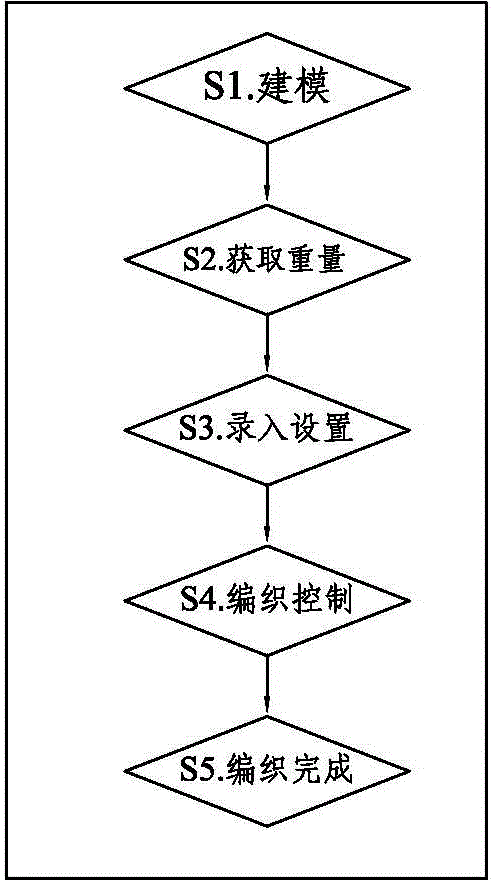

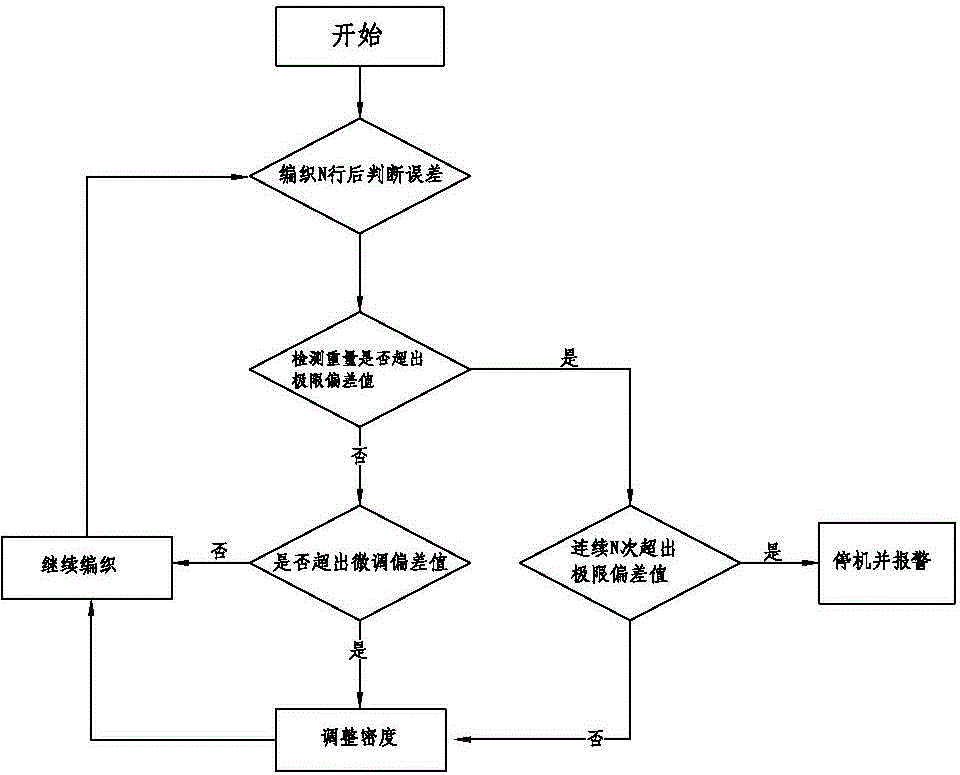

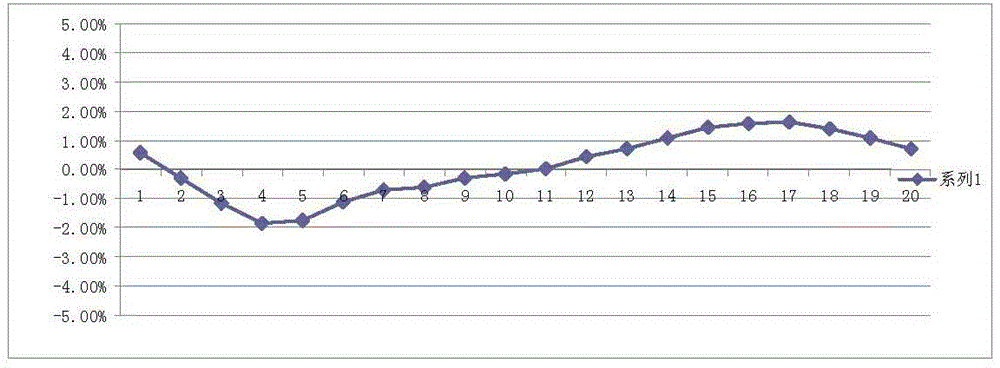

Weight control method for braided fabric

The invention relates to the technical field of textile and discloses a weight control method for a braided fabric. The control method has the following advantages that 1, according to the method, a standard sheet is divided into a plurality of segments and is used as a modeling reference, and thus, a plurality of segmented linear control densities can be realized and a sweater sheet woven by the weight control method is uniform in density and is comfortable to wear; 2, by adopting the method, an operator does not need to have rich weaving experience and a common worker can attend a weaving machine by simple training, so that labor cost is reduced; 3, due to adoption of segmented control and real-time monitoring on the weight, generation of waste sheets is reduced and yield is obviously promoted, so that by adopting the method, the qualified rate of woven sweaters is also greatly improved; 4, by adopting the method, accurate control on the density and the weight can be implemented and the aim of saving yarns also can be fulfilled.

Owner:DONGGUAN DINGHONG ELECTRONICS TECH CO LTD

A triaxial sample preparation device for silty soil with low liquid limit

InactiveCN103048174BHigh dimensional accuracyImprove sealingPreparing sample for investigationSoil scienceConsolidation process

The invention relates to the technical field of preparation of triaxial experiment samples in rock mechanics and discloses a triaxial sample preparation device for low-liquid limit silty soil and a sample preparation method. The device comprises a sample tube, a smoothening device, a vibrator and a loading device. The method comprises the following steps: sleeving a rubber diaphragm in a split cavity; gradually pouring soil sample; controlling the initial dry density through the smoothening device and the vibrator; filling carbon dioxide and air-free water from a base until saturation; and carrying out sample consolidation process according to a secondary dry density. According to the invention, the problem of producing uniform silty soil sample is solved, the split cavity integrates the functions of positioning and sealing so as to improve the dimensional precision and the sealing effect of the sample; a rubber-steel combined vibrating head is adopted to improve the vibration and densification effect; and the matching with a current triaxial apparatus is realized, which reduces the equipment investment; and through the two-stage control of the initial dry density and the secondary dry density, the density of the sample can be optionally appointed within a certain range.

Owner:DALIAN UNIV OF TECH

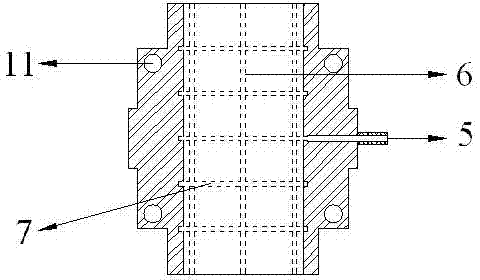

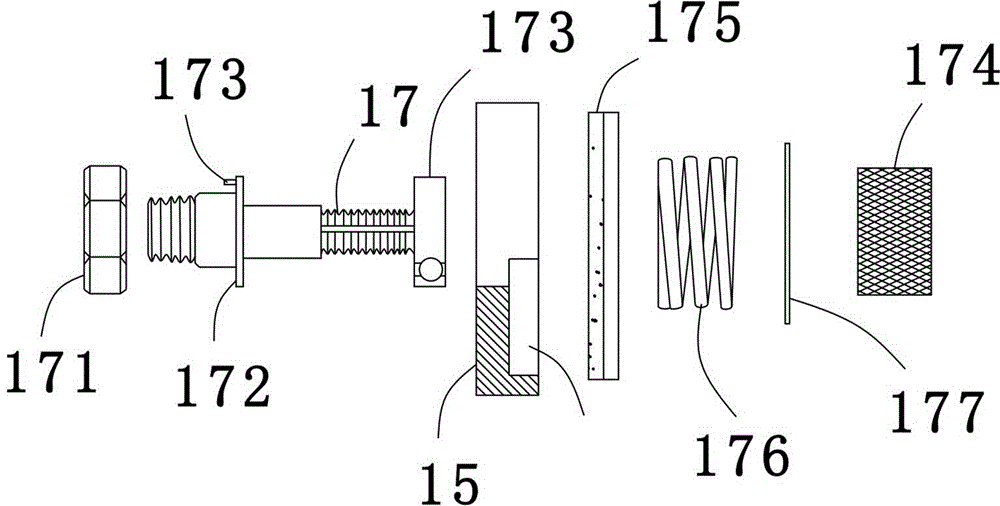

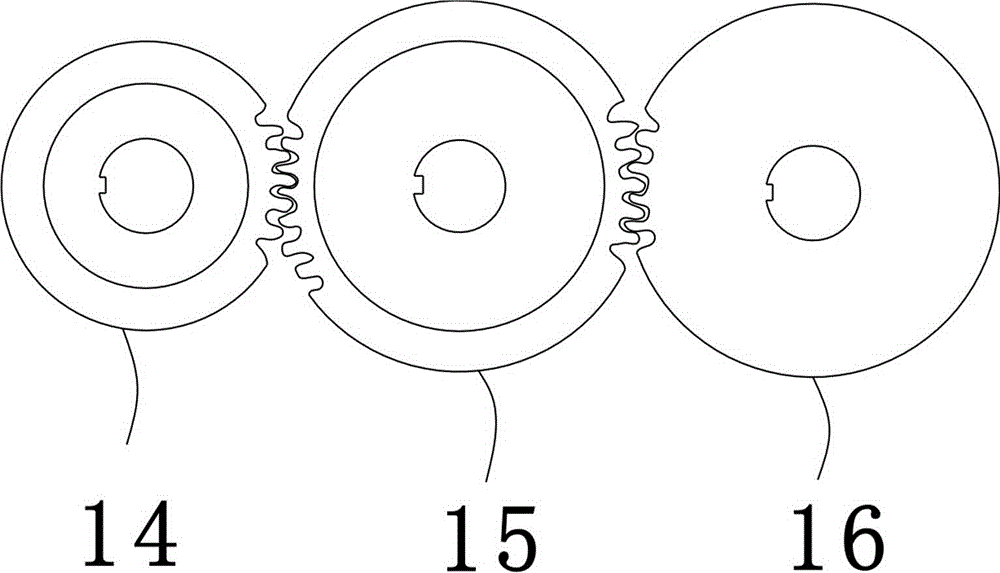

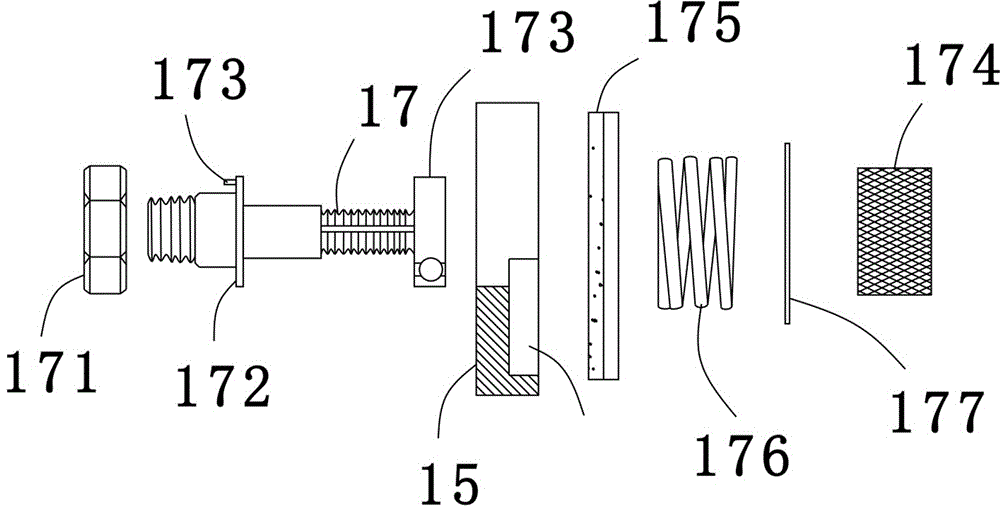

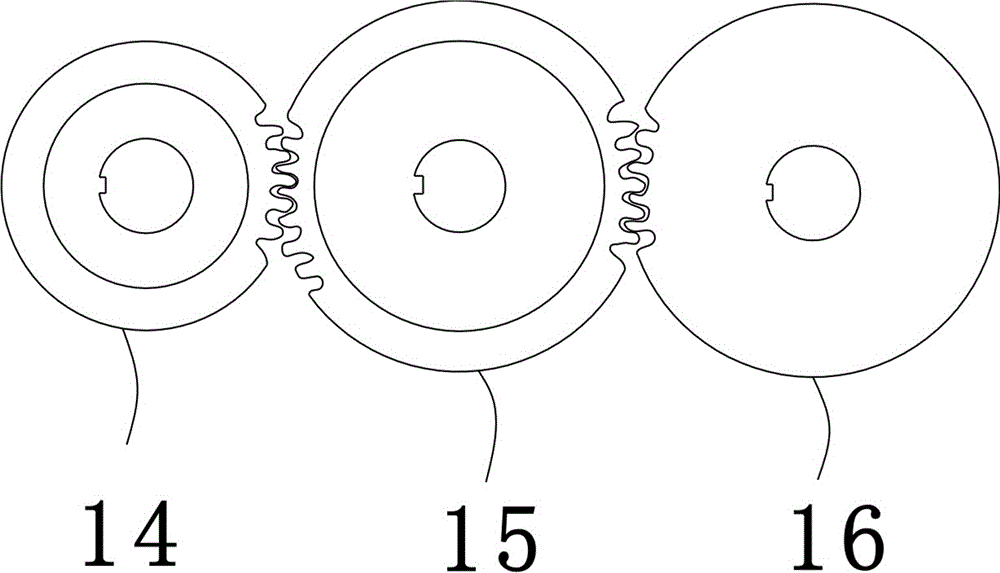

Transformer winding winding equipment using laser to track automatically

ActiveCN104538172APrecise Density ControlPrecise controlGearingCoils manufactureWinding machineLaser probe

The invention discloses a transformer winding winding equipment using laser to track automatically. The transformer winding winding equipment using the laser to track automatically comprises a wire stretcher and a wire winding machine, the wire stretcher comprises wire winding frames and support frames, the wire winding frame sleeves a rotating shaft, a fixed gear is fixed on the rotating shaft, the fixed gear is connected with a tension device, and the tension device comprises a first gear engaged to the fixed gear and a second gear engaged to the first gear; the first gear sleeves a first screw rod, the second gear sleeves a second screw rod, one ends of the first and second screw rods are fixed on the support frame, the first screw rod is provided with a first brake block, the second screw rod is provided with a second brake block, the first brake block presses a first spring at the surface of the first gear, and the second brake block presses a second spring at the surface of the second gear; the wire winding machine comprises a pedestal, a moving frame capable of moving horizontally along the pedestal, a rotating shaft sleeves the moving frame, and a first motor connected with the rotating shaft, and a laser probe used for detecting the copper wire position of the transformer when winding an inner core of the transformer is fixed at the pedestal under the inner core of the transformer.

Owner:南京丰旭电子科技有限公司

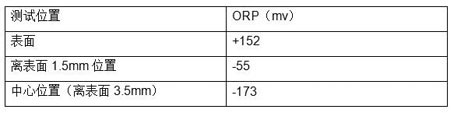

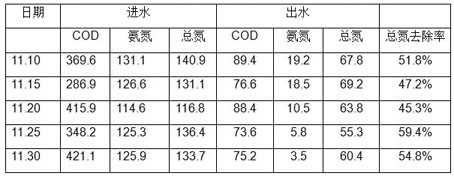

Modified polyurethane carrier and preparation method thereof

ActiveCN113045797AIncrease the attachment surfaceTo achieve the purpose of increasing efficiencyWater treatment parameter controlWater contaminantsCellulosePolymer science

The invention provides a modified polyurethane carrier and a preparation method thereof, and aims to solve the technical problems of small specific surface area, poor adsorbability, poor toxicity impact resistance, poor fluidization property after biofilm formation and the like of the existing suspension carrier. The preparation method of the modified polyurethane carrier is characterized by comprising the following steps: S1, preparation of a coating modification liquid: mixing the following raw materials in parts by weight: 30 to 50 parts of powdered activated carbon, 3.0 to 8.0 parts of hollow glass micro-beads, 0.5 to 1.5 parts of riboflavin, 0.5 to 2.0 parts of L-cysteine, 1.0 to 3.0 parts of reduced iron powder, 1 to 4 parts of sodium carboxymethyl cellulose, 200 to 450 parts of water, 0.5 to 2.0 parts of an organic silicon wetting agent, and 8 to 20 parts of acrylic emulsion. and S2, preparation of a modified polyurethane carrier: infiltrating the outer surface and the inner hole surface of porous polyurethane foam with the coating modification liquid, and curing to obtain the modified polyurethane carrier.

Owner:无锡映川环境技术有限公司

A method for acid-free externalization of lead-acid storage battery and lead-acid storage battery thereof

ActiveCN105280963BExtended service lifeGuaranteed capacityFinal product manufactureCell electrodesWastewaterSpent acid

Owner:江西力之奇新能源科技有限公司

A kind of preparation method of polyimide foam and insulation pipe cover thereof

ActiveCN109942884BGood heat resistance and flame retardant performanceImprove toughnessImidePolymer science

Owner:自贡中天胜新材料科技有限公司

A method of manufacturing an optical fiber preform and its manufacturing equipment

ActiveCN103241938BReal-time access to temperature changesDensity is adjustable and controllable in real timeGlass making apparatusThermal infraredElectromagnetic valve

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

A static pressure shearing sample making apparatus and its making method

InactiveCN103712840BReduce workloadSave test soilPreparing sample for investigationTest samplePulp and paper industry

The invention discloses a static shearing test sample making instrument and a making method of the static shearing test sample making instrument. The static shearing test sample making instrument comprises upper protection rings, internal hexagonal screws, lower protection rings, lower ring cutters, upper ring cutters, a pressing block and a cushion block, and is characterized in that screw holes I are formed in two sides of the cushion block; screw holes II are also formed in two sides of the lower protection rings, and the central distances of the screw holes II are the same as those of the screw holes I; the lower ring cutters and the upper ring cutters are arranged below and above the inner sides of the upper protection rings and the lower protection rings. The static shearing test sample making instrument has incomparable advantages in the sample making precision and the test operation and has the outstanding advantages of simplicity in operation, high sample making efficiency and high precision.

Owner:ZHEJIANG PROVINCIAL CONSTR ENG QUALITY INSPECTION STATION

Method for preparing monovalent selective cation exchange membrane through modification

PendingCN114377731AGood choiceFast aggregationIon-exchange process apparatusDispersed particle separationMembrane surfaceIon-exchange membranes

The invention discloses a method for preparing a monovalent selective cation exchange membrane through modification, which comprises the following steps: 1) soaking a cation exchange membrane in a solution containing Fe < 3 + > ions at room temperature, stirring and standing the solution, and cleaning the surface with water to obtain an iron type cation exchange membrane; and 2) preparing a codeposition buffer solution of dopamine and polyethyleneimine, soaking the iron-type cation exchange membrane prepared in the step 1) in the solution at room temperature to react for 0.5-6 hours, taking out the iron-type cation exchange membrane, and washing the surface with clear water to obtain the monovalent selective ion exchange membrane. According to the method, Fe < 3 + > ions combined in the ion exchange membrane in advance serve as an oxidizing agent to promote rapid polymerization of dopamine, the Fe < 3 + > ions and polyethyleneimine are co-deposited on the surface of the membrane to form a stable modified layer, the operation process is simple, the prepared membrane is good in selectivity, and large-scale production is facilitated.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

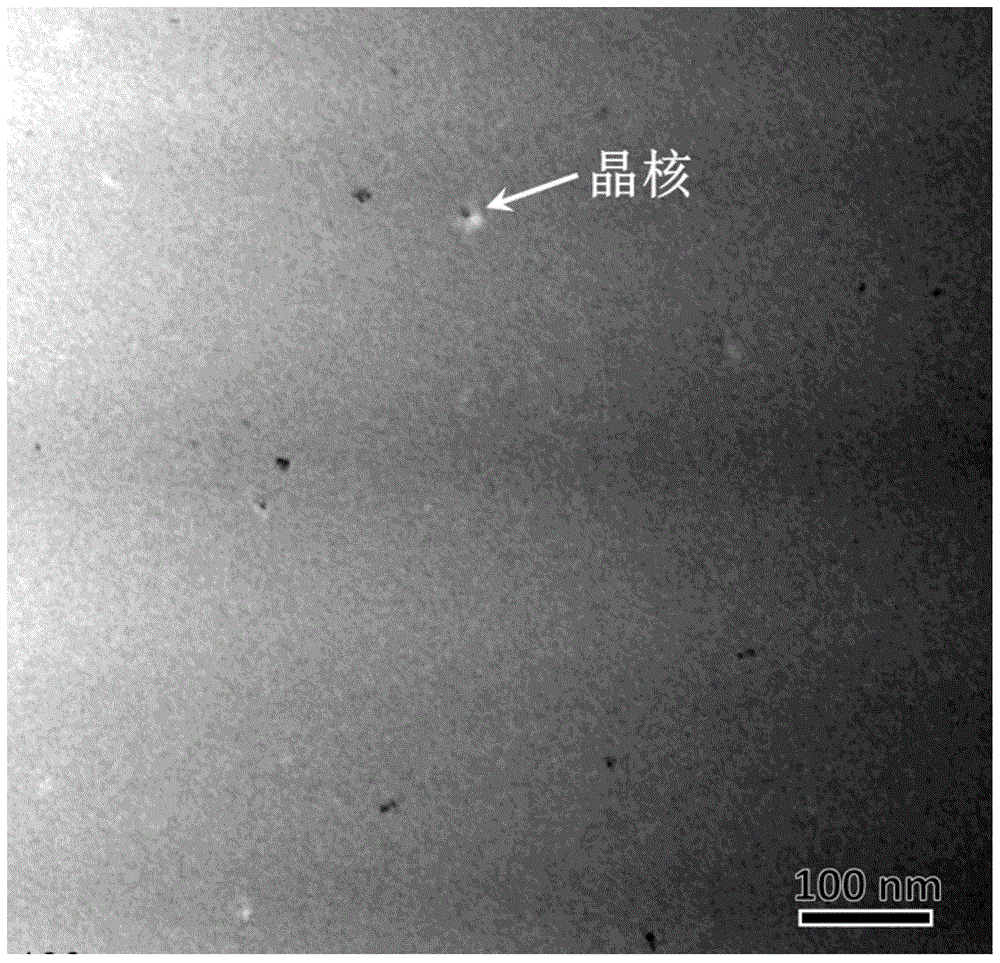

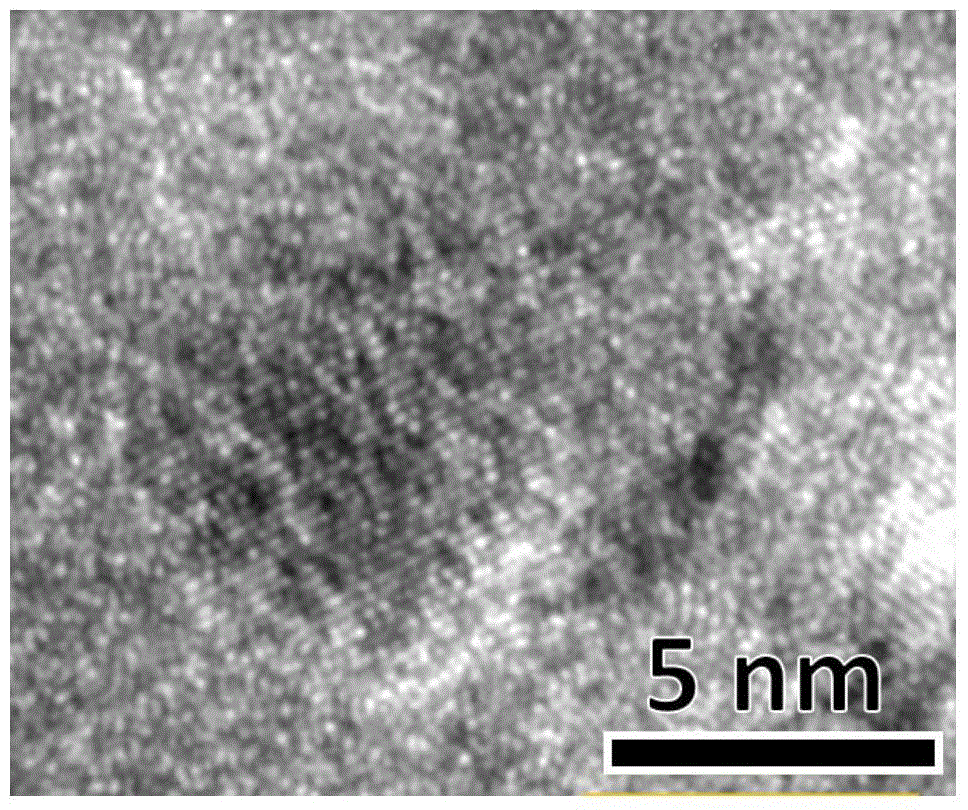

Heat-treating method and device for nanocrystalline alloy strip

ActiveCN105671259AImprove toughnessImprove straightnessFurnace typesMetallic material coating processesPrefabricationNanocrystalline alloy

The invention discloses a heat-treating method for a nanocrystalline alloy strip. The heat-treating method comprises the following steps of (1), unwinding, tensioning, guiding and winding the nanocrystalline magnetically soft alloy strip along a path at a scheduled unwinding rate; (2), processing the nanocrystalline magnetically soft alloy strip with salt bath heating treatment along a section of the path; (3), carrying out constant temperature heating on the nanocrystalline magnetically soft alloy strip subjected to salt bath heating treatment; and (4), cooling the nanocrystalline magnetically soft alloy strip subjected to constant temperature heating. The invention also discloses a heat-treating device for the nanocrystalline alloy strip. According to the heat-treating method and device, salt bath heating treatment is utilized to conduct two-faced fast heating on the strip, so that surface passivation and crystal nucleus prefabrication heat treatment of the strip are achieved. Due to two-faced fast heating, the heat-treating method and device have the advantages that heat treatment time is controlled conveniently and heat treatment temperature is controlled precisely.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

A preparation method of carbon fiber/toughened epoxy resin prepreg for vacuum bag forming process

The invention discloses a preparation method of a carbon fiber / toughened epoxy resin prepreg for a non-autoclave vacuum bag forming process. According to the method, the dissolution degree and the particle size of a curing agent and a toughening agent in epoxy resin are controlled by controlling a resin formula, the particle sizes of the curing agent and the toughening agent and process conditionsfor resin system configuration, and meanwhile, two modification effects are achieved: 1, the resin system is toughened; and 2, the requirements of a non-autoclave process on the viscosity of the resin in the prepreg and a room-temperature storage period are met. The prepared epoxy resin system is prepared into a rubber film, the carbon fiber / epoxy resin prepreg is further prepared by adopting a rubber film calendering method, and the semi-impregnated prepreg (unsaturated impregnated prepreg) is obtained by controlling the pressure and temperature during compounding of the rubber film and carbon fibers.

Owner:BEIHANG UNIV

Laser automatic tracking transformer winding winding equipment

ActiveCN104538172BPrecise Density ControlPrecise controlGearingCoils manufactureWinding machineCopper wire

The invention discloses a transformer winding winding equipment using laser to track automatically. The transformer winding winding equipment using the laser to track automatically comprises a wire stretcher and a wire winding machine, the wire stretcher comprises wire winding frames and support frames, the wire winding frame sleeves a rotating shaft, a fixed gear is fixed on the rotating shaft, the fixed gear is connected with a tension device, and the tension device comprises a first gear engaged to the fixed gear and a second gear engaged to the first gear; the first gear sleeves a first screw rod, the second gear sleeves a second screw rod, one ends of the first and second screw rods are fixed on the support frame, the first screw rod is provided with a first brake block, the second screw rod is provided with a second brake block, the first brake block presses a first spring at the surface of the first gear, and the second brake block presses a second spring at the surface of the second gear; the wire winding machine comprises a pedestal, a moving frame capable of moving horizontally along the pedestal, a rotating shaft sleeves the moving frame, and a first motor connected with the rotating shaft, and a laser probe used for detecting the copper wire position of the transformer when winding an inner core of the transformer is fixed at the pedestal under the inner core of the transformer.

Owner:南京丰旭电子科技有限公司

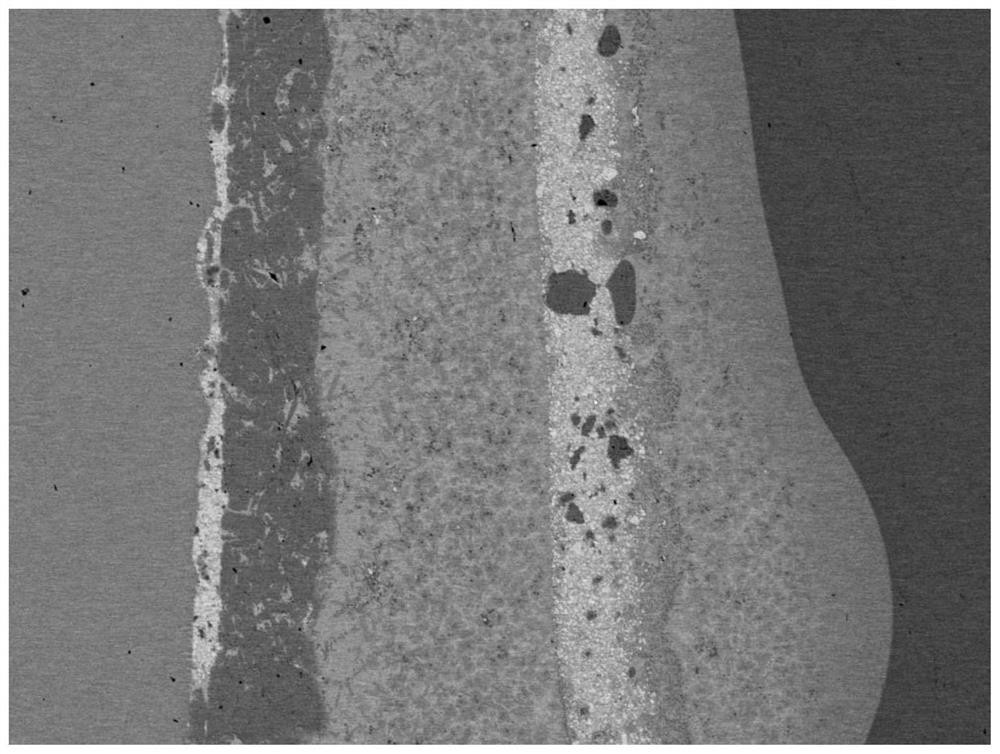

A kind of metal sheet and its preparation method and application

ActiveCN112406215BHigh strengthEasy to makeCoatingsWelding/soldering/cutting articlesNiobiumCopper foil

The invention provides a metal sheet, which includes a copper foil layer, and a first adsorption layer and a second adsorption layer respectively attached on both sides of the copper foil layer; the first adsorption layer includes niobium, vanadium and zinc, and the second adsorption layer includes Chromium and zinc; wherein, the mass percentage of zinc in the first adsorption layer or the second adsorption layer is 5-15%; the mass ratio of niobium and vanadium in the first adsorption layer is 2.5-3.5:1. Also provided is a metal sheet preparation method, which respectively prepares metal slurries using niobium, vanadium, and zinc as metal powder raw materials, and chromium and zinc powder as metal powder raw materials; side surface. Also provided is a method of applying the metal sheet to the welding of titanium alloys and stainless steels. The metal sheet itself provided by the invention has high strength and reduces the cost; the preparation process is simple, and the welding quality is guaranteed. When applied to titanium alloy and stainless steel welding, it realizes layer-by-layer transition, which greatly improves the strength of welded joints.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

A light-weight and high-temperature-resistant ceramic fiber rigid heat-insulating tile and its manufacturing method

ActiveCN105272322BOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Precise intelligent winding machine and winding control method thereof

InactiveCN103552884BPrecise Density ControlPrecise control of tensile stressFilament handlingWinding machineEngineering

The invention discloses a precise intelligent winding machine and a winding control method thereof. The precise intelligent winding machine mainly comprises a support, a guide rail, a pressing arm component, a roller set, a belt feeding servo motor, a winding shaft and pneumatic equipment thereof, a central controller, a winding shaft belt pulley and a motor thereof, and the like. Wound fabric is wound on all rollers in the roller set sequentially through a feeding support, passes a guide roller on the pressing arm component, and then is wound on the winding shaft through a guide head. The pressing arm component is mounted on the guide rail and driven through a synchronous belt. The central controller controls rotational motion of a synchronizing wheel driving motor so as to control position and stepping speed of the pressing arm component, and controls rotational speeds of the belt feeding servo motor and the winding shaft so as to adjust and control tensile stress for winding the fabric. Density, the tensile stress and winding shape for fabric winding can be precisely controlled, the control method is simple and feasible, and a powerful guarantee is provided for smooth proceeding of subsequent dyeing.

Owner:萧振林

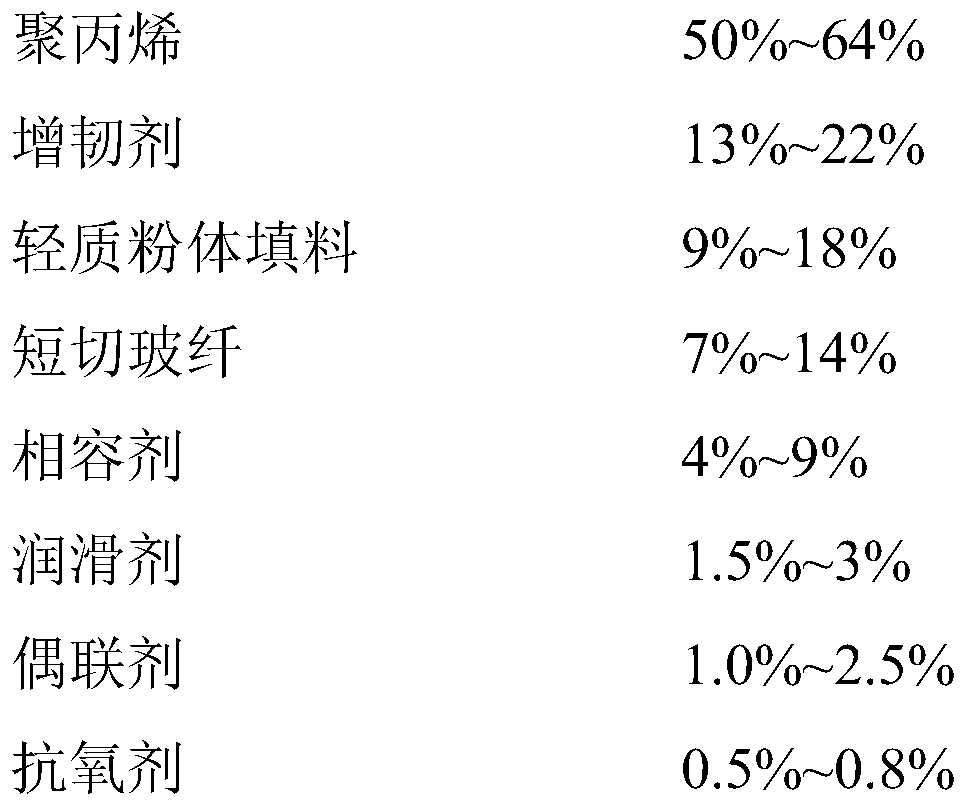

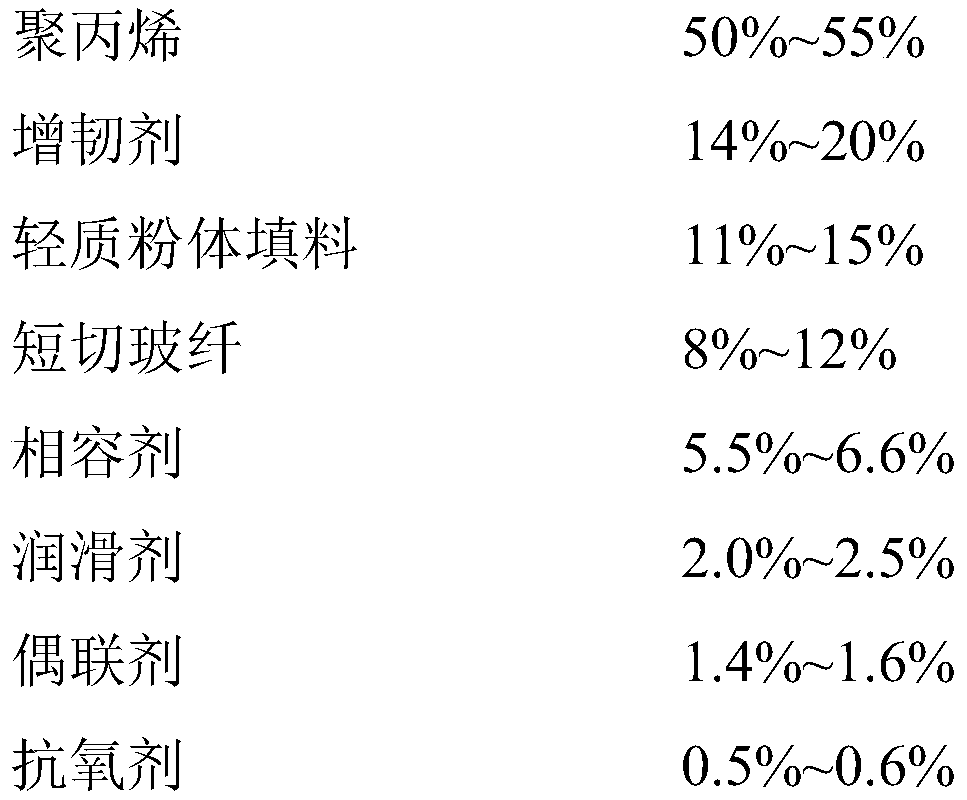

A kind of lightweight high specific strength modified polypropylene material and its preparation method

The invention discloses a light high specific strength modified polypropylene material and a preparation method thereof. The light high specific strength modified polypropylene material is prepared from the following components in percentage by mass through mixing: 48-75% of polypropylene, 10-25% of a toughening agent, 4-20% of light powder packing, 6-15% of chopped glass fiber, 2-10% of a compatilizer, 1-3% of a lubricant, 0.5-3% of a coupling agent and 0.4-1% of an antioxidant. As hollow inorganic powder packing is adopted as a packing material and the chopped glass fiber as a reinforcing material, the synergistic effect of the two components is brought into sufficient play, and reasonable modification processes and preparation methods are used, the completeness of a particle structure of hollow inorganic powder is ensured while the binding strength of the hollow inorganic powder with resin is improved, and thus the material has both excellent properties of low density and high strength finally. The light high specific strength modified polypropylene material disclosed by the invention can meet most plastic property requirements of manufacturing fields such as automobiles, domestic electric appliances, rail transit, aerospace, ships and submarines, and the field of modern sponge city construction, and development with energy conservation and emission reduction and low carbon and environment protection of the fields can be promoted.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

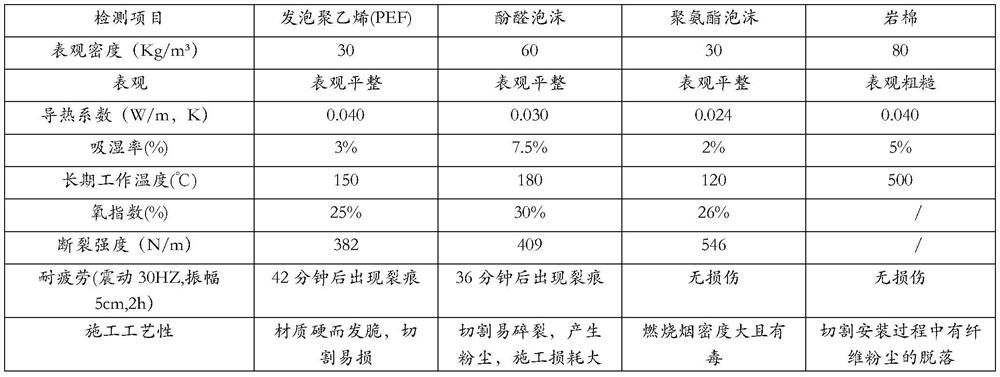

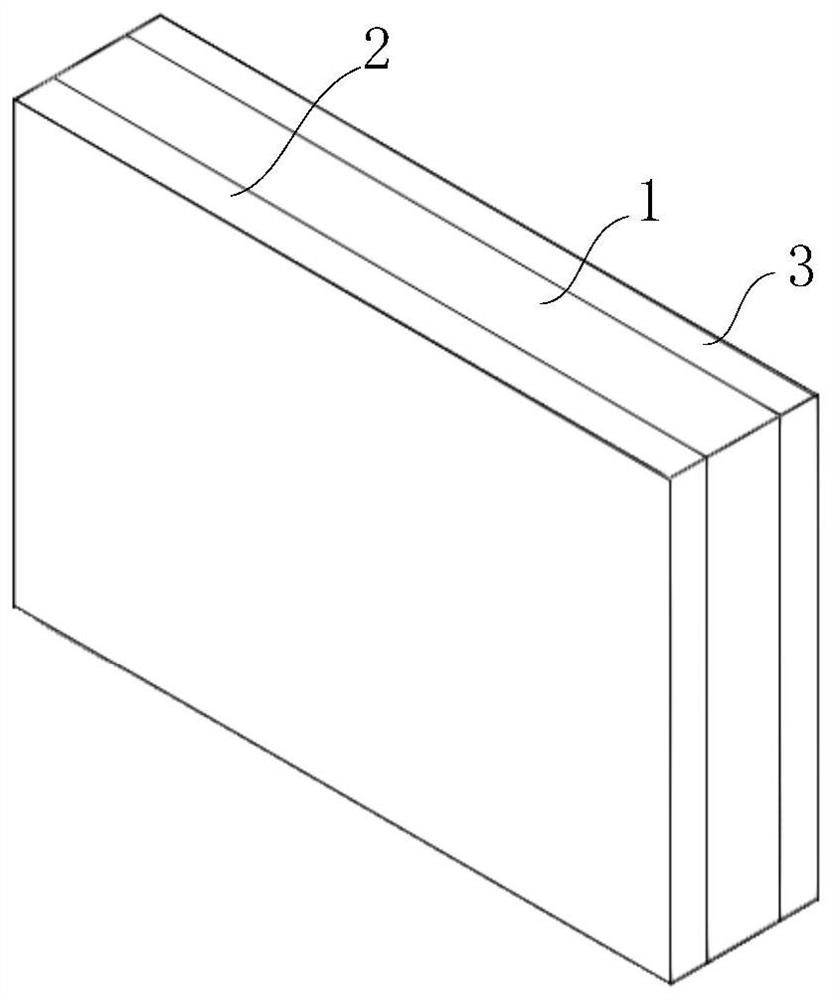

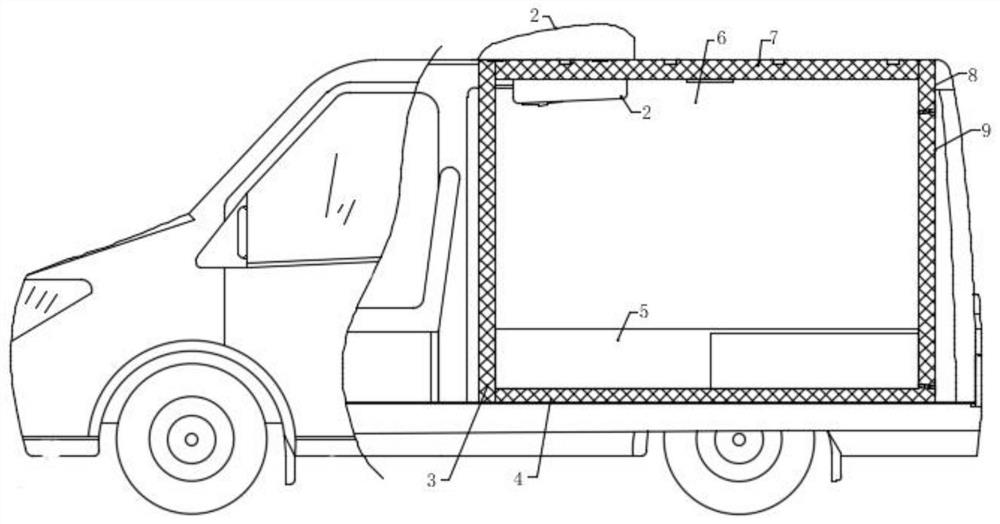

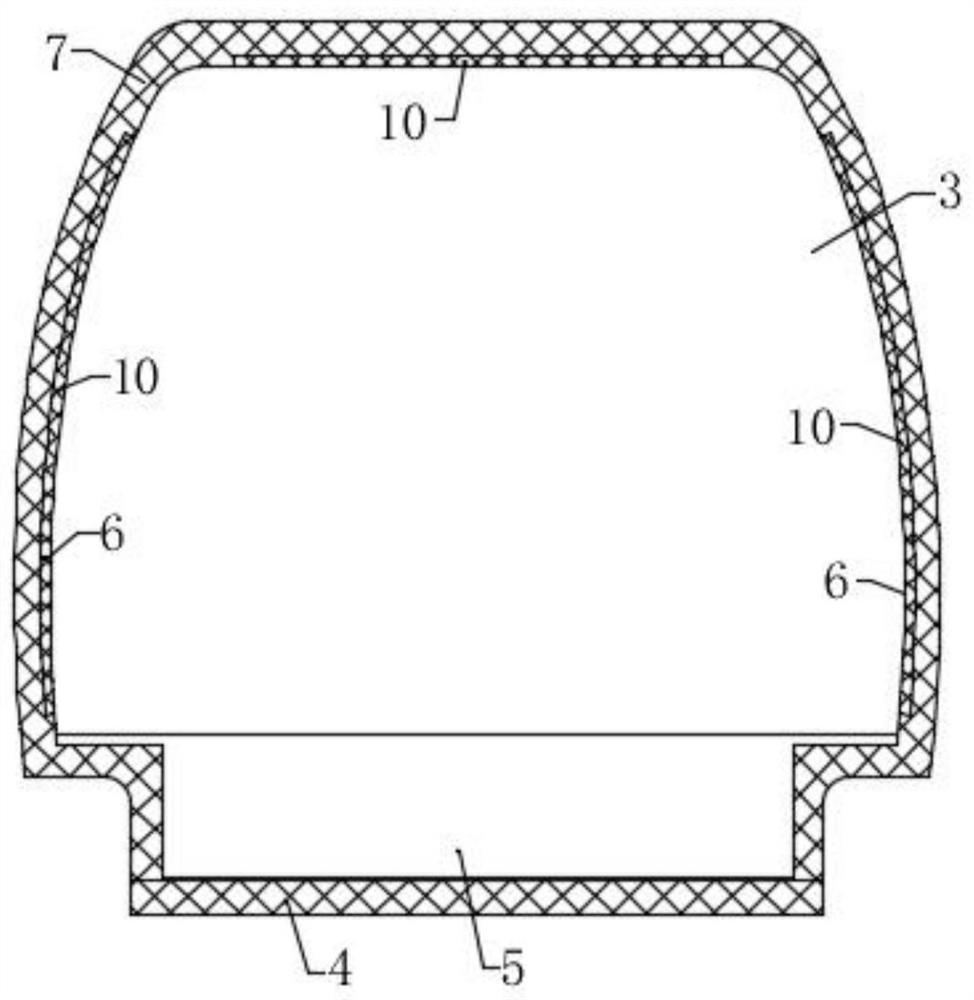

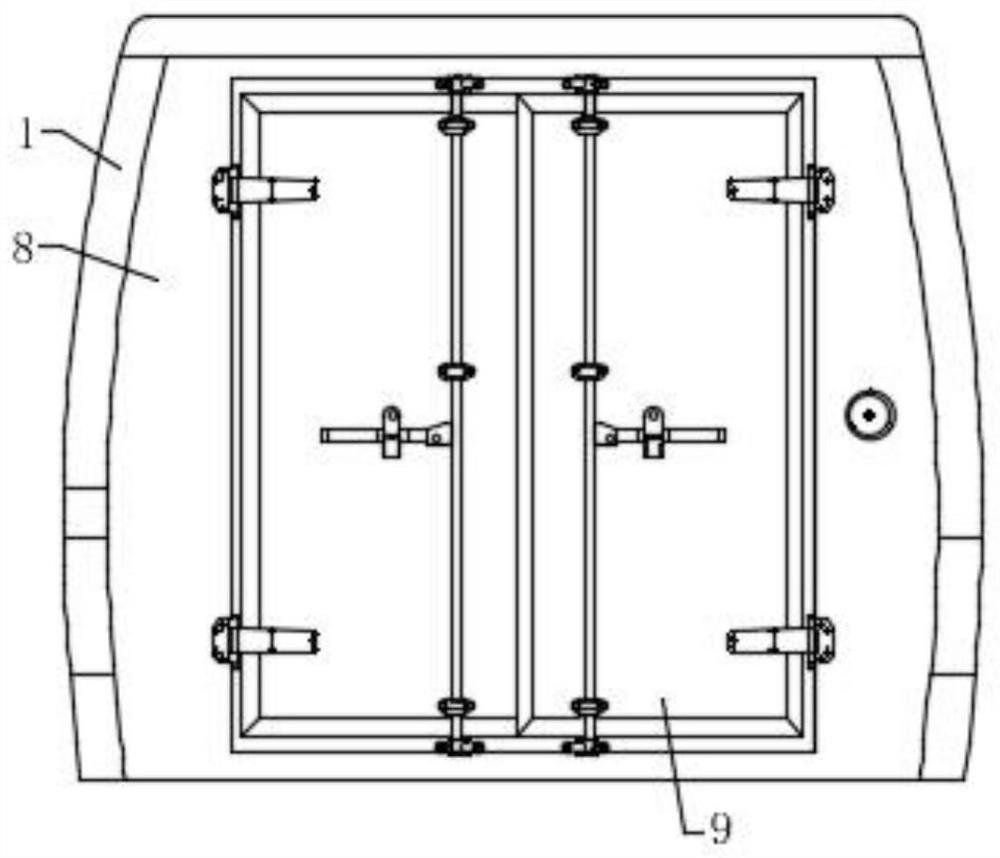

A method of manufacturing an integrated refrigerated compartment

ActiveCN112793684BGuaranteed dimensional stabilityReduce wasteRefrigerated goods vehicleLoading-carrying vehicle superstructuresInsulation layerThermal insulation

The invention provides a method for manufacturing an integral refrigerated carriage, which includes the following steps: A. cutting the cowl into shape according to the template of the outer contour of the cowl and installing it at the front end of the carriage; Fittings and skirt panels; C install the inner contour positioning limiter on the front wall according to the inner contour template of the front wall; D install limit blocks on both sides of the compartment; E install the left and right sides of the overall inner panel and A reinforced insulation layer is compounded in the roof area; F bends the overall inner panel into an arch shape, and pushes it into the passenger compartment to fix it; G installs a molding mold to form a cavity between the passenger compartment and the overall inner panel; H Polyurethane raw materials are injected into the mold cavity to form an integral structure of the insulation layer of the refrigerated compartment; I install the prefabricated rear sealing plate and rear door; J the front wall and rear sealing plate and the overall inner panel are sealed and waterproofed. The invention has high inner space utilization rate, easy control of molding size standard, simplified manufacturing process and improved manufacturing efficiency.

Owner:广州镕禾专用汽车有限公司

A laser powder rapid sintering powder spreading device

ActiveCN107855525BPrecisely control the amount of powder fedPrecise Density ControlAdditive manufacturing apparatusIncreasing energy efficiencyControl systemManufactured material

The invention discloses a laser powder rapid sintering powder spreading device, which comprises a basic installation frame, a powder spreading guide device and its control system, a first powder spreading cylinder and its control system, a forming cylinder and its control system, and a second powder spreading cylinder And its control system, powder spreading roller reciprocating device and its control system, recovery powder cylinder system. The device of the present invention can complete continuous powder spreading work on the laser sintering machine, and recover the dropped raw material powder at the same time. Compared with the prior art, the present invention symmetrically arranges the positions of the powder spreading cylinders, which not only ensures the compactness of the structure of the powder spreading device, but also eliminates the idle travel of the powder spreading roller reciprocating walking device during the movement process, greatly improving the laser powder The working efficiency of the sintering machine.

Owner:HUBEI UNIV OF TECH

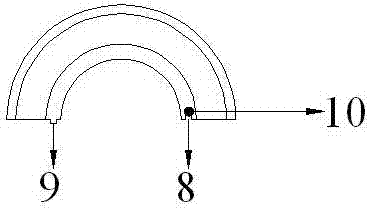

Mold and method for pressing brick tea

ActiveCN107027907AEffective pressure controlPrecise density controlPre-extraction tea treatmentClimate change adaptationEngineeringMechanical engineering

The invention discloses a mold and method for pressing brick tea. The mold for pressing brick tea comprises a base, a brick-shaped mold body, a movable plate and a feed opening, wherein the brick-shaped mold body is arranged above the base; the movable plate is connected to one side of the brick-shaped mold body in a detachable manner; the feed opening is formed in the top end of the brick-shaped mold body; the shape of an air pressure plate is the same as the shape of the feed opening, and the air pressure plate is used for pressing brick tea raw materials into a brick shape; an air cylinder is fixed above the feed opening to provide power for the air pressure plate; the air pressure plate is driven by the air pressure to press the brick tea, so that the pressure of pressing the brick tea each time can be effectively controlled, and the surface of the pressed brick tea is smooth; according to the method for pressing brick tea, the brick tea is pressed layer by layer; and grooves are formed at intervals in the air pressure plate for pressing the brick tea, so that every two adjacent layers of the pressed brick tea are in saw-toothed occlusion, and the density of the brick tea is controlled more accurately.

Owner:李满

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com