A kind of metal sheet and its preparation method and application

A metal sheet and metal powder technology, applied in the field of dissimilar metal welding, can solve the problems of high cost of composite transition layer and general connection effect of a single transition metal, and achieve the effects of high strength, improved strength and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

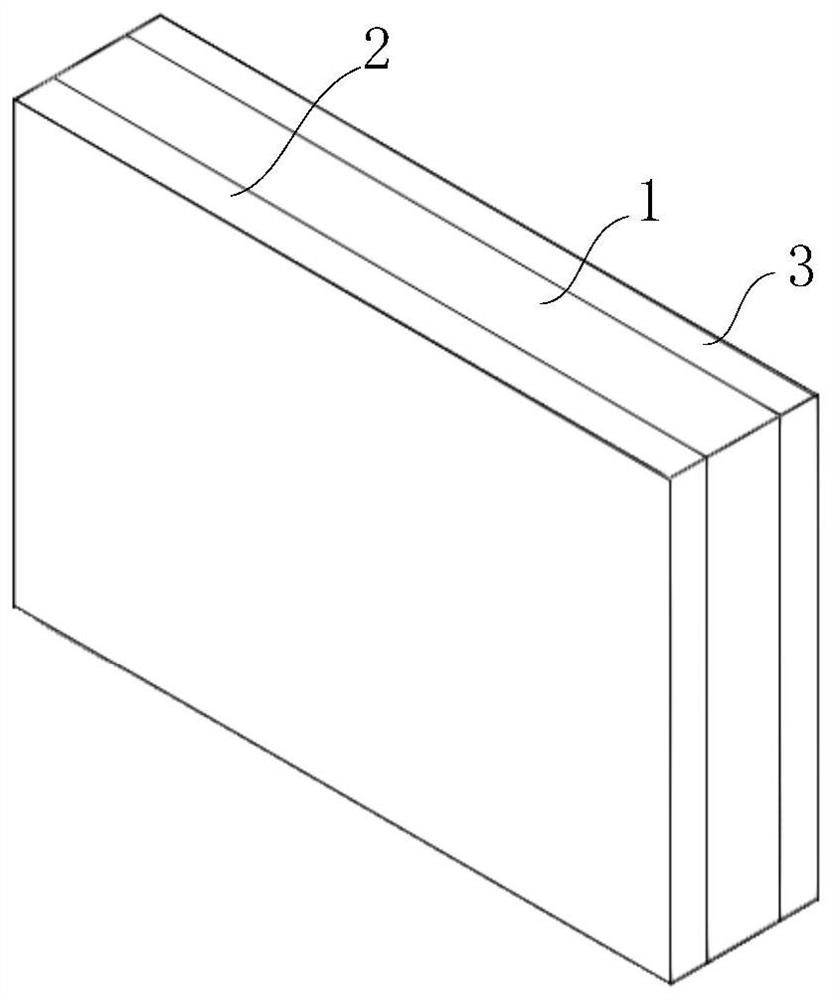

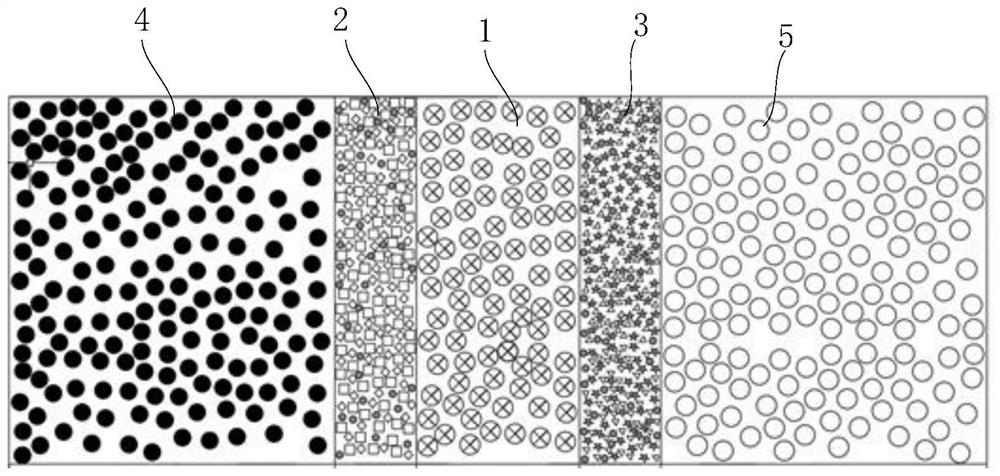

[0048] The invention also discloses a method for preparing a metal sheet. The steps include: separately preparing a metal slurry using niobium, vanadium and zinc as metal powder raw materials, and a metal slurry using chromium and zinc powder as metal powder raw materials; The metal pastes are evenly attached to the surfaces of both sides of the copper foil.

[0049] Wherein the preparation method of metal slurry comprises:

[0050] a. metal powder by mass ratio: metal binder: water=5:1~3:15~25 ratio takes metal powder, metal binder and water;

[0051] b. Heat the water to 90-100°C, add the metal adhesive to the water to dissolve, cool to room temperature, and obtain the bonding solution;

[0052] c. Add the metal powder into the bonding solution, stir to make the mixture uniform, and obtain the metal slurry;

[0053] Wherein, the mass percentage of zinc in the metal powder is 5-15%; the mass ratio of niobium and vanadium in the metal powder using niobium, vanadium and zinc ...

Embodiment 1

[0070] 1. Preparation of metal sheets:

[0071] Prepare metal pastes with niobium, vanadium, and zinc as metal powder raw materials, and chromium and zinc powders as metal powder raw materials:

[0072] Wherein, the mass percentage of zinc in the metal powder is 5%; the mass ratio of niobium and vanadium in the metal powder with niobium, vanadium and zinc as raw materials is 2.5:1.

[0073] Steps include:

[0074]A. metal powder by mass ratio: metal binder: take by weighing metal powder, metal binder and water in the ratio of water=5:1:15;

[0075] b. Heat the water to 90°C, add the metal adhesive to the water to dissolve, cool to room temperature, and obtain the bonding solution;

[0076] c. Add the metal powder into the bonding solution, stir to make the mixture uniform, and obtain the metal slurry;

[0077] Put one kind of metal slurry into the GR630 high-pressure spraying machine, spray on one side of the copper foil surface, and after drying; add another metal slurry i...

Embodiment 2

[0081] 1. Preparation of metal sheets:

[0082] Prepare metal pastes with niobium, vanadium, and zinc as metal powder raw materials, and chromium and zinc powders as metal powder raw materials:

[0083] Wherein, the mass percentage of zinc in the metal powder is 10%; the mass ratio of niobium and vanadium in the metal powder with niobium, vanadium and zinc as raw materials is 3:1.

[0084] Steps include:

[0085] A. be metal powder by mass ratio: metal binder: the ratio of water=5:2:20 takes by weighing metal powder, metal binder and water;

[0086] b. Heat the water to 95°C, add the metal adhesive to the water to dissolve, cool to room temperature, and obtain the bonding solution;

[0087] c. Add the metal powder into the bonding solution, stir to make the mixture uniform, and obtain the metal slurry;

[0088] Put one kind of metal slurry into the GR630 high-pressure spraying machine, spray on one side of the copper foil surface, and after drying; add another metal slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com