Patents

Literature

35results about How to "Reduce or avoid the formation of" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

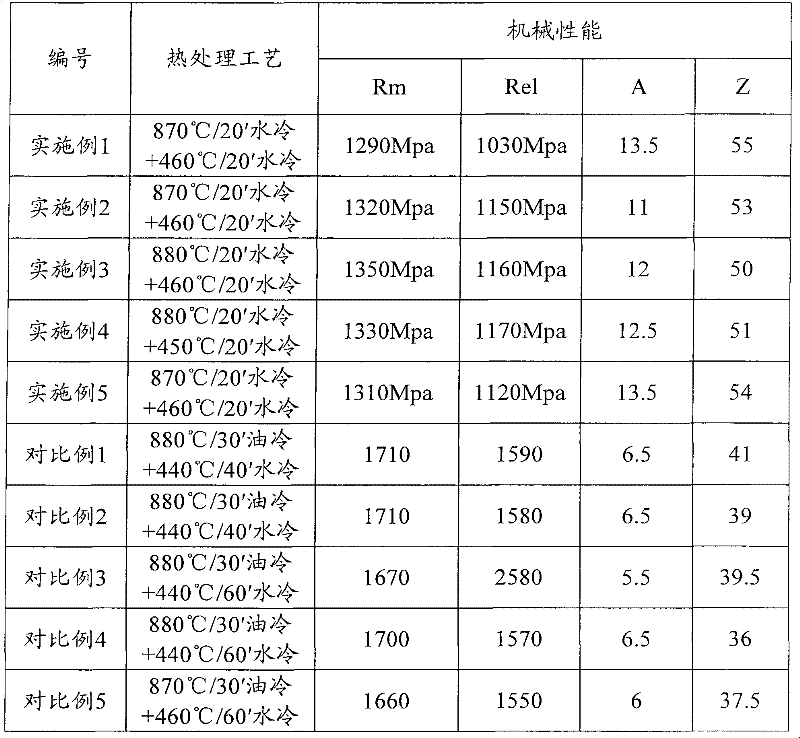

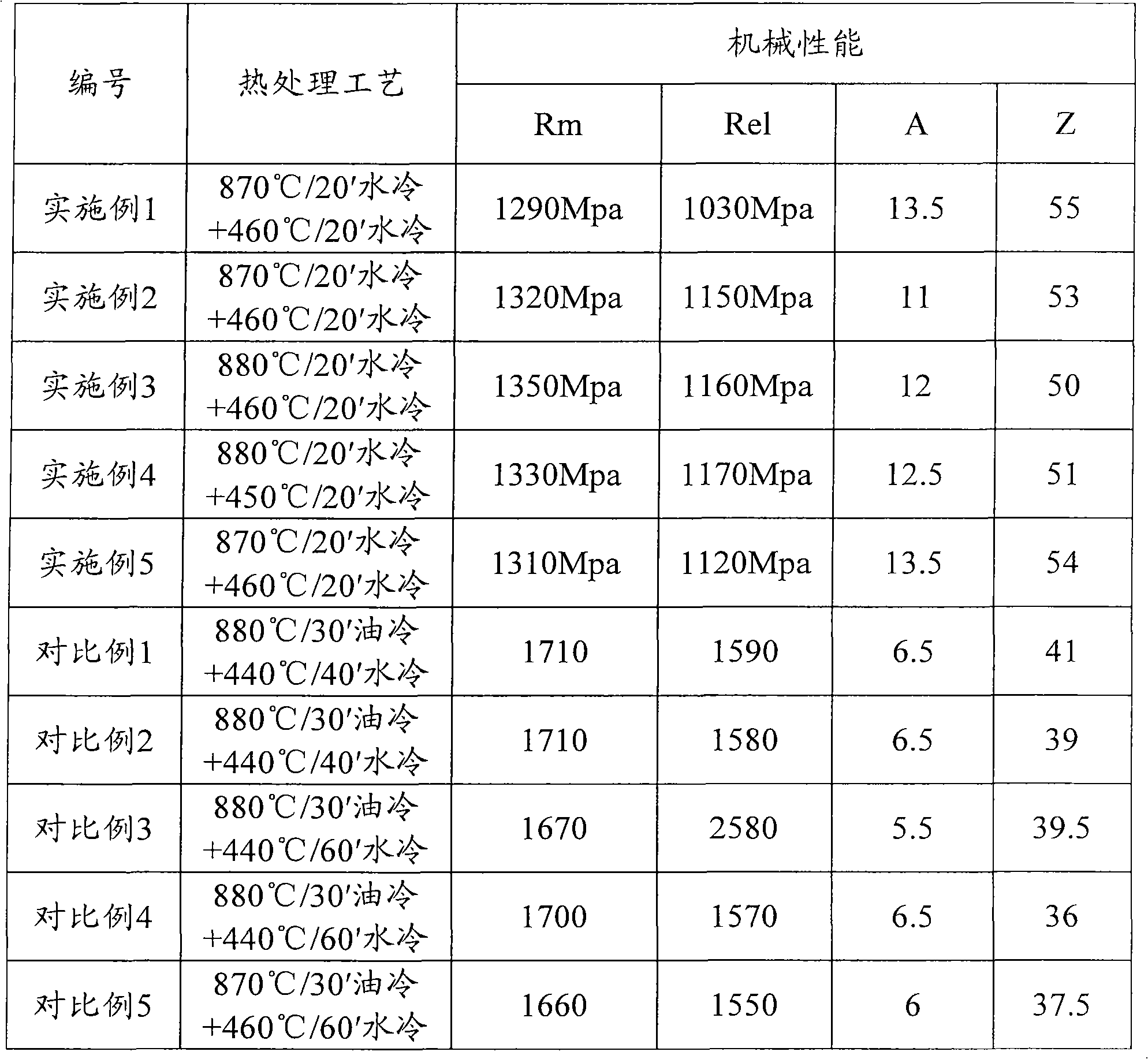

Spring steel and manufacturing and thermal treatment method thereof

InactiveCN102162068AStrong cold forming abilityReduce processTemperature control deviceProcess efficiency improvementShrinkage rateSpring steel

The invention discloses a spring steel, which comprises the following components in percentage by mass: 0.3 to 0.5 percent of C, 1.0 to 2.5 percent of Si, 0.3 to 1.5 percent of Mn, 0.1 to 1.0 percent of Cr, 0.01 to 0.30 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.010 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities, wherein the spring steel can be manufactured into high-speed railway rail buckles by a processing method of cold forming. The invention also discloses a manufacturing and thermal treatment method of the spring steel. By the method, the yield strength (Rm) of the spring steel is more than or equal to 1,000MPa, the tensile strength (Rp0.2) is more than or equal to 1,200MPa, the elongationrate (A) is more than or equal to 6 percent, the section shrinkage rate (Z) is more than or equal to 30 percent, and the buckle requirements of high-speed railway rails are met.

Owner:宝钢特钢有限公司

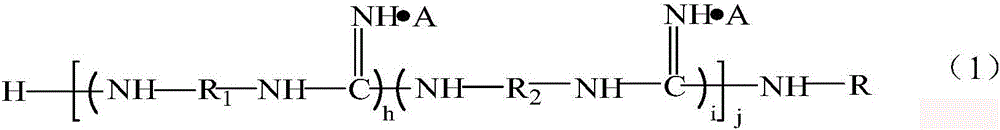

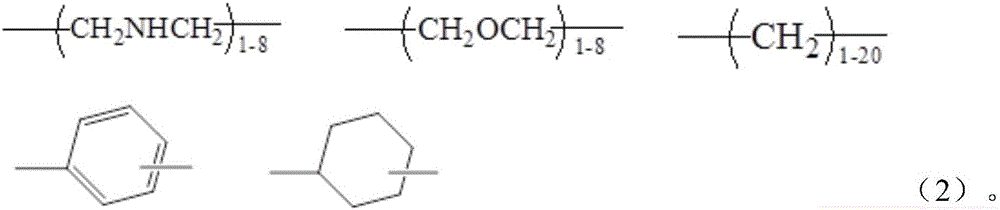

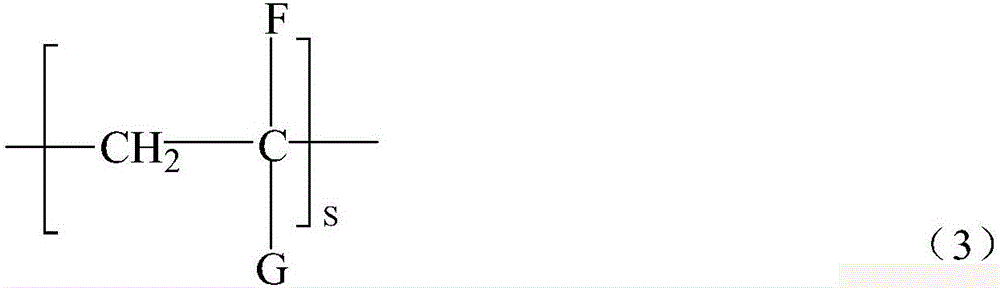

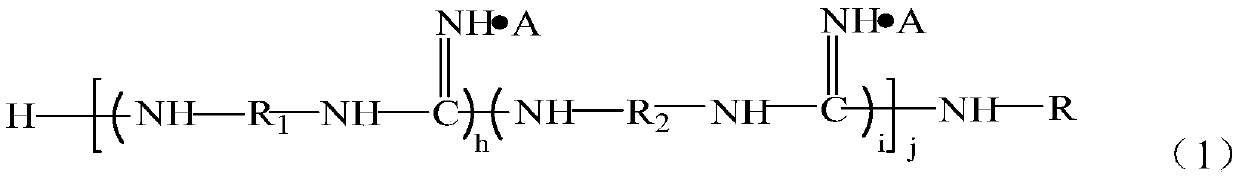

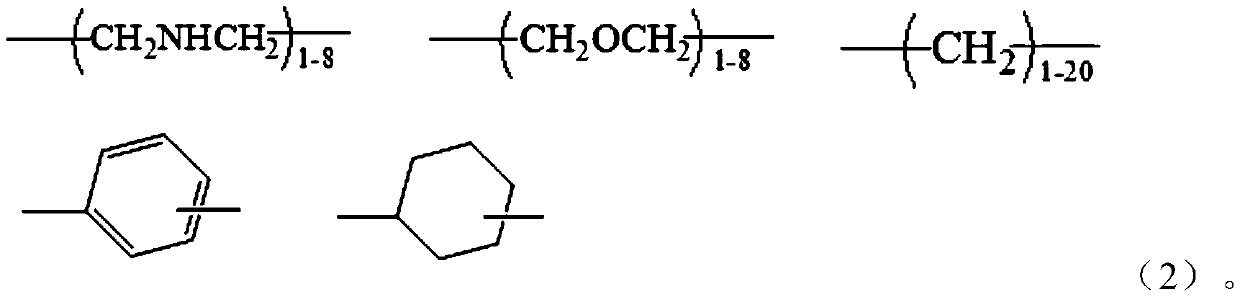

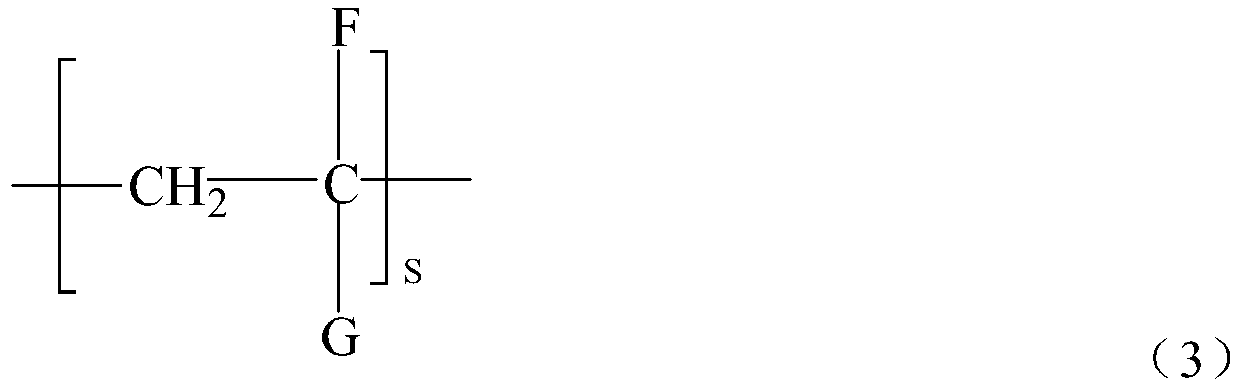

Guanidine oligomer, preparation method thereof, and application thereof by being bonded in general polymer molecular chain

The invention relates to a guanidine oligomer, a preparation method thereof, and application thereof by being bonded in a general polymer molecular chain. Compared with the prior art, the guanidine oligomer disclosed by the invention adopts a non-polar long-chain aliphatic R-group structure to terminate so as to obtain a new guanidine oligomer with R being a -(CH2)4-18CH3 terminated structure, and two very favorable results are obtained. First, due to the termination of the R group, original 4 degrees of functionality are reduced to 2 degrees of functionality, during bonding reaction with a polymer, no cross-linked structure is formed, a drape structure on a molecular chain is formed, and thereby dispersion on the surface of a material is faciliated; moreover, because of the non-polar long-chain aliphatic R-group structure, dispersion on the surface in non-polar polyolefin is easy, so that the molecular chain of the guanidine oligomer is pulled to tend to the surface, and functional effects can be realized. The guanidine oligomer can be widely used in the fields of general high and low molecular weight polyolefins and general condensed polymers, so that the general high and low molecular weight polyolefins and the general condensed polymers have anti-static, easy to dye, and anti-harmful microbial functions.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

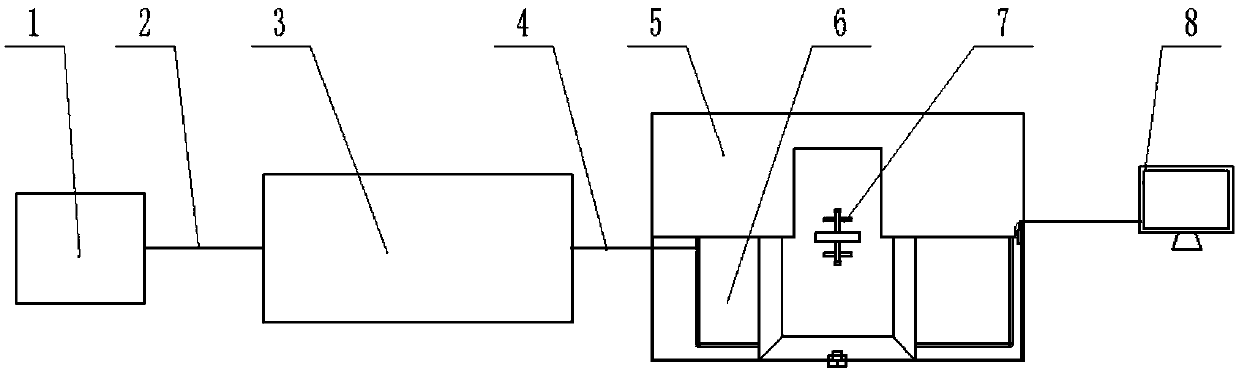

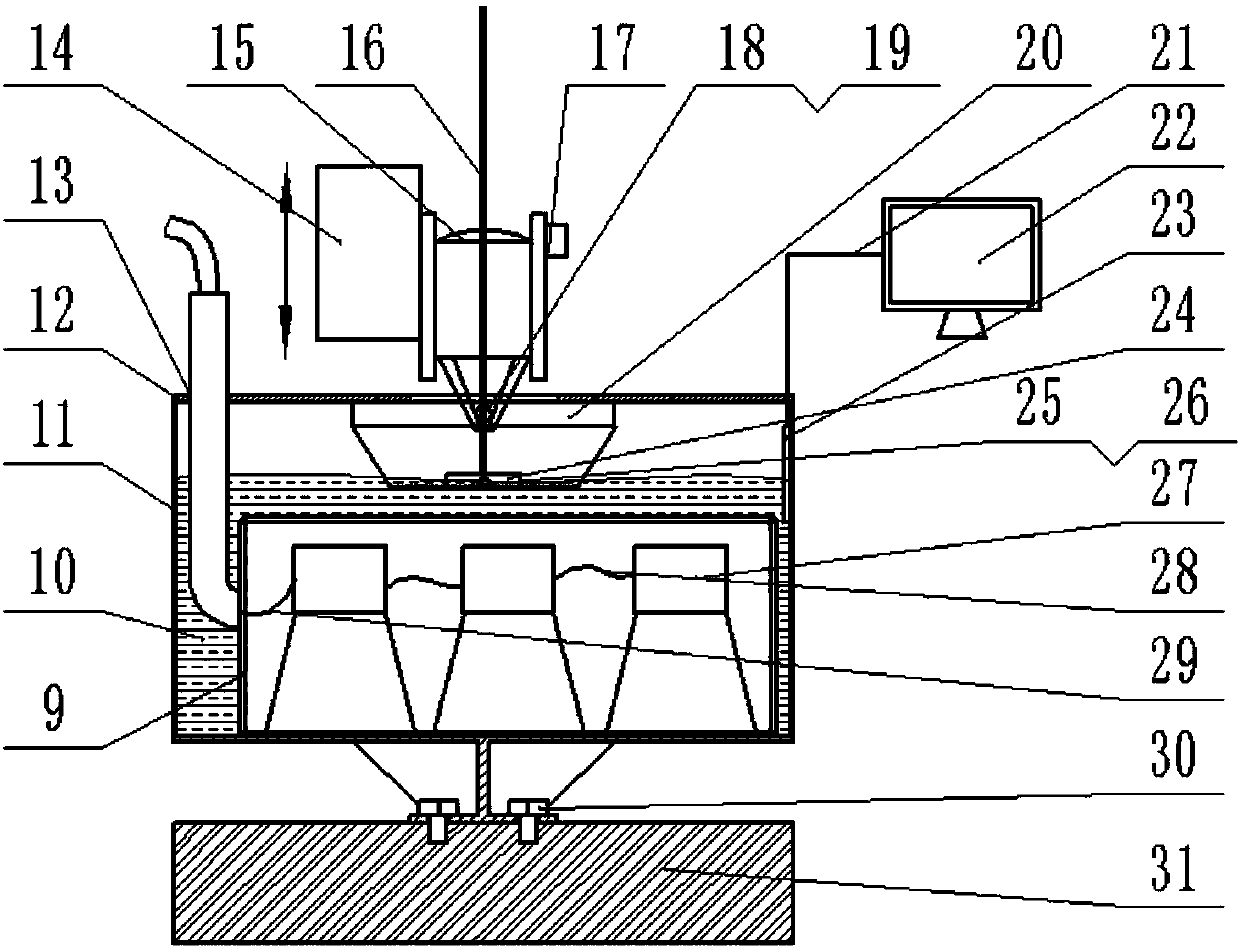

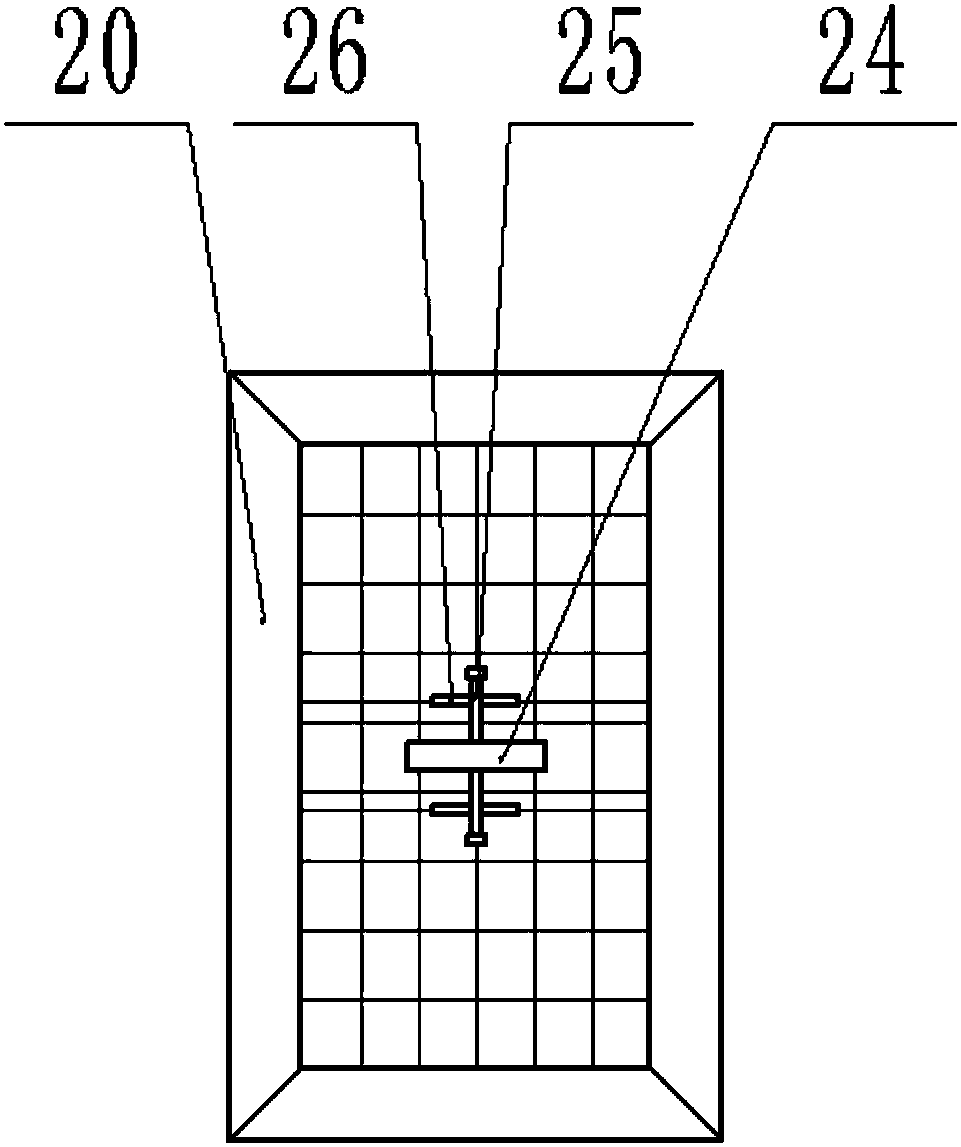

Ultrasonic vibration assistance laser boring method and device

PendingCN107790897AEasy dischargeGood removal effectLaser beam welding apparatusSlagUltrasonic vibration

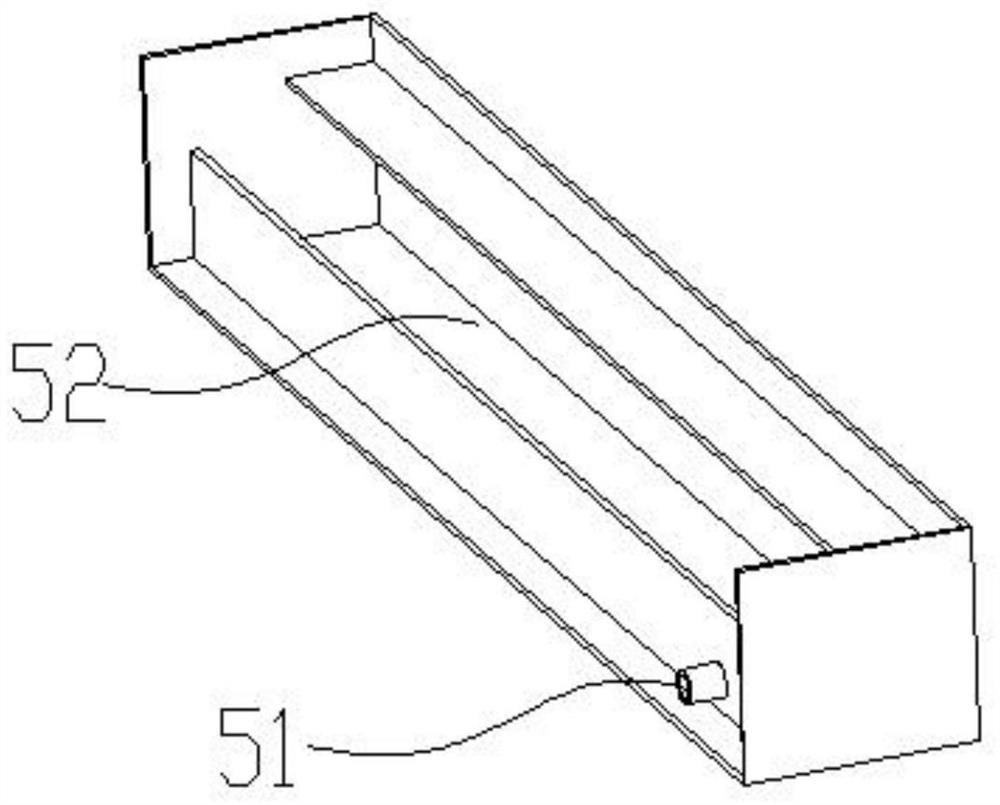

The invention provides an ultrasonic vibration assistance laser boring method and device. The device comprises a power source, an ultrasonic generator, an ultrasonic vibration auxiliary device clamping unit, an ultrasonic vibration generation unit, a workpiece clamping unit and a laser generation unit; the power source is connected with the ultrasonic generator through a first electric wire, the ultrasonic generator is connected with the ultrasonic vibration generation unit through a second electric wire, a workpiece is mounted on the workpiece clamping unit, and when laser boring is carried out, ultrasonic vibration generated by the ultrasonic vibration generation unit can act on the workpiece in the direction perpendicular to the machining surface of the workpiece. A melting material ina hole can be discharged while laser boring is carried out, through the ultrasonic vibration assistance effect, removal of slag can be accelerated, the removal rate of the slag can be improved, the phenomenon that melt is solidified on the hole wall again to form a re-casting layer is reduced or avoided, meanwhile, ultrasonic vibration can obviously improve the hole wall surface quality, the laserboring quality can be improved, and the boring efficiency is improved.

Owner:JIANGSU UNIV

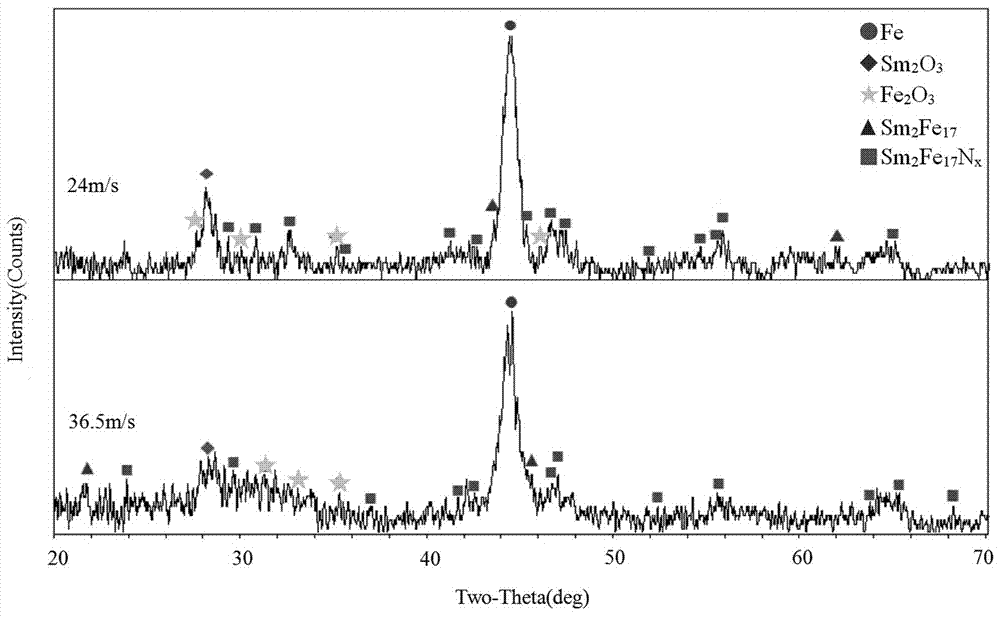

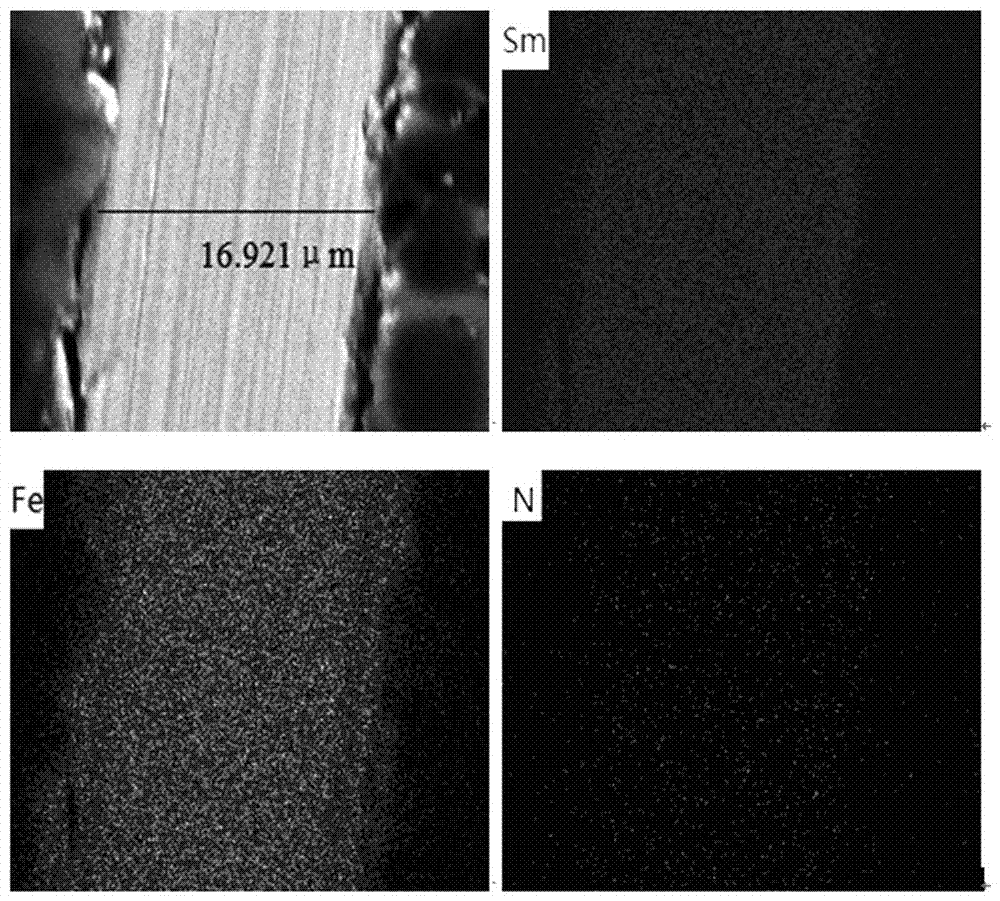

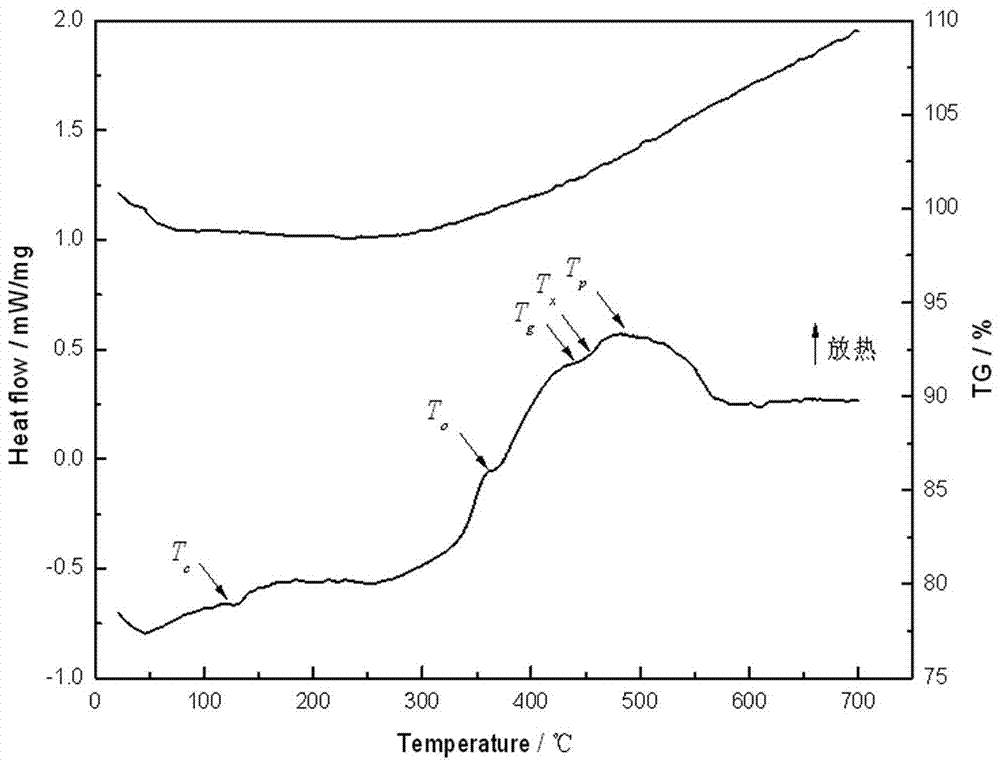

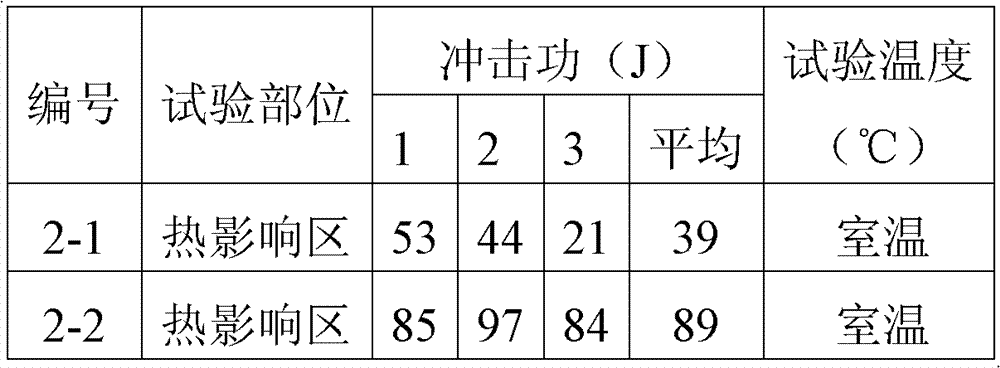

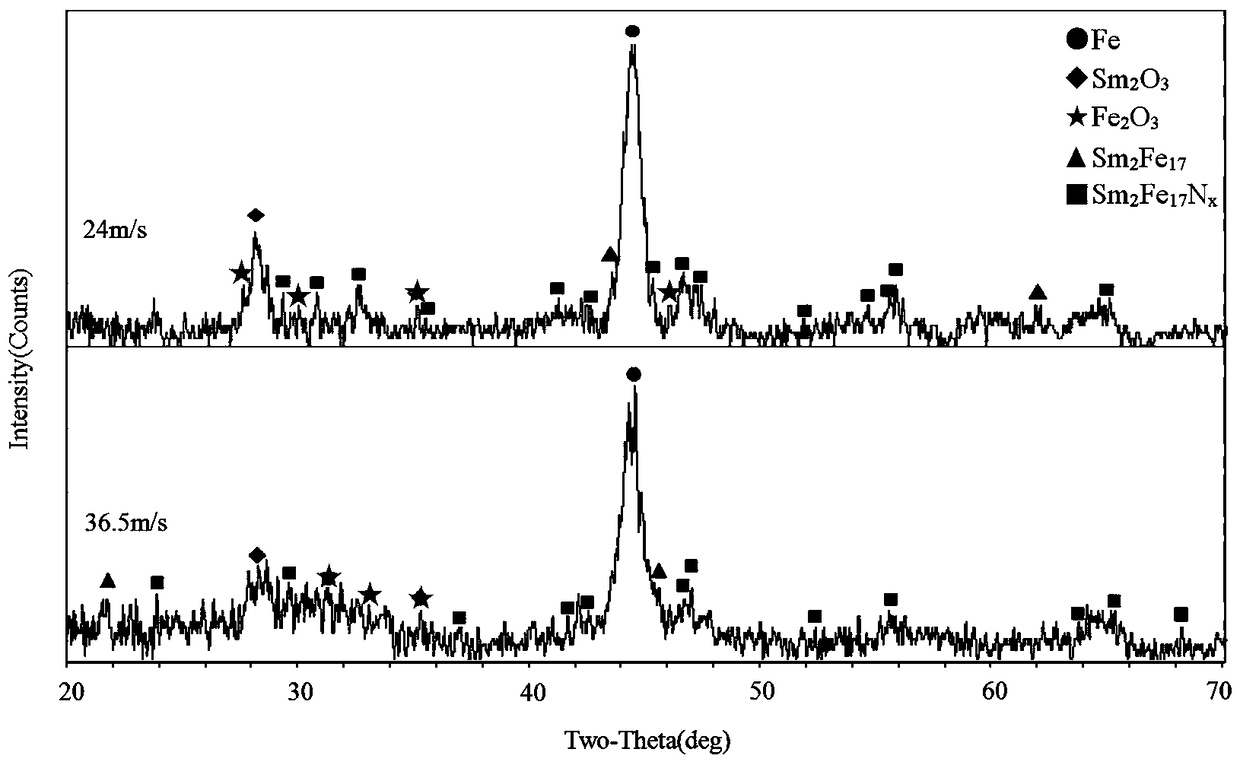

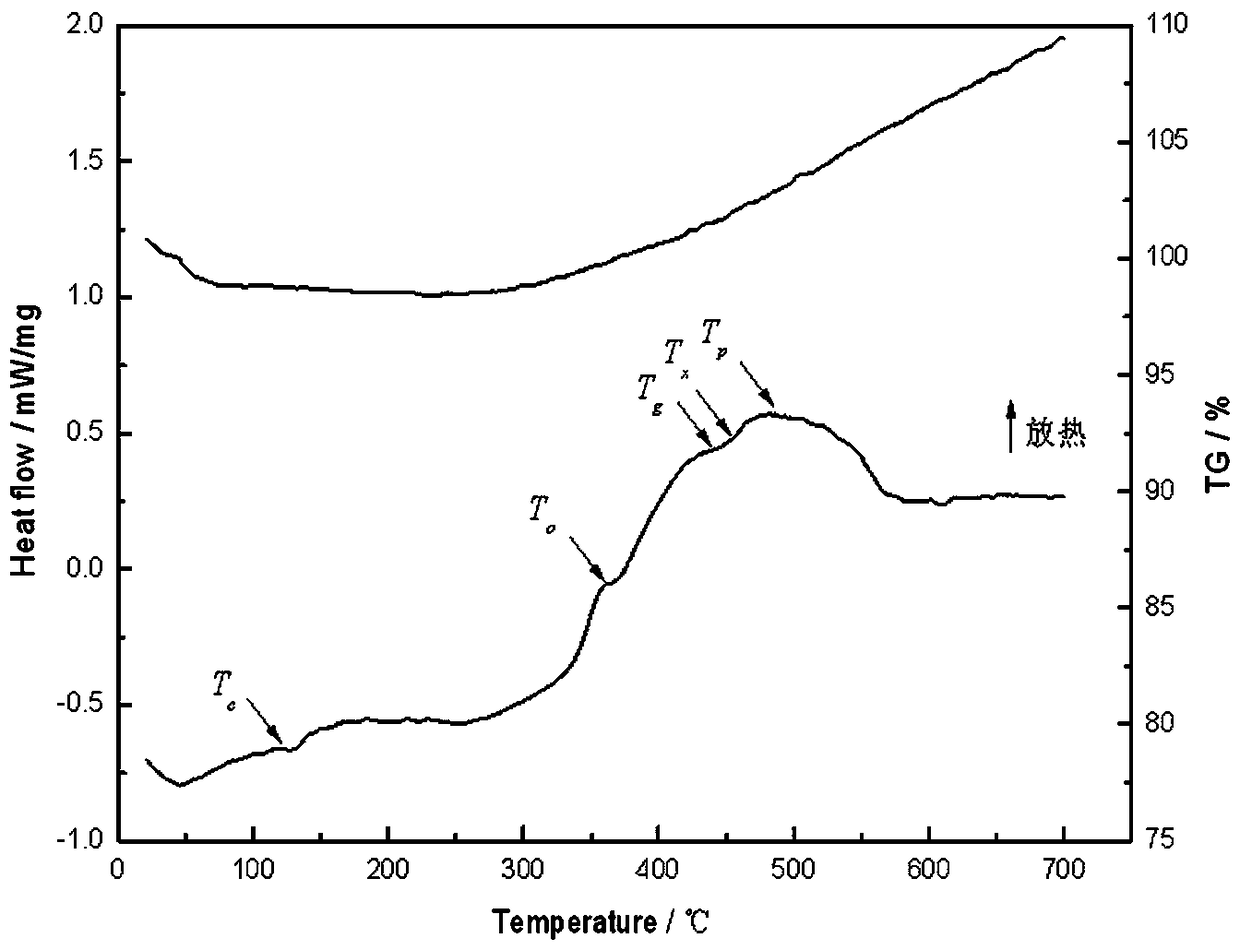

Method for nitridation and crystallization of metastable-state samarium-iron alloy

ActiveCN106960712AGood for spreading and homogenizingIncrease the amount of nitridingSolid state diffusion coatingInductances/transformers/magnets manufactureNitrogen atomMagnet

The invention provides a method for nitridation and crystallization of metastable-state samarium-iron alloy. The method comprises the steps of performing rapid cooling and sudden condensation on molten-state samarium-iron alloy to obtain the metastable-state samarium-iron alloy; performing nitridation and initial crystallization on the metastable-state samarium-iron alloy to obtain nitrided samarium-iron alloy; and performing annealing and crystallization on the nitrided samarium-iron alloy to obtain a samarium-iron nitrogen permanent-magnet material. During nitridation of a metastable-state material, a large amount of rheological units existing in the metastable-state alloy are beneficial for diffusion and homogenization of nitrogen atoms, the nitridation content of the alloy can be remarkably increased, and the nitrogen atoms are uniformly distributed; crystallization is completed before decomposition of Sm<2>Fe<17>N<x>, nitride formation is reduced or prevented, and the metastable-state samarium-iron alloy has a refined microstructure; and moreover, according to the method provided by the invention, the nitridation speed is fast, and the nitridation efficiency of improving a samarium-iron nitrogen magnetic material by the samarium-iron alloy is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Spring steel and manufacturing and thermal treatment method thereof

InactiveCN102162068BGood strength-flexibilityImprove purityTemperature control deviceElectric furnaceCold formedShrinkage rate

The invention discloses a spring steel, which comprises the following components in percentage by mass: 0.3 to 0.5 percent of C, 1.0 to 2.5 percent of Si, 0.3 to 1.5 percent of Mn, 0.1 to 1.0 percent of Cr, 0.01 to 0.30 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.010 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities, wherein the spring steel can be manufactured into high-speed railway rail buckles by a processing method of cold forming. The invention also discloses a manufacturing and thermal treatment method of the spring steel. By the method, the yield strength (Rm) of the spring steel is more than or equal to 1,000MPa, the tensile strength (Rp0.2) is more than or equal to 1,200MPa, the elongationrate (A) is more than or equal to 6 percent, the section shrinkage rate (Z) is more than or equal to 30 percent, and the buckle requirements of high-speed railway rails are met.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

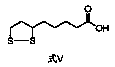

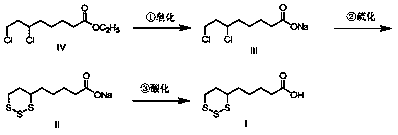

Preparation method of lipoic acid process impurity

The invention relates to a preparation method of a lipoic acid process impurity namely 1,2,3-trithiocyclohexane-4-valeric acid, and belongs to the technical field of preparation of lipoic acid impurities. The preparation method comprises the following steps: carrying out saponification, vulcanization cyclization, acidification, and refining on a lipoic acid intermediate namely 6,8-dichloroethyl caprylate to obtain the product. The preparation method is simple in process, and high in operability and the product is easy to purify.

Owner:JIANGSU TOHOPE PHARMA

Preparation method of samarium-iron-nitrogen series permanent magnet material

ActiveCN107557551AIncrease the amount of nitridingImprove uniformitySolid state diffusion coatingMagnetic materialsDecompositionShear band

The invention discloses a preparation method of a samarium-iron-nitrogen series permanent magnet material. The method comprises the steps that metastable state samarium-iron alloy is subjected to severe plastic deformation and then is subjected to nitrogen treatment and annealing crystallization treatment, and therefore the samarium-iron-nitrogen series permanent magnet material can be obtained. In the method, when the deformed samarium-iron-nitrogen series permanent magnet material is subjected to nitrogen treatment, since the free volume 'defect' content in the metastable state alloy can beincreased through multiple shear bands produced in the severe plastic deformation process, entering and diffusion of nitrogen atoms are facilitated, and the nitriding amount and nitriding uniformity of the alloy can be remarkably improved; since the multiple shear bands are produced through the severe plastic deformation, the follow-up crystallization annealing temperature can also be reduced, andnitride is reduced or prevented from being produced; and generation of the metastable phase is restrained, grains are refined, and coercive force is improved. By means of the method, the nitriding speed can be improved, the nitriding temperature can be reduced, decomposition of a samarium-iron-nitrogen compound is restrained, the microstructure is refined, and the nitriding efficiency of samarium-iron alloy for preparing the samarium-iron-nitrogen magnetic material is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

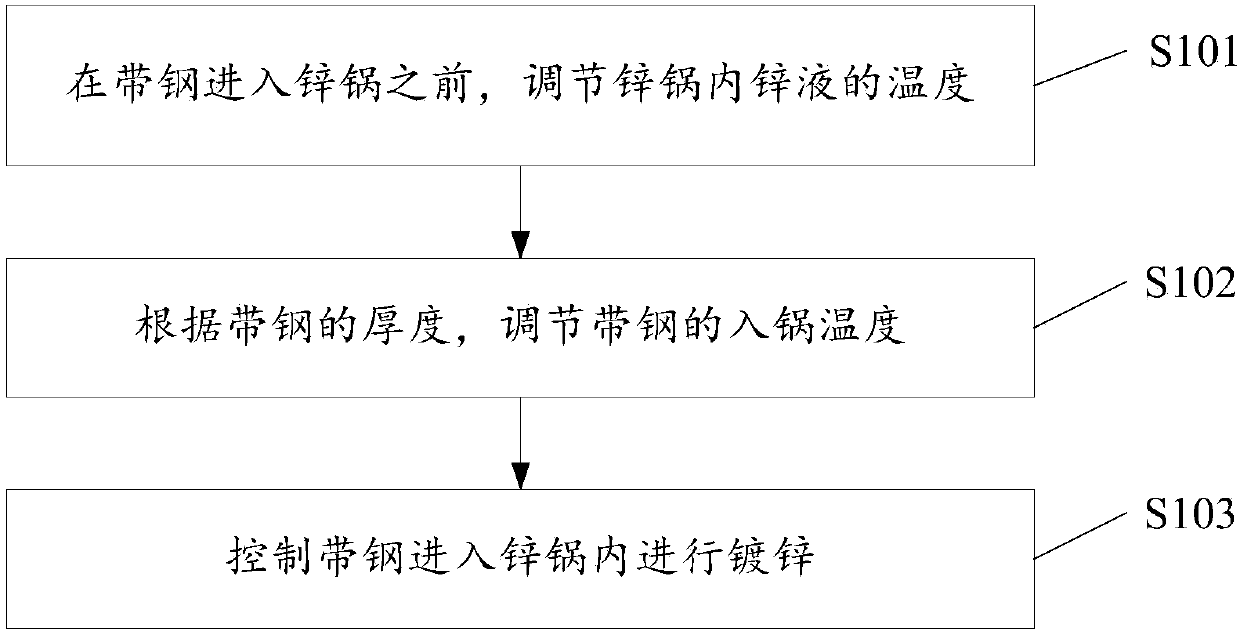

Method for preventing zinc flow lines from appearing in surface of galvanized strip steel

The invention discloses a method for preventing zinc flow lines from appearing in the surface of galvanized strip steel. The method comprises the steps that before strip steel enters a zinc pot, the temperature of zinc liquid in the zinc pot is adjusted; according to the thickness of the strip steel, the pot inlet temperature of the strip steel is adjusted; the strip steel is controlled to enter the zinc pot to be subject to galvanizing. According to the method for preventing zinc flow lines from appearing in surface of galvanized strip steel, the technical effects that the zinc flow lines areprevented from appearing in the surface of the galvanized strip steel, and the attractiveness of the galvanized strip steel is improved are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

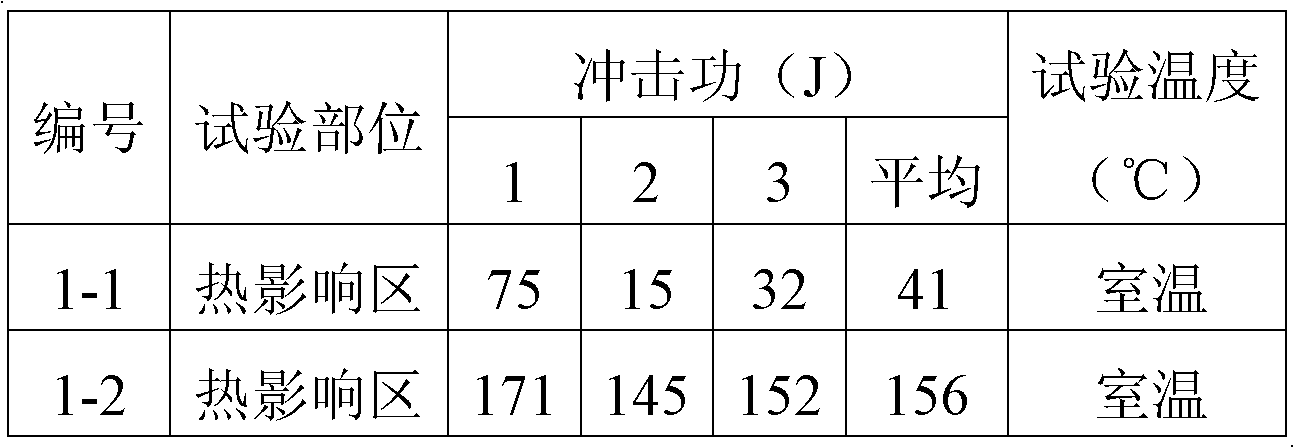

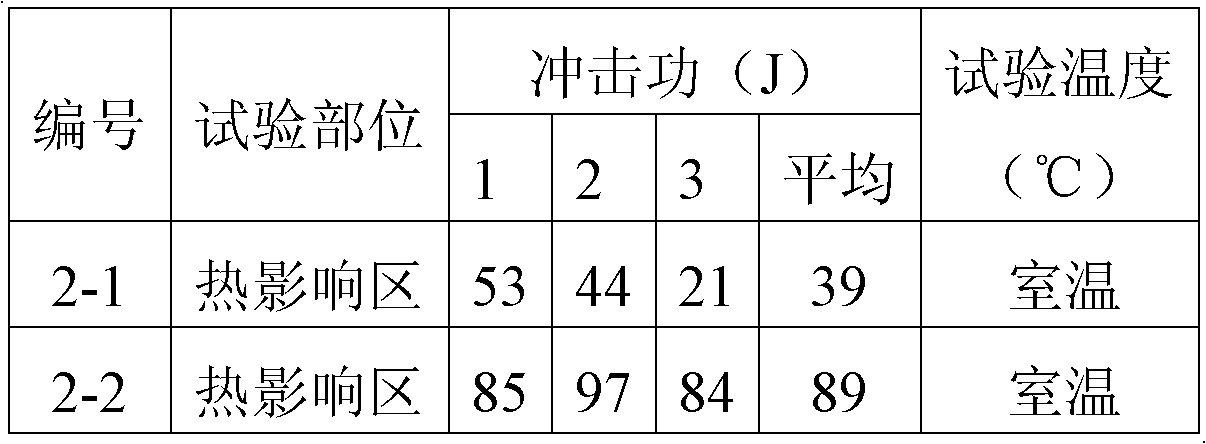

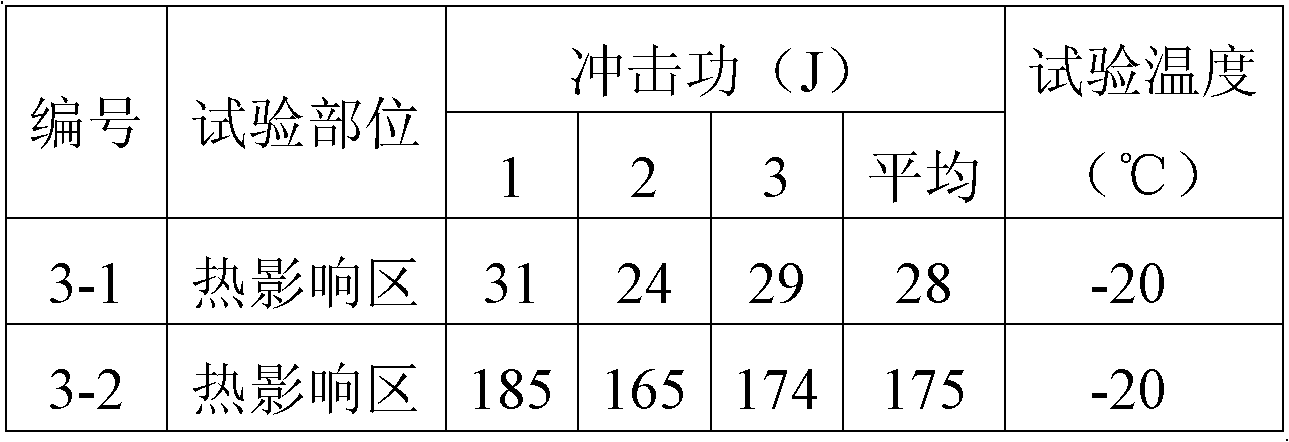

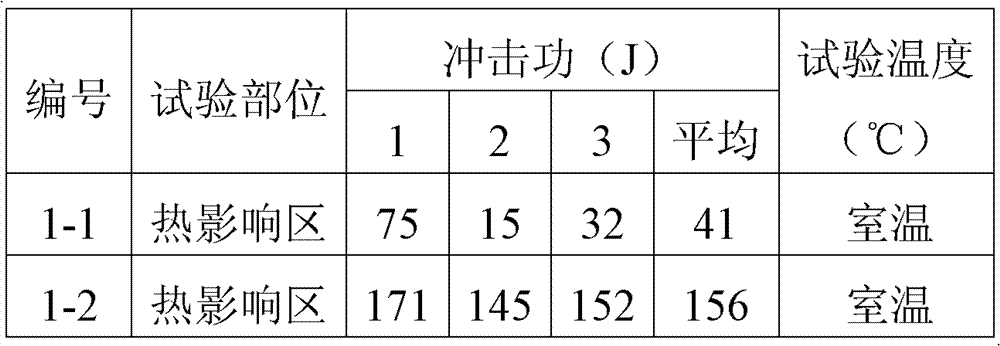

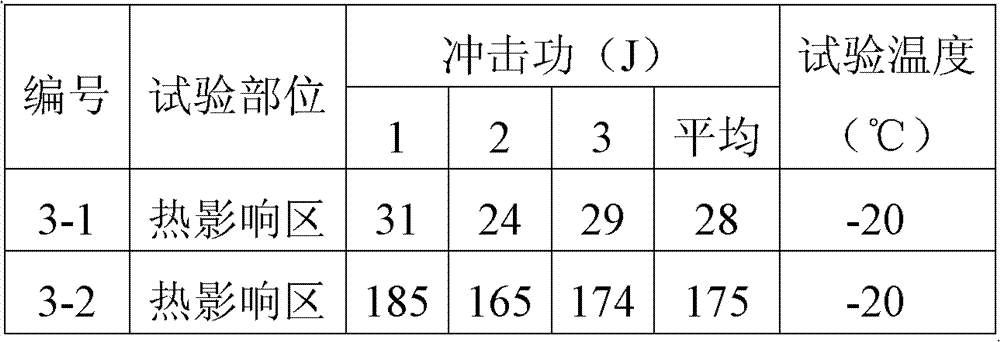

Online process for improving impact toughness of welding heat affected zone

InactiveCN102152012ARaise room temperatureImprove low temperature impact toughnessWelding apparatusEngineeringStreamflow

The invention relates to an online process for improving the impact toughness of a welding heat affected zone. The online process adopts the technical scheme that the compressed gas is directly blown at the position of a welding joint which is 20-1200 mm away from a welding electric arc in the welding process of a steel product; the blowing time is 2-120 s; and the distance between the position of the blown welding joint and the welding electric arc is kept unchanged and synchronously moves forwards along with the welding electric arc. The compressed gas is air, the pressure of the compressedgas is 0.5-3.0 MPa; the flow rate of the compressed gas is 5-30 L / min; the steel product is one of low carbon steel, medium carbon steel, low alloy steel, medium alloy steel and high alloy steel; andthe welding joint is one of welding points formed by welding methods of electric arc welding, submerged-arc welding, gas shielded welding and argon tungsten-arc welding. The online process has the characteristics that the online process is simple, is convenient to operate, has low cost and requires no additionally-arranged special equipment. With the adoption of the process, the impact toughness of the welding heat affected zone can be improved by 60-525 percent.

Owner:WUHAN UNIV OF SCI & TECH +1

Improved die casting forming method

The invention provides an improved die casting forming method. The improved die casting forming method comprises the following steps that S1, smelting is conducted, wherein an aluminum alloy materialis put into a heating furnace to be continuously heated to obtain molten liquid, then compressed argon or compressed nitrogen serves as a carrier, strengthening particles are evenly added into the molten liquid, slag is removed, and standing is conducted to obtain a first melt; S2, stirring is conducted, wherein the first melt is stirred electromagnetically to obtain a cast ingot; S3, smelting isconducted again, wherein the cast ingot is cut into blanks and re-heated to obtain a second melt; S4, mold treatment is conducted, wherein a mold is preheated and subjected to heat preservation for 1h; S5, die casting is conducted, wherein the second melt is transferred into a holding furnace of a low-pressure casting machine for heat preservation, then the second melt is die-cast into a mold cavity under the low-pressure condition, and a die casting is obtained; and S6, heat treatment is conducted, wherein the obtained die casting is subjected to a heat treatment process including solution treatment and incomplete artificial aging. An aluminum alloy product obtained through the method is compact in structure, good in comprehensive mechanical property and physicochemical property, high inmaterial utilization rate and low in cost.

Owner:GUANGDONG HONGTEO ACCURATE TECH (TAISHAN) CO LTD

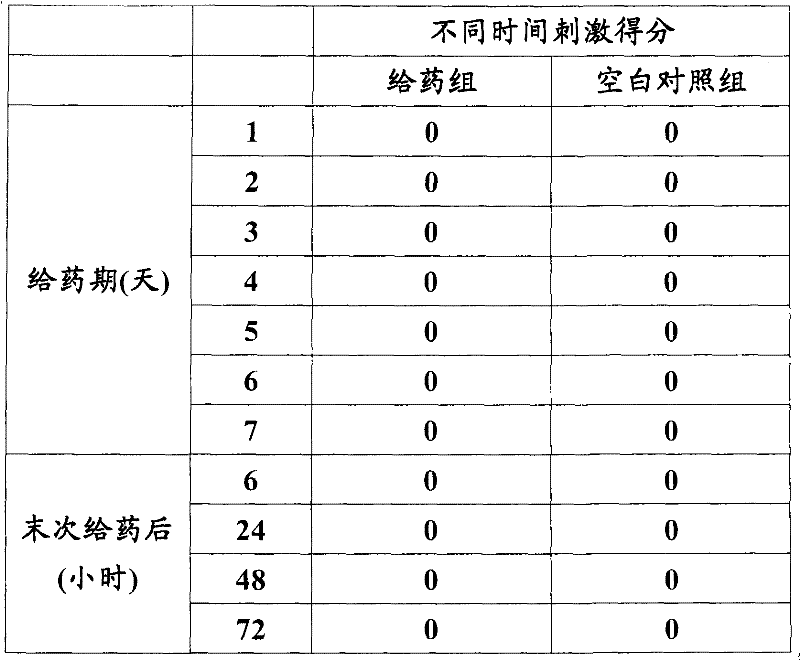

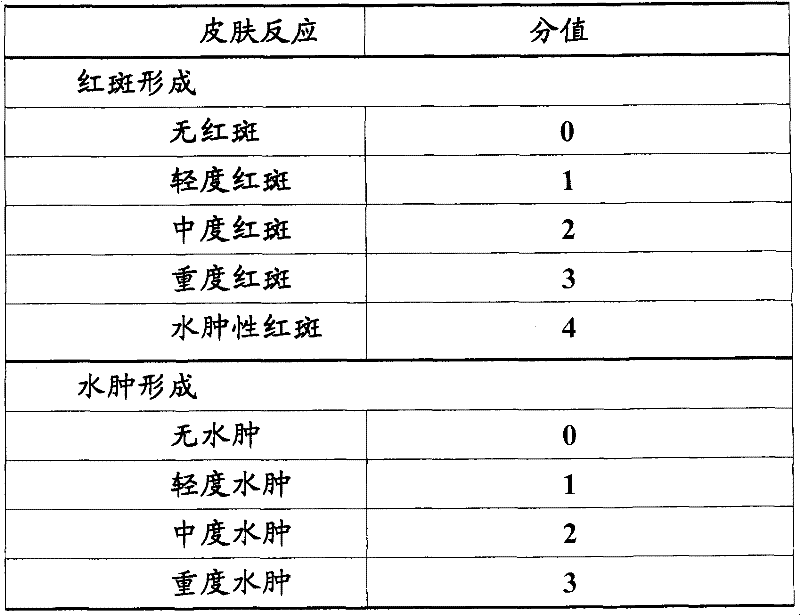

Eye drop of deproteinized calf blood extractive

ActiveCN101780105AImprove surface activityImprove utilizationSenses disorderHydroxy compound active ingredientsEffective treatmentConjunctival lesion

The invention provides an eye drop, which comprises an effective treatment amount of deproteinized calf blood extractive, chitosan and water. The eye drop of the invention is stable and can be used for curing keratonosus, conjunctival lesion and dry eye syndrome.

Owner:SHENYANG XINGQI PHARM CO LTD

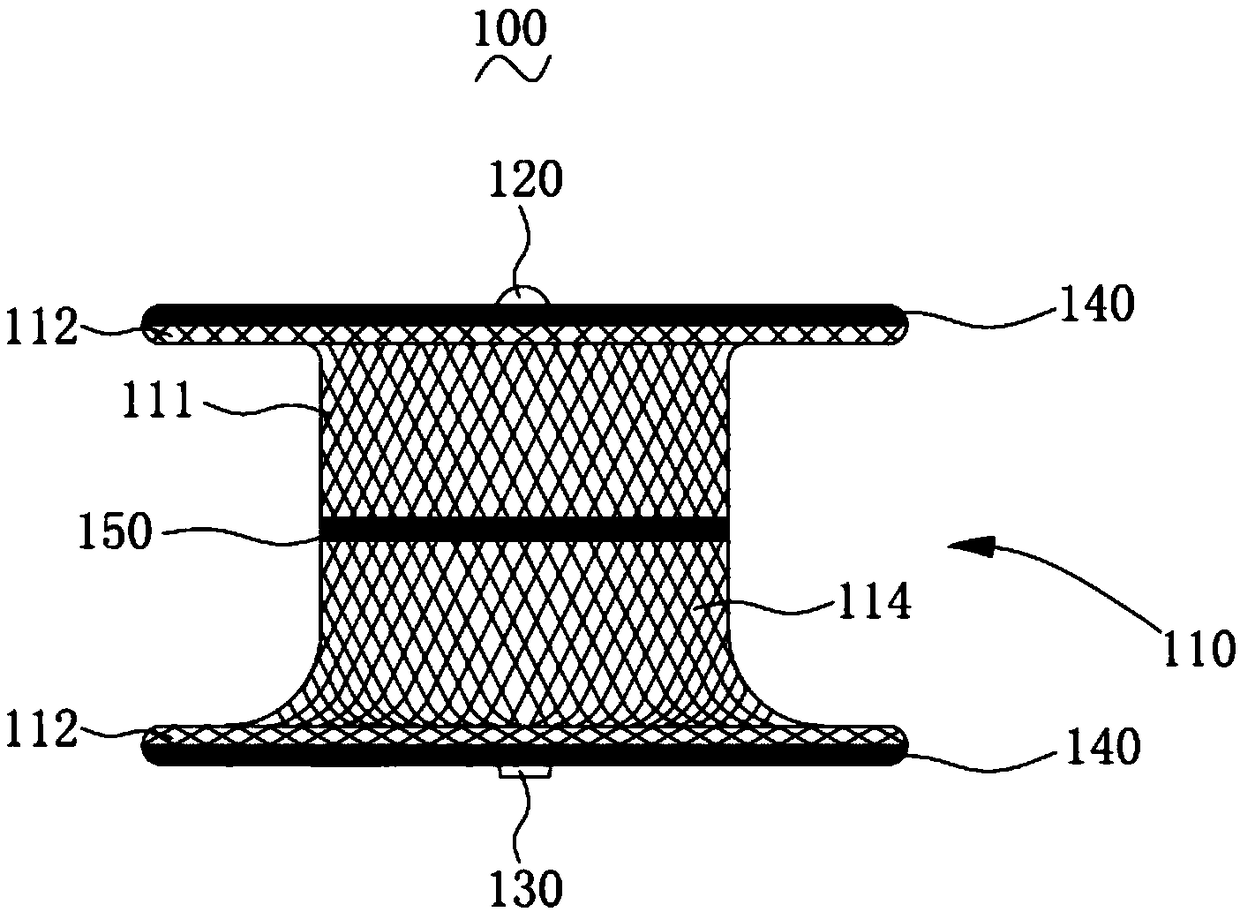

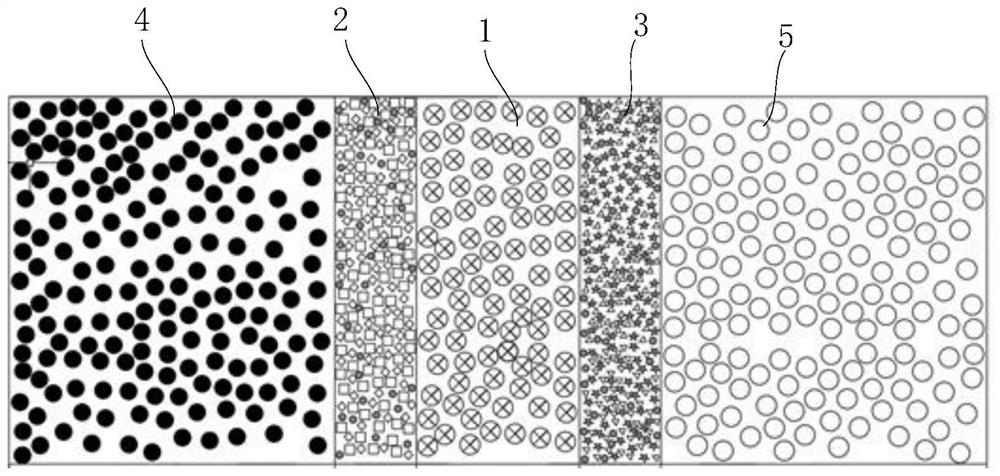

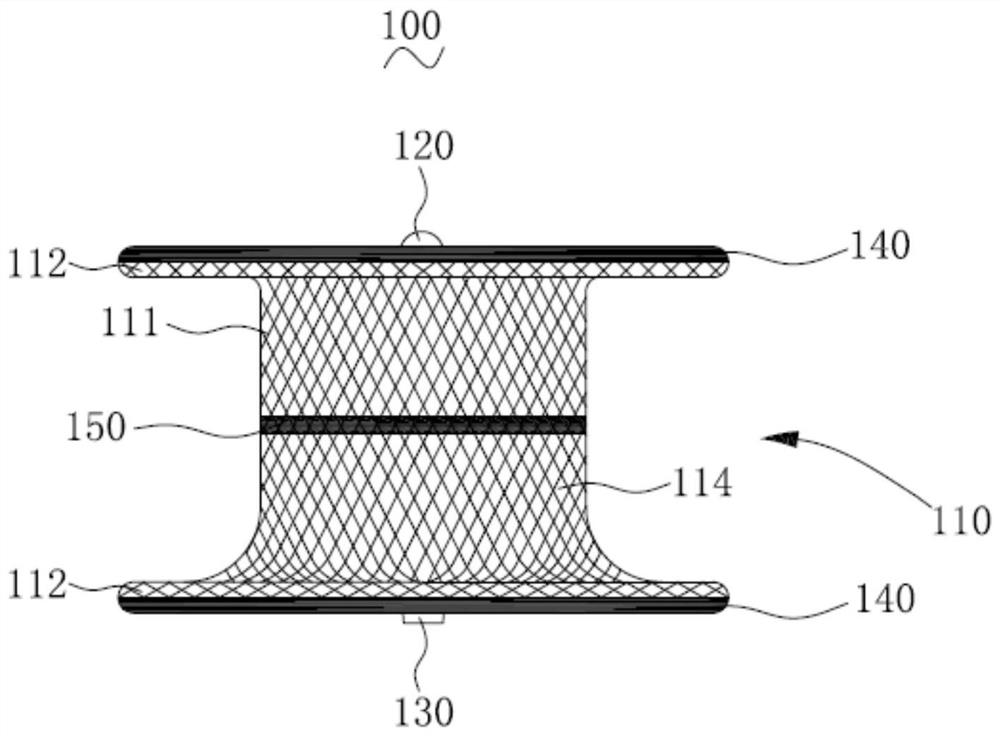

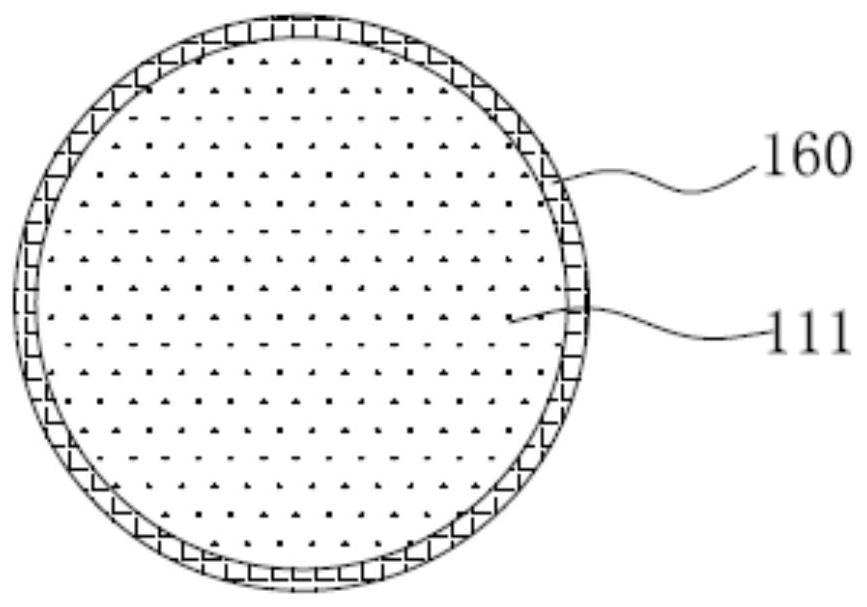

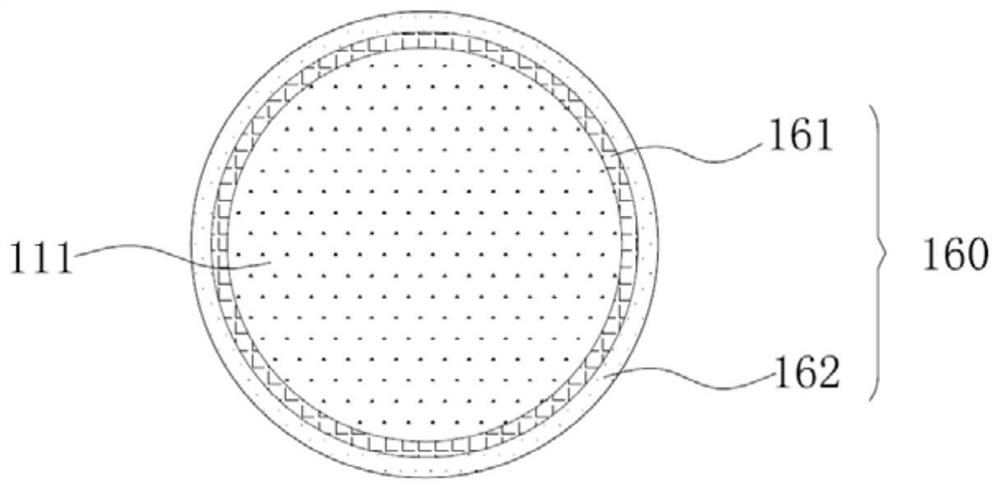

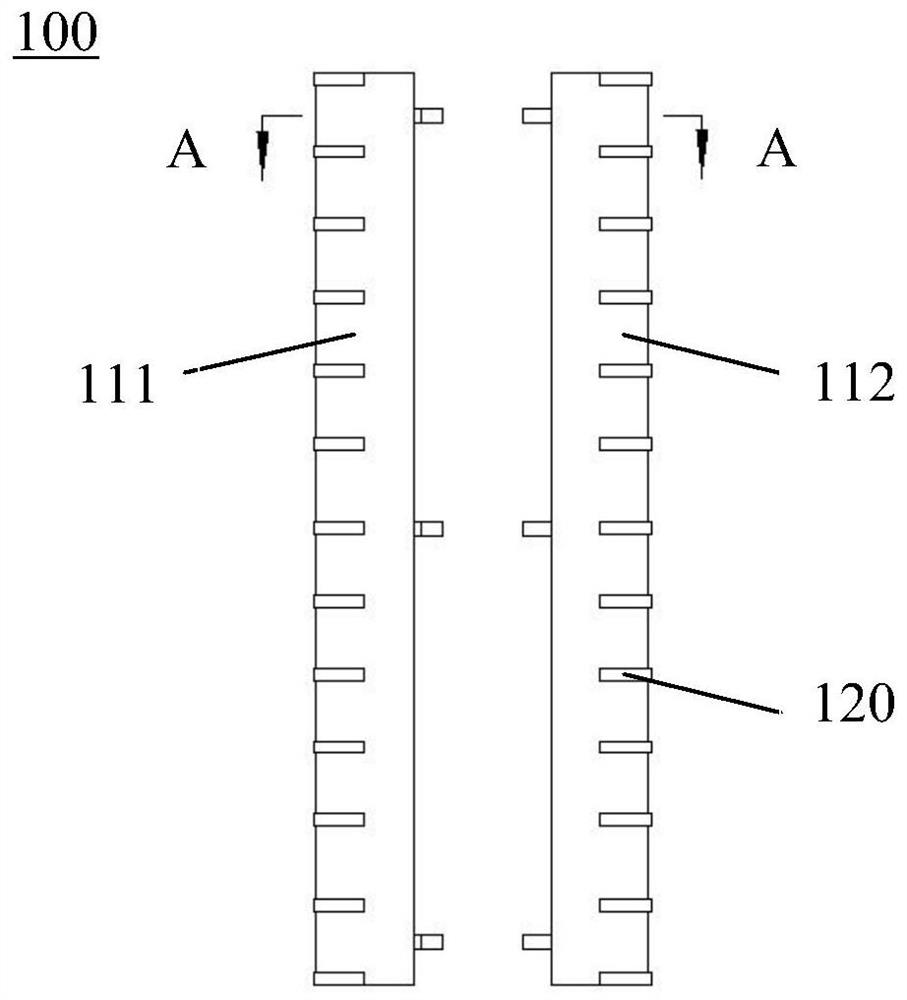

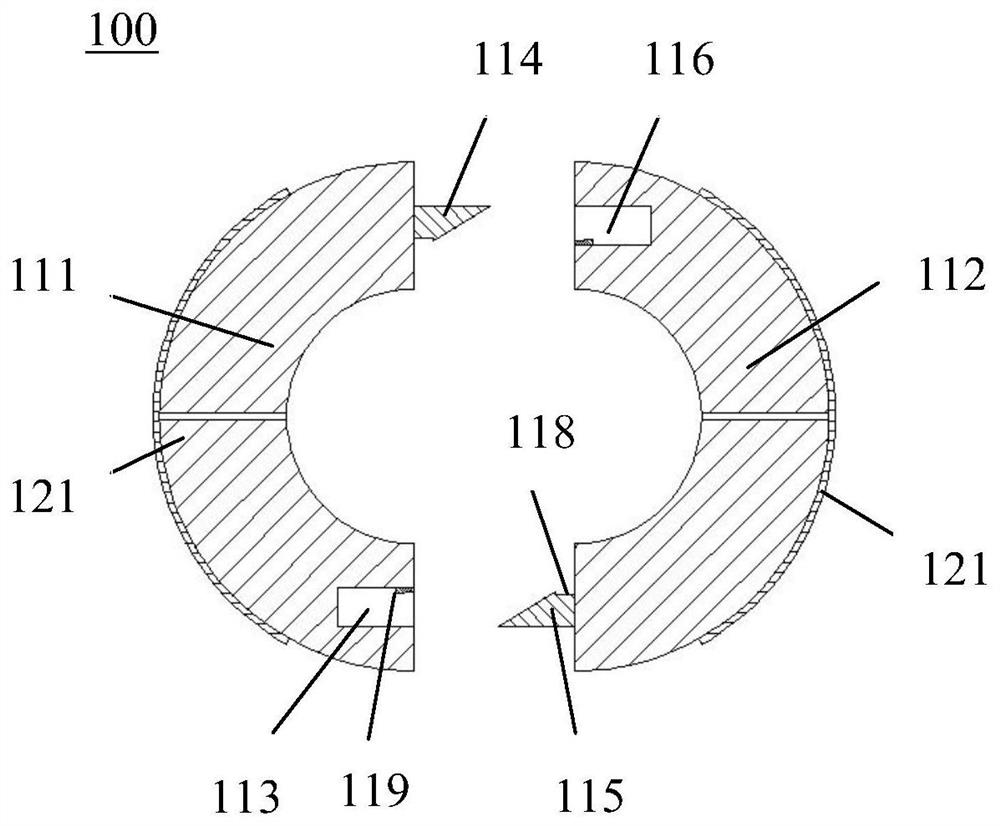

Plugging device and preparation method thereof

ActiveCN109464167ARapid endothelializationReduce or avoid the formation ofSurgeryControl releaseThrombus

The invention relates to a plugging device and a preparation method thereof. The plugging device comprises a supporting net. The surface of the supporting net is coated with an anti-thrombus membrane,and the anti-thrombus membrane comprises an endothelialization promoting membrane. The endothelialization prompting membrane comprises a degradable polymer and endothelialization promoting matter dispersed in the degradable polymer. Or the endothelialization prompting membrane comprises the endothelialization promoting matter. The anti-thrombus membrane further comprises a controlled release membrane covering the endothelialization promoting membrane. The controlled release membrane comprises the degradable polymer. By means of the plugging device, thrombosis can be reduced or avoided.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

Dish-washing machine exhaust system and dish-washing machine

PendingCN112704458AFully condensedReasonable designTableware washing/rinsing machine detailsThermodynamicsWater vapor

The invention relates to a dish-washing machine exhaust system, which comprises a first air duct, a second air duct and an air extractor, one end of the first air duct is connected with an inner container of a dish-washing machine, the other end of the first air duct is connected with the air extractor, and a water box used for containing water is arranged in a skirting board area of the dish-washing machine and provided with an air inlet part and an air outlet part. The other end of the second air duct is connected with the air inlet part. According to the dish-washing machine exhaust system, high-temperature water vapor exhausted in the drying stage is subjected to water bath through the water box, the water vapor is fully condensed, the exhaust temperature and humidity are reduced, exposed condensate water is reduced or prevented from being formed in the follow-up exhaust process, and meanwhile the water box is reasonable in design and convenient for a user to disassemble and assemble.

Owner:VATTI CORP LTD

Guanidine oligomer and its preparation method and its application bonded to general polymer molecular chains

A guanidine oligomer, a method for preparing same, and an application of the guanidine oligomer for being bonded to a molecular chain of a universal polymer. Compared with the prior art, a non-polar long-chain aliphatic R group structure is used for end-capping to obtain a guanidine oligomer end-capped with R which is -(CH2)4-18CH3. There are two extremely favorable results for doing this. First, due to the end-capping with the R group, the original tetrafunctionality is reduced to bifunctionality; during a bonding reaction with a polymer, no cross-linked structure would be formed, but an overhanging structure on a molecular chain is formed; and this is favorable for dispersion on the surface of a material. Moreover, due to the non-polar long-chain aliphatic R group structure, it is easy to achieve distribution on the surface in a non-polar polyolefin, so as to pull the molecular chain of the guanidine oligomer toward the surface and exerting its functionalization. The guanidine oligomer can be widely used in the fields of universal high / low molecular weight polyolefins and universal condensation polymers, and make the universal high / low molecular weight polyolefins and universal condensation polymers antistatic, easy to dye, and resistant to harmful microorganisms.

Owner:SHANGHAI FUYUAN PLASTICS SCI CO LTD

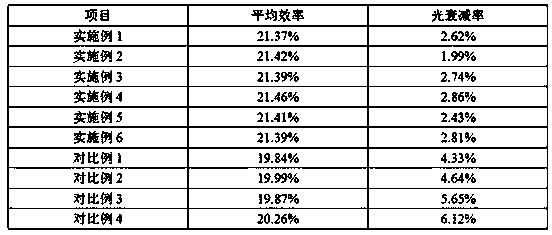

Light attenuation resistant PERC single crystalline silicon solar cell aluminum paste and preparation method thereof

ActiveCN108877989AReduce or avoid the formation ofIncrease the doping concentrationNon-conductive material with dispersed conductive materialCable/conductor manufactureAluminium powderSilicon solar cell

The invention discloses a light attenuation resistant PERC single crystalline silicon solar cell aluminum paste. The aluminum paste is prepared from the following components in parts by weight: 70 to86 parts of aluminum powder, 0.5 to 2.5 parts of an inorganic binder, 10 to 24 parts of an organic binder and 0.1 to 1.5 parts of an inorganic auxiliary agent. The invention also discloses a preparation method of the aluminum paste. The preparation method comprises the following steps: firstly uniformly stirring the organic binder and the inorganic auxiliary agent, then adding the inorganic binderand the aluminum powder in sequence to be stirred uniformly, and finally grinding to obtain the aluminum paste. An PERC single crystalline silicon solar cell obtained by using the aluminum paste hasthe characteristics of high photovoltaic conversion efficiency and light attenuation resistance.

Owner:JIANGXI NUCLEAR IND XINGZHONG NEW MATERIALS

A kind of preparation method of samarium-iron-nitrogen permanent magnet material

ActiveCN107557551BIncrease the amount of nitridingImprove uniformitySolid state diffusion coatingMagnetic materialsDecompositionStrontium

The invention discloses a preparation method of a samarium-iron-nitrogen series permanent magnet material. The method comprises the steps that metastable state samarium-iron alloy is subjected to severe plastic deformation and then is subjected to nitrogen treatment and annealing crystallization treatment, and therefore the samarium-iron-nitrogen series permanent magnet material can be obtained. In the method, when the deformed samarium-iron-nitrogen series permanent magnet material is subjected to nitrogen treatment, since the free volume 'defect' content in the metastable state alloy can beincreased through multiple shear bands produced in the severe plastic deformation process, entering and diffusion of nitrogen atoms are facilitated, and the nitriding amount and nitriding uniformity of the alloy can be remarkably improved; since the multiple shear bands are produced through the severe plastic deformation, the follow-up crystallization annealing temperature can also be reduced, andnitride is reduced or prevented from being produced; and generation of the metastable phase is restrained, grains are refined, and coercive force is improved. By means of the method, the nitriding speed can be improved, the nitriding temperature can be reduced, decomposition of a samarium-iron-nitrogen compound is restrained, the microstructure is refined, and the nitriding efficiency of samarium-iron alloy for preparing the samarium-iron-nitrogen magnetic material is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

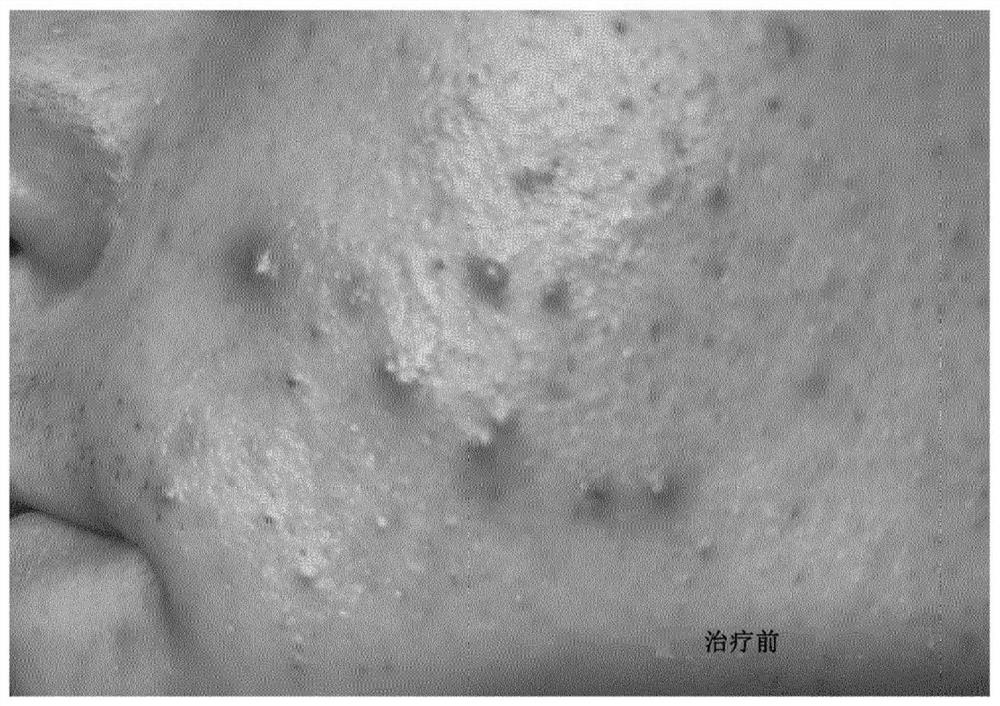

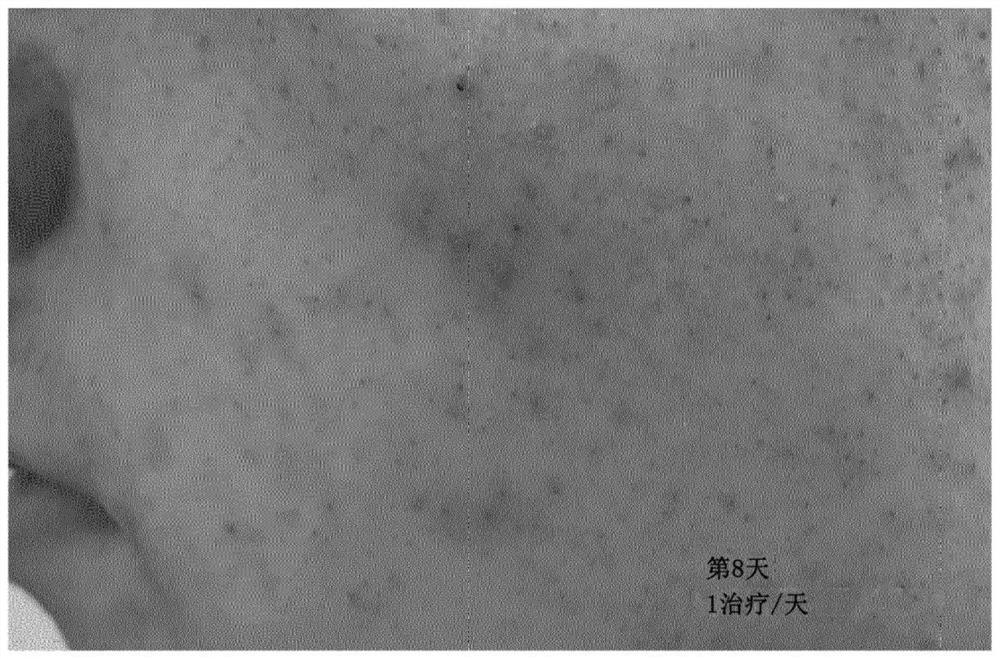

Composition for treatment, alleviation or prophylaxis of acne

PendingCN114040770AReduce or avoid attachmentReduce or avoid the formation ofPharmaceutical delivery mechanismUnknown materialsPathogenicityBiochemistry

Owner:莱托生物股份有限公司

Online process for improving impact toughness of welding heat affected zone

InactiveCN102152012BRaise room temperatureImprove low temperature impact toughnessWelding apparatusShielded metal arc weldingEngineering

Owner:WUHAN UNIV OF SCI & TECH +1

A method for nitriding crystallization of metastable samarium-iron alloy

ActiveCN106960712BFully annealedIncrease the amount of nitridingSolid state diffusion coatingInductances/transformers/magnets manufactureMolten stateFerroniobium

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Eye drop of deproteinized calf blood extractive

ActiveCN101780105BImprove surface activityImprove utilizationSenses disorderHydroxy compound active ingredientsConjunctival lesionEffective treatment

The invention provides an eye drop, which comprises an effective treatment amount of deproteinized calf blood extractive, chitosan and water. The eye drop of the invention is stable and can be used for curing keratonosus, conjunctival lesion and dry eye syndrome.

Owner:SHENYANG XINGQI PHARM CO LTD

A kind of metal sheet and its preparation method and application

ActiveCN112406215BHigh strengthEasy to makeCoatingsWelding/soldering/cutting articlesNiobiumCopper foil

The invention provides a metal sheet, which includes a copper foil layer, and a first adsorption layer and a second adsorption layer respectively attached on both sides of the copper foil layer; the first adsorption layer includes niobium, vanadium and zinc, and the second adsorption layer includes Chromium and zinc; wherein, the mass percentage of zinc in the first adsorption layer or the second adsorption layer is 5-15%; the mass ratio of niobium and vanadium in the first adsorption layer is 2.5-3.5:1. Also provided is a metal sheet preparation method, which respectively prepares metal slurries using niobium, vanadium, and zinc as metal powder raw materials, and chromium and zinc powder as metal powder raw materials; side surface. Also provided is a method of applying the metal sheet to the welding of titanium alloys and stainless steels. The metal sheet itself provided by the invention has high strength and reduces the cost; the preparation process is simple, and the welding quality is guaranteed. When applied to titanium alloy and stainless steel welding, it realizes layer-by-layer transition, which greatly improves the strength of welded joints.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Occluder and its preparation method

ActiveCN109464167BRapid endothelializationReduce or avoid the formation ofSurgeryThrombusBiomedical engineering

The invention relates to an occluder and a preparation method thereof. The occluder includes a supporting net, and the surface of the supporting net is coated with an antithrombotic film, and the antithrombotic film includes an endothelialization promoting film; the endothelializing promoting film contains a degradable polymer and an endothelializing substance dispersed in the degradable polymer. Alternatively, the endothelialization-promoting membrane contains endothelialization-promoting substances, and the antithrombotic membrane further includes a controlled-release membrane covering the endothelialization-promoting membrane, and the controlled-release membrane contains degradable polymers. The occluder can reduce or avoid thrombus formation.

Owner:LIFETECH SCI (SHENZHEN) CO LTD

Air conditioner indoor unit

PendingCN113685903AImprove air treatment effectSimple structureLighting and heating apparatusAir conditioning systemsAir treatmentEnvironmental engineering

The invention provides an air conditioner indoor unit. The air conditioner indoor unit comprises a shell, an airflow actuating device and an air treatment device; the shell is provided with an air return opening, an air outlet and an air treatment channel located between the air return opening and the air outlet; the airflow actuating device is arranged in the air treatment channel and is configured to promote indoor environment air to flow into the air treatment channel from the air return opening to form treatment airflow, and the treatment airflow is blown out from the air outlet after being treated; and the air treatment device is arranged in the air treatment channel and comprises a body part made of an MOF material, and the body part is configured to adsorb specific substance components in the treatment airflow flowing through the surface and / or the interior of the body part. According to the air conditioner indoor unit, the body part made of the MOF material can adsorb multiple substance components, and therefore multiple harmful substance components in the indoor environment air can be absorbed only by arranging the body part in the air conditioner indoor unit, the air treatment capacity of the air conditioner indoor unit can be improved easily, the structure of the air conditioner indoor unit can be simplified, and the manufacturing cost is saved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

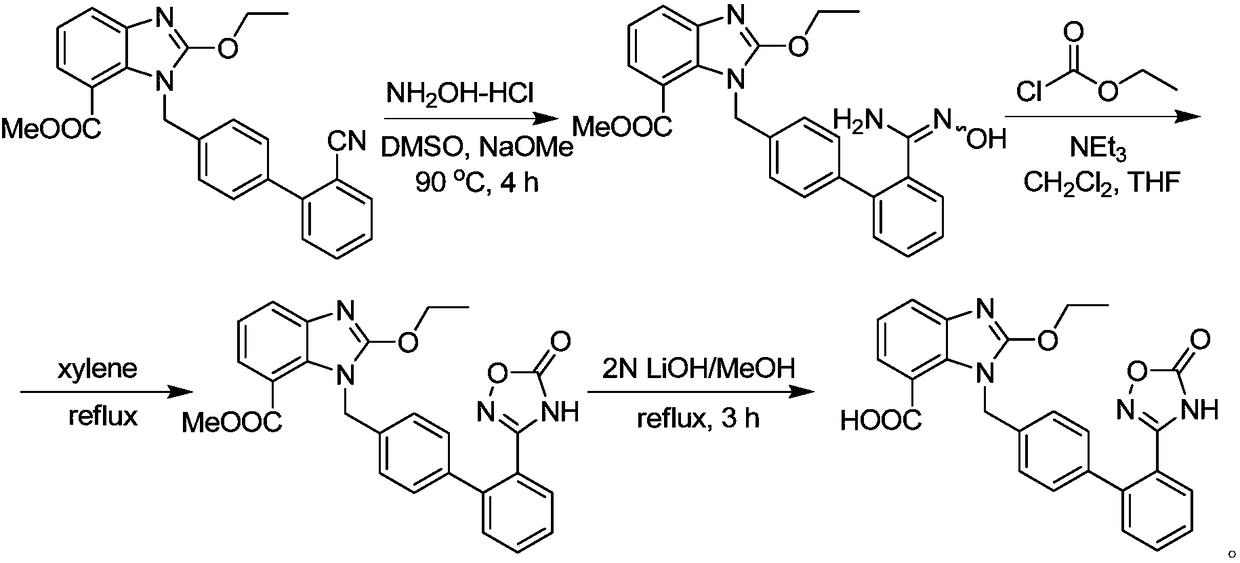

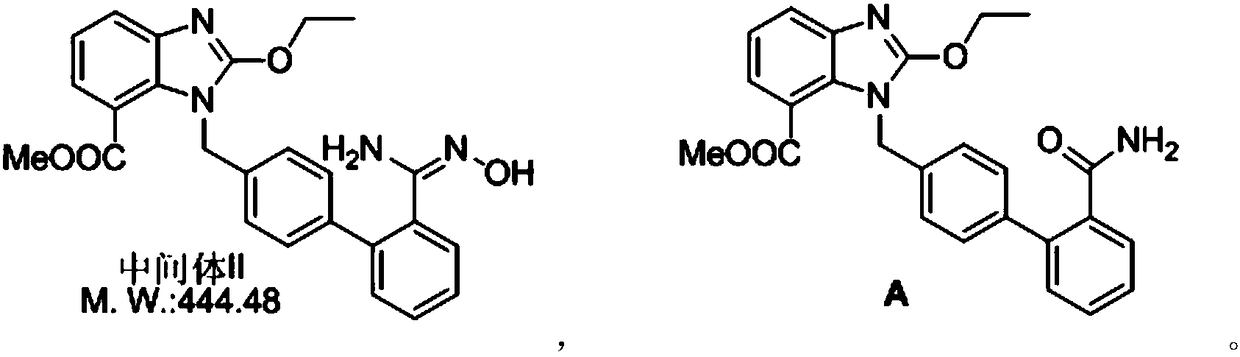

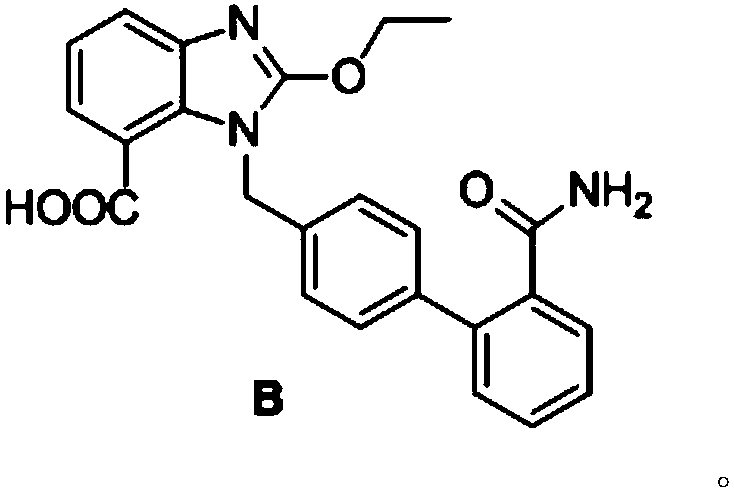

Preparation method of azilsartan impurity a and b

ActiveCN105924400BReduce or avoid the formation ofHigh yieldOrganic chemistryOrganic solventStructural formula

The invention relates to a preparation method for an azilsartan impurity A and an azilsartan impurity B, belonging to the technical field of preparation of azilsartan impurities. The preparation method for the azilsartan impurity A provided by the invention comprises the following steps: subjecting an azilsartan intermediate II and carbonyldimidazole to refluxing reaction under heating in an organic solvent so as to prepare an impurity A, and subjecting the impurity A and an alkaline reagent to reaction under heating in water so as to obtain an impurity B, wherein the azilsartan intermediate II, the impurity A and the impurity B have chemical structural formulas as described in the specification. The preparation method for the azilsartan impurity A and the azilsartan impurity B provided by the invention has simple process and short period; and the prepared target products have high yield and are easy to purify.

Owner:SHANDONG XINHUA PHARMA CO LTD

System for Quantitative Calculation of Concrete Filling Voids During Tunnel Secondary Lining Construction

ActiveCN110847971BSolve the problem of ambiguous perfusion statusReduce or avoid the formation ofMining devicesUnderground chambersMonitoring siteArchitectural engineering

The invention discloses a system for quantitatively calculating concrete pouring voids during the secondary lining construction period of tunnels. The system includes: a plurality of detection units, each detection unit detects the height of the concrete pouring surface, and generates a pouring height representing the concrete The electrical signal; the judgment unit, which receives multiple electrical signal data, and processes each electrical signal data to obtain the height data of the monitoring points distributed according to a certain density on the concrete pouring surface during the secondary lining construction period, and according to these heights data to calculate the volume of unfilled voids above the concrete surface and below the flashing. The invention effectively solves the problem of unclear pouring state of the concrete during the secondary lining construction period, can provide reliable judgment basis for construction personnel, guarantee the quality of lining construction, and reduce or avoid the formation of cavities from the source.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

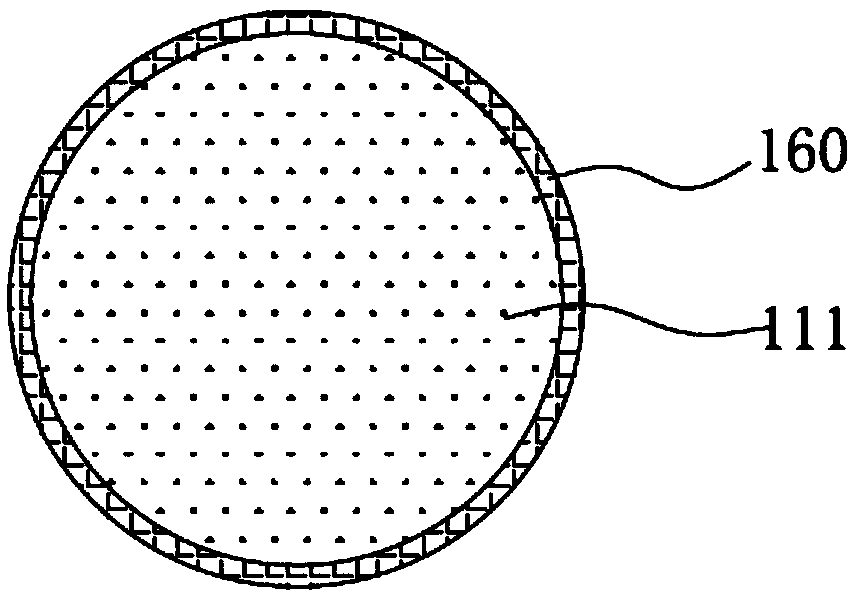

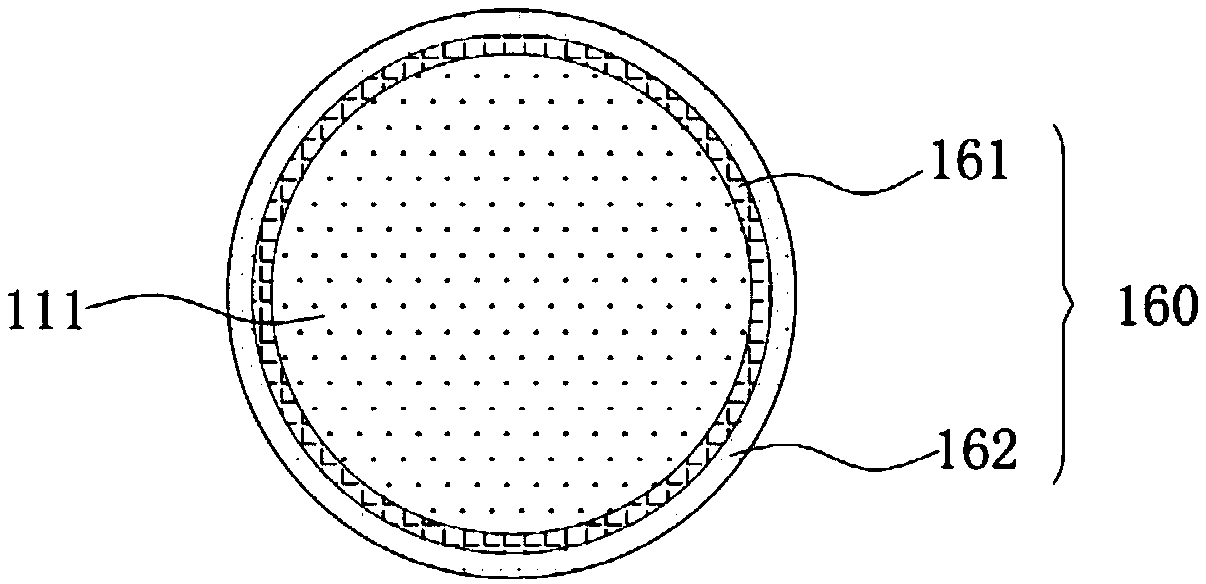

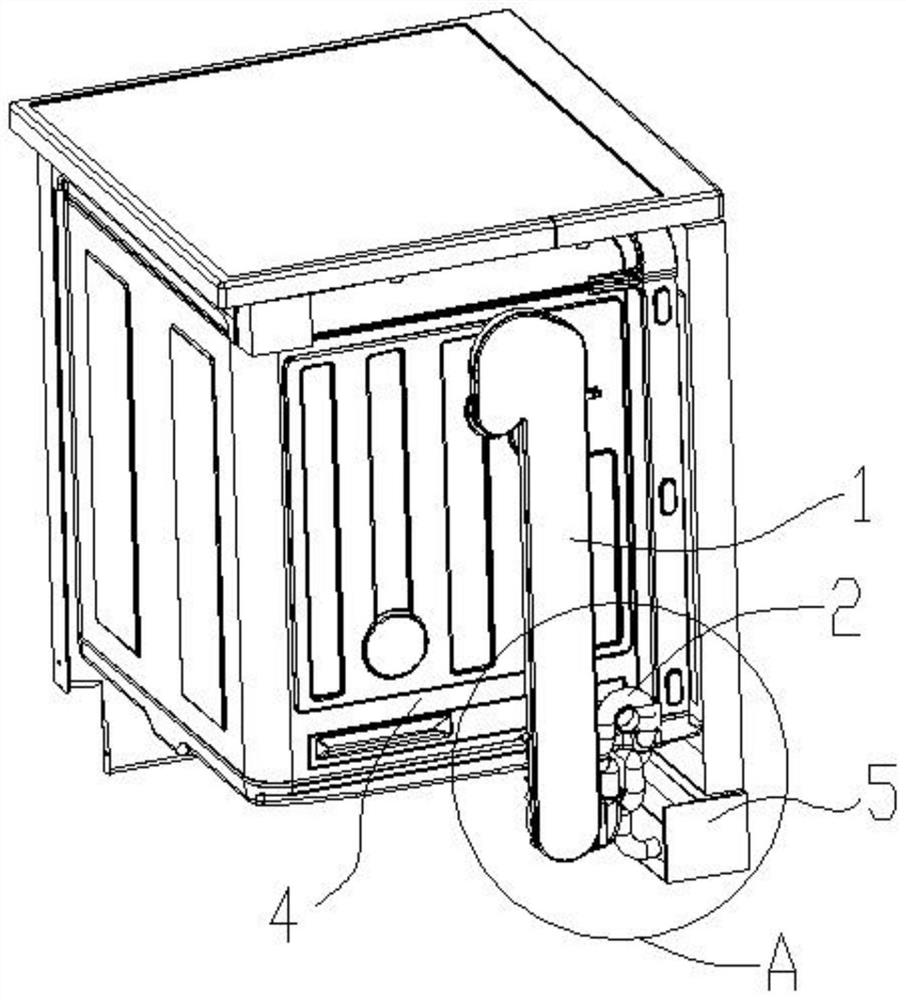

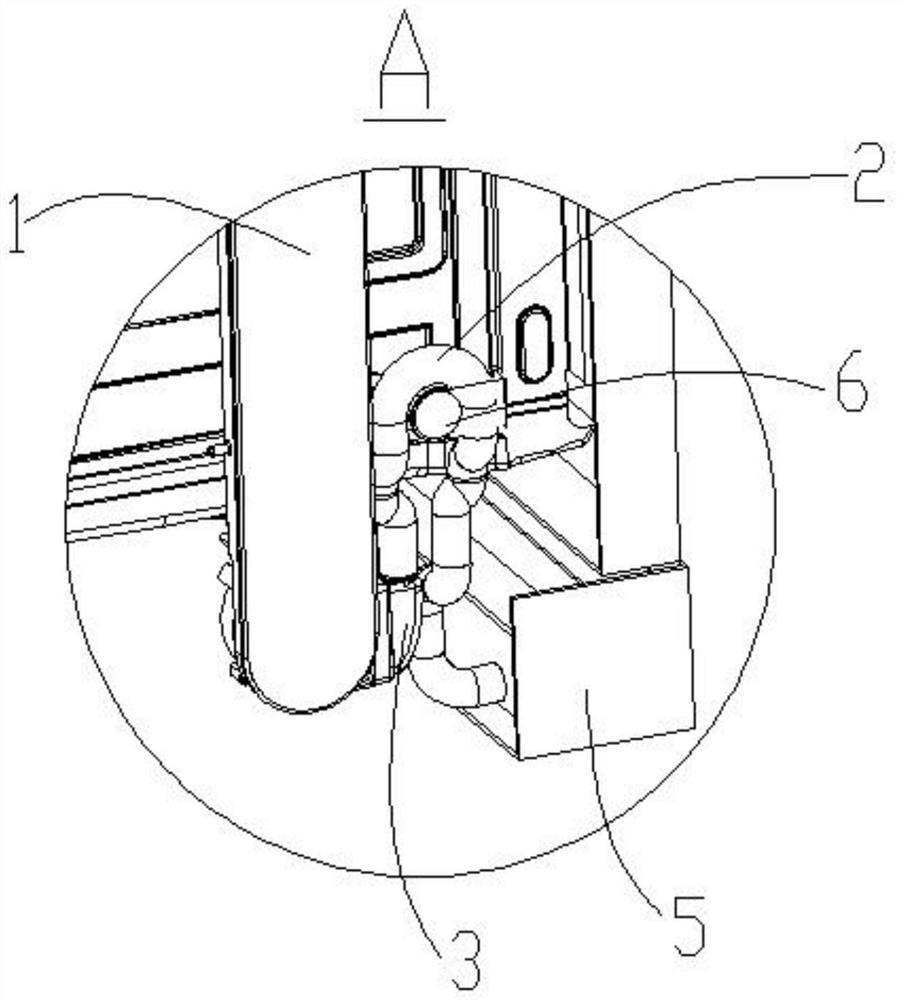

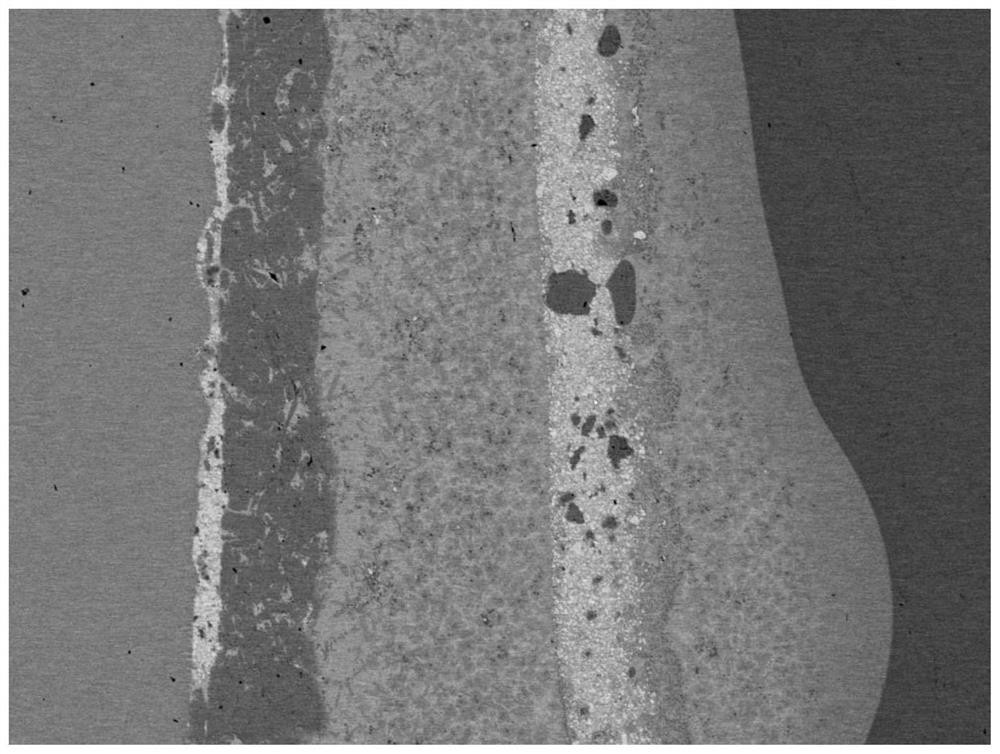

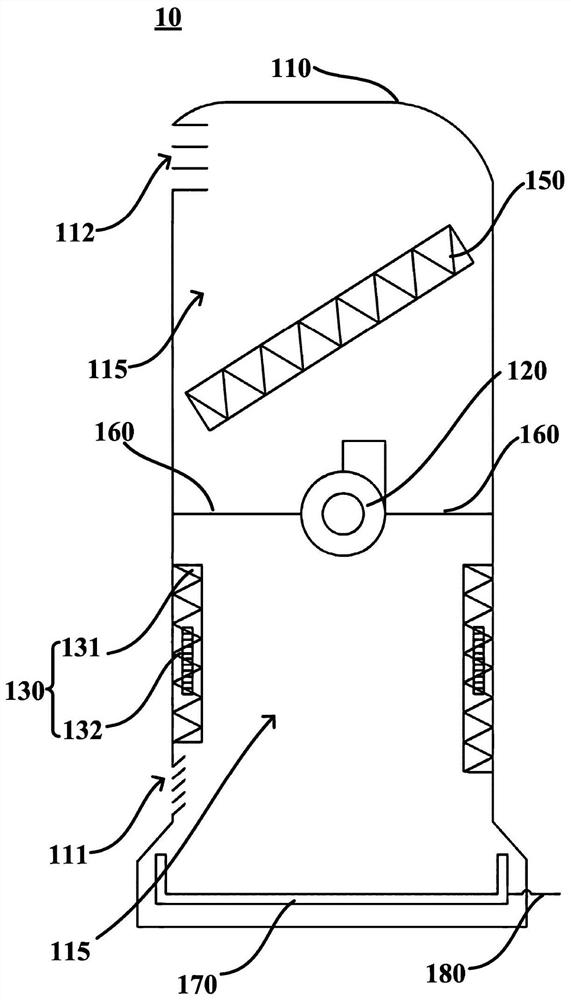

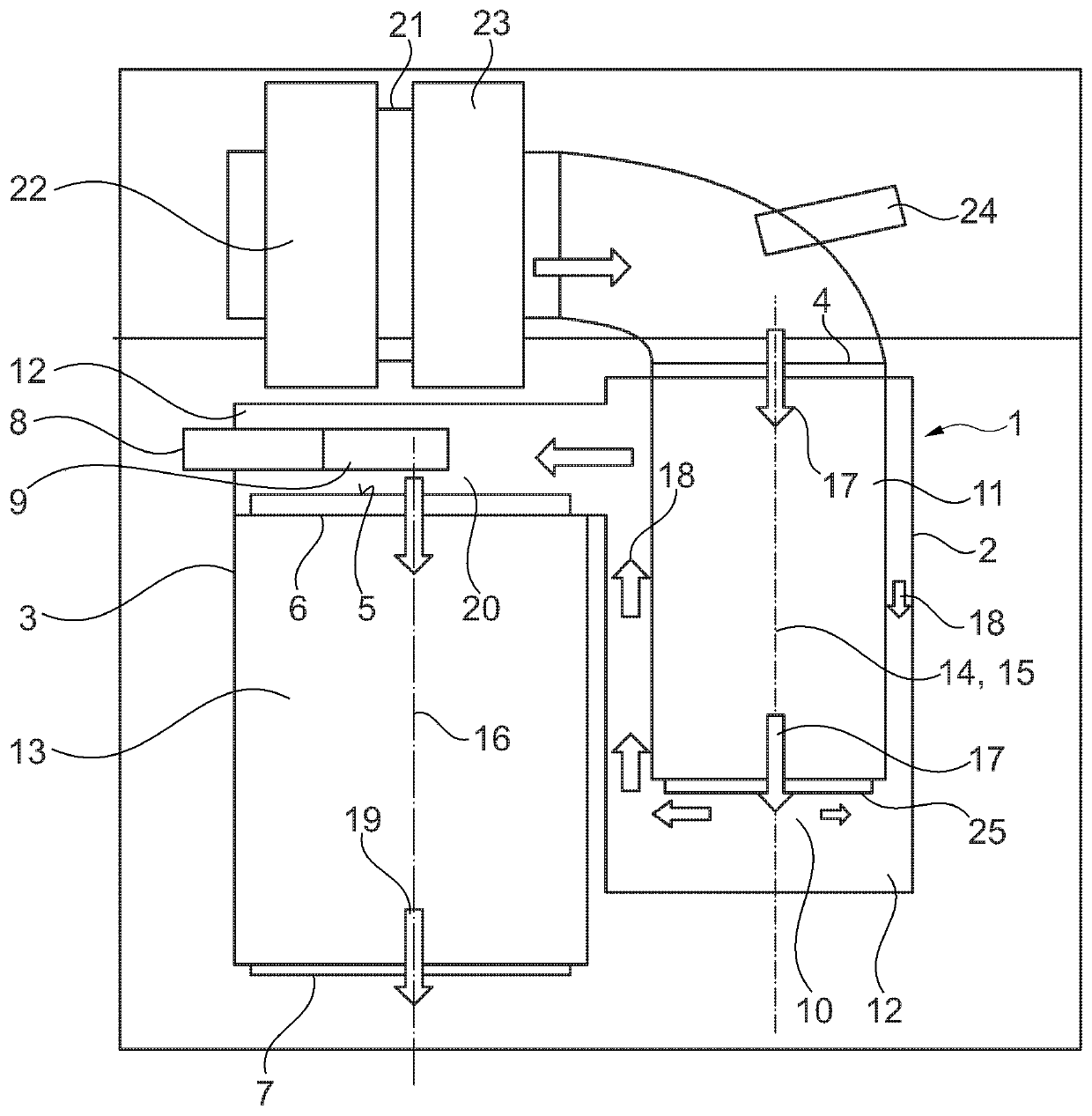

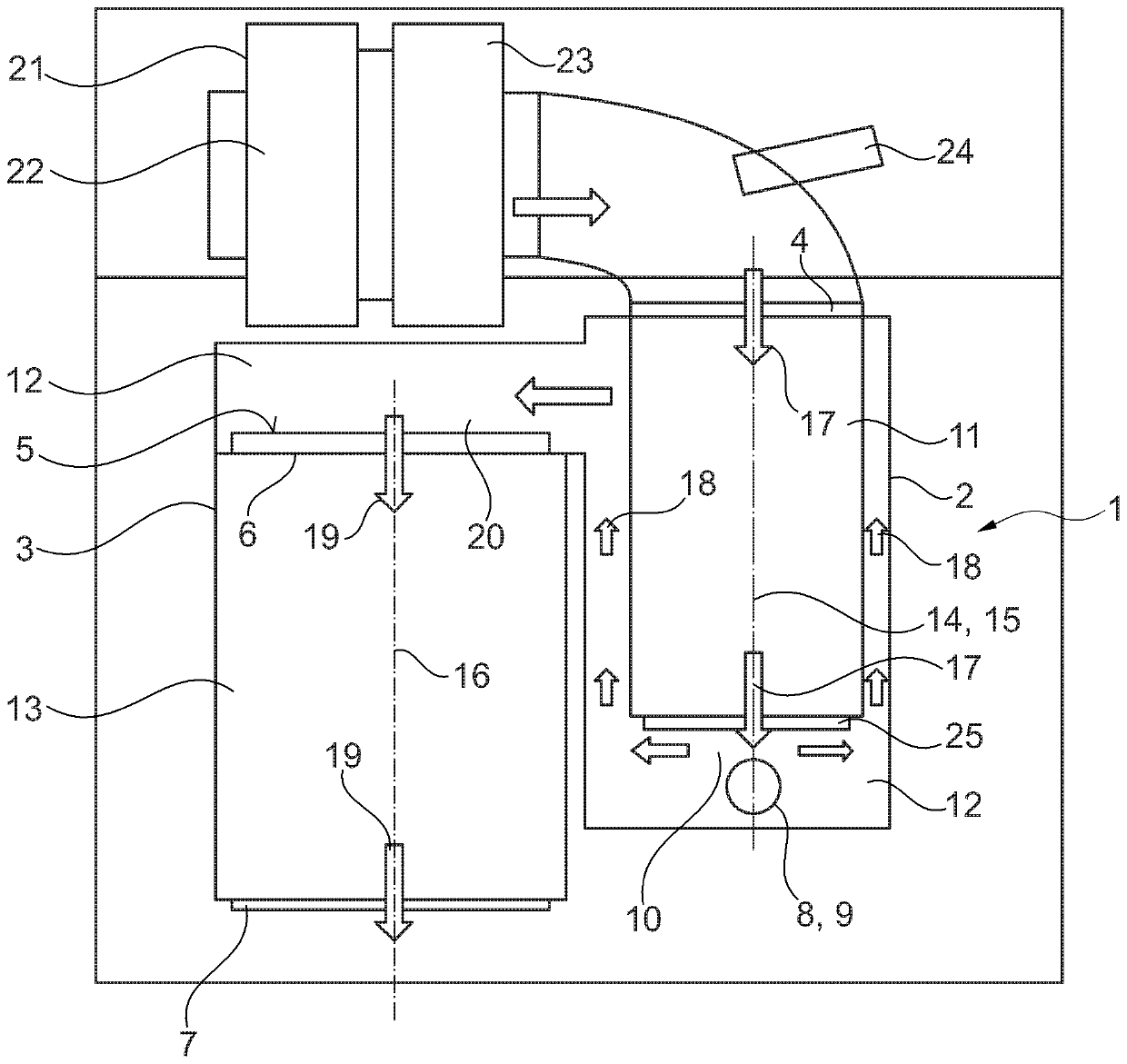

Device for exhaust gas aftertreatment

PendingCN110566321AReduce or prevent the formation ofReduce or avoid the formation ofInternal combustion piston enginesSilencing apparatusEngineeringReducing agent

The invention relates to a device (1) for exhaust gas aftertreatment, comprising a first catalytic converter device (2) and a second catalytic converter device (3) adjoining the first catalytic converter device (2) in the flow direction (17, 18) of the exhaust gas, the first and second catalytic converter devices being arranged spatially adjoining each other. The first catalytic converter device (2) comprises a first flow channel (11) and a second flow channel (12), and the first catalytic converter device (2) is configured to direct exhaust gas through the first flow channel (11) in a first flow direction (17) and then through the second flow channel (12) in a second flow direction (18) opposite to the first flow direction. The second catalytic converter equipment (3) comprises a third flow channel (13); the second flow channel (12) is arranged spatially and fluidically between the first flow channel (11) and the third flow channel (13), and the second catalytic converter device (3) is configured to direct the exhaust gas through the third flow channel (13) in a third flow direction (19) opposite the second flow direction after the exhaust gas has exited the second flow channel (12). The second flow channel (12) comprises means (8) for injecting a reducing agent.

Owner:FORD GLOBAL TECH LLC

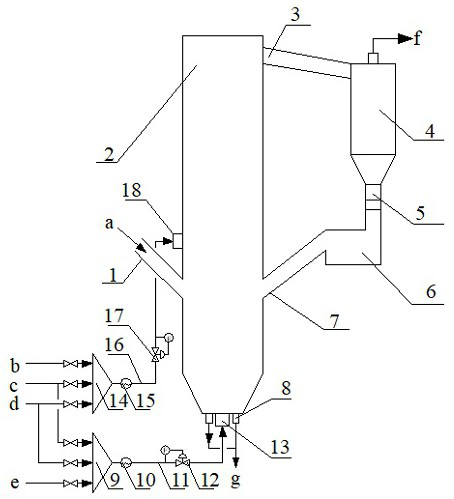

Process for preparing synthesis gas by gasifying raw materials with different coal quality characteristics by adopting oxygen-enriched circulating fluidized bed

PendingCN114686268AReduce or avoid the formation ofSolve problems such as easy slaggingGasification processes detailsGranular/pulverulent flues gasificationWater vaporMixed gas

The invention discloses an oxygen-enriched gasification process for a circulating fluidized bed gasifier, which comprises the following steps: introducing a mixed gas, namely a gasifying agent, formed by mixing oxygen, water vapor and carbon dioxide or air into the fluidized bed gasifier; raw material coal is added into a gasification furnace and is subjected to gasification reaction with a gasification agent; crude synthesis gas containing carbon monoxide and hydrogen generated in the reaction and gasified fly ash are introduced into a cyclone separator together, most of the fly ash settles to enter the bottom of the cyclone separator and returns to the gasifier to be gasified again, and a small amount of the fly ash and the crude synthesis gas enter the next treatment section. According to the oxygen-enriched gasification method of the circulating fluidized bed, the temperature in the gasification furnace can be effectively controlled, and the problem that the bottom of the gasification furnace is prone to slagging due to local overheating is solved. In addition, due to the fact that all the components of the gasifying agent are gas capable of participating in the gasification reaction, controllable components of the coal gasification product crude synthesis gas can be achieved by regulating and controlling the proportion of all the components of the gasifying agent, and the gasifying agents with different component proportions can be matched according to feed coal with different coal quality characteristics.

Owner:新疆宜化化工有限公司 +2

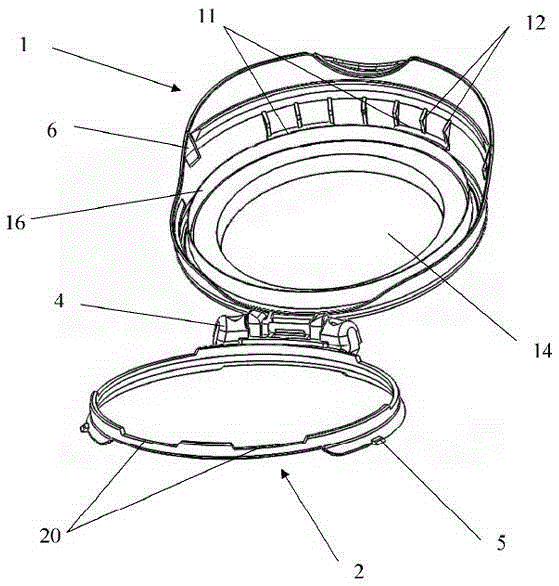

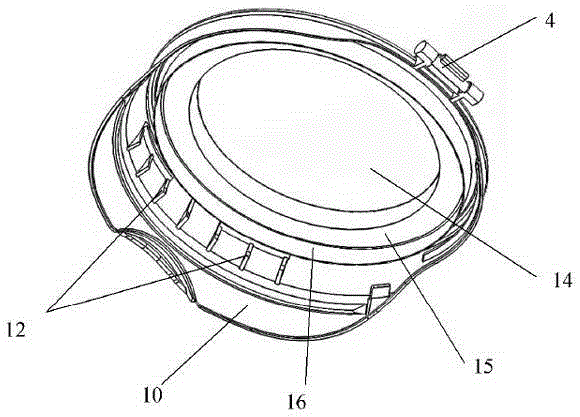

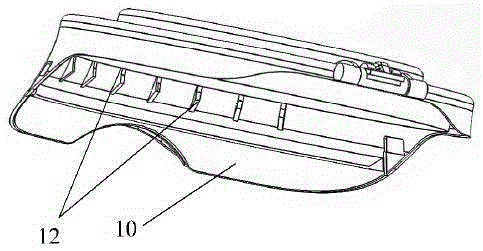

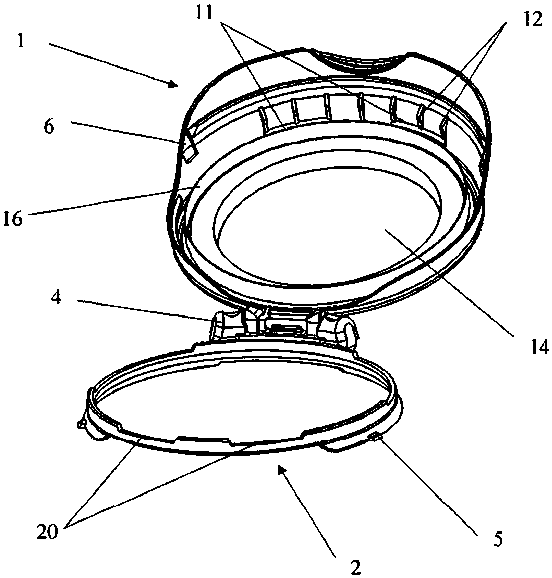

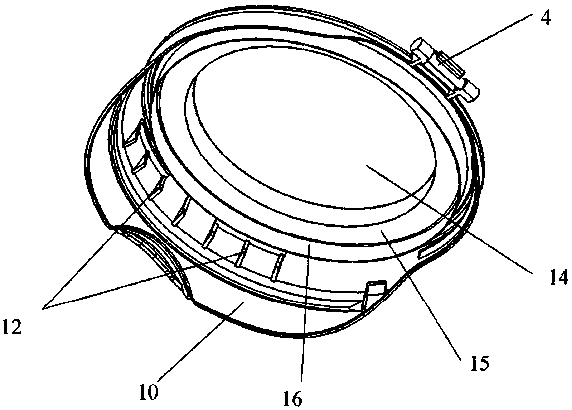

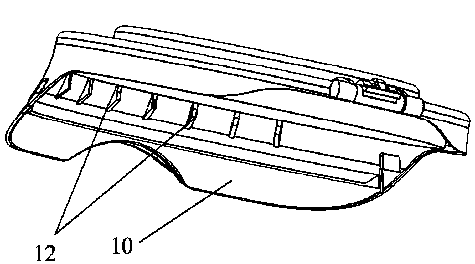

Hygienic seal for container

InactiveCN105377712AImprove air tightnessReduce risk of formationFlexible coversWrappersEngineeringFlange

Hygienic seal for a container (3), comprising an upper lid (1) and a lower ring (2) coupled to said upper lid (1) and being capable of being fitted around the body of the container (3), the upper lid having an extension (10) which projects outwards and is directed towards the lower ring (2) such that in a closed state of the container, the extension (10) of the upper lid (1) partially overlaps the lower ring (2). On an upper flange of the lower ring (2), positioning means (11, 20) are provided which comprise at least one depression (20) complementing a projection (11) which projects internally from the interior face of the extension (10). The interior face of the extension is directed towards the lower ring (2) and has tightening means (12; 120) which contact the lower ring (2) in a closed state of the container (3) when the projection (11) and the depression (20) are in contact with one another.

Owner:约瑟-弗朗西斯科·冈萨雷斯-桑切斯

Hygienic seals for containers

InactiveCN105377712BImprove air tightnessReduce risk of formationFlexible coversWrappersEngineeringMechanical engineering

A hygienic seal for a container comprising a circular upper cover (1) and a lower ring (2) connected to the upper cover (1) and capable of being fitted around the body of the container , the upper cover has an extension protruding outwards and pointing towards the lower ring (2), so that in the closed state of the container, the extension of the upper cover (1) is in contact with the The lower ring (2) described above partially overlaps. A positioning device is provided on the upper flange of the lower ring (2), and the positioning device includes at least one recessed part, which is complementary to the protrusion protruding inward from the inner surface of the extension part, toward the The inner surface of the extension part of the lower ring (2) has a locking device, and when the container is in a closed state and the protrusion and the recess are in contact with each other, the locking device can be in contact with the lower ring ( 2) contact.

Owner:约瑟-弗朗西斯科·冈萨雷斯-桑切斯

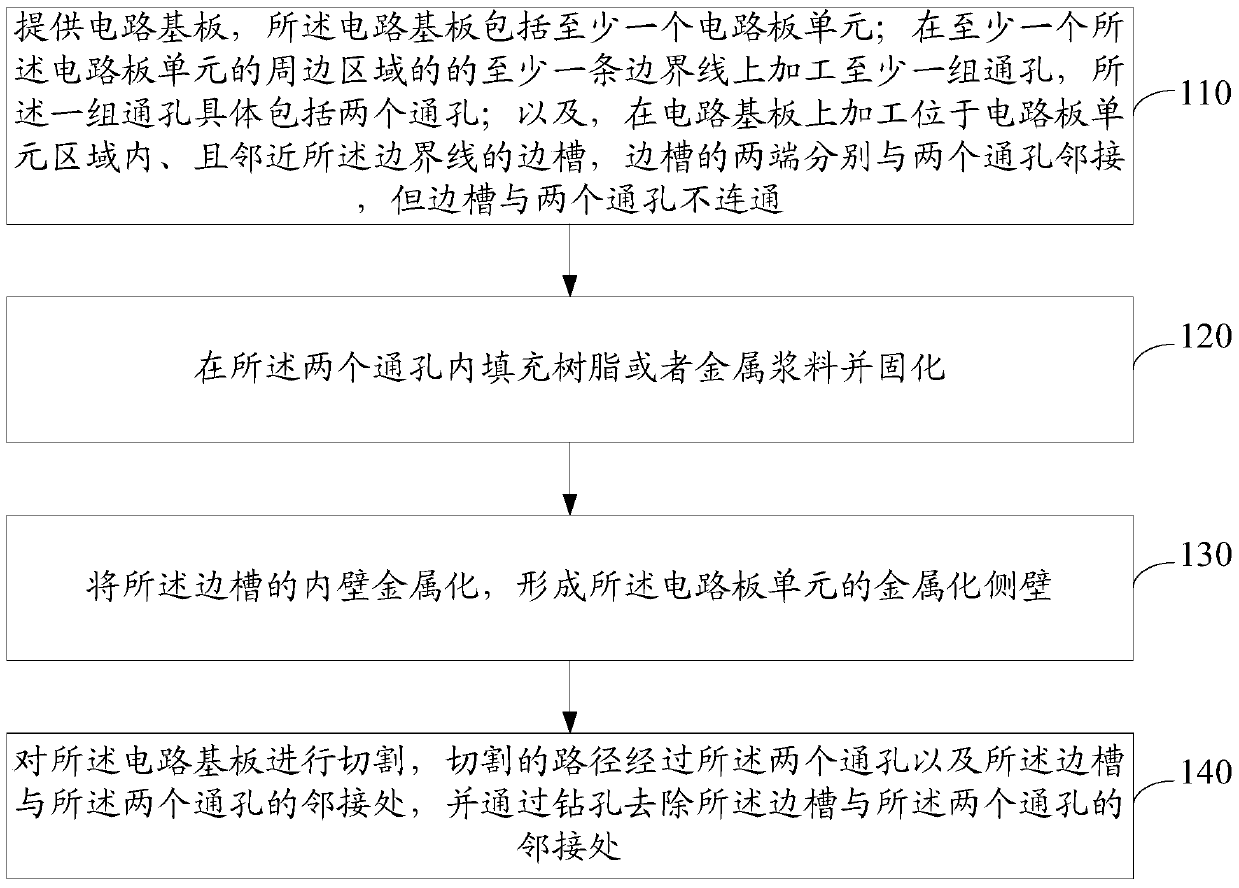

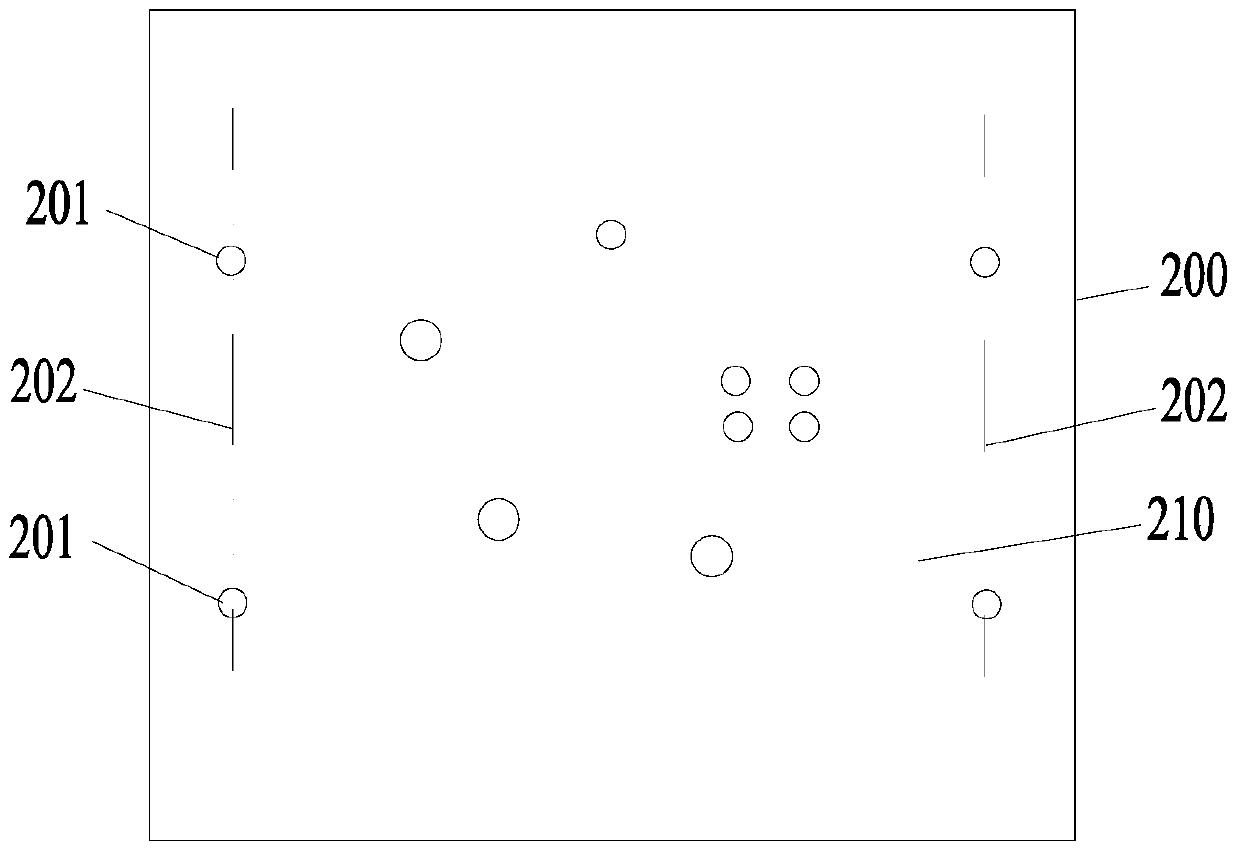

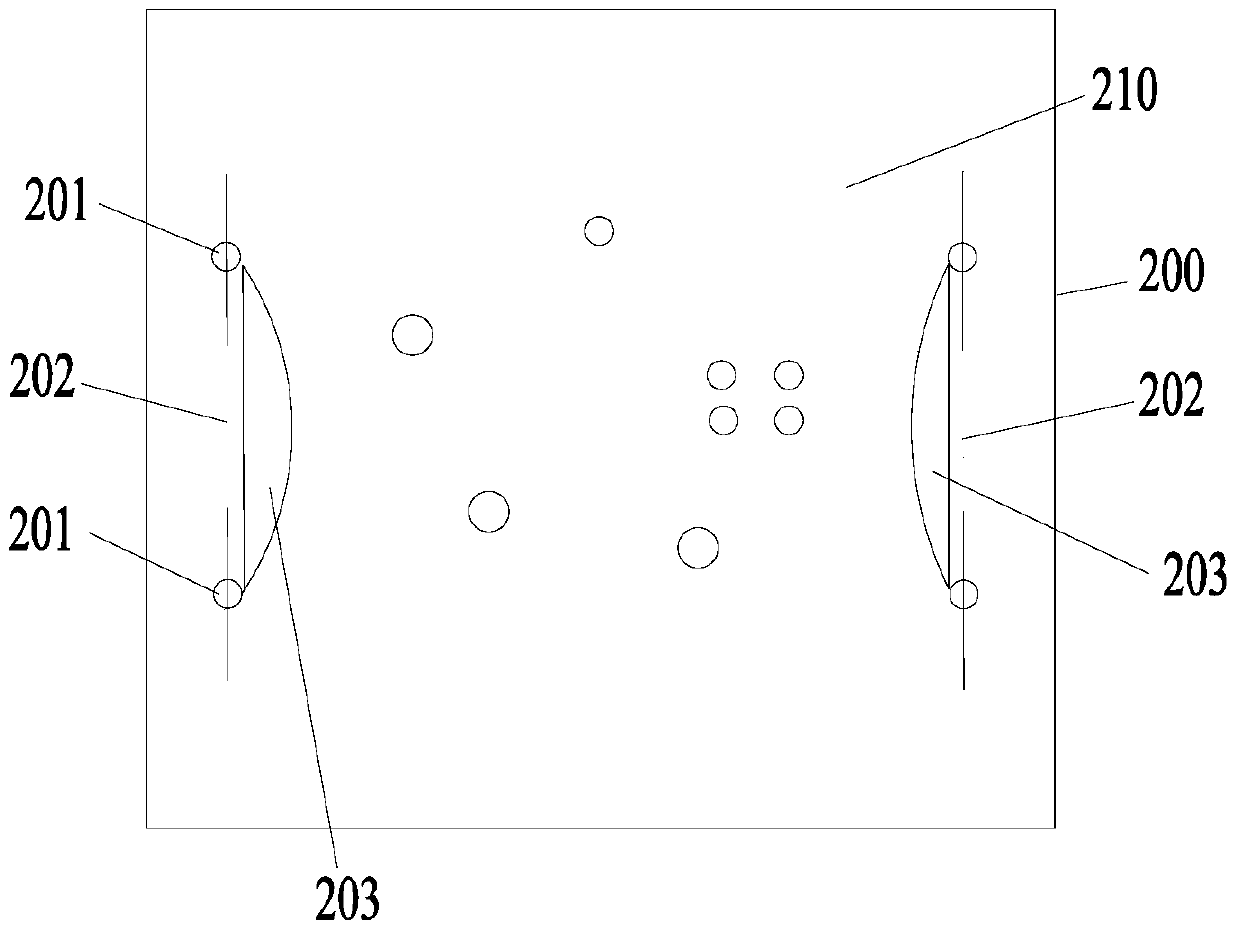

Circuit board with side metal structure and method of making the same

ActiveCN104735900BReduce or avoid the formation ofGood lookingPrinted circuit detailsPrinted circuit manufactureEngineeringMetal

The invention discloses a method for manufacturing a circuit board with a side metal structure to solve the above-mentioned defects in the existing side metallization process of the circuit board. The above method includes: providing a circuit substrate comprising at least one circuit board unit; processing at least one group of two through holes on at least one boundary line of the peripheral area of at least one circuit board unit; processing on the circuit substrate located at In the side groove in the area of the circuit board unit and adjacent to the boundary line, the two ends of the side groove are respectively adjacent to the two through holes, but the side groove is not connected to the two through holes; Fill the two through holes with resin or metal paste and solidify; metallize the inner wall of the side groove to form the metallized side wall of the circuit board unit; cut the circuit board, and cut the path passing through the two through holes and the adjoining places of the side grooves and the two through holes; removing the adjoining places of the side grooves and the two through holes by drilling.

Owner:SHENNAN CIRCUITS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com