Method for nitridation and crystallization of metastable-state samarium-iron alloy

A samarium-iron alloy and metastable technology, which is applied in the field of nitridation and crystallization of metastable samarium-iron alloys, can solve problems such as unreported, and achieve the effects of improving nitriding efficiency, refining microstructure and uniform distribution of nitrogen atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Set the provisioning component to Sm 2 Fe 17 The molten samarium-iron alloy solution is rapidly cooled and quenched by mold cooling technology to prepare amorphous samarium-iron alloy strips, and then the alloy strips are placed in a high-temperature nitriding furnace, and the nitriding temperature of the high-temperature nitriding furnace is controlled to 450°C, the nitriding atmosphere is high-purity nitrogen N 2 , the atmosphere pressure is 0.1MPa, the holding time is 5h, the alloy thin strip is fully nitrided and preliminary crystallized, the alloy thin strip after nitriding is put into a vacuum annealing furnace, fully crystallized and annealed at 530°C, Sm 2 Fe 17 N x permanent magnet material.

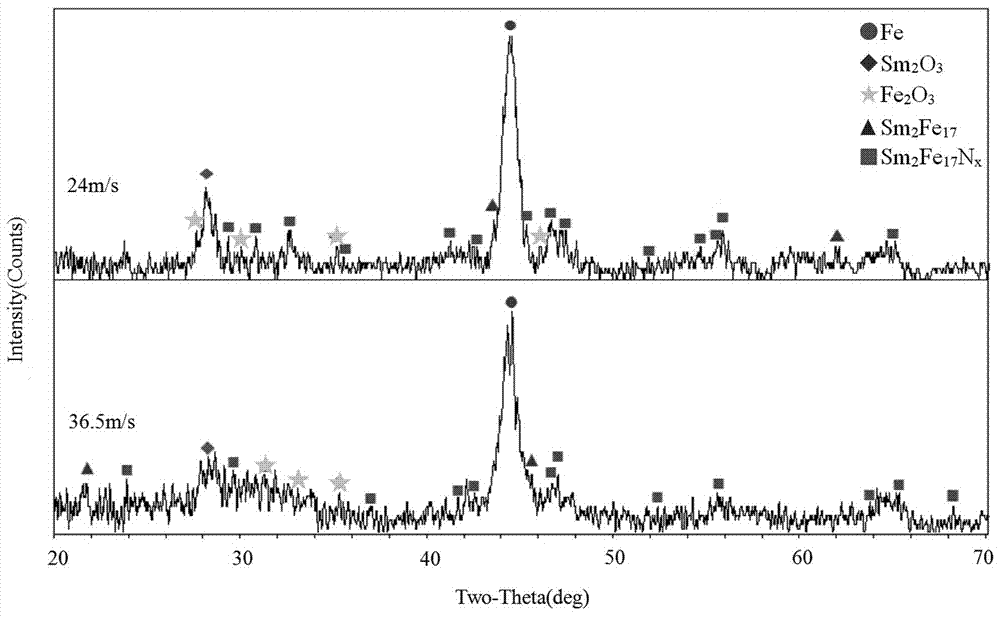

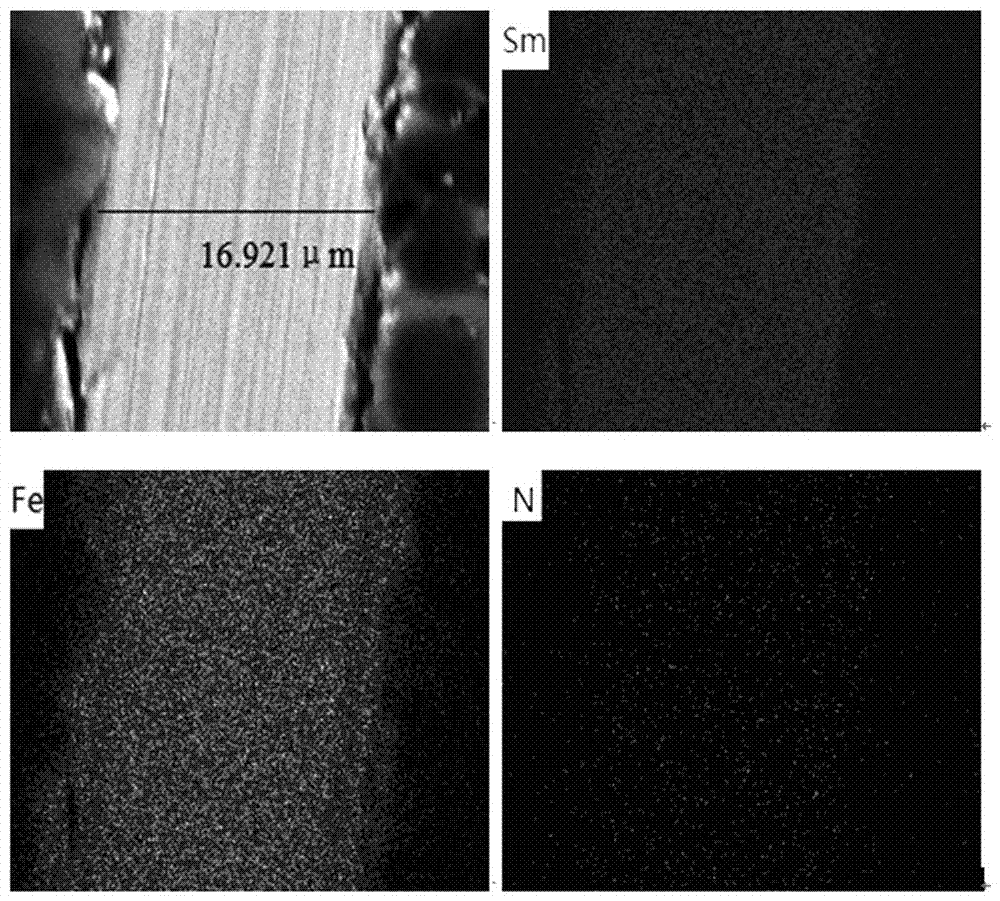

[0023] to the Sm 2 Fe 17 N x Permanent magnet materials are analyzed, the results can be found in figure 1 and figure 2 , figure 1 It is the X-ray diffraction pattern of the amorphous SmFe alloy thin strip obtained in Example 1 after nitriding, and Fig. 2 is t...

Embodiment 2

[0025] Set the provisioning component to Sm 2 Fe 17 The molten samarium-iron alloy solution is rapidly cooled and quenched by mold cooling technology to prepare amorphous samarium-iron alloy strips, and then the alloy strips are placed in a high-temperature nitriding furnace, and the nitriding temperature of the high-temperature nitriding furnace is controlled to 400°C, the nitriding atmosphere is high-purity nitrogen N 2 with NH 3 Mixed gas, the atmosphere pressure is 0.7MPa, and the holding time is 3h, the alloy strip is fully nitrided and preliminary crystallized, and the nitrided alloy strip is then placed in a vacuum annealing furnace, fully crystallized and crystallized at 500°C Annealed, the prepared Sm 2 Fe 17 N x permanent magnet material.

[0026] to the Sm 2 Fe 17 N x The permanent magnet material was analyzed, and the results showed that Sm 2 Fe 17 The diffraction peaks shifted to the low angle by 1~2°, and the nitrogen atoms penetrated into the Sm 2 Fe...

Embodiment 3

[0028] Set the provisioning component to Sm 2 Fe 17 The molten samarium-iron alloy liquid is rapidly cooled and condensed by atomization technology to prepare amorphous samarium-iron alloy powder, and then the alloy powder is put into a high-temperature nitriding furnace, and the nitriding temperature of the high-temperature nitriding furnace is controlled to 350°C, the nitriding atmosphere is high-purity nitrogen N 2, the atmosphere pressure is 0.4MPa, the holding time is 4h, the alloy powder is fully nitrided and preliminary crystallized, the alloy powder after nitriding is put into a vacuum annealing furnace, fully crystallized and annealed at 550 ° C, Sm 2 Fe 17 N x permanent magnet material.

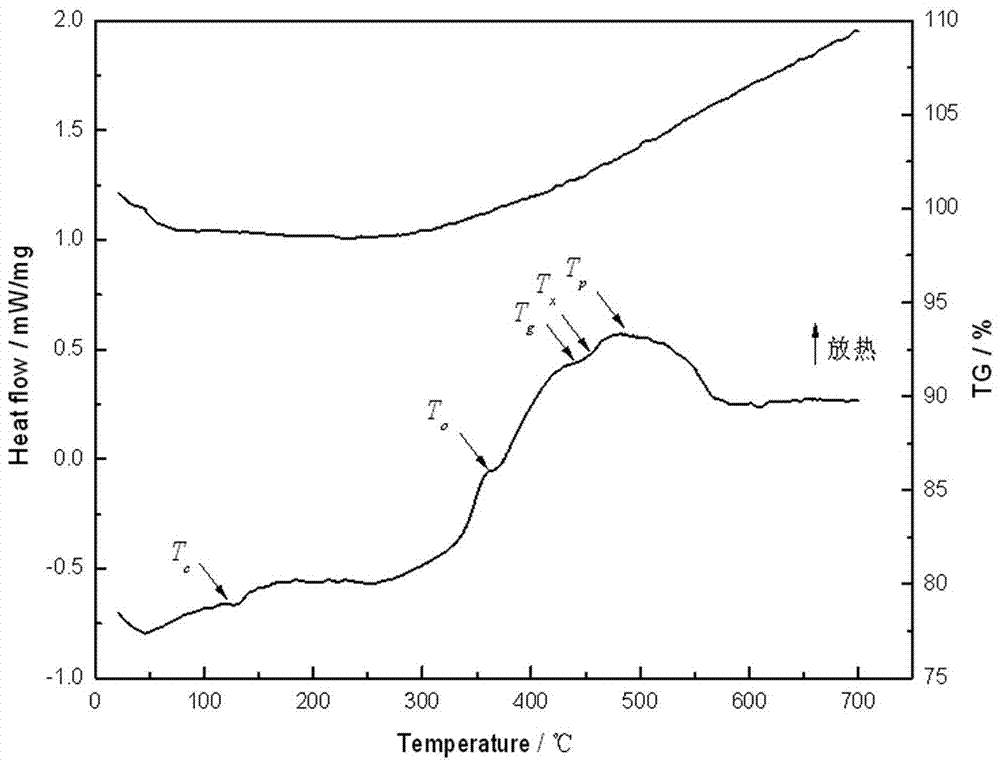

[0029] Carry out thermal analysis to described amorphous samarium-iron alloy powder, the result sees image 3 , image 3 It is the TG-DSC curve that embodiment 3 obtains samarium-iron alloy in argon atmosphere. Depend on image 3 It can be seen that the exothermic peak betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com