Patents

Literature

31results about How to "Fully annealed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

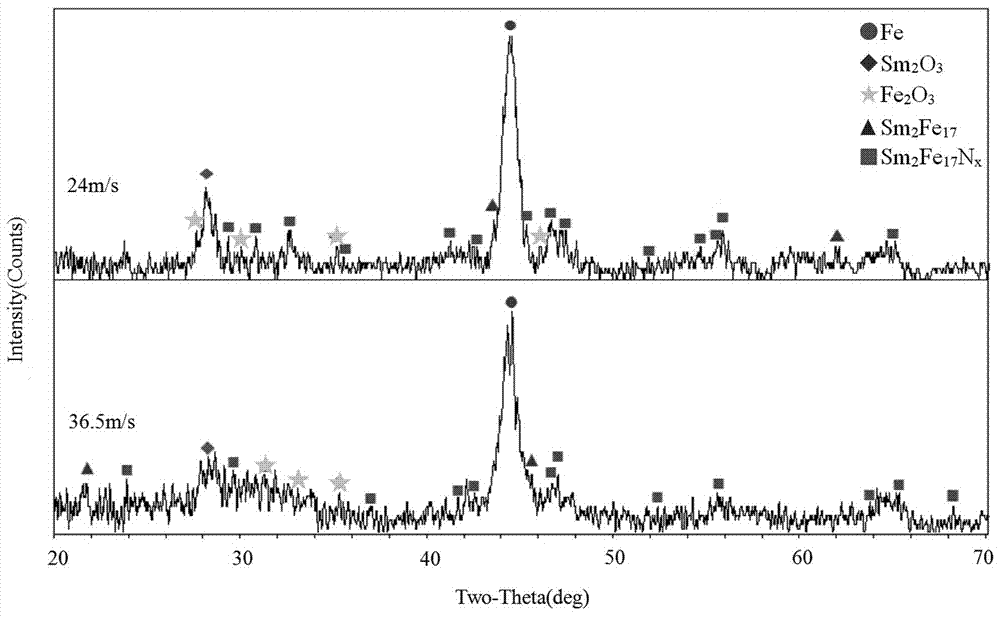

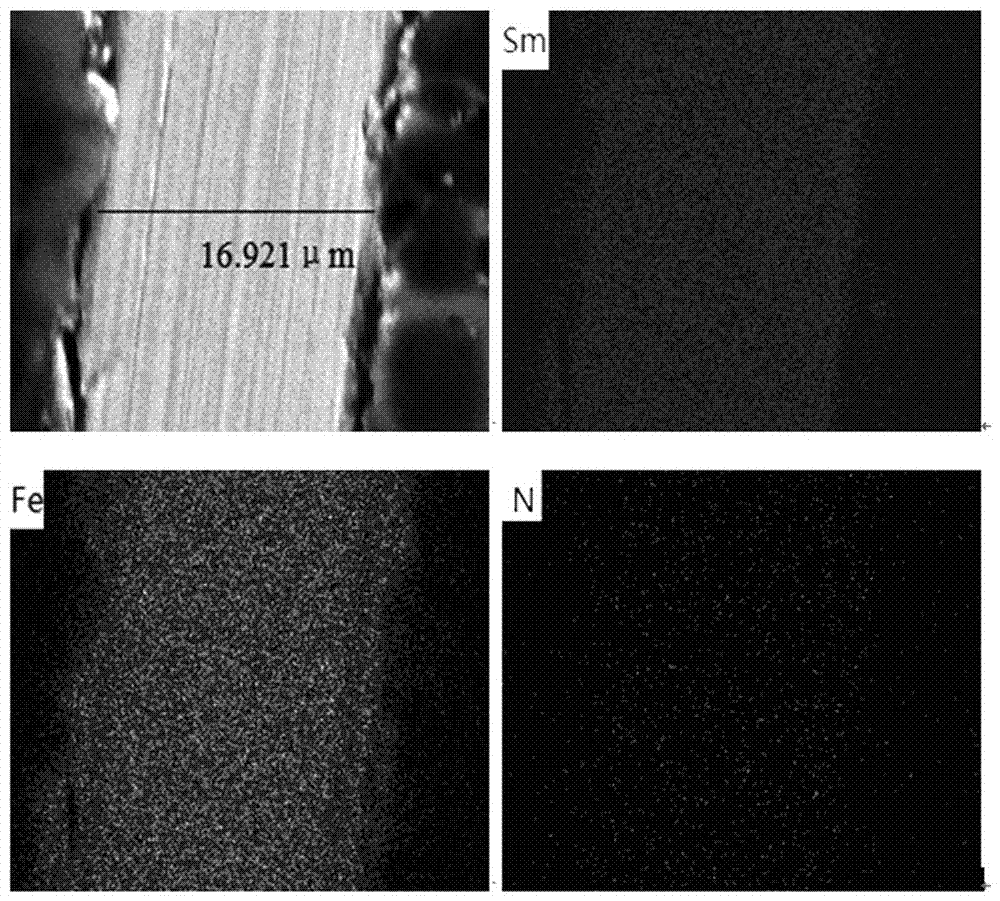

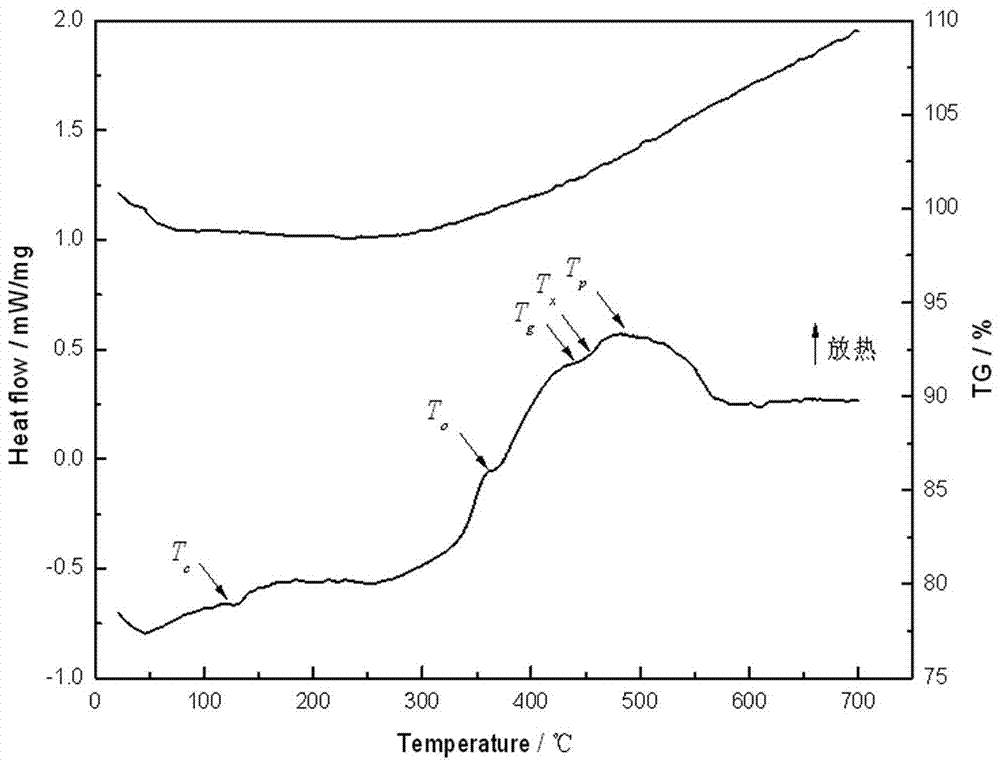

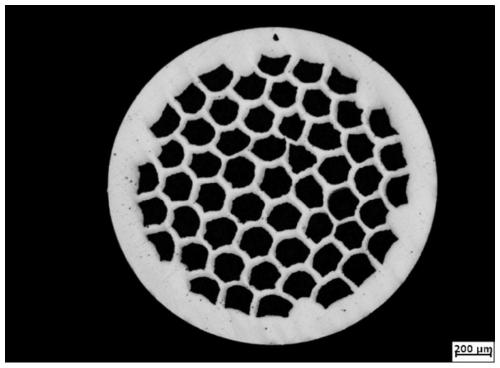

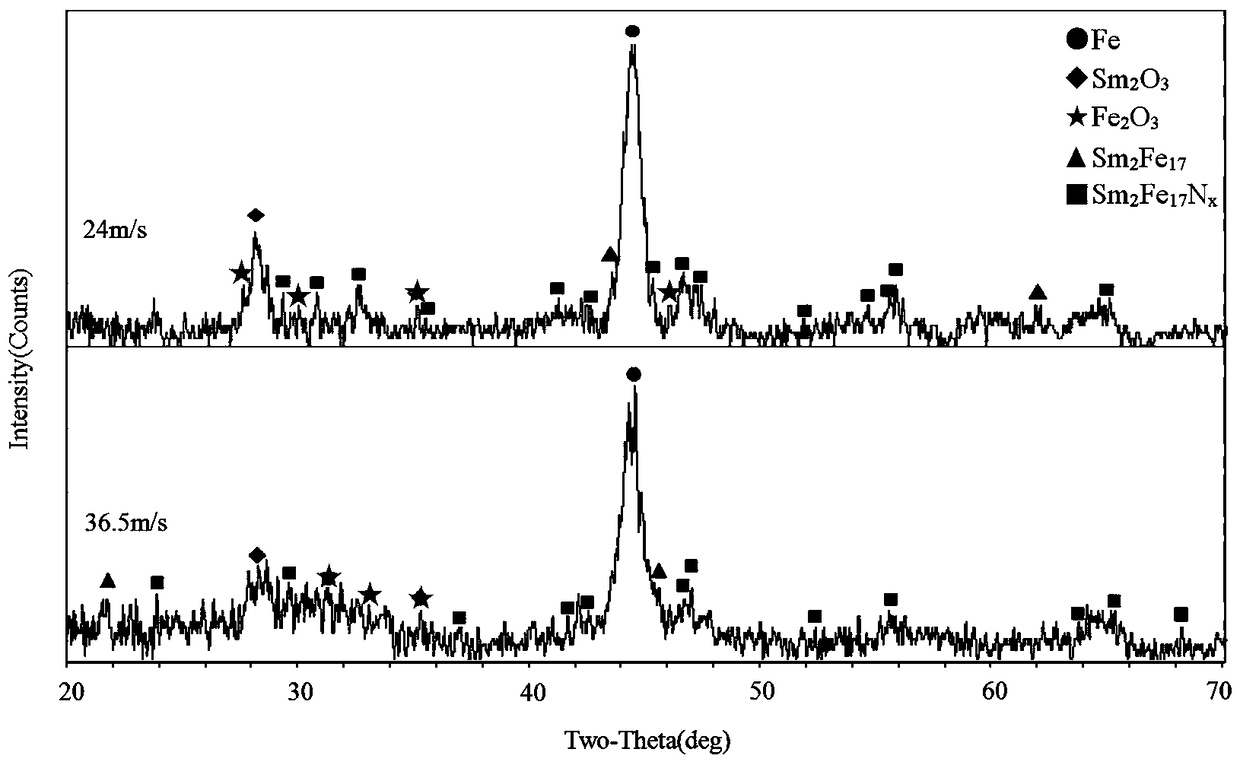

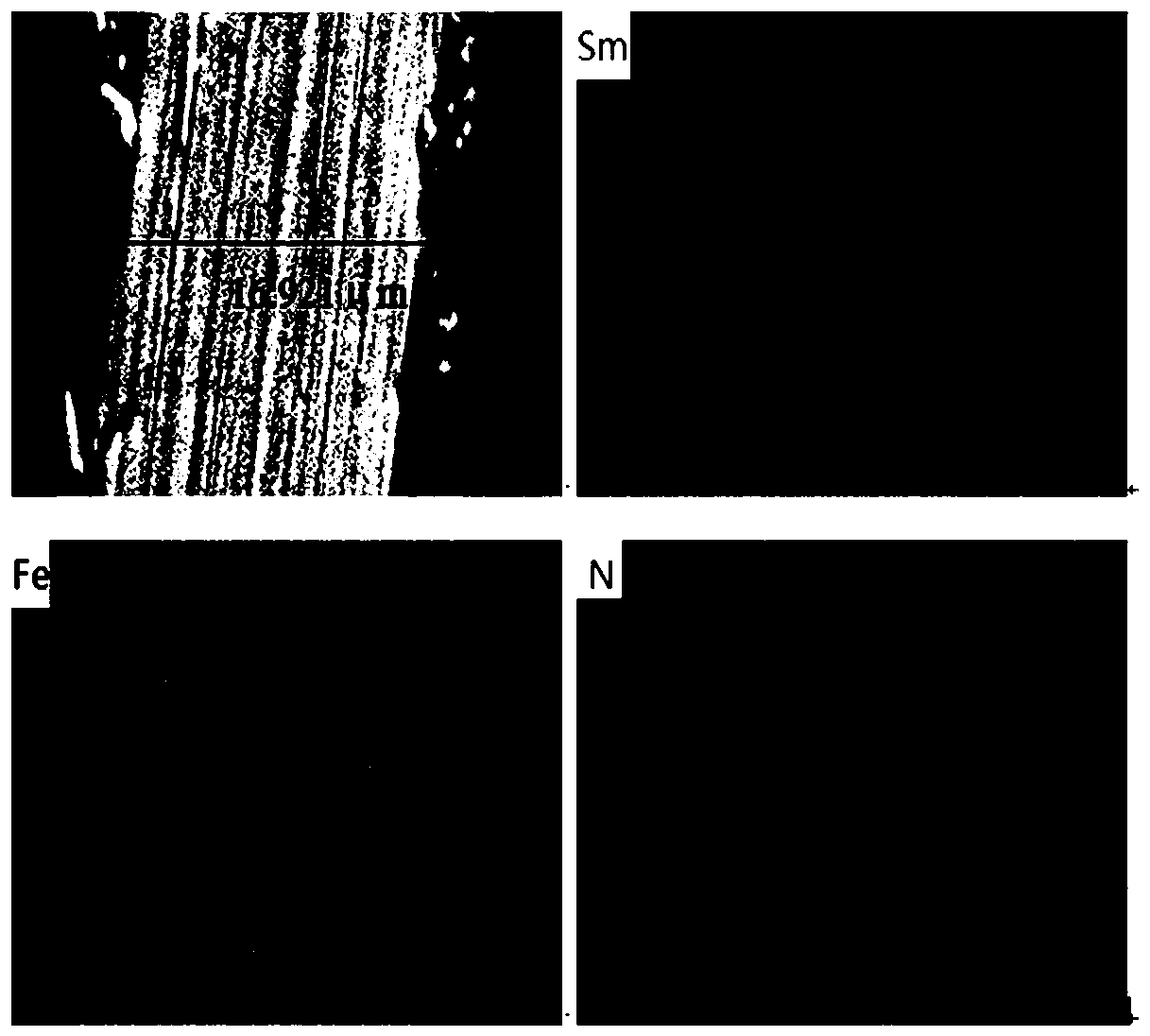

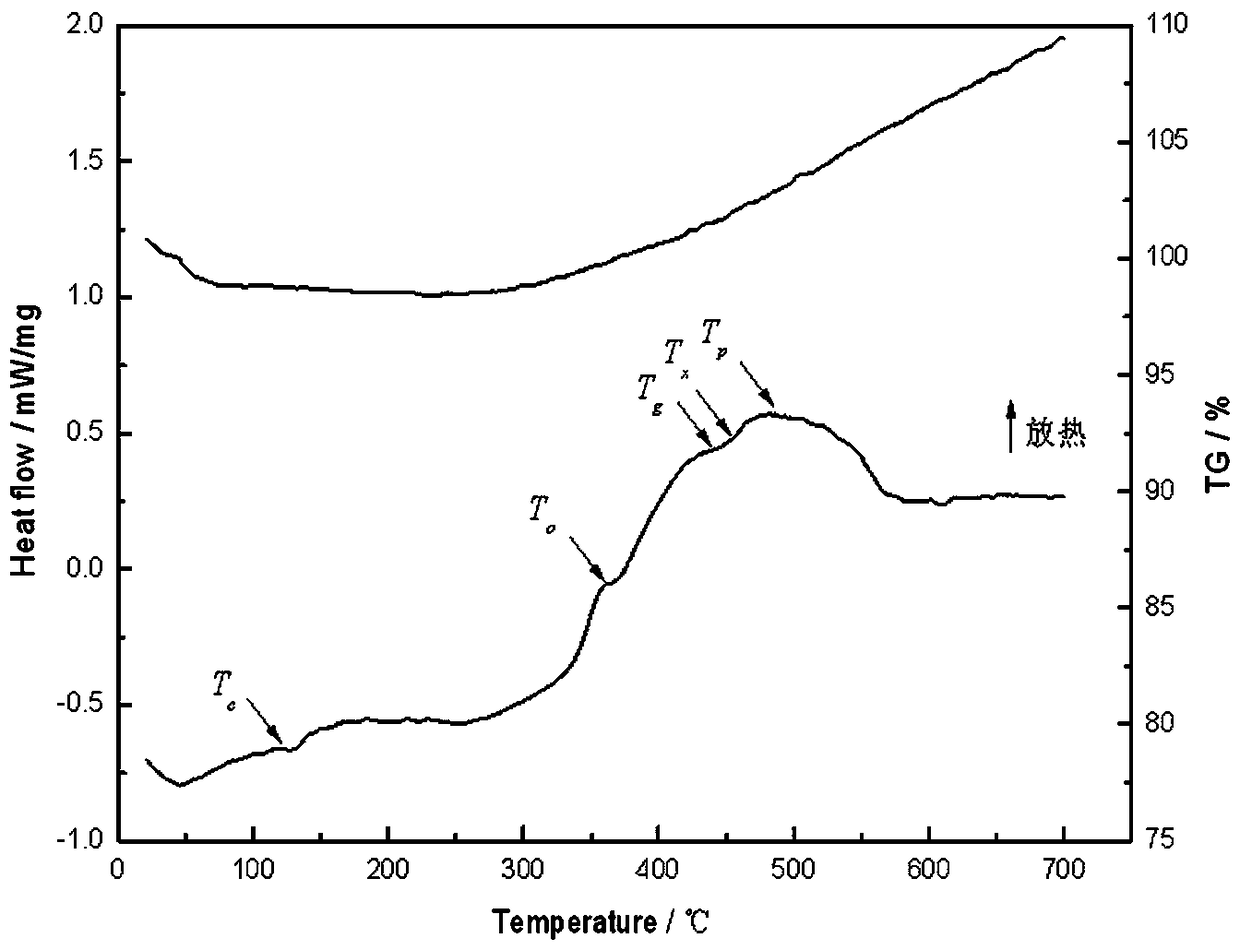

Method for nitridation and crystallization of metastable-state samarium-iron alloy

ActiveCN106960712AGood for spreading and homogenizingIncrease the amount of nitridingSolid state diffusion coatingInductances/transformers/magnets manufactureNitrogen atomMagnet

The invention provides a method for nitridation and crystallization of metastable-state samarium-iron alloy. The method comprises the steps of performing rapid cooling and sudden condensation on molten-state samarium-iron alloy to obtain the metastable-state samarium-iron alloy; performing nitridation and initial crystallization on the metastable-state samarium-iron alloy to obtain nitrided samarium-iron alloy; and performing annealing and crystallization on the nitrided samarium-iron alloy to obtain a samarium-iron nitrogen permanent-magnet material. During nitridation of a metastable-state material, a large amount of rheological units existing in the metastable-state alloy are beneficial for diffusion and homogenization of nitrogen atoms, the nitridation content of the alloy can be remarkably increased, and the nitrogen atoms are uniformly distributed; crystallization is completed before decomposition of Sm<2>Fe<17>N<x>, nitride formation is reduced or prevented, and the metastable-state samarium-iron alloy has a refined microstructure; and moreover, according to the method provided by the invention, the nitridation speed is fast, and the nitridation efficiency of improving a samarium-iron nitrogen magnetic material by the samarium-iron alloy is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

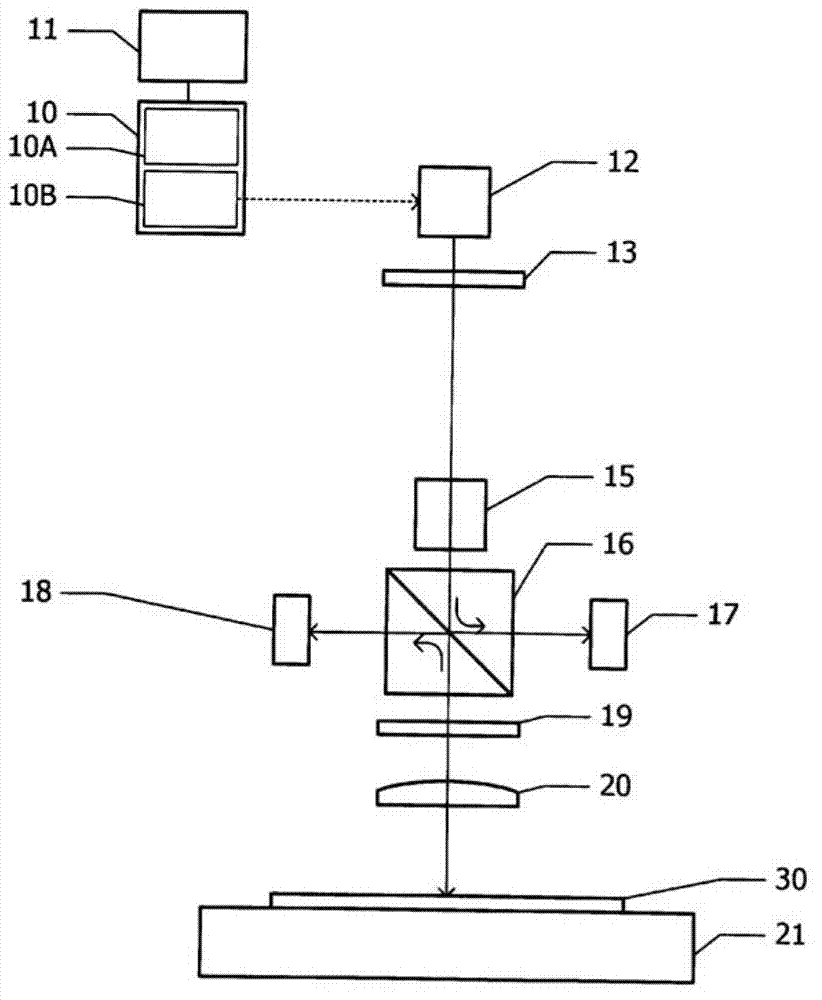

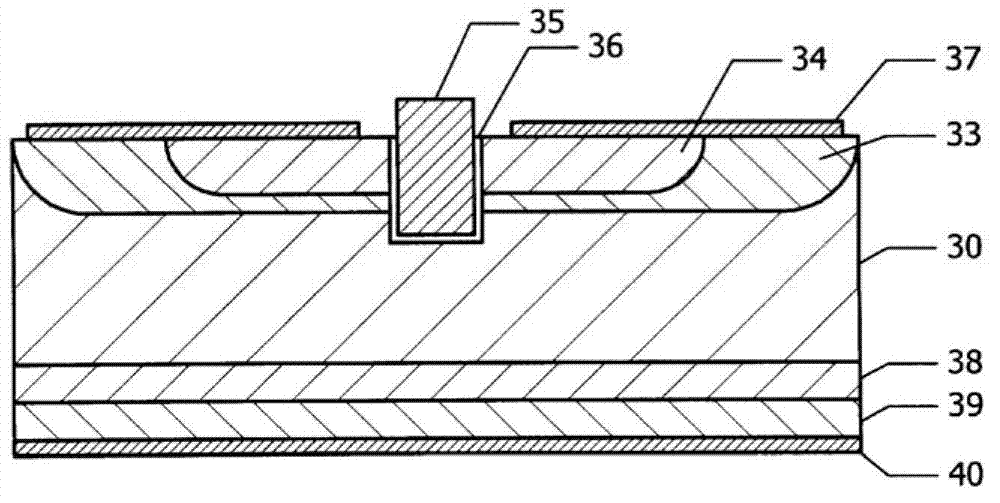

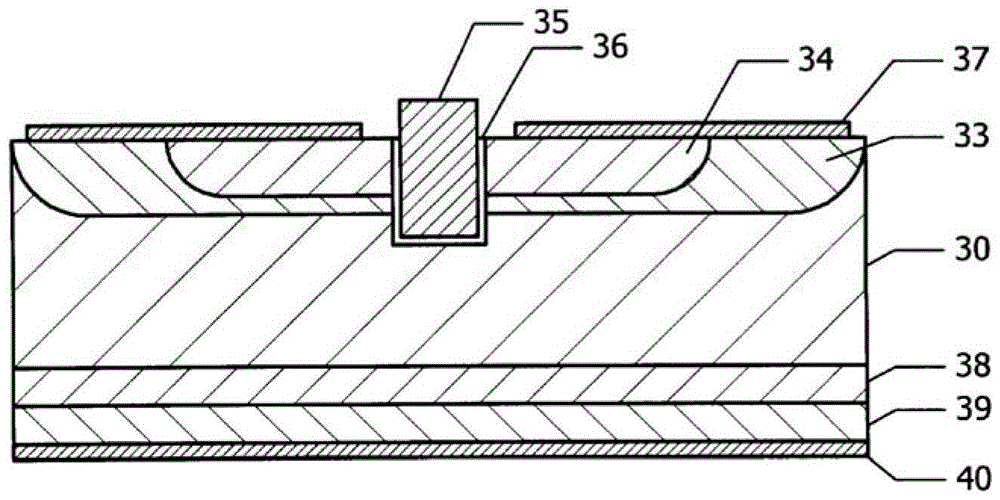

Pressure sensor forming method

ActiveCN104155035AFully annealedReduce internal stressDecorative surface effectsForce measurementLaser processingSemiconductor

A pressure sensor forming method includes the steps that a semiconductor substrate is provided; a bottom electrode layer is formed on the semiconductor substrate; a sacrificial layer is formed on the semiconductor substrate, and the bottom electrode layer is covered with the sacrificial layer; a top electrode layer is formed, and the top face and the side faces of the sacrificial layer and part of the semiconductor substrate are covered with the top electrode layer; the top electrode layer is processed through laser annealing; after the laser processing, an opening penetrating through the top electrode layer in the thickness direction is formed in the top electrode layer, and the sacrificial layer is exposed out of the opening; the sacrificial layer is removed through the opening. Through the pressure sensor forming method, the performance of a formed pressure sensor can be improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Processing technology for copper and titanium composite pipe

The invention discloses a processing technology for a copper and titanium composite pipe. The processing technology includes the following steps that (1) a lubricant is sprayed on the surface of a copper rod, and meanwhile, the copper rod is placed in a titanium pipe to obtain a titanium copper rod; (2) the titanium copper rod in the step (1) is placed into an electric furnace for being heated, and drawing is conducted by being matched with an appropriate mold; (3) the titanium copper rod after drawing is multiply rolled by using a cold press, and oil removal treatment and annealing treatmentare carried out after each rolling; and (4) the burr and crack on the surface of the titanium copper rod are removed, the uneven parts on the two end faces of the titanium copper rod are cut off, polishing is conducted, and the copper and titanium composite pipe is obtained. By means of the processing technology, the copper and titanium composite pipe is manufactured through an explosion method, meanwhile, the lubrication is improved so as to make the surface of the copper and titanium composite pipe be smooth, through the treatment of segmented annealing, the titanium tube billet is thoroughin annealing, refined in grain, and uniform in texture layout, so that the wall thickness of the finished titanium pipe is uniform, and the surface quality is high.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

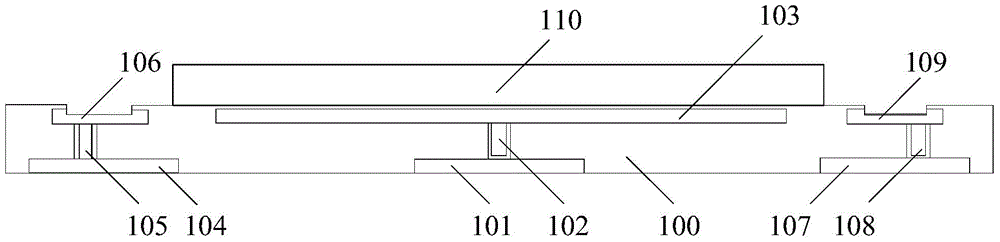

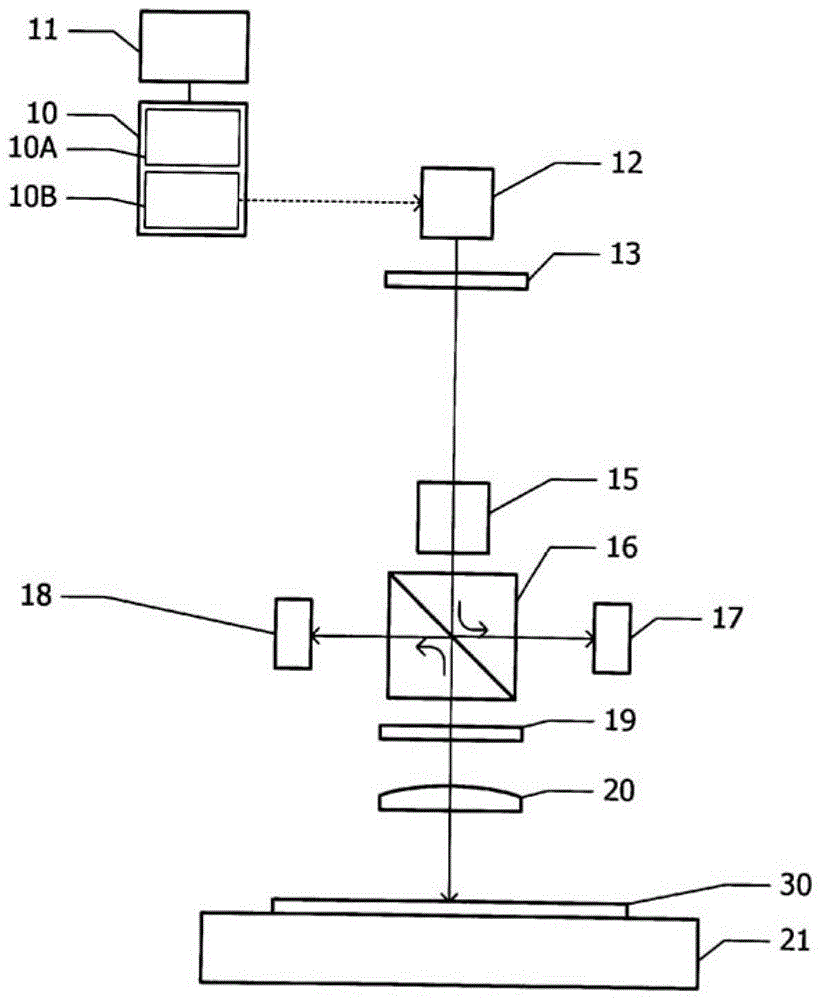

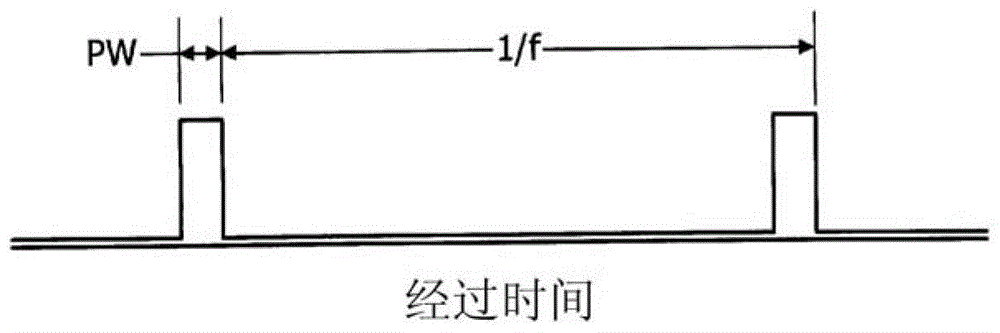

Laser annealing device and laser annealing method

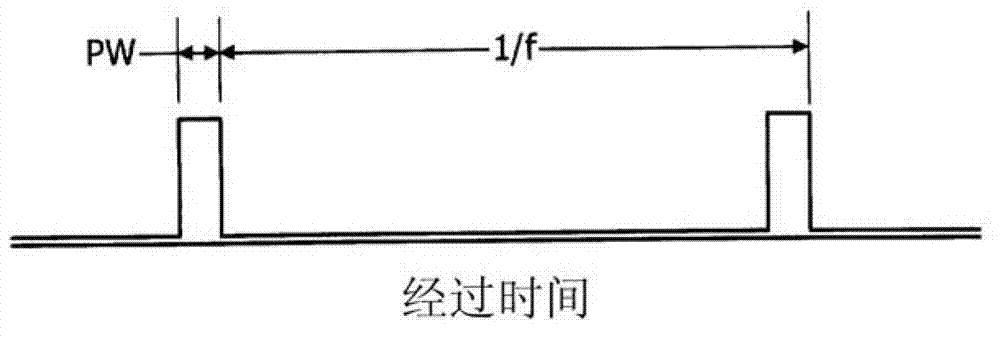

ActiveCN103021826AFully annealedControl heating timeSemiconductor/solid-state device manufacturingMetal working apparatusLaser annealingStart time

Provided are a laser annealing device and a laser annealing method. A general pulse waveform rises sharply from a starting time point of oscillation, shows a peak, and thereafter, decreases gently. At the time point when power shows a peak, the surface of an annealing object is sharply heated and reaches a high temperature. Since time showing the peak is an instant, it is difficult to sufficiently heat a deep region of an annealing object. A laser pulse is emitted from a laser diode when a pulse current is input. An optical system that guides a laser beam emitted from the laser diode to an annealing object. A driver supplies a pulse current that has a time waveform of a top flat and a pulse width of 1 [mu]s to 100 [mu]s to the laser diode.

Owner:SUMITOMO HEAVY IND LTD

Manufacturing method of aluminum alloy conduit having good bending property

ActiveCN107937846AThe difference in wall thickness is reducedHigh dimensional accuracyFurnace typesHeat treatment furnacesCooking & bakingFurnace temperature

The invention provides a manufacturing method of an aluminum alloy conduit having a good bending property. The manufacturing method comprises the steps of sequentially performing heating, extrusion, withdrawal straightening, corrosive washing, rolling, diameter-reducing annealing, drawing, washing, detection and finished product annealing on a hollow ingot to obtain the aluminum alloy conduit, wherein the finished product annealing method comprises the following steps: (1) fixing the temperature of an empty furnace to be 480 to 500 DEG C, maintaining the temperature after the furnace reaches apreset temperature, and baking; (2) after the baking is ended, quickly performing hot-furnace charging to finish charging of the furnace; (3) after charging of the furnace is ended, setting the furnace temperature to be 430 to 450 DEG C, maintaining the temperature and performing annealing treatment; and (4) quickly discharging a product from the furnace after the annealing treatment is ended, and performing air cooling, wherein the time starting from the end point of charging to discharging is shorter than or equal to 65 min. By adopting high-temperature and short-time quick heating, coolingand annealing processes, the manufacturing method provided by the invention can effectively refine grains; the annealing process can be used for obtaining a conduit with a relatively small surface grain size; and the phenomenon of 'Orange Peel', generated in a subsequent bending process, of the aluminum alloy can be prevented.

Owner:SOUTHWEST ALUMINUM GRP

Processing method for copper-titanium alloy tubular product

InactiveCN108941241AImprove anti-corrosion performanceHigh tensile strengthFurnace typesHeat treatment furnacesTitaniumCopper

The invention discloses a processing method for a copper-titanium alloy tubular product. The processing method comprises the following steps: (1) smelting an alloy: putting raw materials in a smeltingfurnace to be smelted; (2) pouring; (3) extruding; (4) rolling; and (5) surface treatment. According to the processing method based on titanium and assisted with copper disclosed by the invention, the prepared alloy tubular product is high in antiseptic property. The tensile strength of the alloy tubular product is good by means of extrusion and rolling.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

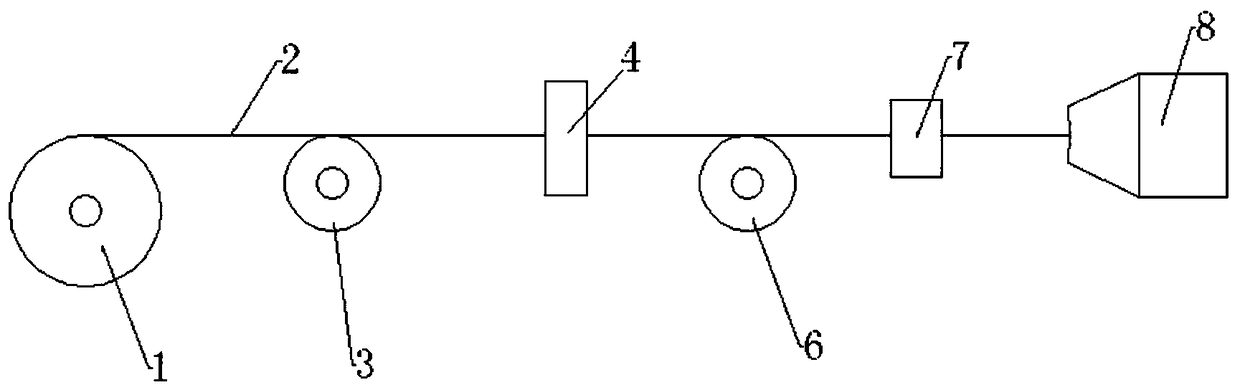

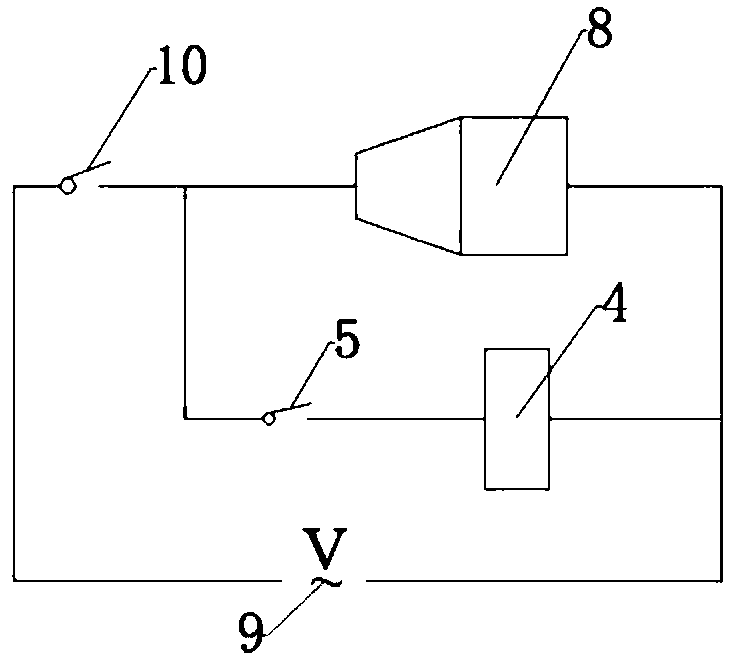

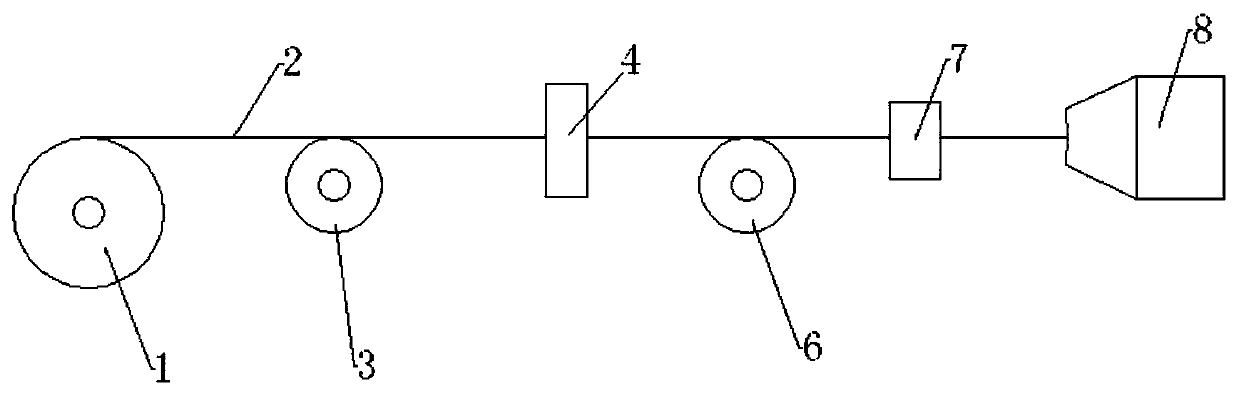

Method for preparing superconducting wire/strip

ActiveCN108878052ASmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsFurnace typesMechanical propertyMetal

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

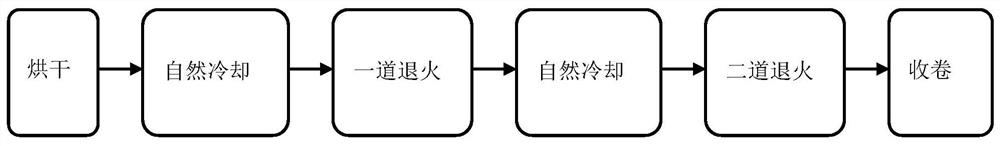

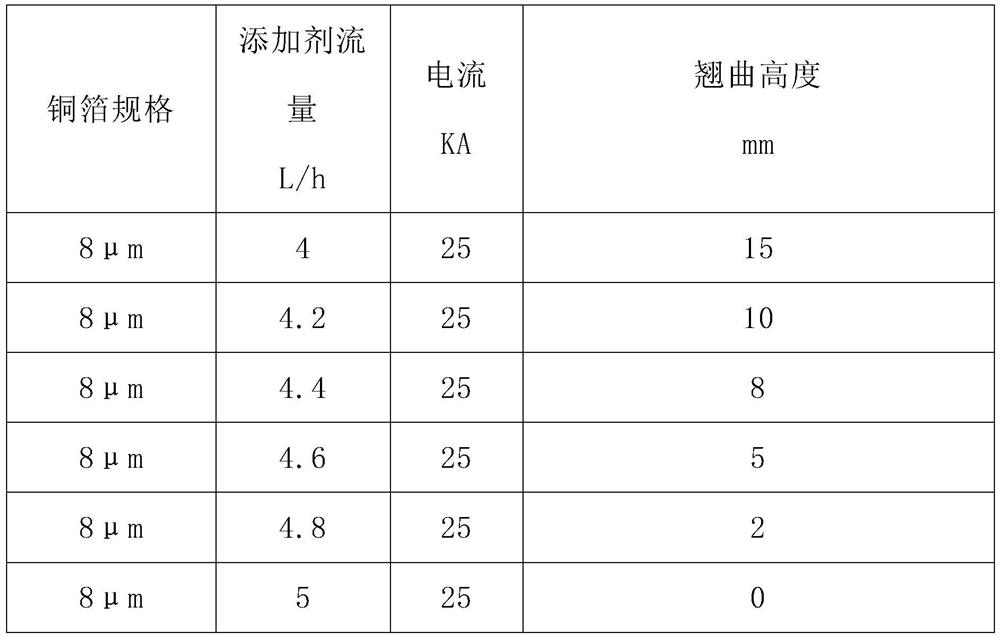

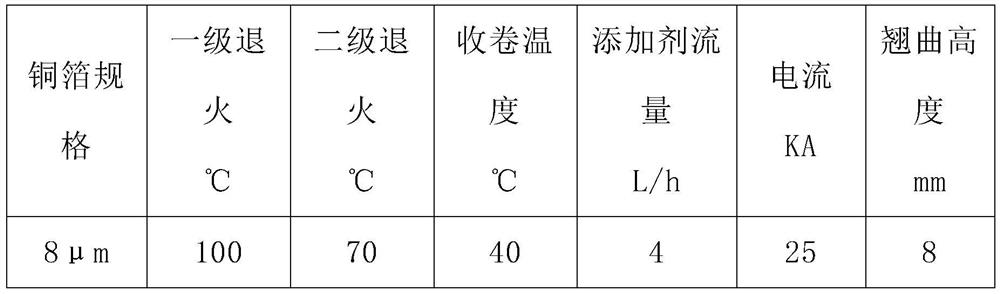

Annealing method for rapidly reducing internal stress of lithium battery copper foil

InactiveCN111733371AFully annealedTo achieve the purpose of stress reliefElectrode carriers/collectorsLi-accumulatorsElectrolysisMetallurgy

The invention discloses an annealing method for rapidly reducing internal stress of a lithium battery copper foil. The annealing method comprises the following steps: adopting a drying system to dry the copper foil, carrying out natural cooling, and entering first-time heating of an annealing system; carrying out natural cooling, and entering second-time heating of the annealing system; and controlling the wound copper foil temperature. Through the annealing method, the electrolysis winding process is utilized for full annealing of the copper foil, and the internal stress of the copper foil isreleased, so that influence of copper foil warping caused by the copper foil internal stress to the rear end application is effectively avoided; the temperature of the copper foil winding process iscontrolled to realize the purpose of releasing the copper foil stress; the electrolysis time is directly utilized to anneal the expanded copper foil, and the annealing method has the advantages of being sufficient in annealing, saving time and being stable in product quality; and with adoption of the annealing method, the treatment time is effectively shortened, and the stability of the copper foil quality is effectively improved.

Owner:JIUJIANG TELFORD ELECTRONICS MATERIAL CO LTD

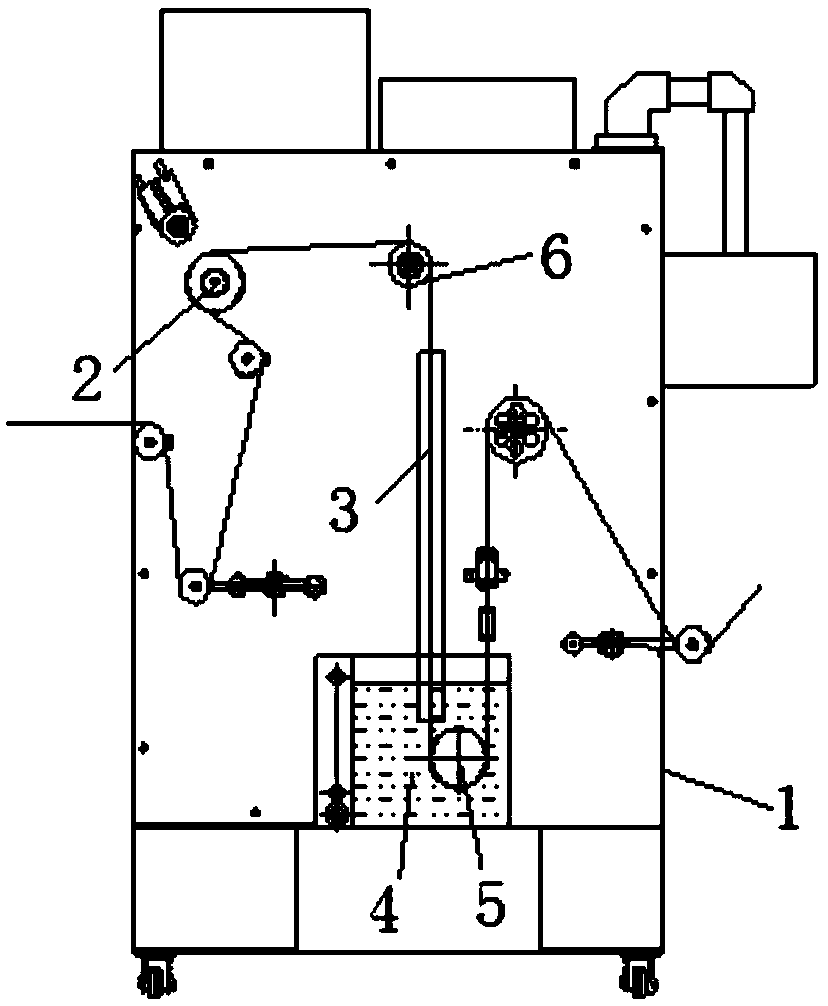

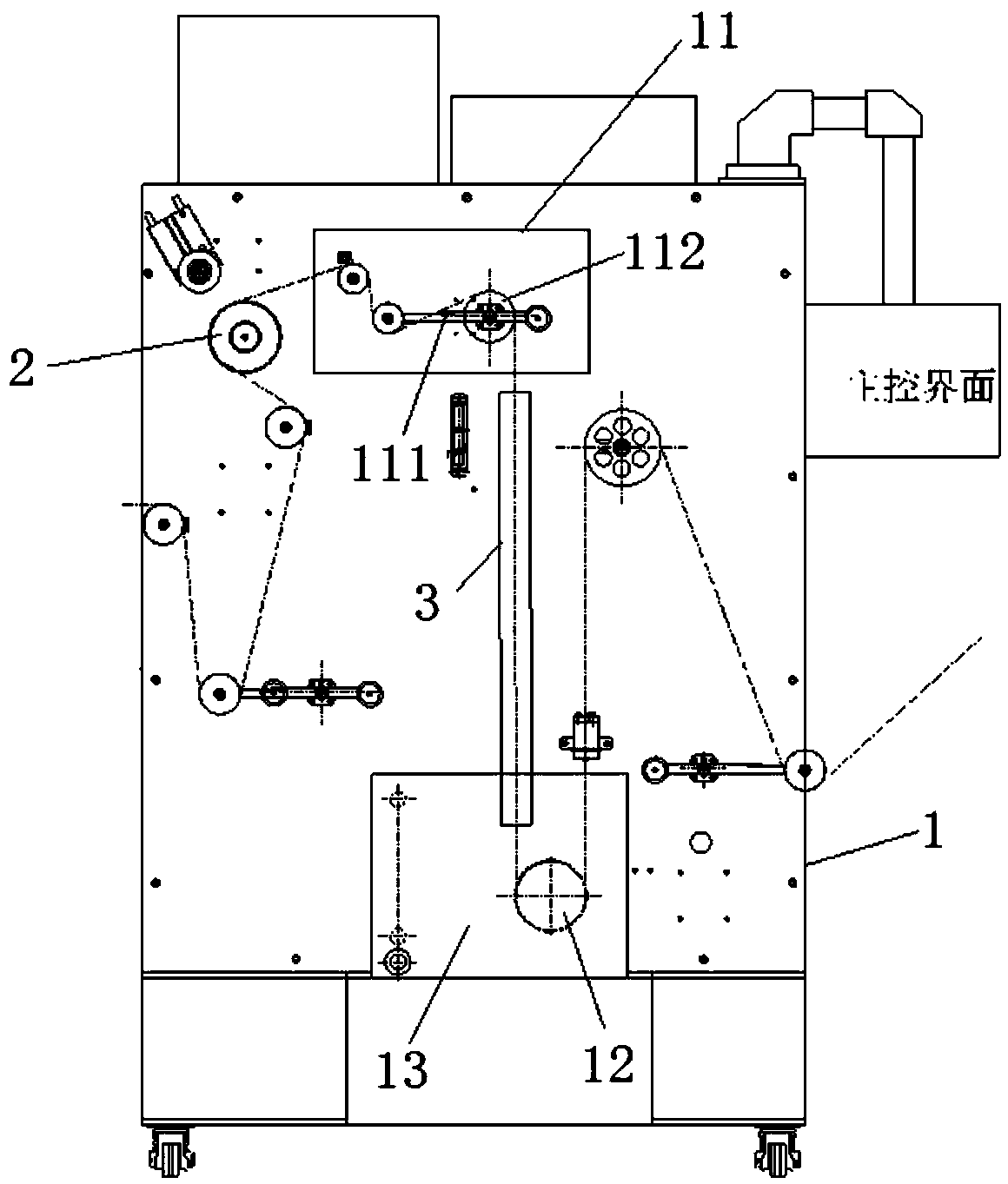

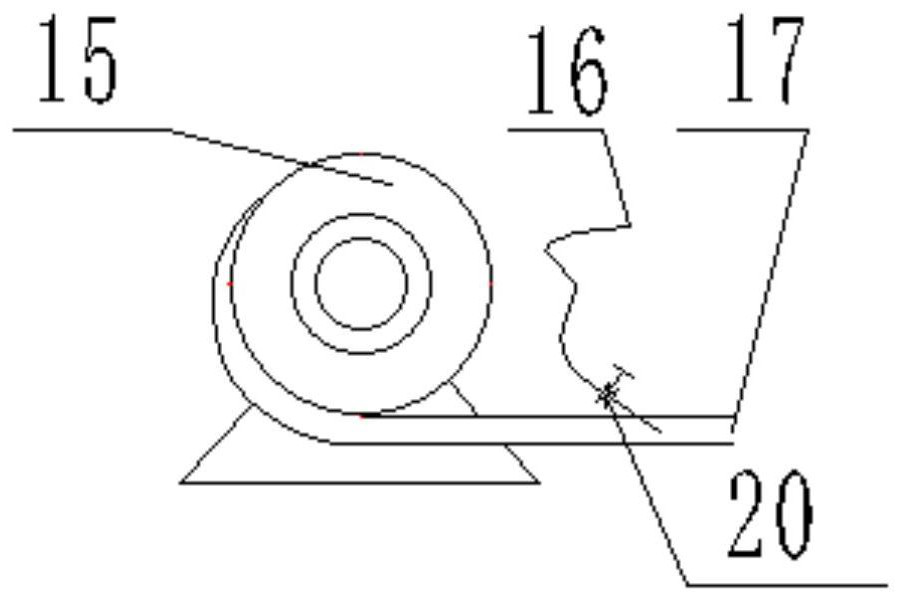

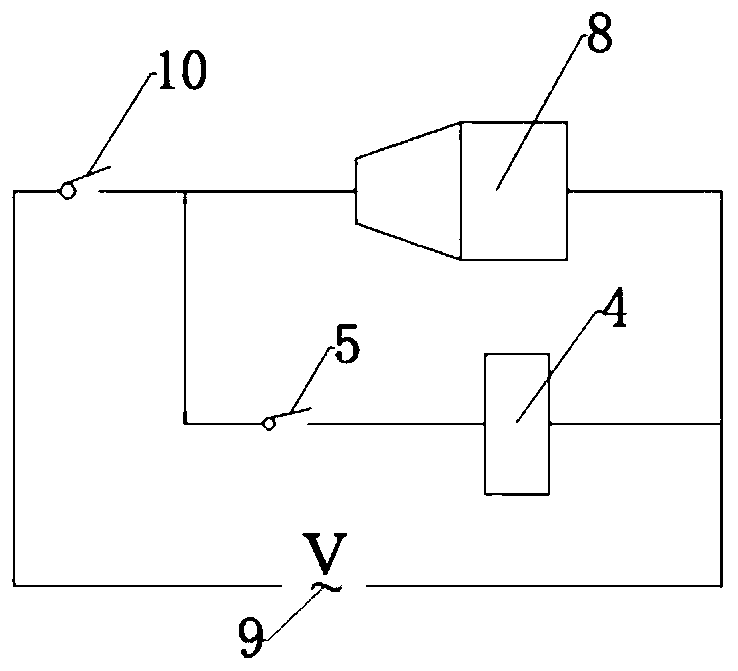

Welding strip annealing device and annealing method

PendingCN109609735AReduce stressLower yield strengthHot-dipping/immersion processesFurnace typesWire rodSaline solutions

The invention discloses a welding strip annealing device. The device comprises a box body, an upper annealing wheel, a glass tube, a saline solution pond, and a passive line passing wheel are arrangedin the box body, the lower end of the glass tube extends into the saline solution pond, the passive line passing wheel is arranged in the saline solution pond. The invention further discloses an annealing method. On the basis of the welding strip annealing device, a saline solution is arranged in the saline solution pond, the upper annealing wheel serves as a positive electrode, the saline solution serves as the negative electrode, the welding strip wire rod passes through the upper annealing wheel and enters the glass tube, and then passes through the glass tube to be immersed in the salinesolution, the positive electrode of the upper annealing wheel and the negative electrode of the saline solution are powered on and pressurized on the two ends of the welding strip wire rod, the welding strip wire rod is heated, and annealing is finished. The annealing device and the annealing method solve the problems that the welding strip is unstable in contact, and prone to slippage and ignition, meanwhile, stress of a cycloid mechanism on the welding strip wire rod can be reduced, the two ends of the electrodes can be charged with higher voltage, annealing is sufficient, and the wire rod yield strength can be effectively reduced.

Owner:XIAN TELISON NEW MATERIAL

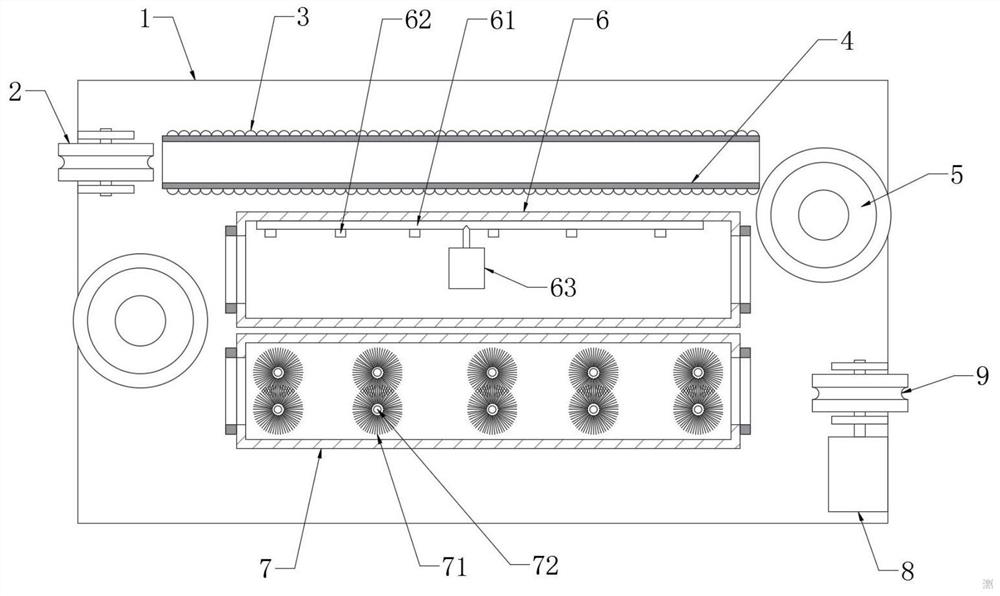

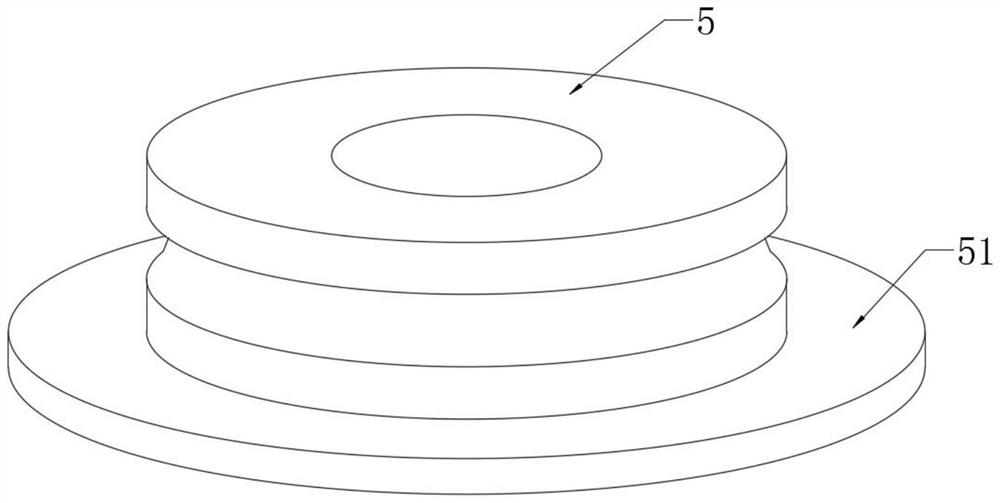

Annealing device for wire and cable manufacturing

ActiveCN113621786AImprove stabilityAvoid Excessive OffsetFurnace typesHeat treatment process controlStructural engineeringElectric cables

Owner:南通锦发电缆有限公司

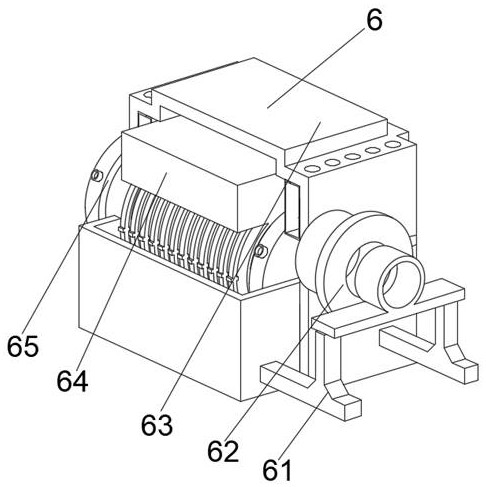

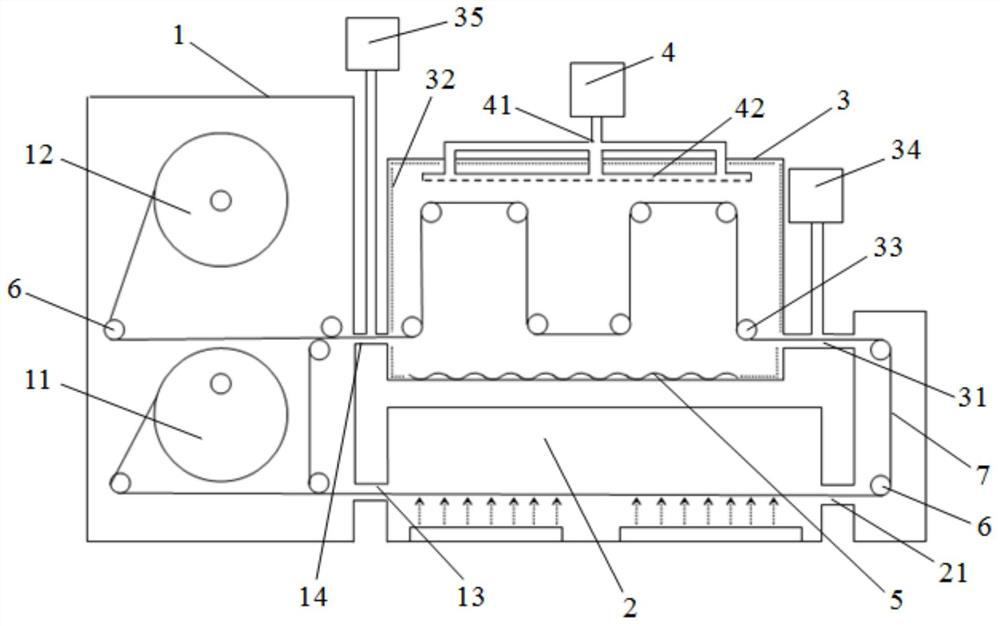

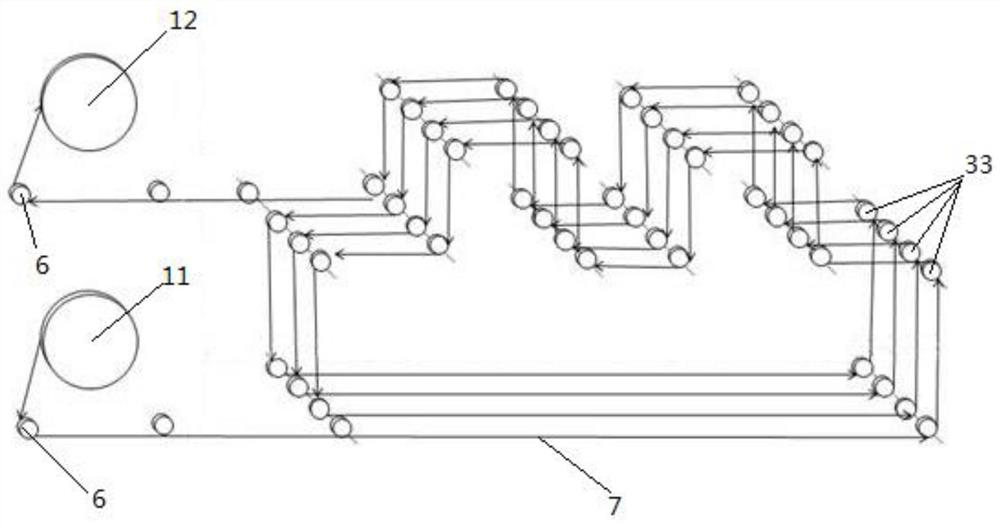

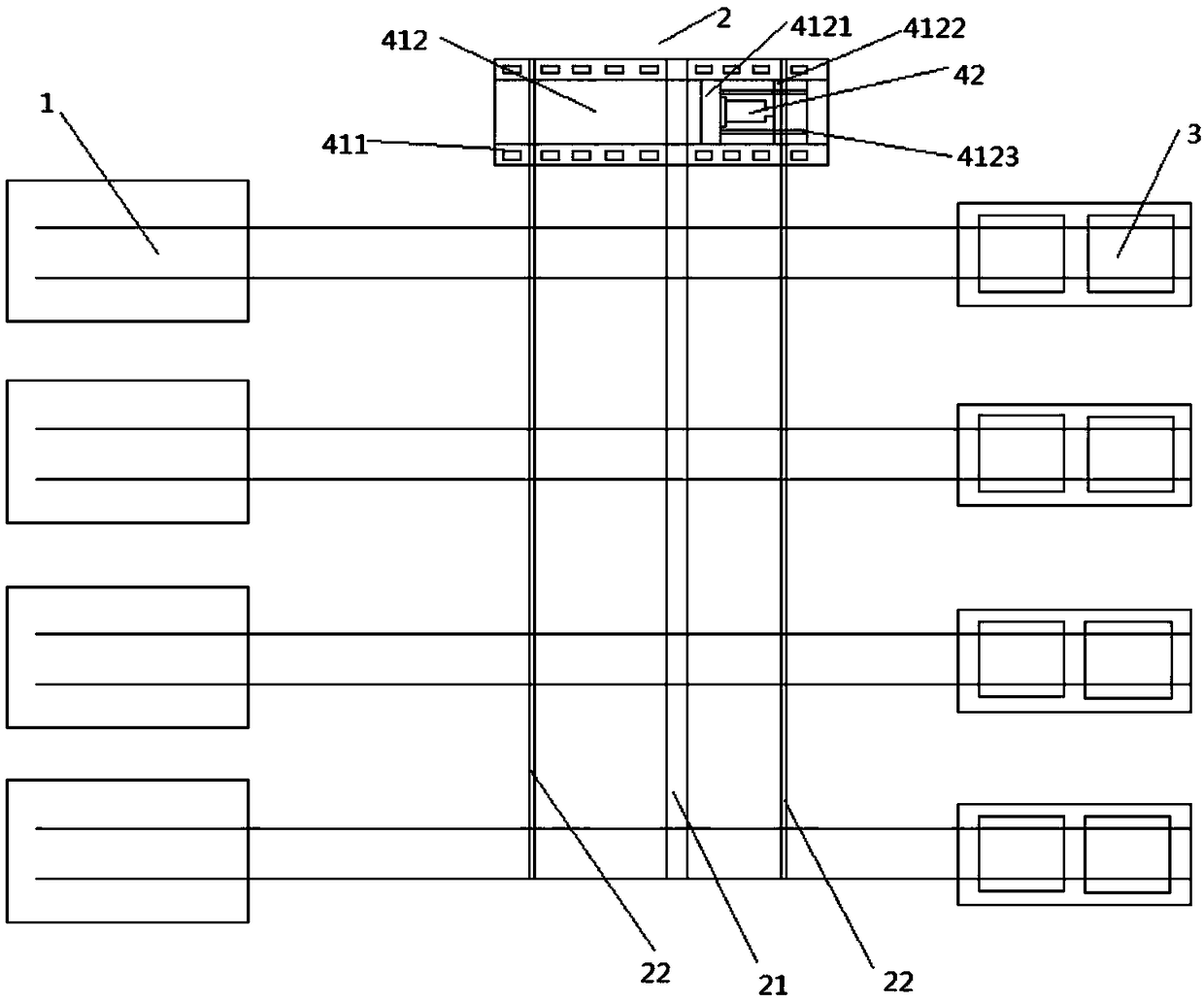

Superconducting strip coating and heat treatment integrated multi-channel winding device

InactiveCN111719132AHigh degree of automationReduce processSuperconductors/hyperconductorsVacuum evaporation coatingTemperature controlHigh temperature superconducting

The invention discloses a superconducting strip coating and heat treatment integrated multi-channel winding device. The superconducting strip coating and heat treatment integrated multi-channel winding device comprises a strip containing cavity, a coating cavity, an annealing cavity and an aerobic device. The strip containing cavity is provided with an unwinding device and a winding device. The coating cavity and the annealing cavity are formed in one side of the strip containing cavity. An unwinding opening is formed in the unwinding device. A winding opening is formed in the winding device.A coating cavity strip outlet is formed in the coating cavity. An annealing strip inlet is formed in the annealing cavity. The annealing cavity is provided with a temperature control device and the aerobic device. A plurality of strip winding mechanisms are arranged in the annealing cavity. A vacuum unit a is arranged at the annealing strip inlet. A vacuum unit b is arranged at the winding opening. According to the scheme, high-temperature superconducting strip coating and heat treatment are conducted synchronously, the annealing efficiency is improved, sufficient annealing is guaranteed, theworking efficiency is improved, the working time is shortened, and the cost and damage caused by improper manual operation are reduced.

Owner:EASTERN SUPERCONDUCTOR SCI & TECH SUZHOU CO LTD

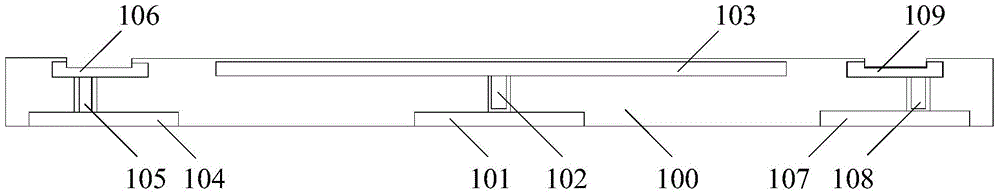

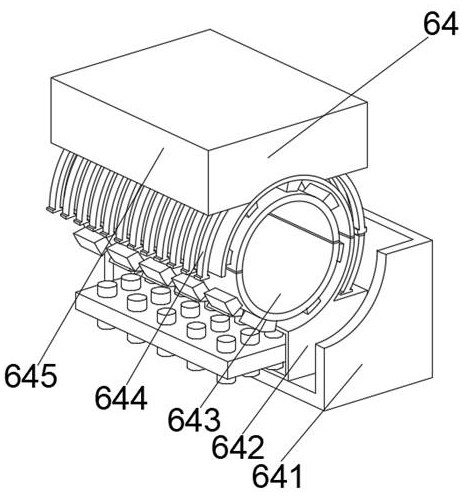

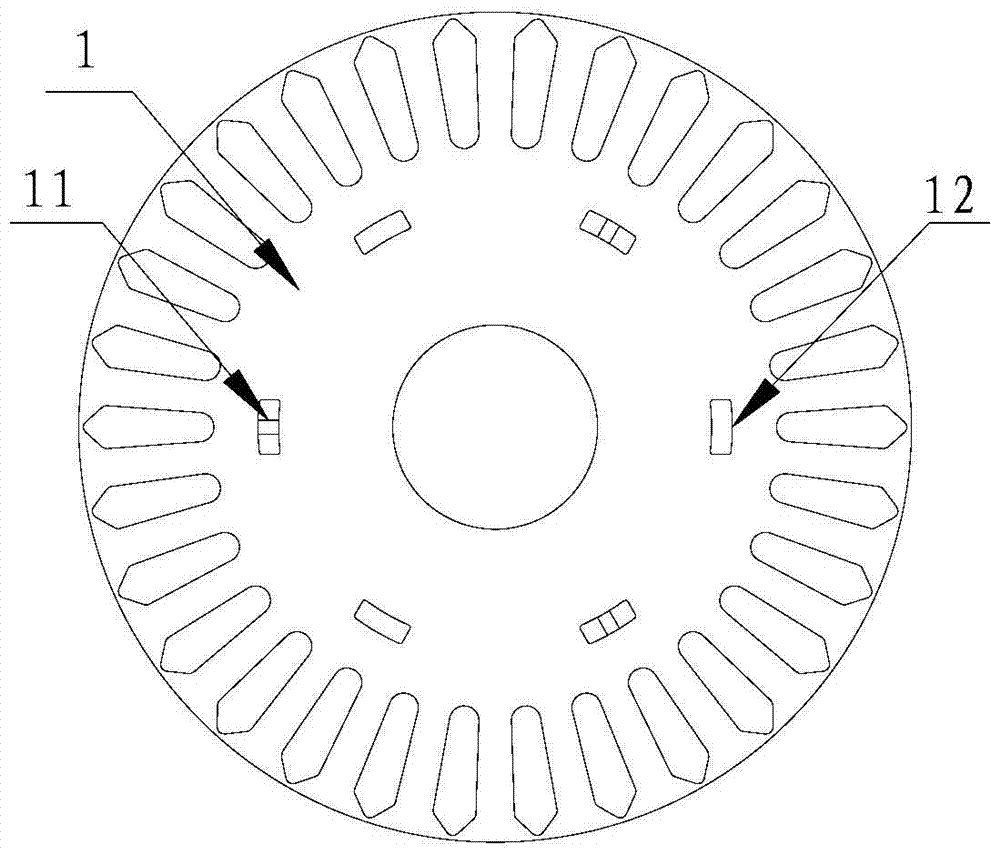

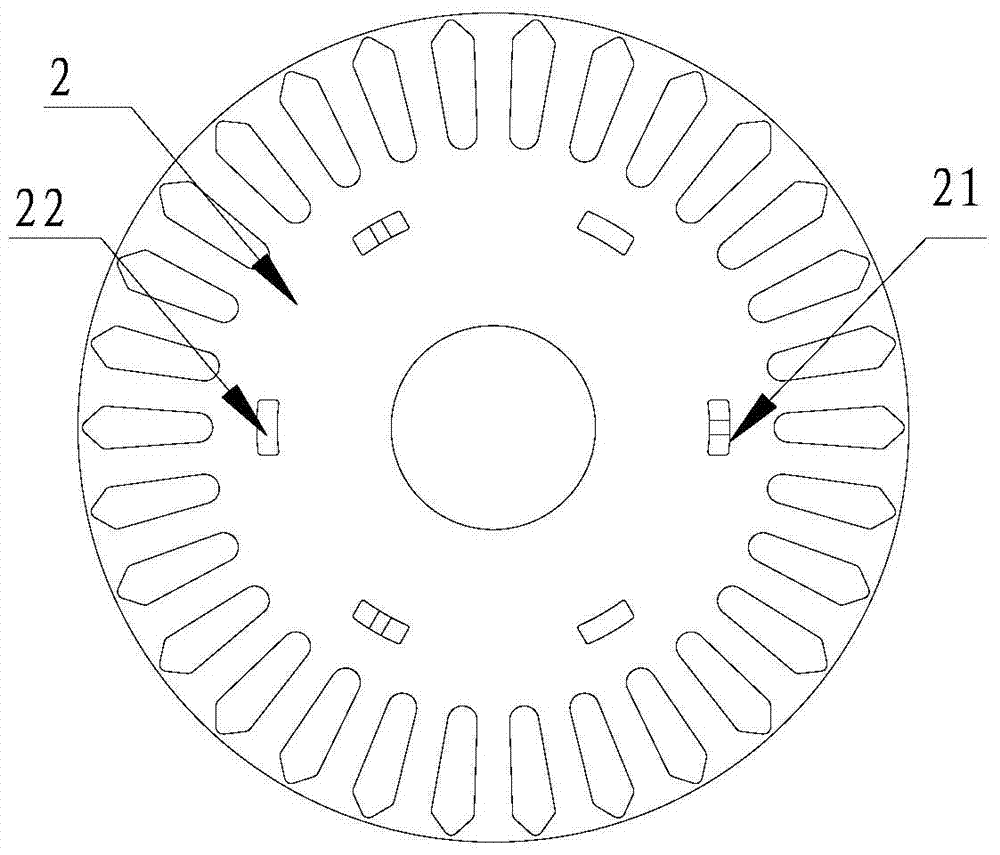

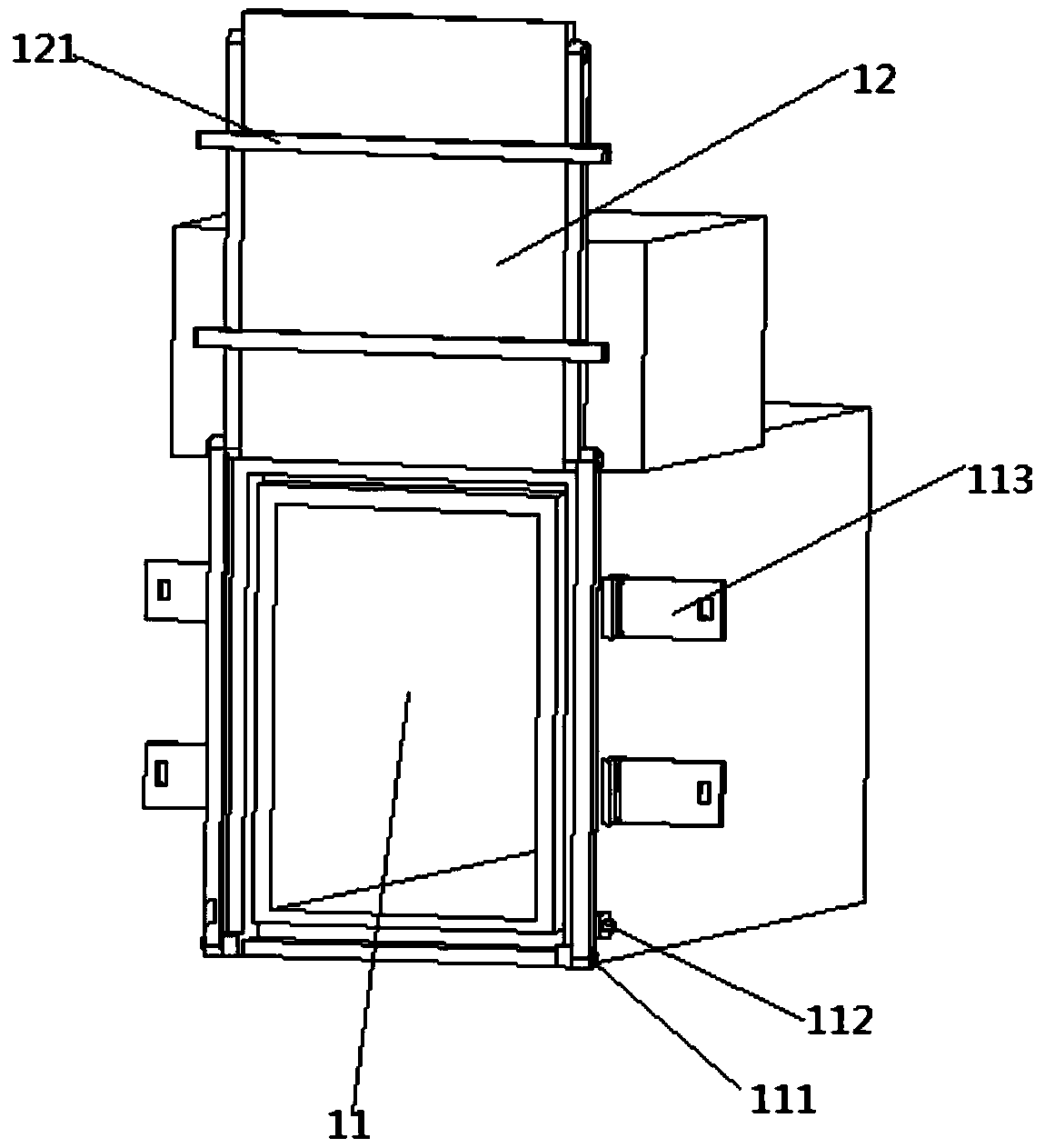

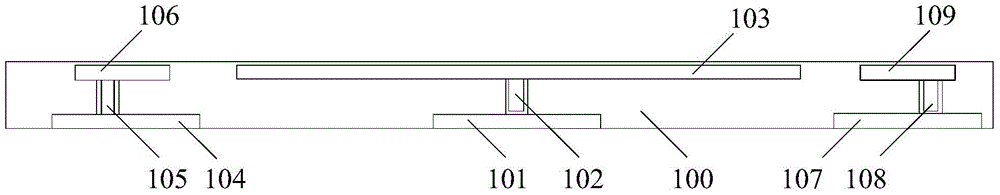

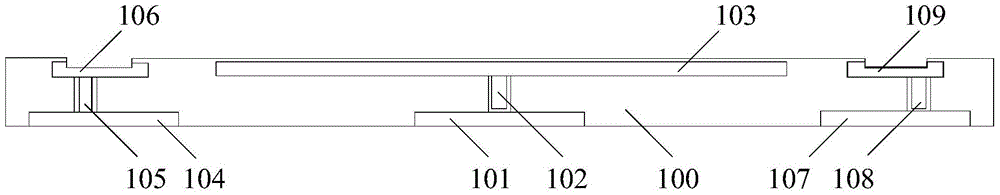

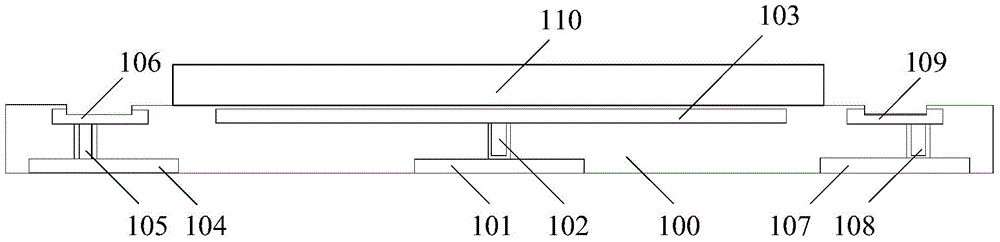

Spacer stacked riveted motor iron core and its manufacturing method and device dedicated to the method

ActiveCN105119394BFully annealedDoes not affect processingManufacturing stator/rotor bodiesMagnetic circuit shape/form/constructionProcessing corePunching

Spacer stacked riveted motor iron core and its manufacturing method and special device for the method, the motor iron core includes a core body, and the iron core body includes a plurality of first punches, a plurality of second punches and a piece of end punching The first punching sheet and the second punching sheet are alternately riveted and superimposed; the end face punching sheet is provided with a plurality of riveted end face riveting through holes, and the end face punching sheet is riveted with the corresponding first punching sheet or the second punching sheet; The manufacturing method includes the following steps: the first cylinder and the second cylinder alternately carry out the state of punching the through hole and the state of the boss of the punching point, punching out the first punching sheet and the second punching sheet and stacking them alternately to form an iron core; The special device includes at least one group of cylinders, a conveyor belt and a central controller, each group of cylinders includes a first cylinder and a second cylinder, and the same group of cylinders is arranged above the conveyor belt and arranged along the conveyor belt. The beneficial effect of the invention is that there is a gap between the punched iron chips and the sheets, which is beneficial to sufficient annealing, and does not affect the processing of the whole iron core to the subsequent process.

Owner:NINGBO HONGDA MOTOR DIE

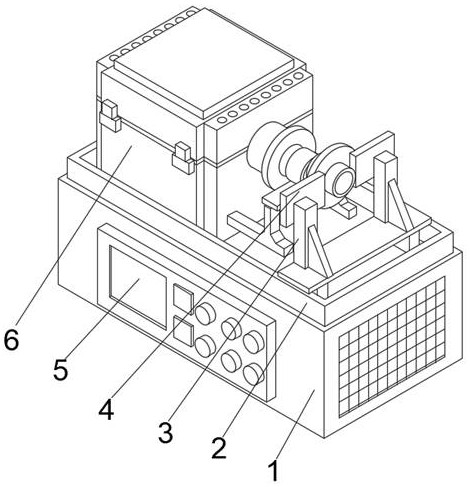

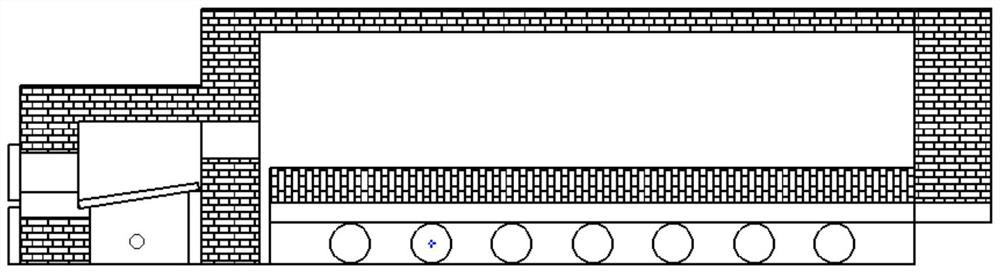

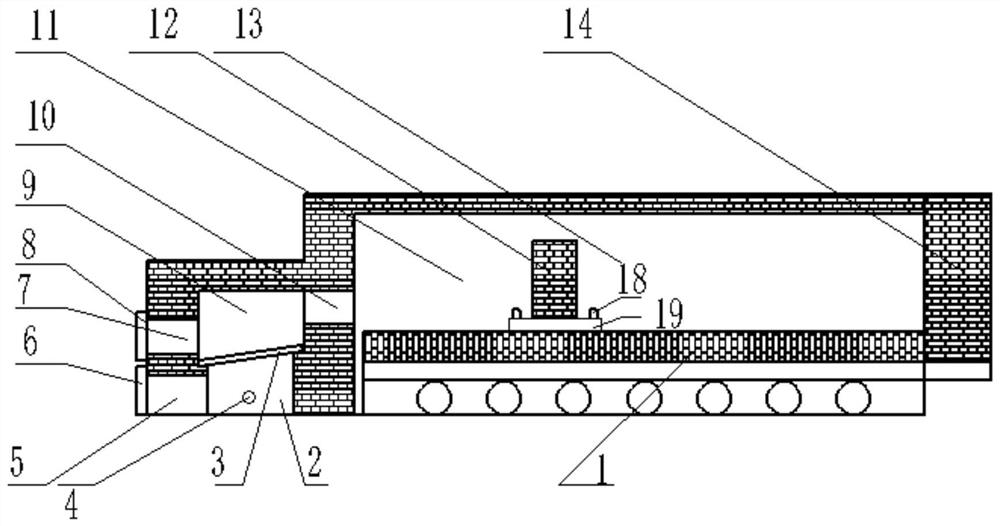

Method for achieving steel casting full-annealing treatment based on iron casting stress relief annealing furnace

ActiveCN113913593AFully annealedRealize full annealing heat treatmentFurnace typesHeat treatment process controlCombustion chamberStress relief

The invention discloses a method for achieving steel casting full-annealing treatment based on an iron casting stress relief annealing furnace. The method comprises the following steps that S1, a fire barrier is additionally arranged on a trolley in a steel casting full-annealing heat treatment chamber of the annealing furnace, the steel casting full-annealing heat treatment chamber is divided into a high-temperature chamber and a low-temperature chamber by the fire barrier, and the high-temperature chamber communicates with a combustion chamber; S2, high-calorific-value coal is added into the combustion chamber; and S3, a combustion fan is started, and compressed air is introduced into the high-temperature chamber when the combustion fan is at a certain temperature. According to the method, structural transformation is simple, full-annealing heat treatment can be effectively conducted on the steel casting, and meanwhile the stress relief heat treatment which does not affect an iron casting is achieved.

Owner:东风汽车零部件集团有限公司通用铸锻分公司

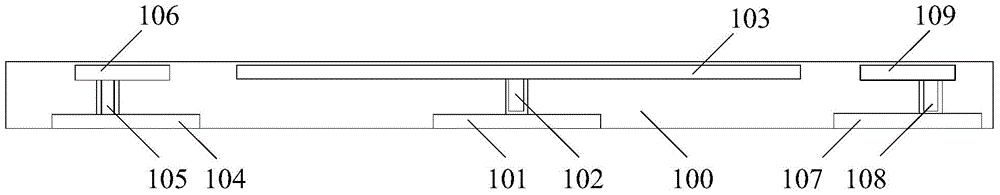

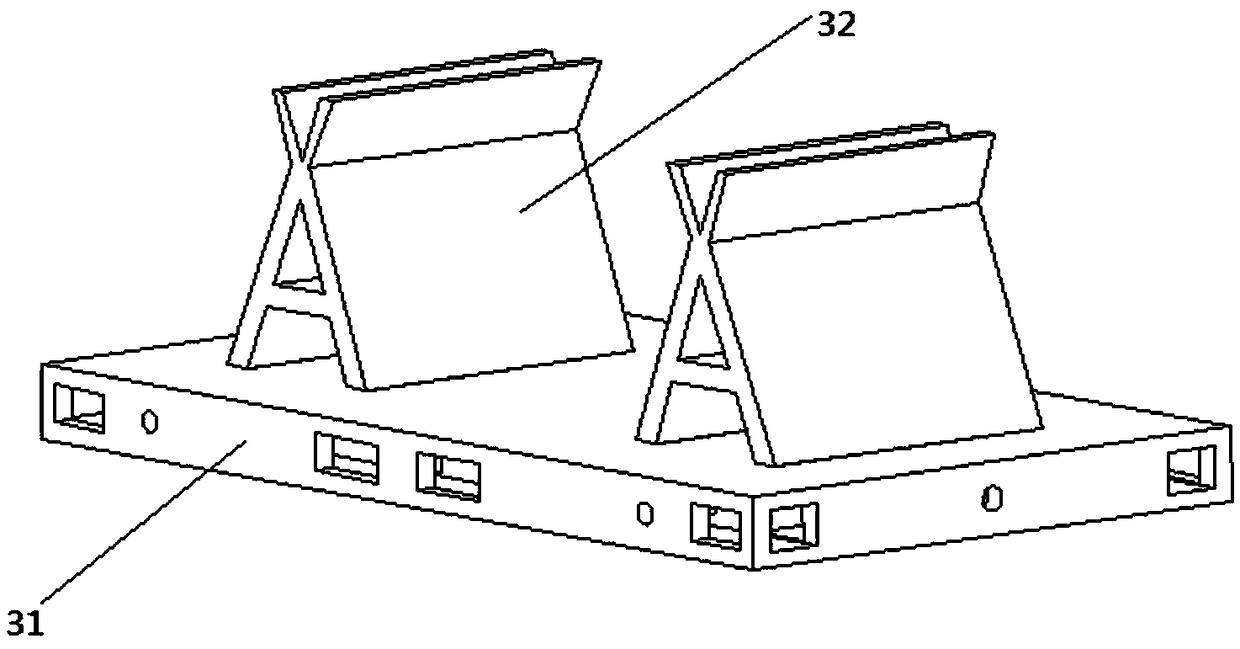

Car-type annealing furnace

PendingCN109468452AFully annealedSave manpower and material resourcesFurnace typesHeat treatment furnacesBogieHydraulic pump

The invention provides a car-type annealing furnace. The furnace comprises annealing furnace bodies, a transporting rail, car supports and a transporting bogie. Each annealing furnace body comprises afurnace body and a furnace door. The transporting rail comprises a limit groove and surface transporting grooves. Each car support comprises a support bottom plate and aluminum roll supporting framesarranged on the support bottom plate, and the support bottom plate is movably connected with the aluminum roll supporting frames. The transporting bogie comprises a transporting support and a hydraulic pump. The annealing furnace bodies are parallel to the car supports, and connected with the car supports through car rails. The transporting bogie is arranged in the surface transporting grooves and the limit groove which are formed between the annealing furnace bodies and the car supports. The car rails are perpendicular to the surface transporting grooves and the limit groove. In the technical field of aluminum plate machining and cleaning, the problems that the leakproofness of annealing furnaces adopted in the annealing process is poor, and the feeding efficiency of a feeding device islow are solved, by means of the technical scheme, the sealing effect is better, a feeding device is efficient, and plate cleaning machining is facilitated.

Owner:NANTONG HENGJIN COMPOSITE MATERIALS

Forming method of pressure sensor

ActiveCN104155035BFully annealedReduce internal stressDecorative surface effectsForce measurementSemiconductorLaser annealing

A method for forming a pressure sensor, comprising: providing a semiconductor substrate; forming a bottom electrode layer on the semiconductor substrate; forming a sacrificial layer on the semiconductor substrate, the sacrificial layer covering the bottom electrode layer; forming a top electrode layer , the top electrode layer covers the top surface, side surfaces and part of the semiconductor substrate of the sacrificial layer; laser annealing is performed on the top electrode layer; after the laser treatment, a through hole is formed in the top electrode layer an opening in the thickness of the top electrode layer, the opening exposing the sacrificial layer; and removing the sacrificial layer through the opening. The forming method can improve the performance of the formed pressure sensor.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

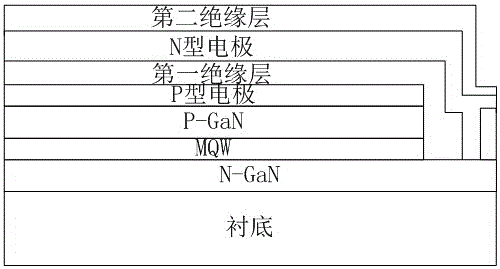

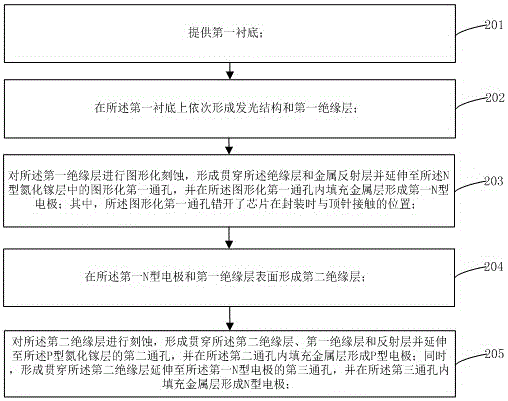

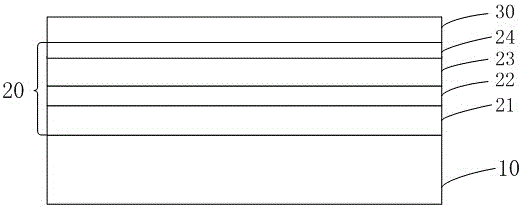

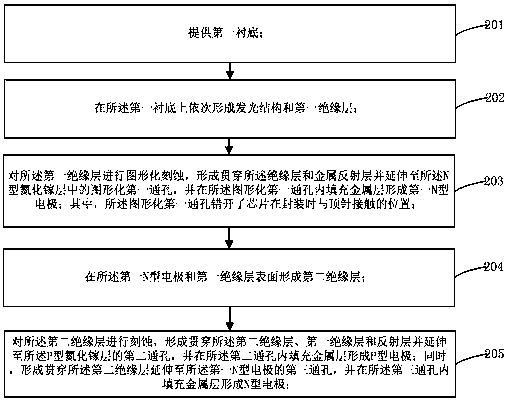

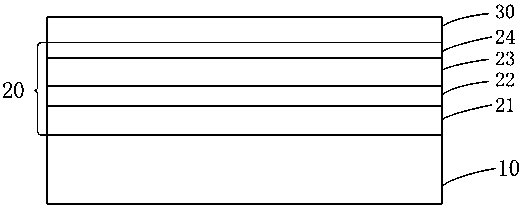

Manufacturing method of flip LED chip

The invention provides a manufacturing method of a flip LED chip. A first substrate is provided; a light-emitting structure and a first insulating layer are sequentially formed on the first substrate; a second insulating layer is formed on a first N-type electrode and the surface of the first insulating layer; the first insulating layer is etched to form a patterned first through hole which runs through the first insulating layer and a metal reflecting layer and extends into a first N-type gallium nitride layer; the contact position of the N-type electrode and a thimble during packaging of the chip is staggered by the patterned first through hole; patterning isolation is carried out on the N-type electrode; a short circuit caused by conduction of a P electrode and the N electrode since the thimble jacks through the insulating layer in the packaging process is prevented; the reliability of the chip in the packaging process is improved; and furthermore, good ohmic contact is formed by full annealing.

Owner:FOSHAN NATIONSTAR SEMICON

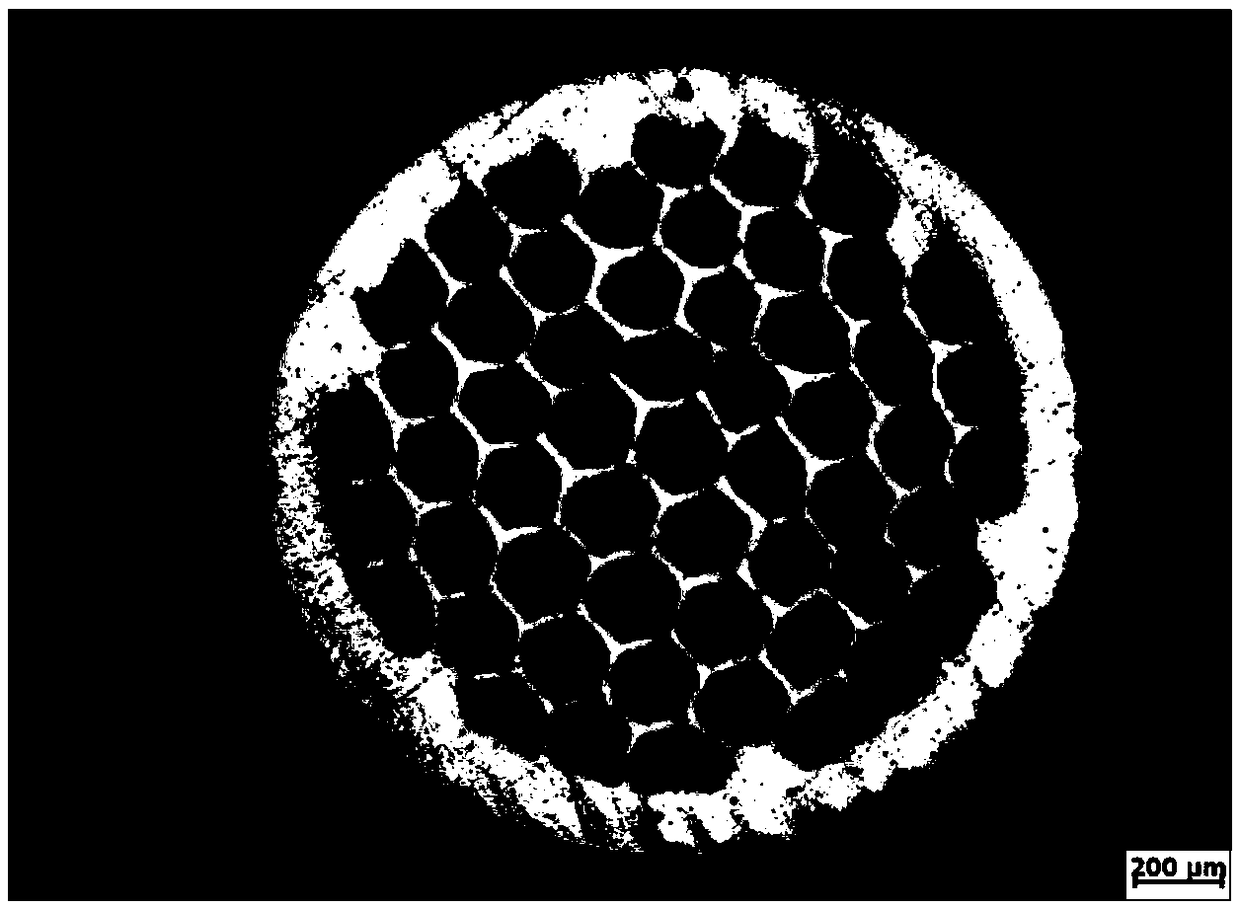

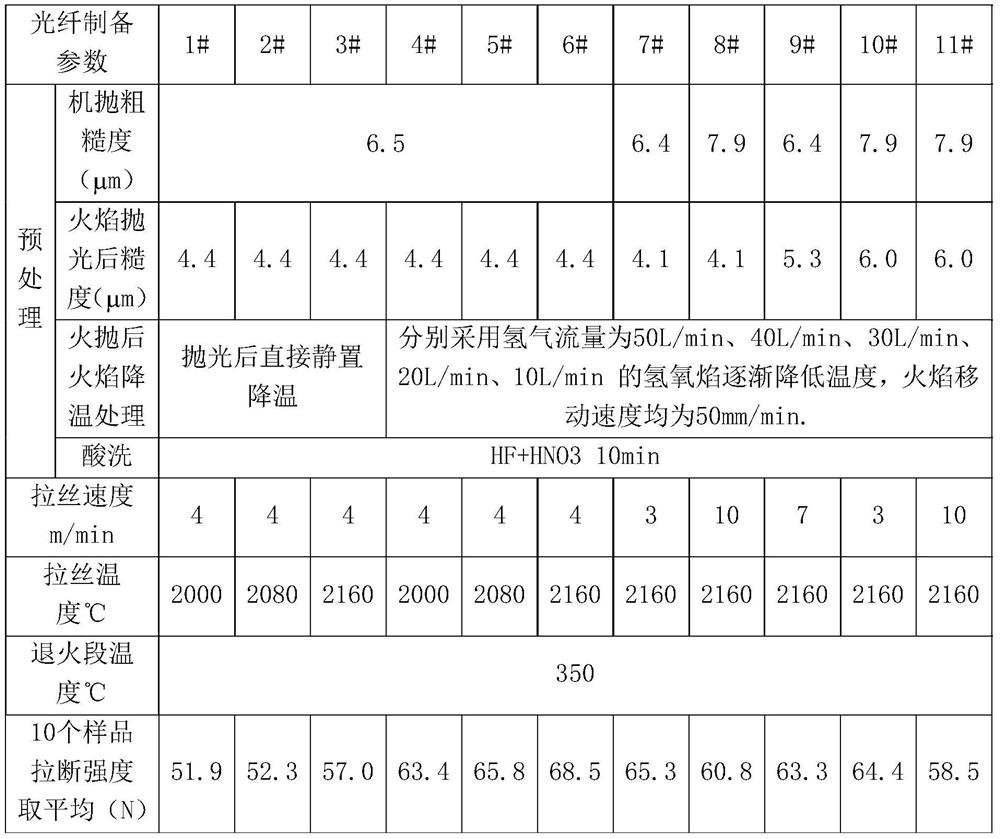

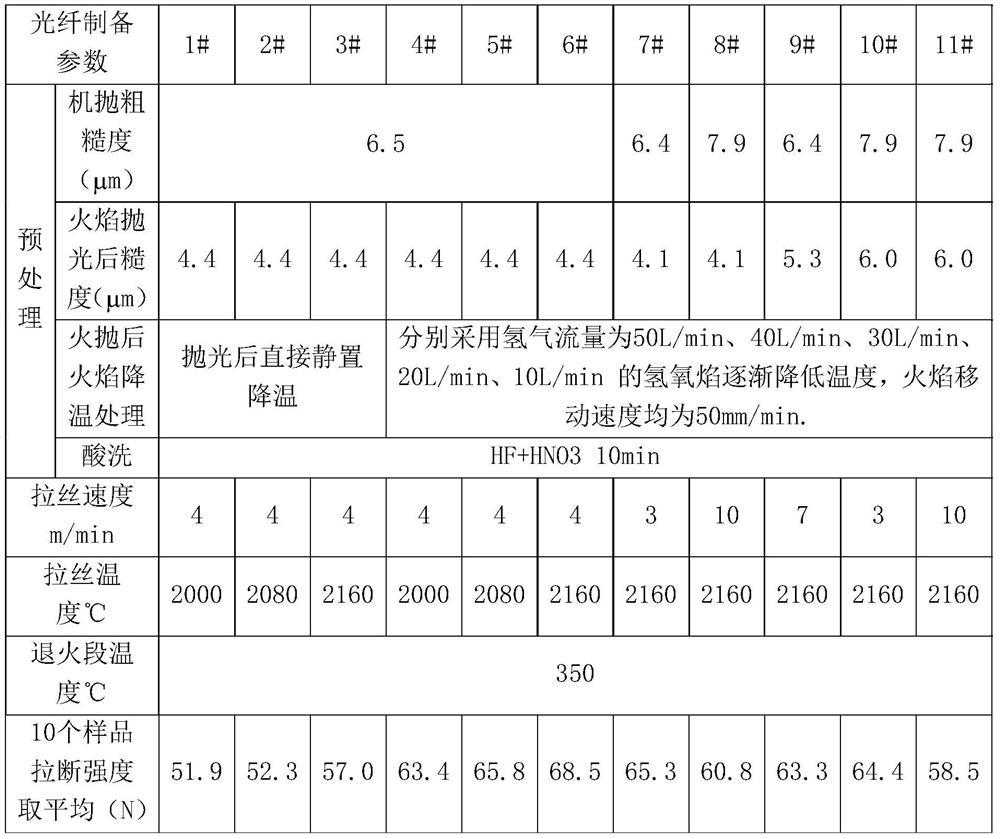

A kind of preparation method of high-strength silica optical fiber

ActiveCN113213748BHigh strengthEliminate temperature gradientsGlass making apparatusBare fiberHydrogen flow

The invention relates to a preparation method of silica optical fiber, in particular to a preparation method of high-strength silica optical fiber, which is used to solve the disadvantage that the strength of the existing silica optical fiber cannot meet the requirements of special application occasions. The preparation method of the high-strength silica optical fiber comprises the following steps: firstly, mechanically polishing a quartz preform with a diameter of 20-35 mm, the roughness after polishing is 6-8 μm, and then performing flame polishing, and the roughness after polishing is 4-6 μm , and then gradually reduce the heating temperature by gradually reducing the flow rate of hydrogen in the oxyhydrogen flame. After stopping the heating, let the quartz preform stand at room temperature, pickle the quartz preform and then draw it. The drawing speed is 3-10m / min , while annealing the bare optical fiber output from the exit of the drawing furnace, the length of the annealing section is 600mm, the annealing temperature is 300-500°C, and finally the bare optical fiber is coated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

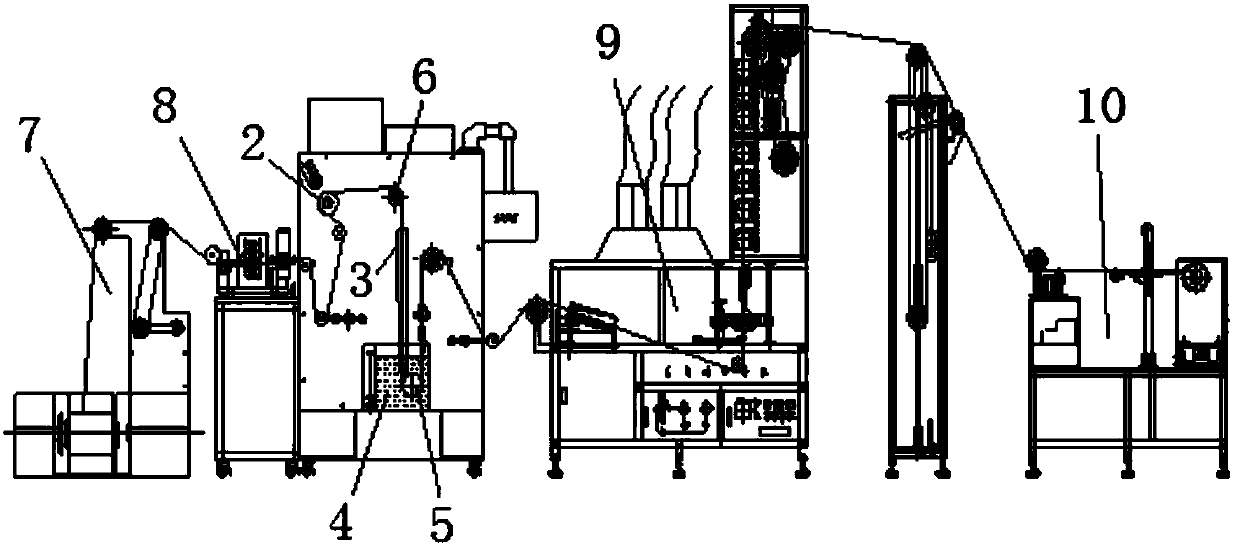

Annealing treatment device for enameled wire processing and using method

PendingCN114058795AExtended annealing timeFully annealedApparatus for heat treatmentFurnace typesSteering wheelCopper wire

The invention provides an annealing treatment device for enameled wire processing and a using method, the device comprises a heating mechanism, awind-heat annealing mechanism, a surface cleaning mechanism, a driving mechanism and a sealing cover which are arranged on a support, the heating mechanism is a spiral copper pipe, and an iron copper wire is subjected to electromagnetic heating treatment through an external radio frequency power supply of the spiral copper pipe; and the wind-heat annealing mechanism is a wind-heat box with a heating function and is used for prolonging the annealing time of the copper wire and fully annealing the copper wire, the surface cleaning mechanism is a cleaning box and is used for timely treating a surface oxide film of the quenched copper wire, the driving mechanism comprises a leading-in wheel, a steering wheel, a leading-out wheel and a gear motor, and a power shaft of the gear motor is connected with the leading-out wheel. The gear motor provides single drive to pull the copper wire, looseness between the leading-in wheel and the leading-out wheel is prevented, the structure is reasonable, the enameled wire is fully and uniformly annealed, high temperature and air contact oxidation is prevented, and stains on the surface of the enameled wire are cleaned in time.

Owner:江苏龙创新材料科技有限公司

A kind of preparation method of superconducting wire/ribbon

ActiveCN108878052BSmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsIncreasing energy efficiencyWire rodHeat treating

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A method for nitriding crystallization of metastable samarium-iron alloy

ActiveCN106960712BFully annealedIncrease the amount of nitridingSolid state diffusion coatingInductances/transformers/magnets manufactureMolten stateFerroniobium

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Laser annealing device and laser annealing method

ActiveCN103021826BFully annealedControl heating timeSemiconductor/solid-state device manufacturingMetal working apparatusStart timePeak value

The invention provides a laser annealing device and a laser annealing method. A general pulse waveform rises sharply from the start of oscillation, shows a peak value, and then gradually decreases. When the power shows a peak value, the surface of the annealing object is rapidly heated to a high temperature. Since the peak time is instantaneous, it is difficult to sufficiently heat the deep region of the annealing object. In the laser annealing apparatus of the present invention, when a pulse current is input, a laser pulse is emitted from a laser diode. The optical system guides the laser beam emitted from the laser diode to the annealing object. The driver supplies a pulse current having a top flat time waveform and a pulse width of 1 μs to 100 μs to the laser diode.

Owner:SUMITOMO HEAVY IND LTD

Preparation method of high-strength quartz optical fiber

ActiveCN113213748AHigh strengthEliminate temperature gradientsGlass making apparatusHydrogen flowOxyhydrogen

The invention relates to a preparation method of a quartz optical fiber, and in particular, relates to a preparation method of a high-strength quartz optical fiber, wherein the method is used for overcoming the defect that the strength of an existing quartz optical fiber cannot meet the requirements of special application occasions. The preparation method of the high-strength quartz optical fiber comprises the following steps: firstly, carrying out mechanical polishing on a quartz preform with the diameter size of 20-35 mm until the roughness is 6-8 [mu]m after polishing, then carrying out flame polishing until the roughness is 4-6 [mu]m after polishing, gradually reducing the heating temperature in a manner of gradually reducing the flow of hydrogen in oxyhydrogen flame, standing the quartz preform to room temperature after stopping heating, carrying out acid pickling treatment on the quartz preform, carrying out wire drawing at a wire drawing speed of 3-10 m / min, annealing a bare optical fiber output from an outlet of a wire drawing furnace at an annealing section length of 600 mm and an annealing temperature of 300-500 DEG C, and finally coating the bare optical fiber.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

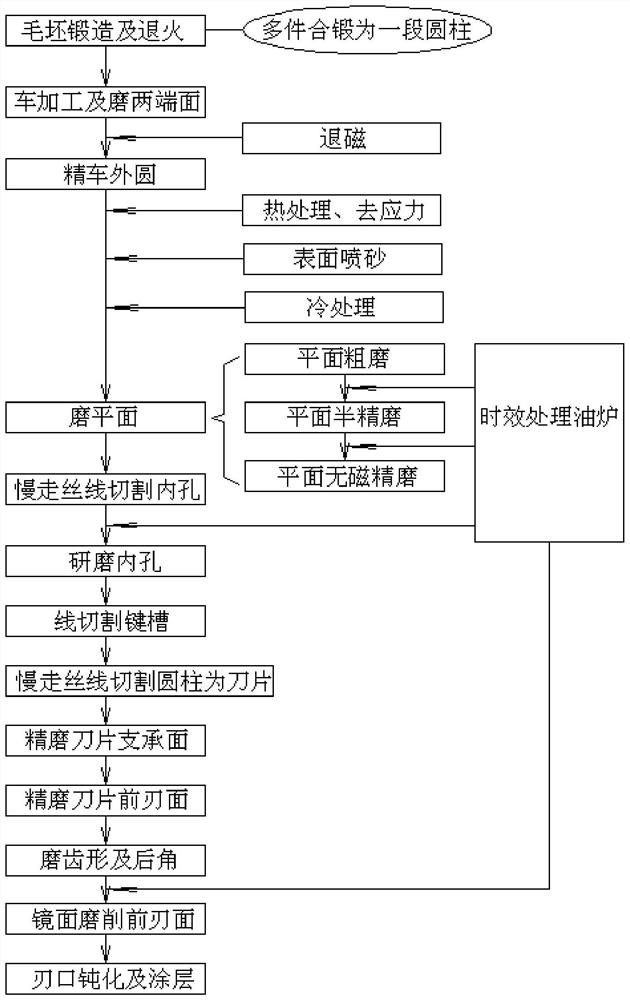

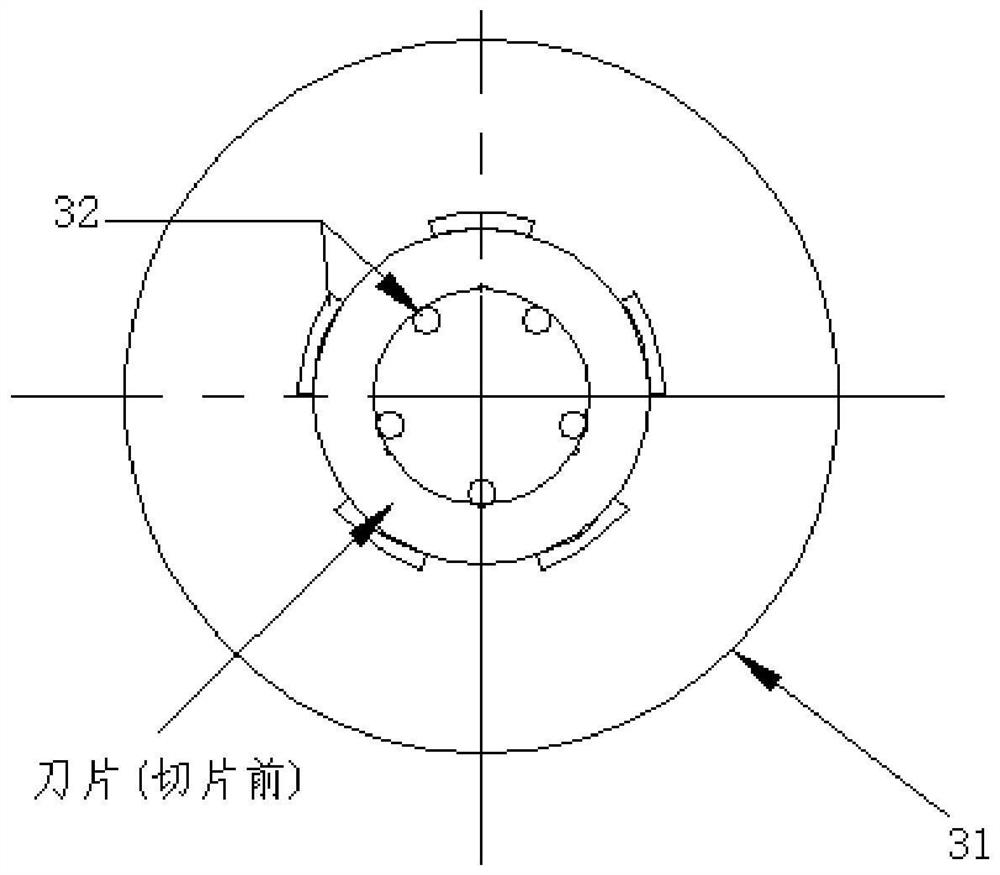

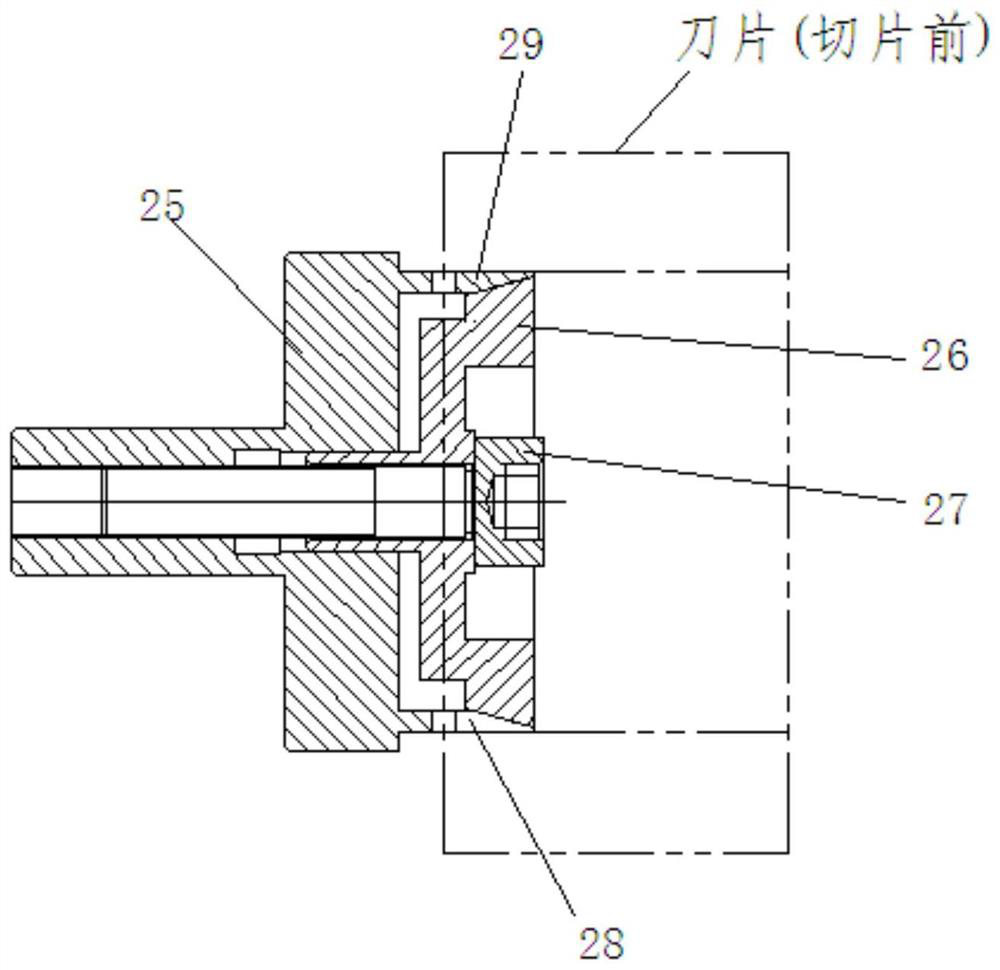

A manufacturing process of an ultra-thin shaper blade

The invention relates to the technical field of slotting cutter manufacturing, and discloses a manufacturing process of an ultra-thin slotting blade. According to the manufacturing procedure, the process sequentially includes the steps of forging and annealing a blank, lathing and grinding the two end faces, performing finish turning on an outer circle, grinding the flat face, cutting an inner hole through a slow-feeding wire, grinding the inner hole, cutting a key groove through the wire, cutting a cylinder into a blade through the slow-feeding wire, accurately grinding a blade supporting face, accurately grinding a blade front edge face, grinding a tooth profile and a relief angle, performing mirror grinding on a front blade face, passivating a cutting edge and conducting coating. In theblank forging and annealing step, multiple blades are combined and forged into the cylinder blank. The demagnetizing step is executed between the step of lathing and grinding the two end faces and the step of performing finish turning on the outer circle. The steps of heat treatment, destressing, surface sand blasting and cold treatment are sequentially executed between the step of performing finish turning on the outer circle and the step of grinding the flat face. By means of the manufacturing process, the manufacturing quality of the ultra-thin slotting blade is improved.

Owner:JIANGYIN SAITE PRECISION TOOL

A kind of optimized preparation method of lf2 aviation catheter

ActiveCN108145386BPipe layingImprove ventilationFurnace typesHeat treatment furnacesStructural engineeringProcess engineering

The invention provides an optimization preparation method of an LF2 aviation guide pipe. The optimization preparation method comprises the following steps of heating, extruding, puling and correcting,etching, rolling, diameter reducing annealing, drawing, straightening, cleaning, detection and finished product annealing for a hollow ingot are carried out in sequence, so that an aluminum alloy conduit is obtained. According to the method, the cutting inclination, the wall thickness difference and the curvature degree of the hollow ingot are specifically controlled, so that the prepared conduithas good dimensional accuracy; the aluminum alloy conduit is prepared by adopting a non-lubricating extrusion process under the specific perforation needle length, and the aluminum alloy conduit withgood inner surface quality is obtained under the condition that the perforating needle is not damaged in the extrusion process; a high-temperature short-time and rapid heating cooling annealing process is adopted, so that a guide pipe with a small surface grain size is obtained, and the phenomenon that the aluminum alloy generates "orange peel" in the follow-up bending process is avoided. According to the optimization preparation method, the LF2 aviation guide pipe with good quality is prepared under the comprehensive action of various processes.

Owner:SOUTHWEST ALUMINUM GRP

A kind of preparation method of aluminum alloy pipe with good bending performance

ActiveCN107937846BPipe layingImprove ventilationFurnace typesHeat treatment furnacesFurnace temperatureIngot

Owner:SOUTHWEST ALUMINUM GRP

A kind of processing technology of titanium alloy tube

Owner:陕西优美特金属材料有限公司

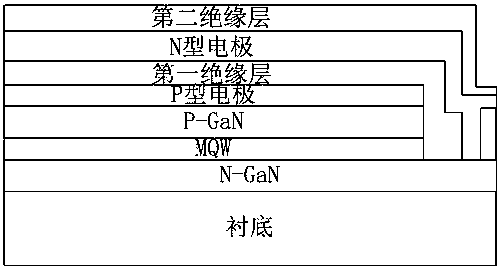

A method of manufacturing a flip-chip led chip

ActiveCN105932143BImprove reliabilityAvoid short circuitSemiconductor devicesOhmic contactGallium nitride

The invention provides a manufacturing method of a flip LED chip. A first substrate is provided; a light-emitting structure and a first insulating layer are sequentially formed on the first substrate; a second insulating layer is formed on a first N-type electrode and the surface of the first insulating layer; the first insulating layer is etched to form a patterned first through hole which runs through the first insulating layer and a metal reflecting layer and extends into a first N-type gallium nitride layer; the contact position of the N-type electrode and a thimble during packaging of the chip is staggered by the patterned first through hole; patterning isolation is carried out on the N-type electrode; a short circuit caused by conduction of a P electrode and the N electrode since the thimble jacks through the insulating layer in the packaging process is prevented; the reliability of the chip in the packaging process is improved; and furthermore, good ohmic contact is formed by full annealing.

Owner:FOSHAN NATIONSTAR SEMICON

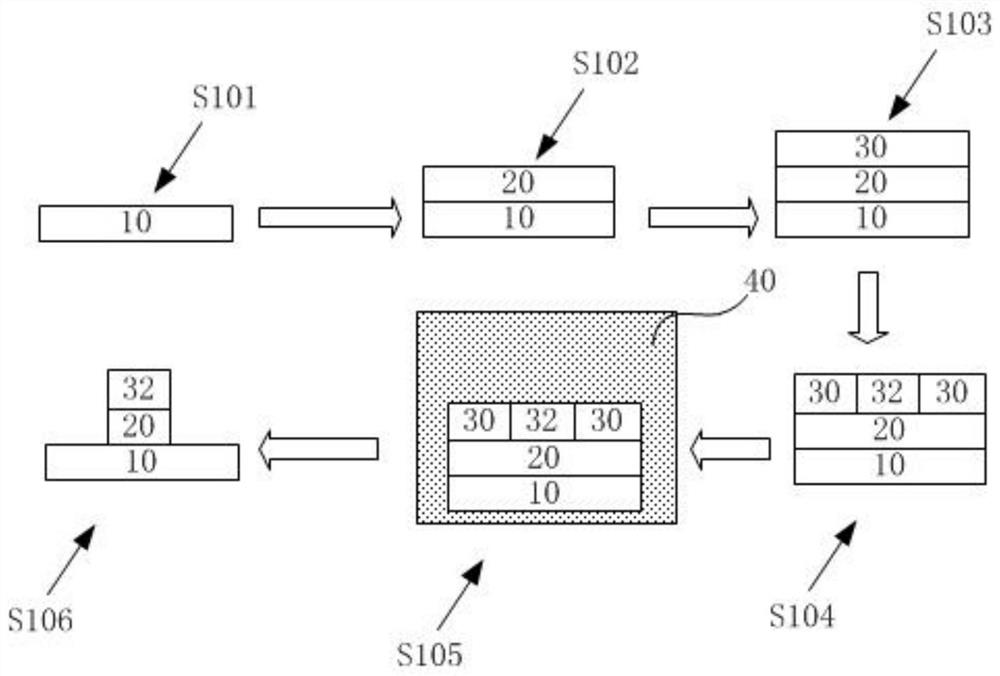

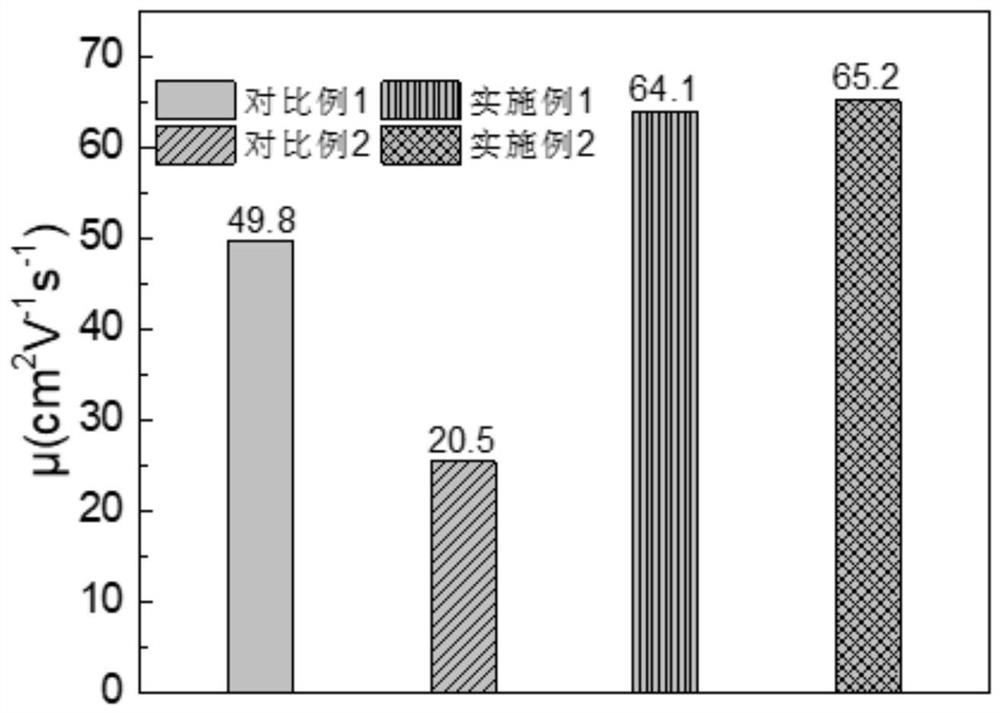

Quantum dot light emitting diode bottom electrode and preparation method thereof

PendingCN114665038AHigh carrier mobilityAvoid negative effectsSolid-state devicesSemiconductor/solid-state device manufacturingLaser etchingCharge carrier mobility

The invention relates to the technical field of display, and provides a quantum dot light emitting diode bottom electrode and a preparation method thereof. According to the invention, the electrode layer is crystallized, so that the conductive metal oxide which is originally in an amorphous state in the electrode layer can be crystallized, and then the non-crystallized part is removed through etching treatment, so that the purpose of full annealing can be achieved, and the carrier mobility of the electrode layer is improved; and the negative influence on the reflecting layer in the conventional heating and annealing treatment process is avoided. Meanwhile, laser etching equipment is not needed in the preparation process, a resist film layer does not need to be prepared either, the preparation technology is simplified, the production cost is reduced, and the method is more suitable for the requirement for small-scale research and development in a laboratory. The bottom electrode of the quantum dot light-emitting diode is used for preparing a top-emitting quantum dot light-emitting diode, and the obtained top-emitting quantum dot light-emitting diode has good light-emitting efficiency and performance.

Owner:TCL CORPORATION

Machining method for thin-walled titanium pipe

The invention discloses a machining method for a thin-walled titanium pipe. The method comprises the following several steps that (1), a blank is manufactured; (2), rolling is carried out, wherein multi-pass rolling is carried out on the titanium pipe blank by adopting a cold press, oil removal treatment and annealing treatment are carried out after rolling of each time, and the annealing treatment specifically comprises the following steps that under a vacuum condition, the titanium pipe blank is rapidly heated to 280-320 DEG C, the temperature is kept for 10-15 minutes, then the titanium pipe blank is slowly heated to 650-750 DEG C, the temperature is kept for 30-60 minutes, then the titanium pipe blank is rapidly cooled to 280-320 DEG C, the temperature is kept for 10-15 minutes, and then the titanium pipe blank is cooled to the normal temperature; and (3), surface treatment is carried out. According to the machining method, multi-pass rolling is carried out on the titanium pipe blank through the cold press, moreover, the oil removal treatment and the annealing treatment are carried out after rolling of each time, through the stepped annealing treatment mode, the titanium pipe blank is sufficiently annealed, grains are refined, and the structure arrangement is uniform, so that a final titanium pipe finished product is uniform in wall thickness, and good in surface quality.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

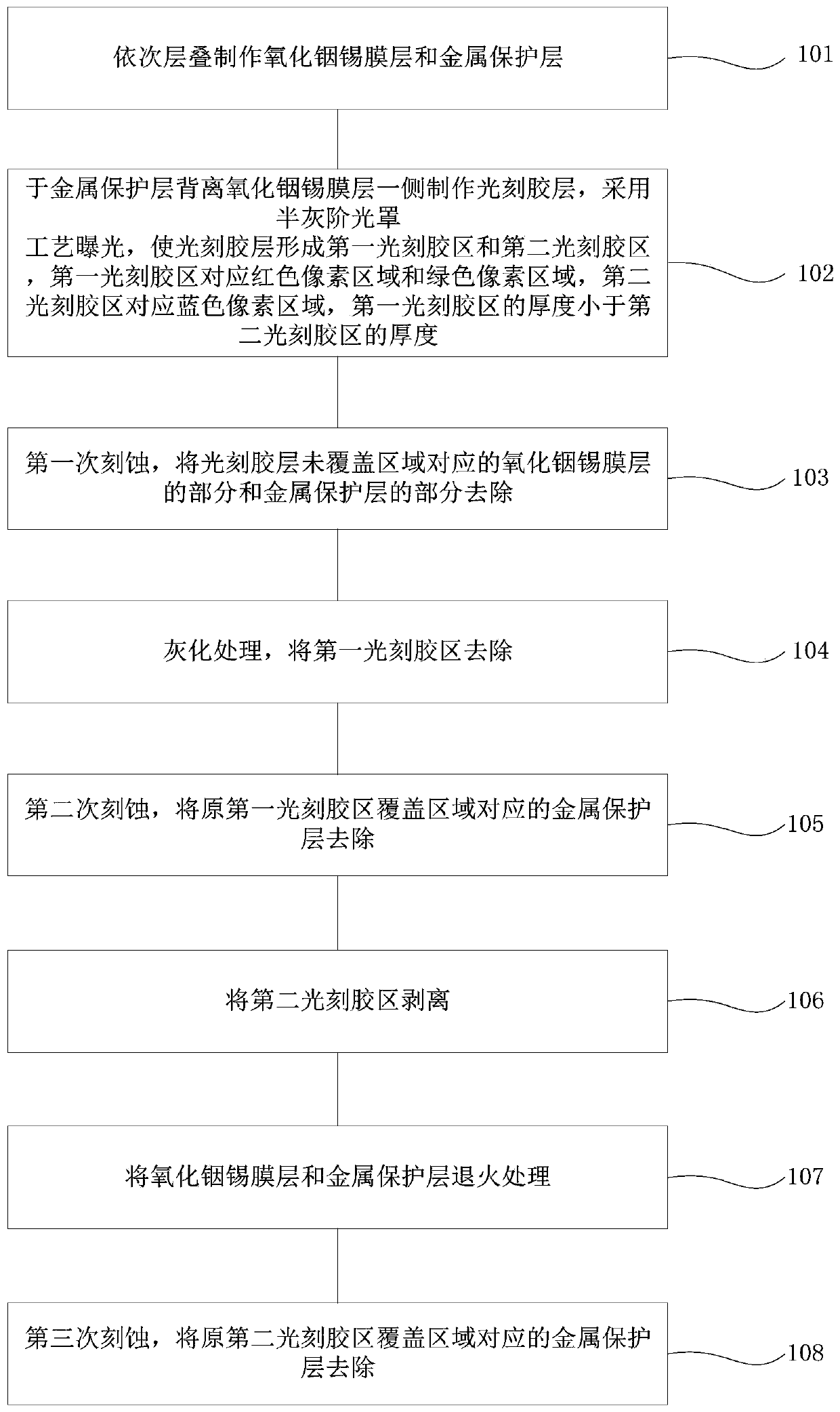

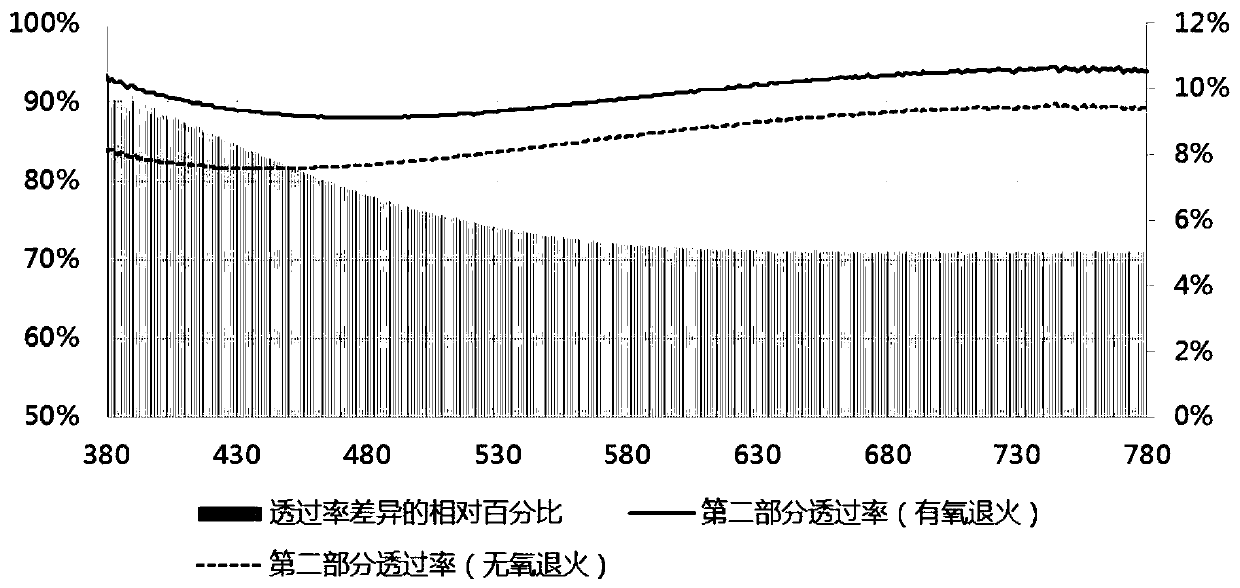

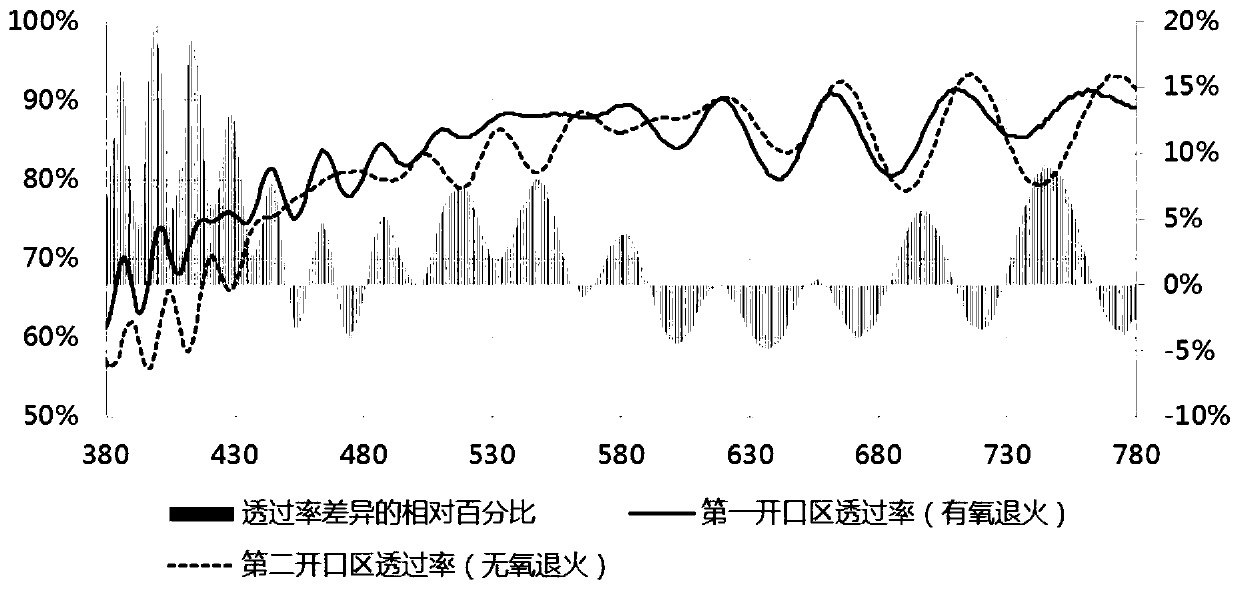

Array substrate manufacturing method, array substrate and liquid crystal display device

ActiveCN111176011AReduce transmittanceImprove transmittanceNon-linear opticsIndiumLiquid-crystal display

The invention relates to an array substrate manufacturing method, an array substrate and a liquid crystal display device and relates to the technical field of display. The manufacturing method of thefirst indium tin oxide film layer comprises steps manufacturing ofan indium tin oxide film layer and a metal protection layer in a stacked mode, manufacturing a photoresist layer on one side, deviating from the indium tin oxide film layer, of the metal protection layer, exposing by adopting a semi-gray-scale photomask process to enable the photoresist layer to form a first photoresist region and asecond photoresist region, the first photoresist region corresponding to a red pixel region and a green pixel region, the second photoresist region corresponding to a blue pixel region, and the thickness of the first photoresist region being smaller than that of the second photoresist region, etching for the first time, carrying out ashing treatment, etching for the second time, peeling off the second photoresist region, carrying out annealing treatment of the indium tin oxide film layer and the metal protective layer, etching for the third time, and finally obtaining the first indium tin oxide film layer. The array substrate manufactured by the method can reduce damage of blue light to eyes.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com