A kind of preparation method of superconducting wire/ribbon

A technology of superconducting wires and strips, which is applied in the usage of superconducting elements, superconducting/high-conducting conductors, superconducting devices, etc. Solve problems such as annealing processing time, achieve the effects of shortening exposure time, improving core wire quality, and reducing annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

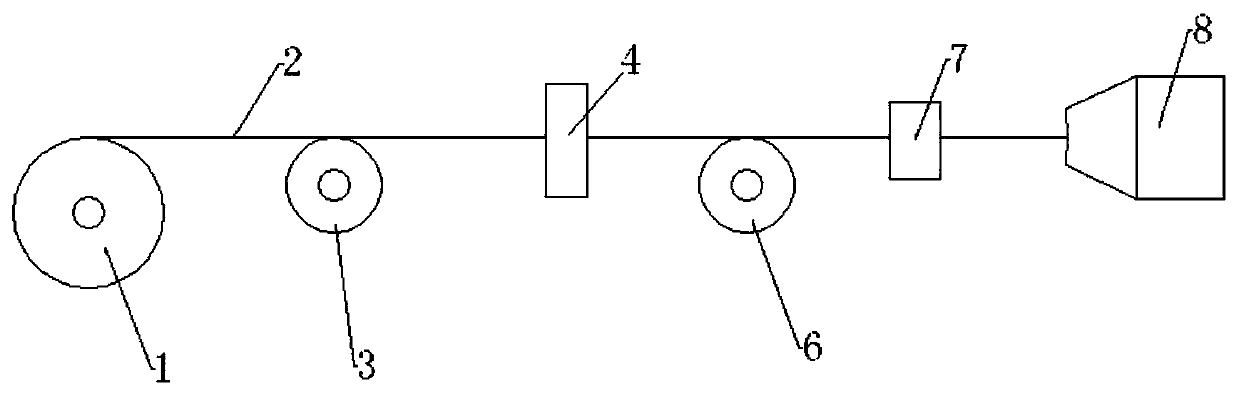

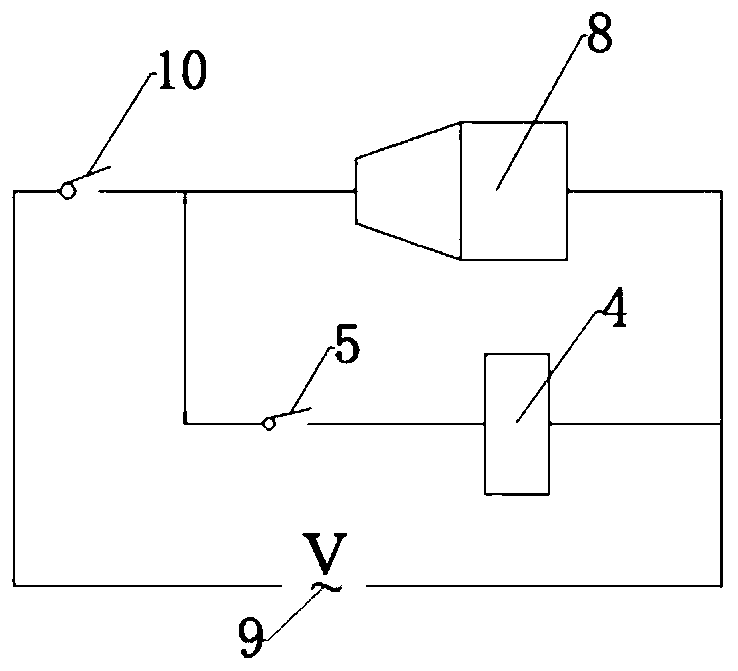

[0045] The method of the present embodiment comprises the following steps:

[0046] Step 1. Wash and wind the 55-core silver-coated Bi-2223 round wire with a diameter of 21mm prepared by the powder tube method and wind it on the pay-off reel 1, and then wind the 55-core silver-coated Bi-2223 round wire The starting end passes through the induction coil of the induction coil device 4 through the first guide pulley 3, and then penetrates into the drawing die 7 through the second guide pulley 6 and is clamped on the pulling device 8 of the wire drawing machine to complete the 55-core silver sheath Bi -Assembly of 2223 round wires; the induction coil of the induction coil device 4 is made of copper and has a diameter of 5cm; the materials of the first guide pulley 3 and the second guide pulley 6 are copper, and the first guide pulley 6 must be checked before use. The surfaces of the first guide pulley 3 and the second guide pulley 6 are polished to mirror surface;

[0047] Step 2...

Embodiment 2

[0061] The method of the present embodiment comprises the following steps:

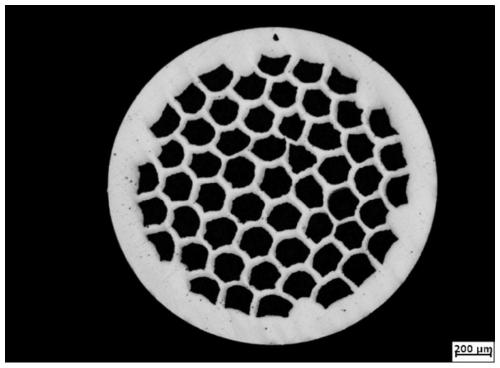

[0062] Step 1. Wash and wind the (37×18+1) core silver alloy sheathed Bi-2212 round wire with a diameter of 21mm prepared by the powder tube method and wind it on the pay-off reel 1, and then wrap the (37×18+ 1) The starting end of the core silver alloy sheathed Bi-2212 round wire runs through the induction coil of the induction coil device 4 through the first guide pulley 3, and then penetrates into the drawing die 7 through the second guide pulley 6 and is clamped in the On the wire drawing machine traction device 8, complete the assembly of the (37 × 18+1) core silver alloy sheath Bi-2212 round wire; the material of the induction coil of the induction coil device 4 is red copper, and the diameter is 3cm; the (37 ×18+1) The structure of the cross-section of the core silver alloy sheathed Bi-2212 round wire is as follows Image 6 shown;

[0063] Step 2: Close the main circuit switch 10 to start the...

Embodiment 3

[0068] The method of the present embodiment comprises the following steps:

[0069]Step 1. Clean and wind the (37×36+1) core silver alloy sheathed Bi-2212 round wire with a diameter of 31mm prepared by the powder tube method and wind it on the pay-off reel 1, and then wrap the (37×36+ 1) The starting end of the core silver alloy sheathed Bi-2212 round wire runs through the induction coil of the induction coil device 4 through the first guide pulley 3, and then penetrates into the drawing die 7 through the second guide pulley 6 and is clamped in the On the pulling device 8 of the wire drawing machine, the assembly of (37×36+1) core silver alloy sheathed Bi-2212 round wire is completed; the material of the induction coil of the induction coil device 4 is copper, and the diameter is 6cm;

[0070] Step 2: Close the main circuit switch 10 to start the wire drawing machine traction device 8, so that the (37×36+1) core silver alloy sheathed Bi-2212 round wire assembled in step 1 ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com