Garnet ferrite and a non-reciprocal circuit element applying the same

A circuit component, red ferrite technology, applied in electrical components, circuits, iron compounds, etc., can solve the problems of increased half-value amplitude and increased insertion loss of isolators, and achieves small temperature changes in characteristics and low loss. , the effect of small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

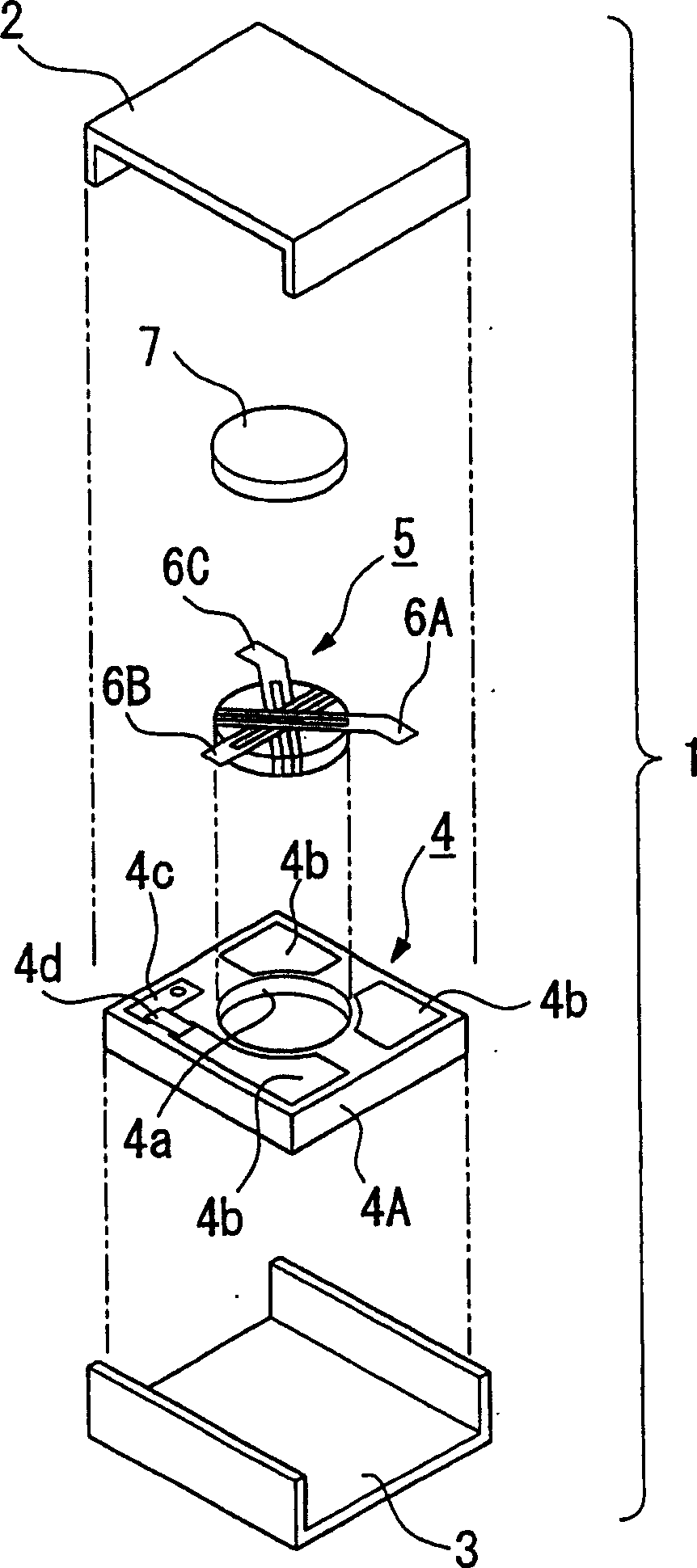

[0085] Embodiment (1-1~1-24)

[0086] According to the composition of each sample shown in Tables 1-2 below, Y 2 o 3 Powder, Gd 2 o 3 Powder, Fe 2 o 3 Powder, Co 3 o 4 Powder, SiO 2 Powder, Al 2 o 3The powders were mixed, and after drying the mixture, it was calcined at 1200° C. for 4 hours to obtain a calcined product. Next, the calcined product was put into the same ball mill as above together with an organic binder, and wet pulverized for 20 hours. The pulverized product is mainly fired at 1350°C to 1500°C in air or in an oxygen atmosphere to obtain Y 3-x Gd x Fe t-2y-z co y Si y Al z o 12 Garnet ferrite samples having such a composition (Examples 1-1 to 1-24).

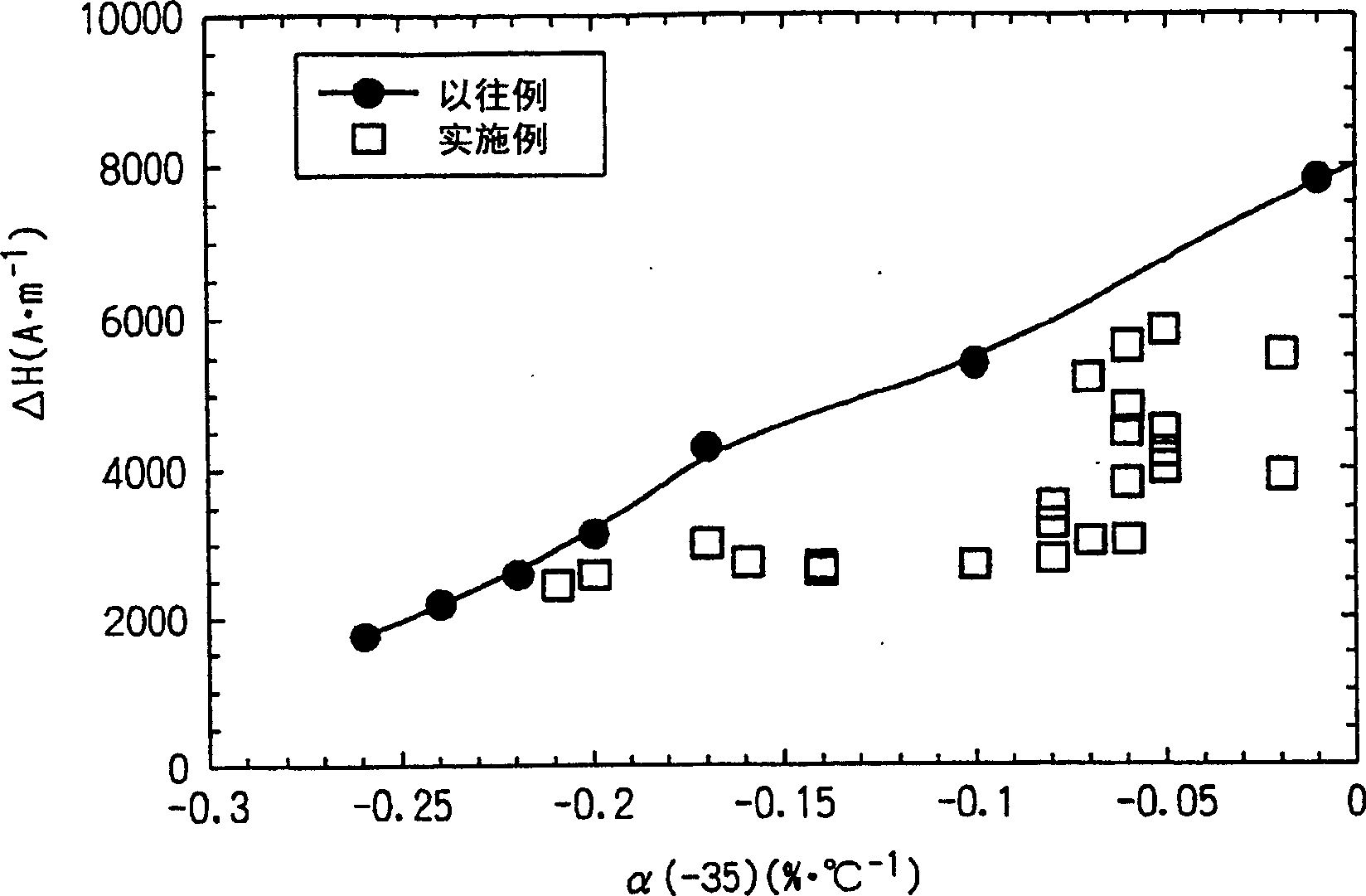

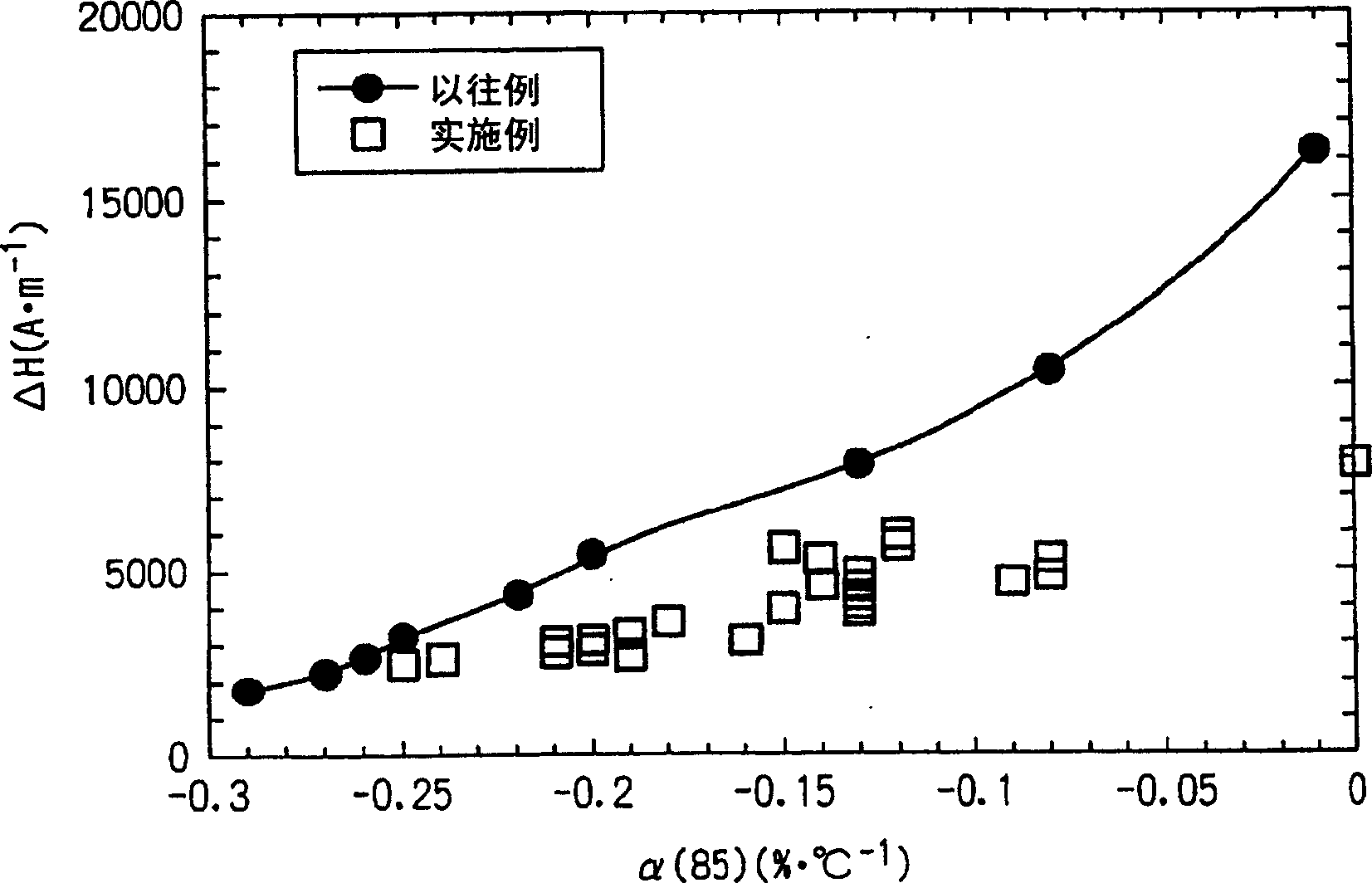

[0087] The 4πMs of the garnet red ferrite samples of Examples 1-1 to 1-24, the magnetization temperature coefficient α (-35) at -35°C to +25°C, and the magnetization temperature coefficient at +25°C to +85°C were obtained. The temperature coefficient of magnetization α (85) and the ferromagnetic ...

Embodiment 2-1~2-3

[0123] In accordance with the composition of each sample shown in Table 5 below, except for the use of Y 2 o 3 Powder, Gd 2 o 3 Powder, Fe 2 o 3 Powder, Co 3 o 4 Powder, SiO 2 Powder, Al 2 o 3 Powder, SnO 2 or ZrO 2 or HfO 2 Except that, the same process as the above-mentioned embodiment was carried out to obtain Y 1.9 Gd 1 Ca 0.1 Fe 4.563 co 0.01 Si0.01 D. 0.1 Al 0.2 o 12 Garnet ferrite samples (Examples 2-1 to 2-3) having such a composition (wherein D is Zr, Hf, or Sn). Table 5 shows the results of obtaining 4πMs, α(-35), α(85), and ΔH of the garnet ferrite samples of Examples 2-1 to 2-3.

Embodiment 3-1

[0138] In accordance with the composition of each sample shown in Table 7 below, except using Y 2 o 3 Powder, Gd 2 o 3 Powder, Fe 2 o 3 Powder, Co 3 o 4 Powder, SiO 2 Powder, In 2 o 3 Powder, Al 2 o 3 Except for the powder, it was processed in the same manner as in the above-mentioned examples to obtain Y 2 Gd 1 Fe 4.563 co 0.01 Si 0.01 In 0.1 Al 0.2 o 12 A garnet ferrite sample having such a composition (Example 3-1). Table 7 shows the results of 4πMs, α(-35), α(85) and ΔH of the garnet ferrite sample of Example 3-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com