Patents

Literature

68results about How to "Eliminate temperature gradients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

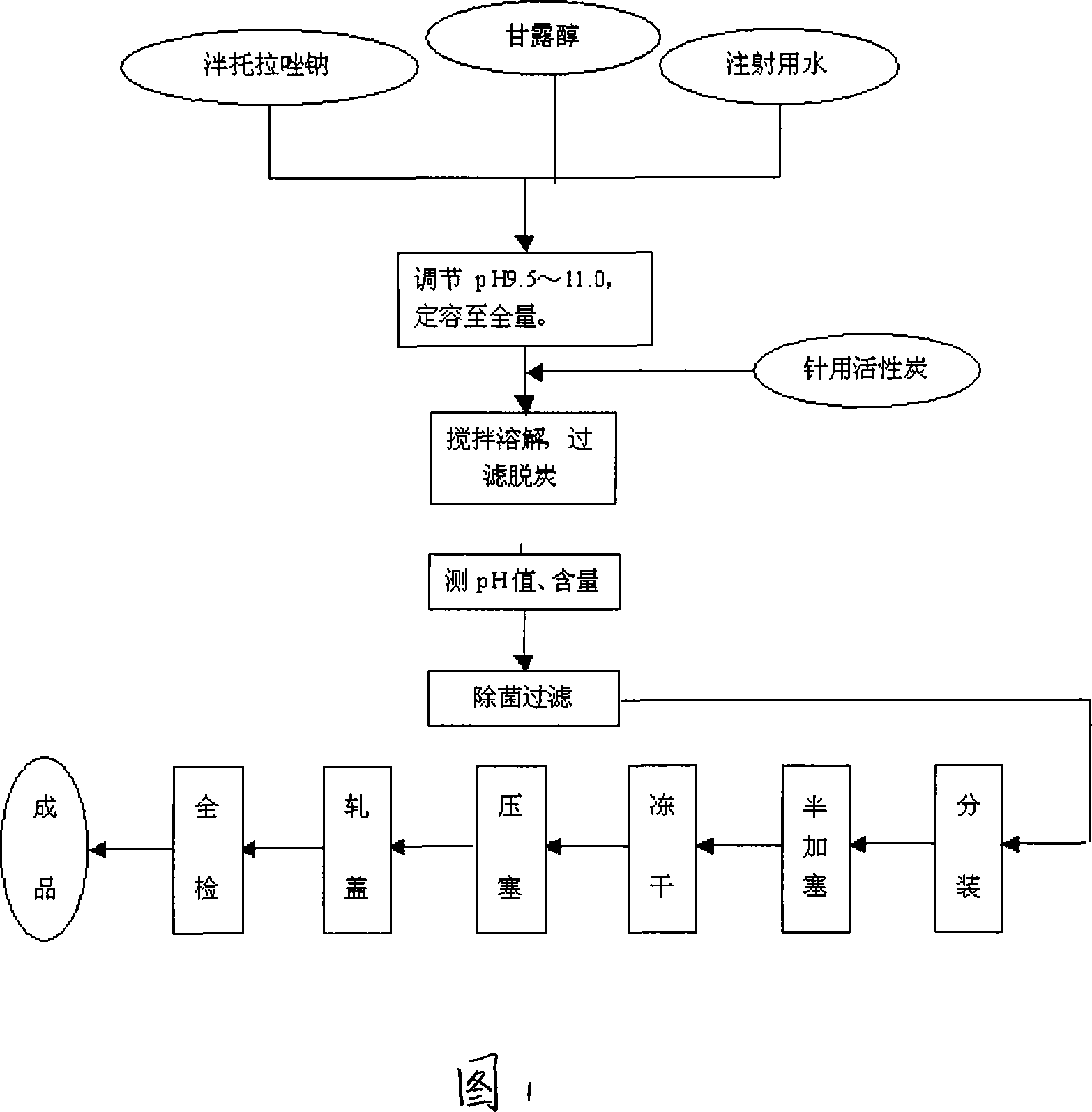

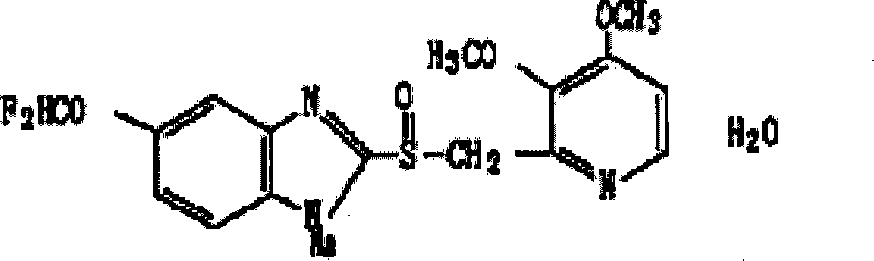

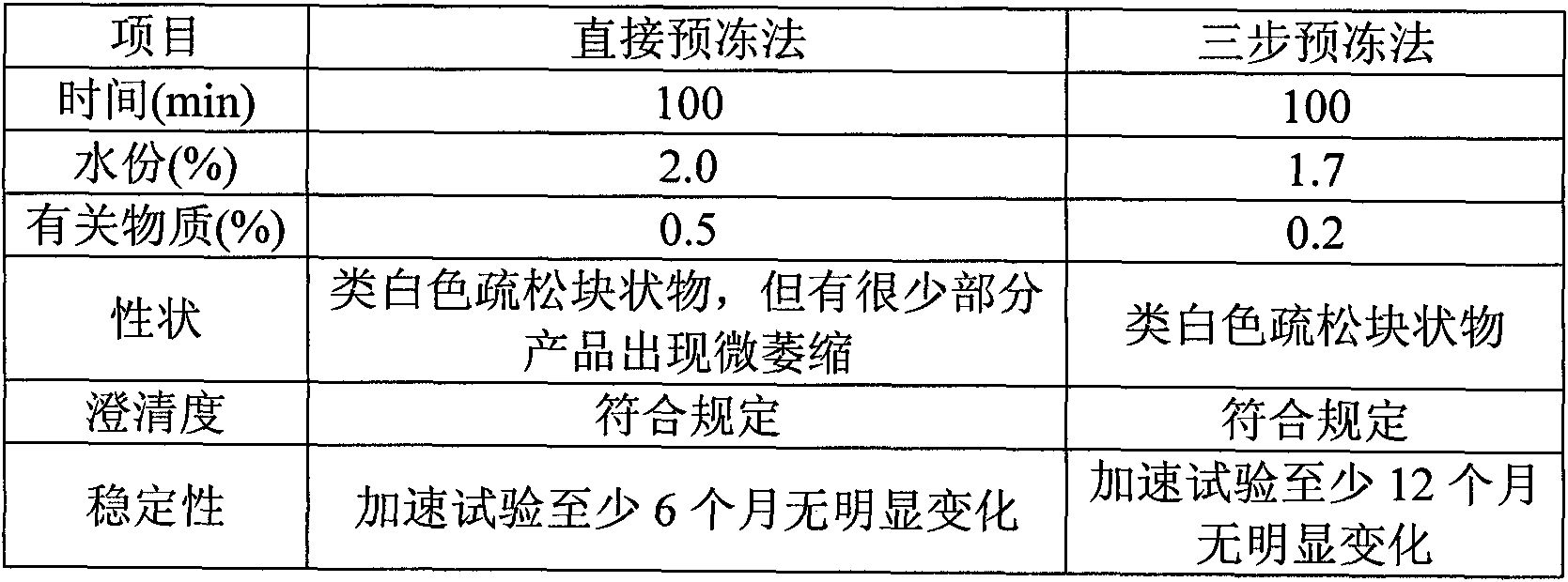

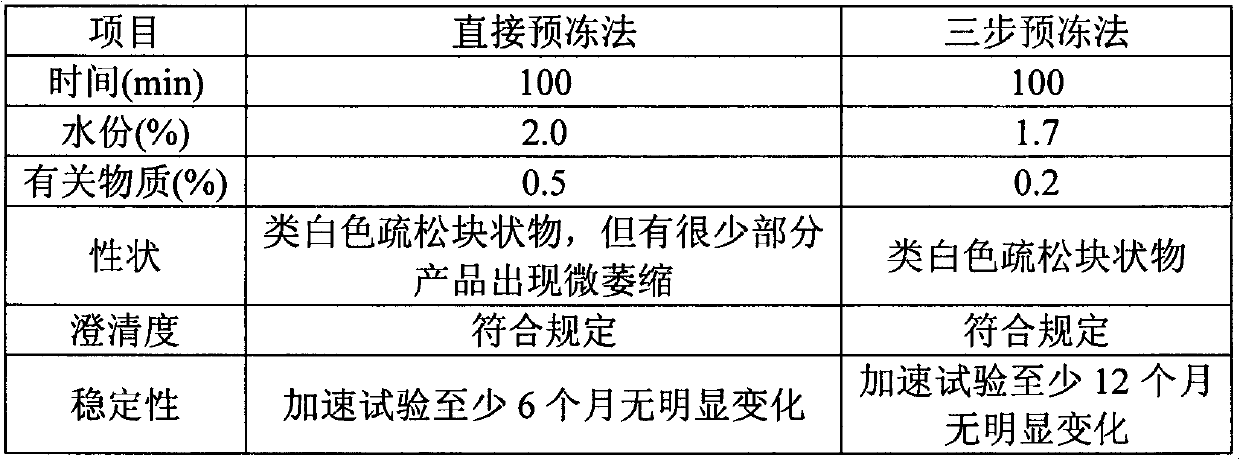

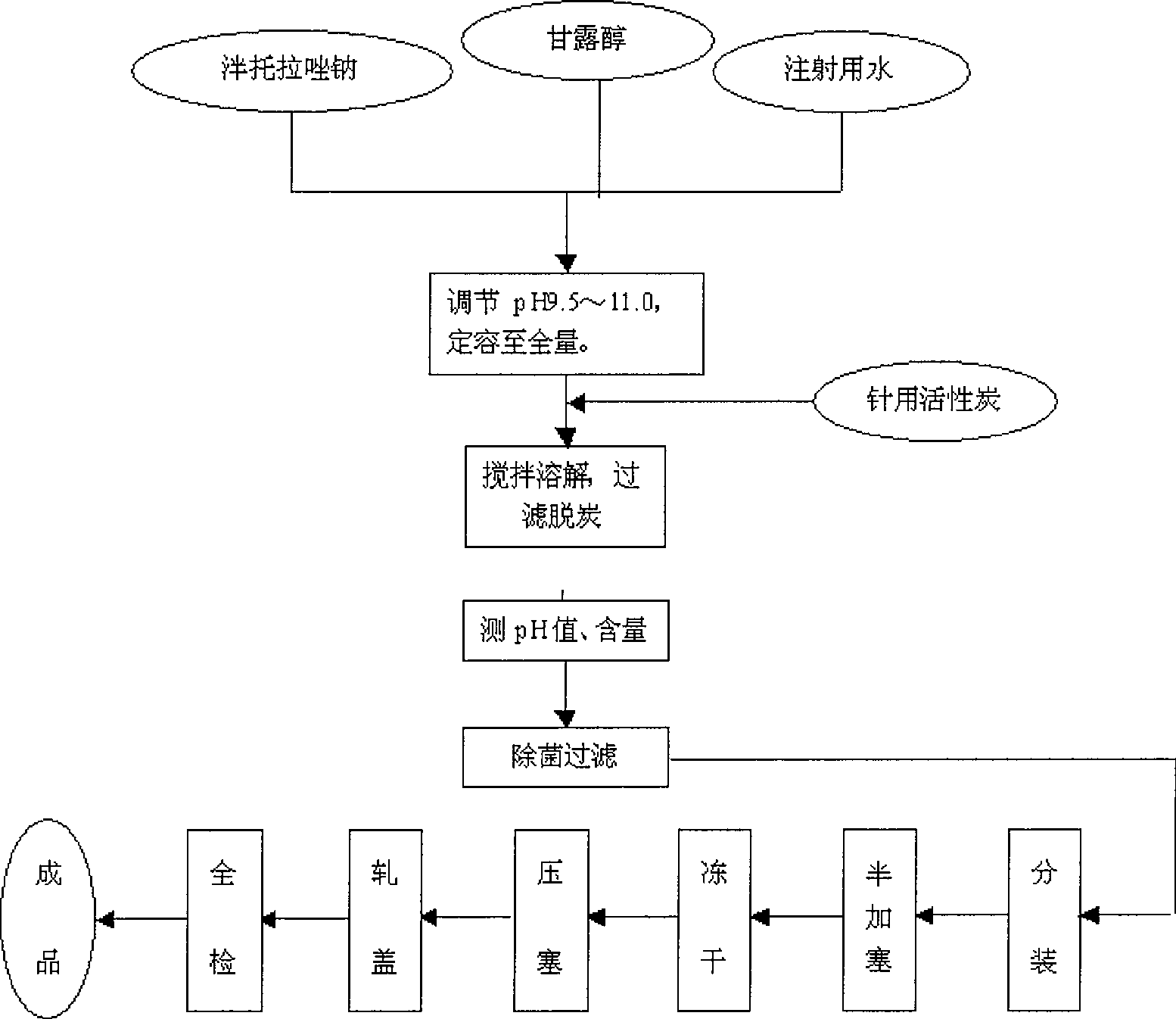

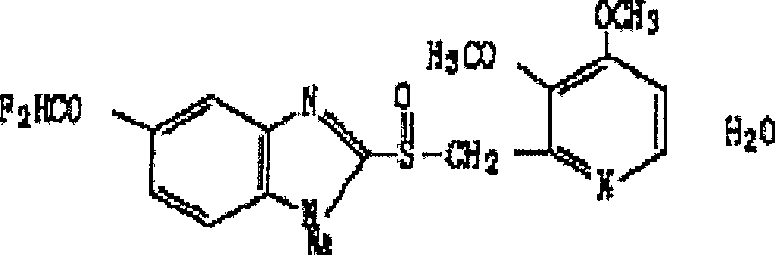

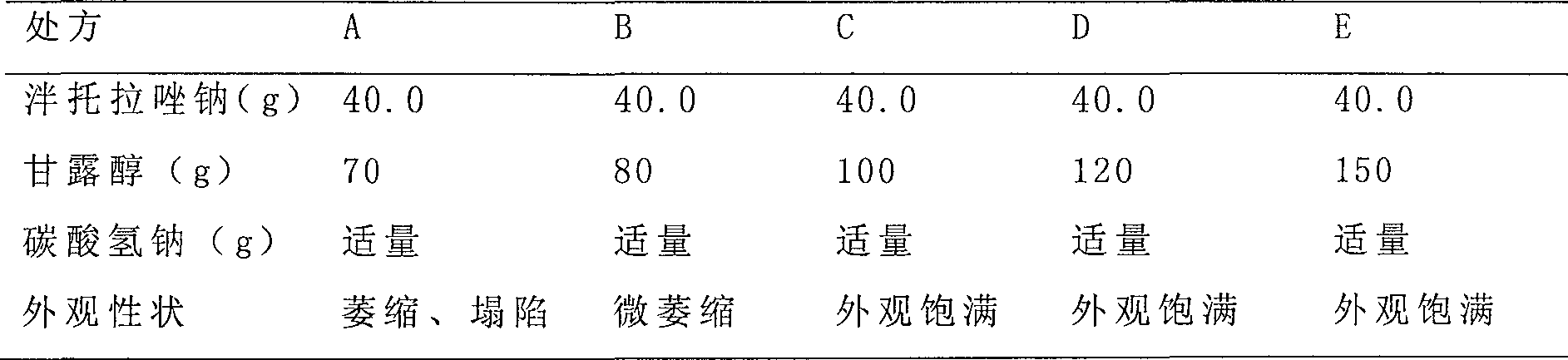

Pantoprazole sodium freeze-dried powder injection and preparing method thereof

ActiveCN101229138ASimple recipeLittle side effectsPowder deliveryOrganic active ingredientsSolubilityMANNITOL/SORBITOL

The invention aims at providing a pantoprazole sodium freeze-dried powder injection and comprises pantoprazole sodium and mannitol with the weight ratio of 1: 2 to 5. The invention is simple in formula and little in side effect; products prepared by the method are plump in appearance, good in complex solubility and excellent in quality with the adoption of an advanced freezing and drying process.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +1

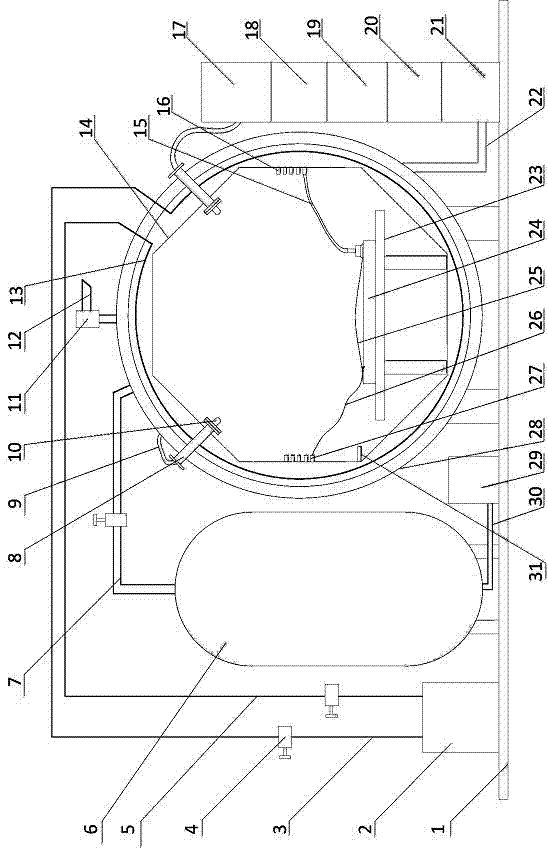

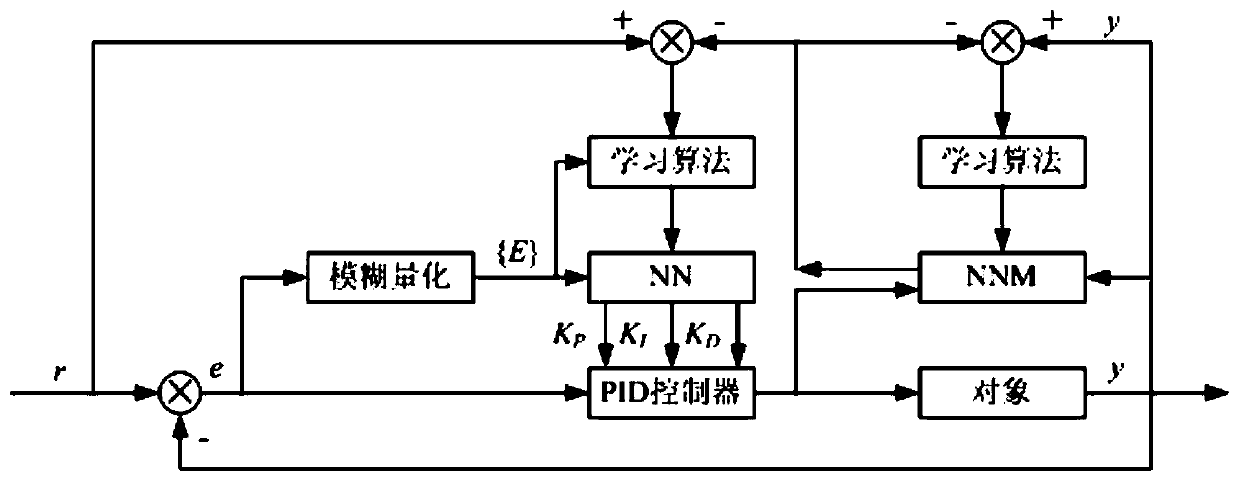

Method and device for forming high-performance composite material structural member through microwave-pressure tank

ActiveCN103587128AShorten the timeMicrowave heating and curing time is shortResonant cavityEngineering

The invention discloses a method and a device for forming a high-performance composite material structural member through a microwave-pressure tank. The device mainly comprises a cooling system (2), a gas storage tank (6), microwave transmission lines (9), microwave radiation antennas (10), a pressure safety valve (11), a polygonal multi-mode resonant cavity (14), a microwave generation and measurement module (17), a temperature measurement and control module (18), a vacuumizing and control module (19), a pressure measurement and control module (20), a power supply module (21), a material platform (23), a forming mold (24), a temperature sensor (26) and a tank body (28). The equipment is microwave forming equipment for the high-performance composite material structural member; a non-solidified composite material structural member is put into the equipment, and the high-performance composite material structural member can be quickly formed by technologies of vacuum bag vacuumizing, gas pressurization and microwave heating; the quality and the performance of the composite material structural member can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

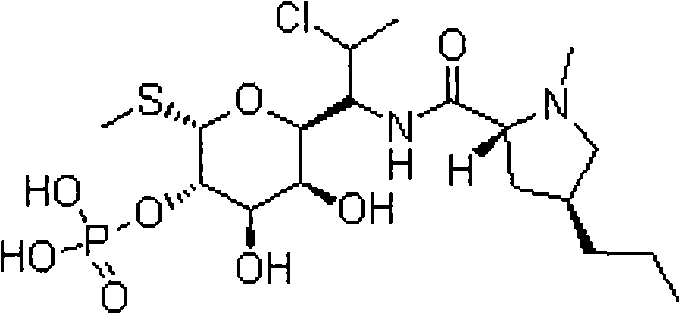

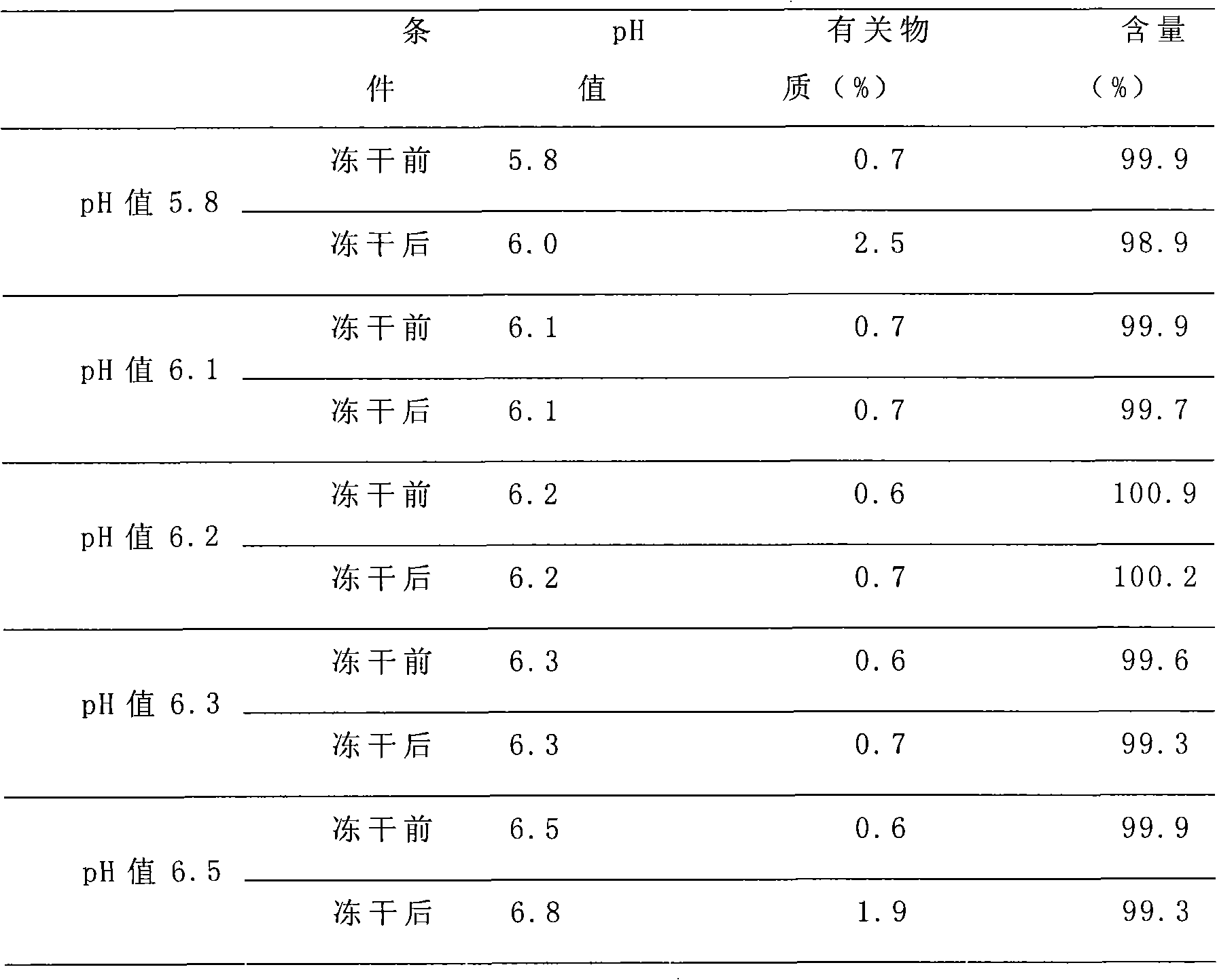

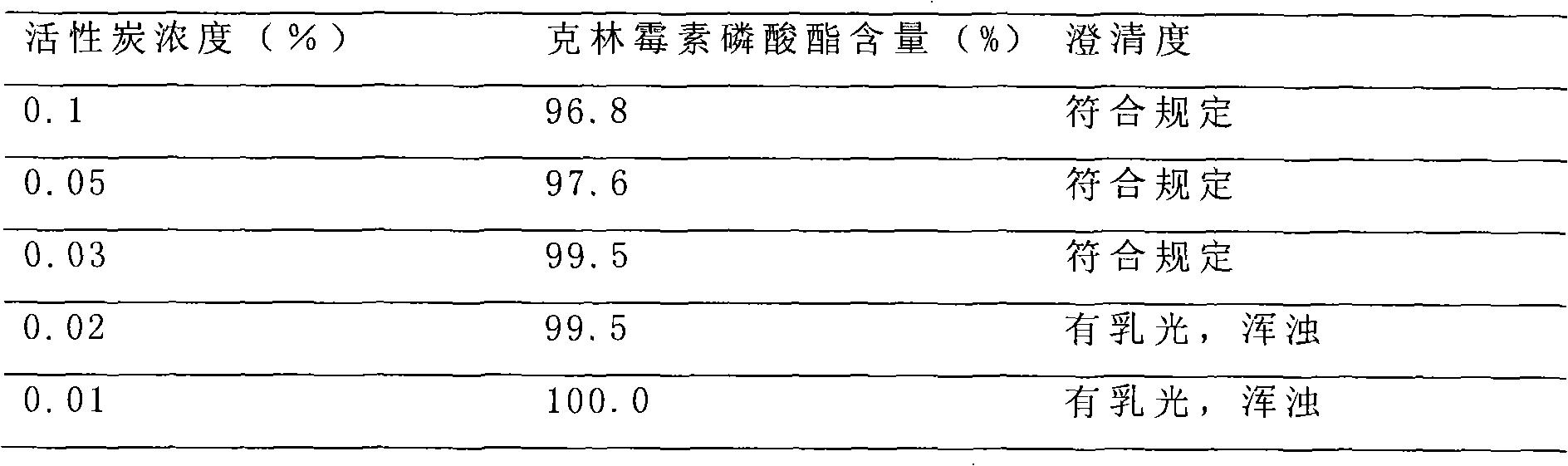

Clindamycin phosphate freeze-dried powder needle and preparation thereof

InactiveCN101301278ASimple recipeLittle side effectsAntibacterial agentsPowder deliverySide effectFreeze-drying

The invention provides a clindamycin phosphate freeze-dried powder injection, which is prepared by the steps that: clindamycin phosphate solution is added with NaOH and is freeze-dried, wherein, the weight ratio of clindamycin phosphate to the NaOH is between 12 and 18 to 1, and the preferred weight ratio is 16.5 to 1. The clindamycin phosphate freeze-dried powder injection has simple formula and less auxiliary materials, overcomes side effects due to the fact that the auxiliary materials are excessively added, and ensures that patients are safer for use.

Owner:BEIJING JINGWEI SHUNKANG MEDICAL TECH DEV

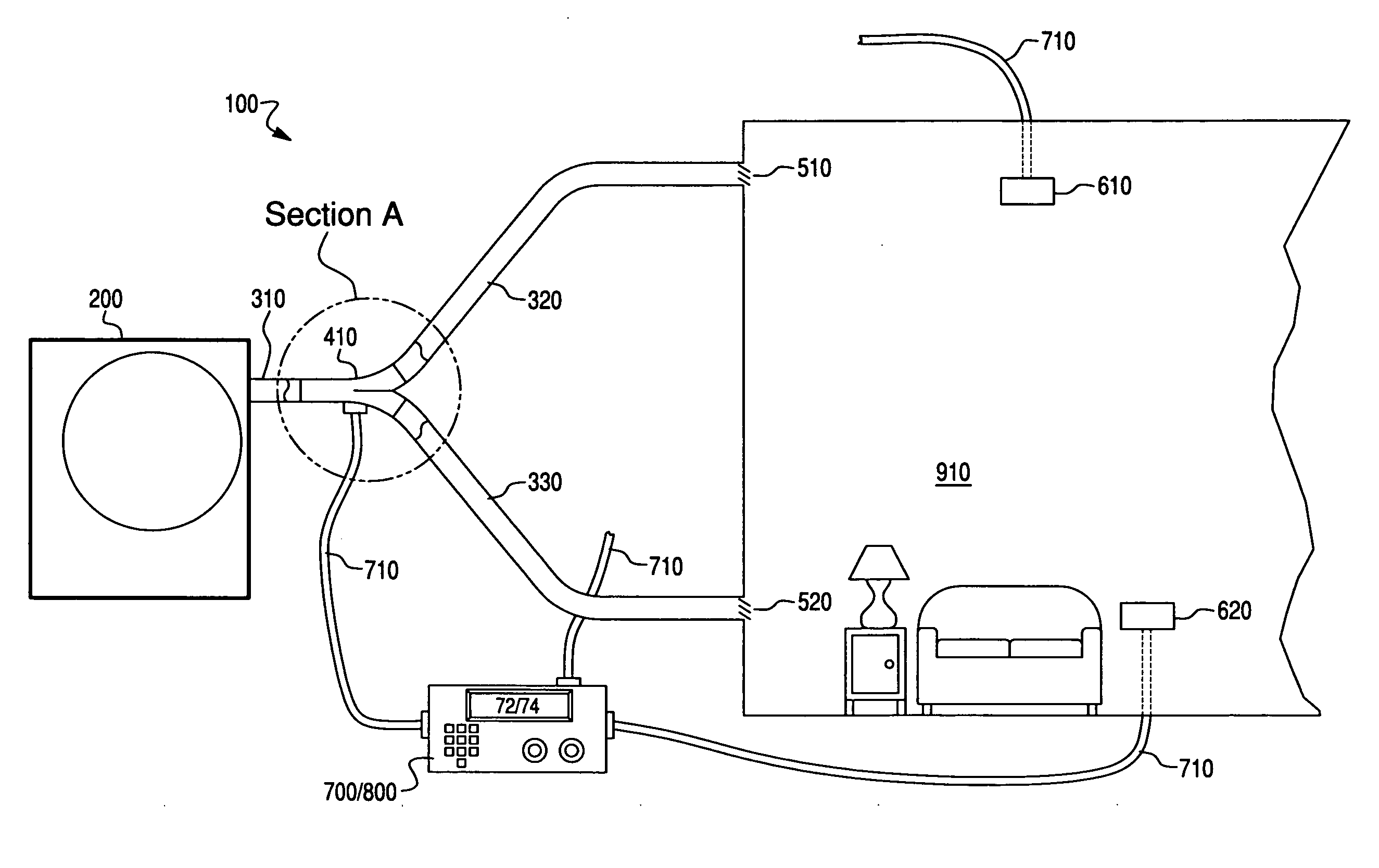

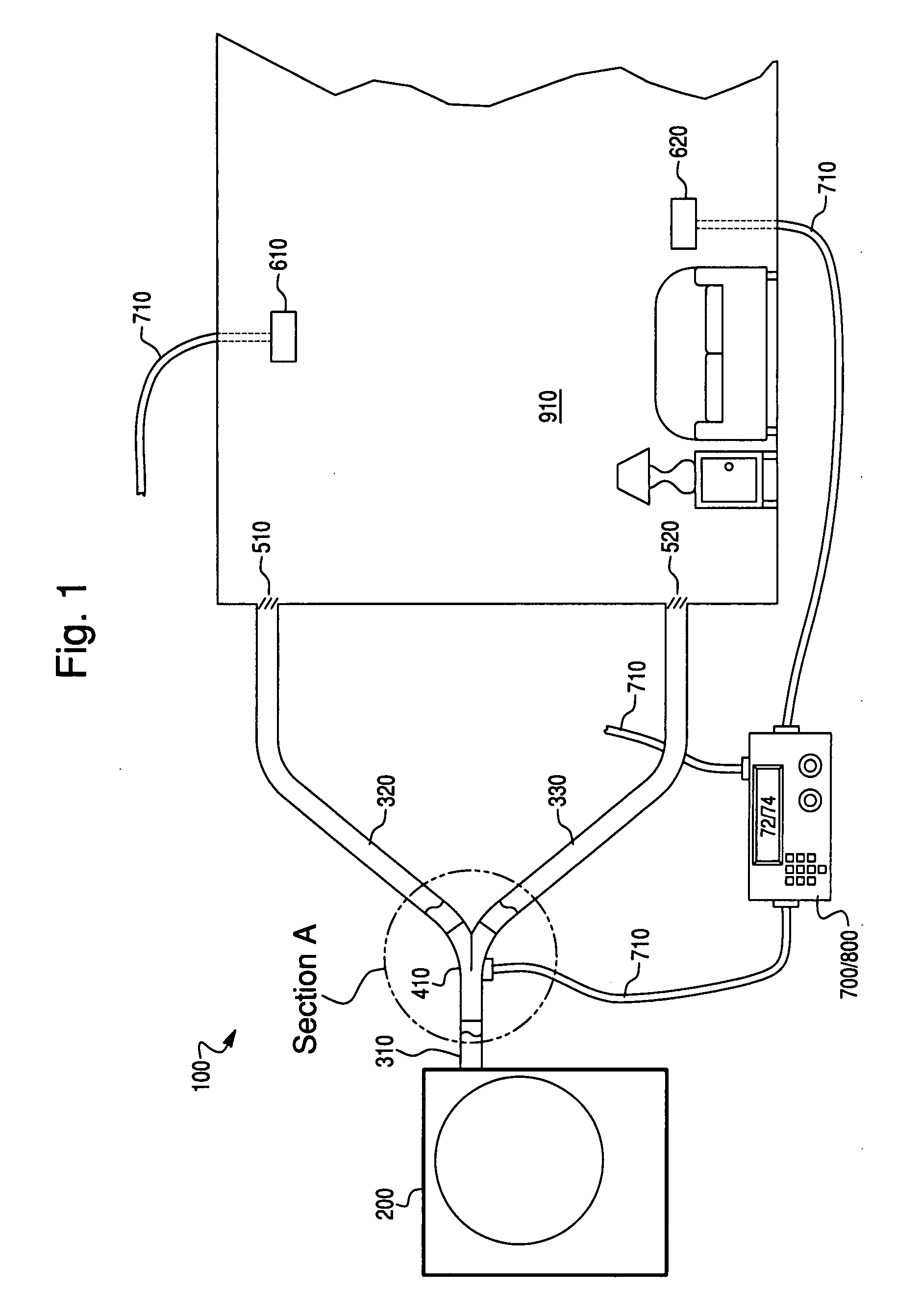

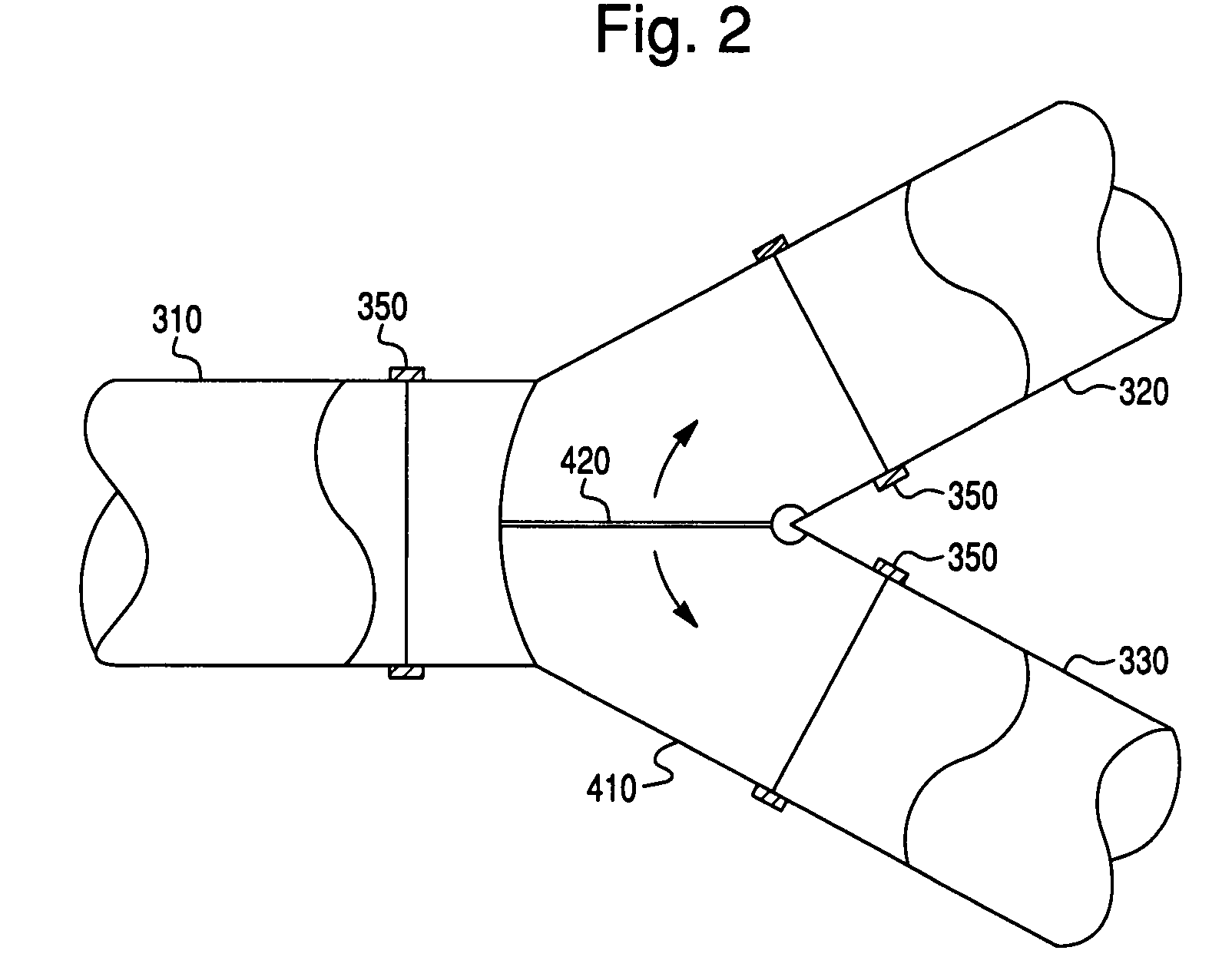

HVAC air distribution system

InactiveUS20080311842A1Eliminate temperature gradientsMechanical apparatusSpace heating and ventilation safety systemsControl engineeringControl cell

An HVAC system including a first diverter valve configured to divert, in varying amounts, an airflow entering the valve out two different outlets, in a manner that does not create a substantial increase in backpressure due to the diversion or otherwise substantially restrict the general flow of air in the HVAC system. The system further includes a first sensor assembly configured to sense a first environmental condition that includes at least one of temperature and a phenomenon indicative of the makeup of room air, a control unit, and a user interface unit, wherein the control unit is in communication with the diverter valve and the first sensor assembly.

Owner:GLACIER BAY

Method for preparing hydrated alumina

ActiveCN103043694AIncrease spawn rateSmall particle sizeAluminium hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateHydrated alumina

The invention discloses a method for preparing hydrated alumina. The method comprises the following process that: (1) bottom water is added into a neutralization reactor and is heated to 50-95 DEG C, an acid aluminium salt water solution is added at the same time so as to control the pH value between 2 and 4, and the pH value is stabilized for a while; (2) the acid aluminium salt water solution and alkali metal aluminate (or alkaline precipitator) solution to regulate the pH value between 6 and 8, and the pH value is stabilized for a while; the alkaline precipitator solution (or the alkaline precipitator solution) is added to regulate the pH value to be between 8.5 and 12, and the pH value is stabilized for a while; (4) the acid aluminium salt water solution is added to regulate the pH value to be between 2 and 4, and the pH value is stabilized for a while; (5) the alkaline precipitator solution or the alkaline precipitator solution is added to regulate the pH value to be between 8.5 and 12, and the pH value is stabilized for a while; the steps (4) and (5) are repeated for 1-4 times; (7) after gelatinizing is completed, aging, filtering, washing and drying are carried out to obtain the hydrated alumina; and the steps (1)-(3) are carried out under the action of ultrasonic waves, and the frequencies of the ultrasonic waves are10-80 kHZ. The hydrated alumina which is prepared through the method is distributed in a centralized manner and has high crystallinity and large pore volumes and pore diameters.

Owner:CHINA PETROLEUM & CHEM CORP +1

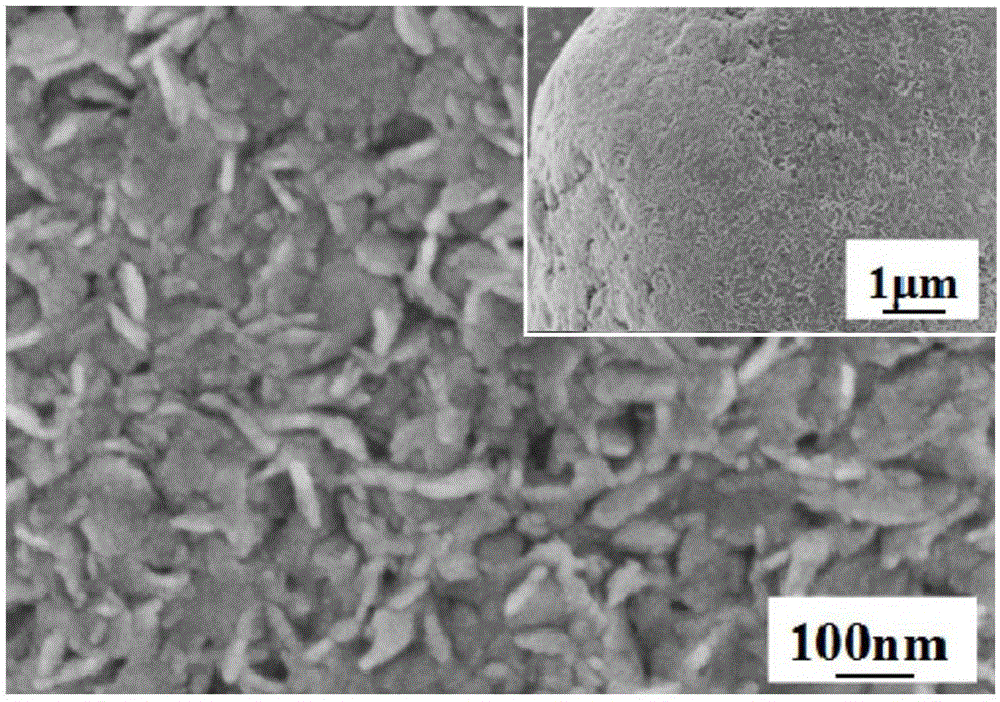

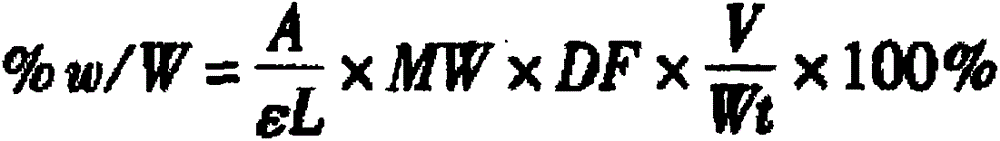

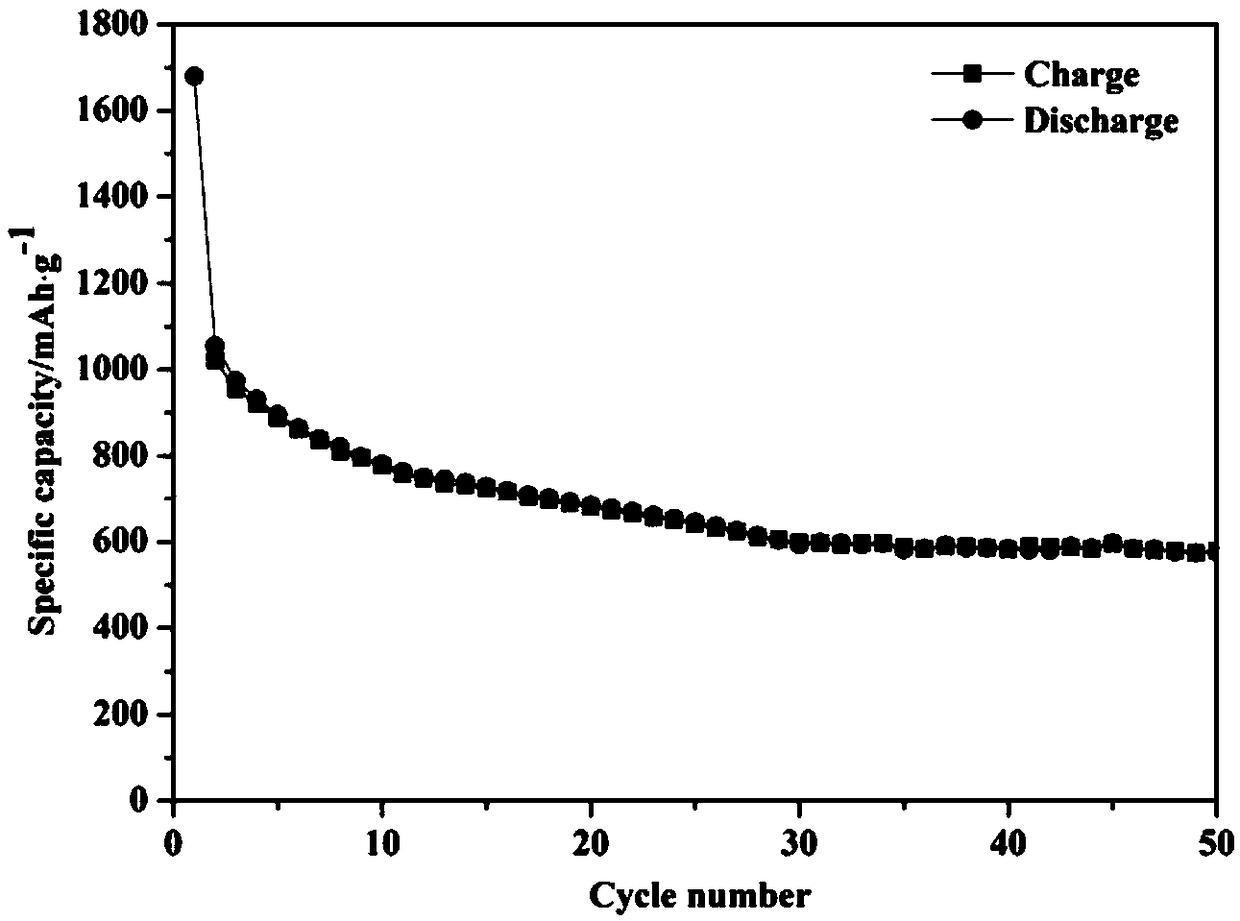

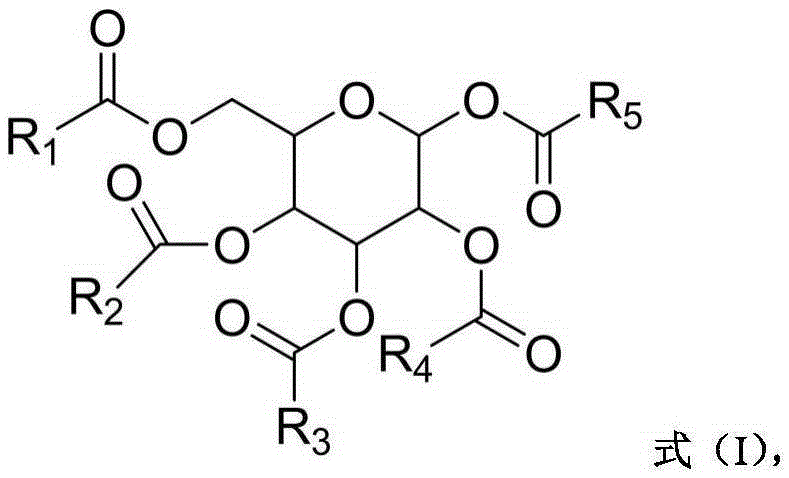

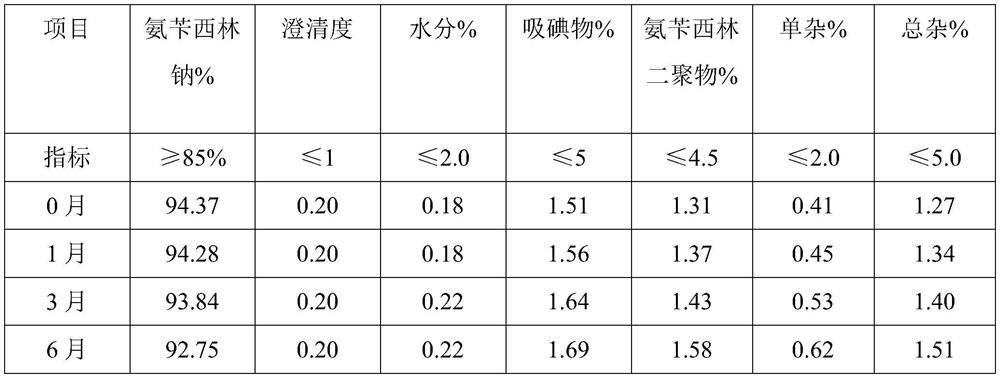

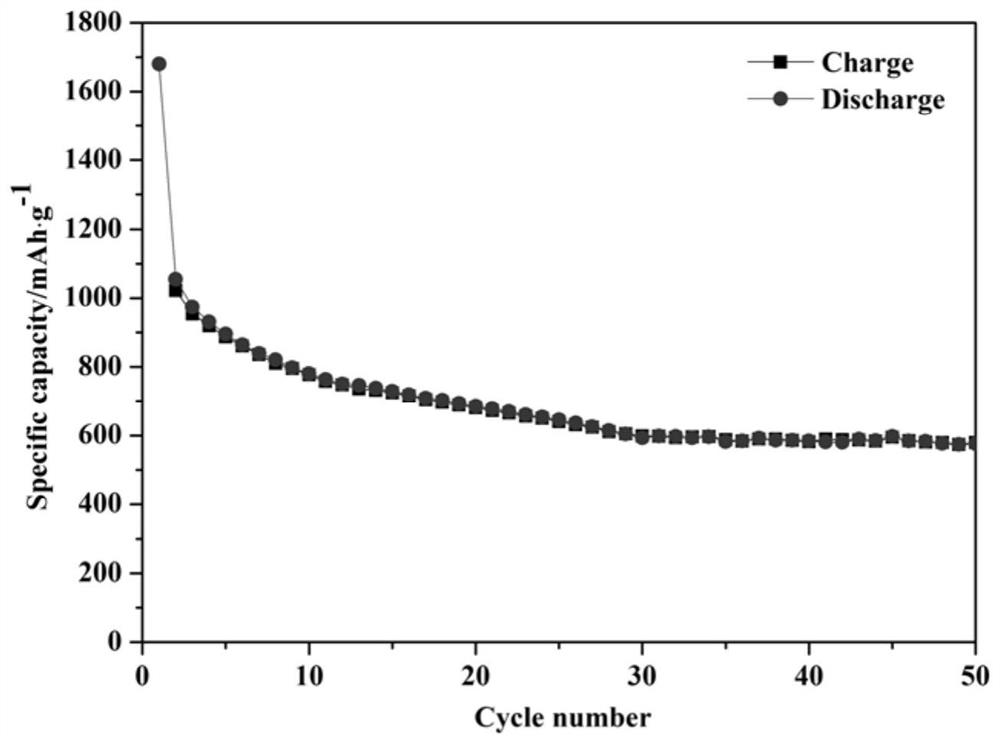

Preparation method for nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability

InactiveCN105098181AReduce manufacturing costImprove charge and discharge performanceNegative electrodesSodium-ion batteryChemistry

The invention discloses a preparation method for a nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability, comprises: 1) preparing an Sn source solution A with the concentration of 0.5-1.2 mol / L, regulating the pH of the solution A to be 1-9; and preparing an S source solution B with the concentration of 0.1-2.4 mol / L; 2) mixing the solution A and the solution B at an element molar ratio of nSn: nS being equal to (1.0-2.5): (2.0-4.3), and uniformly stirring to form a solution D; 3) putting the solution D into a homogenous phase hydrothermal reaction kettle for performing a homogenous phase hydrothermal reaction; and 4), cooling the reaction kettle, then centrifuging, washing, separating and drying to obtain the nano-flake SnS2 sodium-ion battery negative electrode material, wherein under 100 mA / g current density, the initial discharge capacity of the negative electrode material reaches 745 mAh / g; and after circulating for 100 times, the capacity is kept at 560 mAh / g.

Owner:SHAANXI UNIV OF SCI & TECH

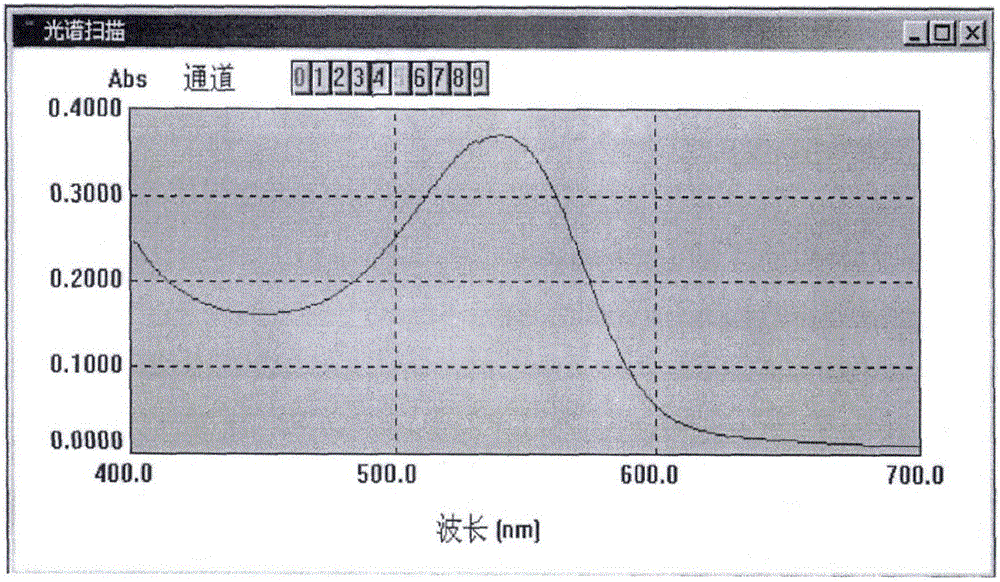

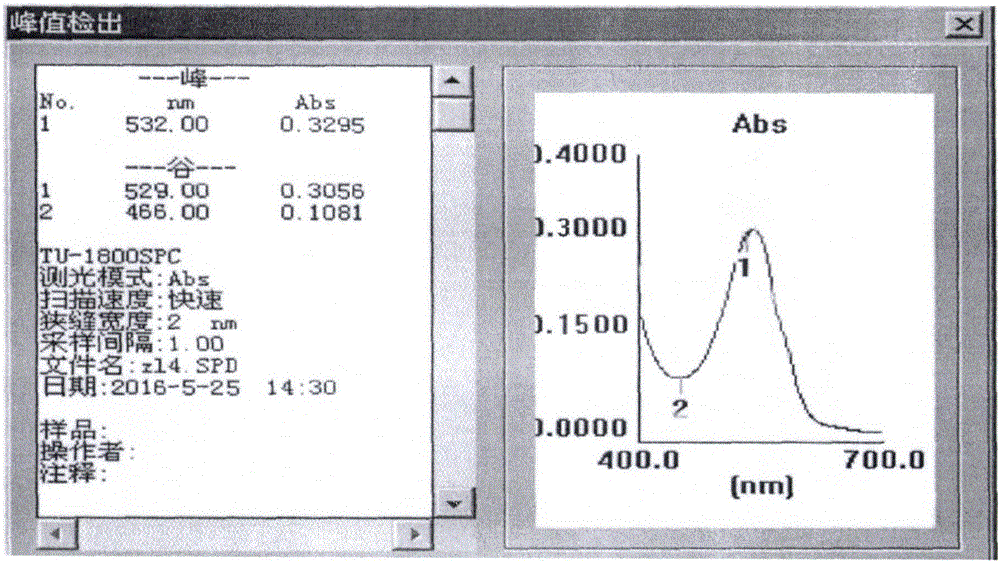

Black rice anthocyanin extracting method

The invention provides a black rice anthocyanin extracting method. The black rice anthocyanin extracting method specifically comprises the following steps: taking a black rice grain as a material, preprocessing the black rice grain, coarsely extracting the anthocyanin in the black rice grain, and then sequentially perform ultrafiltration, nanofiltration, macroporous resin adsorption, ethyl alcohol elution, secondary nanofiltration, and freeze-drying in vacuum to obtain a freeze-dried powder of the black rice anthocyanin. The black rice anthocyanin extracting method provided by the invention is good in selectivity; impurities of polysaccharide, organic acids, proteins and the like in the black rice anthocyanin can be effectively separated; the extracting rate is high, the product quality is high, even trace of the black rice anthocyanin is also extracted, the extracting speed is high, the operation is simple, and the discharge of effluent is low.

Owner:HENAN UNIV OF SCI & TECH

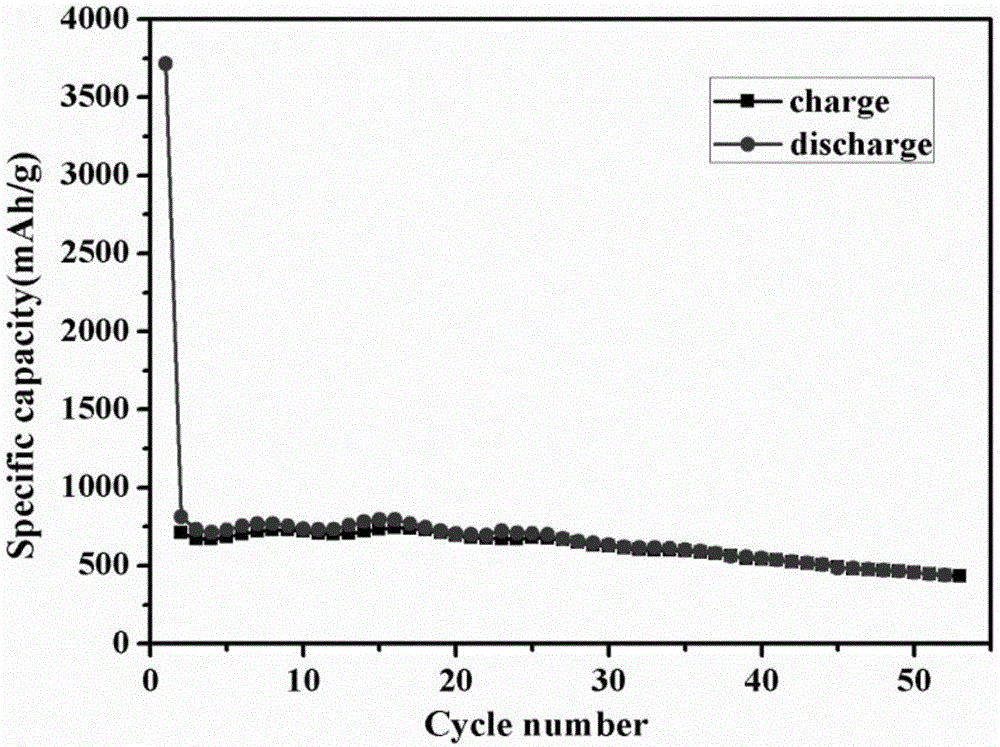

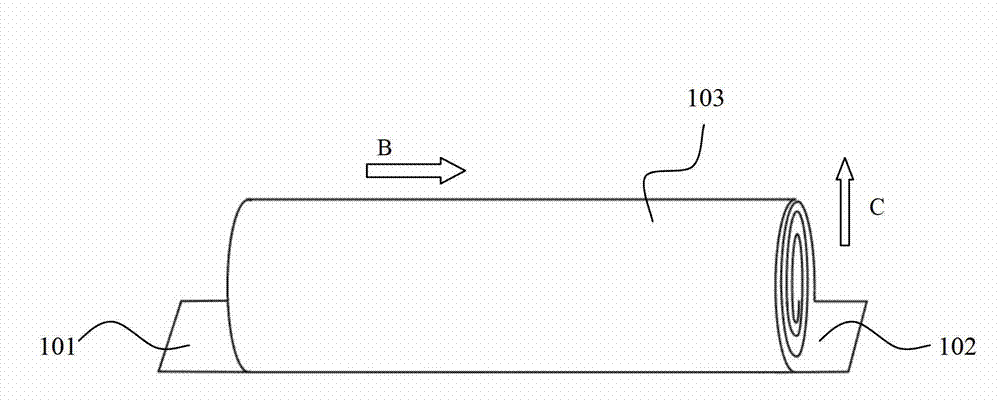

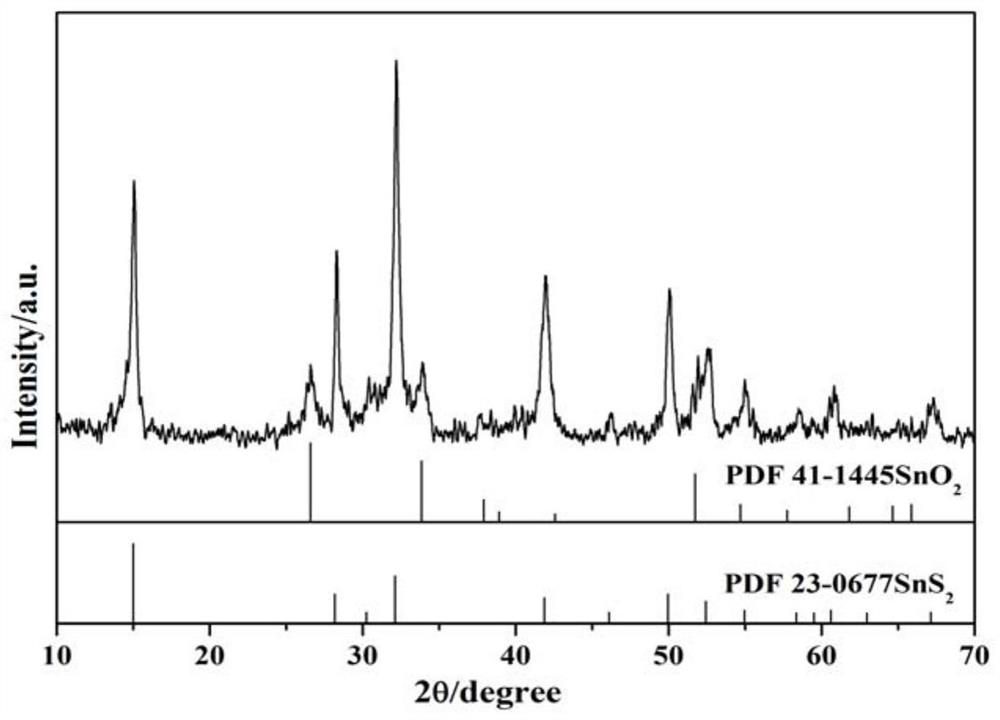

Preparation method of SnS2/SnO2 lithium ion battery anode material in hollow-sphere structure

ActiveCN109301204ALight in massLarge specific surface areaCell electrodesSecondary cellsAnhydrous ethanolEthanol

The invention discloses a preparation method of a SnS2 / SnO2 lithium ion battery anode material in hollow-sphere structure. The method includes: 1) adding SnCl4.5H2O in a mixed liquid of deionized water and anhydrous ethanol to fully dissolve the component for forming a solution A, and dissolving NaOH in the solution A to prepare a solution B; 2) under stirring, adding urea to the solution B and continuously stirring the solution to prepare a uniform mixed solution C, and performing a homogeneous hydrothermal reaction on the mixed solution C; 3) after the reaction is finished, washing and drying a product to obtain a SnO2 precursor; 4) heating the SnO2 precursor to burning to prepare SnO2 powder; 5) dispersing the SnO2 powder in ethanol with stirring to prepare a uniform mixed suspension D;6) adding SnCl4.5H2O and TAA to the suspension D with stirring until the components are completely dissolved to obtain a homogenous suspension E; 7) performing a microwave thermal reaction on the suspension E, when the reaction is finished, moving-out and washing and drying the product to prepare the SnS2 / SnO2 lithium ion battery anode material in hollow-sphere structure.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing corundum abrasive by microwave sintering

InactiveCN107445595AReduce production energy consumptionLower sintering temperatureOther chemical processesMicrowave sinteringEnergy consumption

The invention discloses a method for preparing corundum abrasive by microwave sintering, and belongs to the technical field of abrasive preparation. The corundum abrasive comprises the following raw materials in percentage by weight: 95-98% of Al2O3, 0.5-2.5% of SiO2, 0.5-1% of MgO, 0.2-1% of TiO2, 0.2-1% of MnO2, and 0.1-1% of CuO. The method comprises the following steps: mixing the raw materials; molding; crushing; sieving; grading; performing rubber removing; transferring the rubber-removed blank particles into an SiC crucible; increasing the temperature to reach 1300-1500 DEG C at the rate of 10-20 DEG C per minute; then maintaining the temperature for 5-30min, and performing microwave sintering to obtain the corundum abrasive. With the adoption of the method, energy consumption of the corundum abrasive production can be greatly decreased; in addition, the blank particles are in contact with each other, so that the clearances among the particles are small, the temperature gradient of a sintered body can be reduced, the sintering time is greatly decreased, and as a result, the corundum abrasive sintering quality can be improved.

Owner:河南建筑材料研究设计院有限责任公司

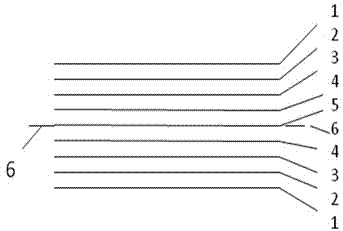

Graphene-based heat conducting piece

InactiveCN104519723AHigh thermal conductivityAvoid overall overheatingLayered productsCooling/ventilation/heating modificationsFiberCarbon fibers

The invention discloses a graphene-based heat conducting piece. The grapheme-based heat conducting piece comprises insulation layers, graphene layers, heat conducting substrates and heat conducting adhesive layers, wherein the heat conducting substrates, the graphene layers and the insulation layers are arranged on the two sides of the heat conducting adhesive layers in sequence from the interior to the exterior; carbon fibers are distributed in the heat conducting adhesive layers. According to the invention, the heat conducting piece is high in heat conductivity; heat can be distributed uniformly quickly; the heat conducting substrate provided with graphene thin films additionally are solider, and more anti-corrosion and oxidation-resistant, and prolongs service lives of power source and equipment; the grapheme-based heat conducting piece is small in size and occupied space, and suitable for heating and heat radiation of batteries which are arrayed in high density.

Owner:WUXI GRAPHENE FILM

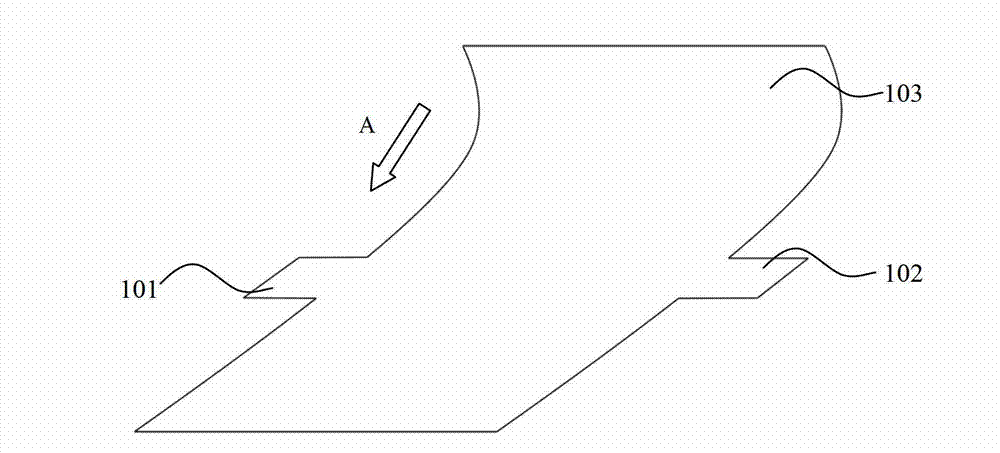

Graphite film heat conductor

ActiveCN103096691AEasy to processEasy to useSemiconductor/solid-state device detailsSolid-state devicesHeat conductingGraphite

The invention discloses a graphite film heat conductor which is made of a graphite film in a coiled mode. The graphite film heat conductor comprises a heat conducting component, a heat contacting component and a cold contacting component, wherein the heat conducting component is located in the middle, and the heat contacting component and the cold contacting component are located at two ends. The graphite film is coiled at least one circle to form the heat conducting component, and the heat contacting component and the cold contacting component are not coiled into circles. According to the graphite film heat conductor, heat is rapidly transferred from a heating device to a heat sink by means of high thermal conductivity of the graphite film and large contacting areas between the graphite film heat conductor, and the heating device and the heat sink. Therefore, a temperature gradient on a heat conduction path is reduced or eliminated, unbalanced-temperature hot spot regions inside equipment are eliminated, and whole reliability and long-time working capability of the device and the equipment are improved. The graphite film heat conductor is easy to machine, convenient to use, and free of limitation of installation positions, and provides powerful help for high-degree integration, and ultra-small and ultra-thin purposes of the equipment.

Owner:WUXI JONES TECH

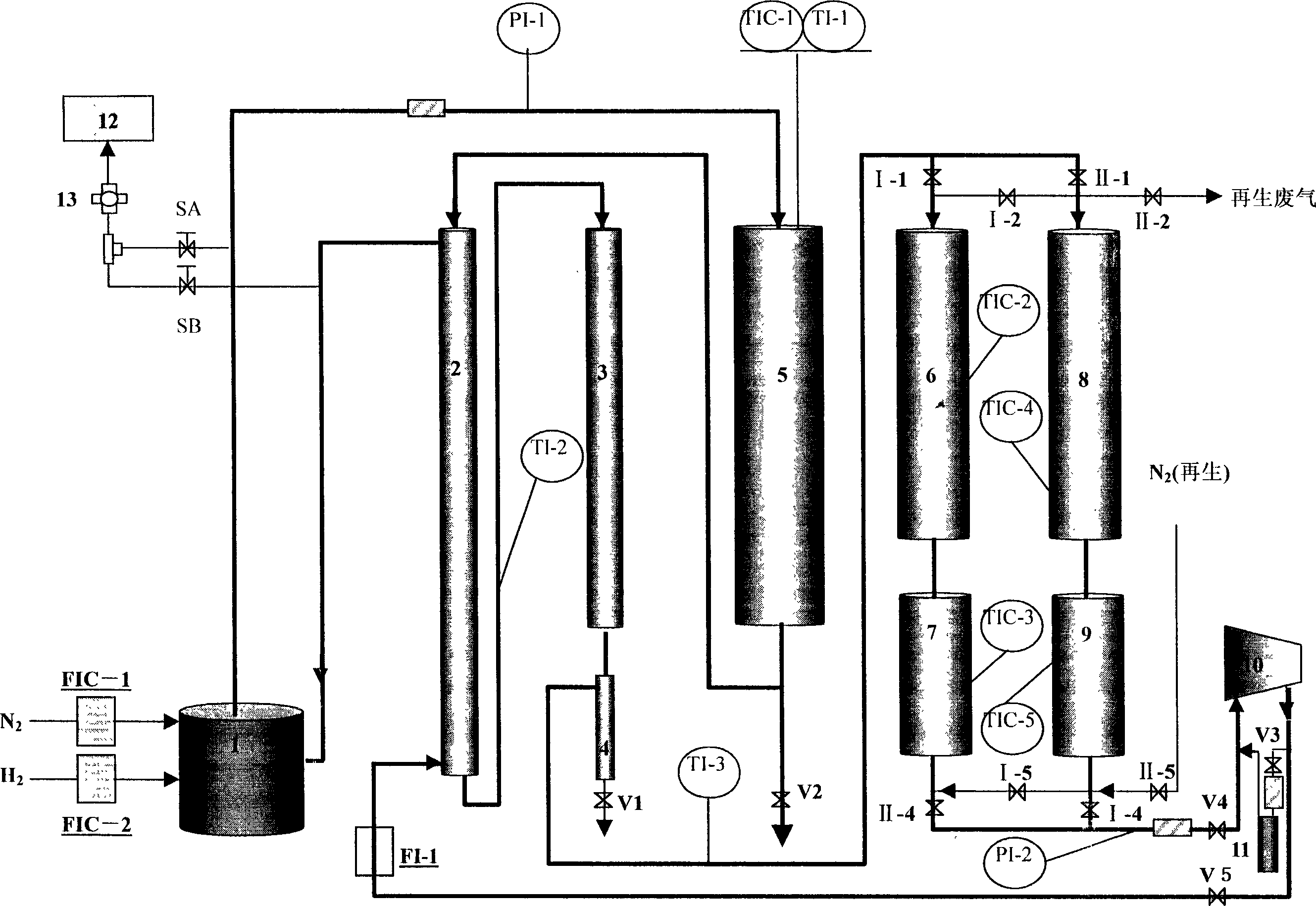

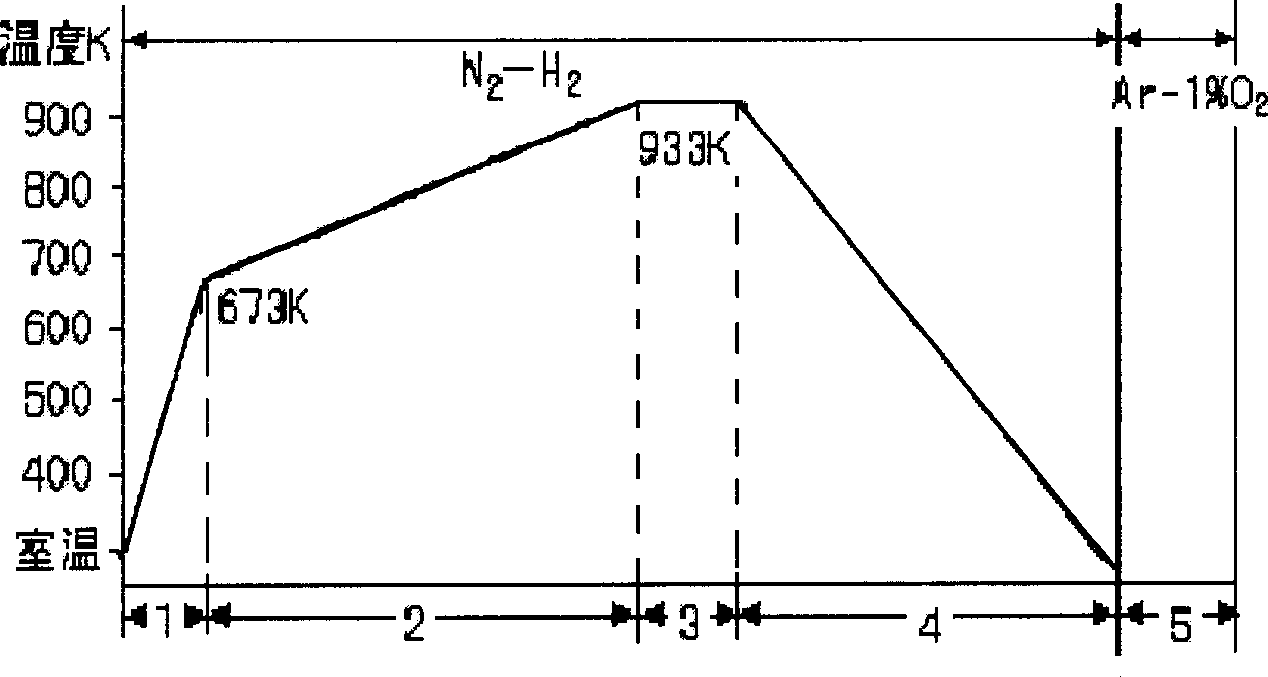

Process and apparatus for preparing metal nitride catalyst material

InactiveCN1887421AIncrease surface areaLarge specific surface areaCatalyst activation/preparationReaction temperatureNitride

The present invention relates to catalyst technology, and is especially process and apparatus for preparing metal nitride catalyst material (gamma-Mo2N). MoO3 / TiO2, MoO3 / NiO-TiO2, MoO3 / Al2O3-TiO2 or MoO3 / Al2O3 is set in a reactor to replace MoO3 with reducing N2-H2 so as to prepare supported metal nitride catalyst Mo2N / TiO2, Mo2N / NiO-TiO2, Mo2N / Al2O3-TiO2 or Mo2N / Al2O3. The reaction conditions include N2-H2 ratio in the gas mixture of 1 / (3-5), reaction temperature of 933K+ / -10K and holding time of 0.5-1 hr. The apparatus includes mainly a mixer, a reactor, a heat exchanger, and a gas chromatogaph connected through pipeline. The present invention can prepare gamma-Mo2N with specific surface area as great as 150 sq m / g, and the preparation process has its operation simpler than that with NH3.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser cladding process

ActiveCN107723702AReduce temperature gradientImprove organizationMetallic material coating processesAlcoholLaser processing

The invention discloses a laser cladding process. The laser cladding process comprises the following steps: putting YCF101 powder in a drying box, drying the YCF101 powder for 5h at a constant temperature of 80 DEG C, then pouring the YCF101 powder into a laser cladding powder feeder, and performing powder feeding coaxially for cladding; grinding a substrate, and cleaning the substrate with alcohol to remove impurities so as to obtain a smooth to-be-cladded substrate; and performing laser cladding layer by layer on the smooth to-be-cladded substrate by employing a IPG optical fiber laser according to a certain laser processing parameter and a certain laser scanning policy. According to the laser cladding process disclosed by the invention, defect accumulation as powder is stuck to a lap joint by way of single form interlaminar lap joint is weakened effectively. The extension direction of the defects is consistent to an interlayered scanning track. By crossed longitudinal interlaminar lap of multiple groups, the defects are uniformly distributed on the cladding plane, and the defect degree is reduced effectively; the extension direction of a bath is also consistent to the scanning direction, so that the high temperature of the bath in the next layer also alleviates pores at the lap joint effectively.

Owner:NORTHEASTERN UNIV

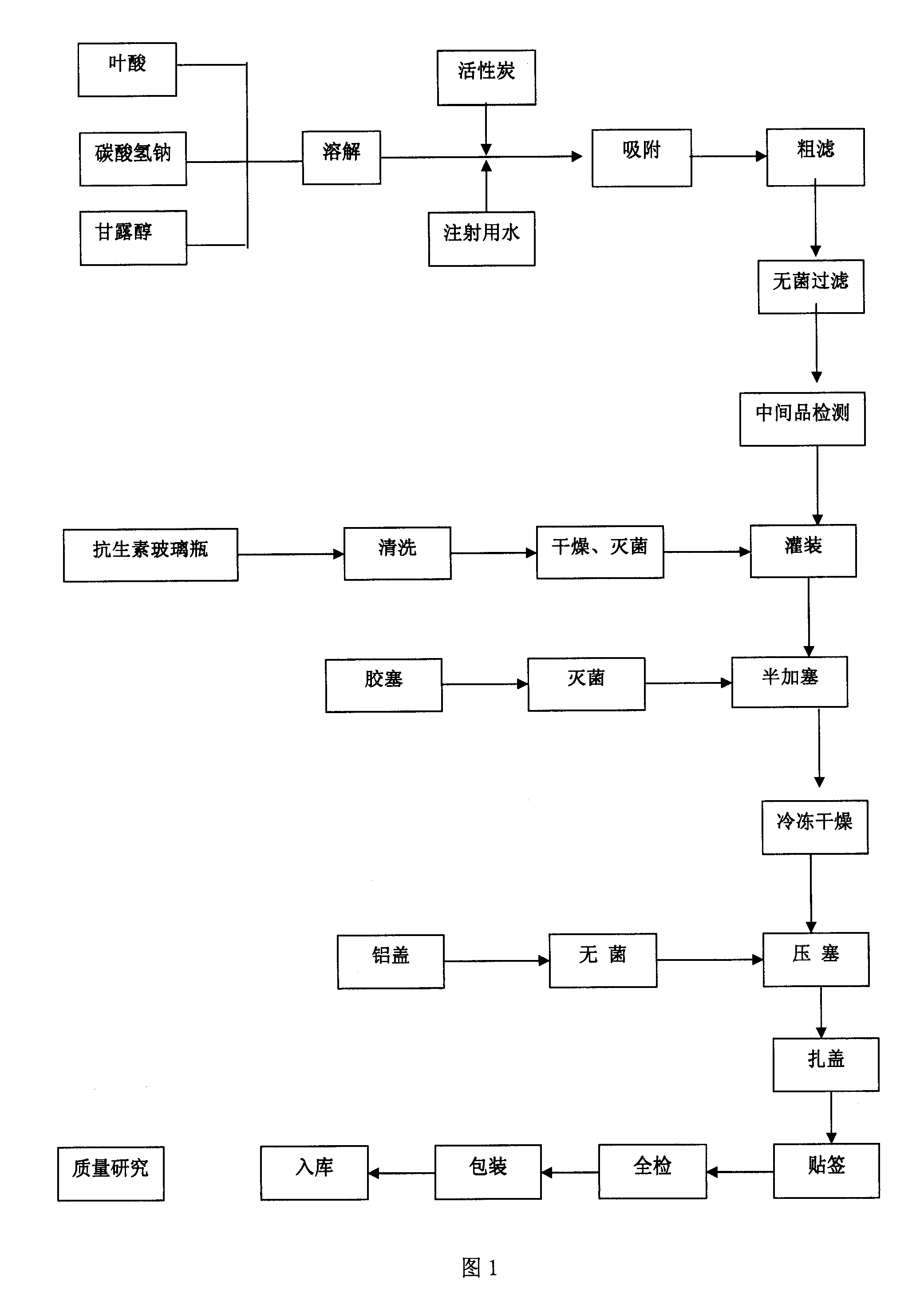

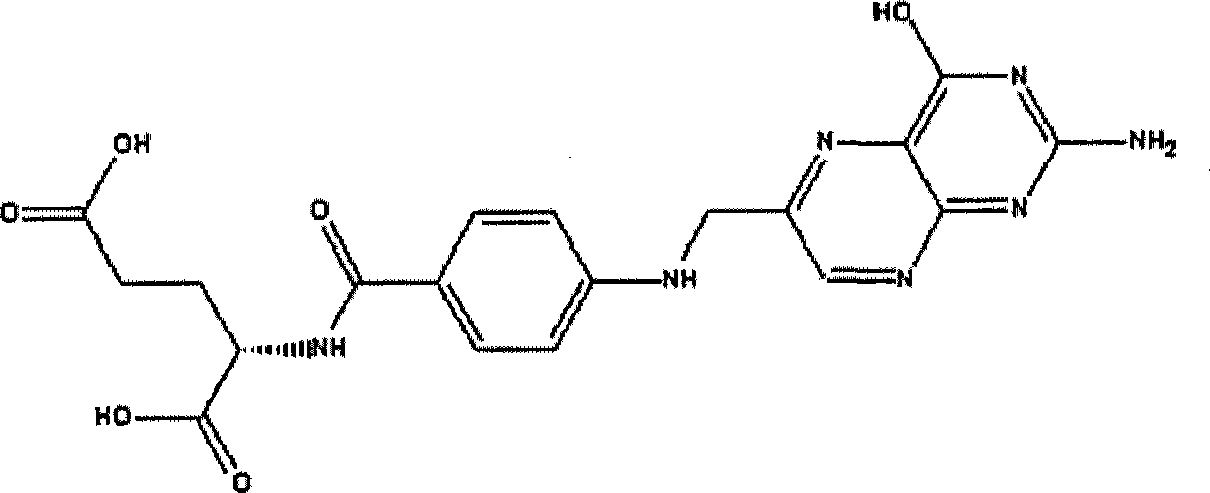

Folic acid freeze-dried injection and preparation thereof

ActiveCN101244042AGood resolubilityHigh clarityOrganic active ingredientsPowder deliverySolubilitySide effect

The invention provides a folic acid lyophiled powder injection and a preparation method, comprising folic acid and mannitol, which is characterized in that the weight ratio of the folic acid and the mannitol is 1:2.5 to 10. The preparation method has the advantages of simple prescription, little side effect, and plump appearance, good double solubility and fine quality for the prepared product due to the adoption of the advanced freeze drying craft.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

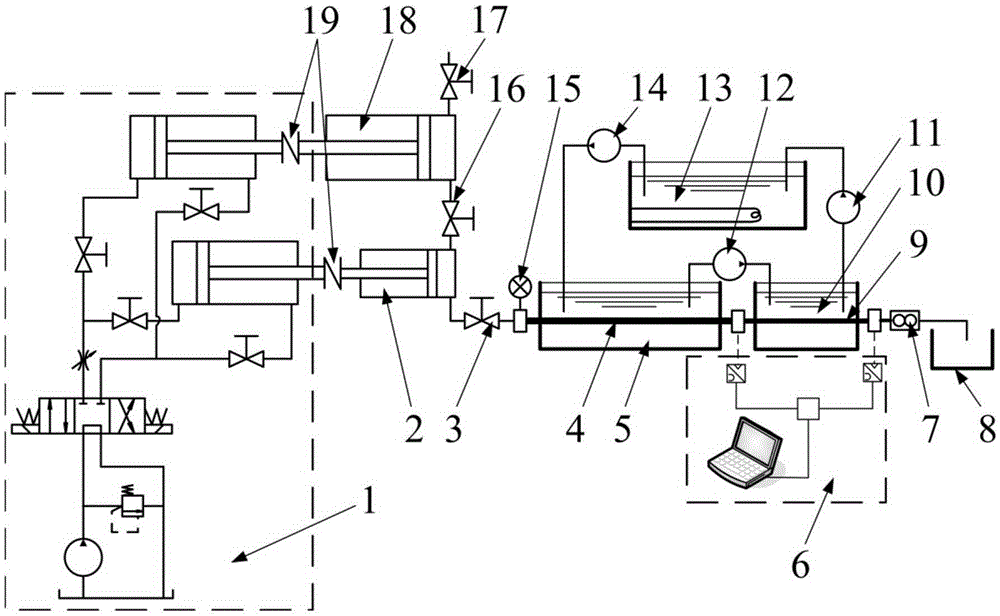

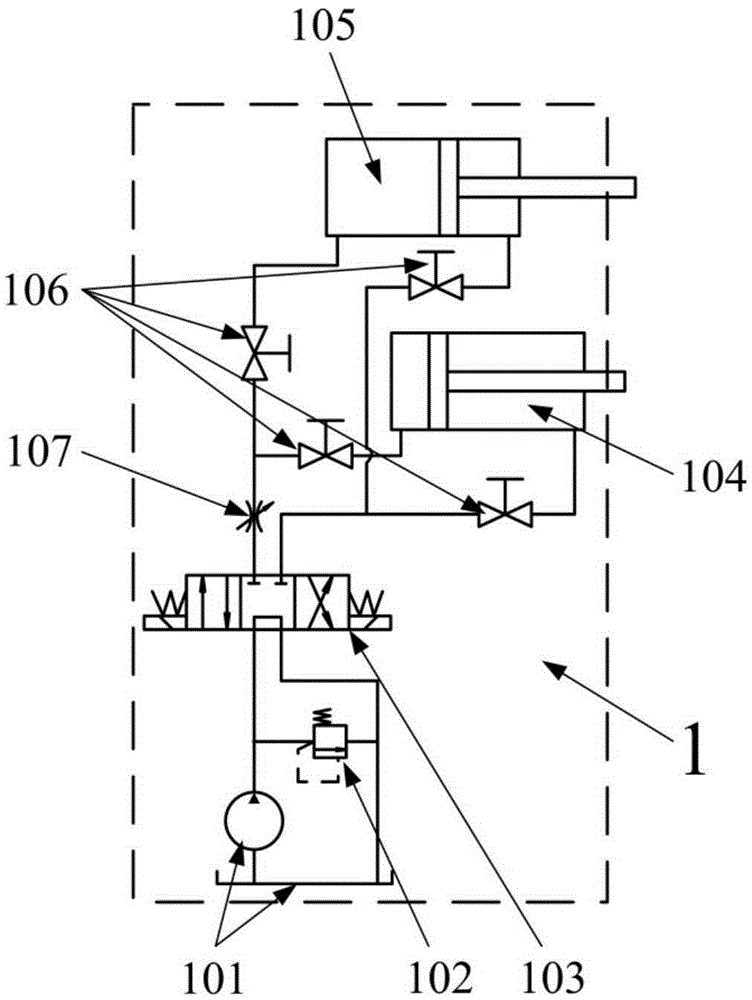

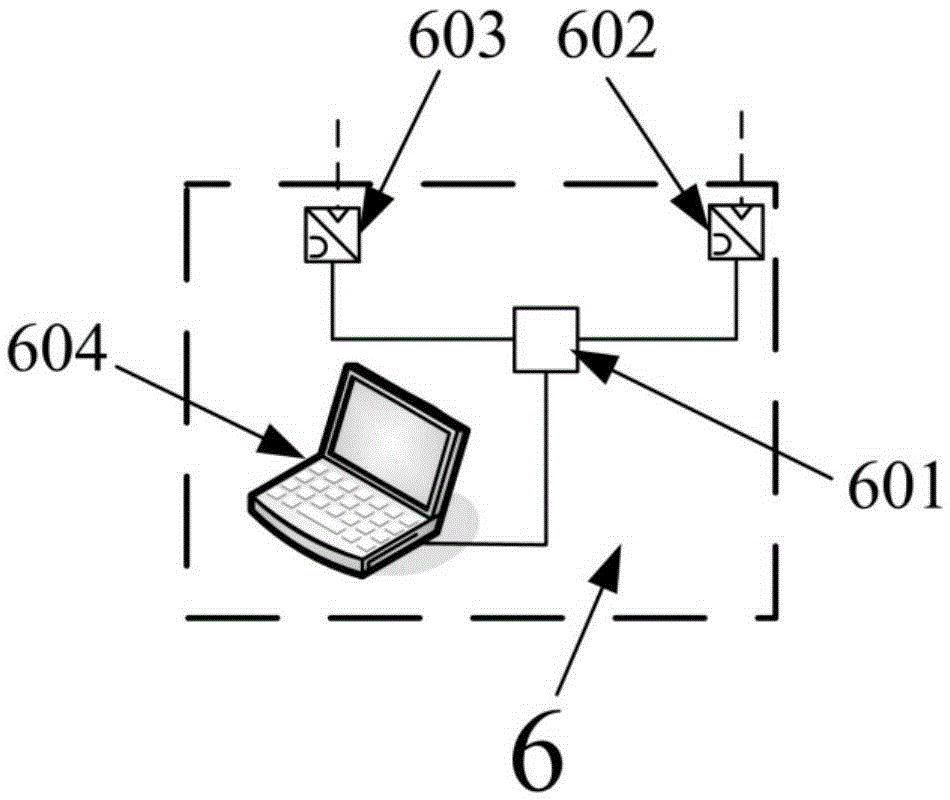

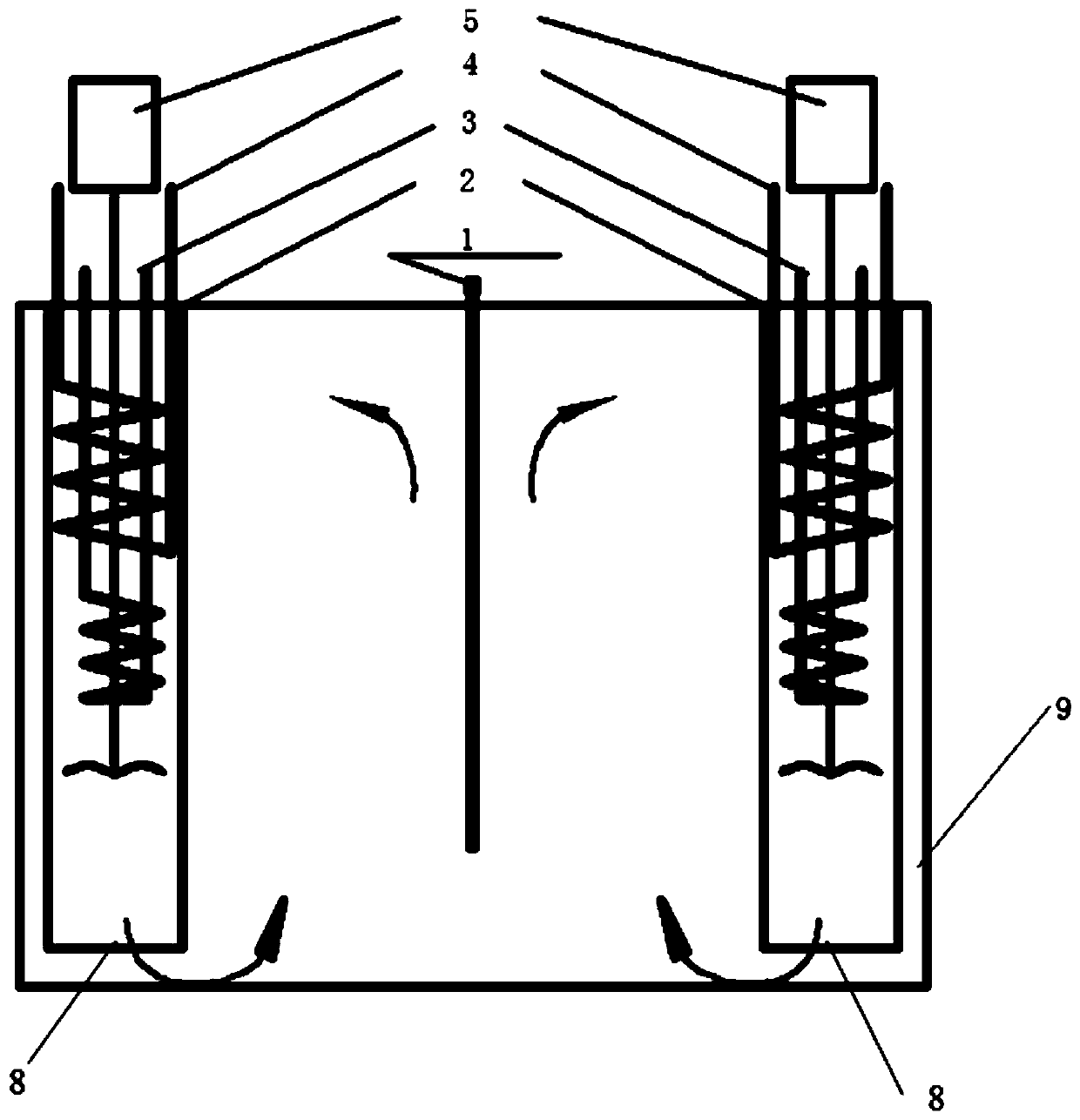

High-viscosity fluid temperature characteristics testing bedstand and method

ActiveCN105241790AEliminate temperature gradientsAccurate temperature controlFlow propertiesWater bathsHydraulic cylinder

The invention discloses a high-viscosity fluid temperature characteristics testing bedstand and a method, wherein the high-viscosity fluid temperature characteristics testing bedstand comprises a hydraulic system, a data collecting system, a water bath circulating heating system, a fluid conveying cylinder 1, a fluid conveying cylinder 2, a testing pipeline and an oval gear flowmeter, the hydraulic system comprises a hydraulic cylinder 1 and a hydraulic cylinder 2, the water bath circulating heating system comprises a constant temperature water bath tank, a water tank 1, a water tank 2, a hot water pump 1, a hot water pump 2 and a hot water pump 3, and the testing pipeline comprises a water bath heating segment and a testing segment. The method pushes fluid in the fluid conveying cylinder 1 and the fluid conveying cylinder 2 to enter the testing pipeline to heat through water bath depend on the hydraulic system, tests pressure drop of the fluid in the testing pipeline through the data collecting system, and inspects flow rate during the testing process through the oval gear flowmeter. The high-viscosity fluid temperature characteristics testing bedstand and the method achieve development of pipe mobility under the coupling influence of accurate control temperature of the fluid in the testing pipeline, large span velocity control and multiple factors.

Owner:CHINA UNIV OF MINING & TECH

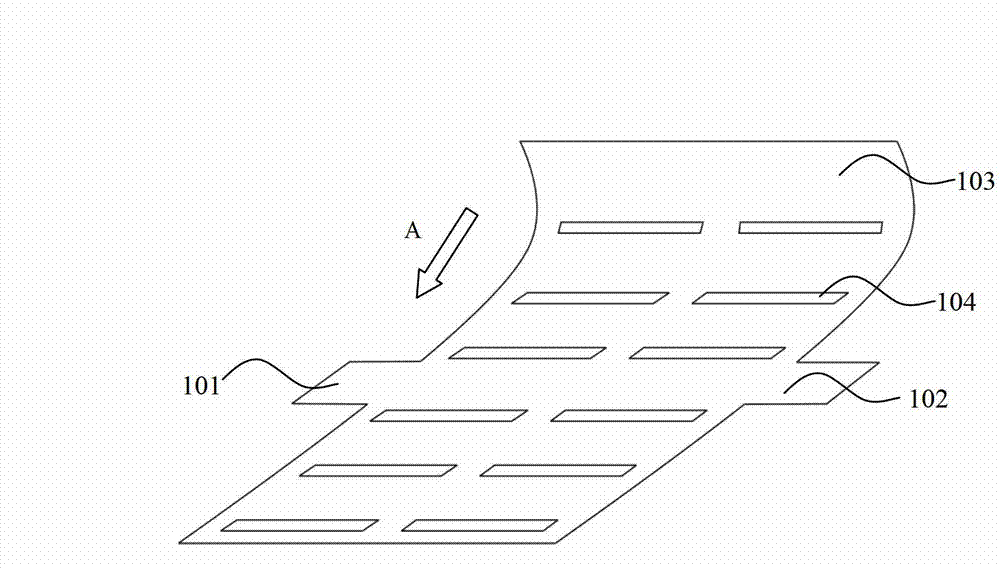

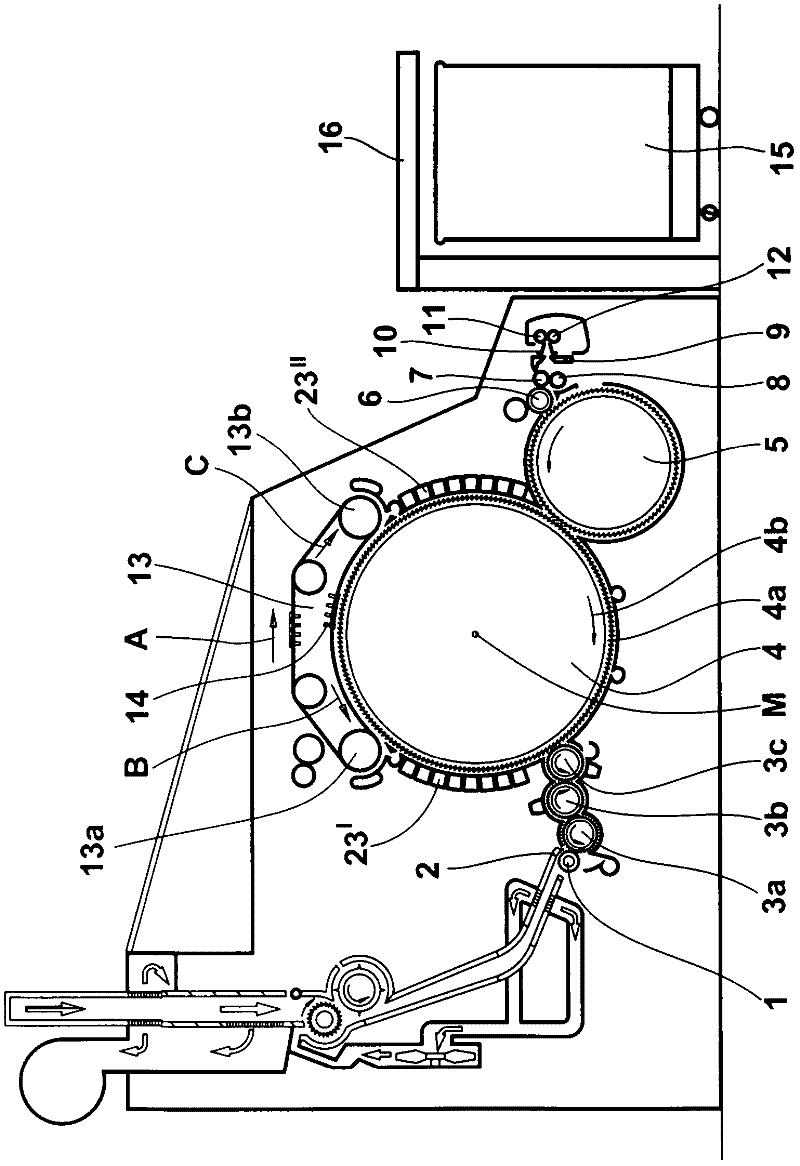

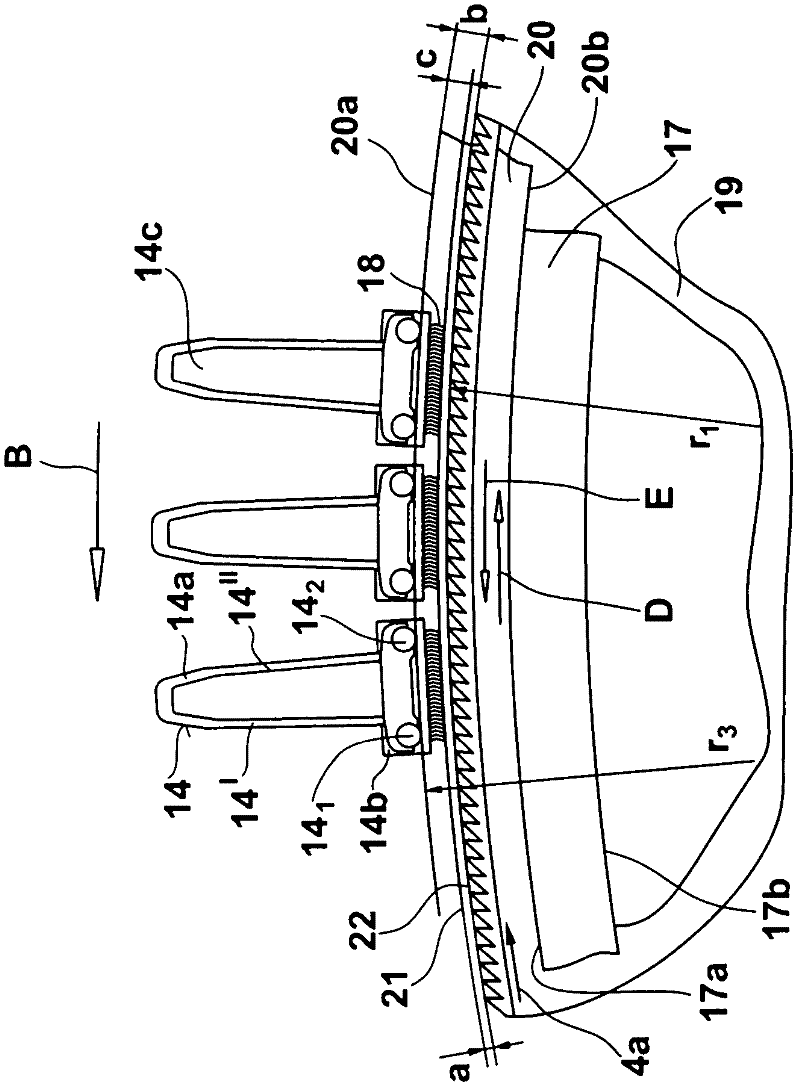

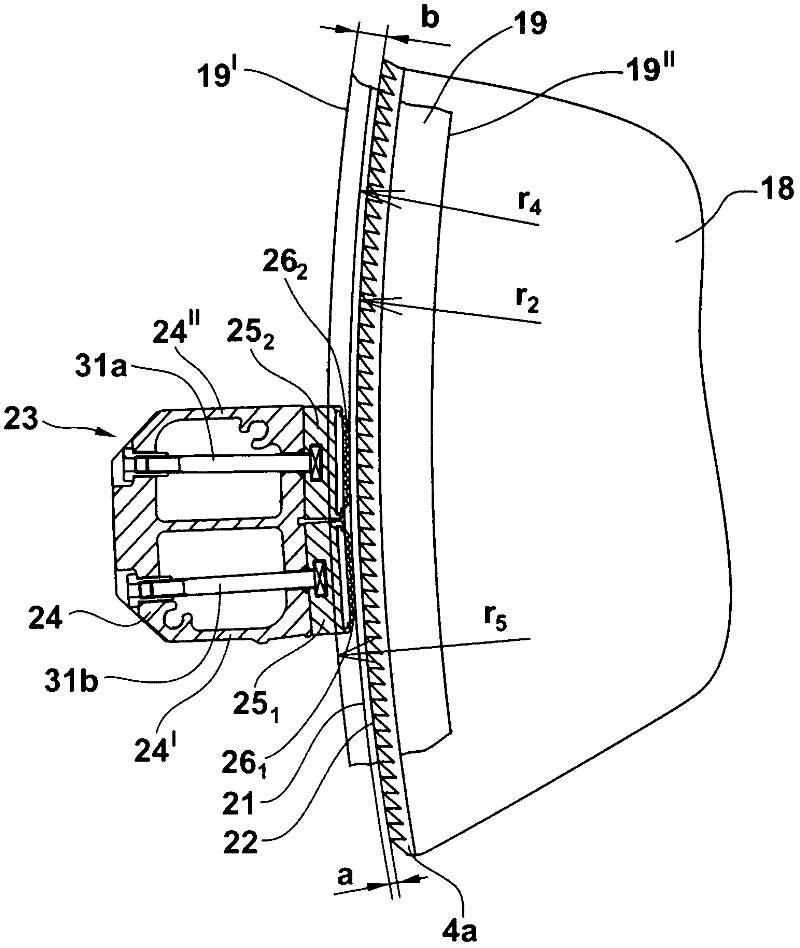

Supplying thermal energy to a working element and/or cover element of a flat card or roller card

ActiveCN102560750AEliminate temperature gradientsSlightly prevents thermal deformationCarding machinesEngineeringThermal energy

Apparatus on a flat card or roller card comprises at least one working element 14 and / or cover element arranged opposite and spaced apart from a clothed roll 4 and extending over the width of the roll. The element has an elongate carrier member comprising a foot and a back, the foot facing towards the roll absorbs operating heat and the back facing away from the roll is in contact with ambient air. To allow adjustment of the working element and / or cover element to different fibre materials and operating circumstances or conditions and to enable the carding nip to be constant, thermal energy is supplied to the back preferably to provide a largely homogeneous temperature distribution having a very small or no temperature gradient in the carrier member. The working element may comprise a fixed card or a revolving flat assembly. In the case of a revolving flat assembly the thermal energy may be supplied by a heating zone which makes brushing contact with the backs of several flats and is preferably confined to the flat entry region. The heating zone may comprise one or more blankets 27 with which a temperature profile may be established over the working width to counteract different temperature gradients

Owner:特吕茨施勒集团欧洲公司

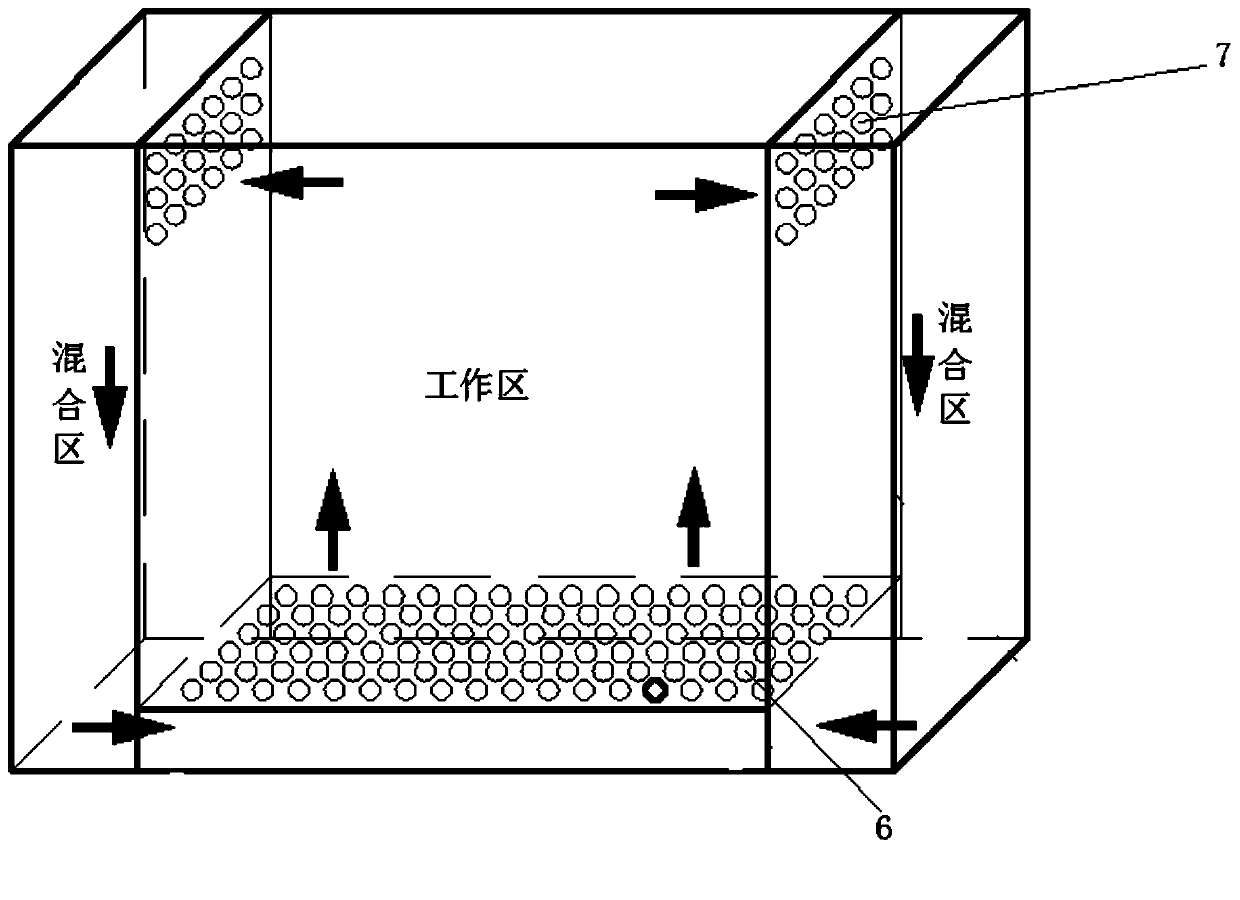

Constant-temperature bath for working viscosity liquid setting value

PendingCN109724896AAccurate temperature environmentGuaranteed uniformityFlow propertiesAuxillary controllers with auxillary heating devicesTemperature controlEngineering

The invention provides a constant-temperature bath for a working viscosity liquid setting value. The constant-temperature groove comprises a bath, a temperature controller, a temperature sensor, a heating refrigeration system and a stirring circulation device. A mixing barrel is disposed inside the bath and is provided with a fluid inlet and a fluid outlet. The height of the fluid inlet is higherthan the height of the fluid outlet. The bottom end of the bath is provided with a diverter grid. The horizontal installation height of the diverter grid is higher than the height of the fluid outletof the mixing barrel. The space enclosed by the outer wall of the mixing barrel and the diverter grid is the working area of the bath. The fluid in the mixing barrel enters the working area of the bath through the fluid outlet and the diverter grid. The fluid of the working area enters the mixing barrel through the fluid inlet. The temperature sensor is fixed in the working area of the bath. The input end and the output end of the temperature controller are respectively connected to the temperature sensor and the heating refrigeration system. The heating refrigeration system and the stirring circulation device are fixed in the mixing barrel. The invention can solve the problem of temperature accuracy, uniformity, and stability of the current constant-temperature bath.

Owner:西安航天计量测试研究所

Stable naloxone hydrochloride lyophilized preparation and preparation method thereof

InactiveCN102727449AGood resolubilityHigh clarityPowder deliveryOrganic active ingredientsSolubilityMANNITOL/SORBITOL

A stable naloxone hydrochloride lyophilized preparation comprises naloxone hydrochloride and mannitol in a weight ratio of 1 : 30 - 200. The lyophilized preparation has a simple formula and fewer side effects, and employs an advanced freeze-drying process. The prepared products have full appearance, good solubility, and excellent quality.

Owner:YAOPHARMA CO LTD

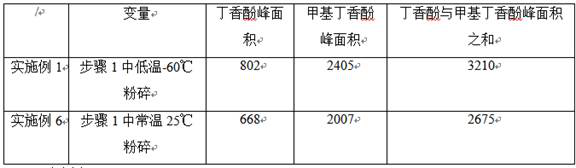

Preparation method and application of pimenta officinalis extract

InactiveCN112023442ASmall sizeNo decompositionTobacco preparationTobacco treatmentEugenolPhysical chemistry

The invention discloses a preparation method and application of a pimenta officinalis extract. The preparation method comprises the following steps of: crushing pimenta officinalis by adopting a low-temperature crushing technology, extracting fragrant substances like eugenol in the pimenta officinalis in a microwave extraction manner under the condition that ethanol is used as an extraction reagent, and adding graphene oxide into the pimenta officinalis filter residue to further improve the extraction of the fragrant substances like eugenol. The low-temperature crushing technology can avoid structural damage of high temperature to heat-sensitive fragrant substances and volatilization loss of the fragrant substances caused by high temperature; the temperature gradient can be eliminated through microwave extraction, the heating speed is high, and extraction of heat-sensitive substances is facilitated; on the one hand, graphene oxide is used as an adsorption medium, and on the other hand,hydrolysis of plant cell walls is accelerated by graphene oxide, so that the cell tissue structure of the filter residue is further destroyed, the extraction efficiency of fragrant substances in thefilter residue is improved, the loss of the fragrant substances is little, and eugenol and other fragrant substances are more in component and higher in fragrance purity, and the fragrance is pure, full and lasting.

Owner:HUBEI CHINA TOBACCO IND +1

Stable naloxone hydrochloride freeze-dry preparation and preparation method thereof

InactiveCN102166198ASimple recipeLittle side effectsOrganic active ingredientsPowder deliverySolubilityMANNITOL/SORBITOL

The invention provides a stable naloxone hydrochloride freeze-dry preparation, comprising naloxone hydrochloride and mannitol, wherein the weight ratio of the naloxone hydrochloride to the mannitol is 1:(30-200). The freeze-dry preparation has the advantages of simple formula and fewer side effects; and moreover, by using an advanced freeze-drying process, the prepared product has the advantages of full appearance, good quick solubility and excellent quality.

Owner:重庆健能医药开发有限公司

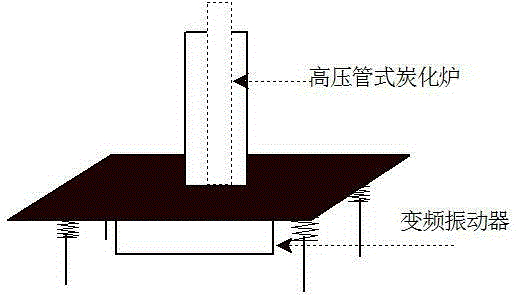

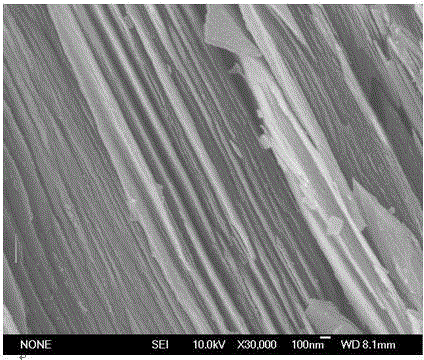

Preparation method of nanometer thin-layer structural carbon material

ActiveCN104477874ALow priceAbundant resourcesMaterial nanotechnologyLaboratory researchFiber structure

The invention relates to a preparation method of a nanometer thin-layer structural carbon material. The preparation method comprises the following steps of: effectively controlling the formation, growth and fusion of an intermediate in a carbonizing process by taking pitch as a raw material and adopting a mechanical method cooperated with coal pitch modification to obtain a carbon material intermediate with an optical microscopic structure showing a good fiber structure; then calcining to obtain the nanometer thin-layer structural carbon material with the microscopic structure which is very clear in structure. The preparation method disclosed by the invention has the greatest advantages of preparing a macroscopic quantity of nanometer thin-layer materials, being low in raw material price and simple in process flow, being hopeful to carry out large-scale production in industrial production and overcoming the defect that the preparation of the similar material reported at present can only obtain a milligram-grade quantity which only achieves the quantity level needed by laboratory research.

Owner:TAIYUAN UNIV OF TECH

Method for preparing electronic cigarette liquid through microwave-assisted extraction

InactiveCN105341998ALess reagent consumptionReduce pollutionGas treatmentTobacco treatmentSolventTobacco leaf extract

The invention discloses a method for preparing an electronic cigarette liquid through microwave-assisted extraction. An extraction liquid and mixed tobacco leaves are mixed and irradiated by microwaves, organic phases are merged after filtering and washing operation, an organic solvent is finally removed, and a tobacco leaf extract is obtained, wherein the extraction liquid and the mixed tobacco leaves are mixed in the weight ratio being (1:1)-(5:1); the adopted power is 400-800 W during microwave irradiation; the faint-scent tobacco leaf extract is prepared from Yunnan Yuxi faint-scent tobacco leaves, Yunnan Dali faint-scent tobacco leaves and Yunnan Qujing faint-scent tobacco leaves. By comparison with conventional extraction methods such as a room-temperature extraction method and a heating reflux method, the extraction time is greatly shortened, the use quantity of solvents is reduced, and the extraction efficiency is remarkably improved. Besides, the extract is prepared from mixed tobacco leaf extracts, and different tobacco leaf extracts complement each other in scent, so that the scent and the taste of the electronic cigarette liquid are more close to those of conventional cigarettes.

Owner:立场电子科技发展(上海)有限公司

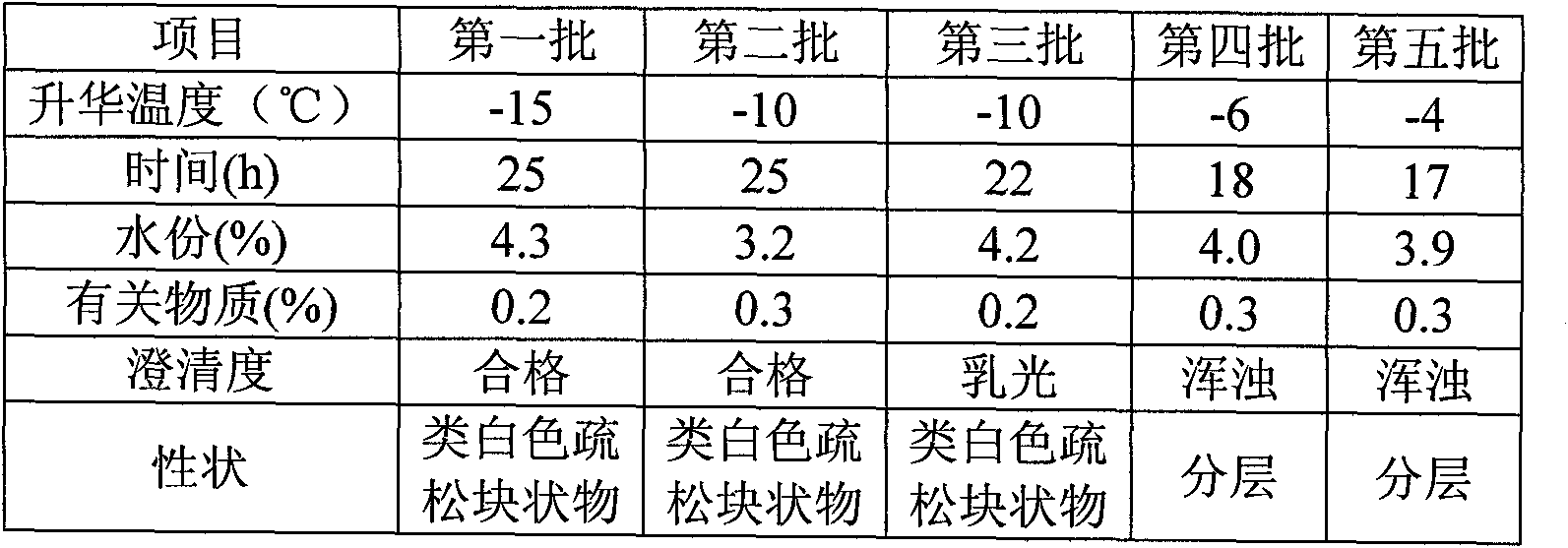

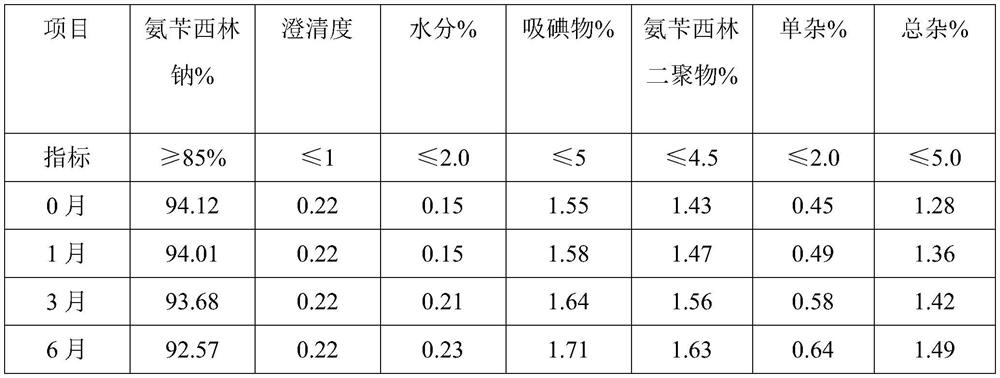

Preparation method of ampicillin sodium for injection

ActiveCN114796131ALower the eutectic point temperatureReduce generationAntibacterial agentsPowder deliveryPhysical chemistryMesoporous silica

The preparation method comprises the following steps: S1, dissolving an ampicillin sodium crude product in deionized water, and adding a proper amount of alkali liquor to adjust the pH value of the solution to 6.7-6.9; s2, adding a magnetic nanotube into the alkalized solution, and stirring and adsorbing in a vacuum environment; s3, separating the magnetic nanotubes by using a magnetic field, and dispersing the magnetic nanotubes into deionized water for oscillation desorption; wherein the magnetic nanotube comprises a multi-layer structure, and the multi-layer structure sequentially comprises a compact silicon dioxide nanotube layer, a Fe3O4 layer and a mesoporous silicon dioxide layer from inside to outside; and S4, merging and crystallizing the ampicillin sodium solution obtained by oscillation desorption to obtain refined ampicillin sodium. The ampicillin sodium molecules are reversibly adsorbed by adopting the special structure of the magnetic nanotube in a weak acid environment, and the inner layer of the silicon dioxide nanotube and the outer layer of the mesoporous silicon dioxide layer can be subjected to physical adsorption reaction with the ampicillin sodium molecules through hydrogen bonds, surface atomic coordination and the like.

Owner:SICHUAN PHARMA

A kind of preparation method of hollow sphere structure tin sulfide/tin oxide lithium ion battery negative electrode material

ActiveCN109301204BLight in massLarge specific surface areaCell electrodesSecondary cellsLithium electrodeTin oxide

Owner:SHAANXI UNIV OF SCI & TECH

Pantoprazole sodium freeze-dried powder injection and preparing method thereof

ActiveCN100484525CGood resolubilityHigh clarityOrganic active ingredientsPowder deliverySolubilityMANNITOL/SORBITOL

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD +1

Composite air brick and argon blowing refining method in continuous casting ladle pouring process

PendingCN114433829AIncrease the lengthReduce the slit widthMelt-holding vesselsManufacturing engineeringIndustrial engineering

The invention relates to a composite air brick and an argon blowing refining method in a continuous casting ladle pouring process. The air brick comprises a pouring body, a dispersion block and a safety warning device, wherein the dispersion block and the safety warning device are arranged in the pouring body from top to bottom; a plurality of slit air channels A penetrating through the dispersion block are vertically formed in the dispersion block; a lower air chamber is arranged at the bottom of the safety warning device, an upper air chamber is arranged at the top of the safety warning device, a plurality of slit air passages B which are through up and down are arranged in the safety warning device, the plurality of slit air passages B are uniformly distributed in the safety warning device along the circumference, and the lower ends of the slit air passages B are gradually inclined outwards; and the slit air passage A, the upper air chamber, the slit air passage B and the lower air chamber are communicated. The air brick has the excellent performance of large air permeability, stable air permeability, long service life and the like, after refining treatment in an LF refining furnace is completed, the air brick is hoisted to a continuous casting rotary table, argon blowing is carried out in the continuous casting steel ladle pouring process to remove inclusions, the soft blowing time in the later stage of LF refining is shortened, the removal rate of the inclusions is increased, and molten steel standing layering is restrained.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

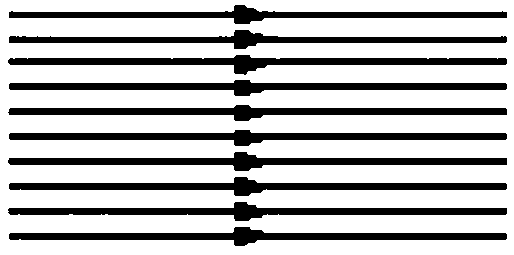

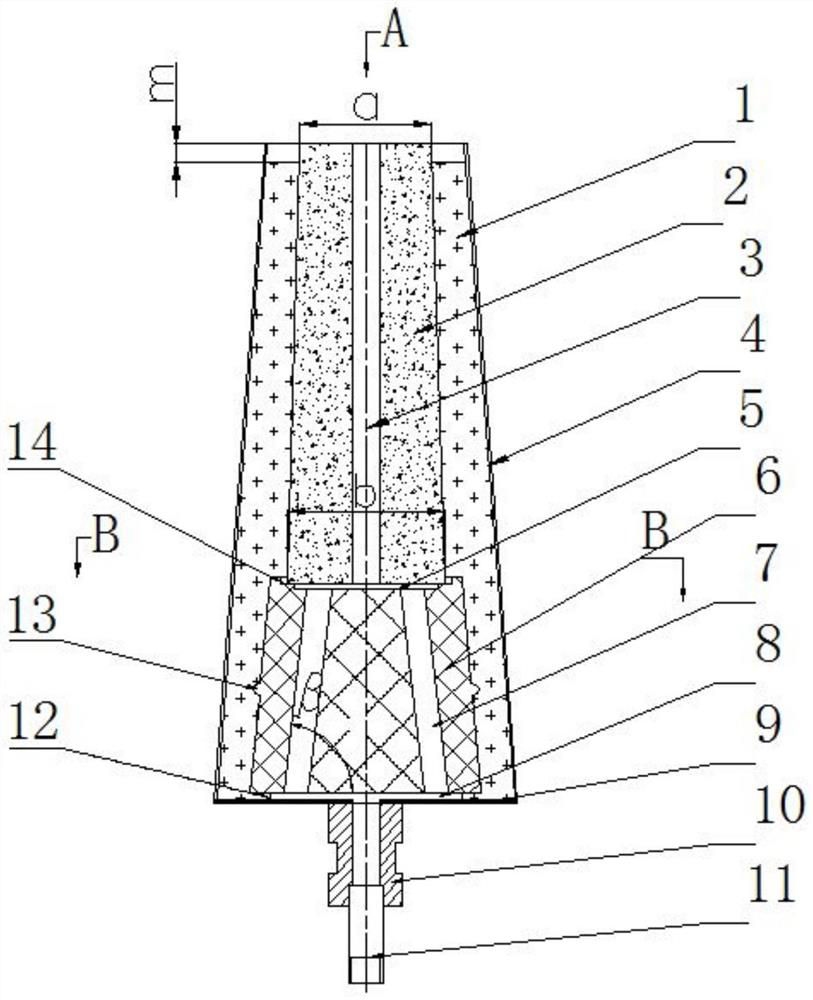

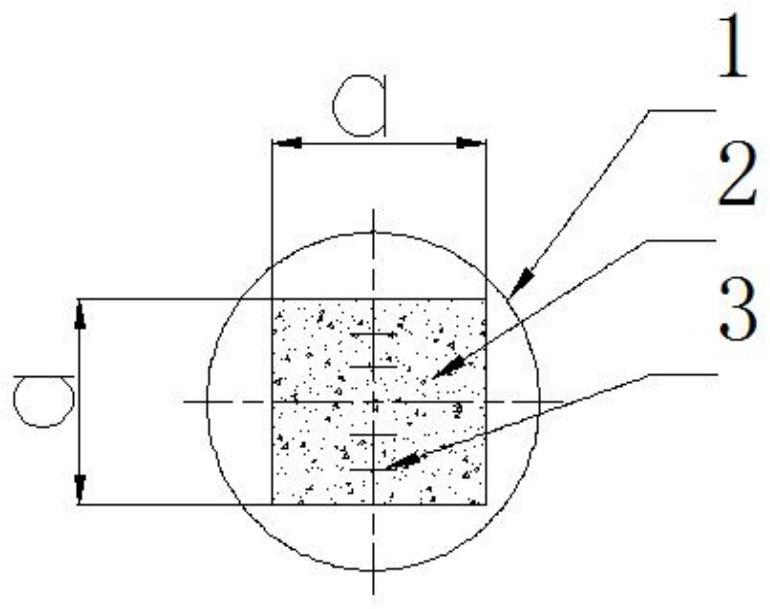

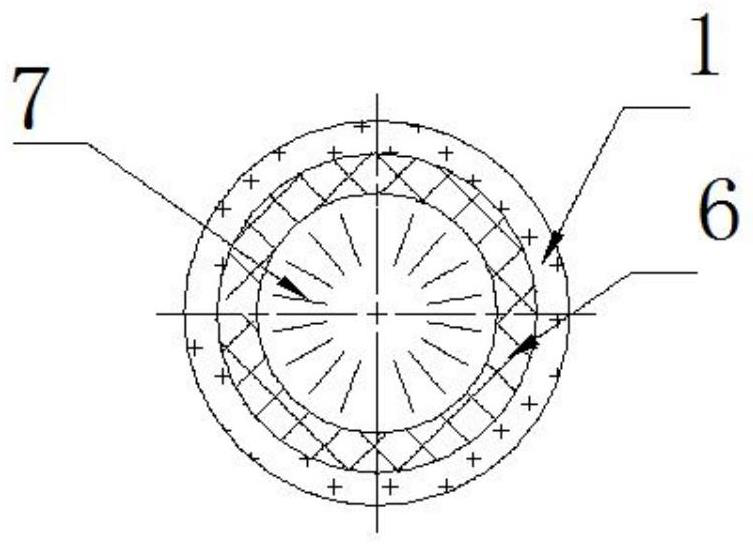

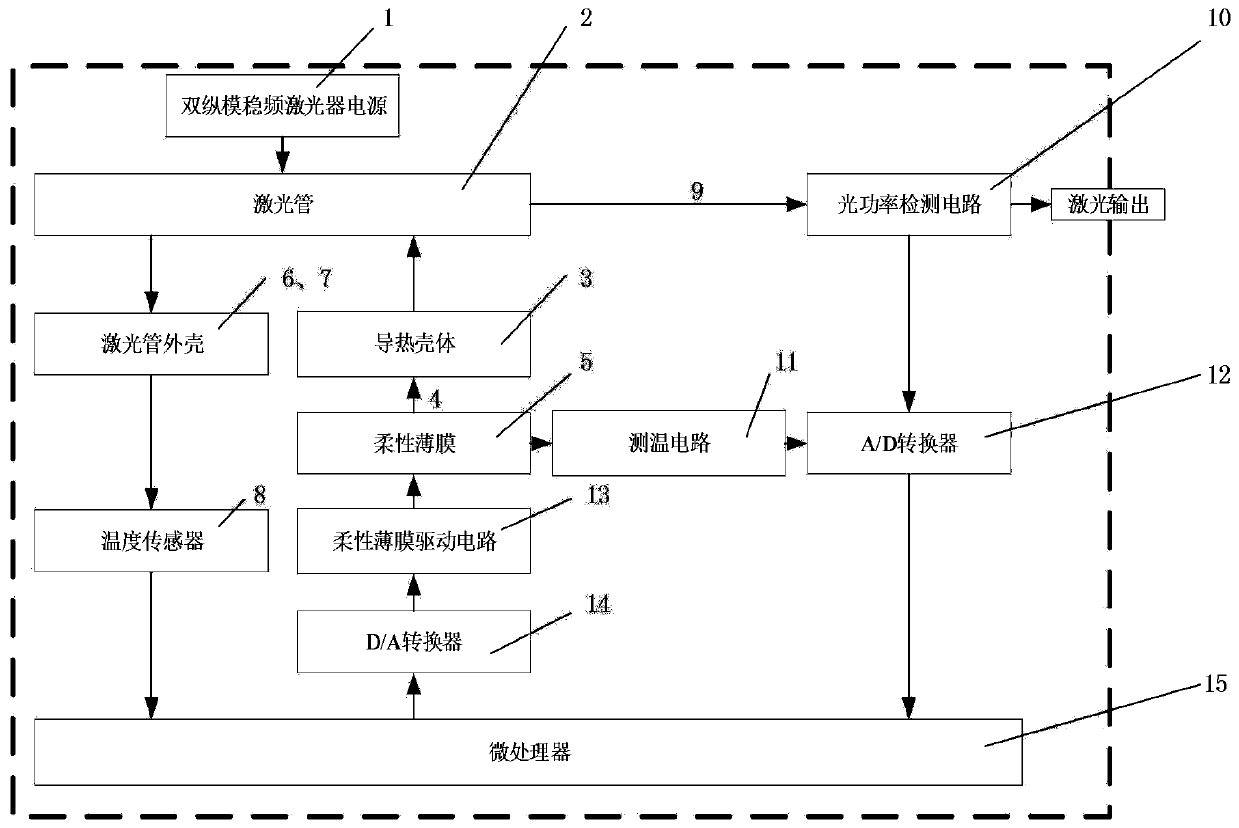

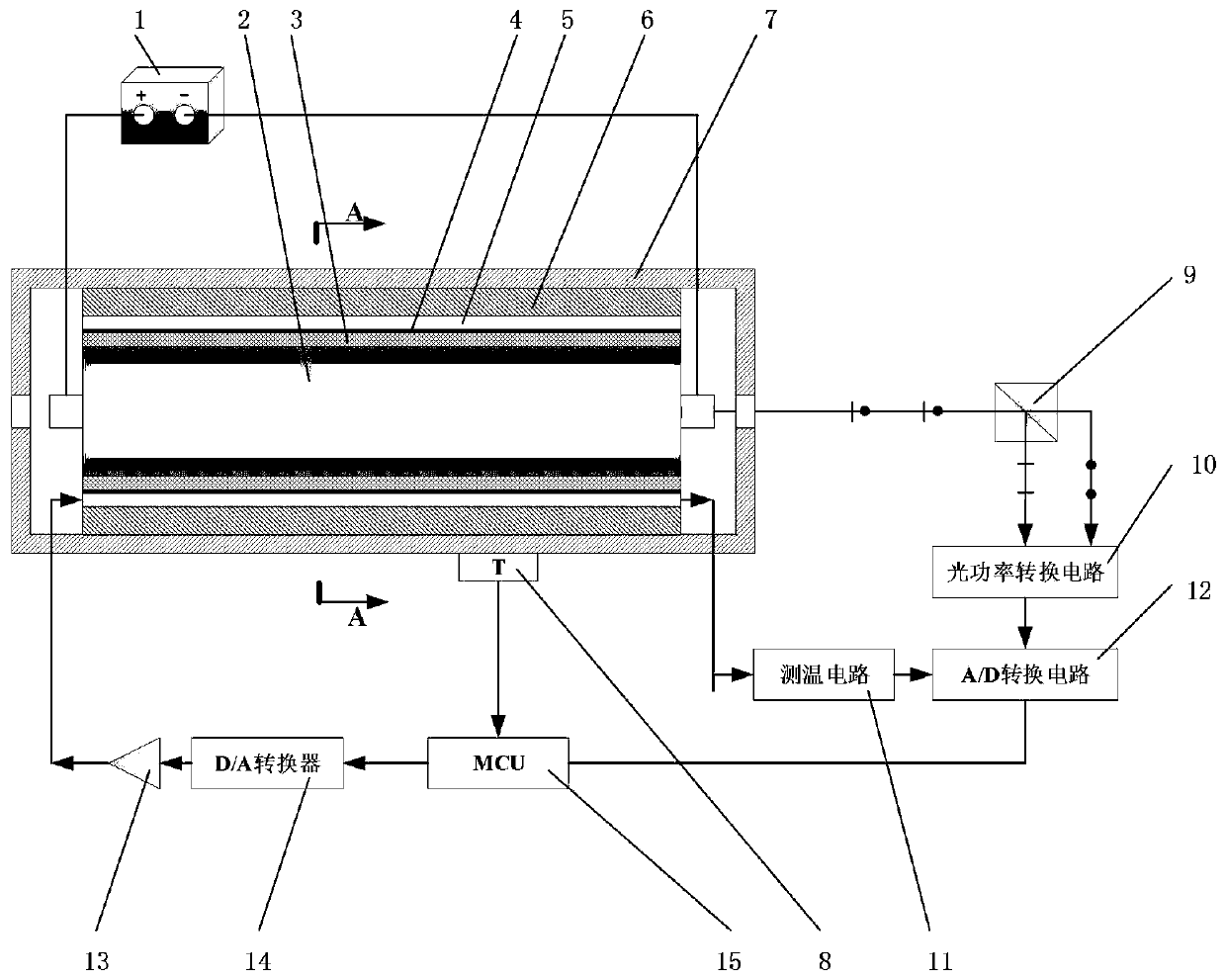

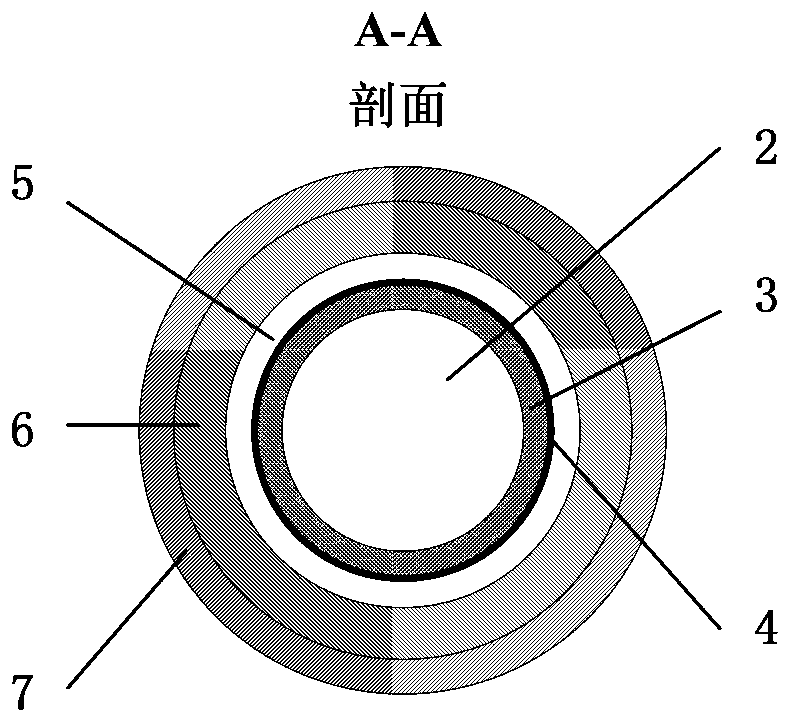

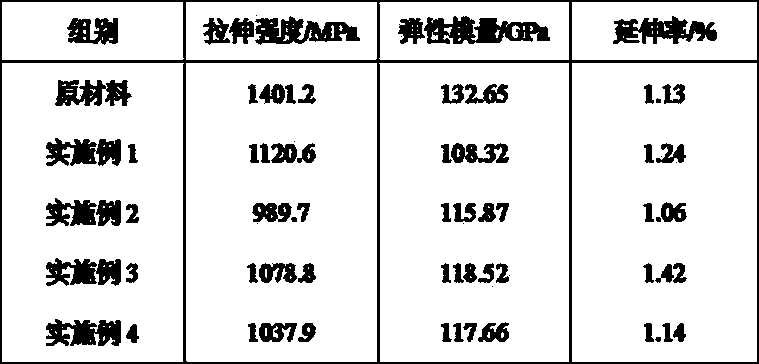

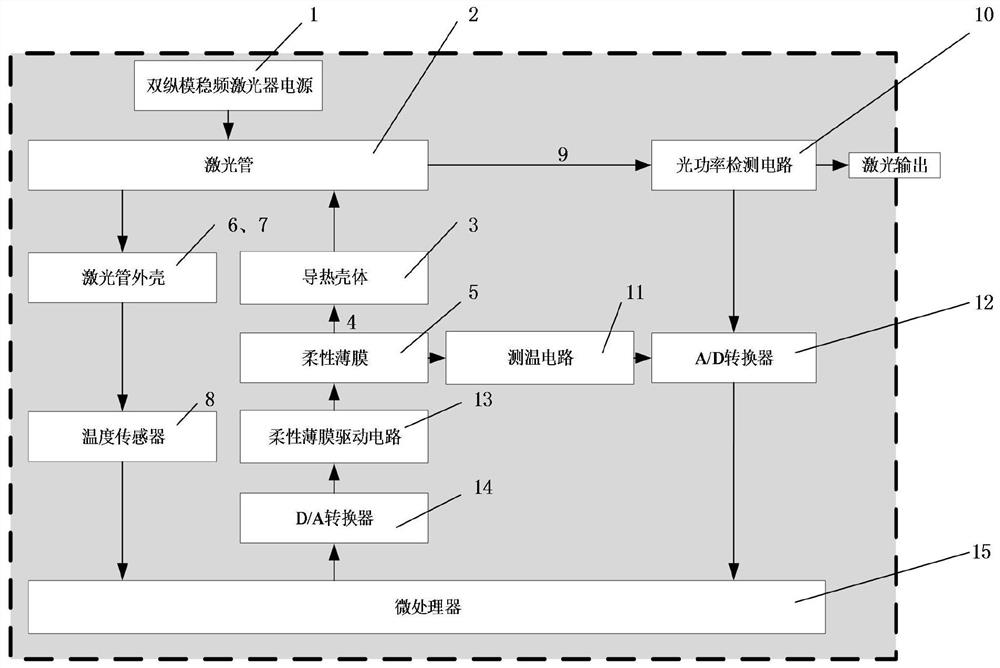

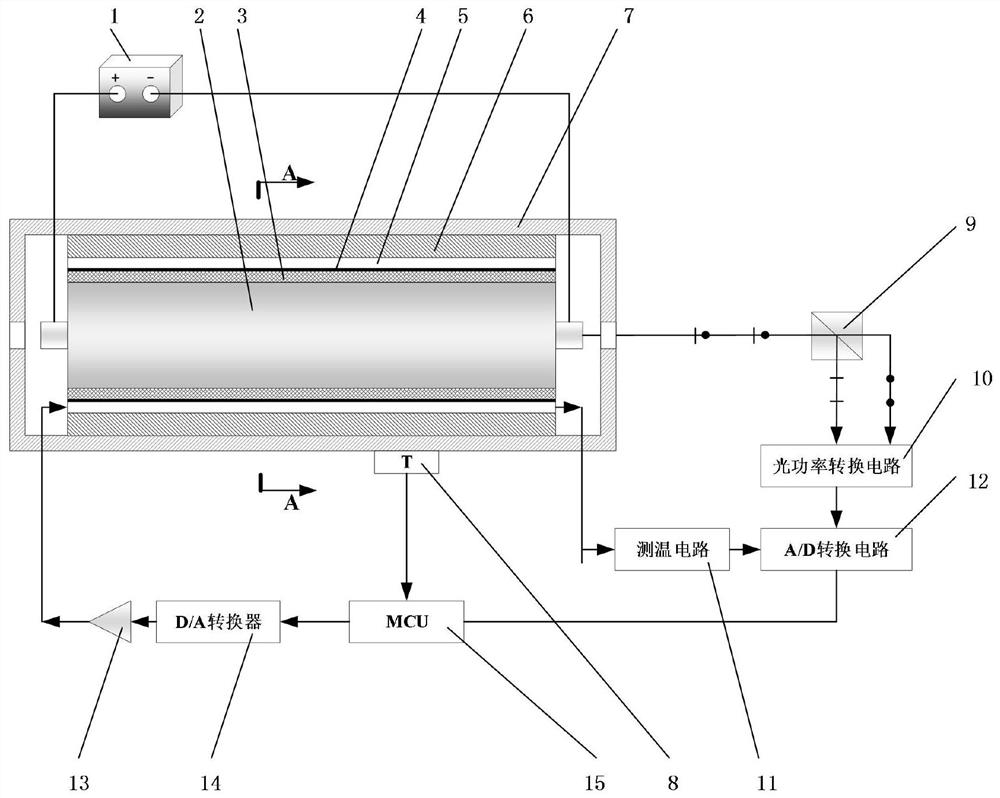

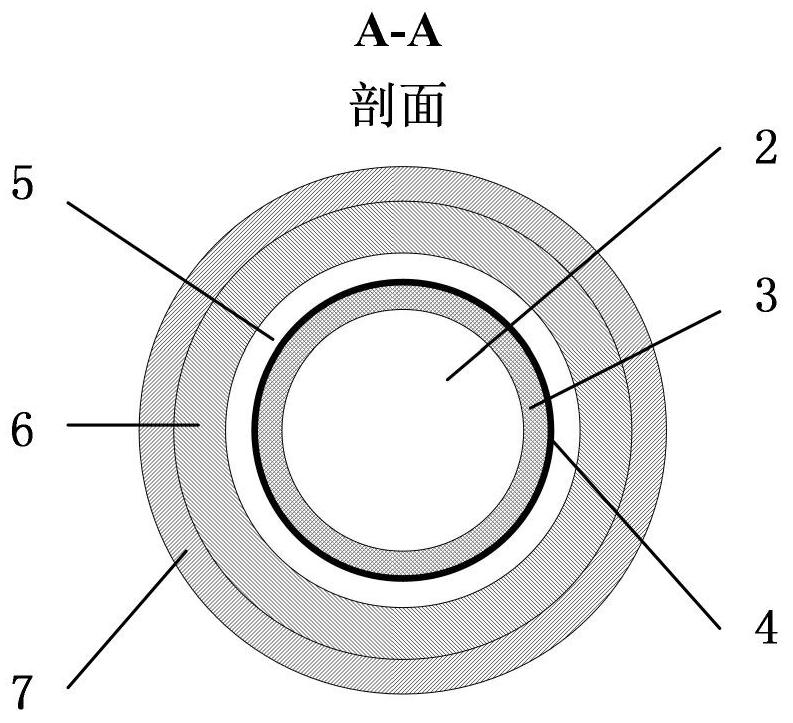

Laser frequency stabilization method and device based on temperature self-sensing flexible film heater

ActiveCN111092362AEliminate temperature gradientsIncreased frequency reproducibilityLaser monitoring arrangementsFrequency stabilizationBeam splitter

The invention provides a laser frequency stabilization method and device based on a temperature self-sensing flexible film heater. The positive electrode and the negative electrode of a double-longitudinal-mode laser power supply are connected with the two ends of a laser tube respectively. The laser tube is nested in a heat conduction shell and is arranged in a heat isolation layer; the positions, close to the two ends of the laser tube, of the heat dissipation layer are each provided with a light transmitting hole. The polarizing beam splitter is arranged outside one of the light transmitting holes; the light power conversion circuit is arranged on a reflection and refraction light path of the polarizing beam splitter, the flexible film, the temperature measurement circuit and the A / D conversion circuit are sequentially connected in a one-way mode, the temperature sensor is bonded to the outer wall of the heat dissipation layer, and the temperature sensor is connected with the microprocessor in a one-way mode. According to the method, the frequency reproducibility of the laser can be improved from 10 <-8 > to 10 <-9 >, the thermal hysteresis effect generated by heat transfer is avoided, and real-time and accurate temperature data are provided for a frequency stabilization algorithm of the laser.

Owner:HARBIN INST OF TECH

Method for recovering carbon fibers from waste carbon/carbon composite

InactiveCN108467511ATake advantage ofReduce pollutionBulk chemical productionCarbon compositesRecovery method

A method for recovering carbon fibers from a waste carbon / carbon composite comprises the following steps: (1) cutting resin-based carbon / carbon composite waste into blocks of 10 cm<3> plus / minus 3 cm<3>, and adding the blocks to a reaction kettle; (2) preparing medium-strong acid and alkali solutions with low boiling point, adding the solutions to the reaction kettle, performing microwave heatingto enable temperature in the kettle to be at 50-120 DEG C, and preserving heat for 1-15 min; (3) adding an alcohol organic solvent with concentration being 10%-50% of to the reaction kettle, and performing full stirring for uniformly mixing solid-liquid substances; (4) performing microwave heating to enable temperature of the kettle to reach 150-280 DEG C and a fluid in the kettle to be in a supercritical state, preserving heat for 1-15 min, and performing cooling; (5) extracting a solid material, washing the solid material to be neutral and drying the solid material at constant temperature toobtain recovered carbon fibers. The recovery method is low in time consumption and energy consumption, quality retention rate of the recovered carbon fibers is higher, cost of recovery of the carbonfibers from the carbon / carbon composite can be reduced remarkably, and efficient recovery and resourceful recycling of the carbon / carbon composite waste are realized.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Heat-conducting film and application

InactiveCN106833546AWide variety of sourcesThe overall thickness is thinHeat-exchange elementsTablet computerCross-link

The invention discloses a heat-conducting film and application. The heat-conducting film is prepared from the following raw materials in parts by weight: 80-160 parts of ethyl acetate, 10-80 parts of a polyimide emulsion, 80-120 parts of an acrylic ester adhesive, 0.05-0.5 part of a cross-linking agent, 10-110 parts of graphene, 0.1-2 parts of a coupling agent, 0-8 parts of a dispersing agent, 110-180 parts of butanone, 0.1-2 parts of an additive and 110-170 parts of toluene. The heat-conducting film is prepared through the steps of weighing ethyl acetate, the polyimide emulsion, the acrylic ester adhesive, cross-linking agent, graphene, the coupling agent, the dispersing agent, butanone, the additive and toluene according to parts by weight; and sintering in a nitrogen condition at a high temperature of 800-3,000 DEG C. The prepared heat-conducting film is light in weight, small in thickness, good in toughness and excellent in heat-conducting property, and can be widely applied to the fields of a smart phone, a tablet computer, LED lighting equipment, a smart television, semiconductor manufacturing equipment and automotive electronic equipment. The used raw materials are wide in source, simple and controllable in preparation, extremely low in production cost and suitable for industrial production.

Owner:江敏

Laser frequency stabilization method and device based on temperature self-sensing flexible film heater

ActiveCN111092362BEliminate temperature gradientsIncreased frequency reproducibilityLaser monitoring arrangementsFrequency stabilizationThermal isolation

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com