Composite air brick and argon blowing refining method in continuous casting ladle pouring process

A technology of composite steel and air-permeable bricks, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve problems such as poor identification, leaking steel, and small air flow, achieve obvious technical comparative advantages, and solve uneven air ventilation , the effect of reducing the slit width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

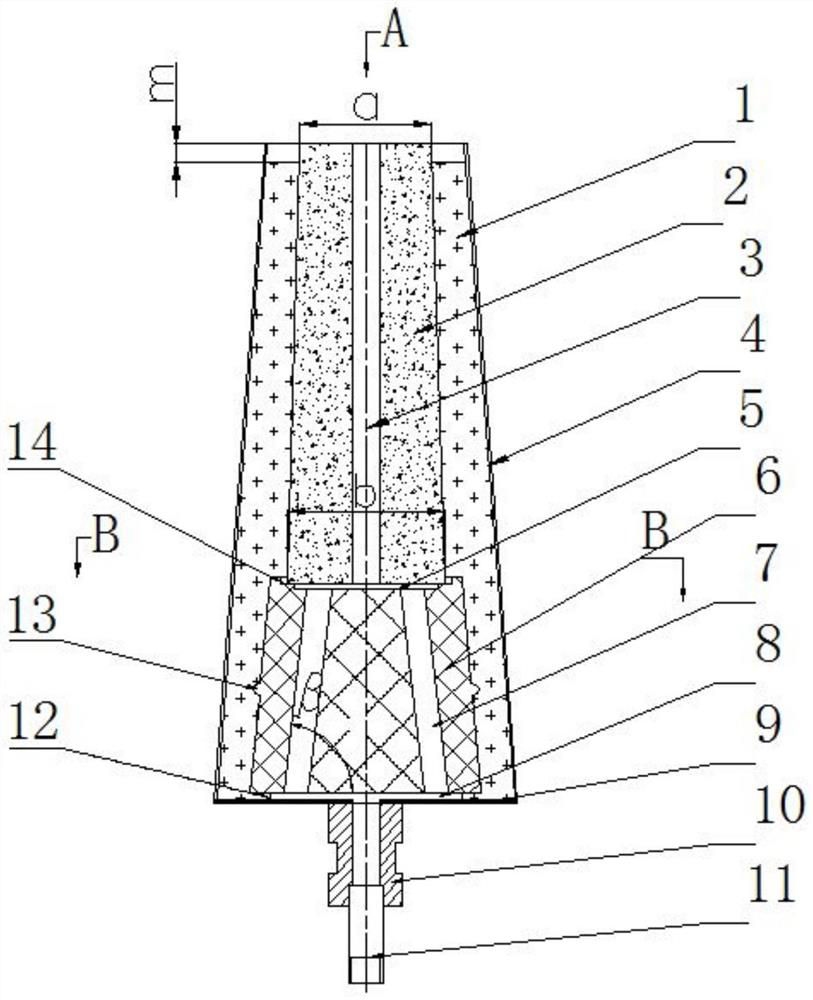

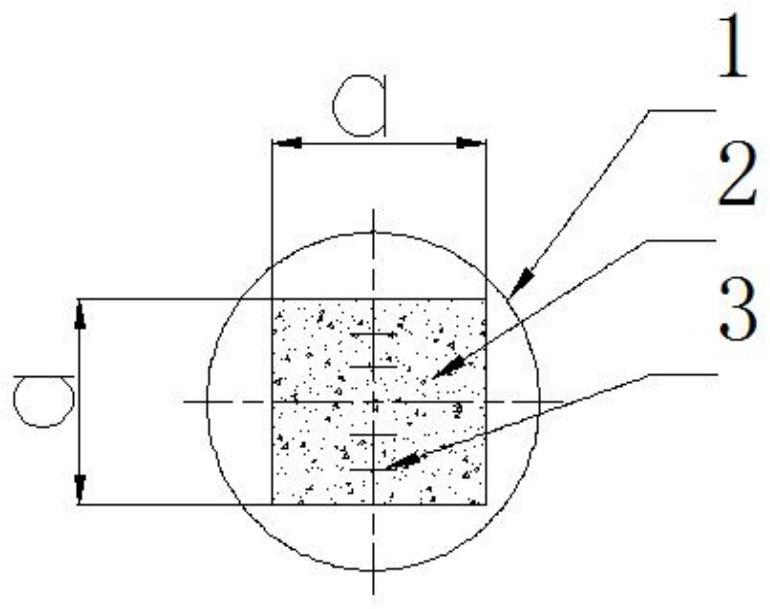

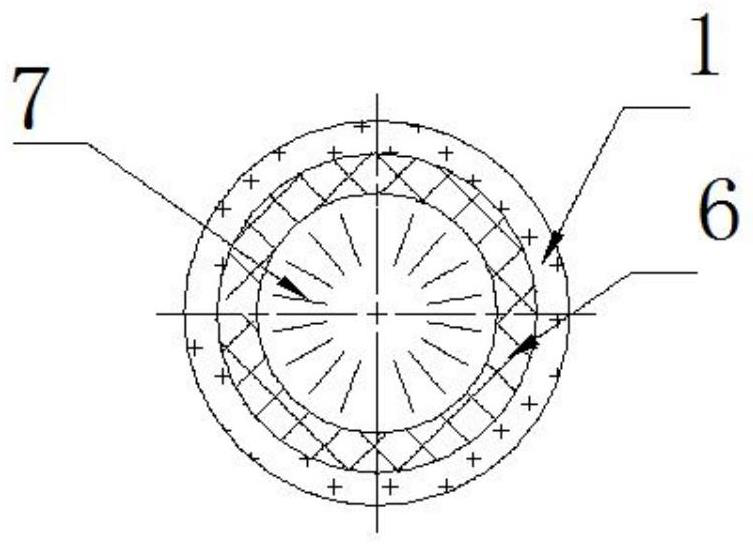

[0050] A composite type ladle bottom blowing air brick, including pouring body 1, diffusion block 2, carbon steel skin 4, upper air chamber 5, safety warning device 6, lower air chamber 8, bottom plate 9, air intake pipe 11, central part of dispersion block A plurality of slit air passages A arranged in parallel in cross-section and longitudinal section, the slit air passage A penetrates the upper and lower end faces of the diffusion block up and down, the lower part of the diffusion block is positioned in the positioning groove 13 on the upper part of the safety warning device 6, and the safety warning device 6 There are a plurality of slit air passages B arranged in a circular cross-section and "eight" in the longitudinal section. The lower end of the diffusion block and the upper end of the slit air passage B communicate with the upper air chamber 5. The slit air passage B The lower end communicates with the lower air chamber 8, the upper end of the safety warning device is ...

Embodiment 2

[0061] A composite ladle bottom blowing air brick, as described in Example 1, the difference is:

[0062] The diffuser block 2 is in the shape of a square prism as a whole, the length a of the upper base is 75 mm, and the length b of the lower base is 90 mm.

[0063] There are 5 slit airways A, the length of the slit is 30 mm, and the width of the slit is 0.16 mm. There are 32 slit airways B, the length of the slit is 30 mm, and the width of the slit is 0.18 mm. The inclination angle β of the slit airway B is 82°.

[0064] The present invention also provides the refining method of argon blowing during the pouring process of a 150t ladle by using composite ladle bottom blowing air bricks as described in Example 2: After the ladle is refined from the LF refining furnace, it is hoisted to the continuous casting turret, blown argon into the The gas pipeline is connected to the argon gas inlet pipeline through the automatic docking device for argon blowing at the bottom of the la...

Embodiment 3

[0066] A composite ladle bottom blowing air brick, as described in Example 1, the difference is:

[0067] The dispersion block 2 is in the shape of a square prism as a whole, the length a of the upper base is 70 mm, and the length b of the lower base is 80 mm.

[0068] The slit airway A is provided with 6 pieces, the length of the slit is 25 mm, and the width of the slit is 0.15 mm. There are 36 slit airways B, the length of the slit is 25 mm, and the width of the slit is 0.2 mm. The inclination angle β of the slit airway B is 85°.

[0069] The upper end surface of the dispersion block 2 is 10 mm higher than the upper end surface of the pouring body 1, which is used for fixing the dispersion block 2 when the pouring body 1 is poured and formed.

[0070] The present invention also provides a method for refining by argon blowing during the pouring process of a 100t ladle by using the composite ladle bottom blowing air brick described in Example 3: after the ladle is refined fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com