Patents

Literature

81results about How to "Large air flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

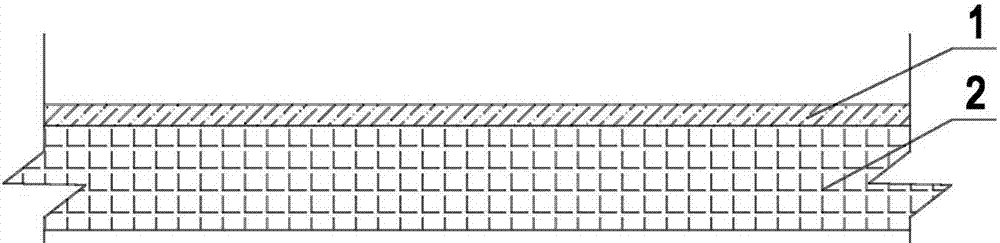

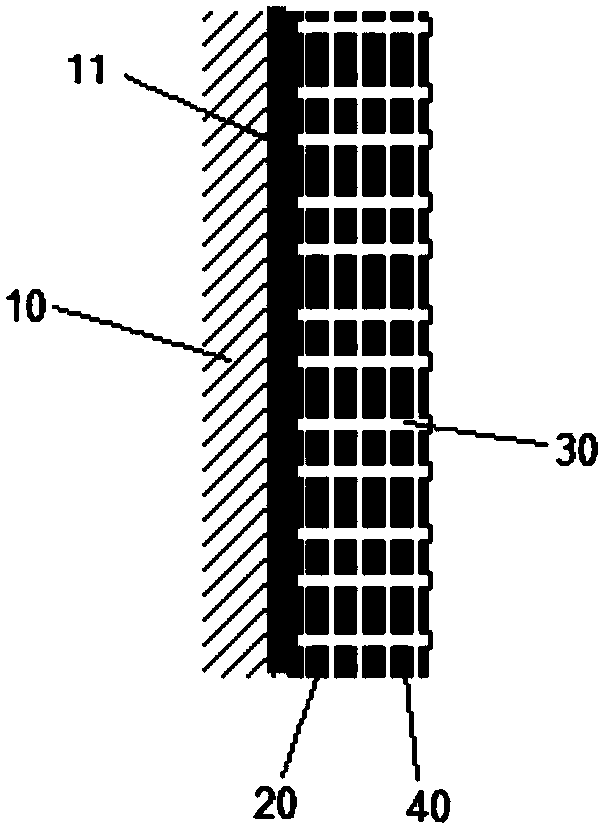

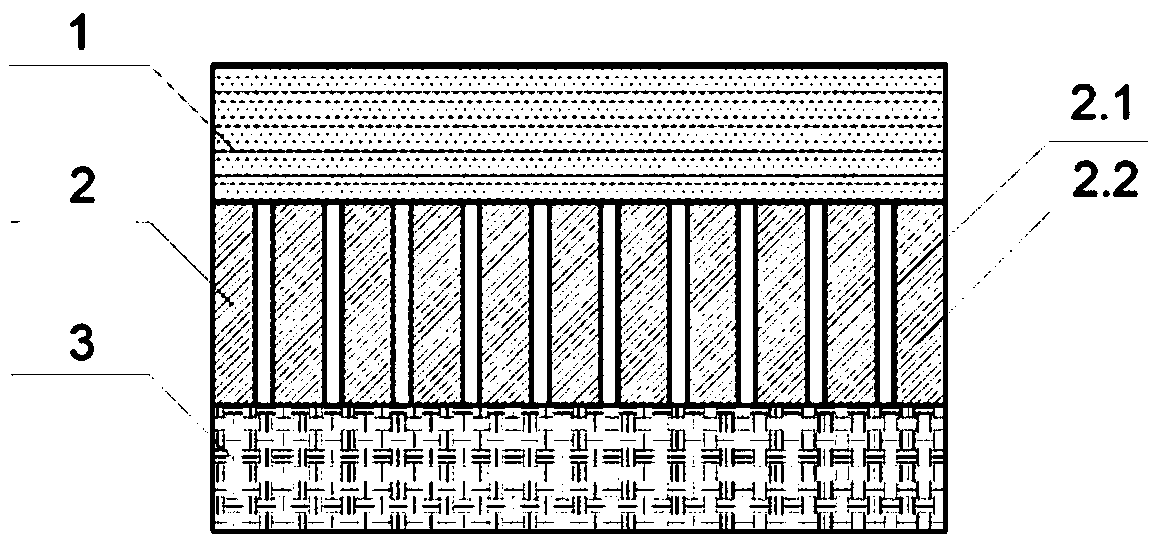

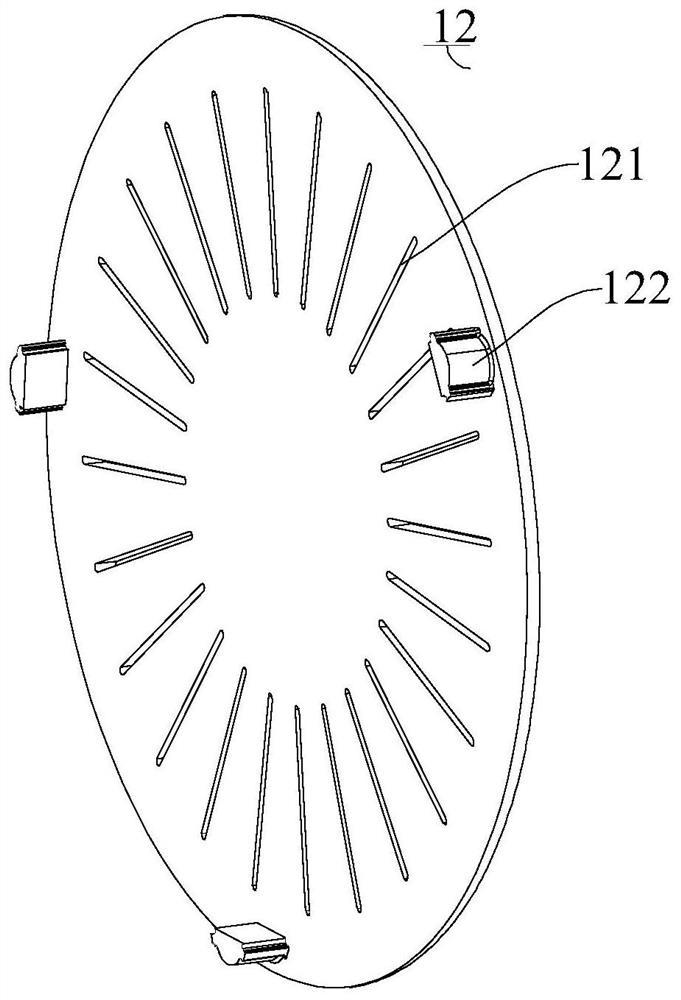

Multifunctional three-layer type air strainer

InactiveCN102225281AEfficacy unchangedReduce resistanceDispersed particle filtrationDeodrantsPolyesterFiber

The invention provides a multifunctional three-layer type air strainer and relates to a strainer. The multifunctional three-layer type air strainer provided by the invention is antimicrobial, self-cleaning and self-nursing, and can be used for increasing a contact area between the strainer and the air, increasing the dust absorbing efficiency, prolonging the service time for filtering, eliminating the planktonic bacteria in air, decomposing harmful matters in air and releasing anion. Three layers of strainers are arranged in the multifunctional three-layer type air strainer, wherein the three layers of strainers are overlapped in turn and then are fixed together with frames by virtue of buckles; the frames and the buckles are arranged on the peripheries of the three layers of strainers; the first layer of strainer is a nonwoven filter cloth layer, a PET (polyester) long fiber filter cloth layer, a glass fiber cloth layer or a stainless steel wire strainer cloth layer; the second layer of strainer is an active carbon strainer cloth layer or a bamboo carbon filter strainer cloth layer; the third layer of strainer is a monofilament filter cloth layer, an apocynum venetum fiber filter cloth layer or a stainless steel wire strainer cloth layer; and the three layers of strainers all contain health functional agents.

Owner:XIAMEN RUNNER IND CORP

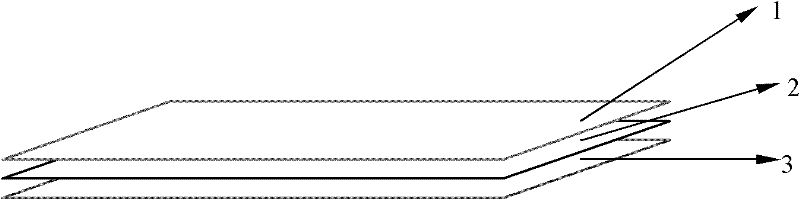

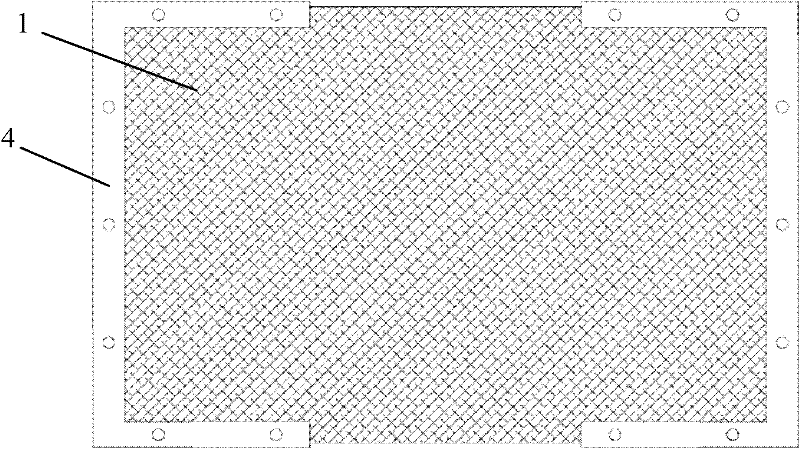

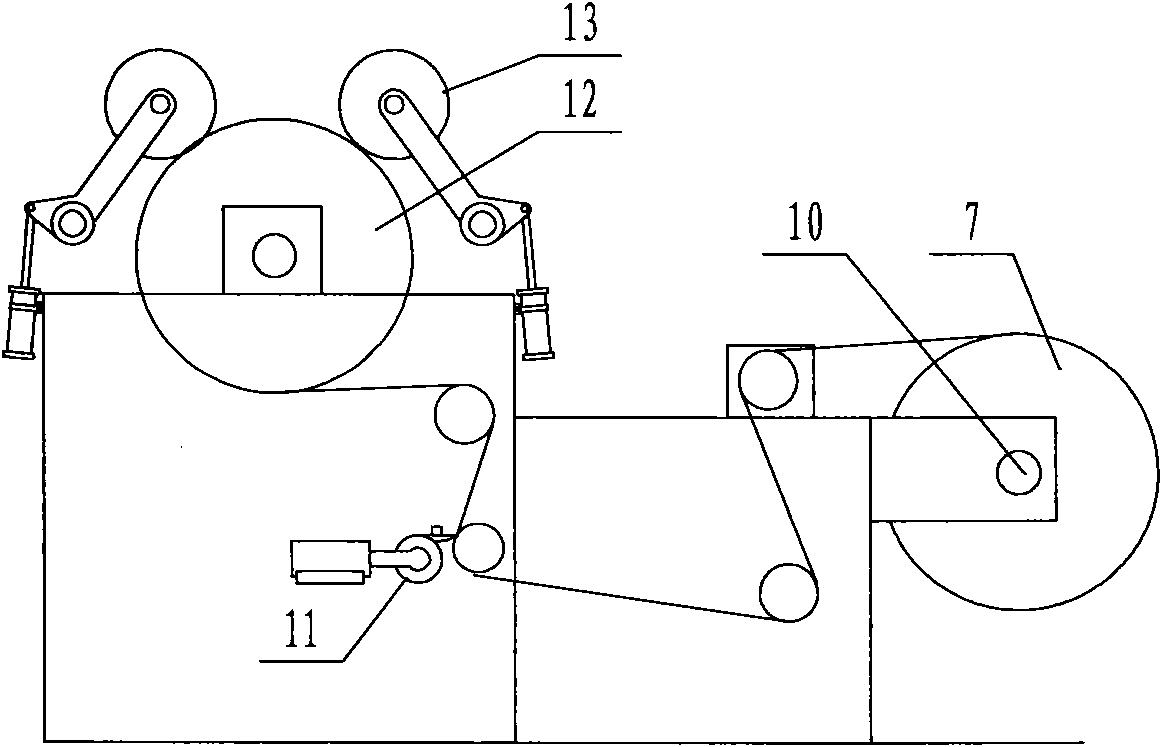

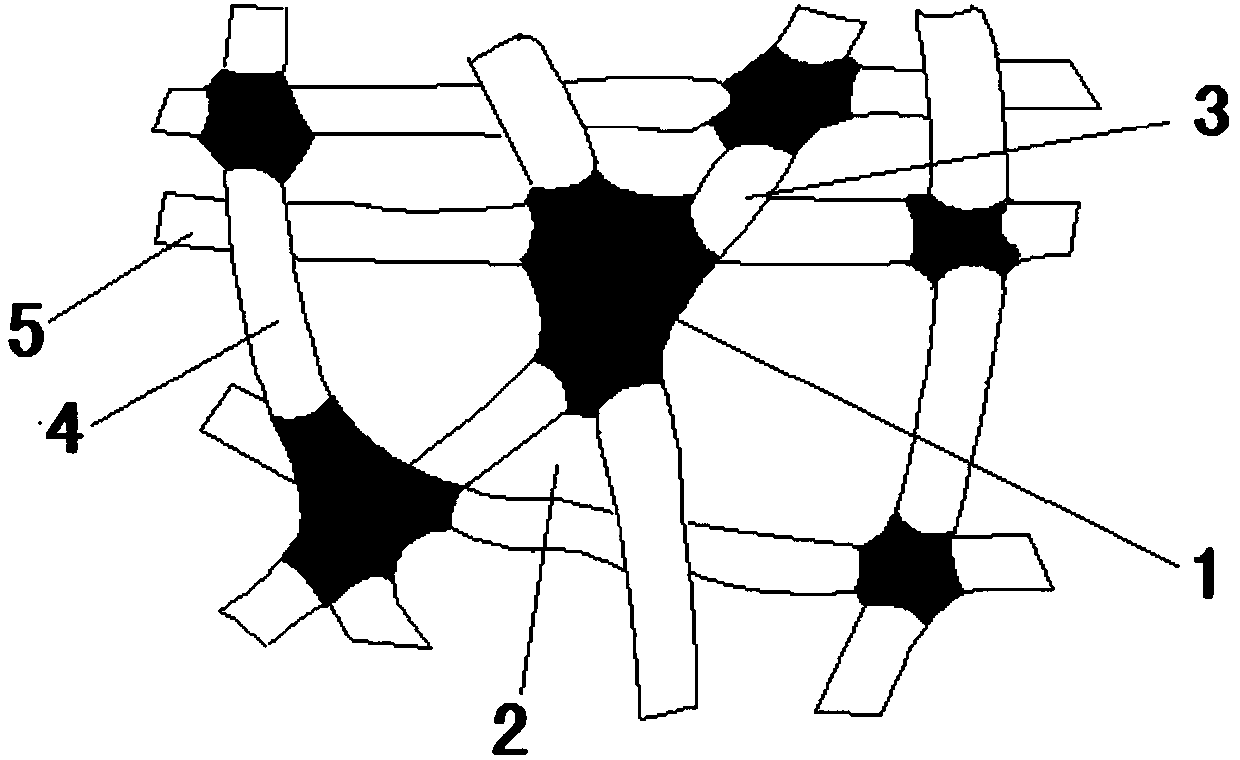

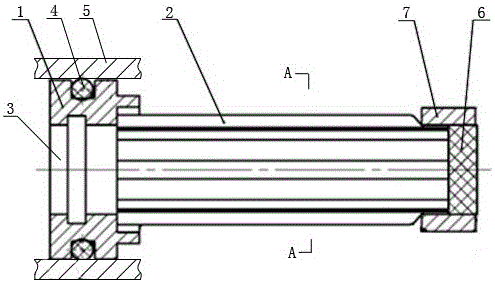

Technique and device for dry formation of low basis weight fluff pulp and capable of eliminating electrostatic flocculation

ActiveCN102551186AFacilitate transfer and strippingImprove uniformityTobacco preparationFlocculationFluff pulp

The invention provides a technique and a device for dry formation of low basis weight fluff pulp and capable of eliminating electrostatic flocculation. The technique for dry formation of low basis weight fluff pulp and elimination of electrostatic flocculation within a quantitative range of from 15g / m2 to 30g / m2, a high-mesh-number woven copper net serving as a formation net is used with an electrostatic elimination device to produce a fluff pulp fiber underlayer of reconstructed tobacco, uniform formation is facilitated, electrostatic elimination is facilitated, and transfer and removal of the formed underlayer fibers from the formation net are facilitated. The technique and the device are characterized in that the formation net is a woven endless net of metal wires, zero potential nets are square-hole static-eliminated nets respectively and horizontally disposed at the top and the bottom of a cylindrical screen, and a frame grounding system is an independent equipotential system using a frame as zero potential.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

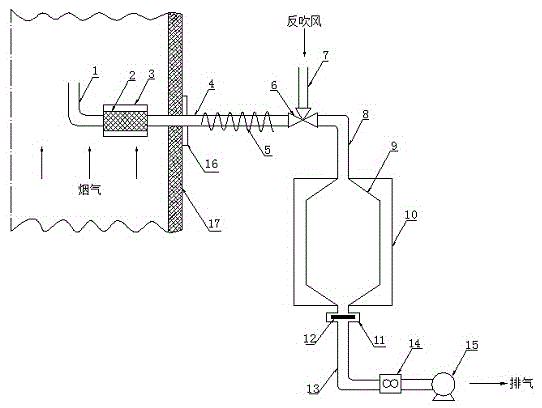

Condensable particle sampling device

ActiveCN104406826AAccurate determination of contentReduce blocking lossWithdrawing sample devicesWeighing by absorbing componentExhaust pipeRefrigerated temperature

The invention provides a condensable particle sampling device. The condensable particle sampling device comprises a sampling head, a filter, a heater, a sampling pipe, a heating band, a three-way ball valve, a reverse blowing pipe, a gas-in pipe, a condenser, a refrigerator, a filter membrane clamp, a filter membrane, an exhaust pipe, a flowmeter and a vacuum pump, wherein the sampling head, the filter, the sampling pipe, the three-way ball valve, the gas-in pipe, the condenser, the filter membrane clamp, the exhaust pipe, the flowmeter and the vacuum pump are sequentially connected; the sampling head and the filter are positioned in a flue, and the heater is arranged on the filter; the sampling pipe is fixed on the flue by a flange, one end of the sampling pipe is positioned in the flue, the other end of the sampling pipe is positioned outside the flue, and the heating band is arranged on the sampling pipe; the two ends of the three-way ball valve are respectively connected with the sampling pipe and the gas-in pipe, and the other end of the three-way ball valve is connected with the reverse blowing pipe; the refrigerator is arranged on the condenser; the filter membrane clamp is positioned outside an outlet of the condenser, and the filter membrane is positioned in the filter membrane clamp.

Owner:深圳睿境环保科技有限公司

Manufacturing process of coke-reducing molding paper of net groove

The invention relates to a manufacturing process of coke-reducing molding paper of a net groove. The molding paper produced by the manufacturing process is used for wrapping the outer surface tows of cigarette filter sticks. The manufacturing process mainly includes two procedures, namely corrugated pressing of the molding paper and corrugated slitting of the molding paper, wherein the corrugated pressing of the molding paper includes the steps of surface gluing of molding paper, drying, corrugated pressing, rolling; and the corrugated slitting of the molding paper includes steps of roll releasing, slitting and respective rolling. In the technical scheme, that the shape of the corrugated molding paper with a groove is relatively fixed is ensured, stroke vertical to the direction of the corrugated groove does not produce, and the requirement of a tip stick shaping machine on the shape of the molding paper is met. For the molding paper produced by the process, the corrugated groove is fixed in shape and does not deform under the influence of smoke temperature and humidity without affecting product quality.

Owner:云南玉溪卷烟厂滤嘴棒分厂 +1

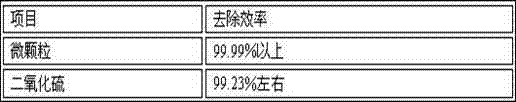

Polytetrafluoroethylene (PTFE) membrane material capable of realizing catalytic degradation function by grafting photocatalyst and application of PTFE membrane material

InactiveCN103394241AEfficient purificationEffectively existCovering/liningsDispersed particle filtrationFiberSemiconductor materials

The invention relates to a polytetrafluoroethylene (PTFE) fiber clearance membrane material capable of realizing a catalytic degradation function by grafting a photocatalyst. The PTFE membrane material consists of a photocatalyst PTFE membrane and a base material, wherein the photocatalyst PTFE membrane covers the surface of the base material and consists of PTFE and the photocatalyst; the photocatalyst is uniformly grafted to a space structure of a fiber clearance membrane of the PTFE; the photocatalyst is a photo semiconductor material which is represented by nano-grade titanium dioxide and has a photocatalysis function; the particle size of the photocatalyst is 4-60nm. The photocatalyst PTFE membrane disclosed by the invention remains the characteristics of PTFE membrane ventilating cloth with high water permeation property, high ventilating property, low resistance, high micro-particle retention rate, high temperature resistance, strong acid resistance, strong alkaline resistance, organic solvent resistance, oxidant resistance, aging resistance, zero stickness, noninflammability, non-toxicity and the like; the catalytic degradation function of the photocatalyst is realized; pollutants such as formaldehyde, benzene, methylbenzene, xylene, ammonia and total volatile organic compound can be effectively degraded; the PTFE membrane material has high-efficiency and broad-spectrum disinfection property and can degrade toxins discharged by germs or fungus and perform harmless treatment on the toxins.

Owner:SHANGHAI FENGDU MOBANG FILM TECH

Pure polyfluortetraethylene gradient overlay film filter material with high intensity

The invention relates to a high-strength pure polytetrafluoroethylene gradient coating filter material, which comprises base cloth, and is characterized in that the base cloth is a polytetrafluoroethylene base cloth; a polytetrafluoroethylene coarse fiber layer and a polytetrafluoroethylene superfine fiber layer are pricked on the polytetrafluoroethylene base cloth; and a polytetrafluoroethylene film is coated on the polytetrafluoroethylene superfine fiber layer. The high-strength pure polytetrafluoroethylene gradient coating filter material has the characteristics of high and low temperature resistance, high acid and alkaline resistance, high humidity resistance, good chemical stability, high filtration efficiency, quick filtration speed, long service life and the like, can be used in various bag-type dusters for flue gas purification, dust removal, dust treatment and material recovery, and has wide application scope.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

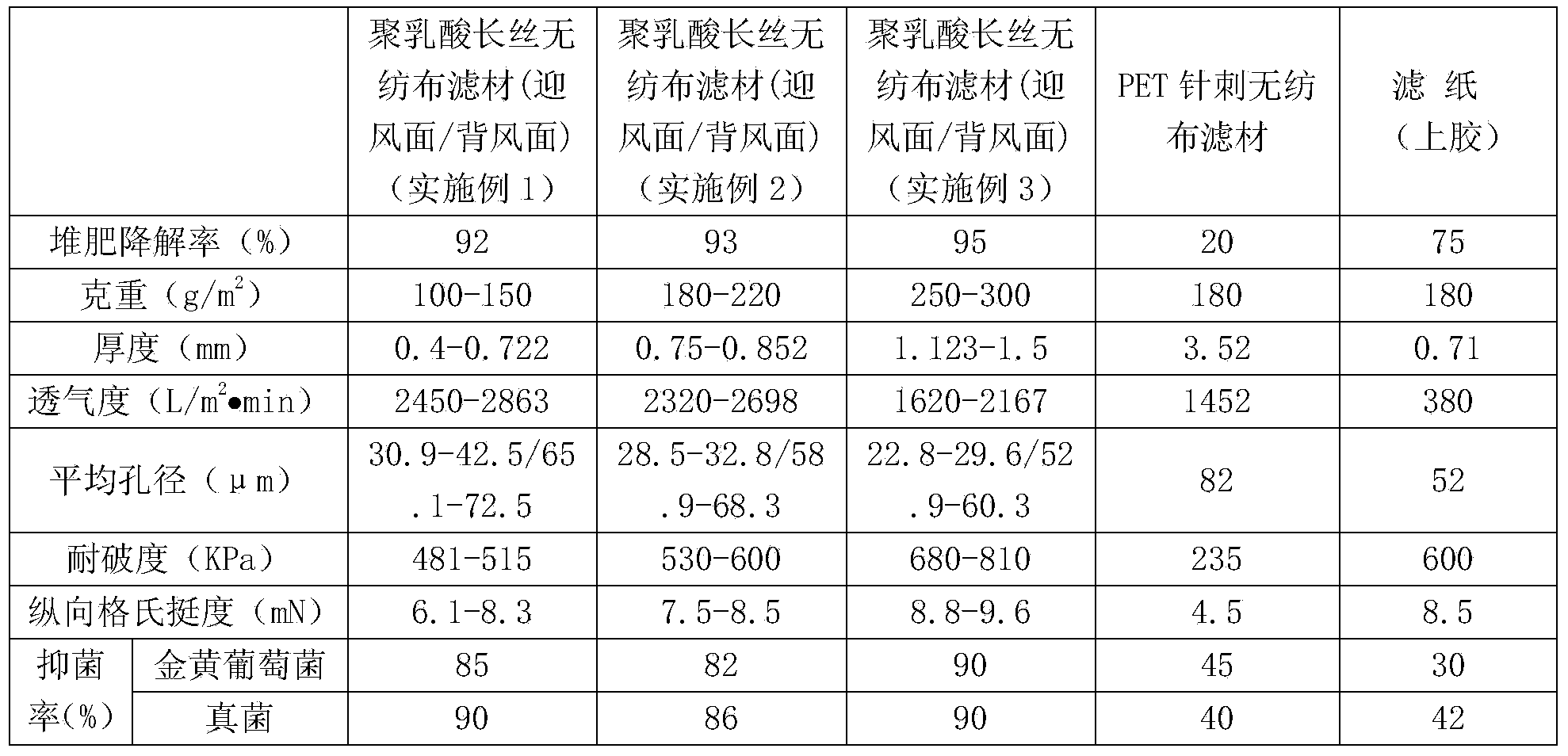

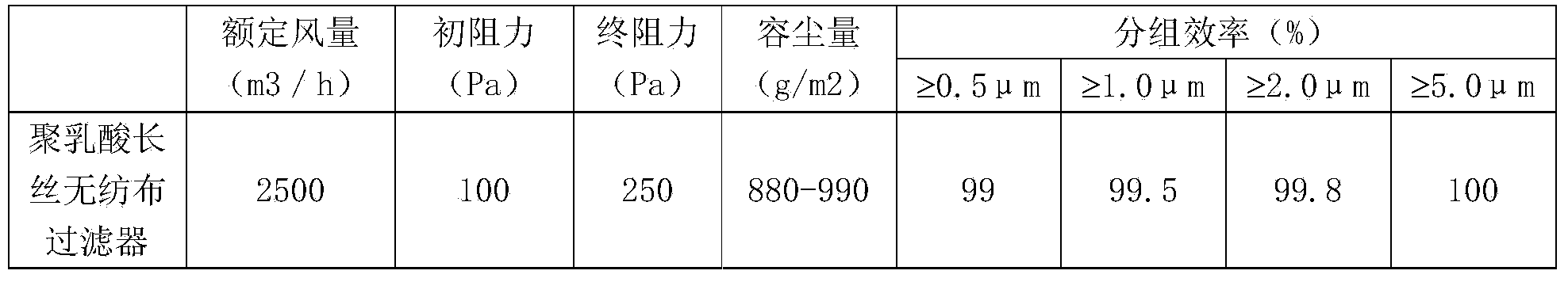

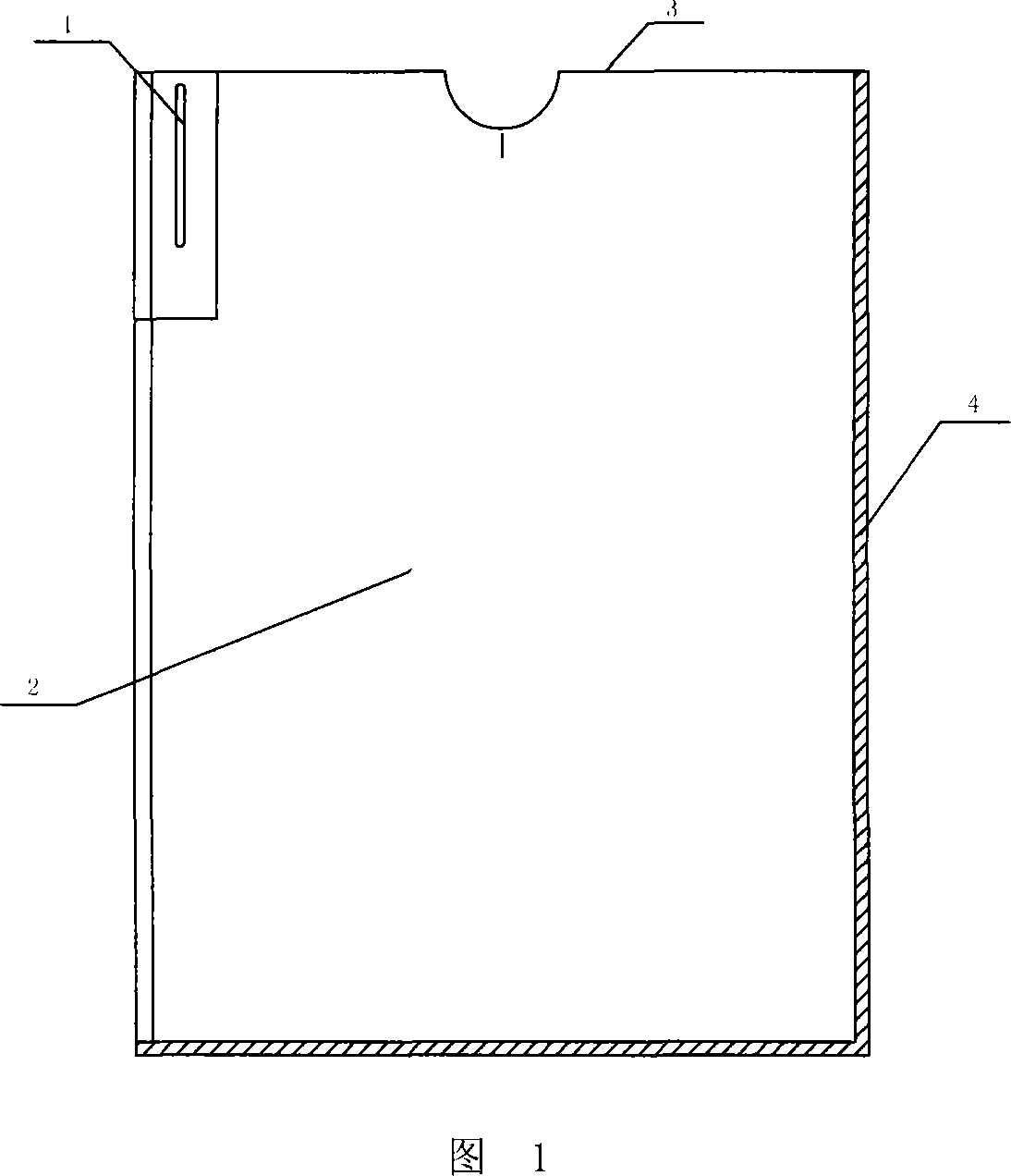

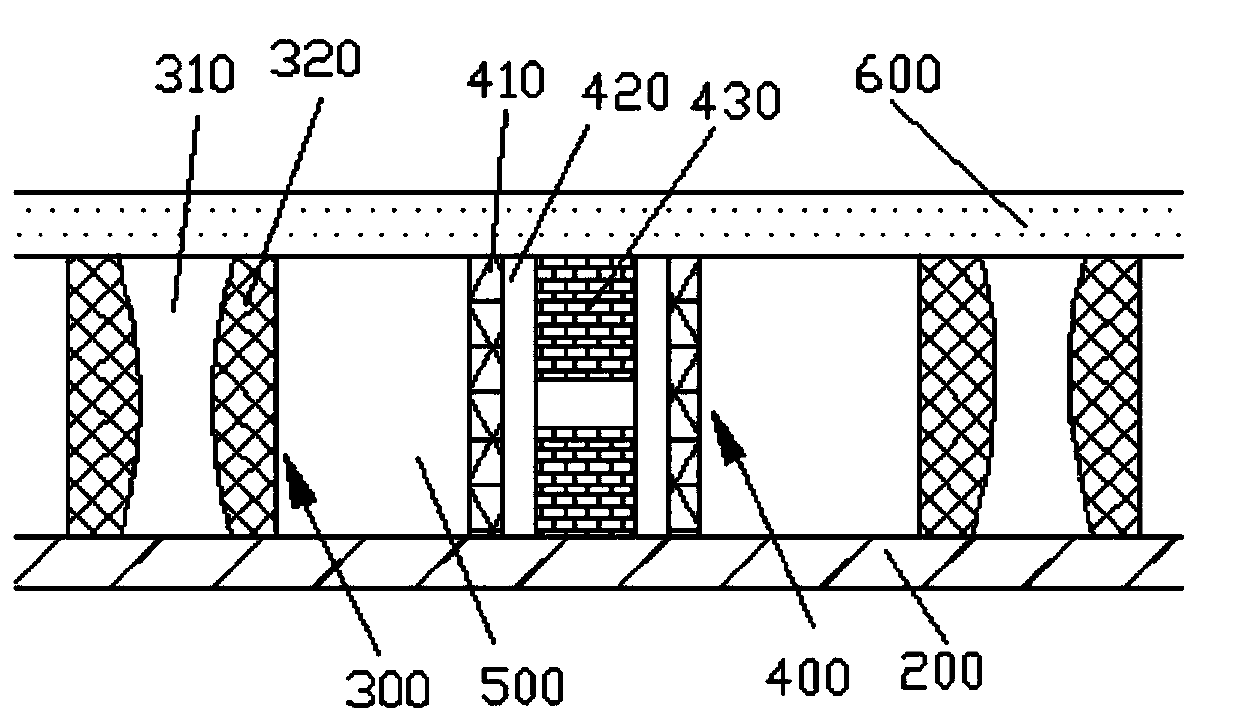

Polylactic acid filament yarn non-woven filter material and application thereof

ActiveCN103520998AImprove adsorption capacityGood Density Gradient StructureDispersed particle filtrationFiltration separationAir filtrationRenewable materials

The invention discloses a polylactic acid filament yarn non-woven filter material and application thereof. Most of the existing air filtration materials adopt non-renewable materials, thus bringing difficulty in follow-up waste treatment. The filter material comprises 100% polylactic acid filament yarn fiber net, and is prepared by the following steps of firstly thoroughly drying pre-crystallized polylactic acid slices; then melting and squeezing by more than two groups of spinning machines, cooling, drafting and separating yarns so as to form nets respectively, and overlaying to form a composite fiber net; finally, rolling the composite fiber net into a whole by a hot mill. The filter material has a surface filtration effect, has the characteristics of high filtration efficiency, large clogging capacity, low resistance, good air permeability, low ash removal frequency, antibacterial performance and deodorization, and can be completely degraded after being discarded.

Owner:山东星地新材料股份有限公司

Closed permeating waterproof fruit film bag

InactiveCN101019494ALarge air flowEliminate fruit rustCoatingsPlant protective coveringsPolyolefinCalcium carbonate

The present invention discloses one kind of closed permeating waterproof fruit film bag. The polyolefin film bag is prepared with LDPE polyolefin resin, LLDPE polyolefin resin or PP-polyolefin copolymer resin, calcium carbonate or talcum powder, coupler, modifier and dispersant as materials in a special plastic film bag making machine. It is provided with one tying rope in the mouth.

Owner:徐世慧

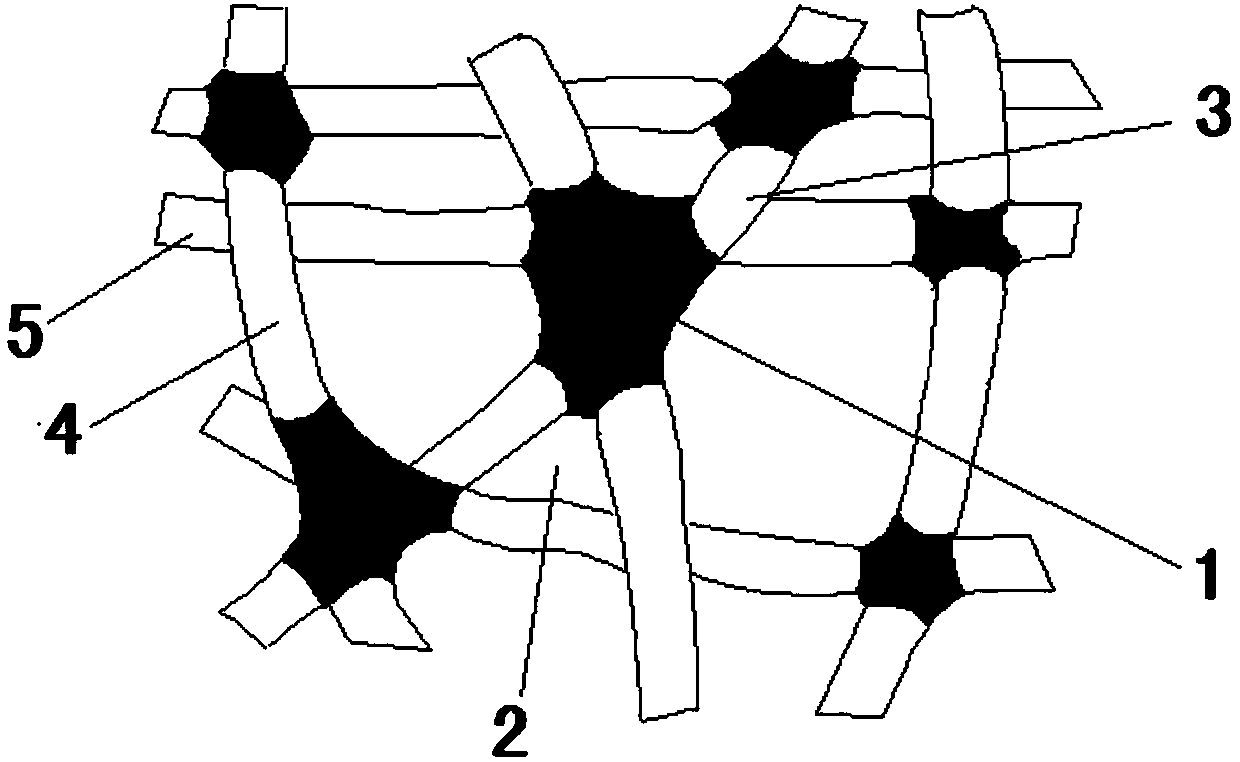

Thermal fabric for plant

ActiveCN103814783AImprove thermal performanceReduce airflowPlant protective coveringsEngineeringFiber

The invention provides a thermal fabric for a plant. The fabric comprises a waterproof layer, a thermal ventilating layer and a sealing layer from outside to inside, wherein the waterproof layer is formed by a chemical fiber blended macromolecule water absorbing resin material, the thermal ventilating layer comprises ventilating parts and a heat conducting part which are arranged at equal intervals and are provided with heat insulating cavities, each ventilating part is made of a flexible stand column with a through hole, the heat conducting part is made of a solid ring, an air bag embedded in the solid ring, and a flexible heat conducting material wrapped by the air bag, under a non-heated state, the flexible heat conducting material is provided with a gap in the middle, and the sealing layer is formed by a flexible water-repellent material. According to the thermal fabric for the plant, the ventilation is increased when the ventilating parts are heated, and the heat dispersion is increased by the heat conducting part; on the contrary, when the temperature is low, the ventilation is reduced by the ventilating parts, and the heat dispersion is reduced by the heat conducting part, so that a tree receives balanced temperature and is effectively protected.

Owner:江苏七彩纺织染整有限公司

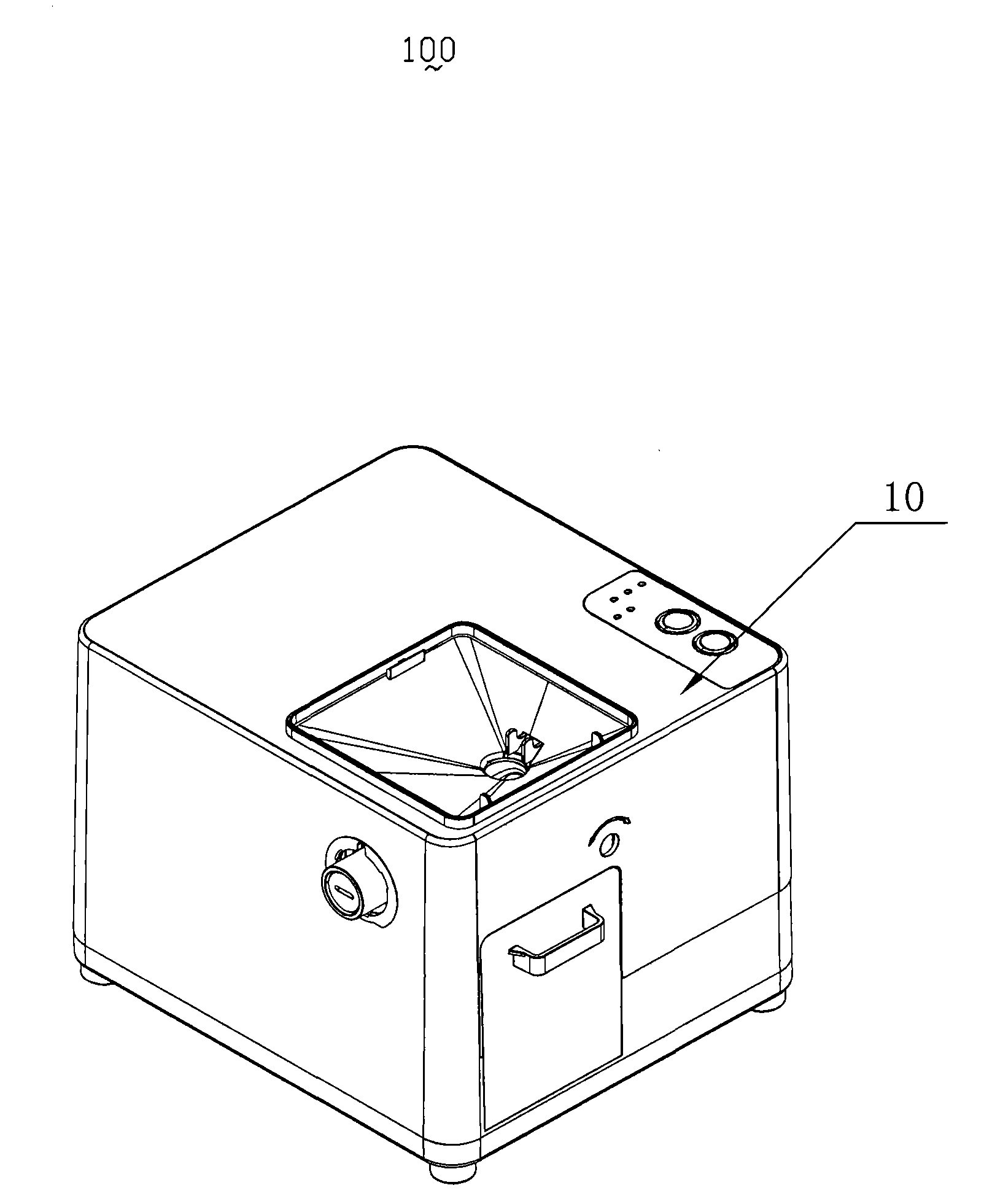

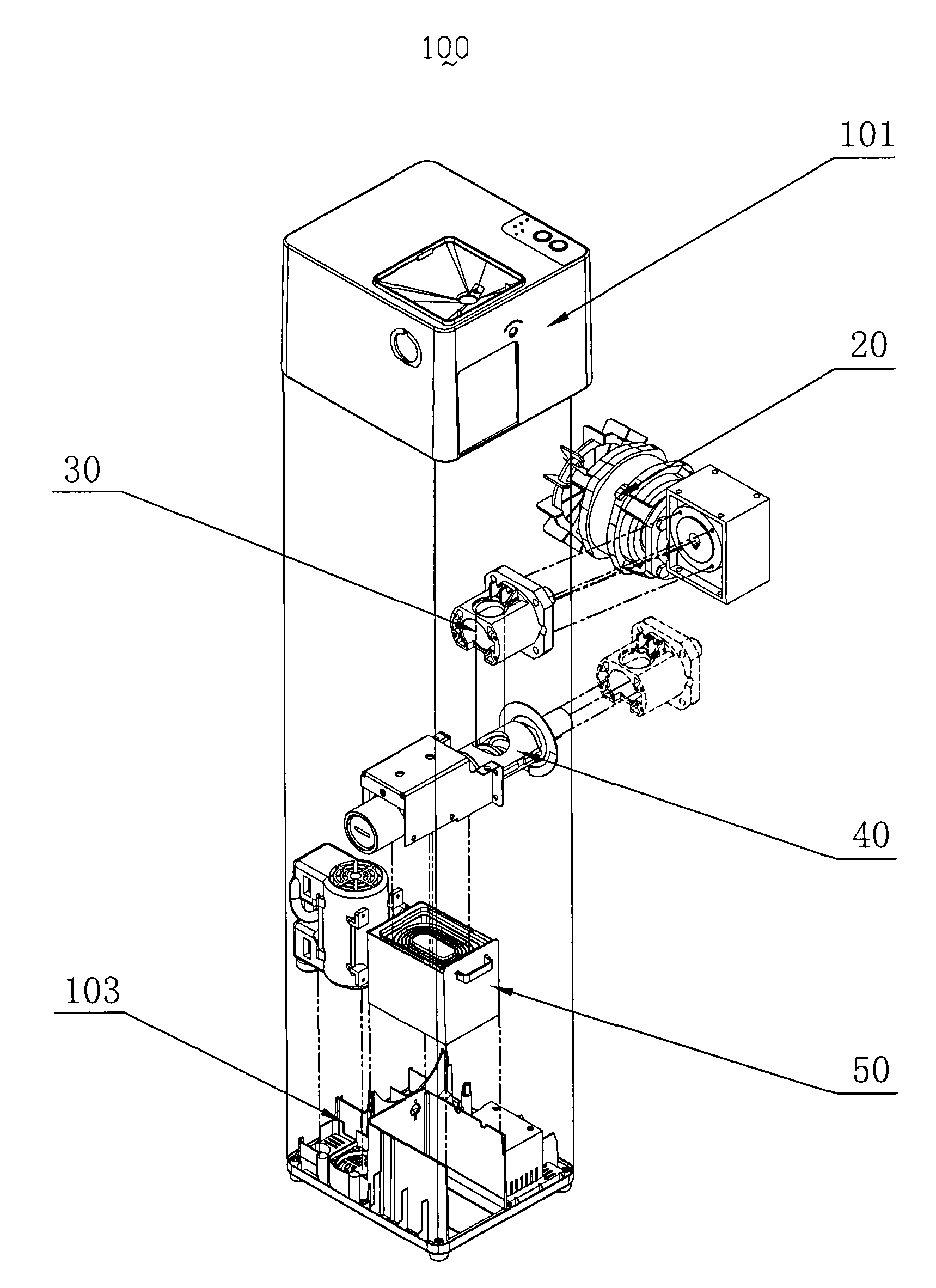

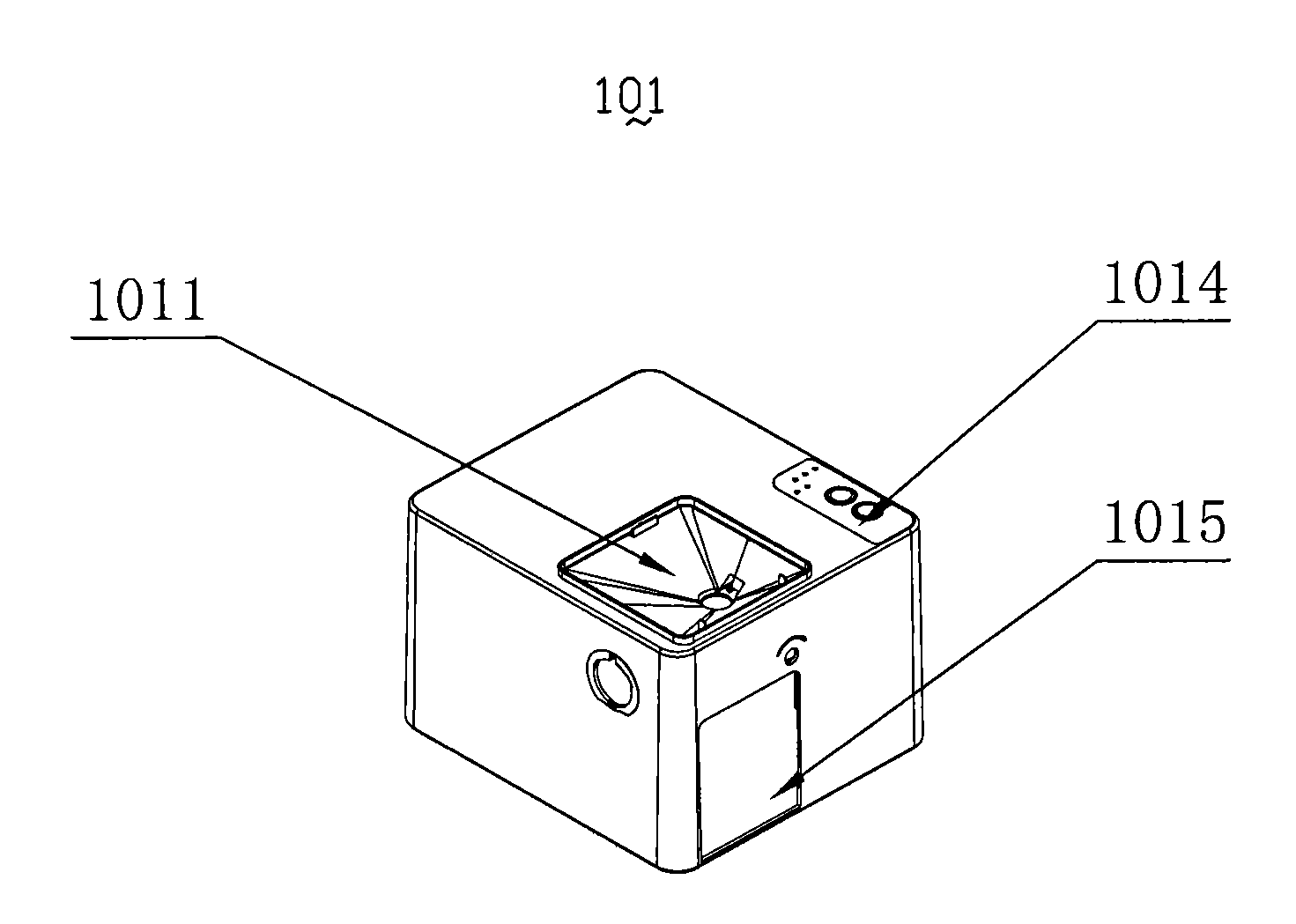

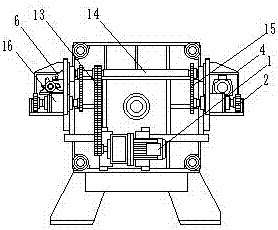

Domestic fine filtration press

InactiveCN103978721ASpeed up filteringImprove oil production efficiencyPressesBlood collectionOil storage

The invention relates to a novel domestic fine filtration press which more thoroughly and more cleanly extracts oil seeds. The novel domestic fine filtration press comprises a driving mechanism, a pressing mechanism and an oil collecting mechanism, wherein the driving mechanism provides power for the pressing mechanism; a material to be pressed enters the pressing mechanism and is pressed; the oil collecting mechanism is used for filtering and collecting oil pressed by the pressing mechanism, and defines an upper-layer oil filtering space and a lower-layer oil collecting space; the upper-layer oil filtering space seals the lower-layer oil collecting space during oil storage; the oil collecting mechanism is used for accelerating filtration and oil collection by utilizing the pressure difference between the upper-layer oil filtering space and the lower-layer oil collecting space. The domestic fine filtration press has the advantages of high filtration rate, clean and directly edible produced oil and the like.

Owner:东莞市格非电器有限公司

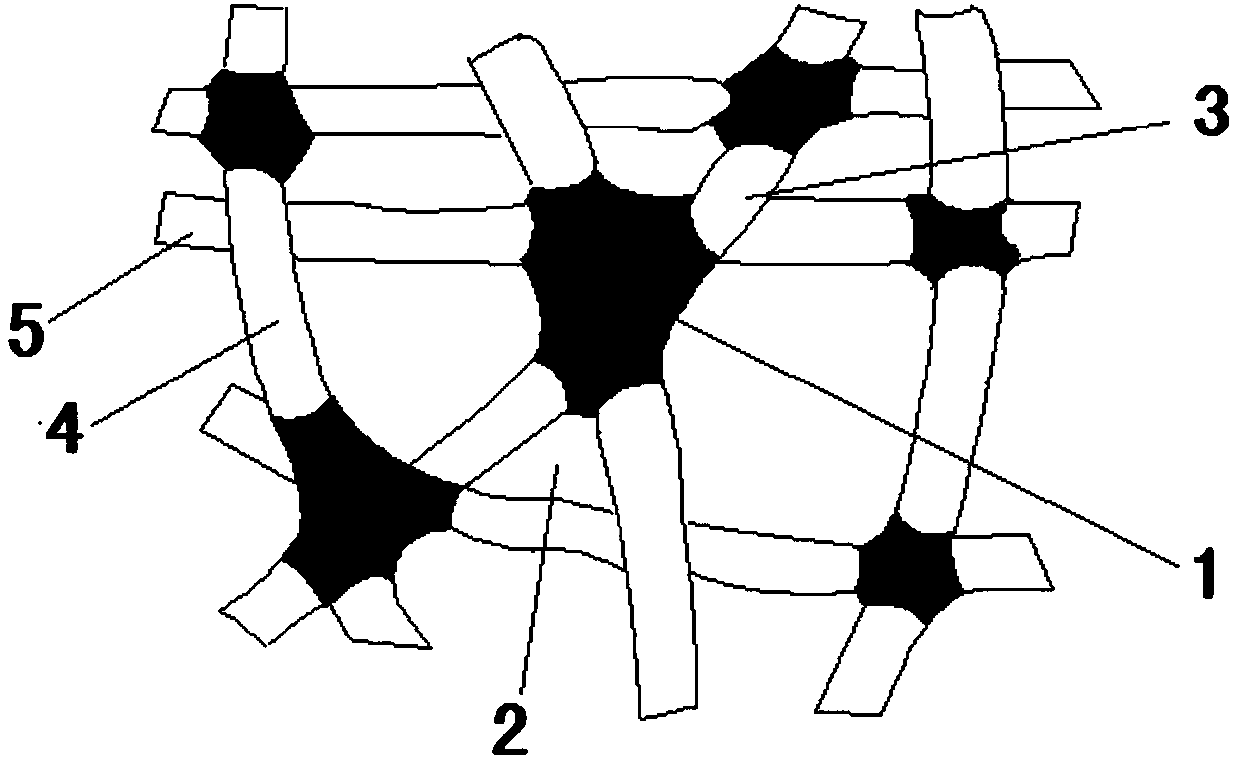

Phase change energy storage infiltration coating sandwich wall cloth and manufacturing method thereof

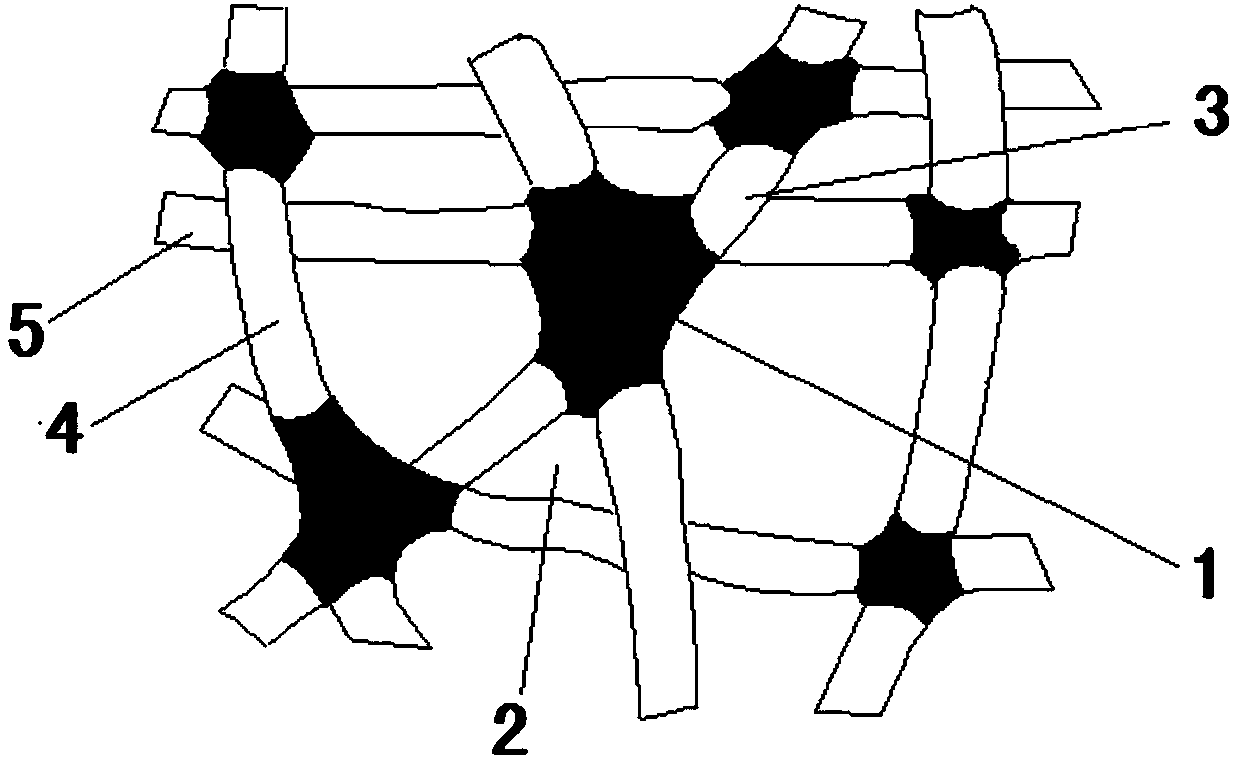

The invention provides a phase change energy storage infiltration coating sandwich wall cloth, and a method for manufacturing the phase change energy storage infiltration coating sandwich wall cloth,or an object decoration method. The phase change energy storage infiltration coating sandwich wall cloth comprises a bottom coating and an infiltration coating composite sandwich coating compound coated on the surface of the bottom coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; the second coating penetrates into meshes of the network structure; and one or more of the second coating, the bottom coating and the fiber texture network sandwich can have a phase change energy storage function. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Fireproof infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158892AAdequate adhesionObvious connection seamCovering/liningsCoatingsFiberCoated surface

The invention provides a fireproof infiltration coating sandwich wall cloth and a method for manufacturing the fireproof infiltration coating sandwich wall cloth or an object decoration method. The fireproof infiltration coating sandwich wall cloth comprises an undercoat layer and an infiltration coating composite sandwich coating composite body, wherein the surface of the undercoat layer is coated with the infiltration coating composite sandwich coating composite body, the infiltration coating composite sandwich coating composite body comprises a transparent or semitransparent second coatinglayer and a fiber texture network sandwich covered with the second coating layer, the fiber texture network sandwich contains a network structure formed by fibers, the second coating layer penetratesinto meshes of the network structure, and one or more of the second coating layer and the undercoat layer can be a fireproof coating layer. The wall cloth with skin textures and / or patterns can be produced in a standardized and large-scale mode, and good crack resistance, air permeability and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

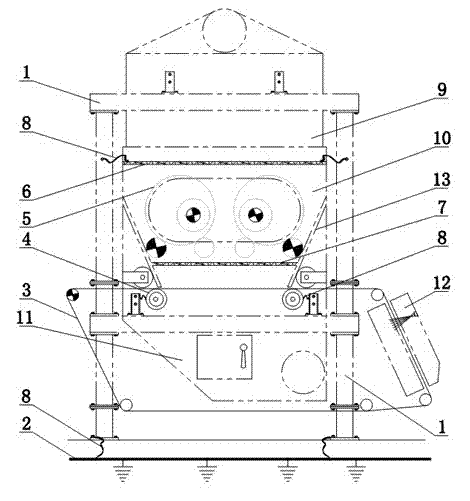

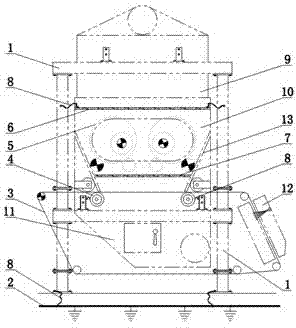

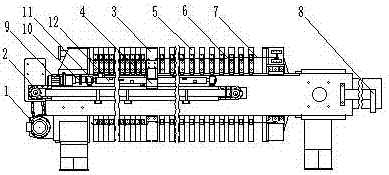

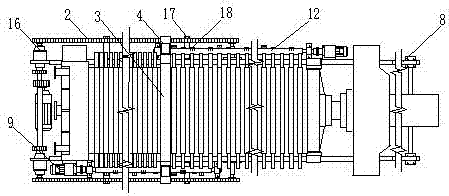

Spiral vibration cake unloading filter press by pulling filter plates twice

The invention provides a spiral vibration cake unloading filter press by pulling filter plates twice. An oil cylinder body is set to be lengthened, that is, the multiple filter plates can be pulled for the first time to reach the spacing of cake unloading, spacing chains are arranged among the filer plates, an oil cylinder bracket is installed at the lower end of the oil cylinder body, an active chain wheel is installed on a pull plate gear motor, a passive chain wheel is installed on an active shaft, driving chain wheels are installed at the two ends of the active shaft and are connected withpassive chains, driven chain wheels are installed at the two ends of a passive shaft, a middle clapboard is installed at the front end of a filter plate pulled for the second time, spiral vibration cake unloading devices comprise vibration gear motors and couplers, bearing bases are arranged at the two ends of each vibration shaft, one end of each vibration shaft is connected with the corresponding coupler through the bearing bases, spirally arranged vibration blocks are arranged above the vibration shaft, each vibration block corresponds to a handle of one filter plate, and the spiral vibration cake unloading devices are installed at the tail end of a main beam at the left side and the head end of a main beam at the right side respectively. The filter plate spiral vibration cake unloading filter press by pulling twice is simple in structure, free of fault rate, low in cost and high in efficiency, reaches the filter cake total recycling rate and increases economic benefit.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

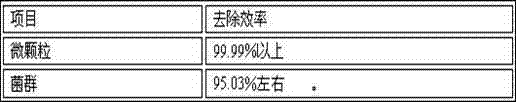

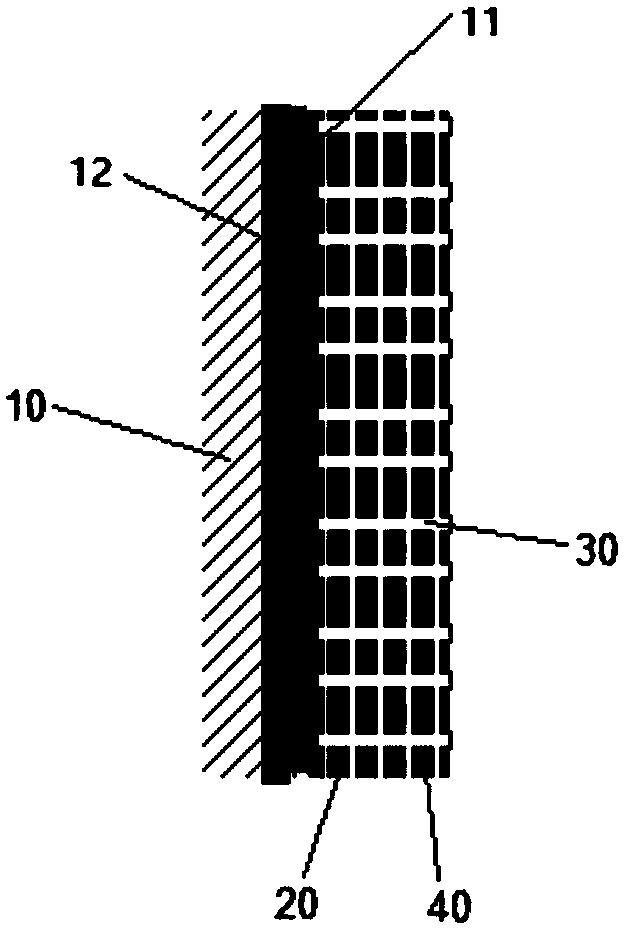

Nuclear track membrane and electrostatic spinning composite membrane and preparation method and application thereof

ActiveCN109603574AImprove breathabilityThe overall thickness is thinSemi-permeable membranesMembranesElectrospinningWastewater

The invention discloses a nuclear track membrane and electrostatic spinning composite membrane and a preparation method and application thereof. The composite membrane is composed of an electrostaticspinning layer, a nuclear track membrane and a base material from top to bottom. The composite membrane is high in rejection rate, good in air permeability and easy to clean; the composite membrane can be applied to the aspects such as liquid filtering and air filtering, and comprises the filter membrane industry fields of waste water treatment, oil-water separation, food and medicine, biochemicalengineering and the like.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Heat insulation infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158891AAdequate adhesionObvious connection seamCovering/liningsSpecial surfacesFiberCrack resistance

The invention provides a heat insulation infiltration coating sandwich wall cloth, and a method for manufacturing the heat insulation infiltration coating sandwich wall cloth, or an object decorationmethod. The heat insulation infiltration coating sandwich wall cloth comprises a heat insulation coating and an infiltration coating composite sandwich coating compound covering the surface of the heat insulation coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the secondcoating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of the network structure. The wall cloth with textures and / orpatterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides an impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, and the second coating permeates into net holes of the network structure. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

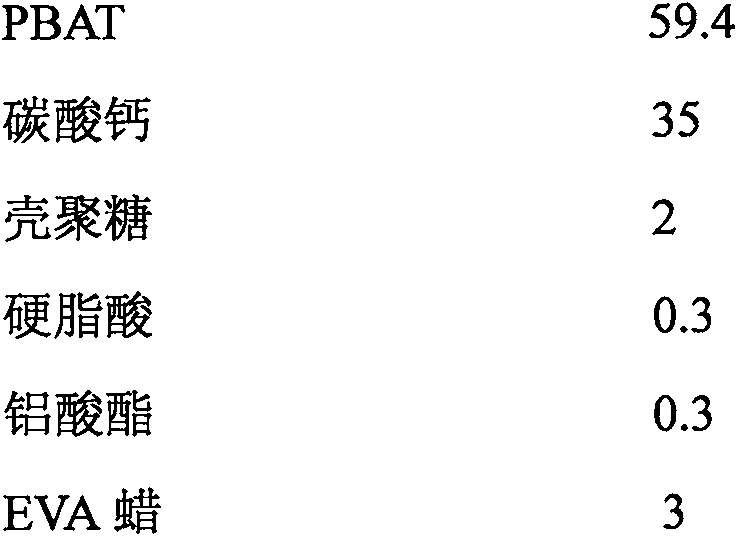

Breathable membrane material

The invention relates to a breathable membrane material, which comprises the following raw materials by weight percentage: 30%-65% of a full degradable biological material, 30%-60% of a pore-foaming agent, 1%-3% of an antibacterial agent, 0.1%-2% of a surface treatment agent, 3%-5% of a dispersant, and 0-1% of other additives. The breathable membrane material provided by the invention is a full degradable antibacterial biological breathable film, can be degraded into small molecules completely after abandonment, is an environment-friendly material, has an antibacterial rate up to 98%, and has the advantages of petroleum resource saving, environmental pollution reduction, low carbon and environmental protection, no harm to human body, good biocompatibility, good dispersion, uniform pore size distribution and large ventilation capacity, etc.

Owner:SHENZHEN JUYI FII CO LTD +1

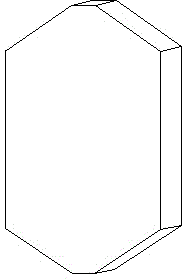

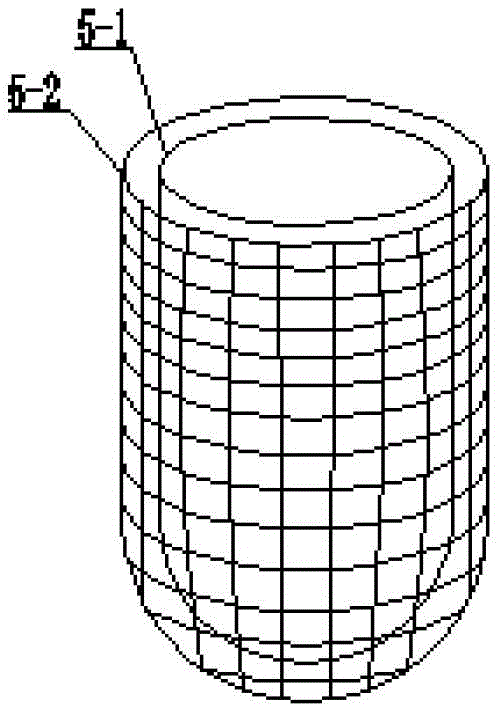

Filter system for flue gas sampling gun

ActiveCN103331063ASmall apertureLarge air flowDispersed particle filtrationWithdrawing sample devicesFiberFlue gas

A filter system for a flue gas sampling gun relates to a filter system and solves the problems that a conventional flue gas sampling gun intakes flue gas directly, dust particles in the flue gas are adhered to the wall of a sampling gun barrel and an absorption bottle, thereby causing sampling channel blockage which influences analysis to flue gas components and the service life of the sampling gun. The filter system for the flue gas sampling gun comprises a filter cylinder and a protective screening, wherein one end of the filter cylinder is opened and the other end of the filter cylinder is sealed, the sealed end of the filter cylinder takes the shape of a warhead, the filter cylinder is a filter cylinder made of wood chip paper, the opened end of the filter cylinder is mounted at the flue gas entry end of the gun barrel, the protective screening and the filter cylinder are the same in shape, and the protective screening is sleeved with the filter cylinder. According to the invention, dust is effectively prevented from entering into the sampling gun, blockage and erosion of dust to the sampling gun can be avoided, and the service life of the sampling gun is prolonged greatly. The filter system provided by the invention is used for sampling and filtering the flue gas of a chimney flue at the outlet of a fuel electric plant denitration system.

Owner:STATE GRID CORP OF CHINA +1

Electromagnetic shielding impregnation coating sandwich wall cloth and manufacturing method thereof

The invention provides an electromagnetic shielding impregnation coating sandwich wall cloth and a method of manufacturing the electromagnetic shielding impregnation coating sandwich wall cloth or anobject decoration method. The electromagnetic shielding impregnation coating sandwich wall cloth comprises a bottom coating and an impregnation coating composite sandwich coating composite body applied to the surface of the bottom coating; and the impregnation coating composite sandwich coating composite body comprises a transparent or semitransparent second coating and a fiber texture network sandwich wrapped in the second coating, the fiber texture network sandwich comprises a network structure formed through fibers, the second coating permeates into net holes of the network structure, and one or more of the bottom coating, the second coating and the fiber texture network sandwich have an electromagnetic shielding function. According to the electromagnetic shielding impregnation coatingsandwich wall cloth and the method, the wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale manner, and the wall cloth has the good anti-cracking performance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Scrawling preventing infiltration coating sandwiched wall cloth and manufacturing method thereof

PendingCN110158885AAdequate adhesionAvoid crackingLiquid surface applicatorsCovering/liningsCoated surfaceFiber

The invention provides scrawling preventing infiltration coating sandwiched wall cloth and a method for manufacturing the scrawling preventing infiltration coating sandwiched wall cloth or an object decoration method. The scrawling preventing infiltration coating sandwiched wall cloth comprises a bottom coating and an infiltration coating composite sandwiched coating composite body applied to thesurface of the bottom coating. The infiltration coating composite sandwiched coating composite body comprises a transparent or semitransparent scrawling preventing coating and a fiber texture networksandwiched core wrapped by the scrawling preventing coating, wherein a network structure formed by fiber is contained in the fiber texture network sandwiched core, and the scrawling preventing coatingseeps into meshes of the network structure. By means of the method, the wall cloth with texture and / or patterns can be manufactured in a standard and large-scale manner, and good crack resisting performance, ventilation performance and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and manufacturing method thereof

The invention provides a magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and a manufacturing method thereof or an object decorating method. The magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth comprises a bottom coating and an infiltrated and coated compound sandwich painting complex coated on the surface of the bottom coating; the infiltratedand coated compound sandwich painting complex comprises a transparent or semitransparent second coating and a fiber texture mesh sandwich wrapped by the second coating, wherein the fiber texture meshsandwich includes a mesh structure formed by fibers inside; the second coating infiltrates into mesh openings of the mesh structure; and one or several of the second coating, the bottom coating and the fiber texture mesh sandwich can possess magnetic attracting performance. The manufacturing method disclosed by the invention is capable of manufacturing the wall cloth with textures and / or patternson a large scale in a standardizing manner, and the wall cloth has good anti-cracking ability, air permeability and decorating property.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

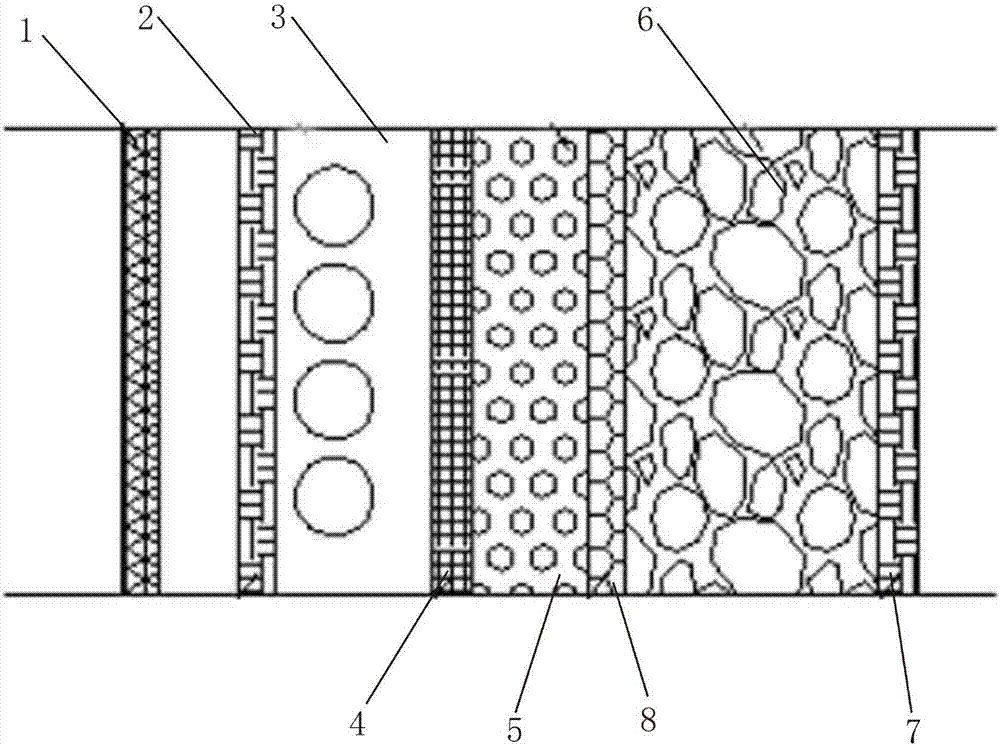

Multistage air purification system

InactiveCN107091499AClean up thoroughlyImprove removal efficiencyGas treatmentMechanical apparatusFiberComposite film

The invention discloses a multistage air purification system which comprises a metal filtering net arranged at the position of a to-be-treated gas inlet. In the gas flowing direction, the inner side of the metal filtering net is sequentially provided with a nanometer Ag-TiO2 composite antibacterial material layer, deep frequency ultraviolet ray transmitting lamps, a carbon fiber filtering layer, a diatom pure filtering layer, a mayan blue filtering layer and an ePTFE porous glass fiber composite film layer; the multiple deep frequency ultraviolet ray transmitting lamps are sequentially distributed inside the system from top to bottom at equal intervals; and a clean air flowing-out opening is arranged outside the ePTFE porous glass fiber composite film layer. By means of the multistage air purification system, air is purified in an efficient, durable and circulated manner, anions beneficial to the human body can be released at the same time, and the multistage air purification system is multifunctional, can achieve efficient degerming, and can remove pm2.5 and formaldehyde.

Owner:程艳青

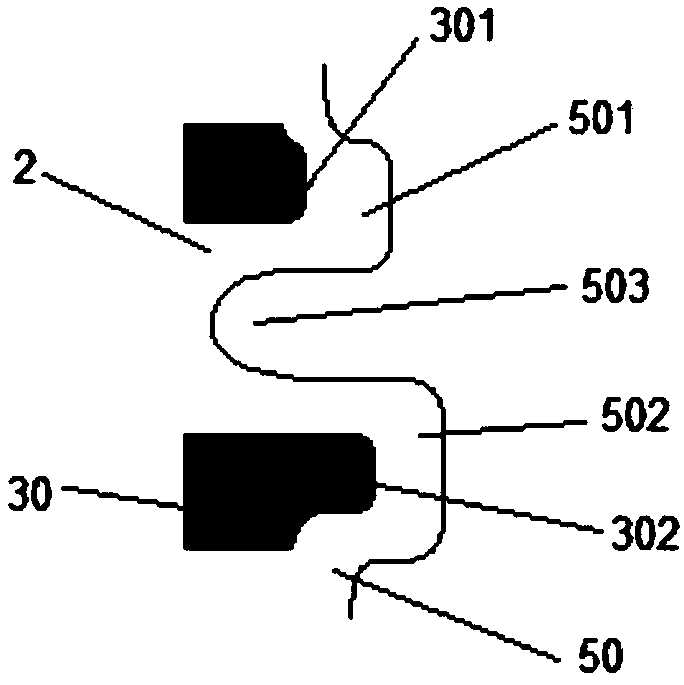

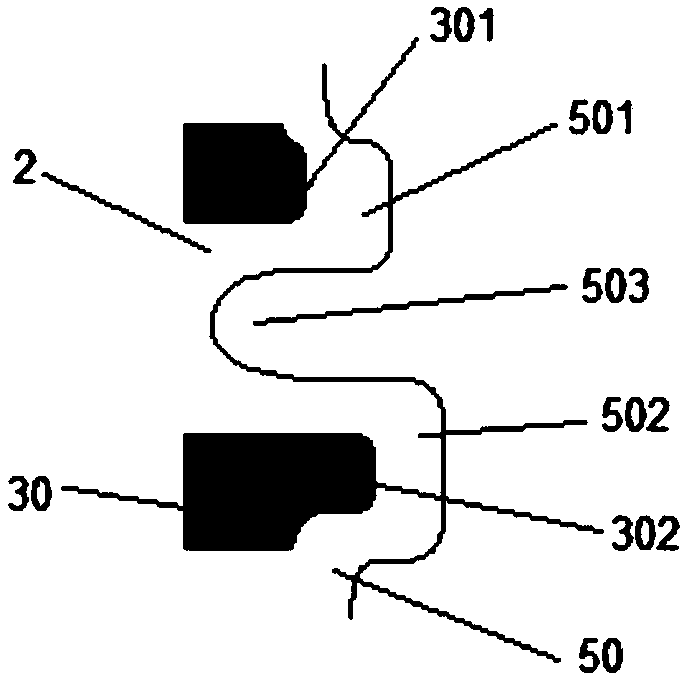

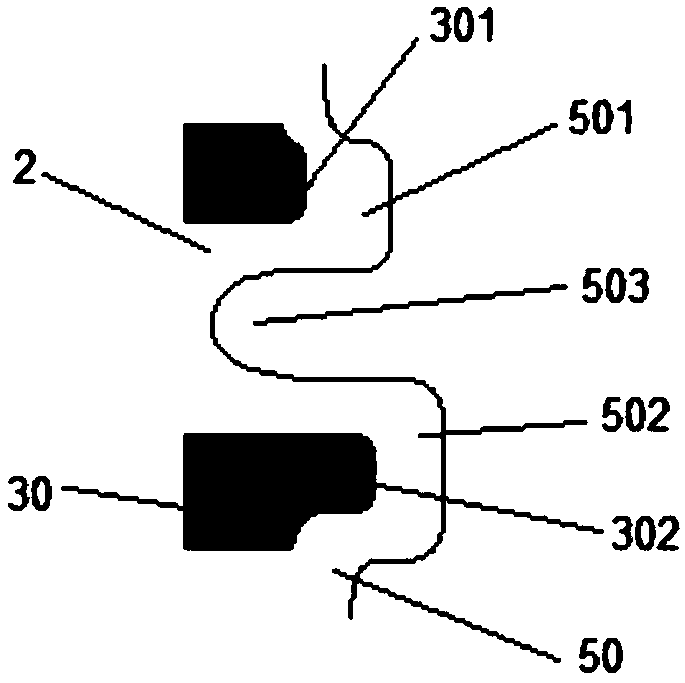

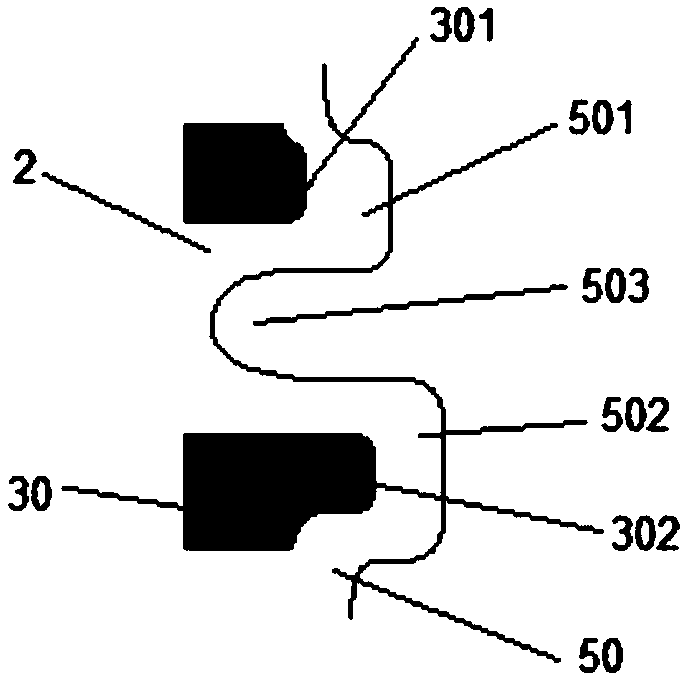

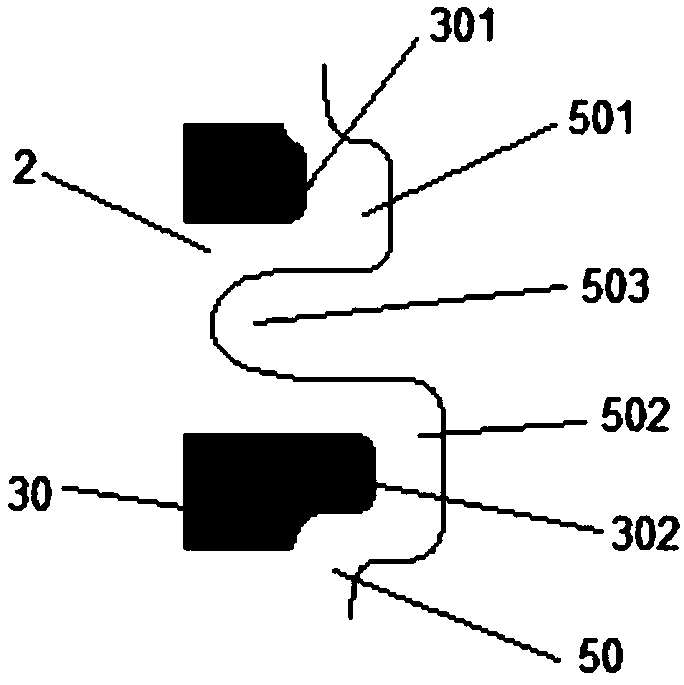

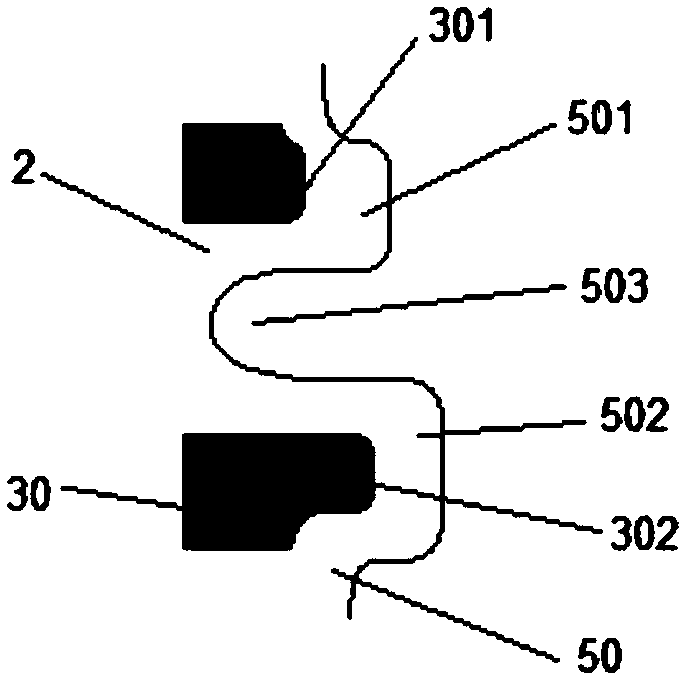

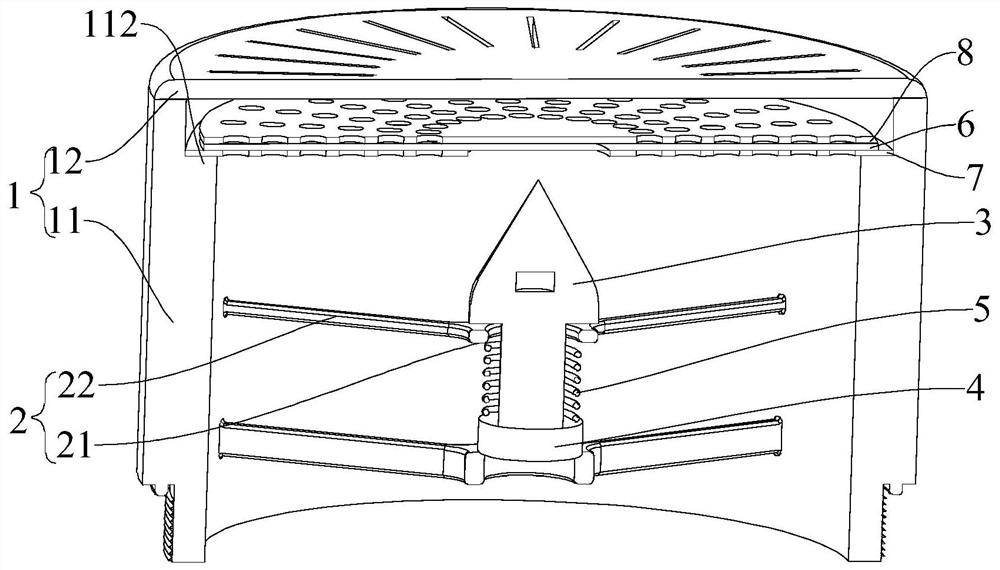

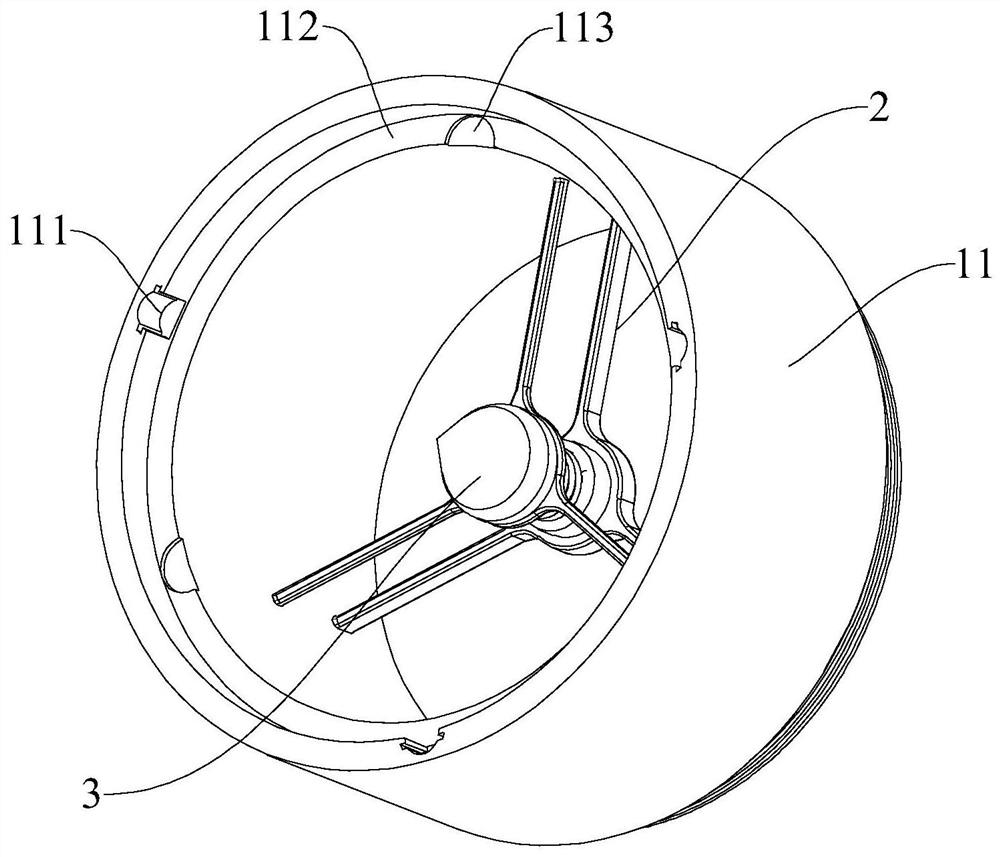

Battery pack explosion-proof valve and battery pack

ActiveCN112713360AImprove the safety of useControl burst pressureVent arrangementsEngineeringMechanical engineering

The invention discloses a battery pack explosion-proof valve and a battery pack.The battery pack explosion-proof valve comprises a body, two limiting supports, an ejector pin, a support, an elastic piece and a breathable film, a vent hole is formed in the top wall of the body, the two limiting supports are arranged on the body in a spaced mode, the ejector pin is arranged on the limiting support located on the upper portion in a penetrating mode, the support is installed on the limiting support located on the lower portion and used for supporting the ejector pin, the elastic piece is arranged on the ejector pin in a sleeving mode, the two ends of the elastic piece abut against the support and the limiting support located on the upper portion respectively, and the breathable film is connected to the body and located between the ejector pin and the top wall of the body. The battery pack explosion-proof valve adopts an integrated structure that the elastic piece is matched with the ejector pin, and the elastic piece moves to push the ejector pin to puncture the breathable film when thermal runaway is triggered, so that the requirements of different bursting pressures are met, the breathable film can be directly communicated with the outside to realize higher air permeability after being damaged, rapid leakage of gas in the battery pack is ensured, and the use safety of the battery pack is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

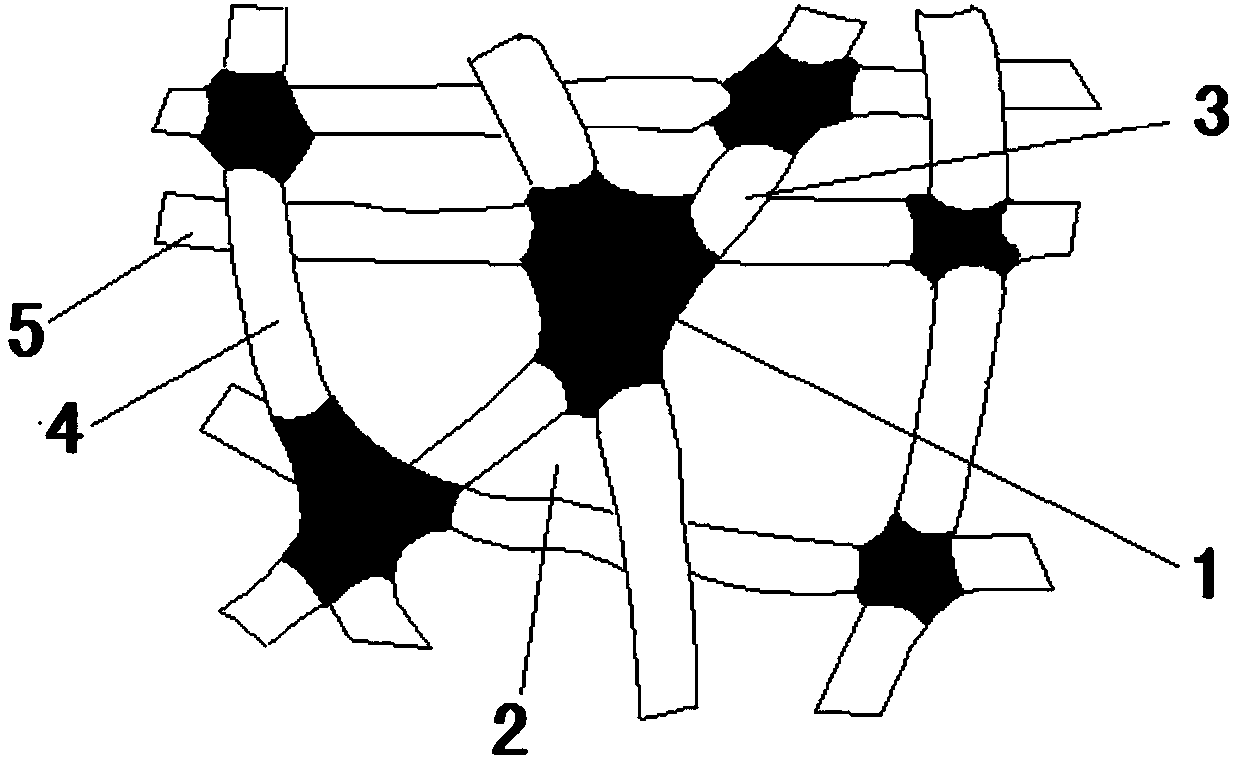

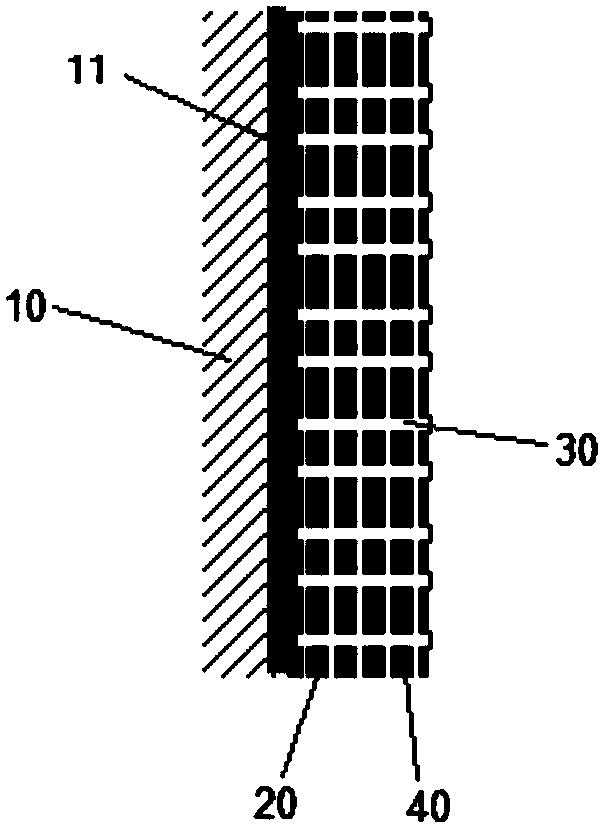

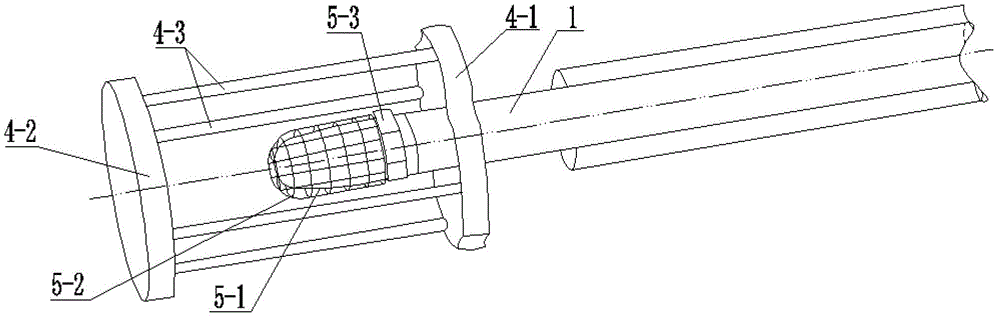

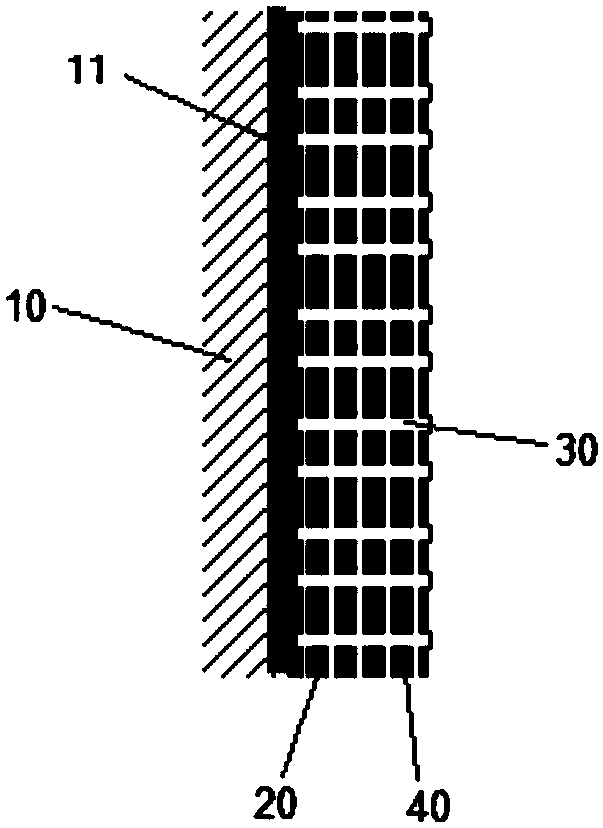

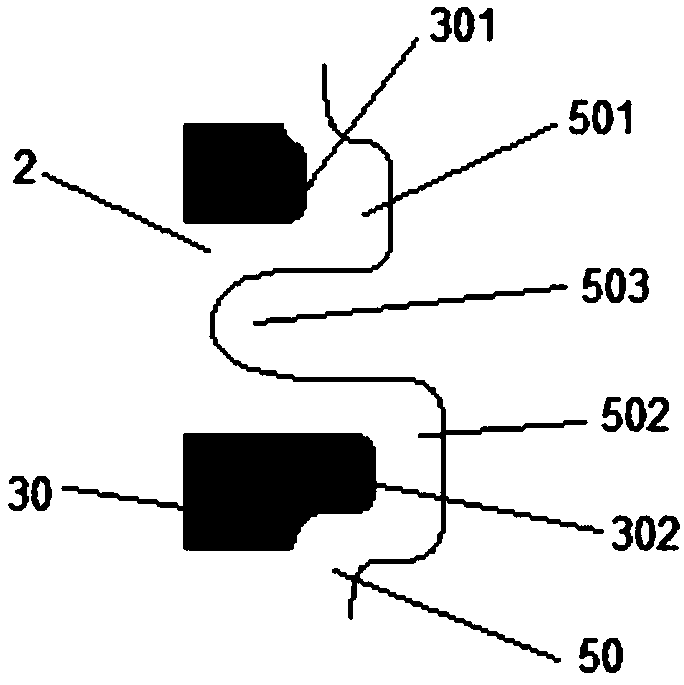

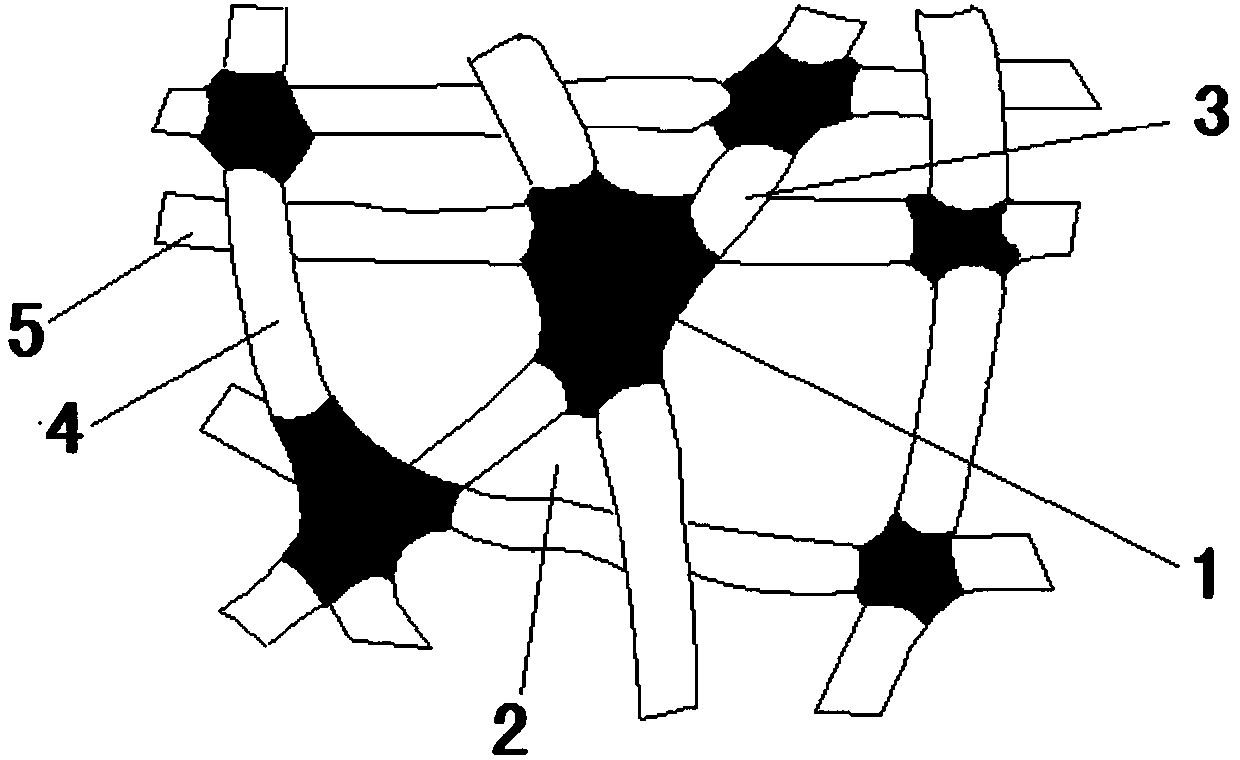

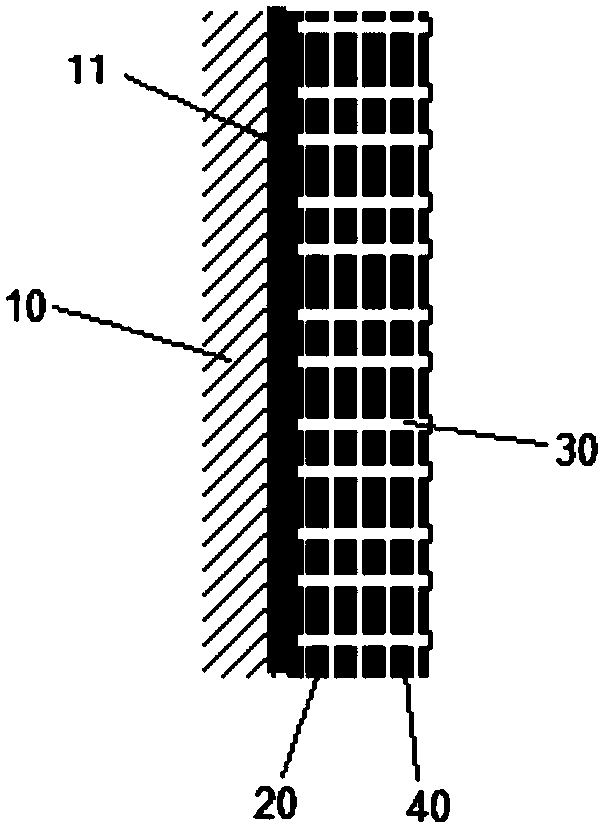

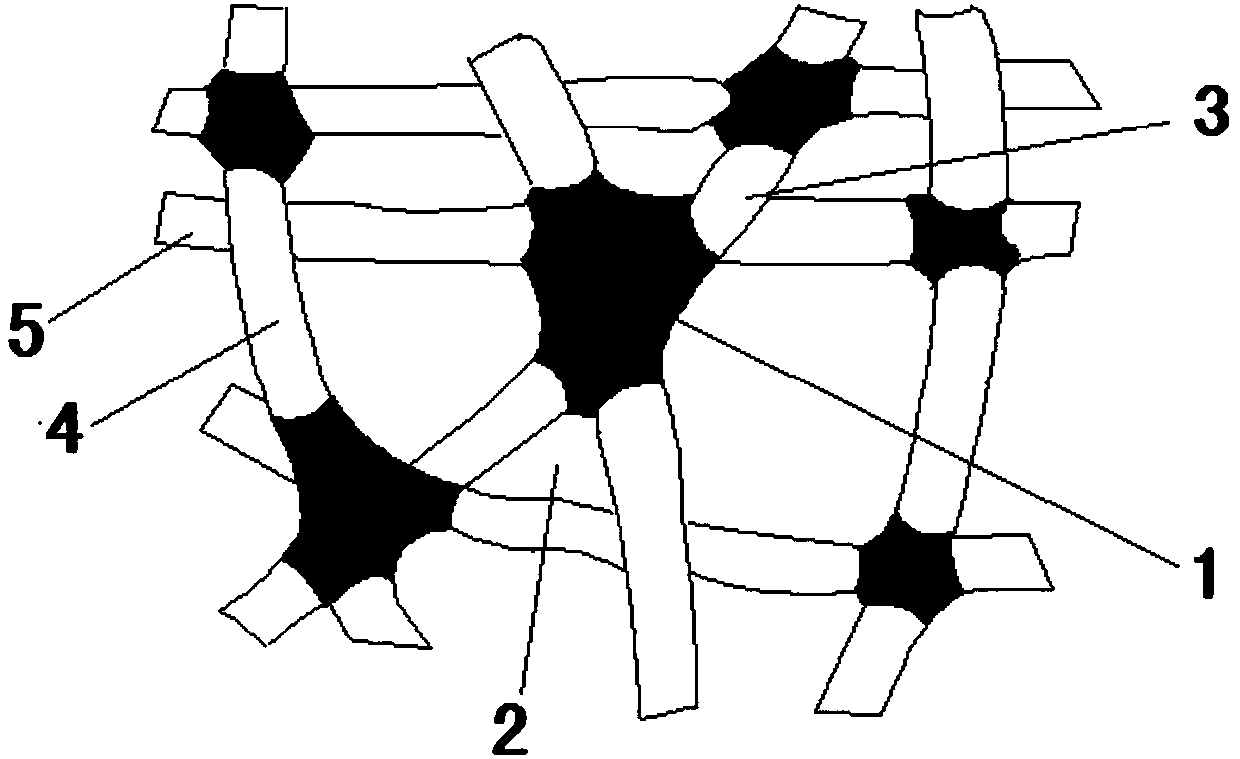

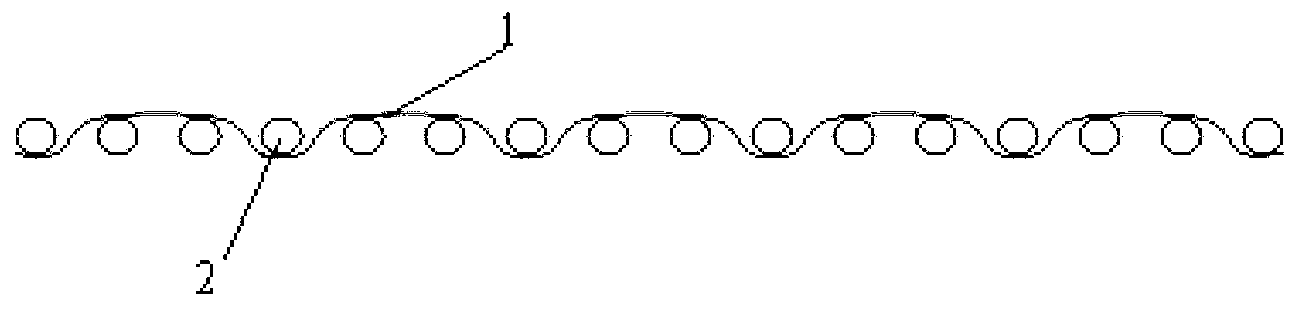

Air dust filter device for control valve of railway truck

InactiveCN106268098AGuarantee air qualityLarge filter areaDispersed particle filtrationEngineeringControl valves

The invention discloses an air dust filter device for a control valve of a railway truck. The air dust filter device is assembled in the control valve of the railway truck and comprises a sealing sleeve and an elongated channel type filter structure. The elongated channel type filter structure is enclosed by filter screens, the front end of the elongated channel type filter structure is connected with the sealing sleeve, an air inlet which is communicated with the insides of channels of the elongated channel type filter structure is formed in the sealing sleeve, the sealing sleeve can be hermetically connected with a body of the control valve by sealing elements, and air which flows into the air dust filter device from the air inlet of the sealing sleeve can be filtered by the elongated channel type filter structure and then flows into the control valve. The air dust filter device has the advantages that original filter screen structures are replaced by the channel type filter structure, accordingly, the filter area can be effectively enlarged, and the filter precision can be effectively improved; inner frameworks are omitted in the filter structure, accordingly, the air dust filter device is high in ventilation property and dirt holding quantity, is durable and can be used in severe environments, and the quality of air which flows into the control valve can be guaranteed.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Preparing method for fireproof PTFE film

The invention discloses a preparing method for a fireproof PTFE film. The method includes the following steps that PTFE powder and a liquid lubricant are mixed to form a mixture; the mixture is evenly sprayed to a metal fiber mesh base material and pressed on a pressing blank to obtain a cylindrical blank; the blank is extruded by a push extruder to obtain a club, and the club is subjected to calendering through a calender to form a PTFE base band; the PTFE base band is subjected to longitudinal drawing and then transverse drawing in a drying oven, finally, a shaped film is formed after sintering and shaping, the shaped film is sprayed with cooling water, and then the PTFE film is obtained. By means of the PTFE film, the filtering precision and ventilation property of filtering products are greatly improved on the condition of extreme condition resistance. The PTFE film has excellent fireproof performance, the high temperature resistance and the corrosion resistance are improved, the PTFE film can well adhere to the base material, and the malleability and mechanical property of the PTFE film are also improved.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

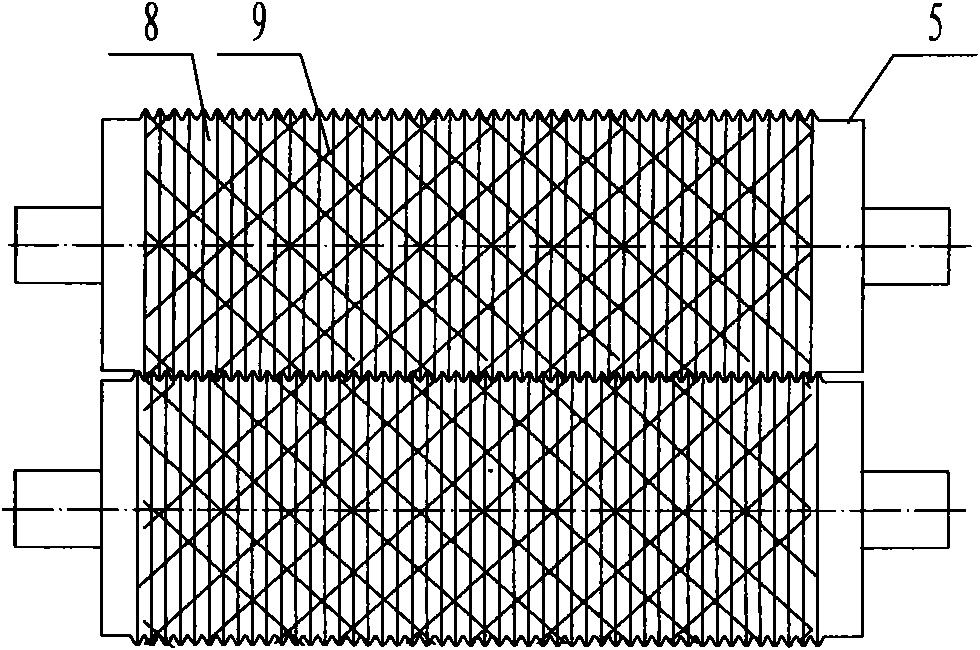

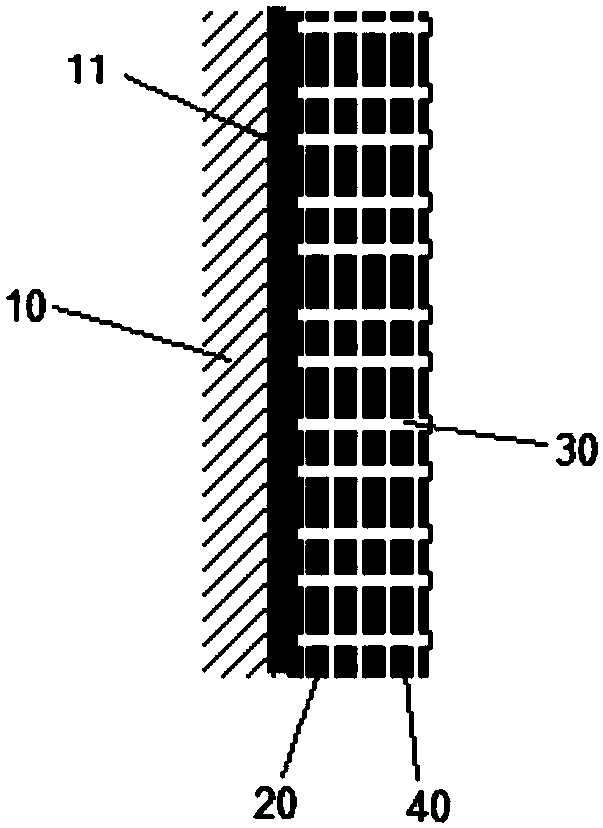

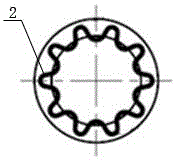

Filter cloth for producing white carbon black

InactiveCN103170181ALarge air flowHigh strengthWoven fabricsFiltration separationPulp and paper industryUltimate tensile strength

The invention relates to the technical field of filter cloth, and in particular relates to filter cloth for producing white carbon black. The filter cloth for producing white carbon black is formed by weaving warps and wefts; the warps are multifilaments; the wefts are monofilaments; in the wrap and weft cross points of the filter cloth, the number of the warp and weft cross points of the wefts above the warps are larger than that of the warp and weft cross points of the weft below the warp; and therefore, the number of the monofilaments arranged on the filter cloth is large, so that the adhesive force of a filter cake is reduced, the permeation volume of the filter cloth is increased, the amount of workers is reduced, and simultaneously the number of the multifilaments arranged below the filter cloth is large, so that the strength of the filter cloth is improved, the service life is prolonged, and the cost of the filter cloth is reduced.

Owner:QUECHEN SILICON CHEM

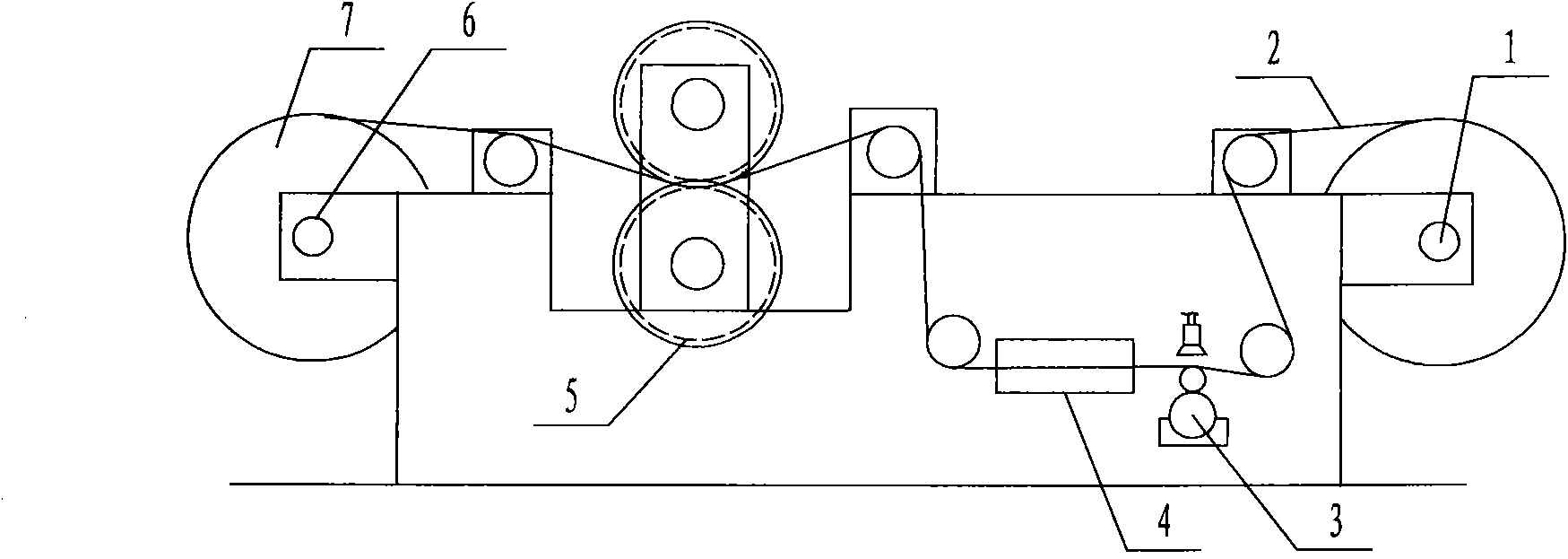

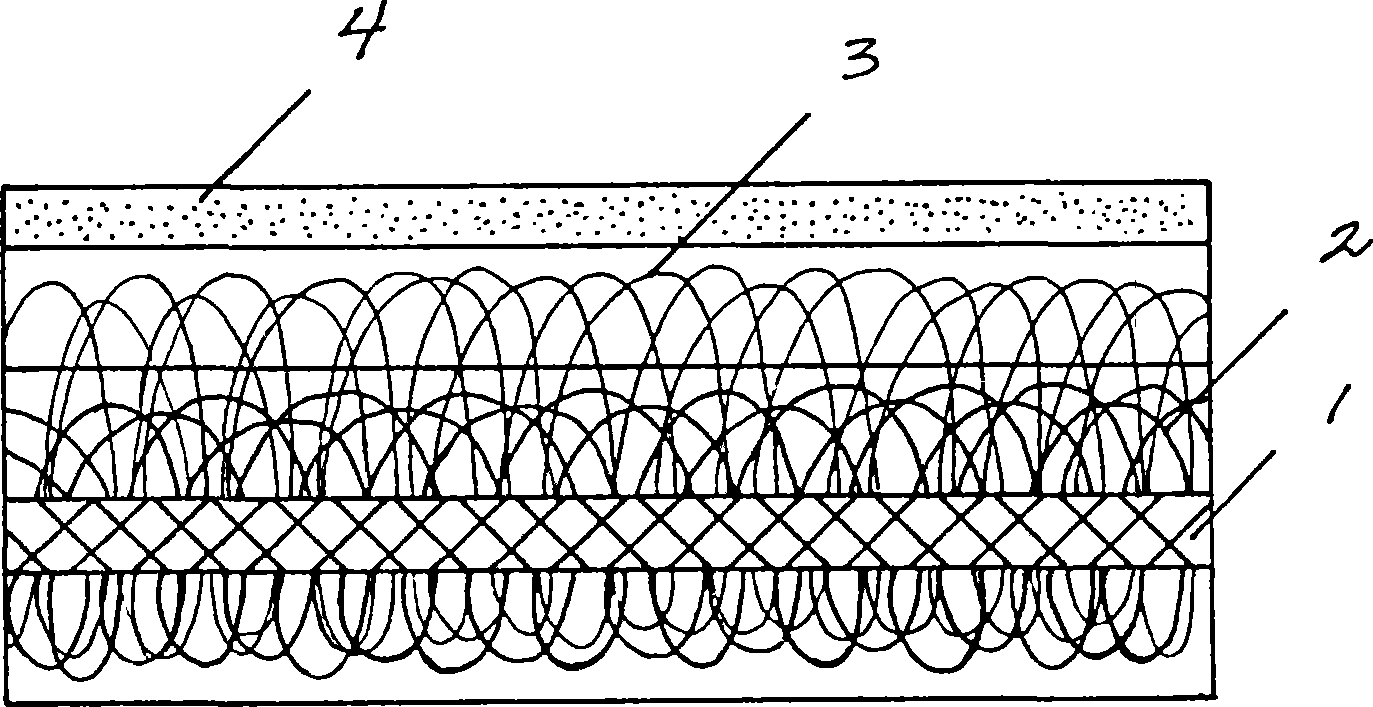

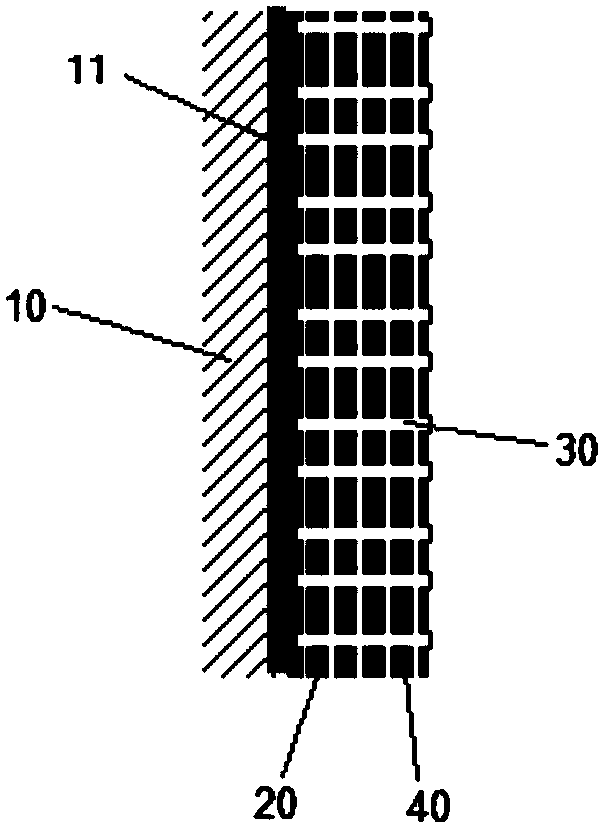

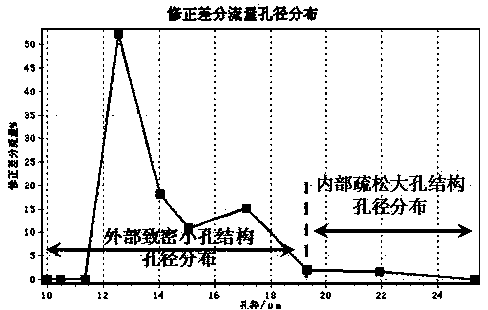

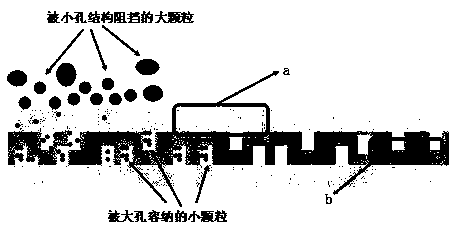

Preparation method and application of PET melt-blown non-woven fabric of gradient structure for secondary molding filtration of double-rolling mill

ActiveCN109162025AIncrease the dirt holding spaceImprove dirt holding capacityFiltration separationNon-woven fabricsPolymer scienceFiltration

The invention relates to a preparation method and application of PET melt-blown non-woven fabric of a gradient structure for the secondary molding filtration of a double-rolling mill. The method comprises a step of preparing a PET melt-blown fiber layer, allowing the obtained fiber layer to pass a hot rolling mill to subjected to first complete thermal bonding at the temperature of 120 DEG C to 160 DEG C and the pressure of 30N to 60 N, a step of allowing the fiber layer to pass the hot rolling mill to subjected to second non-complete thermal bonding at the temperature of 200 to 240 DEG C andthe pressure of 40N to 100N to obtain the PET melt-blown non-woven fabric of the gradient structure. The obtained PET melt-blown non-woven fabric is applied to liquid / gas filtration and has the advantages of large air permeability, high filtration precision, small pressure drop and long service life.

Owner:SHANDONG TAIPENG ENVIRONMENTAL PROTECTION MATERIAL

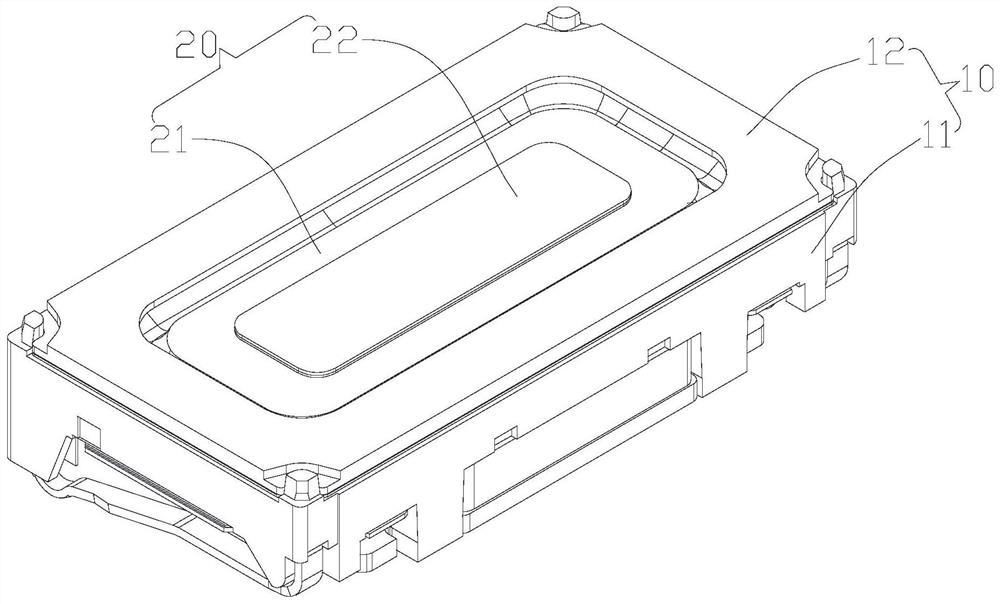

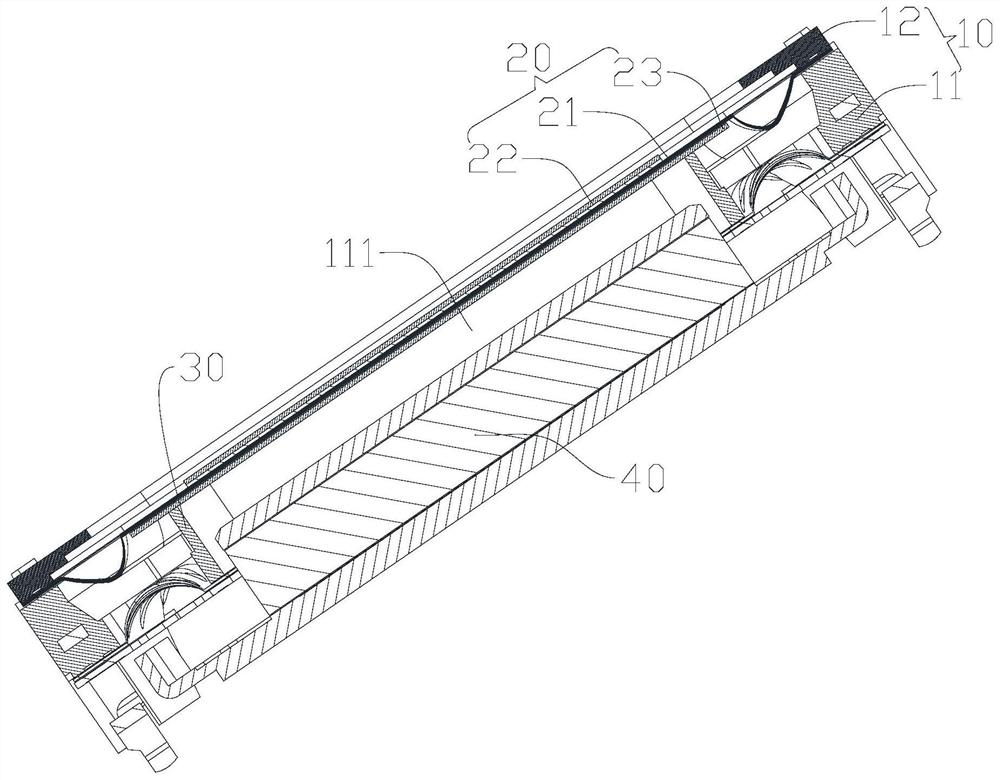

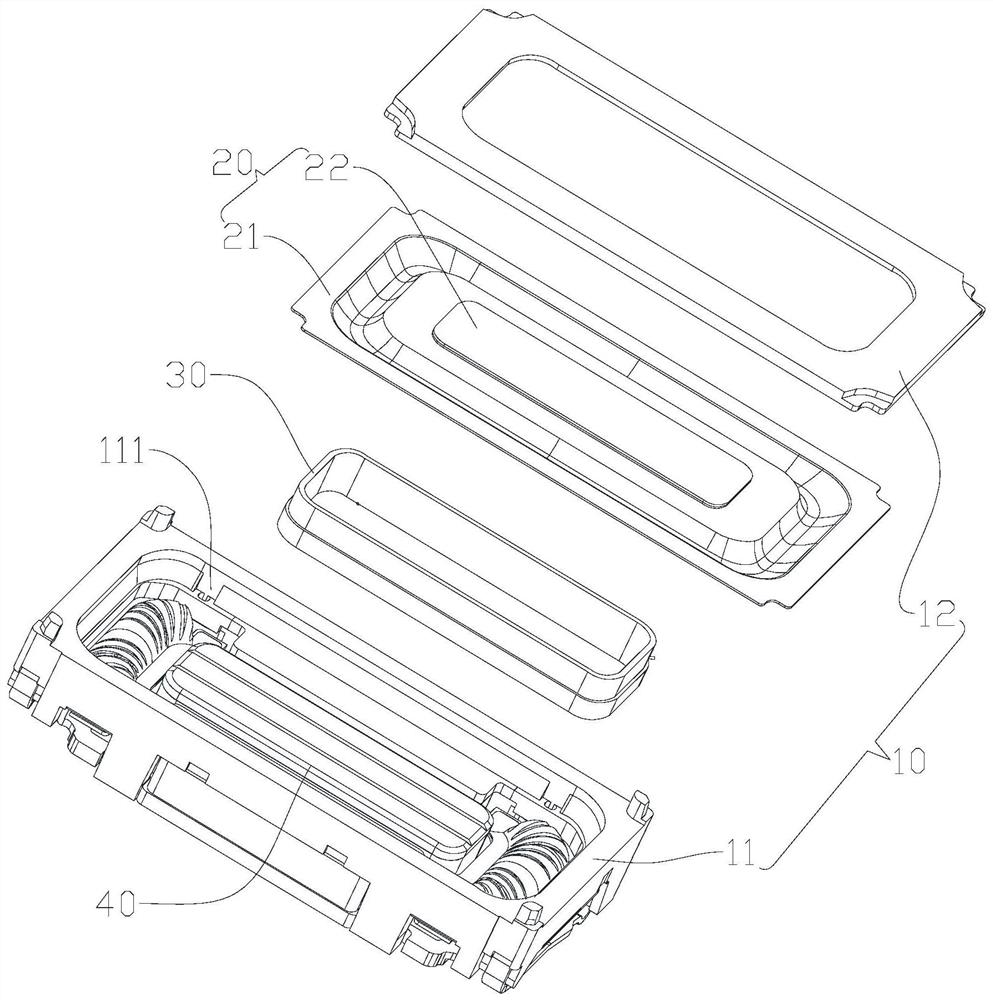

Loudspeaker and electronic equipment

ActiveCN112188372ALarge air flowImprove the sound effectTransducers for subaqueous useEngineeringLoudspeaker

The invention provides a loudspeaker, which comprises a basin frame, a vibration system and a magnetic circuit system arranged in the basin frame, and is characterized in that the vibration system comprises a vibrating diaphragm and a voice coil for driving the vibrating diaphragm to vibrate and produce sound; the vibrating diaphragm comprises a waterproof breathable film, a dome with a hole structure and a voice diaphragm with a through hole; the dome is arranged between the voice diaphragm and the voice coil; the through hole communicates with the hole structure; and the waterproof breathable film is arranged on one side, opposite to the dome, of the voice diaphragm and correspondingly covers the through hole.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU +1

A kind of non-woven fabric with two-component gradient structure for water filtration and its preparation method and application

ActiveCN106521811BExtended service lifeLarge non-rolling pointFiltration separationNon-woven fabricsPolymer scienceFiltration

The invention discloses a two-component gradient structure non-woven fabric for water filtering and a preparation method thereof. The non-woven fabric is composed of a first-layer fiber web and a second-layer fiber web which are bonded together, wherein the first-layer fiber web and the second-layer fiber web are each composed of trefoil PET filament fibers and circular COPET filament fibers which have different finenesses. The preparation method comprises the steps that PET slices and COPET slices which are subjected to pre-crystallization are fully dried; fusion overstocking, spinning, cooling, drafting and separation lapping are conducted through two groups of different spinning assemblies, then the obtained two layers of fiber webs are overlapped to form a composite fiber web, and finally the composite fiber web is subjected to hot air bonding and melting to be reinforced into a whole. According to the two-component gradient structure non-woven fabric for water filtering, the advantages of different fineness filtering in a filter material can be fully exerted, the filtering efficiency is guaranteed, the service life is effectively prolonged, and pressure drop is controlled within a reasonable range; accordingly, the non-woven fabric has the advantages of being free of rolling points, high in ventilation property and filtering precision, low in pressure drop and long in service life.

Owner:SHANDONG TAIPENG ENVIRONMENTAL PROTECTION MATERIAL

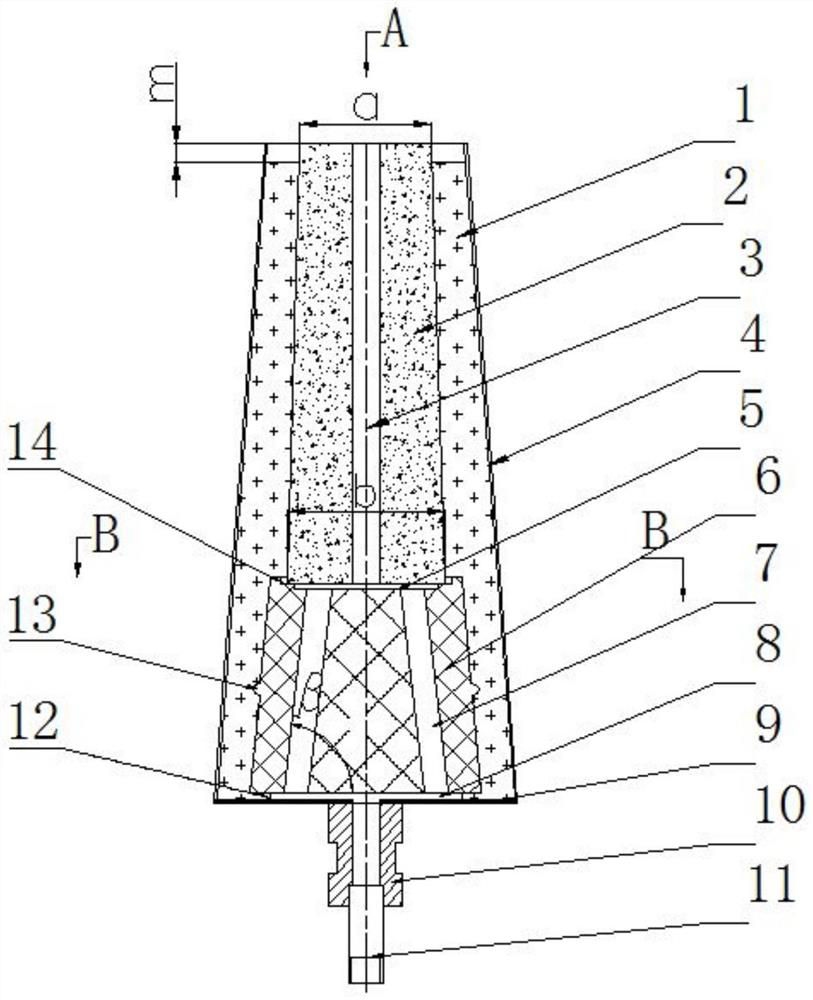

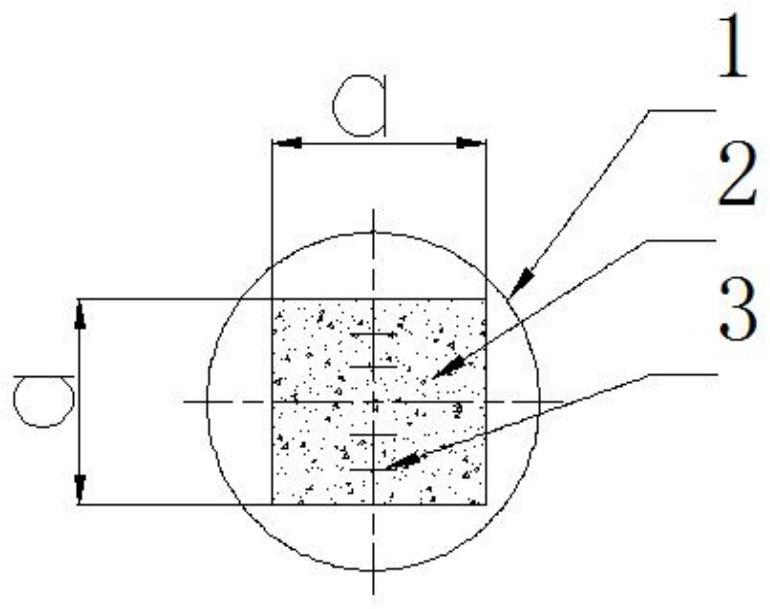

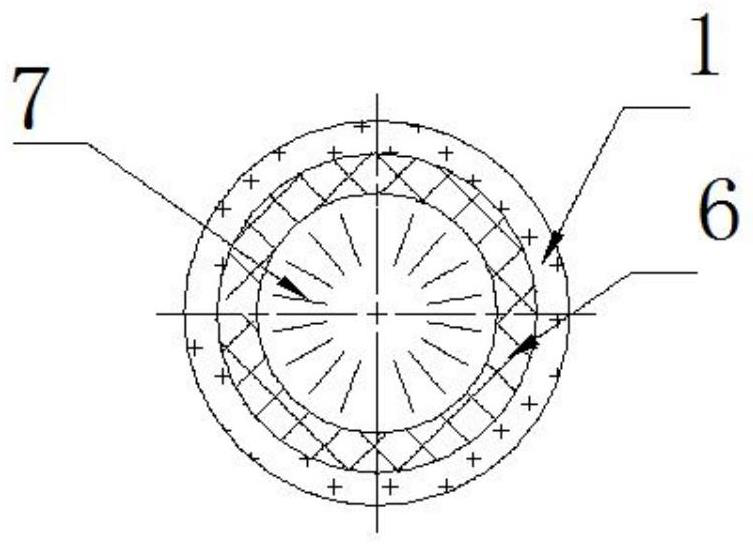

Composite air brick and argon blowing refining method in continuous casting ladle pouring process

PendingCN114433829AIncrease the lengthReduce the slit widthMelt-holding vesselsManufacturing engineeringIndustrial engineering

The invention relates to a composite air brick and an argon blowing refining method in a continuous casting ladle pouring process. The air brick comprises a pouring body, a dispersion block and a safety warning device, wherein the dispersion block and the safety warning device are arranged in the pouring body from top to bottom; a plurality of slit air channels A penetrating through the dispersion block are vertically formed in the dispersion block; a lower air chamber is arranged at the bottom of the safety warning device, an upper air chamber is arranged at the top of the safety warning device, a plurality of slit air passages B which are through up and down are arranged in the safety warning device, the plurality of slit air passages B are uniformly distributed in the safety warning device along the circumference, and the lower ends of the slit air passages B are gradually inclined outwards; and the slit air passage A, the upper air chamber, the slit air passage B and the lower air chamber are communicated. The air brick has the excellent performance of large air permeability, stable air permeability, long service life and the like, after refining treatment in an LF refining furnace is completed, the air brick is hoisted to a continuous casting rotary table, argon blowing is carried out in the continuous casting steel ladle pouring process to remove inclusions, the soft blowing time in the later stage of LF refining is shortened, the removal rate of the inclusions is increased, and molten steel standing layering is restrained.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com