Filter system for flue gas sampling gun

A filter system and sampling gun technology, which is applied in the direction of dispersed particle filtration, sampling device, and dispersed particle separation, etc., can solve the problems of sampling channel blockage, affecting the service life of the sampling gun for flue gas composition analysis, etc., to prolong the service life and prevent dust into the sample gun, avoiding the effect of washout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

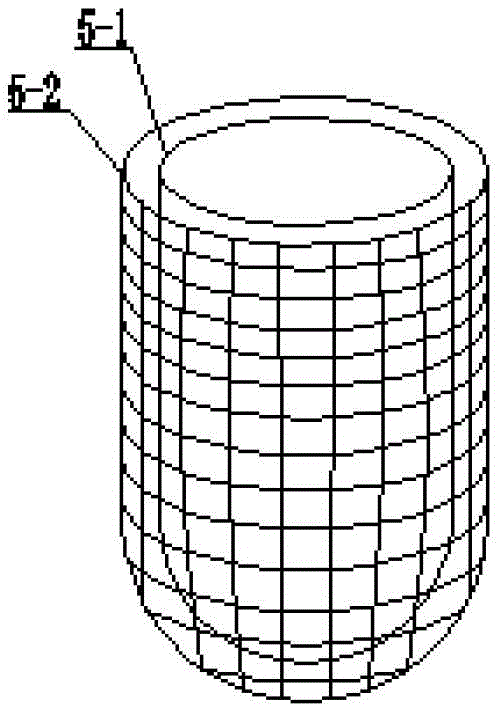

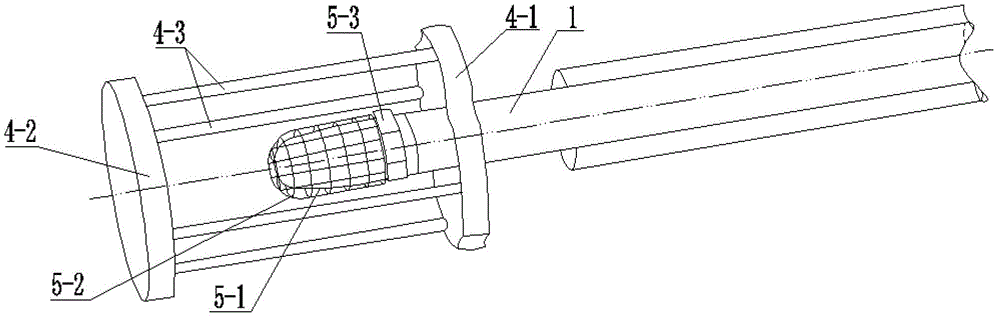

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a filter system for a flue gas sampling gun in this embodiment includes a filter cartridge 5-1 and a protective net 5-2, the filter cartridge 5-1 is a filter cartridge with one end open and the other end closed, The shape of the closed end of the filter cartridge 5-1 is bullet-shaped, and the filter cartridge 5-1 is a wood pulp fiber paper filter cartridge, and the open end of the filter cartridge 5-1 is used to be installed on the smoke inlet end of the gun barrel 1 , the shape of the protective net 5-2 is the same as that of the filter cartridge 5-1, and the protective net 5-2 is set on the filter cartridge 1.

[0009] The filtration particle diameter of the filter cartridge of this embodiment is the same as or smaller than the particle diameter (0.05-600 μm) of dust. This embodiment is used together with the protective cover (flange 4-1, protective ring 4-2 and multiple pilla...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 and figure 2 To describe this embodiment, the protection net 5-2 in this embodiment is a metal protection net. With such setting, the strength of the protective net is high, and the protective effect on the filter cartridge is good. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the protective net 5-2 in this embodiment is a stainless steel round hole or square hole protective net. With such setting, the protection effect of the protective net on the filter cartridge is good. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com