Lithium ion battery diaphragm, preparation method of lithium ion battery diaphragm and lithium ion battery

A technology for lithium ion batteries and separators, used in secondary batteries, battery pack components, separators/films/diaphragms/spacers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

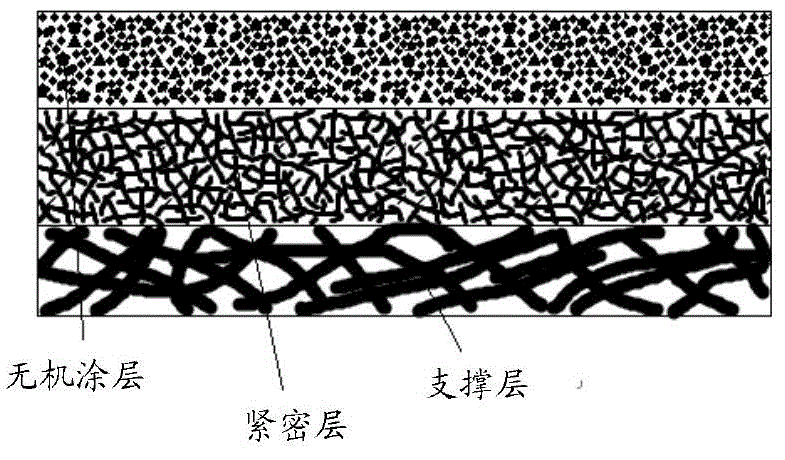

[0081] Example 1 Preparation of three-layer composite lithium-ion battery separator

[0082] Step a: mixing the raw materials of the support layer and the dense layer with water, beating, and diluting to 0.05wt% to obtain the support layer slurry and the dense layer slurry;

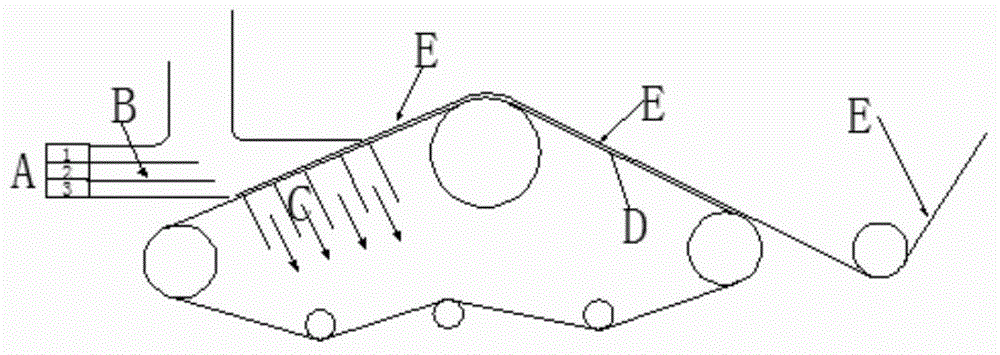

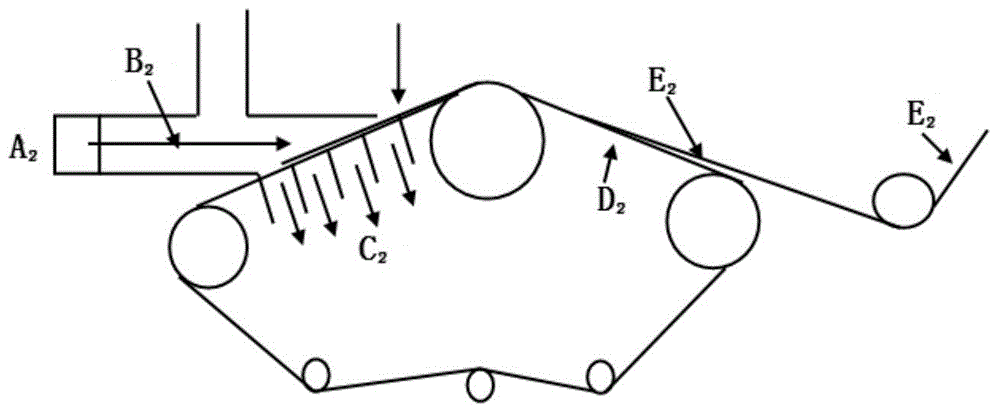

[0083] Step b: the diluted support layer slurry and the dense layer slurry are independently loaded into the inclined wire paper machine (such as figure 1 shown), wherein the support layer slurry is transported to flow channel 1, and the dense layer slurry is transported to flow channel 2, so that the support layer slurry and the dense layer slurry are stacked in the same area successively, and are formed by one-time copying to obtain the support layer and the dense layer. Floor;

[0084] Step c: uniformly disperse the inorganic particles in the binding resin to obtain a coating liquid, uniformly coat the coating liquid on the surface of the dense layer, and dry to obtain a lithium-ion battery separato...

Embodiment 2

[0086] Example 2 Preparation of three-layer composite lithium-ion battery separator

[0087] The preparation method of this example is basically the same as that of Example 1, except that in step a, the raw materials of the support layer and the dense layer are mixed with water, beaten, and diluted to 0.01 wt%.

Embodiment 3

[0088] Example 3 Preparation of three-layer composite lithium-ion battery separator

[0089] The preparation method of this example is basically the same as that of Example 1, except that in step a, the raw materials of the support layer and the dense layer are mixed with water, beaten, and diluted to 0.01 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com