Preparation and application of lithium battery silicon-carbon composite material taking synthetic graphite as carrier

A silicon-carbon composite material and artificial graphite technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor electrical conductivity, poor cycle stability, and large irreversible capacity loss, and achieve high production efficiency, high specific capacity, The effect of improving the first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

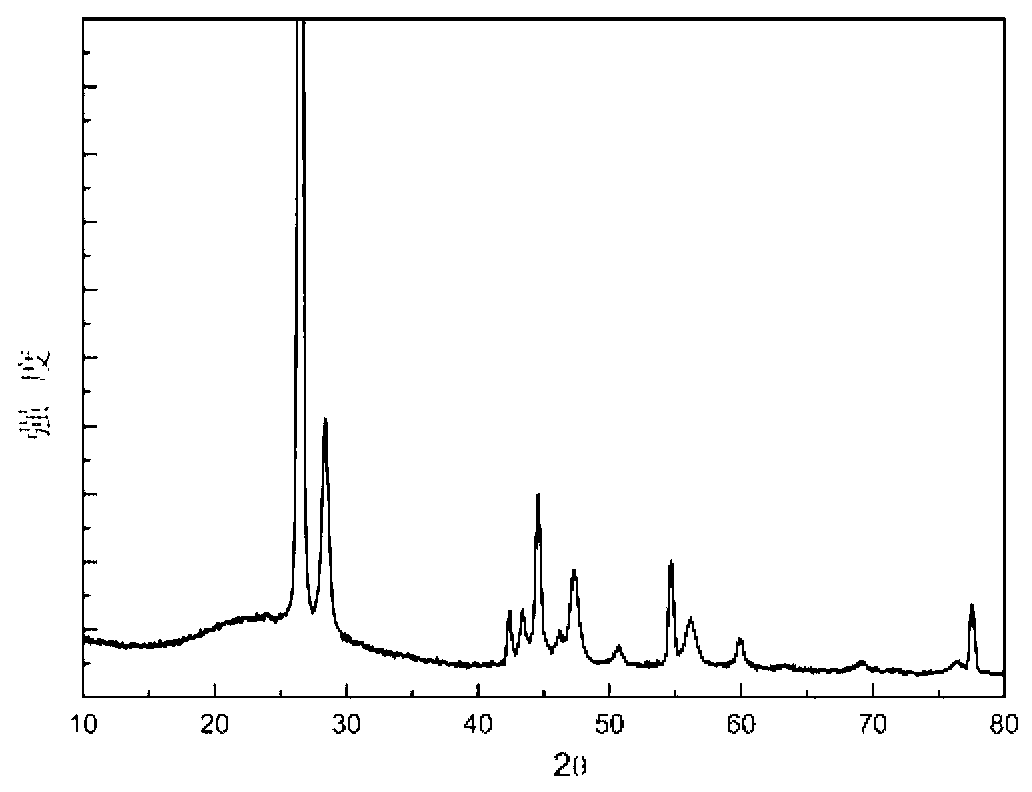

Embodiment 1

[0056] (1) Preparation of silicon-carbon composite anode materials for lithium batteries with artificial graphite as the carrier:

[0057] (1) Dissolve 8.57g of nano-silicon (particle size 50-200nm) in 100mL of absolute ethanol, add 0.1g of polyvinyl alcohol, and sonicate in an ultrasonic cleaner for 1 hour to obtain a mixed solution A; the mass of the mixed solution A The solid content is 10%;

[0058] (2) Dissolve 14.25g of glucose completely in deionized water and stir for 1 hour to obtain mixed solution B;

[0059] (3) Disperse 40g of artificial graphite in 400mL of absolute ethanol and stir for 0.5h to obtain a mixed solution C;

[0060] (4) Slowly add the mixed solution A of step (1) and the mixed solution B of step (2) to the mixed solution C of step (3) at the same time, add absolute ethanol to make the solid content of the entire dispersion system 30%, and Stir quickly (1000r / min) for 1 hour to obtain a mixed solution D; then dry the mixed solution D through a spray...

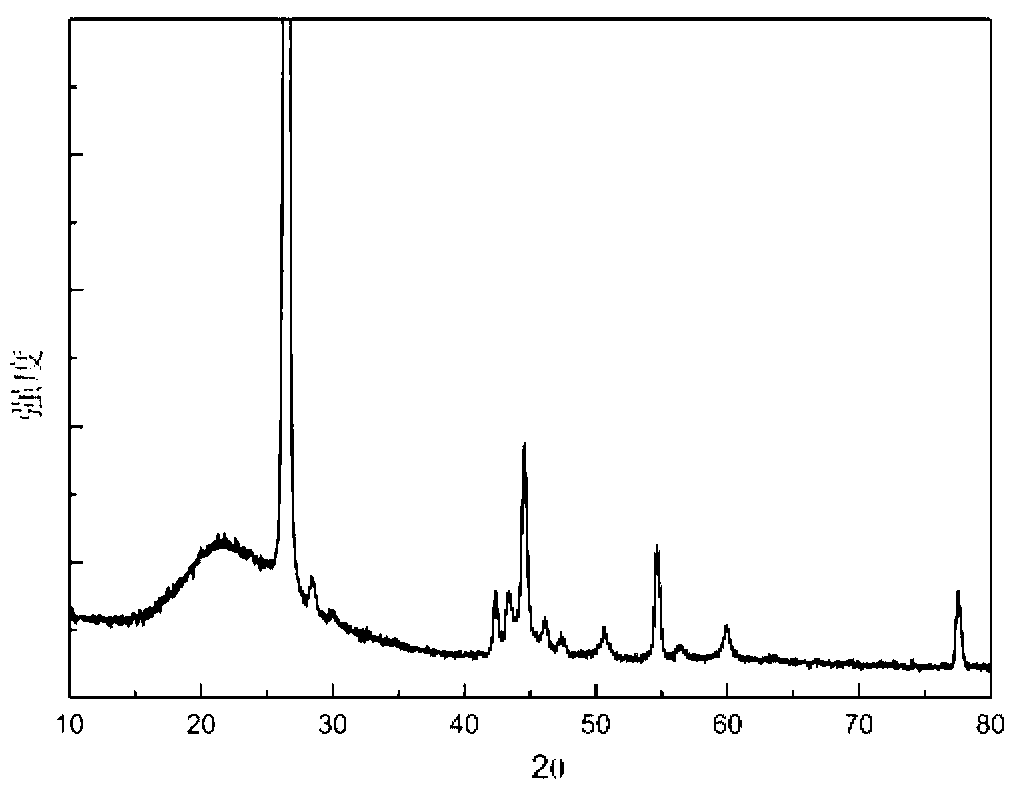

Embodiment 2

[0067] (1) Preparation of silicon-carbon composite anode materials for lithium batteries with artificial graphite as the carrier:

[0068] (1) Disperse 8.57g of nano-silicon (50-200nm in particle size) in 100mL of absolute ethanol, add 0.2g of polyethyleneimine, and sonicate in an ultrasonic cleaner for 2 hours to obtain mixed solution A; The mass solid content is 10%;

[0069] (2) Dissolve 35.7g of citric acid into 300mL of absolute ethanol and stir for 0.5h to obtain mixed solution B;

[0070] (3) Disperse 40g of artificial graphite in 400mL of absolute ethanol and stir for 2 hours to obtain a mixed solution C;

[0071] (4) Slowly add the mixed solution A of step (1) and the mixed solution B of step (2) into the mixed solution C of step (3), add absolute ethanol so that the solid content of the entire dispersion system is 15%, and quickly (800r / min) stirring for 3 hours to obtain the mixed solution D; then the mixed solution D was dried by a spray dryer under certain condi...

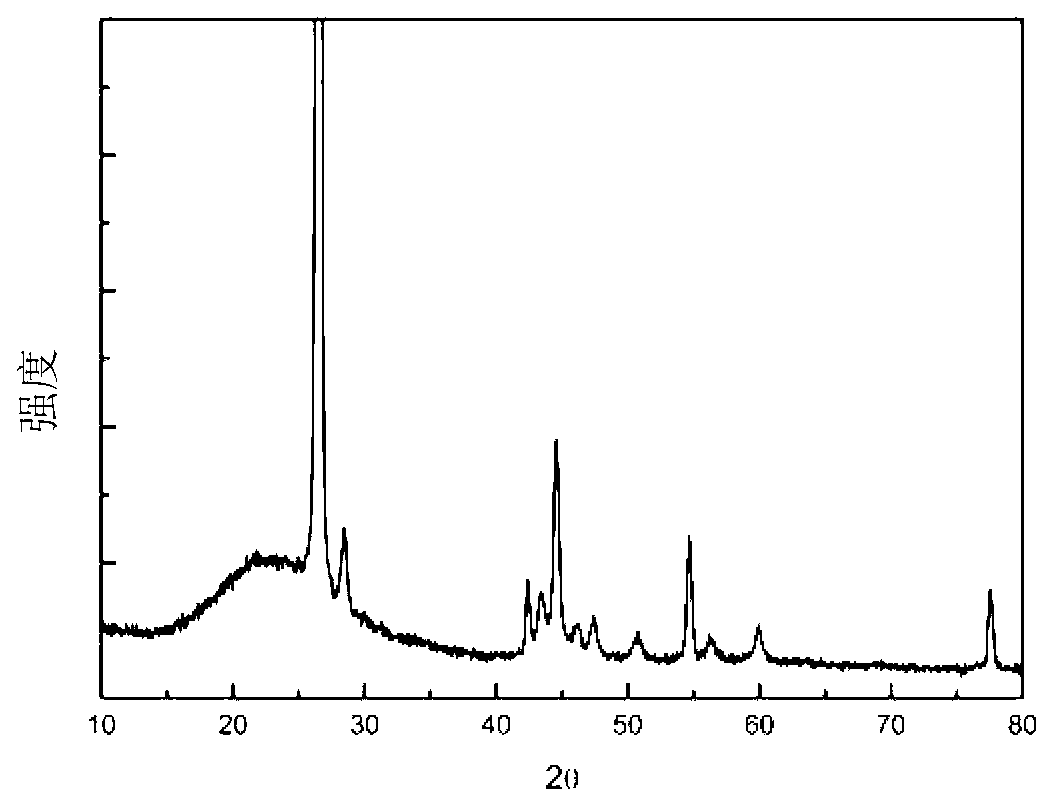

Embodiment 3

[0083] (1) Preparation of silicon-carbon composite anode materials for lithium batteries with artificial graphite as the carrier:

[0084] (1) Dissolve 8.57g of nano-silicon (particle size 50-200nm) in 100mL of absolute ethanol, add 0.4g of nitrogen-methylpyrrolidone, and sonicate in an ultrasonic cleaner for 1.5h to obtain mixed solution A; mixed solution A The mass solid content is 10%;

[0085] (2) Dissolve 4.75g of phenolic resin into 100mL of absolute ethanol, and stir for 2 hours to obtain mixed solution B;

[0086] (3) Dissolve 40g of artificial graphite in 300mL of absolute ethanol, and stir for 1 hour to obtain a mixed solution C;

[0087] (4) Slowly add the mixed solution A of step (1) and the mixed solution B of step (2) to the mixed solution C of step (3) at the same time, add absolute ethanol to make the solid content of the entire dispersion system 10%, and Stir quickly (1200r / min) for 5 hours to obtain the mixed solution D; then dry the mixed solution D through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com