Spiral vibration cake unloading filter press by pulling filter plates twice

A technology of filter press and filter plate, which is applied in the field of filter press with spiral vibration and cake unloading by pulling the filter plate twice, can solve the problems of loss of economic benefits, low filtration efficiency, high investment cost, etc. The effect of air permeability and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

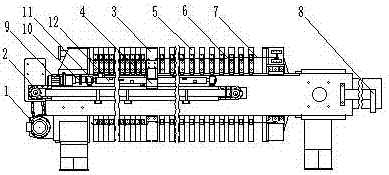

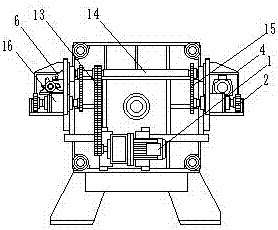

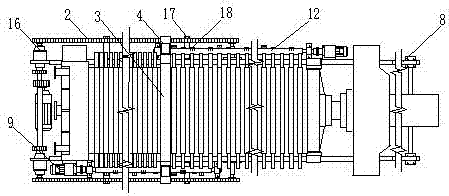

[0023] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention provides a spiral vibration cake unloading filter press that pulls the filter plate twice, and sets the oil cylinder body as an extended type. The lengthened type of the oil cylinder body means that the length of the piston rod can be pulled apart by 50% for the first time. The filter plate 5 reaches the distance for unloading the cake, the piston rod returns to the original position after the filtration is completed, and the piston rod drives the filter plate to be opened once to remove the filter cake, reducing the working time of the filter plate 5 and enabling multiple filter plates 5 to be opened at the same time For cake unloading, there are cake unloading chains 7 on both sides of the filter plate 5 to control the distance, and the upper and lower ends of the filter plate 5 are provided with double-layer spacing chains 7. One end of the bracket 8 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com